Characterisation of Biologically Active Hydrolysates and Peptide Fractions of Vacuum Packaging String Bean (Phaseolus Vulgaris L.)

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material

2.2. Preparation of Yellow String Beans

2.3. Cell Culture with PB and UB Extract Treatment

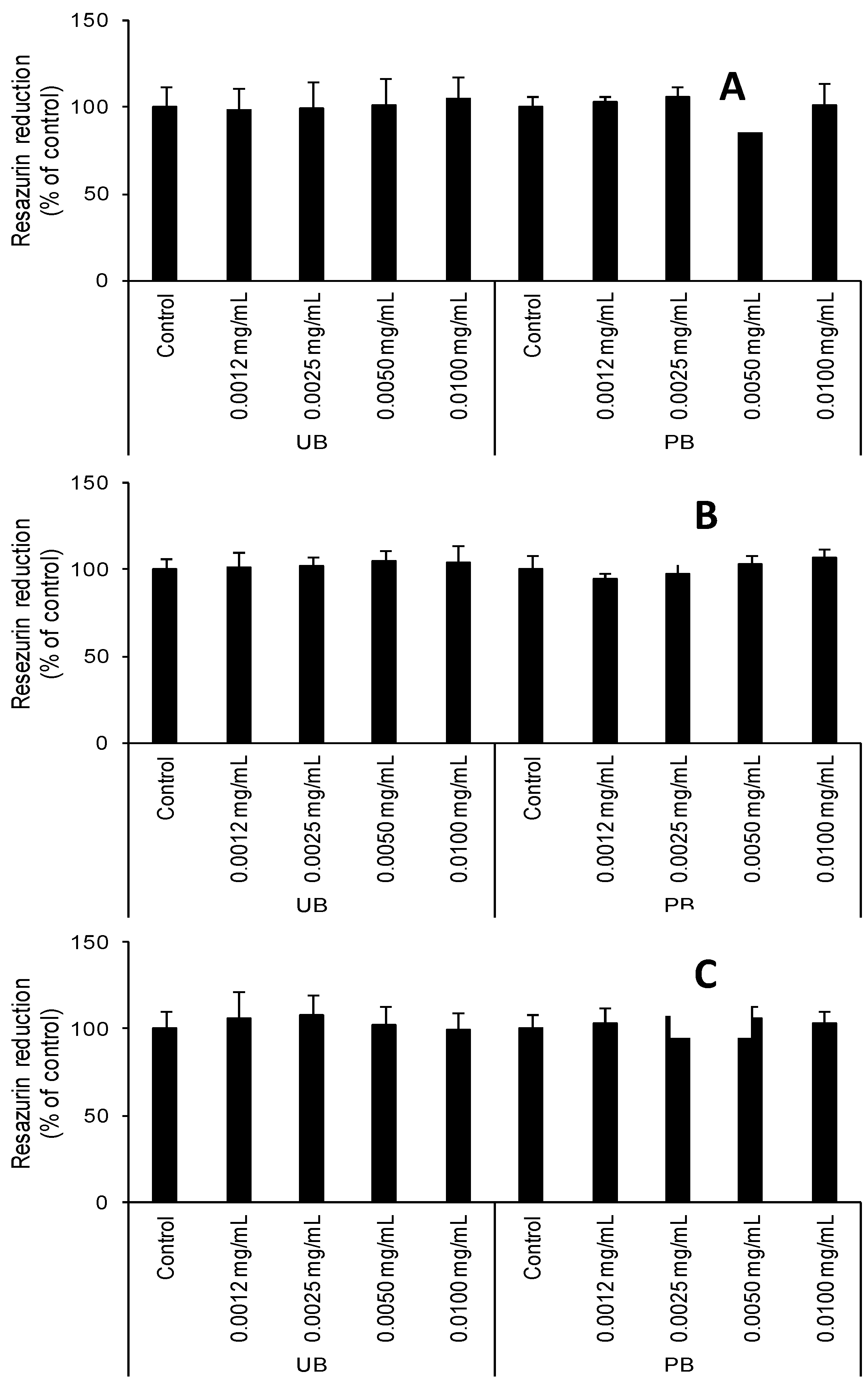

Resazurin Reduction Cell Viability Assay

2.4. Enzymatic Hydrolysis

2.4.1. Peptide Fraction Preparation

2.4.2. Potential Bioaccessibility and Bioavailability of Peptides Obtained from String Bean Proteins

2.5. Nutrient Analysis

2.5.1. Protein Content

2.5.2. Soluble and Insoluble Dietary Fibre

2.5.3. Reducing Sugar Content

2.5.4. Peptide Content

2.6. Nutraceutical Potential of Hydrolysates and Peptide Fractions

2.6.1. Antioxidant Activities

Antiradical Activity (ABTS•+)

Antiradical Activity (DPPH•)

Fe2+ Chelating Activity

Reducing Power (RP)

2.6.2. Inhibition of Enzymes Involved in Metabolic Syndrome Pathogenesis

Assay of ACE Inhibitory Activity

α-Amylase Inhibitory Activity Assay

Lipase Inhibitory Activity Assay

2.7. Antimicrobial Activity of Peptide Fractions

2.7.1. Disc Diffusion Method

2.7.2. Determination of the Minimum Inhibitory Concentration (MIC) and the Minimum Bactericidal Concentration (MBC)

2.8. Statistical Analysis

3. Results

3.1. Effect of Extracts From Pb and UB on Resazurin Reduction in the SCC-15 Cell Line

3.2. Nutrient Composition of PB and UB

3.3. Peptide Content during the Hydrolysis Process

3.4. Potential Bioaccessibility and Bioavailability of Peptides Obtained from String Bean Proteins

3.5. Antioxidant Activity of Hydrolysates and Peptide Fractions Obtained From PB and UB

3.6. Inhibitors of Enzymes Involved in the Pathogenesis of Metabolic Syndrome Obtained From PB and UB

3.7. Antimicrobial Activity of PB and UB Peptide Fractions

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Gawlik-Dziki, U.; Świeca, M.; Dziki, D.; Sȩczyk, Ł.; Złotek, U.; Rózyło, R.; Kaszuba, K.; Ryszawy, D.; Czyz, J. Anticancer and antioxidant activity of bread enriched with broccoli sprouts. BioMed Res. Int. 2014, 2014, 608053. [Google Scholar] [CrossRef] [PubMed]

- De Marchi, E.; Caputo, V.; Nayga, R.M.; Banterle, A. Time preferences and food choices: Evidence from a choice experiment. Food Policy 2016, 62, 99–109. [Google Scholar] [CrossRef]

- Ozcan, A.; Kandirmaz, E.A. Natural ink production and printability studies for smart food packaging. Color Res. Appl. 2020, 45, 495–502. [Google Scholar] [CrossRef]

- Kowalczyk, D. Biopolymer/candelilla wax emulsion films as carriers of ascorbic acid—A comparative study. Food Hydrocoll. 2015, 52, 543–553. [Google Scholar] [CrossRef]

- Fernández, K.; Aspé, E.; Roeckel, M. Scaling up parameters for shelf-life extension of Atlantic Salmon (Salmo salar) fillets using superchilling and modified atmosphere packaging. Food Control 2010, 21, 857–862. [Google Scholar] [CrossRef]

- Cabelllo-Olmo, M.; Oneca, M.; Torre, P.; Díaz, J.; Encio, I.; Barajas, M.; Araña, M. Influence of Storage Temperature and Packaging on Bacteria and Yeast Viability in a Plant-Based. Foods 2020, 9, 302. [Google Scholar] [CrossRef] [Green Version]

- Alcusóon, G.; Sara, R.; Salvador, M.L. LWT—Food Science and Technology Quality related aspects of sous-vide processing of borage (Borago of fi cinalis L.) stems. LWT Food Sci. Technol. 2017, 85, 104–109. [Google Scholar] [CrossRef]

- Kosewski, G.; Górna, I.; Boles, I.; Kowalówka, M.; Wi, B.; Anna, K.G.; Morawska, A.; Jakubowski, K.; Miszczuk, P.; Przys, J. Comparison of antioxidative properties of raw vegetables and thermally processed ones using the conventional and sous-vide methods. Food Chem. 2018, 240, 1092–1096. [Google Scholar] [CrossRef]

- Rizzo, V.; Amoroso, L.; Licciardello, F.; Mazzaglia, A.; Muratore, G.; Restuccia, C.; Lombardo, S.; Pandino, G.; Strano, M.G.; Mauromicale, G. LWT—Food Science and Technology The effect of sous vide packaging with rosemary essential oil on storage quality of fresh-cut potato. LWT Food Sci. Technol. 2018, 94, 111–118. [Google Scholar] [CrossRef]

- World Health Organization Global Report on Diabetes. Isbn 2016, 978, 88.

- Johnson, R.K.; Appel, L.J.; Brands, M.; Howard, B.V.; Lefevre, M.; Lustig, R.H.; Sacks, F.; Steffen, L.M.; Wylie-Rosett, J. Dietary sugars intake and cardiovascular health a scientific statement from the american heart association. Circulation 2009, 120, 1011–1020. [Google Scholar] [CrossRef]

- Bainard, L.D.; Navarro-borrell, A.; Hamel, C.; Braun, K.; Hanson, K.; Gan, Y. Increasing the frequency of pulses in crop rotations reduces soil fungal diversity and increases the proportion of fungal pathotrophs in a semiarid agroecosystem. Agric. Ecosyst. Environ. 2017, 240, 206–214. [Google Scholar] [CrossRef]

- Letícia, S.; De Lima, S.; Juste, M.; Gomes, C.; Pereira, B.; Elizabeth, N.; Alves, G.; Celi, R.; Toledo, L.; Maciel, J.; et al. Whole flour and protein hydrolysate from common beans reduce the inflammation in BALB/c mice fed with high fat high cholesterol diet. Food Res. Int. 2019, 122, 330–339. [Google Scholar]

- Winham, D.M.; Nikl, R.R.; Hutchins, A.M.; Martin, R.L.; Campbell, C.G. Dietitians vary by counseling status in bean promotion with type 2 diabetes clients: A pilot study. Food Sci. Nutr. 2020, 8, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Chalamaiah, M.; Yu, W.; Wu, J. Immunomodulatory and anticancer protein hydrolysates ( peptides ) from food proteins: A review. Food Chem. 2018, 245, 205–222. [Google Scholar] [CrossRef] [PubMed]

- Jakubczyk, A.; Kara, M.; Urszula, Z.; Szymanowska, U.; Baraniak, B. Peptides obtained from fermented faba bean seeds (Vicia faba ) as potential inhibitors of an enzyme involved in the pathogenesis of metabolic syndrome. LWT Food Sci. Technol. 2019, 105, 306–313. [Google Scholar] [CrossRef]

- Lafarga, T.; Bobo, G.; Viñas, I.; Zudaire, L.; Simó, J.; Aguiló-aguayo, I. International Journal of Gastronomy and Food Science Steaming and sous-vide: Effects on antioxidant activity, vitamin C, and total phenolic content of Brassica vegetables. Int. J. Gastron. Food Sci. 2018, 13, 134–139. [Google Scholar] [CrossRef] [Green Version]

- Bradford, M.M. A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Anal. Biochem. 1976, 72, 248–254. [Google Scholar] [CrossRef]

- Szychowski, K.A.; Leja, M.L.; Kaminskyy, D.V.; Binduga, U.E.; Pinyazhko, O.R.; Lesyk, R.B.; Gmiński, J. Study of novel anticancer 4-thiazolidinone derivatives. Chem. Biol. Interact. 2017, 262, 46–56. [Google Scholar] [CrossRef]

- Jakubczyk, A.; Karaś, M.; Złotek, U.; Szymanowska, U. Identification of potential inhibitory peptides of enzymes involved in the metabolic syndrome obtained by simulated gastrointestinal digestion of fermented bean (Phaseolus vulgaris L.) seeds. Food Res. Int. 2017, 100, 489–496. [Google Scholar] [CrossRef]

- Karaś, M.; Baraniak, B.; Rybczyńska, K.; Gmiński, J.; Gaweł-Bęben, K.; Jakubczyk, A. The influence of heat treatment of chickpea seeds on antioxidant and fibroblast growth-stimulating activity of peptide fractions obtained from proteins digested under simulated gastrointestinal conditions. Int. J. Food Sci. Technol. 2015, 50, 2097–2103. [Google Scholar] [CrossRef]

- Karaś, M.; Jakubczyk, A.; Szymanowska, U.; Krystyna, J.; Lewicki, S.; Złotek, U. Different temperature treatments of millet grains affect the biological activity of protein hydrolyzates. Nutrients 2019, 11, 550. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Horwitz, W.; Latimer, G. AOAC: Official Methods of Analysis, 18th ed.; AOAC: Gaithersburg, MD, USA, 2005. [Google Scholar]

- Miller, G.L. Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal. Chem. 1959, 31, 426–428. [Google Scholar] [CrossRef]

- Adler-Nissen, J. Determination of the degree of hydrolysis of food protein hydrolysates by trinitrobenzenesulfonic acid. J. Agric. Food Chem. 2002, 27, 1256–1262. [Google Scholar] [CrossRef]

- Re, R.; Pellegrini, N.; Proteggente, A.; Pannala, A.; Yang, M.; Rice-Evans, C. Antioxidant Activity Applying an Improved Abts Radical Cation Decolorization Assay. Free Radic. Biol. Med. 1999, 26, 1231–1237. [Google Scholar] [CrossRef]

- Brand-Williams, W.; Cuvelier, M.E.; Berset, C. Use of free radical method to evaluate antioxidant activity. Leb. und-Technologie 1995, 28, 25–30. [Google Scholar] [CrossRef]

- Decker, E.A.; Welch, B. Role of Ferritin as a Lipid Oxidation Catalyst in Muscle Food†. J. Agric. Food Chem. 1990, 38, 674–677. [Google Scholar] [CrossRef]

- Hu, L.; Song, R.; Gu, Z. An antioxidant peptide produced by autolysis reactions from wheat germ. African J. Biotechnol. 2012, 11, 3640–3648. [Google Scholar]

- Jakubczyk, A.; Baraniak, B. Angiotensin I converting enzyme inhibitory peptides obtained after in vitro hydrolysis of pea (Pisum sativum var. Bajka) globulins. Biomed Res. Int. 2014, 2014, 438459. [Google Scholar] [CrossRef] [Green Version]

- Chang, B.W.; Chen, R.L.; Huang, I.J.; Chang, H.C. Assays for angiotensin converting enzyme inhibitory activity. Anal. Biochem. 2001, 291, 84–88. [Google Scholar] [CrossRef]

- Świeca, M.; Gawlik-Dziki, U.; Dziki, D.; Baraniak, B.; Czyż, J. The influence of protein-flavonoid interactions on protein digestibility in vitro and the antioxidant quality of breads enriched with onion skin. Food Chem. 2013, 141, 451–458. [Google Scholar] [CrossRef] [PubMed]

- Lum, K.Y.; Tay, S.T.; Le, C.F.; Lee, V.S.; Sabri, N.H.; Velayuthan, R.D.; Hassan, H.; Sekaran, S.D. Activity of Novel Synthetic Peptides against Candida albicans. Sci. Rep. 2015, 5, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Balouiri, M.; Sadiki, M.; Ibnsouda, S.K. Methods for in vitro evaluating antimicrobial activity: A review. J. Pharm. Anal. 2016, 6, 71–79. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gavish, A.; Krayzler, E.; Nagler, R. Tumor Growth and Cell Proliferation Rate in Human Oral Cancer. Arch. Med. Res. 2016, 47, 271–274. [Google Scholar] [CrossRef] [PubMed]

- Mossano, J.; Frederico, R.; Gustavo, J.; Artur, F. Oral squamous cell carcinoma: Review of prognostic and predictive factors. Oral Surg. Oral Med. Oral Pathol. Oral Radiol. 2006, 102, 67–76. [Google Scholar] [CrossRef]

- Leite, I.C.G.; Koifman, S. Survival analysis in a sample of oral cancer patients at a reference hospital in Rio de Janeiro, Brazil. Oral Oncol. 1998, 34, 347–352. [Google Scholar] [CrossRef]

- Deepa, G.T.; Chetti, M.B.; Khetagoudar, M.C.; Adavirao, G.M. Influence of vacuum packaging on seed quality and mineral contents in chilli (Capsicum annuum L.). J. Food Sci. Technol. 2013, 50, 153–158. [Google Scholar] [CrossRef] [Green Version]

- Elwan, M.M.W.; Nasef, I.N.; El-Seifi, S.K.; Hassan, M.A.; Ibrahim, R.E. Storability, shelf-life and quality assurance of sugar snap peas (cv. super sugar snap) using modified atmosphere packaging. Postharvest Biol. Technol. 2015, 100, 205–211. [Google Scholar] [CrossRef]

- Karas, M.; Jakubczyk, A.; Szymanowska, U.; Materska, M.; Zielińska, E. Antioxidant activity of protein hydrolysates from raw heat-treated yellow string beans (Phaseolus vulgaris L.). Acta Sci. Pol. Technol. Aliment. 2014, 13, 385–391. [Google Scholar] [CrossRef]

- Sarmadi, B.H.; Ismail, A. Antioxidative peptides from food proteins: A review. Peptides 2010, 31, 1949–1956. [Google Scholar] [CrossRef]

- Arcan, I.; Yemenicioǧlu, A. Antioxidant activity of protein extracts from heat-treated or thermally processed chickpeas and white beans. Food Chem. 2007, 103, 301–312. [Google Scholar] [CrossRef] [Green Version]

- Fazeli, M.; Mohammad-zadeh, M.; Darroudi, S.; Meshkat, Z.; Moslem, A.; Ghazizadeh, H.; Kargozar, S.; Ferns, G. Diabetes & Metabolic Syndrome: Clinical Research & Reviews New anthropometric indices in the de fi nition of metabolic syndrome in pediatrics. Diabetes Metab. Syndr. Clin. Res. Rev. 2019, 13, 1779–1784. [Google Scholar]

- Grundy, S.M. Metabolic syndrome update. Trends Cardiovasc. Med. 2016, 26, 364–373. [Google Scholar] [CrossRef] [PubMed]

- Akıllıoğlu, H.G.; Karakaya, S. Effects of heat treatment and in vitro digestion on the Angiotensin converting enzyme inhibitory activity of some legume species. Eur. Food Res. Technol. 2009, 229, 915–921. [Google Scholar] [CrossRef]

- Oliver-Salvador, M.D.E.L.C.; Ariza-Ortega, T.D.J.; Zenón-briones, Y.; Luis, J. Angiotensin-I-converting enzyme inhibitory, antimicrobial, and antioxidant effect of bioactive peptides obtained from different varieties of common beans (Phaseolus vulgaris L.) with in vivo antihypertensive activity in spontaneously hypertensive rats. Eur. Food Res. Technol. 2014, 239, 785–794. [Google Scholar]

- Salas, C.E.; Badillo-corona, J.A.; Ramírez-sotelo, G.; Oliver-salvador, C. Biologically active and antimicrobial peptides from plants. BioMed Res. Int. 2015, 2015, 102129. [Google Scholar] [CrossRef] [Green Version]

| Select Compounds of String Bean (g/100 d.m.) | ||||

|---|---|---|---|---|

| Sample | Protein | Soluble Dietary Fibre | No Soluble Dietary Fibre | Free Sugars |

| PB | 2.36 ± 0.17 b | 3.5 ± 0.81 b | 1.14 ± 0.38 a | 1.79 ± 0.03 a |

| UB | 1.82 ± 0.13 a | 2.97 ± 0.98 a | 1.20 ± 0.40 a | 1.74 ± 0.03 a |

| Factor | PB | UB | ||||

|---|---|---|---|---|---|---|

| PAC | 1.86 | 2.21 | ||||

| <3.5 kDa | 3.5–7.0 kDa | <7.0 kDa | <3.5 kDa | 3.5–7.0 kDa | <7.0 kDa | |

| PAV | 6.04 | 4.21 | 1.87 | 1.23 | 1.27 | 2.14 |

| Sample | ABTS (µg mL−1) | DPPH (mg mL−1) | Fe2+ Chelation (mg mL−1) | Reducing Power (A700/peptide content) | ||||

|---|---|---|---|---|---|---|---|---|

| PB | UB | PB | UB | PB | UB | PB | UB | |

| Before hydrolysis | 54.56 ± 2.16 eA | 151.10 ± 18.16 cB | 0.460 ± 0.012 dA | 1.910 ± 0.07 dB | 3.850 ± 0.82 dA | 8.880 ± 0.85 eB | 0.088 ± 0.002 bB | 0.079 ± 0.003 cA |

| Hydrolysate | 22.39 ± 1.17 dA | 27.10 ± 1.66 bB | 0.110 ± 0.009 cA | 0.200 ± 0.007 cB | 1.670 ± 0.66 cA | 1.760 ± 0.61 A | 0.110 ± 0.003 cA | 0.110 ± 0.001 dA |

| Peptide fraction <3.5 kDa | 1.07 ± 0.05 aA | 7.57 ± 0.76 aB | 0.045 ± 0.008 bA | 0.063 ± 0.001 bB | 0.054 ± 0.003 aA | 0.055 ± 0.004 aA | 0.083 ± 0.003 bB | 0.064 ± 0.002 bA |

| Peptide fraction 3.5–7.0 kDa | 7.6 ± 0.89 bA | 7.89 ± 1.09 aA | 0.017 ± 0.008 aA | 0.053 ±0.002 bB | 0.056 ± 0.002 aA | 0.072 ± 0.006 bB | 0.058 ± 0.013 aB | 0.046 ± 0.002 aA |

| Peptide fraction >7.0 kDa | 8.06 ± 0.77 cA | 7.79 ± 1.32 aA | 0.015 ± 0.004 aA | 0.027 ± 0.003 aB | 0.150 ± 0.001 bA | 0.170 ± 0.004 cB | 0.049 ± 0.007 aA | 0.076 ± 0.003 cB |

| Sample | Lipase (mg mL−1) | α-Amylase (mg mL−1) | ACE (mg mL−1) | |||

|---|---|---|---|---|---|---|

| PB | UB | PB | UB | PB | UB | |

| Before hydrolysis | 0.23 ± 0.03 dA | 0.23 ± 0.04 dA | 2.37 ± 0.19 cA | 6.95 ± 0.99 bB | ND | ND |

| Hydrolysate | 0.05 ± 0.008 cA | 0.170 ± 0.01 cB | 1.54 ± 0.07 bA | 1.82 ± 0.05 aA | 8.57 ± 1.06 cA | 15.73 ± 1.61 dB |

| Peptide fraction <3.5 kDa | 0.008 ± 0.001 aA | 0.009 ± 0.0007 aA | 13.72 ± 1.11 dB | 9.22 ± 0.89 bA | 0.84 ± 0.06 bA | 1.11 ± 0.08 cB |

| Peptide fraction 3.5–7.0 kDa | 0.023 ± 0.02 bB | 0.009 ±0.0009 aA | 0.89 ± 0.01 aA | 27.31 ± 1.87 cB | 0.37 ± 0.009 aA | 0.95 ± 0.04 bB |

| Peptide fraction >7.0 kDa | 0.024 ± 0.03 bB | 0.013 ± 0.008 bA | ND | 10.26 ± 2.88 bA | 0.81 ± 0.006 bB | 0.59 ± 0.03 aA |

| Sample | E. coli ATCC 25922 | S. aureus ATCC 29737 | C. albicans ATCC 90028 | |

|---|---|---|---|---|

| Inhibition zone (mm) | ||||

| PB | Peptide fraction <3.5 kDa | 11.80 ± 1.30 a | 14.00 ± 1.00 a | nd |

| Peptide fraction 3.5–7.0 kDa | 13.00 ± 1.40 a | 13.50 ± 1.00 a | ||

| Peptide fraction >7.0 kDa | 12.50 ± 1.00 a | 13.5 ± 1.20 a | ||

| UB | Peptide fraction 3.5–7.0 kDa | 15.40 ± 1.20 a | 16.30 ± 1.50 a | |

| AMP | 13.50 ± 1.00 a | 13.00 ± 1.00 a | na | |

| NE | 23.50 ± 1.50 b | 26.20 ± 1.30 b | ||

| MIC (mg mL−1) | ||||

| PB | Peptide fraction <3.5 kDa | 0.50 | 0.50 | nd |

| Peptide fraction 3.5–7.0 kDa | 1.00 | 0.50 | ||

| Peptide fraction >7.0 kDa | 1.00 | 0.50 | ||

| UB | Peptide fraction 3.5–7.0 kDa | 0.50 | 0.25 | |

| MBC (mg mL−1) | ||||

| PB | Peptide fraction <3.5 kDa | 0.50 | 0.25 | nd |

| Peptide fraction 3.5–7.0 kDa | 0.50 | 0.25 | ||

| Peptide fraction >7.0 kDa | 0.50 | 0.25 | ||

| UB | Peptide fraction 3.5–7.0 kDa | 0.25 | 0.125 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jakubczyk, A.; Karaś, M.; Stanikowski, P.; Rutkowska, B.; Dziedzic, M.; Zielińska, E.; Szychowski, K.A.; Binduga, U.E.; Rybczyńska-Tkaczyk, K.; Baraniak, B. Characterisation of Biologically Active Hydrolysates and Peptide Fractions of Vacuum Packaging String Bean (Phaseolus Vulgaris L.). Foods 2020, 9, 842. https://doi.org/10.3390/foods9070842

Jakubczyk A, Karaś M, Stanikowski P, Rutkowska B, Dziedzic M, Zielińska E, Szychowski KA, Binduga UE, Rybczyńska-Tkaczyk K, Baraniak B. Characterisation of Biologically Active Hydrolysates and Peptide Fractions of Vacuum Packaging String Bean (Phaseolus Vulgaris L.). Foods. 2020; 9(7):842. https://doi.org/10.3390/foods9070842

Chicago/Turabian StyleJakubczyk, Anna, Monika Karaś, Piotr Stanikowski, Beata Rutkowska, Magdalena Dziedzic, Ewelina Zielińska, Konrad A. Szychowski, Urszula E. Binduga, Kamila Rybczyńska-Tkaczyk, and Barbara Baraniak. 2020. "Characterisation of Biologically Active Hydrolysates and Peptide Fractions of Vacuum Packaging String Bean (Phaseolus Vulgaris L.)" Foods 9, no. 7: 842. https://doi.org/10.3390/foods9070842