Cooking Effect on the Bioactive Compounds, Texture, and Color Properties of Cold-Extruded Rice/Bean-Based Pasta Supplemented with Whole Carob Fruit

Abstract

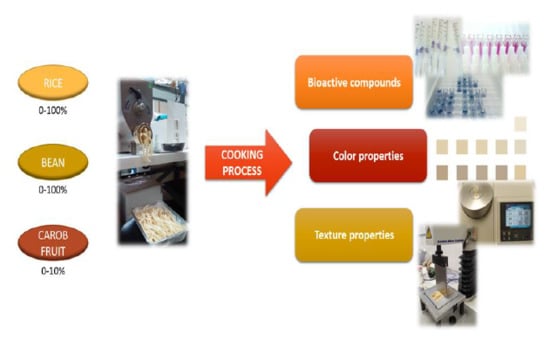

:1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Pasta Formulations and Manufacturing

2.3. Biochemical Characterization

2.3.1. Individual Inositol Phosphates

2.3.2. Soluble Sugars and α-Galactosides

2.3.3. Trypsin and Chymotrypsin Inhibitors

2.3.4. Lectin

2.3.5. Phenolic Composition and Antioxidant Activity

2.4. Color Analysis

2.5. Texture Analysis

2.6. Statistical Analysis

3. Results and Discussion

3.1. Individual Inositol Phosphates

3.2. Soluble Sugars and α-Galactosides

3.3. Trypsin and Chymotrypsin Inhibitors

3.4. Lectin Content

3.5. Phenolic Composition and Antioxidant Activity

3.6. Color Analysis

3.7. Texture Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Chillo, S.; Laverse, J.; Falcone, P.M.; Protopapa, A.; Del Nobile, M.A. Influence of the addition of buckwheat flour and durum wheat bran on spaghetti quality. J. Cereal Sci. 2008, 47, 144–152. [Google Scholar] [CrossRef]

- Foschia, M.; Horstmann, S.W.; Arendt, E.K.; Zannini, E. Legumes as functional ingredients in gluten-free bakery and pasta products. Annu. Rev. Food Sci. Technol. 2017, 8, 75–96. [Google Scholar] [CrossRef] [PubMed]

- Cabrera-Chávez, F.; de la Barca, A.M.C.; Islas-Rubio, A.R.; Marti, A.; Marengo, M.; Pagani, M.A.; Bonomi, F.; Iametti, S. Molecular rearrangements in extrusion processes for the production of amaranth-enriched, gluten-free rice pasta. LWT 2012, 47, 421–426. [Google Scholar] [CrossRef]

- Duranti, M. Grain legume proteins and nutraceutical properties. Fitoterapia 2006, 77, 67–82. [Google Scholar] [CrossRef] [PubMed]

- Arribas, C.; Cabellos, B.; Cuadrado, C.; Guillamón, E.; Pedrosa, M. Extrusion effect on proximate composition, starch and dietary fibre of ready-to-eat products based on rice fortified with carob fruit and bean. LWT Food Sci. Technol. 2019, 111, 387–393. [Google Scholar] [CrossRef]

- Elliott, C. The nutritional quality of gluten-free products for children. Pediatrics 2018, 142, e20180525. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Olmedilla-Alonso, B.; Pedrosa, M.M.; Cuadrado, C.; Brito, M.; Asensio-S-Manzanera, C.; Asensio-Vegas, C. Composition of two Spanish common dry beans (Phaseolus vulgaris), ‘Almonga’ and ‘Curruquilla’, and their postprandial effect in type 2 diabetics. J. Sci. 2013, 93, 1076–1082. [Google Scholar]

- Giuberti, G.; Gallo, A.; Cerioli, C.; Fortunati, P.; Masoero, F. Cooking quality and starch digestibility of gluten free pasta using new bean flour. Food Chem. 2015, 175, 43–49. [Google Scholar] [CrossRef]

- Turfani, V.; Narducci, V.; Durazzo, A.; Galli, V.; Carcea, M. Technological, nutritional and functional properties of wheat bread enriched with lentil or carob flours. LWT 2017, 78, 361–366. [Google Scholar] [CrossRef]

- Goulas, V.; Stylos, E.; Chatziathanasiadou, M.V.; Mavromoustakos, T.; Tzakos, A.G. Functional components of carob fruit: Linking the chemical and biological space. IJMS 2016, 17, 1875. [Google Scholar] [CrossRef]

- Arribas, C.; Cabellos, B.; Cuadrado, C.; Guillamón, E.; Pedrosa, M.M. Bioactive compounds, antioxidant activity, and sensory analysis of rice-based extruded snacks-like fortified with bean and carob fruit flours. Foods 2019, 8, 381. [Google Scholar] [CrossRef] [Green Version]

- Biernacka, B.; Dziki, D.; Gawlik-Dziki, U.; Różyło, R.; Siastała, M. Physical, sensorial, and antioxidant properties of common wheat pasta enriched with carob fiber. LWT 2017, 77, 186–192. [Google Scholar] [CrossRef]

- Feillet, P.; Roulland, T.M. Caroubin: A gluten-like protein isolated from carob bean germ. Cereal Chem. 1998, 75, 488–492. [Google Scholar] [CrossRef]

- Avallone, R.; Plessi, M.; Baraldi, M.; Monzani, A. Determination of Chemical Composition of Carob (Ceratonia siliqua): Protein, Fat, Carbohydrates, and Tannins. J. Food Compos. Anal. 1997, 10, 166–172. [Google Scholar] [CrossRef]

- Sęczyk, Ł.; Świeca, M.; Gawlik-Dziki, U. Effect of carob (Ceratonia siliqua L.) flour on the antioxidant potential, nutritional quality, and sensory characteristics of fortified durum wheat pasta. Food Chem. 2016, 194, 637–642. [Google Scholar] [CrossRef]

- Muzquiz, M.; Varela, A.; Burbano, C.; Cuadrado, C.; Guillamón, E.; Pedrosa, M.M. Bioactive compounds in legumes: Pronutritive and antinutritive actions. Implications for nutrition and health. Phytochem. Rev. 2012, 11, 227–244. [Google Scholar] [CrossRef]

- Pedrosa, M.M.; Cuadrado, C.; Burbano, C.; Muzquiz, M.; Cabellos, B.; Olmedilla-Alonso, B.; Asensio-Vegas, C. Effects of industrial canning on the proximate composition, bioactive compounds contents and nutritional profile of two Spanish common dry beans (Phaseolus vulgaris L.). Food Chem. 2015, 166, 68–75. [Google Scholar] [CrossRef] [Green Version]

- Gallegos-Infante, J.-A.; Bello-Perez, L.A.; Rocha-Guzman, N.E.; Gonzalez-Laredo, R.F.; Avila-Ontiveros, M. Effect of the addition of common bean (Phaseolus vulgaris L.) flour on the in vitro digestibility of starch and undigestible carbohydrates in spaghetti. J. Food Sci. 2010, 75, H151–H156. [Google Scholar] [CrossRef]

- Arribas, C.; Cabellos, B.; Guillamón, E.; Pedrosa, M.M. (FOODCHEM-D-20-02223). Cooking and sensory quality, nutritional composition and dietary fibre content of cold-extruded rice/bean fettuccine fortified with whole carob fruit flour. Food Chem. (in press)

- Burbano, C.; Muzquiz, M.; Ayet, G.; Cuadrado, C.; Pedrosa, M.M. Evaluation of antinutritional factors of selected varieties of Phaseolus vulgaris. J. Sci. 1999, 79, 1468–1472. [Google Scholar]

- Pedrosa, M.M.; Cuadrado, C.; Burbano, C.; Allaf, K.; Haddad, J.; Gelencsér, E.; Takács, K.; Guillamón, E.; Muzquiz, M. Effect of instant controlled pressure drop on the oligosaccharides, inositol phosphates, trypsin inhibitors and lectins contents of different legumes. Food Chem. 2012, 131, 862–868. [Google Scholar] [CrossRef]

- Welham, T.; Domoney, C. Temporal and spatial activity of a promoter from a pea enzyme inhibitor gene and its exploitation for seed quality improvement. Plant. Sci. 2000, 159, 289–299. [Google Scholar] [CrossRef]

- Cuadrado, C.; Hajos, G.; Burbano, C.; Pedrosa, M.M.; Ayet, G.; Muzquiz, M.; Pusztai, A.; Gelencser, E. Effect of Natural Fermentation on the Lectin of Lentils Measured by Immunological Methods. Food Agric. Immunol. 2002, 14, 41–49. [Google Scholar] [CrossRef]

- Dueñas, M.; Fernández, D.; Hernández, T.; Estrella, I.; Muñoz, R. Bioactive phenolic compounds of cowpeas (Vigna sinensis L). Modifications by fermentation with natural microflora and with Lactobacillus plantarum ATCC 14917. J. Sci. 2005, 85, 297–304. [Google Scholar]

- Oomah, B.D.; Cardador-Martínez, A.; Loarca-Piña, G. Phenolics and antioxidative activities in common beans (Phaseolus vulgaris L). J. Sci. 2005, 85, 935–942. [Google Scholar]

- Gallegos-Infante, J.; Rocha-Guzman, N.; Gonzalez-Laredo, R.; Ochoa-Martínez, L.; Corzo, N.; Bello-Perez, L.A.; Medina-Torres, L.; Peralta-Alvarez, L. Quality of spaghetti pasta containing Mexican common bean flour (Phaseolus vulgaris L.). Food Chem. 2010, 119, 1544–1549. [Google Scholar] [CrossRef]

- AACC. Approved Methods of Analysis, 11th Ed. In Method 66-50—Pasta and Noodle Cooking Quality-Firmness; Cereals & Grains Association: St. Paul, MN, USA, 2000; pp. 1–3. [Google Scholar]

- Roy, F.; Boye, J.I.; Simpson, B.K. Bioactive proteins and peptides in pulse crops: Pea, chickpea and lentil. Food Res. Int. 2010, 43, 432–442. [Google Scholar] [CrossRef]

- Plaami, S.; Kumpulainen, J. Inositol phosphate content of some cereal-based foods. J. Food Compos. Anal. 1995, 8, 324–335. [Google Scholar] [CrossRef]

- Anton, A.; Fulcher, R.S. Physical and nutritional impact of fortification of corn starch based extruded snacks with common bean (Phaseolus vulgaris L.) flour: Effects of bean addition and extrusion cooking. Food Chem. 2009, 133, 989–996. [Google Scholar] [CrossRef]

- Sanz-Penella, J.M.; Wronkowska, M.; Soral-Smietana, M.; Haros, M. Effect of whole amaranth flour on bread properties and nutritive value. LWT Food Sci. Technol. 2013, 50, 679–685. [Google Scholar] [CrossRef] [Green Version]

- Tazrart, K.; Zaidi, F.; Lamacchia, C.; Haros, M. Effect of durum wheat semolina substitution with broad bean flour (Vicia faba) on the Maccheronccini pasta quality. Eur. Food Res. Technol. 2016, 242, 477–485. [Google Scholar] [CrossRef] [Green Version]

- Bilgicli, N. Some chemical and sensory properties of gluten-free noodle prepared with different legume, pseudocereal and cereal flour blends. J. Food Nutr. Res. 2013, 52, 251–255. [Google Scholar]

- Torres, A.; Frias, J.; Granito, M.; Guerra, M.; Vidal-Valverde, C. Chemical, biological and sensory evaluation of pasta products supplemented with α-galactoside-free lupin flours. J. Sci. 2007, 87, 74–81. [Google Scholar] [CrossRef]

- Fredrikson, M.; Biot, P.; Alminger, M.; Carlsson, N.; Sandberg, A. Production process for high-quality pea-protein isolate with low content of oligosaccharides and phytate. J. Agric. Food Chem. 2001, 49, 1208–1212. [Google Scholar] [CrossRef] [PubMed]

- Laleg, K.; Cassan, D.; Barron, C.; Prabhasankar, P.; Micard, V. Structural, culinary, nutritional and anti-nutritional properties of high protein, gluten free, 100% legume pasta. PLoS ONE 2016, 11. [Google Scholar] [CrossRef]

- Campos-Vega, R.; Loarca-Piña, G.; Oomah, B.D. Minor components of pulses and their potential impact on human health. Food Res. Int. 2010, 43, 461–482. [Google Scholar] [CrossRef]

- Sparvoli, F.; Bollini, R.; Cominelli, E. Nutritional value. In Grain Legumes; De Ron Antonio, M., Ed.; Springer: New York, NY, USA, 2015; pp. 291–326. [Google Scholar]

- Martinez-Villaluenga, C.; Frias, J.; Vidal-Valverde, C. Alpha-galactosides: Antinutritional factors or functional ingredients? Crit. Rev. Food Sci. 2008, 48, 301–316. [Google Scholar] [CrossRef]

- Campos-Vega, R.; Bassinello, P.; Cardoso-Santiago, R.A.; Oomah, B.D.; Grumezescu, A.M.; Holban, A.M. Chapter 20. In Therapeutic, Probiotic, and Unconventional Foods; Grumezescu, A.M., Holban, A.M., Eds.; Academic Press: Cambridge, MA, USA; pp. 367–386. Available online: https://www.sciencedirect.com/science/article/pii/B9780128146255000194 (accessed on 3 March 2020).

- Giuberti, G.; Gallo, A. Reducing the glycaemic index and increasing the slowly digestible starch content in gluten-free cereal-based foods: A review. Int. J. Food Sci. Technol. 2018, 53, 50–60. [Google Scholar] [CrossRef]

- Zhao, Y.H.; Manthey, F.A.; Chang, S.K.; Hou, H.J.; Yuan, S.H. Quality characteristics of spaghetti as affected by green and yellow pea, lentil, and chickpea flours. J. Food Sci. 2005, 70, s371–s376. [Google Scholar] [CrossRef]

- Frias, J.; Kovács, E.; Sotomayor, C.; Hedley, C.; Vidal-Valverde, C. Processing peas for producing macaroni. LWT Food Sci. Technol. 1997, 204, 66–71. [Google Scholar] [CrossRef]

- Carcea, M.; Narducci, V.; Turfani, V.; Giannini, V. Polyphenols in raw and cooked cereals/pseudocereals/legume pasta and couscous. Foods 2017, 6, 80. [Google Scholar] [CrossRef] [Green Version]

- Gull, A.; Prasad, K.; Kumar, P. Nutritional, antioxidant, microstructural and pasting properties of functional pasta. J. Saudi Soc. Agric. Sci. 2018, 17, 147–153. [Google Scholar] [CrossRef] [Green Version]

- Verardo, V.; Arráez-Román, D.; Segura-Carretero, A.; Marconi, E.; Fernández-Gutiérrez, A.; Caboni, M.F. Determination of free and bound phenolic compounds in buckwheat spaghetti by RP-HPLC-ESI-TOF-MS: Effect of thermal processing from farm to fork. J. Agric. Food Chem. 2011, 59, 7700–7707. [Google Scholar] [CrossRef] [PubMed]

- Rocchetti, G.; Lucini, L.; Chiodelli, G.; Giuberti, G.; Montesano, D.; Masoero, F.; Trevisan, M. Impact of boiling on free and bound phenolic profile and antioxidant activity of commercial gluten-free pasta. Food Res. Int. 2017, 100, 69–77. [Google Scholar] [CrossRef] [PubMed]

- Del Bo, C.; Bernardi, S.; Marino, M.; Porrini, M.; Tucci, M.; Guglielmetti, S.; Cherubini, A.; Carrieri, B.; Kirkup, B.; Kroon, P.; et al. Systematic review on polyphenol intake and health outcomes: Is there sufficient evidence to define a health-promoting polyphenol-rich dietary pattern? Nutrients 2019, 11, 1355. [Google Scholar] [CrossRef] [Green Version]

- Tresserra-Rimbau, A.; Rimm, E.B.; Medina-Remón, A.; Martínez-González, M.A.; de la Torre, R.; Corella, D.; Salas-Salvadó, J.; Gómez-Gracia, E.; Lapetra, J.; Arós, F.; et al. Inverse association between habitual polyphenol intake and incidence of cardiovascular events in the PREDIMED study. Nutr. Metab. Cardiovasc. Dis. 2014, 24, 639–647. [Google Scholar] [CrossRef]

- Rosa-Sibakov, N.; Heiniö, R.-L.; Cassan, D.; Holopainen-Mantila, U.; Micard, V.; Lantto, R.; Sozer, N. Effect of bioprocessing and fractionation on the structural, textural and sensory properties of gluten-free faba bean pasta. LWT Food Sci. Technol. 2016, 67, 27–36. [Google Scholar] [CrossRef]

- Bouasla, A.; Wójtowicz, A.; Zidoune, M.N.; Olech, M.; Nowak, R.; Mitrus, M.; Oniszczuk, A. Gluten-free precooked rice-yellow pea pasta: Effect of extrusion-cooking conditions on phenolic acids composition, selected properties and microstructure. J. Food Sci. 2016, 81, C1070–C1079. [Google Scholar] [CrossRef]

- Jayasena, V.; Nasar-Abbas, S.M. Development and quality evaluation of high-protein and high-dietary-fiber pasta using lupin flour. J. Texture Stud. 2012, 43, 153–163. [Google Scholar] [CrossRef]

- Bouasla, A.; Wójtowicz, A.; Zidoune, M.N. Gluten-free precooked rice pasta enriched with legumes flours: Physical properties, texture, sensory attributes and microstructure. LWT 2017, 75, 569–577. [Google Scholar] [CrossRef]

- Sobota, A.; Zarzycki, P. Effect of pasta cooking time on the content and fractional composition of dietary fiber. J. Food Qual. 2013, 36, 127–132. [Google Scholar] [CrossRef]

- Taherian, A.R.; Mondor, M.; Labranche, J.; Drolet, H.; Ippersiel, D.; Lamarche, F. Comparative study of functional properties of commercial and membrane processed yellow pea protein isolates. Food Res. Int. 2011, 44, 2505–2514. [Google Scholar] [CrossRef]

- Tsai, P.J.; Sun, Y.F.; Hsiao, S.M. Strengthening the texture of dried guava slice by infiltration of phenolic compounds. Food Res. Int. 2010, 43, 825–830. [Google Scholar] [CrossRef]

| Formulation | Rice (%) | Bean (%) | Carob Fruit (%) |

|---|---|---|---|

| 20.0 | 80 | 20 | 0 |

| 20.10 | 70 | 20 | 10 |

| 40.0 | 60 | 40 | 0 |

| 40.10 | 50 | 40 | 10 |

| 60.0 | 40 | 60 | 0 |

| 60.10 | 30 | 60 | 10 |

| 80.0 | 20 | 80 | 0 |

| 80.10 | 10 | 80 | 10 |

| Bean 100% | 0 | 100 | 0 |

| Rice 100% | 100 | 0 | 0 |

| Commercial rice | The product label: rice flour, corn flour, thickener and emulsifier additives, and water. | ||

| Sample | IP3 | IP4 | IP5 | IP6 | Total Inositol Phosphates |

|---|---|---|---|---|---|

| Bean | 0.26 ± 0.01 | 0.42 ± 0.01 | 1.39 ± 0.03 | 10.12 ± 0.03 | 12.20 |

| Carob fruit | n.d. | 0.15 ± 0.01 | 0.36 ± 0.04 | 0.15 ± 0.01 | 0.66 |

| Rice | 0.10 ± 0.01 | 0.03 ± 0.03 | 0.22 ± 0.01 | 1.53 ± 0.05 | 1.88 |

| P-20.0 | 0.23 ± 0.001 e f, A | 0.39 ± 0.02 b, A | 0.71 ± 0.07 b, A | 2.51 ± 0.13 c, A | 3.83 c, A |

| P-20.10 | 0.22 ± 0.001 c d, A | 0.36 ± 0.02 b, A | 0.70 ± 0.04 b, A | 2.51 ± 0.18 c, A | 3.79 c, A |

| P-40.0 | 0.25 ± 0.02 j, A | 0.55 ± 0.03 d e A | 1.08 ± 0.04 c d, A | 3.29 ± 0.21 e f, A | 5.16 d, A |

| P-40.10 | 0.22 ± 0.001 d e, A | 0.52 ± 0.05 c d, A | 0.97 ± 0.18 c, A | 3.11 ± 0.12 e, A | 4.83 d, A |

| P-60.0 | 0.24 ± 0.01 h i, A | 0.56 ± 0.02 c d, A | 1.28 ± 0.07 d e, A | 3.57 ± 0.11 f g, A | 5.65 e, A |

| P-60.10 | 0.24 ± 0.01 g h i, A | 0.64 ± 0.10 f, A | 1.18 ± 0.57 c d e, A | 4.09 ± 0.34 h, A | 6.15 f, A |

| P-80.0 | 0.23 ± 0.01 f g, A | 0.66 ± 0.03 f g, A | 1.84 ± 0.08 f g, A | 4.80 ± 0.11 j, A | 7.53 h, A |

| P-80.10 | 0.24 ± 0.01 i j, A | 0.70 ± 0.01 g, A | 1.97 ± 0.09 g, A | 5.16 ± 0.20 j, A | 8.06 i, A |

| P-Bean | 0.25 ± 0.001 h, A | 0.75 ± 0.02 h, A | 2.29 ± 0.12 h, A | 5.73 ± 0.58 k, A | 9.03 j, A |

| P-Rice | n.d. | 0.27 ± 0.02 a, A | 0.47 ± 0.12 a, A | 1.48 ± 0.13 b, A | 2.22 b, A |

| P-Commercial rice | n.d. | 0.25 ± 0.01 a, A | 0.29 ± 0.01 a, A | 0.37 ± 0.06 a, A | 0.84 a, A |

| PC-20.0 | 0.22 ± 0.001 b c d, B | 0.39 ± 0.02 b, A | 0.74 ± 0.03 b, A | 2.81 ± 0.20 d, B | 4.15 c, A |

| PC-20.10 | 0.21 ± 0.001 b, B | 0.38 ± 0.01 b, A | 0.76 ± 0.02 b, A | 2.40 ± 0.18 c, A | 3.75 c, A |

| PC-40.0 | 0.22 ± 0.001 c d, B | 0.48 ± 0.02 c, B | 1.07 ± 0.07 c d, A | 3.35 ± 0.08 e f, A | 5.12 d, A |

| PC-40.10 | 0.21 ± 0.001 b c d, A | 0.48 ± 0.03 c, B | 1.18 ± 0.11 c d e, A | 3.35 ± 0.06 e f, A | 5.23 d, A |

| PC-60.0 | 0.23 ± 0.001 e f, B | 0.52 ± 0.03 c d e, A | 1.27 ± 0.10 d e, A | 3.84 ± 0.12 g h, A | 5.86 e f, A |

| PC-60.10 | 0.22 ± 0.001 d e, B | 0.54 ± 0.03 d e, B | 1.39 ± 0.06 e, A | 3.91 ± 0.17 h, A | 6.05 f, A |

| PC-80.0 | 0.23 ± 0.001 f g h, A | 0.63 ± 0.04 f, A | 1.76 ± 0.12 f g, A | 4.82 ± 0.16 j, A | 7.43 h, A |

| PC-80.10 | 0.23 ± 0.001 f g, B | 0.57 ± 0.01 e, B | 1.64 ± 0.05 f, B | 4.54 ± 0.32 j, B | 6.98 g, B |

| PC-Bean | 0.21 ± 0.001 b c, B | 0.57 ± 0.03 c d, A | 1.91 ± 0.08 g, B | 5.28 ± 0.11 j, B | 7.97 i, A |

| PC-Rice | n.d. | 0.26 ± 0.01 a, A | 0.46 ± 0.03 a, A | 1.40 ± 0.08 b, A | 2.12 b, A |

| PC-Commercial rice | n.d. | 0.29 ± 0.01 a, A | 0.34 ± 0.03 a, A | 0.53 ± 0.12 a, A | 1.16 a, A |

| Sample | Sucrose | Maltose | Raffinose | Ciceritol | Stachyose | Total α-Galactosides |

|---|---|---|---|---|---|---|

| Bean | 30.00 ± 0.95 | n.d. | 5.92 ± 0.09 | 0.34 ± 0.01 | 26.85 ± 0.25 | 32.77 |

| Carob fruit | 150.46 ± 10.04 | n.d. | 5.84 ± 0.02 | n.d. | n.d. | 5.84 |

| Rice | 2.98 ± 0.15 | n.d. | n.d. | n.d. | n.d. | n.d. |

| P-20.0 | 8.59 ± 0.39 b, A | n.d. | 6.40 ± 0.58 e, A | 2.73 ± 0.30 b, A | 3.95 ± 0.38 a, A | 10.35 d, A |

| P-20.10 | 25.46 ± 0.09 I, A | n.d. | 8.31 ± 0.16 g, A | 2.19 ± 0.22 b, A | 3.47 ± 0.25 a, A | 11.78 e, A |

| P-40.0 | 14.18 ± 0.34 f, A | n.d. | 9.11 ± 0.27 h, A | 4.71 ± 0.08 e, A | 9.06 ± 0.18 b, A | 18.17 h, A |

| P-40.10 | 36.70 ± 0.78 p, A | n.d. | 8.00 ± 0.80 g, A | 6.43 ± 0.14 f, A | 13.37 ± 0.32 d, A | 21.37 j, A |

| P-60.0 | 23.77 ± 0.74 k, A | n.d. | 9.05 ± 0.29 h, A | 7.88 ± 0.17 g, A | 17.25 ± 0.37 f, A | 26.30 k, A |

| P-60.10 | 41.98 ± 0.68 q, A | n.d. | 13.13 ± 0.22 j, A | 10.09 ± 0.27 h, A | 17.41 ± 0.36 f, A | 30.54 m, A |

| P-80.0 | 29.63 ± 1.06 n, A | n.d. | 11.84 ± 0.89 i, A | 12.90 ± 0.94 j, A | 26.92 ± 1.45 i, A | 38.76 n, A |

| P-80.10 | 57.44 ± 0.52 r, A | n.d. | 18.72 ± 0.20 l, A | 13.55 ± 0.48 k, A | 26.12 ± 0.41 h, A | 44.85 o, A |

| P-Bean | 36.53 ± 0.93 p, A | n.d. | 13.82 ± 0.25 k, A | 12.36 ± 0.18 i, A | 30.71 ± 0.34 j, A | 44.53 o, A |

| P-Rice | 64.46 ± 1.44 s, A | 64.77 ± 1.30 d, A | n.d. | n.d. | n.d. | n.d. |

| P-Commercial rice | 18.32 ± 0.35 h, A | 15.51 ± 1.21 b, A | n.d. | n.d. | n.d. | n.d. |

| PC-20.0 | 5.76 ± 0.44 a, B | n.d. | 0.77 ± 0.08 a, B | 1.37 ± 0.17 a, B | 3.73 ± 0.06 a, A | 4.51 b, B |

| PC-20.10 | 18.00 ± 0.28 g, B | n.d. | 1.77 ± 0.09 b, B | 2.54 ± 0.17 b, A | 3.89 ± 0.12 a, A | 5.67 c, B |

| PC-40.0 | 9.66 ± 0.35 c, B | n.d. | 1.86 ± 0.23 b, B | 4.06 ± 0.28 d, B | 9.78 ± 0.18 b, A | 11.64 e, B |

| PC-40.10 | 22.37 ± 0.54 j, B | n.d. | 4.03 ± 0.31 b, B | 4.82 ± 0.79 e, B | 11.17 ± 1.02 c, B | 15.20 g, B |

| PC-60.0 | 11.76 ± 0.16 d, B | n.d. | 2.14 ± 0.11 c, B | 3.41 ± 0.14 c, B | 11.01 ± 0.09 c, B | 13.15 f, B |

| PC-60.10 | 27.20 ± 1.81 m, B | n.d. | 5.13 ± 0.23 d, B | 3.52 ± 0.23 c, B | 10.74 ± 0.50 c, A | 15.87 g, B |

| PC-80.0 | 21.02 ± 0.55 i, B | n.d. | 7.03 ± 0.05 f, B | 7.66 ± 0.03 g, B | 20.51 ± 0.72 g, B | 27.54 l, B |

| PC-80.10 | 30.28 ± 0.81 n, B | n.d. | 7.33 ± 0.12 f, B | 4.70 ± 0.20 e, B | 19.34 ± 0.23 e, B | 26.67 l, B |

| PC-Bean | 17.57 ± 0.41 g, B | n.d. | 3.72 ± 0.29 c, B | 3.31 ± 0.12 c, B | 15.89 ± 0.35 e, B | 19.61 i, B |

| PC-Rice | 12.80 ± 0.11 e, B | 10.85 ± 0.71 a, B | n.d. | n.d. | n.d. | n.d. |

| PC-Commercial rice | 34.55 ± 0.33 o, B | 24.06 ± 0.79 c, B | n.d. | n.d. | n.d. | n.d. |

| Sample | Trypsin Inhibitors | Chymotrypsin Inhibitors | Lectin |

|---|---|---|---|

| Bean | 23.21 ± 0.66 | 7.74 ± 0.28 | 0.59 ± 0.01 |

| Carob fruit | 0.30 ± 0.02 | n.d. | - |

| Rice | 0.15 ± 0.01 | n.d. | - |

| P-20.0 | 2.33 ± 0.07 b, A | 2.98 ± 0.25 b c, A | 0.26 ± 0.04 a |

| P-20.10 | 3.10 ± 0.28 c, A | 2.76 ± 0.23 b, A | 0.36 ± 0.17 a b |

| P-40.0 | 5.67 ± 0.08 d, A | 5.85 ± 0.54 d, A | 0.38 ± 0.10 a b |

| P-40.10 | 6.19 ± 0.40 d e, A | 8.22 ± 0.84 g, A | 0.42 ± 0.12 a b |

| P-60.0 | 7.57 ± 0.56 f, A | 10.85 ± 1.05 h, A | 0.34 ± 0.18 a b |

| P-60.10 | 7.25 ± 0.51 f, A | 10.23 ± 1.08 h, A | 0.39 ± 0.12 a b |

| P-80.0 | 10.26 ± 0.77 g, A | 16.15 ± 0.75 j, A | 0.54 ± 0.10 b |

| P-80.10 | 10.19 ± 0.42 g, A | 7.70 ± 0.32 e f, A | 0.56 ± 0.28 b |

| P-Bean | 13.19 ± 0.75 j, A | 16.87 ± 0.57 j, A | 0.58 ± 0.14 b |

| P-Rice | 0.50 ± 0.04 a, A | 0.56 ± 0.13 a, A | n.d. |

| P-Commercial rice | 0.66 ± 0.03 a, A | 0.40 ± 0.10 a, A | n.d. |

| PC-20.0 | 2.45 ± 0.07 b, A | 3.41 ± 0.34 b c, A | n.d. |

| PC-20.10 | 3.17 ± 0.22 c, A | 4.01 ± 0.86 c, B | n.d. |

| PC-40.0 | 5.67 ± 0.35 d, A | 6.85 ± 0.61 e, B | n.d. |

| PC-40.10 | 6.35 ± 0.36 e, A | 7.45 ± 0.74 e f, A | n.d. |

| PC-60.0 | 6.96 ± 0.37 f, A | 12.26 ± 1.01 i, B | n.d. |

| PC-60.10 | 7.13 ± 0.72 f, A | 12.08 ± 1.55 i, B | n.d. |

| PC-80.0 | 11.10 ± 0.34 h, B | 16.30 ± 1.27 j, A | n.d. |

| PC-80.10 | 10.24 ± 0.74 g, A | 8.21 ± 0.72 g, A | n.d. |

| PC-Bean | 12.12 ± 0.35 i, B | 16.62 ± 1.10 j, A | n.d. |

| PC-Rice | 0.15 ± 0.02 a, A | 0.47 ± 0.01 a, A | n.d. |

| PC-Commercial rice | 0.33 ± 0.01 a, A | 0.29 ± 0.02 a, A | n.d. |

| Sample | Total Phenols | Tartaric Esters | Flavonols | Anthocyanins | Antioxidant Activity (ORAC) |

|---|---|---|---|---|---|

| Bean | 2.88 ± 0.02 | 0.21 ± 0.01 | 0.08 ± 0.001 | 36.96 ± 0.24 | 24.33 ± 0.07 |

| Carob fruit | 20.73 ± 0.10 | 0.72 ± 0.01 | 0.75 ± 0.001 | 18.00 ± 0.15 | 69.89 ± 1.62 |

| Rice | 0.90 ± 0.03 | 0.02 ± 0.001 | 0.03 ± 0.001 | 18.70 ± 0.83 | 3.80 ± 0.30 |

| P-20.0 | 2.88 ± 0.20 d e, A | 0.07 ± 0.001 c d, A | 0.03 ± 0.001 c, A | 10.65 ± 0.001 g h, A | 5.26 ± 0.65 c d, A |

| P-20.10 | 5.77 ± 0.06 l, A | 0.14 ± 0.02 i, A | 0.10 ± 0.001 g, A | 10.64 ± 0.001 g h, A | 10.49 ± 0.69 g h, A |

| P-40.0 | 4.58 ± 0.01 g h, A | 0.09 ± 0.001 e f, A | 0.03 ± 0.001 b c, A | 8.25 ± 0.001 e f g h, A | 6.94 ± 0.67 f, A |

| P-40.10 | 5.40 ± 0.21 j k, A | 0.14 ± 0.001 i, A | 0.08 ± 0.001 f, A | 9.16 ± 0.001 f g h, A | 9.67 ± 1.23 h i, A |

| P-60.0 | 4.70 ± 0.40 g h i, A | 0.09 ± 0.001 f, A | 0.03 ± 0.001 c, A | 8.25 ± 0.001 d e f g h, A | 9.20 ± 0.52 g h, A |

| P-60.10 | 5.80 ± 0.31 k l, A | 0.15 ± 0.001 j, A | 0.10 ± 0.001 g, A | 6.32 ± 0.001 b c d e f, A | 12.39 ± 0.27 k, A |

| P-80.0 | 4.48 ± 0.34 g, A | 0.12 ± 0.001 g, A | 0.04 ± 0.001 d, A | 5.70 ± 0.001 b c d e f, A | 11.06 ± 0.64 j, A |

| P-80.10 | 7.27 ± 0.21 m, A | 0.20 ± 0.01 k, A | 0.10 ± 0.001 g, A | 6.87 ± 0.001 c d e f g, A | 13.68 ± 0.58 l, A |

| P-Bean | 5.11 ± 0.13 i j, A | 0.12 ± 0.001 g h, A | 0.04 ± 0.001 d, A | 7.05 ± 0.001 c d e f g, A | 12.46 ± 0.19 k, A |

| P-Rice | 2.28 ± 0.10 a b c, A | 0.06 ± 0.001 a b, A | 0.02 ± 0.001 a b, A | 12.43 ± 0.001 h, A | 4.57 ± 0.25 b c, A |

| P-Commercial rice | 2.50 ± 0.12 b c d, A | 0.08 ± 0.001 e, A | 0.02 ± 0.001 a b, A | 2.78 ± 0.001 a b, A | 4.38 ± 0.42 a b, A |

| PC-20.0 | 2.35 ± 0.20 b c, B | 0.09 ± 0.001 e f, B | 0.02 ± 0.001 a b, B | 1.77 ± 0.001 a, B | 5.12 ± 0.54 c d, A |

| PC-20.10 | 4.47 ± 0.07 g, B | 0.13 ± 0.001 h i, A | 0.09 ± 0.001 f, B | 3.09 ± 0.001 a b c, B | 8.20 ± 0.74 g h, A |

| PC-40.0 | 3.52 ± 0.22 f, B | 0.07 ± 0.001 c d, B | 0.02 ± 0.001 a b, B | 3.89 ± 0.01 a b c, B | 5.97 ± 0.36 f, A |

| PC-40.10 | 4.59 ± 0.25 g h, B | 0.13 ± 0.001 h i, A | 0.08 ± 0.001 f, A | 2.91 ± 0.01 a b c, B | 10.01 ± 0.62 h i, A |

| PC-60.0 | 3.21 ± 0.27 e f, B | 0.06 ± 0.001 c d, B | 0.02 ± 0.001 a b, B | 1.37 ± 0.001 a, B | 8.77 ± 0.86 g h, A |

| PC-60.10 | 5.03 ± 0.26 h i j, B | 0.14 ± 0.001 j, A | 0.10 ± 0.001 g, A | 0.91 ± 0.001 a, B | 10.32 ± 1.22 k, A |

| PC-80.0 | 3.29 ± 0.20 e f, B | 0.09 ± 0.001 f, B | 0.03 ± 0.001 c, B | 5.33 ± 0.001 a b c d e, A | 8.09 ± 0.72 j, A |

| PC-80.10 | 5.83 ± 0.55 k l, B | 0.14 ± 0.001 i, B | 0.07 ± 0.001 e, B | 6.41 ± 0.001 b c d e f, A | 9.31 ± 0.60 l, A |

| PC-Bean | 2.66 ± 0.18 c d, B | 0.06 ± 0.001 b c, B | 0.01 ± 0.001 a, B | 3.22 ± 0.001 a b c, A | 6.99 ± 0.65 k, A |

| PC-Rice | 2.11 ± 0.06 a b, A | 0.05 ± 0.001 a, A | 0.02 ± 0.001 a b, A | 13.19 ± 0.001 i, B | 4.66 ± 0.74 b c, A |

| PC-Commercial rice | 1.80 ± 0.07 a, B | 0.07 ± 0.001 d, A | 0.01 ± 0.001 a, A | 2.63 ± 0.001 a b c d, A | 3.08 ± 0.51 a b, A |

| Formulation | Uncooked Pasta (P-) | Cooked Pasta (PC-) | ||||

|---|---|---|---|---|---|---|

| L* | a* | b* | L* | a* | b* | |

| 20.0 | 84.56 ± 0.21 g h, A | 1.42 ± 0.03 f, A | 16.62 ± 0.14 h, A | 65.03 ± 1.30 d, B | –1.57 ± 0.17 a b, B | 12.37 ± 1.26 c, B |

| 20.10 | 69.31 ± 0.15 e, A | 4.58 ± 0.07 j, A | 14.59 ± 0.17 e f, A | 44.44 ± 1.42 a, B | 7.37 ± 0.63 m, B | 12.60 ± 0.78 c d, B |

| 40.0 | 84.98 ± 0.12 h, A | 1.72 ± 0.05 f g, A | 18.16 ± 0.23 i, A | 65.69 ± 0.61 d, B | –1.27 ± 0.21 b c, B | 15.00 ± 0.76 f, B |

| 40.10 | 70.07 ± 0.12 e, A | 4.27 ± 0.06 j, A | 15.39 ± 0.12 f g, A | 45.73 ± 1.17 a b, B | 6.42 ± 0.47 l, B | 12.56 ± 0.42 c d, B |

| 60.0 | 83.25 ± 0.28 f g, A | 2.51 ± 0.06 h, A | 20.56 ± 0.44 j, A | 65.63 ± 1.08 d, B | –1.04 ± 0.30 c, B | 16.23 ± 1.19 g h, B |

| 60.10 | 69.05 ± 0.29 e, A | 4.23 ± 0.01 j, A | 15.41 ± 0.11 f g, A | 47.06 ± 1.48 b, B | 5.68 ± 0.50 k, B | 11.58 ± 0.63 b c, B |

| 80.0 | 83.66 ± 0.12 g h, A | 2.12 ± 0.03 g h, A | 19.58 ± 0.08 i, A | 65.43 ± 1.19 d, B | –0.50 ± 0.4 d, B | 17.77 ± 1.24 i, B |

| 80.10 | 68.44 ± 0.27 e, A | 4.69 ± 0.08 j, A | 18.29 ± 0.27 j, A | 46.26 ± 1.04 b, B | 5.84 ± 0.52 k, B | 13.63 ± 0.63 d e, B |

| Bean 100% | 81.93 ± 0.16 f, A | 3.44 ± 0.03 i, A | 22.85 ± 0.14 k, A | 64.53 ± 1.20 d, B | 0.63 ± 0.35 e, B | 19.98 ± 0.61 j, B |

| Rice 100% | 87.02 ± 0.10 i, A | 0.69 ± 0.01 e, A | 11.55 ± 0.05 b c, A | 62.93 ± 2.09 c, B | –1.86 ± 0.11 a, B | 4.42 ± 0.61 a, B |

| Commercial rice | 92.01 ± 0.05 j, A | 0.30 ± 0.001 e, A | 11.07 ± 0.10 b, A | 70.08 ± 1.36 e, B | –1.60 ± 0.19 a b, B | 12.66 ± 1.54 c d, B |

| Hardness | Stickiness | Adhesiveness | Cutting | ||

|---|---|---|---|---|---|

| Sample | (N) | (N) | (N·s) | Firmness (N) | Consistency (N·s) |

| PC-20.0 | 58.31 ± 0.62 d | 9.21 ± 0.19 a | –0.44 ± 0.12 a | 3.14 ± 0.04 d e | 5.39 ± 0.06 b |

| PC-20.10 | 44.49 ± 0.44 b | 6.66 ± 0.16 b c | –0.41 ± 0.09 a b c | 3.14 ± 0.02 d e | 5.39 ± 0.04 b |

| PC-40.0 | 55.56 ± 0.21 c d | 6.96 ± 0.20 b c | –0.39 ± 0.11 a b c | 3.23 ± 0.02 d e | 6.17 ± 0.05 c d |

| PC-40.10 | 53.51 ± 0.25 c d | 5.88 ± 0.18 c d | –0.35 ± 0.07 b c d | 4.02 ± 0.08 f | 5.49± 0.10 b c |

| PC-60.0 | 58.21 ± 0.37 d | 4.61 ± 0.12 d | –0.30 ± 0.06 d | 3.33 ± 0.04 e | 6.47 ± 0.08 d |

| PC-60.10 | 53.21 ± 0.42 c | 6.47 ± 0.12 c | –0.40 ± 0.05 a b c | 2.74 ± 0.04 b c | 5.29 ± 0.09 b |

| PC-80.0 | 63.50 ± 0.46 e | 7.94 ± 0.14 a b | –0.45 ± 0.07 a | 4.02 ± 0.03 f | 8.13 ± 0.09 e |

| PC-80.10 | 68.21± 0.70 f | 6.17 ± 0.13 c | –0.42 ± 0.06 a b | 2.94 ± 0.07 c d | 6.66± 0.09 d |

| PC-Bean | 70.36 ± 0.65 f | 4.51 ± 0.15 d | –0.32 ± 0.09 c d | 4.70 ± 0.03 g | 10.58 ± 0.15 f |

| PC-Rice | 35.28 ± 1.17 a | 9.11 ± 0.35 a | –0.39 ± 0.10 a b | 1.96 ± 0.04 a | 3.53 ± 0.08 a |

| PC-Commercial | 31.26 ± 0.32 a | 2.74 ± 0.04 e | –0.37 ± 0.09 a b c d | 2.45 ± 0.03 b | 8.53± 0.11 e |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arribas, C.; Cabellos, B.; Cuadrado, C.; Guillamón, E.; Pedrosa, M.M. Cooking Effect on the Bioactive Compounds, Texture, and Color Properties of Cold-Extruded Rice/Bean-Based Pasta Supplemented with Whole Carob Fruit. Foods 2020, 9, 415. https://doi.org/10.3390/foods9040415

Arribas C, Cabellos B, Cuadrado C, Guillamón E, Pedrosa MM. Cooking Effect on the Bioactive Compounds, Texture, and Color Properties of Cold-Extruded Rice/Bean-Based Pasta Supplemented with Whole Carob Fruit. Foods. 2020; 9(4):415. https://doi.org/10.3390/foods9040415

Chicago/Turabian StyleArribas, Claudia, Blanca Cabellos, Carmen Cuadrado, Eva Guillamón, and Mercedes M. Pedrosa. 2020. "Cooking Effect on the Bioactive Compounds, Texture, and Color Properties of Cold-Extruded Rice/Bean-Based Pasta Supplemented with Whole Carob Fruit" Foods 9, no. 4: 415. https://doi.org/10.3390/foods9040415

APA StyleArribas, C., Cabellos, B., Cuadrado, C., Guillamón, E., & Pedrosa, M. M. (2020). Cooking Effect on the Bioactive Compounds, Texture, and Color Properties of Cold-Extruded Rice/Bean-Based Pasta Supplemented with Whole Carob Fruit. Foods, 9(4), 415. https://doi.org/10.3390/foods9040415