A Review on Adventitious Lactic Acid Bacteria from Table Olives

Abstract

:1. Introduction

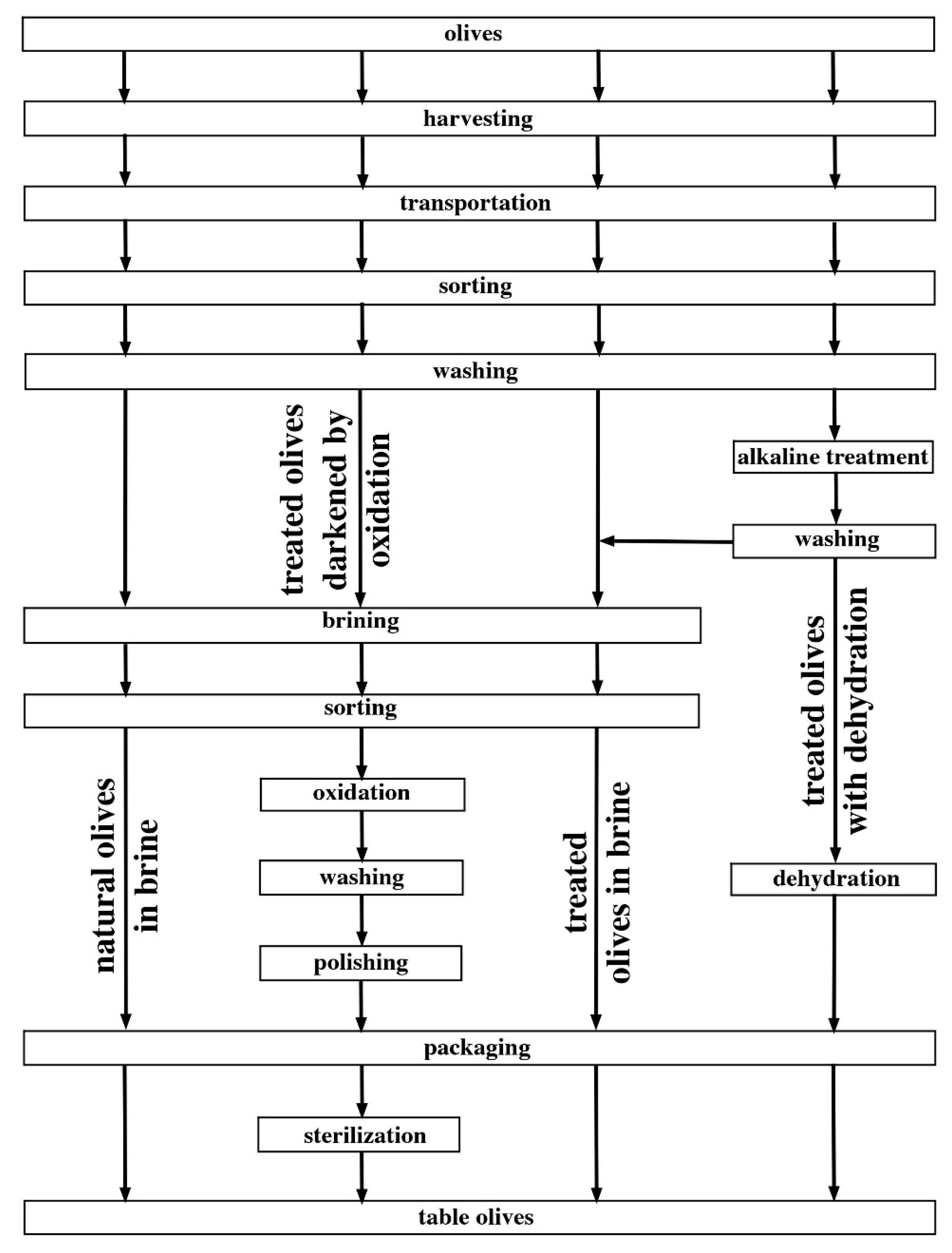

2. Processing Methods of Table Olives

3. Fermentation of Table Olives

3.1. Spontaneous Fermentation

3.2. Controlled Fermentation

4. Importance of LAB from Table Olives

4.1. Selection of Relevant Publications

4.2. Current Relevance

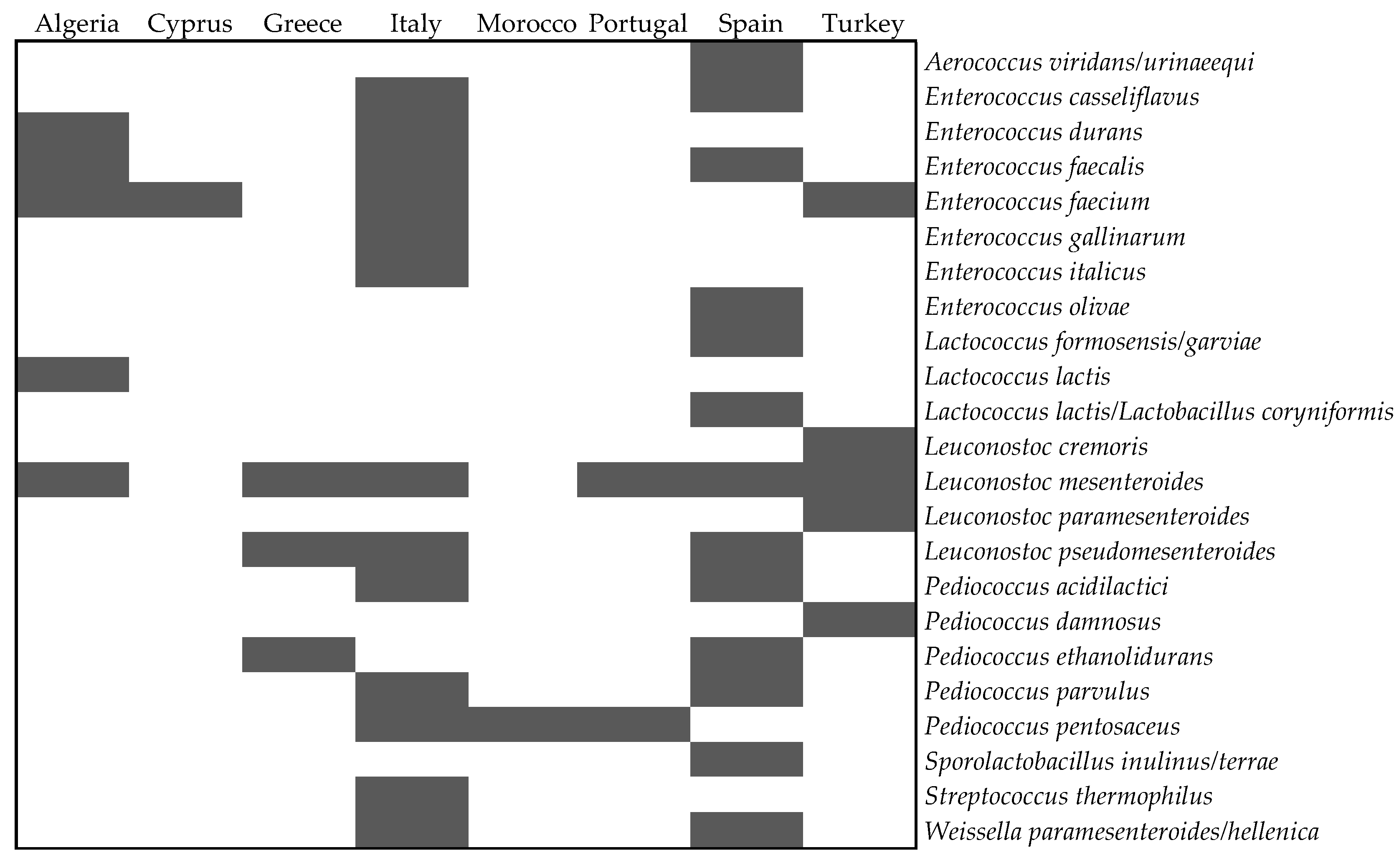

5. LAB Species Isolated from Table Olives

5.1. Compilation of Identified LAB Species

5.2. Statistical Analysis of LAB Species Data

5.3. From Research Findings to Industrial Applications and Commercialization of LAB

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- International Olive Council. Table Olives—About Olives. Available online: https://www.internationaloliveoil.org/olive-world/table-olives/ (accessed on 7 June 2020).

- International Olive Oil Council. Trade Standard Applying to Table Olives. 2004. Available online: https://www.internationaloliveoil.org/wp-content/uploads/2019/11/COI-OT-NC1-2004-Eng.pdf (accessed on 7 June 2020).

- Sun, W.; Frost, B.; Liu, J. Oleuropein, Unexpected Benefits! Oncotarget 2017, 8, 17409. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tofalo, R.; Schirone, M.; Perpetuini, G.; Angelozzi, G.; Suzzi, G.; Corsetti, A. Microbiological and chemical profiles of naturally fermented table olives and brines from different Italian cultivars. Antonie Van Leeuwenhoek 2012, 102, 121–131. [Google Scholar] [CrossRef] [PubMed]

- Campus, M.; Değirmencioğlu, N.; Comunian, R. Technologies and trends to improve table olive quality and safety. Front. Microbiol. 2018, 9, 617. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- International Olive Council. Economic Affairs & Promotion Unit—Prices & Balances. Available online: https://www.internationaloliveoil.org/what-we-do/economic-affairs-promotion-unit/#prices (accessed on 7 June 2020).

- International Olive Council. Economic Affairs & Promotion Unit—Figures. Available online: https://www.internationaloliveoil.org/what-we-do/economic-affairs-promotion-unit/#figures (accessed on 7 June 2020).

- Findik, M. What are natural olives? How are they produced? Olivae (Off. J. Int. Olive Counc.) 2016, 123, 23–26. [Google Scholar]

- Rejano, L.; Montaño, A.; Casado, F.J.; Sánchez, A.H.; de Castro, A. Table olives: Varieties and variations. In Olives and Olive Oil in Health and Disease Prevention, 1st ed.; Preedy, V.R., Watson, R.R., Eds.; Academic Press: London, UK, 2010; pp. 5–15. ISBN 9780123744203. [Google Scholar]

- Zhllima, E.; Chan-Halbrendt, C.; Merkaj, E.; Imami, D.; Vercuni, A.; Qinami, I. Analysis of consumer preferences for table olives—The case of Albanian urban consumers. J. Food Prod. Mark. 2014, 21, 521–532. [Google Scholar] [CrossRef]

- Akpinar-Bayizit, A.; Yilmaz-Ersan, L.; Ozcan, T.; Delikanli-Kiyak, B.; Yildiz, E.; Vural, H. Consumers’ behavior towards table olives. Int. J. Food Eng. 2017, 3, 83–88. [Google Scholar] [CrossRef] [Green Version]

- López-López, A.; Moreno-Baquero, J.M.; Rodríguez-Gómez, F.; García-García, P.; Garrido-Fernández, A. Sensory assessment by consumers of traditional and potentially probiotic green Spanish-style table olives. Front. Nutr. 2018, 5, 53. [Google Scholar] [CrossRef] [Green Version]

- Kailis, S.; Harris, D.J. Producing Table Olives; Landlinks Press: Collingwood, Australia, 2007; pp. 1–16. ISBN 9780643092037. [Google Scholar]

- Kazou, M.; Tzamourani, A.; Panagou, E.Z.; Tsakalidou, E. Unraveling the microbiota of natural black cv. Kalamata fermented olives through 16S and ITS metataxonomic analysis. Microorganisms 2020, 8, 672. [Google Scholar] [CrossRef]

- Medina, E.; Ruiz-Bellido, M.A.; Romero-Gil, V.; Rodríguez-Gómez, F.; Montes-Borrego, M.; Landa, B.B.; Arroyo-López, F.N. Assessment of the bacterial community in directly brined Aloreña de Málaga table olive fermentations by metagenetic analysis. Int. J. Food Microbiol. 2016, 236, 47–55. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Corsetti, A.; Perpetuini, G.; Schirone, M.; Tofalo, R.; Suzzi, G. Application of starter cultures to table olive fermentation: An overview on the experimental studies. Front. Microbiol. 2012, 3, 248. [Google Scholar] [CrossRef] [Green Version]

- Randazzo, C.L.; Rajendram, R.; Caggia, C. Lactic acid bacteria in table olive fermentation. In Olives and Olive Oil in Health and Disease Prevention, 1st ed.; Preedy, V.R., Watson, R.R., Eds.; Academic Press: London, UK, 2010; pp. 369–376. ISBN 9780123744203. [Google Scholar]

- Bleve, G.; Tufariello, M.; Durante, M.; Grieco, F.; Ramires, F.A.; Mita, G.; Tasioula-Margari, M.; Logrieco, A.F. Physico-chemical characterization of natural fermentation process of Conservolea and Kalamata table olives and development of a protocol for the pre-selection of fermentation starters. Food Microbiol. 2015, 46, 368–382. [Google Scholar] [CrossRef] [PubMed]

- Bonatsou, S.; Tassou, C.; Panagou, E.; Nychas, G.J. Table olive fermentation using starter cultures with multifunctional potential. Microorganisms 2017, 5, 30. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- de Castro, A.; Sánchez, A.; López-López, A.; Cortés-Delgado, A.; Medina, E.; Montaño, A. Microbiota and metabolite profiling of spoiled Spanish-style green table olives. Metabolites 2018, 8, 73. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Perpetuini, G.; Prete, R.; Garcia-Gonzalez, N.; Khairul Alam, M.; Corsetti, A. Table olives more than a fermented food. Foods 2020, 9, 178. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hurtado, A.; Reguant, C.; Bordons, A.; Rozès, N. Lactic acid bacteria from fermented table olives. Food Microbiol. 2012, 31, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Hurtado, A.; Reguant, C.; Bordons, A.; Rozès, N. Influence of fruit ripeness and salt concentration on the microbial processing of Arbequina table olives. Food Microbiol. 2009, 26, 827–833. [Google Scholar] [CrossRef]

- Hurtado, A.; Reguant, C.; Bordons, A.; Rozès, N. Evaluation of a single and combined inoculation of a Lactobacillus pentosus starter for processing cv. Arbequina natural green olives. Food Microbiol. 2010, 27, 731–740. [Google Scholar] [CrossRef]

- Psani, M.; Kotzekidou, P. Technological characteristics of yeast strains and their potential as starter adjuncts in Greek-style black olive fermentation. World J. Microbiol. Biotechnol. 2006, 22, 1329–1336. [Google Scholar] [CrossRef]

- Ditu, L.M.; Gheorghe, I. Introduction in soft chemistry and food fermentation. In Soft Chemistry and Food Fermentation (Handbook of Food Bioengineering); Grumezescu, A.M., Holban, A.M., Eds.; Elsevier: London, UK, 2017; Volume 3, pp. 1–22. ISBN 978-0-12-811412-4. [Google Scholar]

- Martorana, A.; Alfonzo, A.; Settanni, L.; Corona, O.; La Croce, F.; Caruso, T.; Moschetti, G.; Francesca, N. An innovative method to produce green table olives based on “pied de cuve” technology. Food Microbiol. 2015, 50, 126–140. [Google Scholar] [CrossRef] [Green Version]

- Heperkan, D. Microbiota of table olive fermentations and criteria of selection for their use as starters. Front. Microbiol. 2013, 4, 143. [Google Scholar] [CrossRef] [Green Version]

- Peres, C.M.; Peres, C.; Hernández-Mendoza, A.; Malcata, F.X. Review on fermented plant materials as carriers and sources of potentially probiotic lactic acid bacteria—with an emphasis on table olives. Trends Food Sci. Technol. 2012, 26, 31–42. [Google Scholar] [CrossRef]

- de Angelis, M.; Campanella, D.; Cosmai, L.; Summo, C.; Rizzello, C.G.; Caponio, F. Microbiota and metabolome of un-started and started Greek-type fermentation of Bella di Cerignola table olives. Food Microbiol. 2015, 52, 18–30. [Google Scholar] [CrossRef] [PubMed]

- Anagnostopoulos, D.A.; Kamilari, E.; Tsaltas, D. Evolution of bacterial communities, physicochemical changes and sensorial attributes of natural whole and cracked Picual table olives during spontaneous and inoculated fermentation. Front. Microbiol. 2020, 11, 1128. [Google Scholar] [CrossRef] [PubMed]

- Pino, A.; De Angelis, M.; Todaro, A.; Van Hoorde, K.; Randazzo, C.L.; Caggia, C. Fermentation of Nocellara Etnea table olives by functional starter cultures at different low salt concentrations. Front. Microbiol. 2018, 9, 1125. [Google Scholar] [CrossRef] [Green Version]

- Lucena-Padrós, H.; Caballero-Guerrero, B.; Maldonado-Barragán, A.; Ruiz-Barba, J.L. Microbial diversity and dynamics of Spanish-style green table-olive fermentations in large manufacturing companies through culture-dependent techniques. Food Microbiol. 2014, 42, 154–165. [Google Scholar] [CrossRef] [Green Version]

- Kumar, B.V.; Vijayendra, S.V.N.; Reddy, O.V.S. Trends in dairy and non-dairy probiotic products—a review. J. Food Sci. Technol. 2015, 52, 6112–6124. [Google Scholar] [CrossRef] [Green Version]

- Omar, S.H. Oleuropein in olives and its pharmacological effects. Sci. Pharm. 2010, 78, 133–154. [Google Scholar] [CrossRef] [Green Version]

- Blana, V.A.; Grounta, A.; Tassou, C.C.; Nychas, G.J.E.; Panagou, E.Z. Inoculated fermentation of green olives with potential probiotic Lactobacillus pentosus and Lactobacillus plantarum starter cultures isolated from industrially fermented olives. Food Microbiol. 2014, 38, 208–218. [Google Scholar] [CrossRef]

- M’hir, S.; Minervini, F.; Di Cagno, R.; Chammem, N.; Hamdi, M. Technological, functional and safety aspects of enterococci in fermented vegetable products: A mini-review. Ann. Microbiol. 2012, 62, 469–481. [Google Scholar] [CrossRef]

- Bevilacqua, A.; de Stefano, F.; Augello, S.; Pignatiello, S.; Sinigaglia, M.; Corbo, M.R. Biotechnological innovations for table olives. Int. J. Food Sci. Nutr. 2015, 66, 127–131. [Google Scholar] [CrossRef]

- Lanza, B. Abnormal fermentations in table-olive processing: Microbial origin and sensory evaluation. Front. Microbiol. 2013, 4, 91. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Botta, C.; Cocolin, L. Microbial dynamics and biodiversity in table olive fermentation: Culture-dependent and -independent approaches. Front. Microbiol. 2012, 3, 245. [Google Scholar] [CrossRef] [Green Version]

- Perona, J.S.; Botham, K.M. Olive oil as a functional food: Nutritional and health benefits. In Handbook of Olive Oil: Analysis and Properties, 2nd ed.; Aparicio, R., Harwood, J., Eds.; Springer: Boston, MA, USA, 2013; pp. 677–714. ISBN 978-1-4614-7777-8. [Google Scholar]

- International Olive Council. World Olive Day. Olivae (Off. J. Int. Olive Counc.) 2016, 123, 1–55. Available online: https://www.internationaloliveoil.org/786-olivae-123/ (accessed on 7 June 2020).

- Stiles, M.E.; Holzapfel, W.H. Lactic acid bacteria of foods and their current taxonomy. Int. J. Food Microbiol. 1997, 36, 1–29. [Google Scholar] [CrossRef]

- Carr, F.J.; Chill, D.; Maida, N. The lactic acid bacteria: A literature survey. CRC Crit. Rev. Microbiol. 2002, 28, 281–370. [Google Scholar] [CrossRef]

- Vinderola, G.; Ouwehand, A.; Salminen, S.; von Wright, A. Lactic Acid Bacteria: Microbiological and Functional Aspects, 5th ed.; CRC Press: New York, NY, USA, 2019; ISBN 9780429614439. [Google Scholar]

- Abriouel, H.; Benomar, N.; Lucas, R.; Gálvez, A. Culture-independent study of the diversity of microbial populations in brines during fermentation of naturally-fermented Aloreña green table olives. Int. J. Food Microbiol. 2011, 144, 487–496. [Google Scholar] [CrossRef]

- Yalçınkaya, S.; Kılıç, G.B. Isolation, identification and determination of technological properties of the halophilic lactic acid bacteria isolated from table olives. J. Food Sci. Technol. 2019, 56, 2027–2037. [Google Scholar] [CrossRef]

- Lucena-Padrós, H.; Ruiz-Barba, J.L. Microbial biogeography of Spanish-style green olive fermentations in the province of Seville, Spain. Food Microbiol. 2019, 82, 259–268. [Google Scholar] [CrossRef]

- Idoui, T.; Boudjerda, J.; Leghouchi, E.; Karam, N.E.; Karam, N.E. Naturally fermented Jijelian black olives: Microbiological characteristics and isolation of lactic acid bacteria. Grasas Aceites 2009, 60, 516–520. [Google Scholar] [CrossRef] [Green Version]

- De Bellis, P.; Valerio, F.; Sisto, A.; Lonigro, S.L.; Lavermicocca, P. Probiotic table olives: Microbial populations adhering on olive surface in fermentation sets inoculated with the probiotic strain Lactobacillus paracasei IMPC2.1 in an industrial plant. Int. J. Food Microbiol. 2010, 140, 6–13. [Google Scholar] [CrossRef]

- Randazzo, C.L.; Restuccia, C.; Romano, A.D.; Caggia, C. Lactobacillus casei, Dominant species in naturally fermented Sicilian green olives. Int. J. Food Microbiol. 2004, 90, 9–14. [Google Scholar] [CrossRef]

- Ghabbour, N.; Lamzira, Z.; Thonart, P.; Cidalia, P.; Markaoui, M.; Asehraou, A. Selection of oleuropein-degrading lactic acid bacteria strains isolated from fermenting Moroccan green olives. Grasas Aceites 2011, 62, 84–89. [Google Scholar] [CrossRef] [Green Version]

- Korukluoglu, M.; Gurbuz, O.; Sahin, I. Identification of lactic acid bacteria in fresh olive microflora. Turk. J. Biol. 2002, 8, 109–113. (In Turkish) [Google Scholar]

- Kumral, A.; Basoglu, F.; Sahin, I. Effect of the use of different lactic starters on the microbiological and physicochemical characteristics of naturally black table olives of Gemlik cultivar. J. Food Process. Preserv. 2009, 33, 651–664. [Google Scholar] [CrossRef]

- Mourad, K.; Nour-Eddine, K. Microbiological study of naturally fermented Algerian green olives: Isolation and identification of lactic acid bacteria and yeasts along with the effects of brine solutions obtained at the end of olive fermentation on Lactobacillus plantarum growth. Grasas Aceites 2006, 57, 292–300. [Google Scholar] [CrossRef] [Green Version]

- Franzetti, L.; Scarpellini, M.; Vecchio, A.; Planeta, D. Microbiological and safety evaluation of green table olives marketed in Italy. Ann. Microbiol. 2011, 61, 843–851. [Google Scholar] [CrossRef]

- Tofalo, R.; Perpetuini, G.; Schirone, M.; Ciarrocchi, A.; Fasoli, G.; Suzzi, G.; Corsetti, A. Lactobacillus pentosus dominates spontaneous fermentation of Italian table olives. Leb. Wiss. Technol. 2014, 57, 710–717. [Google Scholar] [CrossRef]

- Randazzo, C.L.; Todaro, A.; Pino, A.; Pitino, I.; Corona, O.; Mazzaglia, A.; Caggia, C. Giarraffa and Grossa di Spagna naturally fermented table olives: Effect of starter and probiotic cultures on chemical, microbiological and sensory traits. Food Res. Int. 2014, 62, 1154–1164. [Google Scholar] [CrossRef]

- Pino, A.; Vaccalluzzo, A.; Solieri, L.; Romeo, F.V.; Todaro, A.; Caggia, C.; Arroyo-López, F.N.; Bautista-Gallego, J.; Randazzo, C.L. Effect of sequential inoculum of beta-glucosidase positive and probiotic strains on brine fermentation to obtain low salt Sicilian table olives. Front. Microbiol. 2019, 10, 174:1–174:15. [Google Scholar] [CrossRef]

- Comunian, R.; Ferrocino, I.; Paba, A.; Daga, E.; Campus, M.; Di Salvo, R.; Cauli, E.; Piras, F.; Zurru, R.; Cocolin, L. Evolution of microbiota during spontaneous and inoculated Tonda di Cagliari table olives fermentation and impact on sensory characteristics. Leb. Wiss. Technol. 2017, 84, 64–72. [Google Scholar] [CrossRef]

- Doulgeraki, A.I.; Hondrodimou, O.; Iliopoulos, V.; Panagou, E.Z. Lactic acid bacteria and yeast heterogeneity during aerobic and modified atmosphere packaging storage of natural black Conservolea olives in polyethylene pouches. Food Control. 2012, 26, 49–57. [Google Scholar] [CrossRef]

- Randazzo, C.L.; Ribbera, A.; Pitino, I.; Romeo, F.V.; Caggia, C. Diversity of bacterial population of table olives assessed by PCR-DGGE analysis. Food Microbiol. 2012, 32, 87–96. [Google Scholar] [CrossRef] [PubMed]

- Aponte, M.; Blaiotta, G.; La Croce, F.; Mazzaglia, A.; Farina, V.; Settanni, L.; Moschetti, G. Use of selected autochthonous lactic acid bacteria for Spanish-style table olive fermentation. Food Microbiol. 2012, 30, 8–16. [Google Scholar] [CrossRef] [PubMed]

- Martorana, A.; Di Miceli, C.; Alfonzo, A.; Settanni, L.; Gaglio, R.; Caruso, T.; Moschetti, G.; Francesca, N. Effects of irrigation treatments on the quality of table olives produced with the Greek-style process. Ann. Microbiol. 2017, 67, 37–48. [Google Scholar] [CrossRef] [Green Version]

- Guantario, B.; Zinno, P.; Schifano, E.; Roselli, M.; Perozzi, G.; Palleschi, C.; Uccelletti, D.; Devirgiliis, C. In Vitro and In Vivo selection of potentially probiotic lactobacilli from Nocellara del Belice table olives. Front. Microbiol. 2018, 9, 595. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Aponte, M.; Ventorino, V.; Blaiotta, G.; Volpe, G.; Farina, V.; Avellone, G.; Lanza, C.M.; Moschetti, G. Study of green Sicilian table olive fermentations through microbiological, chemical and sensory analyses. Food Microbiol. 2010, 27, 162–170. [Google Scholar] [CrossRef]

- Lucena-Padrós, H.; Jiménez, E.; Maldonado-Barragán, A.; Rodríguez, J.M.; Ruiz-Barba, J.L. PCR-DGGE assessment of the bacterial diversity in Spanish-style green table-olive fermentations. Int. J. Food Microbiol. 2015, 205, 47–53. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Doulgeraki, A.I.; Pramateftaki, P.; Argyri, A.A.; Nychas, G.J.E.; Tassou, C.C.; Panagou, E.Z. Molecular characterization of lactic acid bacteria isolated from industrially fermented Greek table olives. Leb. Wiss. Technol. 2013, 50, 353–356. [Google Scholar] [CrossRef]

- Montaño, A.; Sánchez, A.H.; Casado, F.J.; Beato, V.M.; de Castro, A. Degradation of ascorbic acid and potassium sorbate by different Lactobacillus species isolated from packed green olives. Food Microbiol. 2013, 34, 7–11. [Google Scholar] [CrossRef] [PubMed]

- Benítez-Cabello, A.; Bautista-Gallego, J.; Garrido-Fernández, A.; Rantsiou, K.; Cocolin, L.; Jiménez-Díaz, R.; Arroyo-López, F.N. RT-PCR–DGGE analysis to elucidate the dominant bacterial species of industrial Spanish-style green table olive fermentations. Front. Microbiol. 2016, 7, 1291. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Peres, C.M.; Alves, M.; Hernandez-Mendoza, A.; Moreira, L.; Silva, S.; Bronze, M.R.; Vilas-Boas, L.; Peres, C.; Malcata, F.X. Novel isolates of lactobacilli from fermented Portuguese olive as potential probiotics. Leb. Wiss. Technol. 2014, 59, 234–246. [Google Scholar] [CrossRef] [Green Version]

- Hurtado, A.; Reguant, C.; Esteve-Zarzoso, B.; Bordons, A.; Rozès, N. Microbial population dynamics during the processing of Arbequina table olives. Food Res. Int. 2008, 41, 738–744. [Google Scholar] [CrossRef]

- Bautista-Gallego, J.; Arroyo-López, F.N.; Rantsiou, K.; Jiménez-Díaz, R.; Garrido-Fernández, A.; Cocolin, L. Screening of lactic acid bacteria isolated from fermented table olives with probiotic potential. Food Res. Int. 2013, 50, 135–142. [Google Scholar] [CrossRef]

- Argyri, A.A.; Nisiotou, A.A.; Mallouchos, A.; Panagou, E.Z.; Tassou, C.C. Performance of two potential probiotic Lactobacillus strains from the olive microbiota as starters in the fermentation of heat shocked green olives. Int. J. Food Microbiol. 2014, 171, 68–76. [Google Scholar] [CrossRef] [PubMed]

- Argyri, A.A.; Nisiotou, A.A.; Pramateftaki, P.; Doulgeraki, A.I.; Panagou, E.Z.; Tassou, C.C. Preservation of green table olives fermented with lactic acid bacteria with probiotic potential under modified atmosphere packaging. Leb. Wiss. Technol. 2015, 62, 783–790. [Google Scholar] [CrossRef]

- Grounta, A.; Doulgeraki, A.I.; Panagou, E.Z. Quantification and characterization of microbial biofilm community attached on the surface of fermentation vessels used in green table olive processing. Int. J. Food Microbiol. 2015, 203, 41–48. [Google Scholar] [CrossRef]

- Panagou, E.Z.; Schillinger, U.; Franz, C.M.A.P.; Nychas, G.J.E. Microbiological and biochemical profile of cv. Conservolea naturally black olives during controlled fermentation with selected strains of lactic acid bacteria. Food Microbiol. 2008, 25, 348–358. [Google Scholar] [CrossRef]

- Campaniello, D.; Bevilacqua, A.; D’Amato, D.; Corbo, M.R.; Altieri, C.; Sinigaglia, M. Microbial characterization of table olives processed according to Spanish and natural styles. Food Technol. Biotechnol. 2005, 43, 289–294. [Google Scholar]

- Martorana, A.; Alfonzo, A.; Settanni, L.; Corona, O.; La Croce, F.; Caruso, T.; Moschetti, G.; Francesca, N. Effect of the mechanical harvest of drupes on the quality characteristics of green fermented table olives. J. Sci. Food Agric. 2016, 96, 2004–2017. [Google Scholar] [CrossRef] [Green Version]

- Randazzo, C.L.; Russo, N.; Pino, A.; Mazzaglia, A.; Ferrante, M.; Conti, G.O.; Caggia, C. Effects of selected bacterial cultures on safety and sensory traits of Nocellara Etnea olives produced at large factory scale. Food Chem. Toxicol. 2018, 115, 491–498. [Google Scholar] [CrossRef]

- Cocolin, L.; Alessandria, V.; Botta, C.; Gorra, R.; De Filippis, F.; Ercolini, D.; Rantsiou, K. NaOH-debittering induces changes in bacterial ecology during table olives fermentation. PLoS ONE 2013, 8, e69074. [Google Scholar] [CrossRef]

- Oliveira, M.; Brito, D.; Catulo, L.; Leitão, F.; Gomes, L.; Silva, S.; Vilas-Boas, L.; Peito, A.; Fernandes, I.; Gordo, F.; et al. Biotechnology of olive fermentation of ‘Galega’ Portuguese variety. Grasas Aceites 2004, 55, 219–226. [Google Scholar] [CrossRef]

- Bautista-Gallego, J.; Arroyo-López, F.N.; Romero-Gil, V.; Rodríguez-Gómez, F.; Garrido-Fernández, A. Evaluating the effects of zinc chloride as a preservative in cracked table olive packing. J. Food Prot. 2011, 74, 2169–2176. [Google Scholar] [CrossRef] [PubMed]

- Abriouel, H.; Benomar, N.; Cobo, A.; Caballero, N.; Fuentes, M.A.F.; Pérez-Pulido, R.; Gálvez, A. Characterization of lactic acid bacteria from naturally-fermented Manzanilla Aloreña green table olives. Food Microbiol. 2012, 32, 308–316. [Google Scholar] [CrossRef] [PubMed]

- Benítez-Cabello, A.; Romero-Gil, V.; Rodríguez-Gómez, F.; Garrido-Fernández, A.; Jiménez-Díaz, R.; Arroyo-López, F.N. Evaluation and identification of poly-microbial biofilms on natural green Gordal table olives. Antonie Van Leeuwenhoek 2015, 108, 597–610. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bautista-Gallego, J.; Arroyo-López, F.N.; Romero-Gil, V.; Rodríguez-Gómez, F.; García-García, P.; Garrido-Fernández, A. Fermentation profile of green Spanish-style Manzanilla olives according to NaCl content in brine. Food Microbiol. 2015, 49, 56–64. [Google Scholar] [CrossRef] [PubMed]

- Bautista-Gallego, J.; Rodríguez-Gómez, F.; Romero-Gil, V.; Benítez-Cabello, A.; Arroyo-López, F.N.; Garrido-Fernández, A. Reduction of the bitter taste in packaged natural black Manzanilla olives by zinc chloride. Front. Nutr. 2018, 5, 102. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Benítez-Cabello, A.; Calero-Delgado, B.; Rodríguez-Gómez, F.; Garrido-Fernández, A.; Jiménez-Díaz, R.; Arroyo-López, F.N. Biodiversity and multifunctional features of lactic acid bacteria isolated from table olive biofilms. Front. Microbiol. 2019, 10, 836. [Google Scholar] [CrossRef] [PubMed]

- Mourad, K.; Halima, Z.K.; Nour-Eddine, K. Isolation of lactic acid bacteria for its possible use in the fermentation of green Algerian olives. Grasas Aceites 2004, 55, 385–393. [Google Scholar] [CrossRef]

- Kulišić, T.; Berković, K.; Pavić, S.; Šustra, A. The processing of turning colour olives of Oblica cultivar. Agric. Conspec. Sci. 2004, 69, 103–107. [Google Scholar]

- Argyri, A.A.; Zoumpopoulou, G.; Karatzas, K.A.G.; Tsakalidou, E.; Nychas, G.J.E.; Panagou, E.Z.; Tassou, C.C. Selection of potential probiotic lactic acid bacteria from fermented olives by In Vitro tests. Food Microbiol. 2013, 33, 282–291. [Google Scholar] [CrossRef]

- Tufariello, M.; Durante, M.; Ramires, F.A.; Grieco, F.; Tommasi, L.; Perbellini, E.; Falco, V.; Tasioula-Margari, M.; Logrieco, A.F.; Mita, G.; et al. New Process for production of fermented black table olives using selected autochthonous microbial resources. Front. Microbiol. 2015, 6, 1007. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bevilacqua, A.; Altieri, C.; Corbo, M.R.; Sinigaglia, M.; Ouoba, L.I.I. Characterization of lactic acid bacteria isolated from Italian Bella di Cerignola table olives: Selection of potential multifunctional starter cultures. J. Food Sci. 2010, 75, 536–544. [Google Scholar] [CrossRef] [PubMed]

- Bleve, G.; Tufariello, M.; Durante, M.; Perbellini, E.; Ramires, F.A.; Grieco, F.; Cappello, M.S.; de Domenico, S.; Mita, G.; Tasioula-Margari, M.; et al. Physico-chemical and microbiological characterization of spontaneous fermentation of Cellina di Nardò and Leccino table olives. Front. Microbiol. 2014, 5, 570. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Asehraou, A.; Peres, C.; Faid, M.; Brito, D. Reducing the bloater spoilage incidence in fermented green olives during storage. Grasas Aceites 2002, 53, 330–334. [Google Scholar] [CrossRef] [Green Version]

- Chamkha, M.; Sayadi, S.; Bru, V.; Godon, J.J. Microbial diversity in Tunisian olive fermentation brine as evaluated by small subunit rRNA—single strand conformation polymorphism analysis. Int. J. Food Microbiol. 2008, 122, 211–215. [Google Scholar] [CrossRef] [PubMed]

- Lucena-Padrós, H.; Ruiz-Barba, J.L. Diversity and enumeration of halophilic and alkaliphilic bacteria in Spanish-style green table-olive fermentations. Food Microbiol. 2016, 53, 53–62. [Google Scholar] [CrossRef] [Green Version]

- Anagnostopoulos, D.; Bozoudi, D.; Tsaltas, D. Enterococci Isolated from Cypriot Green Table Olives as a New Source of Technological and Probiotic Properties. Fermentation 2018, 4, 48. [Google Scholar] [CrossRef] [Green Version]

- Ercolini, D.; Villani, F.; Aponte, M.; Mauriello, G. Fluorescence in situ hybridisation detection of Lactobacillus plantarum group on olives to be used in natural fermentations. Int. J. Food Microbiol. 2006, 112, 291–296. [Google Scholar] [CrossRef]

- Papadelli, M. Evaluation of two lactic acid bacteria starter cultures for the fermentation of natural black table olives (Olea europaea L. cv Kalamon). Pol. J. Microbiol. 2015, 64, 265–271. [Google Scholar] [CrossRef]

- Hansen, E.B. Commercial bacterial starter cultures for fermented foods of the future. Int. J. Food Microbiol. 2002, 78, 119–131. [Google Scholar] [CrossRef]

- Malo, P.; Urquhart, E. Fermented foods: Use of starter cultures. In Encyclopedia of Food and Health; Caballero, B., Finglas, P.M., Toldrá, F., Eds.; Academic Press: London, UK, 2016; Volume 2, pp. 681–685. ISBN 978-0-12-384947-2. [Google Scholar]

- Giraffa, G. Studying the dynamics of microbial populations during food fermentation. FEMS Microbiol. Rev. 2004, 28, 251–260. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Perricone, M.; Corbo, M.R.; Sinigaglia, M.; Bevilacqua, A. Use of starter cultures in olives: A not-correct use could cause a delay of performances. Food Nutr. Sci. 2013, 4, 721–726. [Google Scholar] [CrossRef] [Green Version]

- Carnevali, P.; Ciati, R.; Leporati, A.; Paese, M. Liquid sourdough fermentation: Industrial application perspectives. Food Microbiol. 2007, 24, 150–154. [Google Scholar] [CrossRef] [PubMed]

- Pistarino, E.; Aliakbarian, B.; Casazza, A.A.; Paini, M.; Cosulich, M.E.; Perego, P. Combined effect of starter culture and temperature on phenolic compounds during fermentation of Taggiasca black olives. Food Chem. 2013, 138, 2043–2049. [Google Scholar] [CrossRef] [PubMed]

- Servili, M.; Settanni, L.; Veneziani, G.; Esposto, S.; Massitti, O.; Taticchi, A.; Urbani, S.; Montedoro, G.F.; Corsetti, A. The use of Lactobacillus pentosus 1MO to shorten the debittering process time of black table olives (cv. Itrana and Leccino): A pilot-scale application. J. Agric. Food Chem. 2006, 54, 3869–3875. [Google Scholar] [CrossRef]

- Martorana, A.; Alfonzo, A.; Gaglio, R.; Settanni, L.; Corona, O.; La Croce, F.; Vagnoli, P.; Caruso, T.; Moschetti, G.; Francesca, N. Evaluation of different conditions to enhance the performances of Lactobacillus pentosus OM13 during industrial production of Spanish-style table olives. Food Microbiol. 2017, 61, 150–158. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bleve, G.; Tufariello, M.; Durante, M.; Perbellini, E.; Mita, G.; Ramires, F.A.; Grieco, F.; Logrieco, A.F. Method for Production of Fermented Table Olives. Patent EP2901867, 5 August 2015. [Google Scholar]

- Lavermicocca, P.; Lonigro, S.L.; Visconti, A.; De Angelis, M.; Valerio, F.; Morelli, L. Table Olives Containing Probiotic Microorganisms. Patent WO2005053430, 16 June 2005. [Google Scholar]

- Ruiz-Barba, J.L.; Jiménez-Díaz, R. A novel Lactobacillus pentosus-paired starter culture for Spanish-style green olive fermentation. Food Microbiol. 2012, 30, 253–259. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mastralexi, A.; Mantzouridou, F.T.; Tsimidou, M.Z. Evolution of safety and other quality parameters of the Greek PDO table olives ‘Prasines Elies Chalkidikis’ during industrial scale processing and storage. Eur. J. Lipid Sci. Technol. 2018, 121, 1800171. [Google Scholar] [CrossRef]

- Domínguez-Manzano, J.; Olmo-Ruiz, C.; Bautista-Gallego, J.; Arroyo-López, F.N.; Garrido-Fernández, A.; Jiménez-Díaz, R. Biofilm formation on abiotic and biotic surfaces during Spanish style green table olive fermentation. Int. J. Food Microbiol. 2012, 157, 230–238. [Google Scholar] [CrossRef]

| Method Name | Debittering Treatment | Fermentation | Brine Treatment | Drying | Oxidation Treatment | Final Polishing | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Adventitious Fermentation | Alkaline, %NaOH | Water Washing | Spontaneous | Starter Culture | % Salt | Salt | Heat | None | Aeration + Iron Salts | None | Sterilization | Tight Packaging | Gross Open Sell | Acidified Water | |

| Natural 1 | 8–10 | ||||||||||||||

| Treated 2 | 2–5 | 10–11 | |||||||||||||

| Darkened by oxidation 3 | 1–2 | 8–10 | |||||||||||||

| Dehydrated/ Shriveled | |||||||||||||||

| Species | Country | Processing Method | Olive Cultivar | Study Objective | Reference |

|---|---|---|---|---|---|

| Lactobacillus sp. | Spain | Natural green olives | Aloreña | Identification of microbial diversity | [46] |

| Lactobacillus acidipiscis | Turkey | - (black olives) | - | Halophilic LAB identification | [47] |

| - (green olives) | - | Halophilic LAB identification | [47] | ||

| Spain | Treated green olives (Spanish-style) | Manzanilla | Identification of microbial diversity and biogeography | [48] | |

| Lactobacillus alimentarius | Turkey | - (black olives) | - | Halophilic LAB identification | [47] |

| Lactobacillus brevis | Algeria | Natural black olives | Chemlal | LAB identification; Technological characterization | [49] |

| Natural black olives | Hamra | LAB identification; Technological characterization | [49] | ||

| Natural black olives | Sigoise | LAB identification; Technological characterization | [49] | ||

| Italy | Natural green olives | Bella di Cerignola | Identification of microbial diversity; Probiotic starter culture application | [50] | |

| Natural green olives | - | LAB identification | [51] | ||

| Morocco | Treated green olives (Picholine-style) | Picholine | Selection of oleuropein-degrading LAB strains | [52] | |

| Turkey | Natural green olives | - | LAB identification; Identification of microbial diversity | [53] | |

| Natural black olives | Gemlik | Starter culture application | [54] | ||

| Lactobacillus casei | Algeria | Natural green olives | Sigoise | LAB identification | [55] |

| Italy | Natural green olives | Bella di Cerignola | Identification of microbial diversity; Probiotic starter culture application | [50] | |

| - (green olives) | - | Identification of microbial diversity; Safety evaluation | [56] | ||

| Natural black olives | Cellina di Nardò | LAB identification; Physico-chemical characterization | [57] | ||

| Natural black olives | Itrana nera | LAB identification; Physico-chemical characterization | [57] | ||

| Natural green olives | Nocellara del Belice | LAB identification; Physico-chemical characterization | [57] | ||

| Natural green olives | Itrana bianca | LAB identification; Physico-chemical characterization | [57] | ||

| Natural green olives | Giarraffa | (Probiotic) Starter culture application | [58] | ||

| Natural green olives | Grossa di Spagna | (Probiotic) Starter culture application | [58] | ||

| Natural green olives | Nocellara Etnea | Starter culture application | [32,59] | ||

| Natural green olives | - | LAB identification | [51] | ||

| Lactobacillus casei ssp. tolerens | Algeria | Natural black olives | Chemlal | LAB identification; Technological characterization | [49] |

| Natural black olives | Hamra | LAB identification; Technological characterization | [49] | ||

| Natural black olives | Sigoise | LAB identification; Technological characterization | [49] | ||

| Lactobacillus collinoides | Italy | Natural green olives | Tonda di Cagliari | Identification of microbial diversity; Sensory analysis | [60] |

| Lactobacillus coryniformis | Greece | Natural black olives | Conservolea | Identification of microbial diversity; Evaluation of storage conditions | [61] |

| Italy | Natural green olives | Bella di Cerignola | Identification of microbial diversity; Probiotic starter culture application | [50] | |

| Natural green olives | Geracese | Identification of microbial diversity; Starter culture application | [62] | ||

| Treated green olives (Spanish-style) | Nocellara del Belice | Starter culture application | [63] | ||

| Natural green olives | Nocellara del Belice | Improvement of table olives’ growing conditions and processing method | [27,64] | ||

| Treated green olives (Spanish-style) | Nocellara del Belice | LAB identification; Probiotic characterization | [65] | ||

| Treated green olives | Nocellara | Identification of microbial diversity; Sensory analysis | [66] | ||

| Spain | Treated green olives (Spanish-style) | Manzanilla | Identification of microbial diversity | [33] | |

| Lactobacillus coryniformis ssp. coryniformis/torquens | Spain | Treated green olives (Spanish-style) | Manzanilla | Identification of microbial diversity and biogeography | [48] |

| Lactobacillus curvatus | Algeria | Natural black olives | Chemlal | LAB identification; Technological characterization LAB identification; Technological characterization LAB identification; Technological characterization | [49] |

| Natural black olives | Hamra | [49] | |||

| Natural black olives | Sigoise | [49] | |||

| Lactobacillus farciminis | Turkey | - (green olives) | - | Halophilic LAB identification | [47] |

| Lactobacillus fermentum | Italy | Natural black olives | Peranzana | LAB identification; Physico-chemical characterization | [57] |

| Natural green olives | Bella di Cerignola | LAB identification; Physico-chemical characterization | [57] | ||

| Lactobacillus helveticus | Italy | Natural black olives | Cellina di Nardò | LAB identification; Physico-chemical characterization | [57] |

| Lactobacillus mali | Italy | Natural green olives | Bella di Cerignola | Identification of microbial diversity; Probiotic starter culture application | [50] |

| Lactobacillus namurensis | Turkey | - (black olives) | - | Halophilic LAB identification | [47] |

| Lactobacillus oligofermentans | Italy | Treated green olives (Spanish-style) | Nocellara del Belice | LAB identification; Probiotic characterization | [65] |

| Lactobacillus paracasei | Algeria | Natural green olives | Sigoise | LAB identification | [55] |

| Italy | Natural green olives | Bella di Cerignola | Identification of microbial diversity; Probiotic starter culture application | [50] | |

| Natural green olives | Giarraffa | (Probiotic) Starter culture application | [58] | ||

| Natural green olives | Nocellara Etnea | Starter culture application | [59] | ||

| Spain | Treated green olives (Spanish-style) | Manzanilla | Identification of microbial diversity | [33,67] | |

| Lactobacillus paracasei ssp. paracasei | Greece | Treated green olives (Spanish-style) | Conservolea | LAB identification | [68] |

| Treated green olives (Spanish-style) | Halkidiki | LAB identification | [68] | ||

| Lactobacillus paracollinoides | Italy | Natural green olives | Geracese | Identification of microbial diversity; Starter culture application | [62] |

| Spain | Treated green olives (Spanish-style) | - | Identification of ascorbic acid and potassium sorbate degrading LAB | [69] | |

| Natural green olives | Aloreña | Identification of microbial diversity | [46] | ||

| Lactobacillus paracollinoides/collinoides | Spain | Treated green olives (Spanish-style) | Manzanilla | Identification of microbial diversity and biogeography | [33,48,67] |

| Lactobacillus parafarraginis | Spain | Treated green olives (Spanish-style) | - | Identification of ascorbic acid and potassium sorbate degrading LAB | [69] |

| Treated green olives (Spanish-style) | Manzanilla | Identification of microbial diversity and biogeography | [33,48,67] | ||

| Treated green olives (Spanish-style) | Manzanilla | Identification of microbial diversity | [70] | ||

| Treated green olives (Spanish-style) | Gordal | Identification of microbial diversity | [70] | ||

| Lactobacillus paraplantarum | Greece | Natural black olives | Conservolea | LAB identification | [68] |

| Natural black olives | Kalamata | LAB identification | [68] | ||

| Natural black olives | Conservolea | Identification of microbial diversity; Evaluation of storage conditions | [61] | ||

| Italy | - (green olives) | - | Identification of microbial diversity; Safety evaluation | [56] | |

| Natural green olives | Tonda di Cagliari | Identification of microbial diversity; Sensory analysis | [60] | ||

| Portugal | Natural black olives | Galega | Probiotic characterization | [71] | |

| Spain | Natural green olives | Arbequina | Identification of microbial diversity | [72] | |

| Treated green olives (Spanish-style) | Manzanilla | LAB identification; Probiotic characterization | [73] | ||

| Treated green olives (Spanish-style) | Manzanilla | Identification of microbial diversity; Identification of LAB species | [33,67] | ||

| Lactobacillus pentosus | Greece | Natural black olives | Conservolea | LAB identification | [68] |

| Natural black olives | Kalamata | LAB identification | [68] | ||

| Treated green olives (Spanish-style) | Halkidiki | Starter culture application | [74] | ||

| Treated green olives (Spanish-style) | Conservolea | LAB identification LAB identification | [68] | ||

| Treated green olives (Spanish-style) | Halkidiki | [68] | |||

| Treated green olives (Spanish-style) | Halkidiki | Shelf life evaluation | [75] | ||

| Treated green olives (Spanish-style) | Halkidiki | Identification of microbial diversity (biofilm on fermentation vessels) | [76] | ||

| Natural black olives | Conservolea | Identification of microbial diversity; Evaluation of storage conditions | [61] | ||

| Natural black olives | Conservolea | Identification of microbial diversity; Starter culture application | [77] | ||

| Italy | Natural green olives | Bella di Cerignola | Identification of microbial diversity; Probiotic starter culture application | [50] | |

| Natural black olives | Cellina di Nardò | LAB identification; Physico-chemical characterization | [57] | ||

| Natural black olives | Itrana nera | LAB identification; Physico-chemical characterization | [57] | ||

| Natural black olives | Peranzana | LAB identification; Physico-chemical characterization | [57] | ||

| Natural green olives | Nocellara del Belice | LAB identification; Physico-chemical characterization | [57] | ||

| Natural green olives | Itrana bianca | LAB identification; Physico-chemical characterization | [57] | ||

| Natural green olives | Bella di Cerignola | LAB identification; Physico-chemical characterization | [57] | ||

| Natural green olives | Bella di Cerignola | Identification of microbial diversity | [78] | ||

| - (green olives) | - | Identification of microbial diversity; Safety evaluation | [56] | ||

| Natural green olives | Tonda di Cagliari | Identification of microbial diversity; Sensory analysis | [60] | ||

| Treated green olives (Spanish-style) | Nocellara del Belice | Starter culture application | [63] | ||

| Treated green olives (Spanish-style) | Bella di Cerignola | Identification of microbial diversity | [78] | ||

| Natural green olives | Giarraffa | (Probiotic) Starter culture application | [58] | ||

| Natural green olives | Grossa di Spagna | (Probiotic) Starter culture application | [58] | ||

| Natural green olives | Nocellara del Belice | Improvement of table olives’ growing conditions; Mechanical harvest evaluation | [64,79] | ||

| Treated green olives (Spanish-style) | Nocellara del Belice | LAB identification; Probiotic characterization | [65] | ||

| Natural green olives | Nocellara Etnea | Starter culture application; Safety evaluation; Sensory analysis | [80] | ||

| Natural green olives | Nocellara Etnea | Starter culture application | [32,59] | ||

| Treated green olives | Nocellara Etnea | Identification of microbial diversity; Evaluation of NaOH treatment | [81] | ||

| Treated green olives | Nocellara | Identification of microbial diversity; Sensory analysis | [66] | ||

| Morocco | Treated green olives(Picholine-style) | Picholine | Selection of oleuropein-degrading LAB strains | [52] | |

| Portugal | Natural black olives (in brine) | Galega | Identification of microbial diversity; Chemical characterization; Sensory analysis | [82] | |

| Spain | Natural green olives | Arbequina | Identification of microbial diversity | [24,72] | |

| Natural green olives | Aloreña | LAB identification; Technological and probiotic characterization; Influence of salt concentrations on shelf life | [73,83,84] | ||

| Natural green olives | Gordal | Identification of microbial diversity on biofilms | [85] | ||

| Natural green olives | Gordal | LAB identification; Probiotic characterization | [73] | ||

| Natural green olives | Manzanilla | LAB identification; Probiotic characterization | [73] | ||

| Treated green olives (Spanish-style) | Gordal | LAB identification; Probiotic characterization | [73] | ||

| Treated green olives (Spanish-style) | - | Identification of ascorbic acid and potassium sorbate degrading LAB | [69] | ||

| Treated green olives (Spanish-style) | Manzanilla | LAB identification; Probiotic characterization; Influence of salt concentrations during fermentation | [73,86] | ||

| Treated green olives (Spanish-style) | Manzanilla | Identification of microbial diversity and LAB species and biogeography | [33,48,67] | ||

| Natural black olives (in brine) | Manzanilla | Influence of salt concentrations in packaging brine | [87] | ||

| Treated green olives (Spanish-style) | Manzanilla | LAB identification; Selection of a multifunctional starter culture | [88] | ||

| Treated green olives (Spanish-style) | Gordal | LAB identification; Selection of a multifunctional starter culture | [88] | ||

| Treated green olives (Spanish-style) | Aloreña | LAB identification; Selection of a multifunctional starter culture | [88] | ||

| Natural green olives | Manzanilla | LAB identification; Selection of a multifunctional starter culture | [88] | ||

| Natural green olives | Gordal | LAB identification; Selection of a multifunctional starter culture | [88] | ||

| Natural green olives | Aloreña | LAB identification; Selection of a multifunctional starter culture | [88] | ||

| Lactobacillus pentosus/plantarum | Spain | Natural green olives | Aloreña | Identification of microbial diversity | [46] |

| Lactobacillus plantarum | Algeria | Natural black olives | Chemlal | LAB identification; Technological characterization LAB identification; Technological characterization LAB identification; Technological characterization | [49] |

| Natural black olives | Hamra | [49] | |||

| Natural black olives | Sigoise | [49] | |||

| Natural green olives | Sigoise | Identification of microbial diversity | [89] | ||

| Natural green olives | Sigoise | LAB identification | [55] | ||

| Croatia | Treated green olives (Californian-style) | Oblica | Technological, physico-chemical characterization; LAB identification | [90] | |

| Greece | Natural black olives | Conservolea | LAB identification; Physico-chemical, probiotic characterization | [18,68,91] | |

| Natural black olives | Kalamata | LAB identification; Physico-chemical, probiotic characterization | [18,68,91] | ||

| Treated green olives (Spanish-style) | Conservolea | LAB identification; Probiotic characterization | [68,91] | ||

| Treated green olives (Spanish-style) | Halkidiki | LAB identification; Probiotic characterization | [68,91] | ||

| Natural black olives | Conservolea | Development of new processing method | [92] | ||

| Natural black olives | Conservolea | Identification of microbial diversity; Evaluation of storage conditions | [61] | ||

| Italy | Natural green olives | Bella di Cerignola | Identification of microbial diversity; Probiotic starter culture application | [50] | |

| Treated green olives (Spanish-style) | Bella di Cerignola | Selection of a multifunctional starter culture | [93] | ||

| - (green olives) | - | Identification of microbial diversity; Safety evaluation | [56] | ||

| Natural black olives | Cellina di Nardò | Identification of microbial diversity and LAB; Physico-chemical characterization | [57] | ||

| Natural black olives | Cellina di Nardò | Identification of microbial diversity; Physico-chemical characterization | [94] | ||

| Natural black olives | Leccino | Identification of microbial diversity; Physico-chemical characterization | [94] | ||

| Natural black olives | Itrana nera | LAB identification; Physico-chemical characterization | [57] | ||

| Natural black olives | Peranzana | LAB identification; Physico-chemical characterization | [57] | ||

| Natural green olives | Nocellara del Belice | LAB identification; Physico-chemical characterization | [57] | ||

| Natural green olives | Itrana bianca | LAB identification; Physico-chemical characterization | [57] | ||

| Natural green olives | Bella di Cerignola | LAB identification; Physico-chemical characterization | [57] | ||

| Natural green olives | Bella di Cerignola | Identification of microbial diversity | [78] | ||

| Natural green olives | Nocellara Etnea | Identification of microbial diversity; Starter culture application | [62] | ||

| Natural green olives | Geracese | Identification of microbial diversity; Starter culture application | [62] | ||

| Natural green olives | Tonda di Cagliari | Identification of microbial diversity; Sensory analysis | [60] | ||

| Natural green olives | Giarraffa | (Probiotic) Starter culture application | [58] | ||

| Natural green olives | Grossa di Spagna | (Probiotic) Starter culture application | [58] | ||

| Treated green olives (Spanish-style) | Bella di Cerignola | Identification of microbial diversity | [78] | ||

| Natural black olives | Cellina di Nardò | Development of new processing method | [92] | ||

| Natural black olives | Leccino | Development of new processing method | [92] | ||

| Natural green olives | Nocellara del Belice | Improvement of table olives’ growing conditions and processing method; Mechanical harvest evaluation | [27,64,79] | ||

| Natural green olives | Nocellara Etnea | Starter culture application; Safety evaluation; Sensory analysis | [80] | ||

| Natural green olives | Nocellara Etnea | Starter culture application | [32,59] | ||

| Treated green olives | Nocellara Etnea | Identification of microbial diversity; Evaluation of NaOH treatment | [81] | ||

| Natural green olives | - | LAB identification | [51] | ||

| Morocco | Treated green olives (Spanish-style) | Picholine | Processing method improvement; Reducing bloater spoilage incidence | [95] | |

| Treated green olives (Picholine-style) | Picholine | Selection of oleuropein-degrading LAB strains | [52] | ||

| Portugal | Natural black olives (in brine) | Galega | Identification of microbial diversity; Chemical characterization; Sensory analysis | [82] | |

| Natural black olives | Galega | Probiotic characterization | [71] | ||

| Spain | Natural green olives | Arbequina | Identification of microbial diversity; Influence of salt concentrations during fermentation; Influence of fruit ripeness | [23,24,72] | |

| Natural green olives | Aloreña | Influence of salt concentrations on shelf life | [83] | ||

| Treated green olives (Spanish-style) | Manzanilla | LAB identification; Probiotic characterization | [73] | ||

| Treated green olives (Spanish-style) | Manzanilla | Identification of microbial diversity and LAB species | [33,48,67] | ||

| Natural black olives (in brine) | Manzanilla | Influence of salt concentrations in packaging brine | [87] | ||

| Treated green olives (Spanish-style) | Manzanilla | LAB identification; Selection of a multifunctional starter culture | [88] | ||

| Treated green olives (Spanish-style) | Gordal | LAB identification; Selection of a multifunctional starter culture | [88] | ||

| Natural green olives | Manzanilla | LAB identification; Selection of a multifunctional starter culture | [88] | ||

| Natural green olives | Gordal | LAB identification; Selection of a multifunctional starter culture | [88] | ||

| Natural green olives | Aloreña | LAB identification; Selection of a multifunctional starter culture | [88] | ||

| Tunisia | - | - | Identification of microbial diversity | [96] | |

| Turkey | - (black olives) | - | Halophilic LAB identification | [47] | |

| - (green olives) | - | Halophilic LAB identification | [47] | ||

| Natural green olives | - | LAB identification; Identification of microbial diversity | [53] | ||

| Lactobacillus rapi | Spain | Treated green olives (Spanish-style) | - | Identification of ascorbic acid and potassium sorbate degrading LAB | [69] |

| Treated green olives (Spanish-style) | Manzanilla | Identification of microbial diversity and biogeography | [33,48,67] | ||

| Lactobacillus rhamnosus | Algeria | Natural green olives | Sigoise | LAB identification | [55] |

| Italy | Natural green olives | Nocellara Etnea | Starter culture application; Safety evaluation; Sensory analysis | [80] | |

| Spain | Treated green olives (Spanish-style) | Manzanilla | Identification of microbial diversity and biogeography | [33,48,67] | |

| Lactobacillus sanfranciscensis | Spain | Treated green olives (Spanish-style) | Manzanilla | Identification of microbial diversity | [70] |

| Lactobacillus vaccinostercus | Italy | Natural green olives | Bella di Cerignola | Identification of microbial diversity; Probiotic starter culture application | [50] |

| Lactobacillus vaccinostercus/suebicus | Spain | Natural green olives | Aloreña | Identification of microbial diversity | [46] |

| Lactobacillus veridesens | Algeria | Natural black olives | Chemlal | LAB identification; Technological characterization LAB identification; Technological characterization LAB identification; Technological characterization | [49] |

| Natural black olives | Hamra | [49] | |||

| Natural black olives | Sigoise | [49] |

| Species | Country | Processing Method | Olive Cultivar | Study Objective | Ref. |

|---|---|---|---|---|---|

| Aerococcus viridans/urinaeequi | Spain | Treated green olives (Spanish-style) | Manzanilla | Identification of microbial diversity | [33,67,97] |

| Enterococcus durans | Algeria | Natural green olives | Sigoise | LAB identification | [55] |

| Italy | Natural black olives | Cellina di Nardò | LAB identification; Physico-chemical characterization | [4] | |

| Natural green olives | Itrana bianca | LAB identification; Physico-chemical characterization | [4] | ||

| Natural green olives | Bella di Cerignola | LAB identification; Physico-chemical characterization | [4] | ||

| Enterococcus casseliflavus | Italy | Treated green olives (Spanish-style) | Nocellara del Belice | LAB identification; Probiotic characterization | [65] |

| Spain | Treated green olives (Spanish-style) | Manzanilla | Identification of microbial diversity and biogeography | [33,48,67] | |

| Enterococcus casseliflavus species group 1 | Italy | Natural green olives | Bella di Cerignola | Identification of microbial diversity; Probiotic starter culture application | [50] |

| Enterococcus faecalis | Algeria | Natural green olives | - | Identification of microbial diversity | [89] |

| Natural green olives | Sigoise | LAB identification | [55] | ||

| Italy | Treated green olives (Spanish-style) | Bella di Cerignola | Selection of a multifunctional starter culture | [93] | |

| - (green olives) | - | Identification of microbial diversity; Safety evaluation | [56] | ||

| Spain | Treated green olives (Spanish-style) | Manzanilla | Identification of microbial diversity and biogeography | [48] | |

| Enterococcus faecium | Algeria | Natural green olives | Sigoise | LAB identification | [55] |

| Cyprus | Natural green olives | - | Technological and probiotic characterization | [98] | |

| Italy | Natural green olives | Tonda di Cagliari | Identification of microbial diversity; Sensory analysis | [60] | |

| Natural green olives | - | LAB identification | [51] | ||

| Turkey | - (black olives) | - | Halophilic LAB identification | [47] | |

| - (green olives) | - | Halophilic LAB identification | [47] | ||

| Enterococcus gallinarum | Italy | Treated green olives (Spanish-style) | Nocellara del Belice | LAB identification; Probiotic characterization | [65] |

| Enterococcus italicus | Italy | Natural green olives | Bella di Cerignola | Identification of microbial diversity; Probiotic starter culture application | [50] |

| Enterococcus olivae | Spain | Treated green olives (Spanish-style) | Manzanilla | Identification of microbial diversity | [33,67,97] |

| Lactococcus formosensis/garviae | Spain | Treated green olives (Spanish-style) | Manzanilla | Identification of microbial diversity and biogeography | [48] |

| Lactococcus lactis | Algeria | Natural green olives | - | Identification of microbial diversity | [89] |

| Natural green olives | Sigoise | LAB identification | [55] | ||

| Lactococcus lactis/Lactobacillus coryniformis | Spain | Natural green olives | Aloreña | Identification of microbial diversity | [46] |

| Leuconostoc cremoris | Turkey | Natural black olives | Gemlik | Starter culture application | [54] |

| Leuconostoc mesenteroides | Algeria | Natural black olives | Chemlal | LAB identification; Technological characterization | [49] |

| Natural black olives | Hamra | LAB identification; Technological characterization | [49] | ||

| Natural black olives | Sigoise | LAB identification; Technological characterization | [49] | ||

| Greece | Natural black olives | Kalamata | Physico-chemical characterization | [18] | |

| Natural black olives | Conservolea | LAB identification | [68] | ||

| Natural black olives | Kalamata | LAB identification | [68] | ||

| Natural black olives | Kalamata | Development of new processing method | [92] | ||

| Italy | Natural green olives | Bella di Cerignola | Identification of microbial diversity | [78] | |

| Treated green olives (Spanish-style) | Bella di Cerignola | Identification of microbial diversity | [78] | ||

| Natural black olives | Leccino | LAB identification | [99] | ||

| Natural green olives | Bella di Cerignola | Identification of microbial diversity; Probiotic starter culture application | [50] | ||

| - (green olives) | - | Identification of microbial diversity; Safety evaluation | [56] | ||

| Natural green olives | Grossa di Spagna | (Probiotic) Starter culture application | [58] | ||

| Treated green olives (Spanish-style) | Nocellara del Belice | LAB identification; Probiotic characterization | [65] | ||

| Portugal | Natural black olives (in brine) | Galega | Identification of microbial diversity; Chemical characterization; Sensory analysis | [82] | |

| Turkey | Natural green olives | - | LAB identification; Identification of microbial diversity | [53] | |

| Leuconostoc mesenteroides ssp. mesenteroides | Greece | Natural black olives | Kalamata | Starter culture application | [100] |

| Leuconostoc paramesenteroides | Turkey | Natural black olives | Gemlik | Starter culture application | [54] |

| Leuconostoc mesenteroides ssp. group 2 | Spain | Treated green olives (Spanish-style) | Manzanilla | Identification of microbial diversity and biogeography | [48] |

| Leuconostoc pseudomesenteroides | Greece | Natural black olives | Conservolea | LAB identification | [68] |

| Natural black olives | Kalamata | LAB identification | [68] | ||

| Italy | Natural black olives | Leccino | LAB identification | [99] | |

| Spain | Natural green olives | Aloreña | Technological characterization | [84] | |

| Pediococcus acidilactici | Italy | - (green olives) | - | Identification of microbial diversity; Safety evaluation | [56] |

| Spain | Treated green olives (Spanish-style) | Manzanilla | Identification of microbial diversity | [67] | |

| Pediococcus damnosus | Turkey | Natural green olives | - | LAB identification; Identification of microbial diversity | [53] |

| Pediococcus ethanolidurans | Spain | Treated green olives (Spanish-style) | - | Identification of ascorbic acid and potassium sorbate degrading LAB | [69] |

| Treated green olives (Spanish-style) | Manzanilla | Identification of microbial diversity and biogeography | [33,48,67] | ||

| Greece | Natural black olives | Conservolea | Identification of microbial diversity; Evaluation of storage conditions | [61] | |

| Pediococcus parvulus | Italy | - (green olives) | - | Identification of microbial diversity; Safety evaluation | [56] |

| Natural green olives | Geracese | Identification of microbial diversity; Starter culture application | [62] | ||

| Natural green olives | Tonda di Cagliari | Identification of microbial diversity; Sensory analysis | [60] | ||

| Spain | Treated green olives (Spanish-style) | Manzanilla | Identification of microbial diversity and biogeography | [33,48,67] | |

| Natural green olives | Aloreña | Technological characterization | [84] | ||

| Pediococcus pentosaceus | Italy | Natural black olives | Leccino | LAB identification | [99] |

| Natural green olives | Nocellara del Belice | Improvement of table olives’ growing conditions and processing method | [27,64] | ||

| Morocco | Treated green olives (Picholine-style) | Picholine | Selection of oleuropein-degrading LAB strains | [52] | |

| Portugal | Natural black olives (in brine) | Galega | Microbial and chemical characterization | [82] | |

| Sporolactobacillus inulinus/terrae | Spain | Treated green olives (Spanish-style) | Manzanilla | Identification of microbial diversity and biogeography | [33,48] |

| Streptococcus thermophilus | Italy | Natural green olives | Geracese | Identification of microbial diversity; Starter culture application | [62] |

| Weissella paramesenteroides | Italy | Natural green olives | Bella di Cerignola | Identification of microbial diversity; Probiotic starter culture application | [50] |

| Spain | Treated green olives (Spanish-style) | Manzanilla | Identification of microbial diversity and biogeography | [48] | |

| Weissella paramesenteroides/hellenica | Spain | Treated green olives (Spanish-style) | Manzanilla | Identification of microbial diversity | [33,67] |

| Lactobacillus Species | Olive Color | Method Type | Country | |

|---|---|---|---|---|

| Lactobacillus species | 1.000 | - | ||

| Olive color | 0.471 | 1.000 | - | |

| Method type | 0.433 | 0.949 | 1.000 | - |

| Country | 0.500 | 0.618 | 0.552 | 1.000 |

| Lactobacillus Species | Method Type | Cultivar | |

|---|---|---|---|

| Lactobacillus species | 1.000 | - | |

| Method type | 0.364 | 1.000 | - |

| Cultivar | 0.347 | 0.673 | 1.000 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Portilha-Cunha, M.F.; Macedo, A.C.; Malcata, F.X. A Review on Adventitious Lactic Acid Bacteria from Table Olives. Foods 2020, 9, 948. https://doi.org/10.3390/foods9070948

Portilha-Cunha MF, Macedo AC, Malcata FX. A Review on Adventitious Lactic Acid Bacteria from Table Olives. Foods. 2020; 9(7):948. https://doi.org/10.3390/foods9070948

Chicago/Turabian StylePortilha-Cunha, M. Francisca, Angela C. Macedo, and F. Xavier Malcata. 2020. "A Review on Adventitious Lactic Acid Bacteria from Table Olives" Foods 9, no. 7: 948. https://doi.org/10.3390/foods9070948

APA StylePortilha-Cunha, M. F., Macedo, A. C., & Malcata, F. X. (2020). A Review on Adventitious Lactic Acid Bacteria from Table Olives. Foods, 9(7), 948. https://doi.org/10.3390/foods9070948