Development of High-Moisture Meat Analogues with Hemp and Soy Protein Using Extrusion Cooking

Abstract

:1. Introduction

2. Materials and Methods

2.1. Moisture Content

2.2. Viscosity

2.3. Thermal Properties

2.4. High-Moisture Extrusion Processing

2.5. Texture Properties

2.6. Colour Determination and Appearance of HMMA

2.7. Statistical Analysis

3. Results and Discussion

3.1. Moisture Content

3.2. Pasting Properties

3.3. Thermal Properties

3.4. Texture Properties

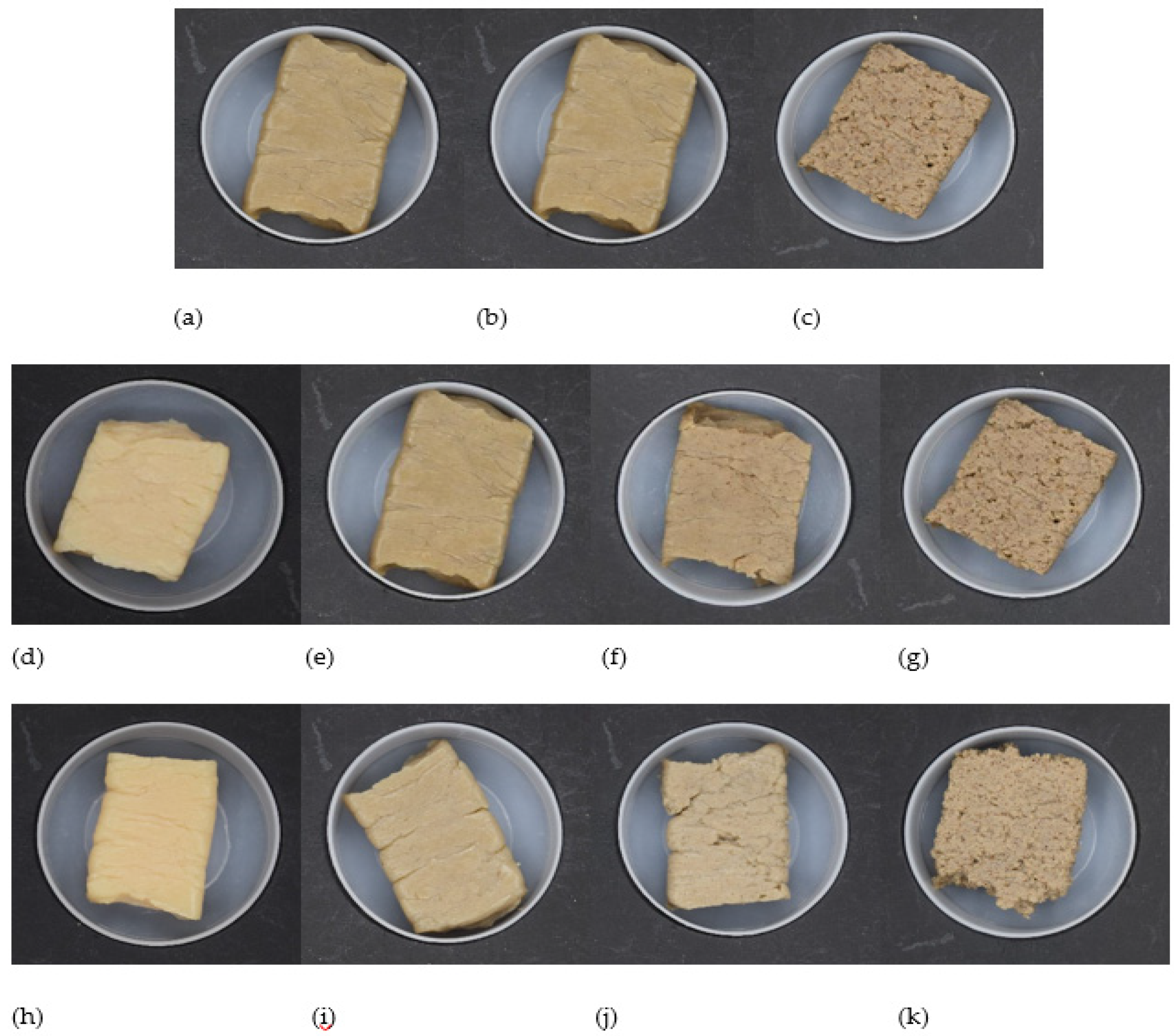

3.5. Colour Determination and Appearance of HMMA

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

| Screw Configuration for Meat Analogue Product | |||

|---|---|---|---|

| 1. | SE-30/30A | 18. | SE-20/20R |

| 2. | SE-30/30R | 19. | SE-20/20R |

| 3. | SE-30/30R | 20. | SE-20/20R |

| 4. | SE-30/30R | 21. | KBW-45/5/20/R |

| 5. | SE-30/30R | 22. | KBW-45/5/30/R |

| 6. | SE-20/20R | 23. | SE-20/10L |

| 7. | SE-20/20R | 24. | SE-30/30R |

| 8. | SE-20/20R | 25. | SE-20/10L |

| 9. | SE-20/20R | 26. | SE-30/30R |

| 10. | SE-30/30R | 27. | SE-20/10L |

| 11. | SE-30/30R | 28. | KBW-45/5/30/R |

| 12. | SE-20/20R | 29. | KBW-45/5/20/L |

| 13. | KBW-45/5/20/R | 30. | SE-30/15R |

| 14. | SE-30/30R | 31. | SE-20/20R |

| 15. | SE-30/30R | 32. | SE-20/20R |

| 16. | SE-30/30R | 33. | SE-20/20R |

| 17. | SE-20/20R | 34. | SE-30/30R |

References

- Richi, E.B.; Baumer, B.; Conrad, B.; Darioli, R.; Schmid, A.; Keller, U. Health Risks Associated with Meat Consumption: A Review of Epidemiological Studies. Int. J. Vitam. Nutr. Res. 2015, 85, 70–78. [Google Scholar] [CrossRef]

- Gerber, P.; Steinfeld, H.; Henderson, B.; Mottet, A.; Opio, C.; Dijkman, J.; Falcucci, A.; Tempio, G. Tackling Climate Change through Livestock—A Global Assessment of Emissions and Mitigation Opportunities; Food and Agriculture Organization of the United Nations (FAO): Rome, Italy, 2013. [Google Scholar] [CrossRef] [Green Version]

- Röös, E.; Bajželj, B.; Smith, P.; Patel, M.; Little, D.; Garnett, T. Greedy or Needy? Land Use and Climate Impacts of Food in 2050 under Different Livestock Futures. Glob. Environ. Chang. 2017, 47, 1–12. [Google Scholar] [CrossRef]

- EAT-Lancet Commission. Healthy Diets from Sustainable Food Systems: Food Planet Health; EAT-Lancet Commission: Stockholm, Sweden, 2019. [Google Scholar]

- Deloitte. Plant-Based Alternatives-Driving Industry M&A Contents; Deloitte LLP: London, UK, 2019. [Google Scholar]

- Liu, K.S.; Hsieh, F.H. Protein-Protein Interactions in High Moisture-Extruded Meat Analogs and Heat-Induced Soy Protein Gels. JAOCS J. Am. Oil Chem. Soc. 2007, 84, 741–748. [Google Scholar] [CrossRef]

- Lin, S.; Huff, H.E.; Hsieh, F. Texture and Chemical Characteristics of Soy Protein Meat Analog Extruded at High Moisture. J. Food Sci. 2000, 65, 264–269. [Google Scholar] [CrossRef]

- Lin, S.; Huff, H.E.; Hsieh, F. Extrusion Process Parameters, Sensory Characteristics, and Structural Properties of a High Moisture Soy Protein Meat Analog. J. Food Sci. 2002, 67, 1066–1072. [Google Scholar] [CrossRef]

- Cheftel, J.C.; Kitagawa, M.; Queguiner, C. New Protein Texturization Processes by Extrusion Cooking at High Moisture Levels. Food Rev. Int. 1992, 8, 235–275. [Google Scholar] [CrossRef]

- Pietsch, V.L.; Bühler, J.M.; Karbstein, H.P.; Emin, M.A. High Moisture Extrusion of Soy Protein Concentrate: Influence of Thermomechanical Treatment on Protein-Protein Interactions and Rheological Properties. J. Food Eng. 2019, 251, 11–18. [Google Scholar] [CrossRef]

- Chiang, J.H.; Loveday, S.M.; Hardacre, A.K.; Parker, M.E. Effects of Soy Protein to Wheat Gluten Ratio on the Physicochemical Properties of Extruded Meat Analogues. Food Struct. 2019, 19. [Google Scholar] [CrossRef]

- Osen, R.; Toelstede, S.; Eisner, P.; Schweiggert-Weisz, U. Effect of High Moisture Extrusion Cooking on Protein-Protein Interactions of Pea (Pisum sativum L.) Protein Isolates. Int. J. Food Sci. Technol. 2015, 50, 1390–1396. [Google Scholar] [CrossRef]

- Osen, R.; Toelstede, S.; Wild, F.; Eisner, P.; Schweiggert-Weisz, U. High Moisture Extrusion Cooking of Pea Protein Isolates: Raw Material Characteristics, Extruder Responses, and Texture Properties. J. Food Eng. 2014, 127, 67–74. [Google Scholar] [CrossRef]

- Schreuders, F.K.G.; Dekkers, B.L.; Bodnár, I.; Erni, P.; Boom, R.M.; van der Goot, A.J. Comparing Structuring Potential of Pea and Soy Protein with Gluten for Meat Analogue Preparation. J. Food Eng. 2019. [Google Scholar] [CrossRef]

- Young, E.M. Revival of Industrial Hemp: A Systematic Analysis of the Current Global Industry to Determine Limitations and Identify Future Potentials within the Concept of Sustainability. Master’s Thesis, Lund University, Lund, Sweden, 9 December 2005. [Google Scholar]

- Wang, Q.; Xiong, Y.L. Processing, Nutrition, and Functionality of Hempseed Protein: A Review. Compr. Rev. Food Sci. Food Saf. 2019, 18. [Google Scholar] [CrossRef] [Green Version]

- Zhang, J.; Liu, L.; Liu, H.; Yoon, A.; Rizvi, S.S.H.; Wang, Q. Changes in Conformation and Quality of Vegetable Protein during Texturization Process by Extrusion. Crit. Rev. Food Sci. Nutr. 2019, 59, 3267–3280. [Google Scholar] [CrossRef]

- Raikos, V.; Neacsu, M.; Russell, W.; Duthie, G. Comparative Study of the Functional Properties of Lupin, Green Pea, Fava Bean, Hemp, and Buckwheat Flours as Affected by PH. Food Sci. Nutr. 2014, 2, 802–810. [Google Scholar] [CrossRef] [Green Version]

- Tang, C.H.; Ten, Z.; Wang, X.S.; Yang, X.Q. Physicochemical and Functional Properties of Hemp (Cannabis sativa L.) Protein Isolate. J. Agric. Food Chem. 2006, 54, 8945–8950. [Google Scholar] [CrossRef]

- AACC. AACC Method 44-15A. Moisture—Air-Oven Method. In AACC Approved Methods of Analysis, 10th ed.; American Association of Cereal Chemists International: St. Paul, MN, USA, 2000. [Google Scholar]

- AACC. AACC Method 76-21.02. General Pasting Method for Wheat or Rye Flour or Starch Using the Rapid Visco Analyser. In AACC Approved Methods of Analysis, 11th ed.; American Association of Cereal Chemists International: St. Paul, MN, USA, 1997. [Google Scholar]

- Samard, S.; Gu, B.Y.; Ryu, G.H. Effects of Extrusion Types, Screw Speed and Addition of Wheat Gluten on Physicochemical Characteristics and Cooking Stability of Meat Analogues. J. Sci. Food Agric. 2019, 99, 4922–4931. [Google Scholar] [CrossRef]

- Texture Profile Analysis. Available online: https://texturetechnologies.com/resources/texture-profile-analysis#tpa-measurements (accessed on 6 March 2020).

- Da Silva, V.B.; da Costa, M.P. Influence of Processing on Rheological and Textural Characteristics of Goat and Sheep Milk Beverages and Methods of Analysis. In Processing and Sustainability of Beverages; Grumezescu, A.M., Holban, A.M., Eds.; Woodhead Publishing Limited: Duxford, UK, 2019; pp. 373–412. [Google Scholar] [CrossRef]

- Morey, A.; Owens, C.M. Methods for Measuring Meat Texture. In Poultry Quality Evaluation: Quality Attributes and Consumer Values; Petracci, M., Berri, C., Eds.; Elsevier Ltd.: Duxford, UK, 2017; pp. 115–132. [Google Scholar] [CrossRef]

- Alamu, E.O.; Maziya-Dixon, B.; Dixon, A.G. Evaluation of Proximate Composition and Pasting Properties of High Quality Cassava Flour (HQCF) from Cassava Genotypes (Manihot Esculenta Crantz) of β-Carotene-Enriched Roots. LWT 2017, 86, 501–506. [Google Scholar] [CrossRef]

- Bemiller, J.N. Pasting, Paste, and Gel Properties of Starch-Hydrocolloid Combinations. Carbohydr. Polym. 2011, 86, 386–423. [Google Scholar] [CrossRef]

- Cozzolino, D. The Use of the Rapid Visco Analyser (RVA) in Breeding and Selection of Cereals. J. Cereal Sci. 2016, 70, 282–290. [Google Scholar] [CrossRef]

- Kitabatake, N.; Tahara, M.; Dol, E. Thermal Denaturation of Soybean Protein at Low Water Contents. Agric. Biol. Chem. 1990, 54, 2205–2212. [Google Scholar] [CrossRef]

- Palanisamy, M.; Töpfl, S.; Berger, R.G.; Hertel, C. Physico-Chemical and Nutritional Properties of Meat Analogues Based on Spirulina/Lupin Protein Mixtures. Eur. Food Res. Technol. 2019, 245, 1889–1898. [Google Scholar] [CrossRef]

- Camire, M.E.; Camire, A.L.; Krumhar, K. Chemical and Nutritional Changes. Crit. Rev. Food Sci. Nutr. 1990, 29, 35–57. [Google Scholar] [CrossRef] [PubMed]

- Santillán-Moreno, A.; Martínez-Bustos, F.; Castaño-Tostado, E.; Amaya-Llano, S.L. Physicochemical Characterization of Extruded Blends of Corn Starch-Whey Protein Concentrate-Agave Tequilana Fiber. Food Bioprocess Technol. 2011, 4, 797–808. [Google Scholar] [CrossRef]

- Malav, O.P.; Talukder, S.; Gokulakrishnan, P.; Chand, S. Meat Analog: A Review. Crit. Rev. Food Sci. Nutr. 2015, 55, 1241–1245. [Google Scholar] [CrossRef] [PubMed]

| Raw Material | Moisture Content (%) |

|---|---|

| 100% SPI | 6.39 ± 0.03 |

| 100% HPC | 8.02 ± 0.07 |

| Mixtures (HPC:SPI) (%) | Calculated Moisture Content (%) |

| 20:80 | 6.72 |

| 40:60 | 7.04 |

| 60:40 | 7.37 |

| Formulation | Screw Speed (rpm) | Target Moisture Content (%) | Temperature (°C) (Zone 1–2–3–4) | Selected Trial |

|---|---|---|---|---|

| 0% HPC (100% SPI) | 500 | 70 | 40–60–80–100 | √ |

| 75 | √ | |||

| 20% HPC | 800 | 65 | 40–60–80–100 | √ |

| 70 | √ | |||

| 75 | √ | |||

| 600 | 75 | |||

| 80 | ||||

| 400 | 75 | |||

| 300 | 75 | |||

| 40% HPC | 800 | 65 | 40–60–80–100 | √ |

| 70 | √ | |||

| 75 | √ | |||

| 60% HPC | 800 | 60 | 40–60–80–100 | |

| 62.5 | ||||

| 65 | √ | |||

| 70 | √ | |||

| 75 | √ | |||

| 65 | 60–80–100–120 |

| Formula | Moisture Content (%) | Hardness (g) | Springiness | Resilience | Chewiness (g) |

|---|---|---|---|---|---|

| 0% HPC (100% SPI) | 70 | 527 ± 33 aC | 0.99 ± 0.01 aA | 0.51 ± 0.01 aB | 459 ± 34 aC |

| 75 | 545 ± 66 aB | 0.99 ± 0.00 aA | 0.48 ± 0.01 bB | 465 ± 44 aC | |

| 20% HPC | 65 | 3444 ± 186 aA | 0.88 ± 0.14 aA | 1.59 ± 0.88 aA | 2944 ± 123 aA |

| 70 | 1911 ± 18 bA | 0.95 ± 0.06 aA | 0.55 ± 0.02 aB | 1630 ± 19 bA | |

| 75 | 798 ± 21 cA | 0.96 ± 0.05 aA | 0.52 ± 0.01 aA | 670 ± 8 cB | |

| 40% HPC | 65 | 3275 ± 76 aA | 0.91 ± 0.14 aA | 0.57 ± 0.03 bA | 2692 ± 71 aB |

| 70 | 1700 ± 66 bB | 1.19 ± 0.12 aA | 1.66 ± 0.26 aA | 1435 ± 44 bB | |

| 75 | 851 ± 42 cA | 0.97 ± 0.04 aA | 0.51 ± 0.04 bAB | 721 ± 29 cA | |

| 60% HPC | 65 | 2640 ± 84 aB | 1.02 ± 0.19 aA | 1.20 ± 0.60 aA | 2128 ± 34 aC |

| 70 | 1719 ±116b bB | 0.93 ± 0.04 aA | 0.52 ± 0.07 aB | 1410 ± 59 bB | |

| 75 | Too soft and brittle to measure | ||||

| Sample | Colorimeter | Visual Appearance | ||

|---|---|---|---|---|

| Moisture Content (%) | L* | a* | b* | |

| 0% HPC (100% SPI) | ||||

| 70 | 61.67 ± 0.25 A | −0.24 ± 0.07 A | 13.48 ± 0.43 A | Light colour, compact |

| 75 | 62.55± 0.21 A | −0.29 ± 0.19 A | 13.00 ± 0.53 A | Light colour, compact |

| 20% HPC | ||||

| 65 | 46.19 ± 0.68 aB | 0.84 ± 0.08 aB | 8.45 ± 0.23 aB | Compact |

| 70 | 46.84 ± 0.68 bC | 0.69 ± 0.15 bC | 9.20 ± 0.42 bB | Compact |

| 75 | 48.87 ± 0.29 bC | 0.30 ± 0.09 bC | 8.78 ±0.14 abB | Less compact |

| 40% HPC | ||||

| 65 | 45.92 ± 1.30 aC | 1.64 ± 0.35 aD | 9.22 ± 1.02 aB | Compact, dark spot |

| 70 | 48.65 ± 0.52 bB | 1.73 ± 0.11 aD | 10.90 ± 0.45 aC | Compact |

| 75 | 50.96 ± 0.78 bD | 0.95 ± 0.15 bC | 10.34 ± 0.40 aC | Pale, less compact |

| 60% HPC | ||||

| 65 | 45.43 ± 0.33 aC | 2.34 ± 0.20 aE | 7.98 ± 0.72 aB | Less compact |

| 70 | 50.42 ± 0.56 bBD | 2.29 ± 0.04 aE | 10.11 ± 0.47 bB | Less compact |

| 75 | 49.78 ± 1.01 bD | 2.23 ± 0.15 aE | 9.56 ± 0.41 bC | Came out foamy |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zahari, I.; Ferawati, F.; Helstad, A.; Ahlström, C.; Östbring, K.; Rayner, M.; Purhagen, J.K. Development of High-Moisture Meat Analogues with Hemp and Soy Protein Using Extrusion Cooking. Foods 2020, 9, 772. https://doi.org/10.3390/foods9060772

Zahari I, Ferawati F, Helstad A, Ahlström C, Östbring K, Rayner M, Purhagen JK. Development of High-Moisture Meat Analogues with Hemp and Soy Protein Using Extrusion Cooking. Foods. 2020; 9(6):772. https://doi.org/10.3390/foods9060772

Chicago/Turabian StyleZahari, Izalin, Ferawati Ferawati, Amanda Helstad, Cecilia Ahlström, Karolina Östbring, Marilyn Rayner, and Jeanette K. Purhagen. 2020. "Development of High-Moisture Meat Analogues with Hemp and Soy Protein Using Extrusion Cooking" Foods 9, no. 6: 772. https://doi.org/10.3390/foods9060772