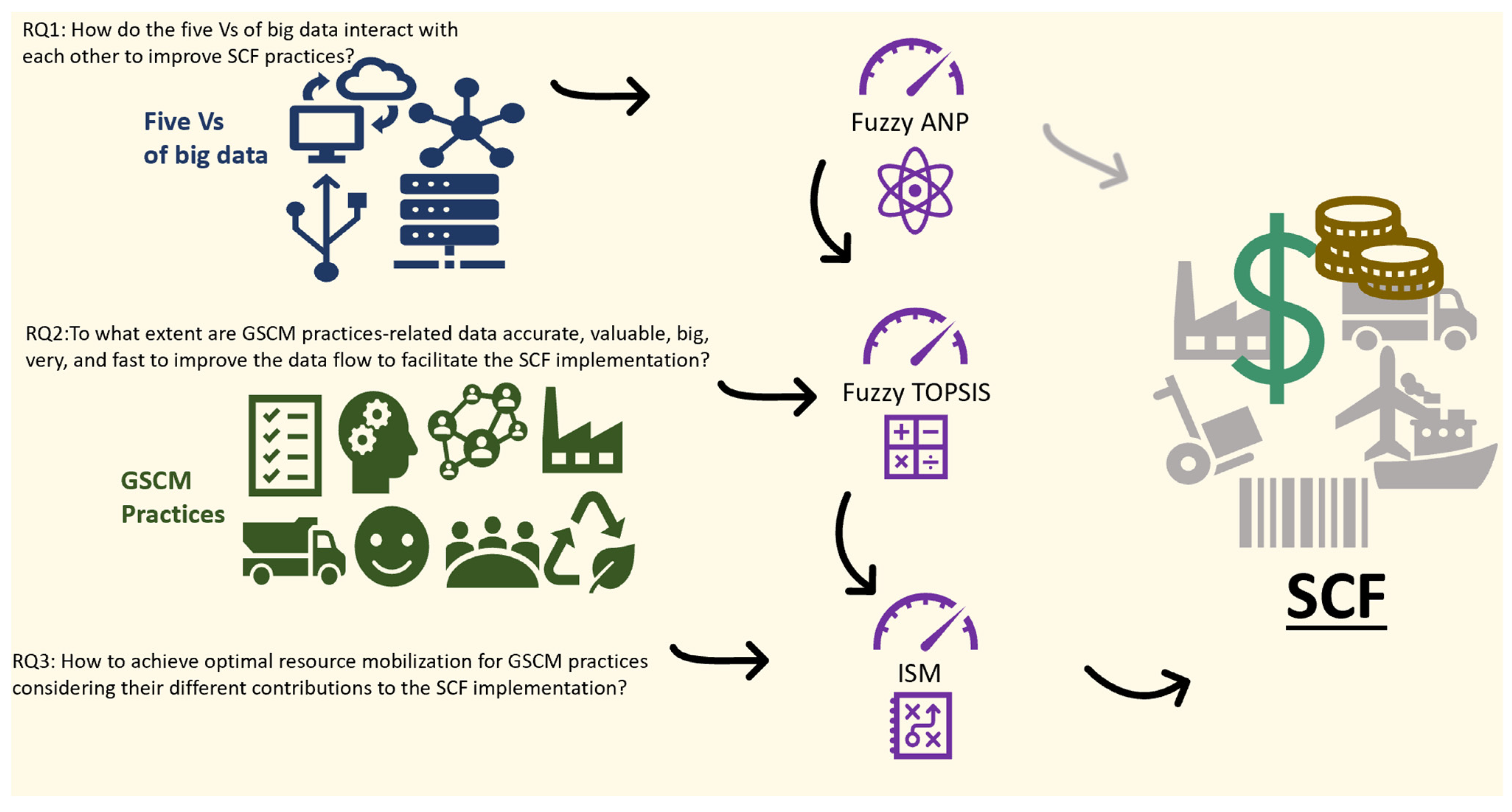

Measuring the Environmental Maturity of the Supply Chain Finance: A Big Data-Based Multi-Criteria Perspective

Abstract

:1. Introduction

2. Background

2.1. Top Management Commitment

2.2. Organizational Interaction Maturity

2.3. Quality Management

2.4. Environmental Management

2.5. Customer Relationship Management

2.6. Green Human Resource Management

2.7. Supplier Selection

2.8. Smart Process and Design

2.9. MCDM Applications in GSCM

3. Methods and Applications

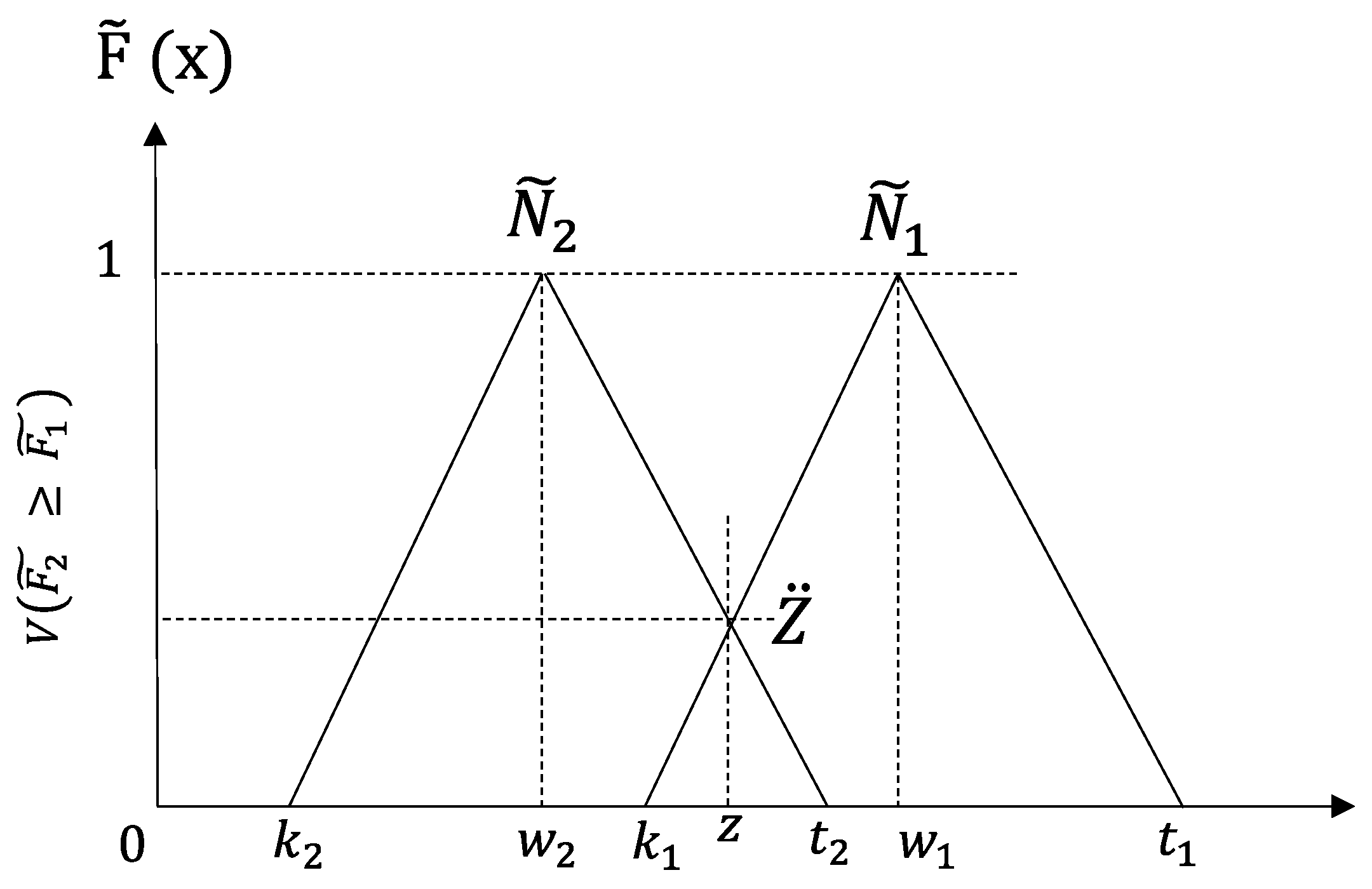

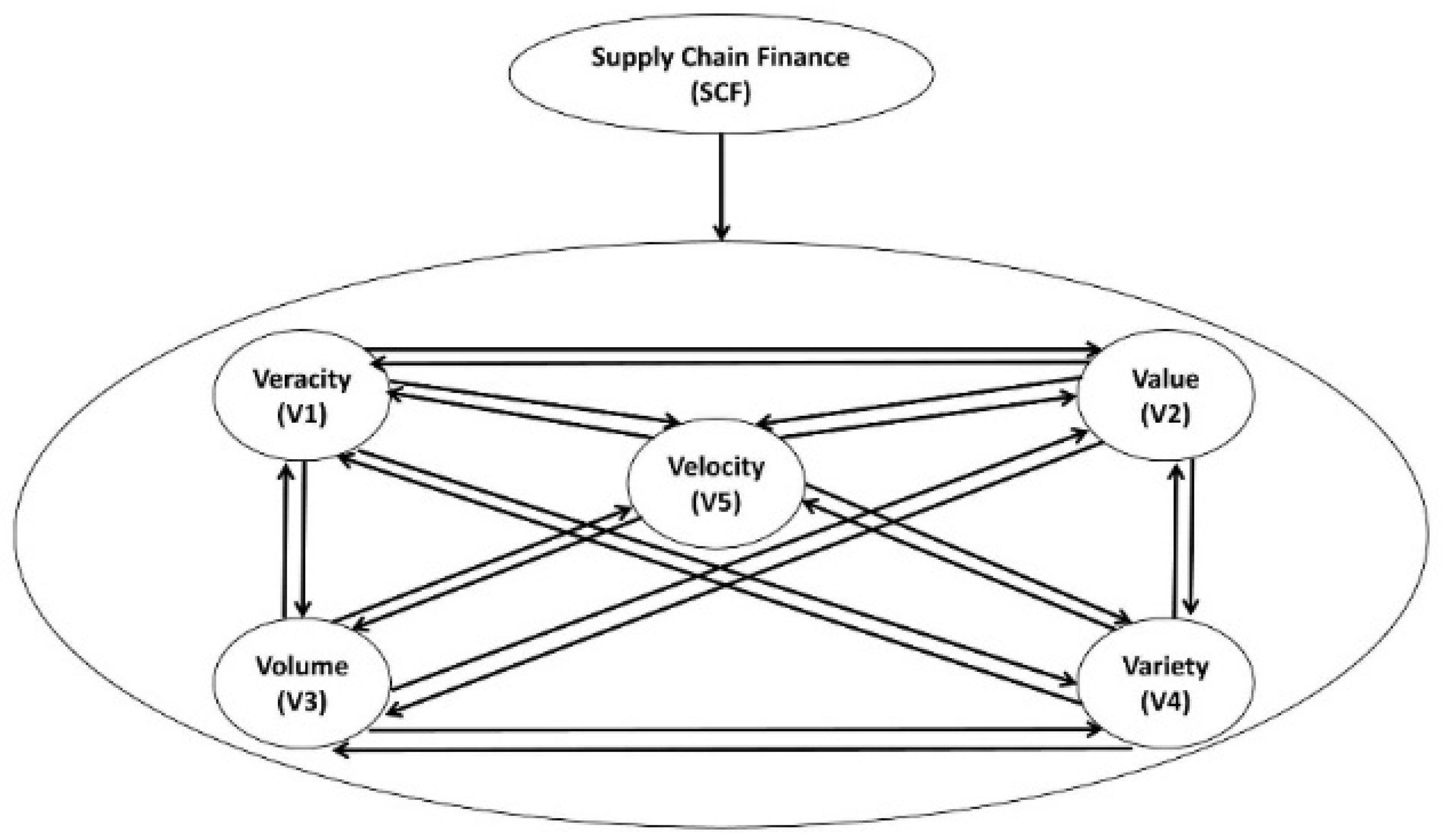

3.1. Fuzzy Analytic Network Process

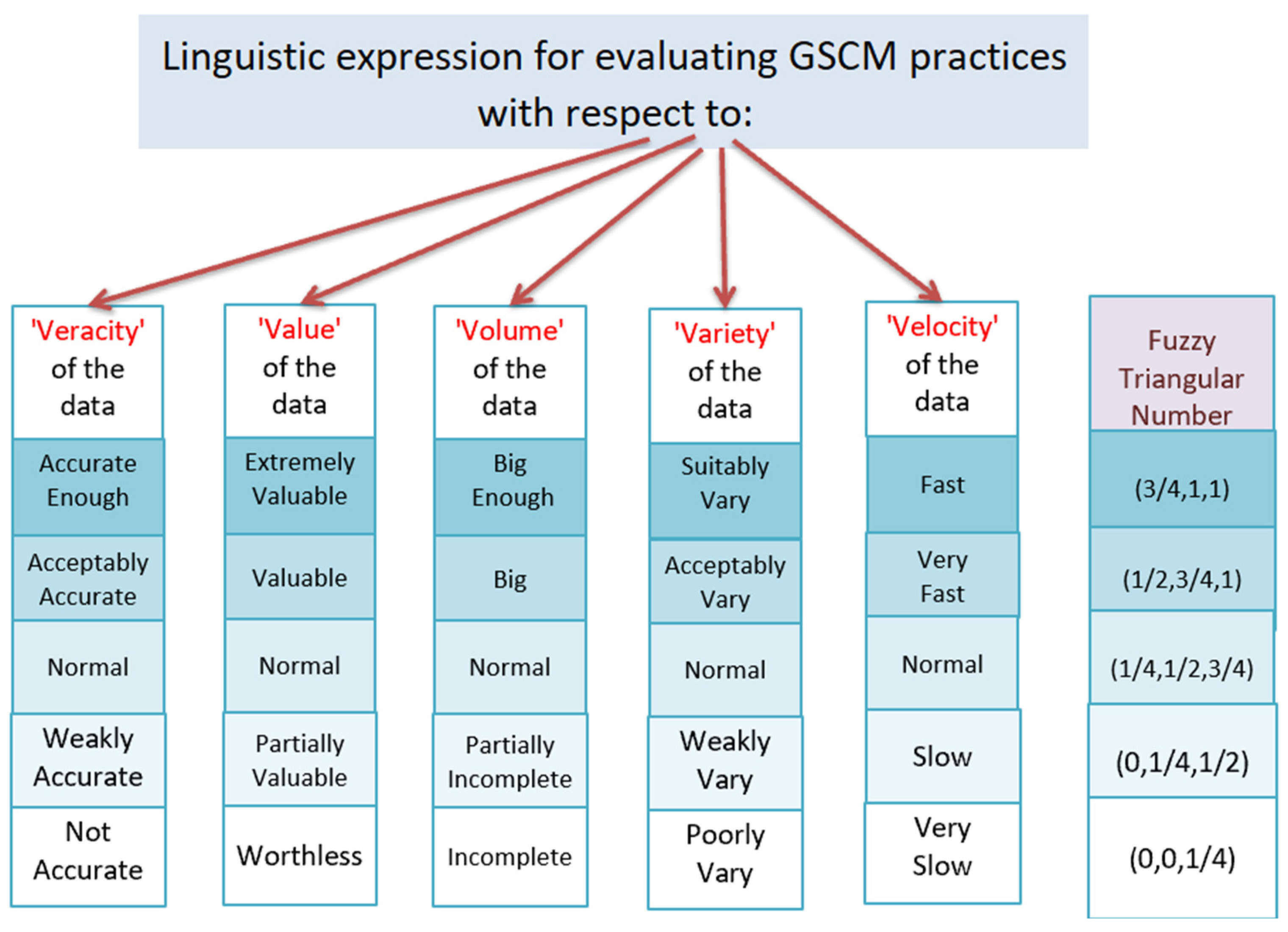

3.2. Fuzzy TOPSIS

- Aggregating the weights of the criteria and alternatives collected from decision-makers, as shown in Equations (10) and (11):

- Constructing the fuzzy decision matrix of the criteria () and the alternatives (), as shown in Equations (12) and (13):

- Normalizing the matrix () by calculating (). The normalized matrix () can be expressed as indicated in Equations (14)–(16):

- Computing the weighted normalized decision matrix () by multiplying each by the corresponding , as shown in Equations (17) and (18):

- Identifying the fuzzy positive ideal solution (FPIS, ) and the fuzzy negative ideal solution (FNIS, ), as shown below:where = (1, 1, 1) and = (0, 0, 0)

- Computing the distances and from and for each , respectively, as shown in Equations (21)–(23):where the distances between two triangular fuzzy numbers are calculated according to the vertex method shown below:

- Finding the closeness coefficient using Equation (24):

- Ranking the corresponding alternatives according to the value of .

3.3. Interpretive Structural Modeling

- Identifying the practices, such as factors, initiatives, barriers, or elements, to be examined.

- Describing the contextual relationships among the sets of practices through four symbols:

- V: if implementing practice Ä leads to the successful implementation of practice Ë.

- A: if implementing practice Ë leads to the successful implementation of practice Ä.

- X: if both practice Ä and practice Ë lead to successful reciprocal implementation.

- O: if there is no relationship between practice Ä and practice Ë.

- Forming the structural self-interaction matrix (SSIM) as a result of the pair-wise contextual relationships among the examined practices.

- Extracting the reachability matrix from the SSIM, which is converted into an initial reachability matrix in accordance with the following replacement rules:

- If the (α, β) entry is V, then the (α, β) entry in the reachability matrix becomes 1, and the (β, α) entry becomes 0.

- If the (α, β) entry is A, then the (α, β) entry in the reachability matrix becomes 0, and the (β, α) entry becomes 1.

- If the (α, β) entry is X, then the (α, β) entry in the reachability matrix becomes 1, and the (β, α) entry also becomes 1.

- If the (α, β) entry is O, then the (α, β) entry in the reachability matrix becomes 0, and the (β, α) entry also becomes 0.

- The initial reachability matrix then has to be tested for transitivity to ensure that if practice Ä leads to the implementation of practice Ë, and practice Ë leads to the implementation of practice Ü, then practice Ä leads to practice Ü. The resulting matrix is referred to as the final reachability matrix.

- Based on the final reachability matrix, the set of practices can be classified into four categories: driving, linkage, dependent, and autonomous.

- Based on the final reachability matrix, the set of practices can also be hierarchized. The final diagraph can then be developed in accordance with the identified levels.

3.4. The Application of Fuzzy ANP

3.5. The Application of Fuzzy TOPSIS

3.6. The Application of ISM

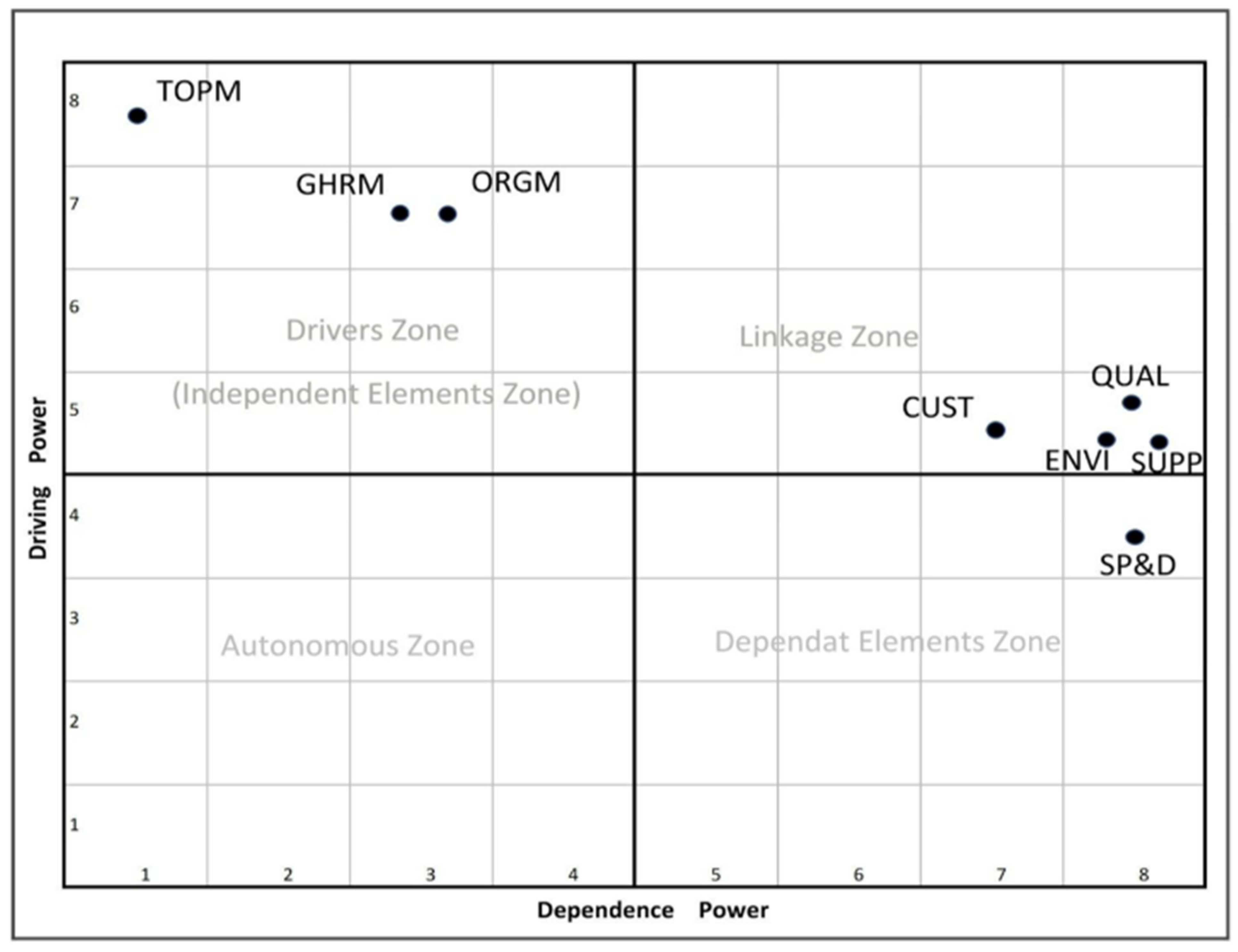

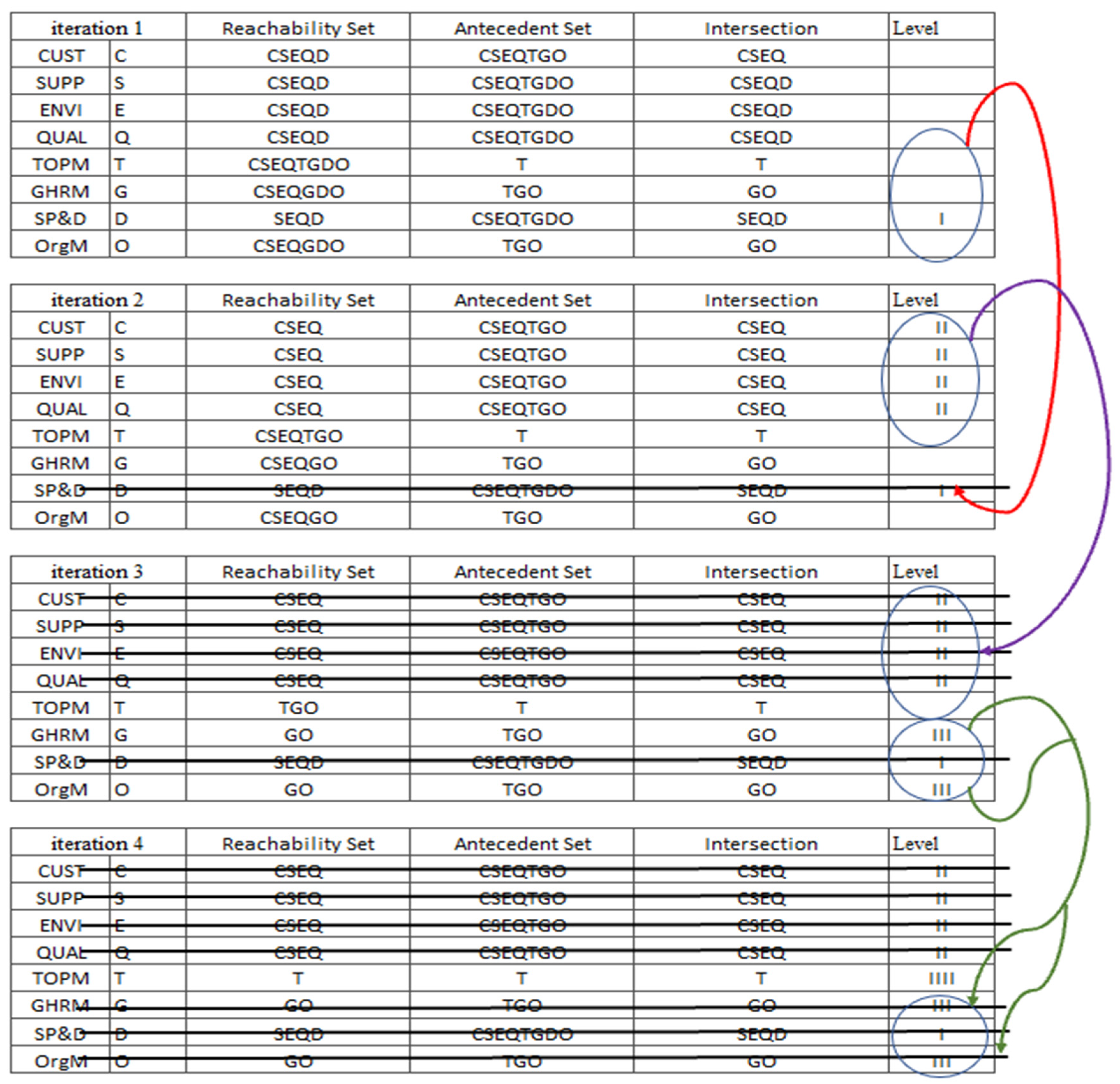

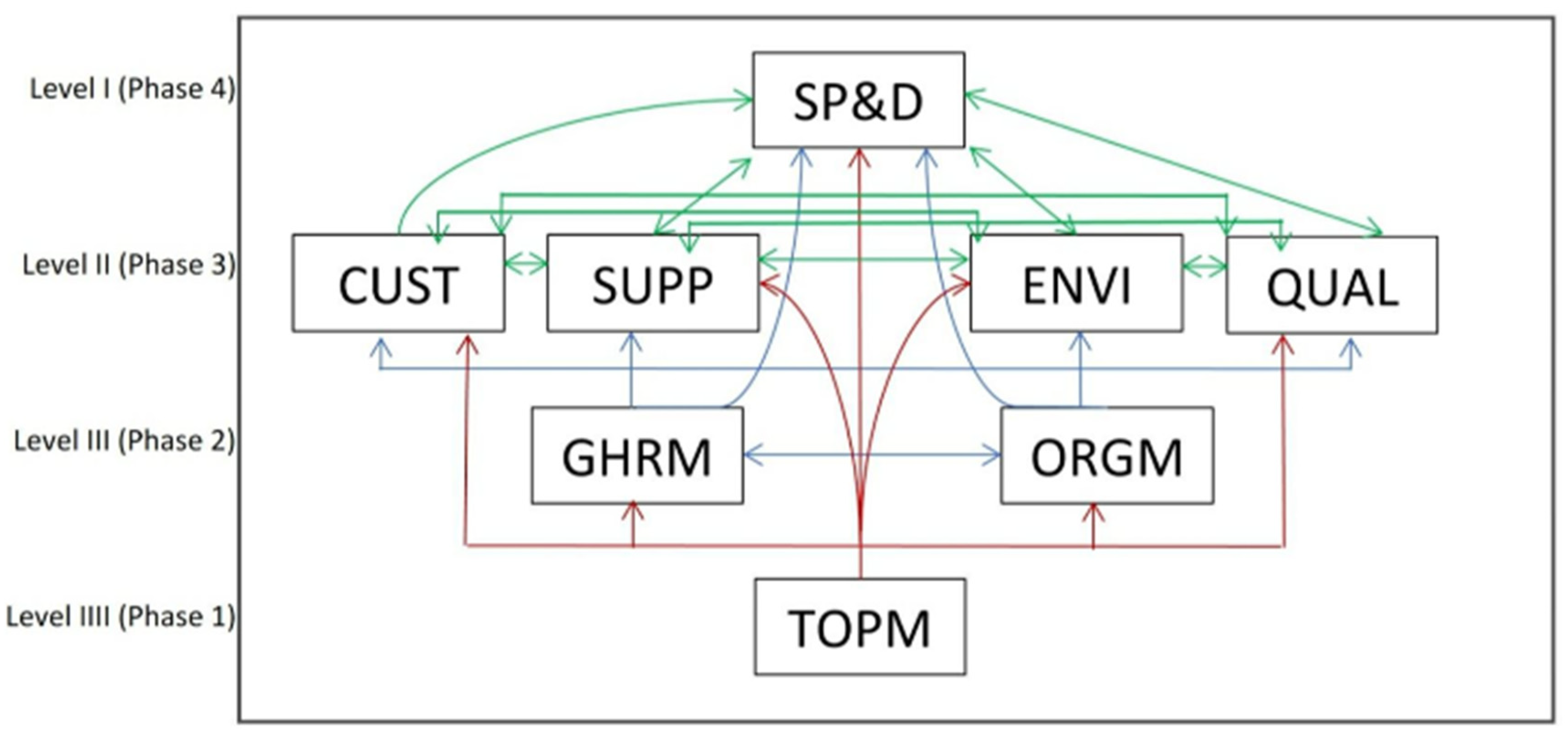

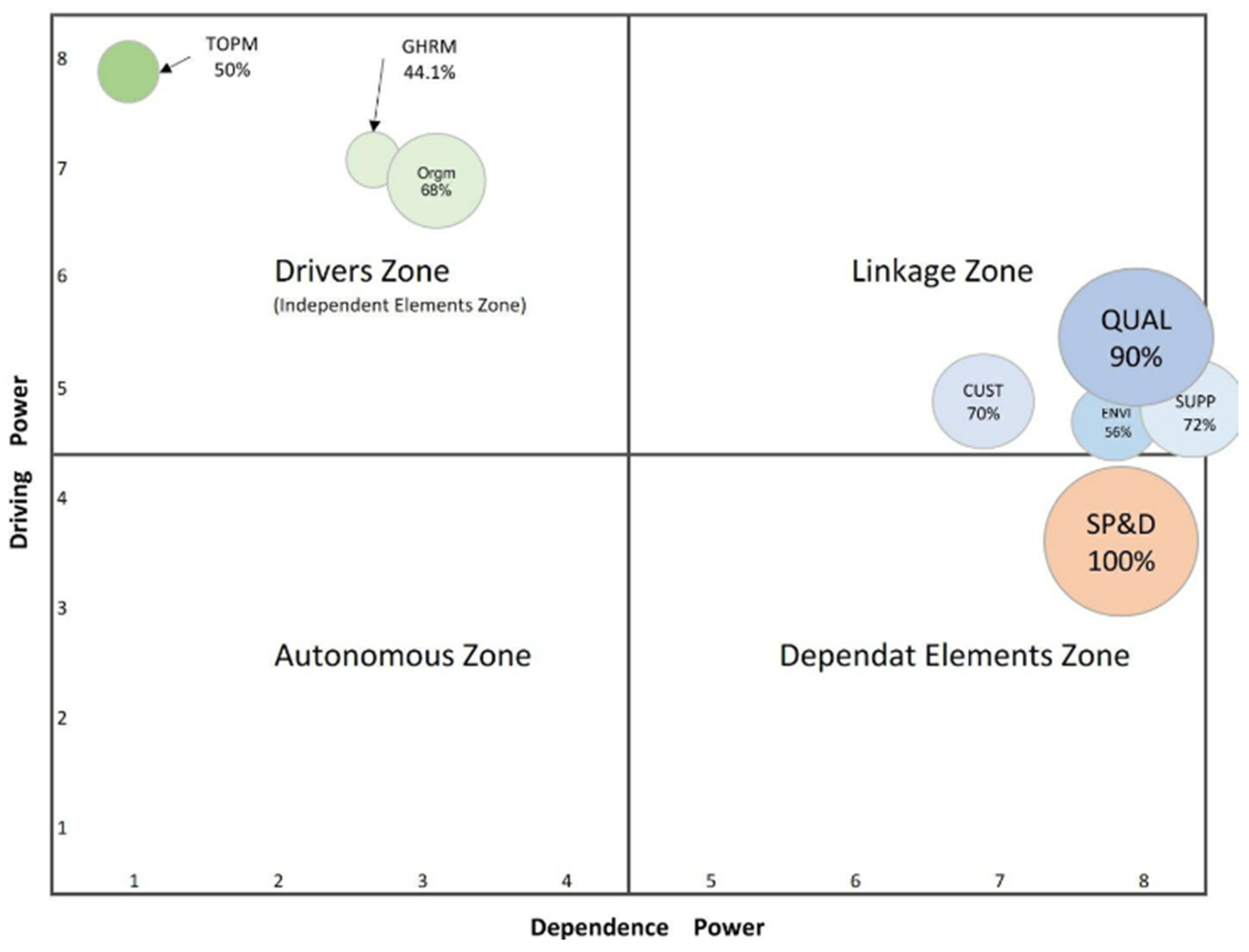

- classification of GCSM practices into four categories: independent (drivers or driving practices), linkage, dependent, and autonomous practices;

- identification of the influence of each GSCM practice.

4. Results

4.1. Inner- and Outer-Dependence of the Five Vs of Big Data

4.2. Fuzzy TOPSIS Results

4.2.1. Overall Rankings

4.2.2. Basic Readiness and Relative Readiness Indices

4.3. ISM Results

5. Implications, Contributions, and Directions for Future Studies

6. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Anderson, J.C.; Narus, J.A. Business marketing: Understand what customers value. Harv. Bus. Rev. 1998, 76, 53–67. [Google Scholar]

- AlKhidir, T.; Zailani, S. Going green in supply chain towards environmental sustainability. Glob. J. Environ. Res. 2009, 3, 246–251. [Google Scholar]

- Govindan, K.; Kaliyan, M.; Kannan, D.; Haq, A.N. Barriers analysis for green supply chain management implementation in Indian industries using analytic hierarchy process. Int. J. Prod. Econ. 2014, 147, 555–568. [Google Scholar] [CrossRef]

- Mudgal, R.K.; Shankar, R.; Talib, P.; Raj, T. Modelling the barriers of green supply chain practices: An Indian perspective. Int. J. Logist. Syst. Manag. 2010, 7, 81–107. [Google Scholar] [CrossRef]

- Hervani, A.A.; Helms, M.M.; Sarkis, J. Performance measurement for green supply chain management. Benchmarking Int. J. 2005, 12, 330–353. [Google Scholar] [CrossRef] [Green Version]

- Ravi, V.; Shankar, R. Analysis of interactions among the barriers of reverse logistics. Technol. Forecast. Soc. Chang. 2005, 72, 1011–1029. [Google Scholar] [CrossRef]

- Chen, L. Sustainability and Company Performance: EVIDENCE from the Manufacturing Industry; Linköping University Electronic Press: Linköping, Sweden, 2015; Volume 1698, ISBN 9176859673. [Google Scholar]

- Bowen, F.E.; Cousins, P.D.; Lamming, R.C.; Farukt, A.C. The role of supply management capabilities in green supply. Prod. Oper. Manag. 2001, 10, 174–189. [Google Scholar] [CrossRef]

- Azar, A.; Zarakani, M.; Mirhosseini, S.S.; Masouleh, M.H. The mediation role of social capital in relationship between buyer-supplier relationship with green supply chain collaboration. Int. J. Logist. Syst. Manag. 2018, 29, 82–101. [Google Scholar] [CrossRef]

- Camerinelli, E. Supply chain finance. J. Paym. Strateg. Syst. 2009, 3, 114–128. [Google Scholar]

- Gomm, M.L. Supply chain finance: Applying finance theory to supply chain management to enhance finance in supply chains. Int. J. Logist. Res. Appl. 2010, 13, 133–142. [Google Scholar] [CrossRef]

- Wuttke, D.A.; Blome, C.; Henke, M. Focusing the financial flow of supply chains: An empirical investigation of financial supply chain management. Int. J. Prod. Econ. 2013, 145, 773–789. [Google Scholar] [CrossRef]

- Hofmann, E. Supply Chain Finance: Some Conceptual Insights. Beiträge Zu Beschaffung Und Logistik; Springer: Berlin/Heidelberg, Germany, 2005; pp. 203–214. [Google Scholar]

- Pfohl, H.-C.; Gomm, M. Supply chain finance: Optimizing financial flows in supply chains. Logist. Res. 2009, 1, 149–161. [Google Scholar] [CrossRef]

- Chen, X.; Hu, C. The value of supply chain finance. Supply Chain Manag. Appl. Simul. 2011, 111–132. [Google Scholar] [CrossRef] [Green Version]

- Grosse-Ruyken, P.T.; Wagner, S.M.; Jönke, R. What is the right cash conversion cycle for your supply chain? Int. J. Serv. Oper. Manag. 2011, 10, 13–29. [Google Scholar]

- More, D.; Basu, P. Challenges of supply chain finance. Bus. Process. Manag. J. 2013, 19, 624–647. [Google Scholar] [CrossRef]

- Gelsomino, L.M.; Mangiaracina, R.; Perego, A.; Tumino, A. Supply chain finance: A literature review. Int. J. Phys. Distrib. Logist. Manag. 2016, 46. [Google Scholar] [CrossRef]

- Opresnik, D.; Taisch, M. The value of big data in servitization. Int. J. Prod. Econ. 2015, 165, 174–184. [Google Scholar] [CrossRef]

- Addo-Tenkorang, R.; Helo, P.T. Big data applications in operations/supply-chain management: A literature review. Comput. Ind. Eng. 2016, 101, 528–543. [Google Scholar] [CrossRef]

- Sheng, J.; Amankwah-Amoah, J.; Wang, X. A multidisciplinary perspective of big data in management research. Int. J. Prod. Econ. 2017, 191, 97–112. [Google Scholar] [CrossRef]

- Brinch, M. Understanding the value of big data in supply chain management and its business processes. Int. J. Oper. Prod. Manag. 2018, 38, 1589–1614. [Google Scholar] [CrossRef] [Green Version]

- Kuo, Y.-H.; Kusiak, A. From data to big data in production research: The past and future trends. Int. J. Prod. Res. 2019, 57, 4828–4853. [Google Scholar] [CrossRef] [Green Version]

- Tiwari, S.; Wee, H.-M.; Daryanto, Y. Big data analytics in supply chain management between 2010 and 2016: Insights to industries. Comput. Ind. Eng. 2018, 115, 319–330. [Google Scholar] [CrossRef]

- Touboulic, A.; McCarthy, L.; Matthews, L. Re-imagining supply chain challenges through critical engaged research. J. Supply Chain Manag. 2020, 56, 36–51. [Google Scholar] [CrossRef]

- Lis, A.; Sudolska, A.; Tomanek, M. Mapping Research on Sustainable Supply-Chain Management. Sustainability 2020, 12, 3987. [Google Scholar] [CrossRef]

- Konstantakopoulos, G.D.; Gayialis, S.P.; Kechagias, E.P. Vehicle routing problem and related algorithms for logistics distribution: A literature review and classification. Oper. Res. 2020, 1–30. [Google Scholar] [CrossRef]

- Mohtashami, Z.; Aghsami, A.; Jolai, F. A green closed loop supply chain design using queuing system for reducing environmental impact and energy consumption. J. Clean. Prod. 2020, 242, 118452. [Google Scholar] [CrossRef]

- Tundys, B.; Wiśniewski, T. The Selected Method and Tools for Performance Measurement in the Green Supply Chain—Survey Analysis in Poland. Sustainability 2018, 10, 549. [Google Scholar] [CrossRef] [Green Version]

- Zulqarnain, R.M.; Xin, X.L.; Siddique, I.; Khan, W.A.; Yousif, M.A. TOPSIS Method Based on Correlation Coefficient under Pythagorean Fuzzy Soft Environment and Its Application towards Green Supply Chain Management. Sustainability 2021, 13, 1642. [Google Scholar] [CrossRef]

- Qu, G.; Zhang, Z.; Qu, W.; Xu, Z. Green Supplier Selection Based on Green Practices Evaluated Using Fuzzy Approaches of TOPSIS and ELECTRE with a Case Study in a Chinese Internet Company. Int. J. Environ. Res. Public Health 2020, 17, 3268. [Google Scholar] [CrossRef] [PubMed]

- Susanty, A.; Sari, D.P.; Rinawati, D.I.; Setiawan, L. The role of internal and external drivers for successful implementation of GSCM practices. J. Manuf. Technol. Manag. 2019, 30, 391–420. [Google Scholar] [CrossRef]

- Liu, S.; Eweje, G.; He, Q.; Lin, Z. Turning motivation into action: A strategic orientation model for green supply chain management. Bus. Strategy Environ. 2020, 29, 2908–2918. [Google Scholar] [CrossRef]

- Lahkani, M.J.; Wang, S.; Urbański, M.; Egorova, M. Sustainable B2B E-commerce and blockchain-based supply chain finance. Sustainability 2020, 12, 3968. [Google Scholar] [CrossRef]

- Chen, J.; Cai, T.; He, W.; Chen, L.; Zhao, G.; Zou, W.; Guo, L. A blockchain-driven supply chain finance application for auto retail industry. Entropy 2020, 22, 95. [Google Scholar] [CrossRef] [Green Version]

- Stević, Ž.; Brković, N. A novel integrated FUCOM-MARCOS model for evaluation of human resources in a transport company. Logistics 2020, 4, 4. [Google Scholar] [CrossRef] [Green Version]

- Zhu, Q.; Sarkis, J.; Cordeiro, J.J.; Lai, K.-H. Firm-level correlates of emergent green supply chain management practices in the Chinese context. Omega 2008, 36, 577–591. [Google Scholar] [CrossRef]

- Kannan, D.; de Sousa Jabbour, A.B.L.; Jabbour, C.J.C. Selecting green suppliers based on GSCM practices: Using fuzzy TOPSIS applied to a Brazilian electronics company. Eur. J. Oper. Res. 2014, 233, 432–447. [Google Scholar] [CrossRef]

- Rice, S. Commitment to excellence: Practical approaches to environmental leadership. Environ. Qual. Manag. 2003, 12, 9. [Google Scholar] [CrossRef]

- Daily, B.F.; Bishop, J.W. TQM workforce factors and employee involvement: The pivotal role of teamwork. J. Manag. Issues 2003, 15, 393–412. [Google Scholar]

- Pun, K.F.; Chin, K.S.; Gill, R. Determinants of employee involvement practices in manufacturing enterprises. Total Qual. Manag. 2001, 12, 95–109. [Google Scholar] [CrossRef]

- Daily, B.F.; Huang, S.-C. Achieving sustainability through attention to human resource factors in environmental management. Int. J. Oper. Prod. Manag. 2001, 21, 1539–1552. [Google Scholar] [CrossRef]

- Carter, C.R.; Carter, J.R. Interorganizational determinants of environmental purchasing: Initial evidence from the consumer products industries. Decis. Sci. 1998, 29, 659–684. [Google Scholar] [CrossRef]

- Lambert, D.M.; Cooper, M.C. Issues in supply chain management. Ind. Mark. Manag. 2000, 29, 65–83. [Google Scholar] [CrossRef]

- Min, H.; Galle, W.P. Green purchasing practices of US firms. Int. J. Oper. Prod. Manag. 2001, 21, 1222–1238. [Google Scholar] [CrossRef]

- Zsidisin, G.A.; Siferd, S.P. Environmental purchasing: A framework for theory development. Eur. J. Purch. Supply Manag. 2001, 7, 61–73. [Google Scholar] [CrossRef]

- Hamner, B. Effects of green purchasing strategies on supplier behaviour. In Greening the Supply Chain; Springer: Berlin/Heidelberg, Germany, 2006; pp. 25–37. [Google Scholar]

- Eltayeb, T.K.; Zailani, S.; Ramayah, T. Green supply chain initiatives among certified companies in Malaysia and environmental sustainability: Investigating the outcomes. Resour. Conserv. Recycl. 2011, 55, 495–506. [Google Scholar] [CrossRef]

- Sarkis, J.; Zhu, Q.; Lai, K. An organizational theoretic review of green supply chain management literature. Int. J. Prod. Econ. 2011, 130, 1–15. [Google Scholar] [CrossRef]

- Barney, J.B. Is the resource-based “view” a useful perspective for strategic management research? Yes. Acad. Manag. Rev. 2001, 26, 41–56. [Google Scholar]

- Russo, M.V.; Fouts, P.A. A resource-based perspective on corporate environmental performance and profitability. Acad. Manag. J. 1997, 40, 534–559. [Google Scholar]

- Hart, S.L. A natural-resource-based view of the firm. Acad. Manag. Rev. 1995, 20, 986–1014. [Google Scholar] [CrossRef] [Green Version]

- Christmann, P. Effects of “best practices” of environmental management on cost advantage: The role of complementary assets. Acad. Manag. J. 2000, 43, 663–680. [Google Scholar]

- Cao, Z.; Huo, B.; Li, Y.; Zhao, X. The impact of organizational culture on supply chain integration: A contingency and configuration approach. Supply Chain Manag. Int. J. 2015, 20, 24–41. [Google Scholar] [CrossRef]

- Gosling, J.; Jia, F.; Gong, Y.; Brown, S. The role of supply chain leadership in the learning of sustainable practice: Toward an integrated framework. J. Clean. Prod. 2016, 137, 1458–1469. [Google Scholar] [CrossRef] [Green Version]

- Teixeira, A.A.; Jabbour, C.J.C.; de Sousa Jabbour, A.B.L.; Latan, H.; De Oliveira, J.H.C. Green training and green supply chain management: Evidence from Brazilian firms. J. Clean. Prod. 2016, 116, 170–176. [Google Scholar] [CrossRef]

- Pereira-Moliner, J.; Claver-Cortés, E.; Molina-Azorín, J.F.; Tarí, J.J. Quality management, environmental management and firm performance: Direct and mediating effects in the hotel industry. J. Clean. Prod. 2012, 37, 82–92. [Google Scholar] [CrossRef]

- Llach, J.; Perramon, J.; del Mar Alonso-Almeida, M.; Bagur-Femenías, L. Joint impact of quality and environmental practices on firm performance in small service businesses: An empirical study of restaurants. J. Clean. Prod. 2013, 44, 96–104. [Google Scholar] [CrossRef]

- Zhu, Q.; Cordeiro, J.; Sarkis, J. Institutional pressures, dynamic capabilities and environmental management systems: Investigating the ISO 9000–Environmental management system implementation linkage. J. Environ. Manag. 2013, 114, 232–242. [Google Scholar] [CrossRef] [PubMed]

- De Giovanni, P.; Vinzi, V.E. Covariance versus component-based estimations of performance in green supply chain management. Int. J. Prod. Econ. 2012, 135, 907–916. [Google Scholar] [CrossRef]

- Green, K.W.; Zelbst, P.J.; Bhadauria, V.S.; Meacham, J. Do environmental collaboration and monitoring enhance organizational performance? Ind. Manag. Data Syst. 2012, 112, 186–205. [Google Scholar] [CrossRef]

- De Sousa Jabbour, A.B.L.; Jabbour, C.J.C.; Latan, H.; Teixeira, A.A.; de Oliveira, J.H.C. Quality management, environmental management maturity, green supply chain practices and green performance of Brazilian companies with ISO 14001 certification: Direct and indirect effects. Transp. Res. Part E Logist. Transp. Rev. 2014, 67, 39–51. [Google Scholar] [CrossRef]

- Green, K.W.; Zelbst, P.J.; Meacham, J.; Bhadauria, V.S. Green supply chain management practices: Impact on performance. Supply Chain Manag. Int. J. 2012, 17, 290–305. [Google Scholar] [CrossRef]

- Bag, S.; Anand, N. Modeling green supply chain management framework using ISM and MICMAC analysis. Afr. J. Bus. Manag. 2014, 8, 1053–1065. [Google Scholar]

- Dubey, R.; Bag, S.; Ali, S.S. Green supply chain practices and its impact on organisational performance: An insight from Indian rubber industry. Int. J. Logist. Syst. Manag. 2014, 19, 20–42. [Google Scholar] [CrossRef]

- Dubey, R.; Gunasekaran, A.; Ali, S.S. Exploring the relationship between leadership, operational practices, institutional pressures and environmental performance: A framework for green supply chain. Int. J. Prod. Econ. 2015, 160, 120–132. [Google Scholar] [CrossRef]

- Dubey, R.; Gunasekaran, A.; Papadopoulos, T.; Childe, S.J. Green supply chain management enablers: Mixed methods research. Sustain. Prod. Consum. 2015, 4, 72–88. [Google Scholar] [CrossRef] [Green Version]

- Rao, P.; Holt, D. Do green supply chains lead to competitiveness and economic performance? Int. J. Oper. Prod. Manag. 2005, 25, 898–916. [Google Scholar] [CrossRef]

- Arimura, T.H.; Darnall, N.; Katayama, H. Is ISO 14001 a gateway to more advanced voluntary action? The case of green supply chain management. J. Environ. Econ. Manag. 2011, 61, 170–182. [Google Scholar] [CrossRef]

- Darnall, N.; Jolley, G.J.; Handfield, R. Environmental management systems and green supply chain management: Complements for sustainability? Bus. Strategy Environ. 2008, 17, 30–45. [Google Scholar] [CrossRef]

- Nawrocka, D. Inter-organizational use of EMSs in supply chain management: Some experiences from Poland and Sweden. Corp. Soc. Responsib. Environ. Manag. 2008, 15, 260–269. [Google Scholar] [CrossRef]

- Nawrocka, D.; Brorson, T.; Lindhqvist, T. ISO 14001 in environmental supply chain practices. J. Clean. Prod. 2009, 17, 1435–1443. [Google Scholar] [CrossRef]

- Ochieng, O.S.; Awino, Z.B.; Njihia, M.J.; Iraki, W.N. Green supply chain management practices and performance of ISO 14001 certified manufacturing firms in East Africa. DBA Afr. Manag. Rev. 2016, 6, 103–128. [Google Scholar]

- Brockhaus, S.; Kersten, W.; Knemeyer, A.M. Where do we go from here? Progressing sustainability implementation efforts across supply chains. J. Bus. Logist. 2013, 34, 167–182. [Google Scholar] [CrossRef]

- Mota, B.; Gomes, M.I.; Carvalho, A.; Barbosa-Povoa, A.P. Towards supply chain sustainability: Economic, environmental and social design and planning. J. Clean. Prod. 2015, 105, 14–27. [Google Scholar] [CrossRef]

- Thun, J.; Müller, A. An empirical analysis of green supply chain management in the German automotive industry. Bus. Strategy Environ. 2010, 19, 119–132. [Google Scholar] [CrossRef]

- Laari, S.; Töyli, J.; Solakivi, T.; Ojala, L. Firm performance and customer-driven green supply chain management. J. Clean. Prod. 2016, 112, 1960–1970. [Google Scholar] [CrossRef]

- Lee, S.; Klassen, R.D. Drivers and enablers that foster environmental management capabilities in small-and medium-sized suppliers in supply chains. Prod. Oper. Manag. 2008, 17, 573–586. [Google Scholar] [CrossRef]

- Baines, T.; Brown, S.; Benedettini, O.; Ball, P. Examining green production and its role within the competitive strategy of manufacturers. J. Ind. Eng. Manag. 2012, 5, 53–87. [Google Scholar] [CrossRef] [Green Version]

- Jayaram, J.; Avittathur, B. Green supply chains: A perspective from an emerging economy. Int. J. Prod. Econ. 2015, 164, 234–244. [Google Scholar] [CrossRef]

- Aragón-Correa, J.A.; Martín-Tapia, I.; Hurtado-Torres, N.E. Proactive environmental strategies and employee inclusion: The positive effects of information sharing and promoting collaboration and the influence of uncertainty. Organ. Environ. 2013, 26, 139–161. [Google Scholar] [CrossRef]

- Cantor, D.E.; Morrow, P.C.; Montabon, F. Engagement in environmental behaviors among supply chain management employees: An organizational support theoretical perspective. J. Supply Chain Manag. 2012, 48, 33–51. [Google Scholar] [CrossRef]

- Jabbour, C.J.C.; de Sousa Jabbour, A.B.L. Green human resource management and green supply chain management: Linking two emerging agendas. J. Clean. Prod. 2016, 112, 1824–1833. [Google Scholar] [CrossRef] [Green Version]

- Muduli, K.; Govindan, K.; Barve, A.; Kannan, D.; Geng, Y. Role of behavioural factors in green supply chain management implementation in Indian mining industries. Resour. Conserv. Recycl. 2013, 76, 50–60. [Google Scholar] [CrossRef]

- Daily, B.F.; Bishop, J.W.; Massoud, J.A. The role of training and empowerment in environmental performance. Int. J. Oper. Prod. Manag. 2012, 32, 631–647. [Google Scholar] [CrossRef]

- Jabbour, C.J.C.; Santos, F.C.A. Relationships between human resource dimensions and environmental management in companies: Proposal of a model. J. Clean. Prod. 2008, 16, 51–58. [Google Scholar] [CrossRef]

- Gupta, S.; Kumar, V. Sustainability as corporate culture of a brand for superior performance. J. World Bus. 2013, 48, 311–320. [Google Scholar] [CrossRef] [Green Version]

- Jabbour, C.J.C.; Santos, F.C.A.; Fonseca, S.A.; Nagano, M.S. Green teams: Understanding their roles in the environmental management of companies located in Brazil. J. Clean. Prod. 2013, 46, 58–66. [Google Scholar] [CrossRef]

- Jabbour, A.B.L.S.; Jabbour, C.J.C. Are supplier selection criteria going green? Case studies of companies in Brazil. Ind. Manag. Data Syst. 2009, 109, 477–495. [Google Scholar] [CrossRef]

- Lee, A.H.I.; Kang, H.-Y.; Hsu, C.-F.; Hung, H.-C. A green supplier selection model for high-tech industry. Expert Syst. Appl. 2009, 36, 7917–7927. [Google Scholar] [CrossRef]

- Büyüközkan, G.; Çifçi, G. A novel hybrid MCDM approach based on fuzzy DEMATEL, fuzzy ANP and fuzzy TOPSIS to evaluate green suppliers. Expert Syst. Appl. 2012, 39, 3000–3011. [Google Scholar] [CrossRef]

- Tseng, M.-L.; Chiu, A.S.F. Evaluating firm’s green supply chain management in linguistic preferences. J. Clean. Prod. 2013, 40, 22–31. [Google Scholar] [CrossRef]

- Awasthi, A.; Kannan, G. Green supplier development program selection using NGT and VIKOR under fuzzy environment. Comput. Ind. Eng. 2016, 91, 100–108. [Google Scholar] [CrossRef]

- Fallahpour, A.; Olugu, E.U.; Musa, S.N.; Khezrimotlagh, D.; Wong, K.Y. An integrated model for green supplier selection under fuzzy environment: Application of data envelopment analysis and genetic programming approach. Neural Comput. Appl. 2016, 27, 707–725. [Google Scholar] [CrossRef]

- Bakeshlou, E.A.; Khamseh, A.A.; Asl, M.A.G.; Sadeghi, J.; Abbaszadeh, M. Evaluating a green supplier selection problem using a hybrid MODM algorithm. J. Intell. Manuf. 2017, 28, 913–927. [Google Scholar] [CrossRef]

- Qin, J.; Liu, X.; Pedrycz, W. An extended TODIM multi-criteria group decision making method for green supplier selection in interval type-2 fuzzy environment. Eur. J. Oper. Res. 2017, 258, 626–638. [Google Scholar] [CrossRef]

- Yazdani, M.; Chatterjee, P.; Zavadskas, E.K.; Zolfani, S.H. Integrated QFD-MCDM framework for green supplier selection. J. Clean. Prod. 2017, 142, 3728–3740. [Google Scholar] [CrossRef]

- Banaeian, N.; Mobli, H.; Fahimnia, B.; Nielsen, I.E.; Omid, M. Green supplier selection using fuzzy group decision making methods: A case study from the agri-food industry. Comput. Oper. Res. 2018, 89, 337–347. [Google Scholar] [CrossRef]

- Lin, R.-J.; Tan, K.-H.; Geng, Y. Market demand, green product innovation, and firm performance: Evidence from Vietnam motorcycle industry. J. Clean. Prod. 2013, 40, 101–107. [Google Scholar] [CrossRef]

- Wong, C.W.Y.; Lai, K.; Shang, K.; Lu, C. Uncovering the value of green advertising for environmental management practices. Bus. Strategy Environ. 2014, 23, 117–130. [Google Scholar] [CrossRef]

- Chan, H.K.; Yee, R.W.Y.; Dai, J.; Lim, M.K. The moderating effect of environmental dynamism on green product innovation and performance. Int. J. Prod. Econ. 2016, 181, 384–391. [Google Scholar] [CrossRef]

- Pires, A.; Martinho, G.; Ribeiro, R.; Mota, M.; Teixeira, L. Extended producer responsibility: A differential fee model for promoting sustainable packaging. J. Clean. Prod. 2015, 108, 343–353. [Google Scholar] [CrossRef]

- Abdullah, N.A.H.N.; Yaakub, S. Reverse logistics: Pressure for adoption and the impact on firm’s performance. Int. J. Bus. Soc. 2014, 15, 151. [Google Scholar]

- Huang, X.; Tan, B.L.; Ding, X. An exploratory survey of green supply chain management in Chinese manufacturing small and medium-sized enterprises. J. Manuf. Technol. Manag. 2015, 26, 80–103. [Google Scholar] [CrossRef]

- Rezaei, J. A systematic review of multi-criteria decision-making applications in reverse logistics. Transp. Res. Procedia 2015, 10, 766–776. [Google Scholar] [CrossRef] [Green Version]

- Vieira, B.O.; Guarnieri, P.; Nofal, R.; Nofal, B. Multi-Criteria Methods Applied in the Studies of Barriers Identified in the Implementation of Reverse Logistics of E-Waste: A Research Agenda. Logistics 2020, 4, 11. [Google Scholar] [CrossRef]

- Kechagias, E.P.; Gayialis, S.P.; Konstantakopoulos, G.D.; Papadopoulos, G.A. An application of a multi-criteria approach for the development of a process reference model for supply chain operations. Sustainability 2020, 12, 5791. [Google Scholar] [CrossRef]

- Büyüközkan, G.; Çifçi, G. Evaluation of the green supply chain management practices: A fuzzy ANP approach. Prod. Plan. Control 2012, 23, 405–418. [Google Scholar] [CrossRef]

- Wang, X.; Chan, H.K. A hierarchical fuzzy TOPSIS approach to assess improvement areas when implementing green supply chain initiatives. Int. J. Prod. Res. 2013, 51, 3117–3130. [Google Scholar] [CrossRef]

- Rehman, M.A.A.; Shrivastava, R.L. An innovative approach to evaluate green supply chain management (GSCM) drivers by using interpretive structural modeling (ISM). Int. J. Innov. Technol. Manag. 2011, 8, 315–336. [Google Scholar] [CrossRef]

- Mathiyazhagan, K.; Govindan, K.; NoorulHaq, A.; Geng, Y. An ISM approach for the barrier analysis in implementing green supply chain management. J. Clean. Prod. 2013, 47, 283–297. [Google Scholar] [CrossRef]

- Jayant, A.; Azhar, M. Analysis of the barriers for implementing green supply chain management (GSCM) practices: An interpretive structural modeling (ISM) approach. Procedia Eng. 2014, 97, 2157–2166. [Google Scholar] [CrossRef] [Green Version]

- Dev, N.K.; Shankar, R. Green supply chain: An ISM-based roadmap to boundaries of environmental sustainability. In Systems Thinking Approach for Social Problems; Springer: Berlin/Heidelberg, Germany, 2015; pp. 1–12. [Google Scholar]

- Görener, A. Comparing AHP and ANP: An application of strategic decisions making in a manufacturing company. Int. J. Bus. Soc. Sci. 2012, 3, 194–208. [Google Scholar]

- Saaty, T.L. The modern science of multicriteria decision making and its practical applications: The AHP/ANP approach. Oper. Res. 2013, 61, 1101–1118. [Google Scholar] [CrossRef]

- Ayağ, Z.; Özdemir, R.G. An intelligent approach to ERP software selection through fuzzy ANP. Int. J. Prod. Res. 2007, 45, 2169–2194. [Google Scholar] [CrossRef]

- Carlucci, D. Evaluating and selecting key performance indicators: An ANP-based model. Meas. Bus. Excel. 2010, 14, 66–76. [Google Scholar] [CrossRef]

- Alidrisi, H.; Mohamed, S. Resource allocation for strategic quality management: A goal programming approach. Int. J. Qual. Reliab. Manag. 2012, 29, 265–283. [Google Scholar] [CrossRef] [Green Version]

- Palczewski, K.; Sałabun, W. The fuzzy TOPSIS applications in the last decade. Procedia Comput. Sci. 2019, 159, 2294–2303. [Google Scholar] [CrossRef]

- Önüt, S.; Kara, S.S.; Işik, E. Long term supplier selection using a combined fuzzy MCDM approach: A case study for a telecommunication company. Expert Syst. Appl. 2009, 36, 3887–3895. [Google Scholar] [CrossRef]

- Li, J.; Fang, H.; Song, W. Sustainable supplier selection based on SSCM practices: A rough cloud TOPSIS approach. J. Clean. Prod. 2019, 222, 606–621. [Google Scholar] [CrossRef]

- Alidrisi, H. Development of a study plan for industrial engineering program using Interpretive Structural Modeling technique. Int. J. Eng. Educ. 2015, 31, 1410–1418. [Google Scholar]

- Partani, T.; Marashi, S.V.; Alishahi, M.H. Using fuzzy analytic network process (FANP) in a swot analysis. Glob. J. Comput. Sci. Technol. 2013, 13, 17–32. [Google Scholar]

- Bhattacharya, A.; Mohapatra, P.; Kumar, V.; Dey, P.K.; Brady, M.; Tiwari, M.K.; Nudurupati, S.S. Green supply chain performance measurement using fuzzy ANP-based balanced scorecard: A collaborative decision-making approach. Prod. Plan. Control 2014, 25, 698–714. [Google Scholar] [CrossRef] [Green Version]

- Ayağ, Z.; Özdemir, R.G. An intelligent approach to machine tool selection through fuzzy analytic network process. J. Intell. Manuf. 2011, 22, 163–177. [Google Scholar] [CrossRef] [Green Version]

- Yang, J.L.; Tzeng, G.-H. An integrated MCDM technique combined with DEMATEL for a novel cluster-weighted with ANP method. Expert Syst. Appl. 2011, 38, 1417–1424. [Google Scholar] [CrossRef]

- Yazgan, H.R. Selection of dispatching rules with fuzzy ANP approach. Int. J. Adv. Manuf. Technol. 2011, 52, 651–667. [Google Scholar] [CrossRef]

- Saaty, T.L. Exploring the interface between hierarchies, multiple objectives and fuzzy sets. Fuzzy Sets Syst. 1978, 1, 57–68. [Google Scholar] [CrossRef]

- Van Laarhoven, P.J.M.; Pedrycz, W. A fuzzy extension of Saaty’s priority theory. Fuzzy Sets Syst. 1983, 11, 229–241. [Google Scholar] [CrossRef]

- Chang, D.-Y. Extent analysis and synthetic decision. Optim. Tech. Appl. 1992, 1, 352–355. [Google Scholar]

- Chang, D.-Y. Applications of the extent analysis method on fuzzy AHP. Eur. J. Oper. Res. 1996, 95, 649–655. [Google Scholar] [CrossRef]

- Buckley, J.J. Fuzzy hierarchical analysis. Fuzzy Sets Syst. 1985, 17, 233–247. [Google Scholar] [CrossRef]

- Hsieh, T.-Y.; Lu, S.-T.; Tzeng, G.-H. Fuzzy MCDM approach for planning and design tenders selection in public office buildings. Int. J. Proj. Manag. 2004, 22, 573–584. [Google Scholar] [CrossRef]

- Gu, X.; Zhu, Q. Fuzzy multi-attribute decision-making method based on eigenvector of fuzzy attribute evaluation space. Decis. Support Syst. 2006, 41, 400–410. [Google Scholar] [CrossRef]

- Wang, L.; Chu, J.; Wu, J. Selection of optimum maintenance strategies based on a fuzzy analytic hierarchy process. Int. J. Prod. Econ. 2007, 107, 151–163. [Google Scholar] [CrossRef]

- Zeng, J.; An, M.; Smith, N.J. Application of a fuzzy based decision making methodology to construction project risk assessment. Int. J. Proj. Manag. 2007, 25, 589–600. [Google Scholar] [CrossRef]

- Erensal, Y.C.; Öncan, T.; Demircan, M.L. Determining key capabilities in technology management using fuzzy analytic hierarchy process: A case study of Turkey. Inf. Sci. 2006, 176, 2755–2770. [Google Scholar] [CrossRef]

- Heo, E.; Kim, J.; Boo, K.-J. Analysis of the assessment factors for renewable energy dissemination program evaluation using fuzzy AHP. Renew. Sustain. Energy Rev. 2010, 14, 2214–2220. [Google Scholar] [CrossRef]

- Chan, F.T.S.; Kumar, N.; Tiwari, M.K.; Lau, H.C.W.; Choy, K. Global supplier selection: A fuzzy-AHP approach. Int. J. Prod. Res. 2008, 46, 3825–3857. [Google Scholar] [CrossRef]

- Chen, C.-T. Extensions of the TOPSIS for group decision-making under fuzzy environment. Fuzzy Sets Syst. 2000, 114, 1–9. [Google Scholar] [CrossRef]

- Junior, F.R.L.; Osiro, L.; Carpinetti, L.C.R. A comparison between Fuzzy AHP and Fuzzy TOPSIS methods to supplier selection. Appl. Soft Comput. 2014, 21, 194–209. [Google Scholar] [CrossRef]

- Harary, F.; Norman, R.Z.; Cartwright, D. Structural Models: An Introduction to the Theory of Directed Graphs; Wiley: Hoboken, NJ, USA, 1965. [Google Scholar]

- Waller, R.J. Contextual relations and mathematical relations in interpretive structural modeling. IEEE Trans. Syst. Man Cybern. 1980, 10, 143–145. [Google Scholar]

- Ohuchi, A.; Kurihara, M.; Kaji, I. Implication theory and algorithm for reachability matrix model. IEEE Trans. Syst. Man. Cybern. 1986, 16, 610–616. [Google Scholar] [CrossRef]

- Warfield, J.N. An Assault on Complexity; Battelle, Office of Corporate Communications: Columbus, OH, USA, 1973. [Google Scholar]

- Kanungo, S.; Bhatnagar, V. Beyond generic models for information system quality: The use of interpretive structural modeling (ISM). Syst. Res. Behav. Sci. 2002, 19, 531–549. [Google Scholar] [CrossRef]

- Mandal, A.; Deshmukh, S. Vendor Selection Using Interpretive Structural Modelling (ISM). Int. J. Oper. Prod. Manag. 1994, 14, 52–59. [Google Scholar] [CrossRef]

- Jharkharia, S.; Shankar, R. IT enablement of supply chains: Modeling the enablers. Int. J. Prod. Perform. Manag. 2004, 53, 700–712. [Google Scholar] [CrossRef]

- Thakkar, J.; Deshmukh, S.G.; Gupta, A.D.; Shankar, R. Development of a balanced scorecard: An integrated approach of Interpretive Structural Modeling (ISM) and Analytic Network Process (ANP). Int. J. Product. Perform. Manag. 2006, 56, 25–59. [Google Scholar] [CrossRef]

- Singh, M.D.; Kant, R. Knowledge management barriers: An interpretive structural modeling approach. Int. J. Manag. Sci. Eng. Manag. 2008, 3, 141–150. [Google Scholar] [CrossRef]

- Kannan, G.; Haq, A.N.; Sasikumar, P.; Arunachalam, S. Analysis and selection of green suppliers using interpretative structural modelling and analytic hierarchy process. Int. J. Manag. Decis. Mak. 2008, 9, 163–182. [Google Scholar] [CrossRef]

- Yin, R.K. Case Study Research and Applications: Design and Methods, 6th ed.; SAGE Publications: Thousand Oaks, CA, USA, 2017. [Google Scholar]

- Darko, A.; Chan, A.P.C.; Ameyaw, E.E.; Owusu, E.K.; Pärn, E.; Edwards, D.J. Review of application of analytic hierarchy process (AHP) in construction. Int. J. Constr. Manag. 2019, 19, 436–452. [Google Scholar] [CrossRef]

- Bertoni, M. Multi-Criteria Decision Making for Sustainability and Value Assessment in Early PSS Design. Sustainability 2019, 11, 1952. [Google Scholar] [CrossRef] [Green Version]

- Chunhua, F.; Shi, H.; Guozhen, B. A group decision making method for sustainable design using intuitionistic fuzzy preference relations in the conceptual design stage. J. Clean. Prod. 2020, 243, 118640. [Google Scholar] [CrossRef]

- De Almeida Santos, D.; Luiz Gonçalves Quelhas, O.; Francisco Simões Gomes, C.; Perez Zotes, L.; Luiz Braga França, S.; de Souza, G.V.P.; de Araújo, R.A.; da Silva Carvalho Santos, S. Proposal for a Maturity Model in Sustainability in the Supply Chain. Sustainability 2020, 12, 9655. [Google Scholar] [CrossRef]

- Kravchenko, M.; Pigosso, D.C.A.; McAloone, T.C. A Trade-Off Navigation Framework as a Decision Support for Conflicting Sustainability Indicators within Circular Economy Implementation in the Manufacturing Industry. Sustainability 2021, 13, 314. [Google Scholar] [CrossRef]

| Acronym | Descriptions | |

|---|---|---|

| AHP | Analytic Hierarchy Process | |

| AI | Artificial Intelligence | |

| ANP | Analytic Network Process | |

| BPM | Business Process Modeling | |

| BRI | Basic Readiness Index | |

| CUST | Customer Relationship Management | |

| DM | Decision Making | |

| ELECTRE | Elimination Et Choice Translating Reality | |

| EMM | Environmental Management Maturity | |

| ENVI | Environmental Management | |

| GD | Green Distribution | |

| GHRM | Green Human Resource Management | |

| GM | Green Manufacturing | |

| GP | Green Purchasing | |

| GSCM | Green Supply Chain Management | |

| HRM | Human resource management | |

| IoT | Internet of Things | |

| ISM | Interpretive Structural Modeling | |

| ISO 14001 | The International Standard that Specifies Requirements for an Effective Environmental Management System | |

| MCDM | Multicriteria Decision-Making | |

| MM | Materials Management | |

| OM | Operations Management | |

| ORGM | Organizational Interaction Maturity | |

| PROMETHEE | Preference Ranking Organization Method for Enrichment Evaluations | |

| QUAL | Quality Management | |

| RQ | Research Question | |

| RRI | Relative Readiness Index | |

| SCF | Supply Chain Finance | |

| SCM | Supply Chain Management | |

| SMT | Strategic Matrix Tool | |

| SP&D | Smart Process and Design | |

| SUPP | Supplier Selection | |

| TOPM | Top Management Commitment | |

| TOPSIS | Technique For Order Preference By Similarity To Ideal Solution | |

| VRP | Vehicle Routing Problem | |

| 5Vs | Five Vs of big data (value, volume, velocity, variety, and veracity) | |

| Research Gap/Aspect | Supporting Literature |

|---|---|

| Top Management Commitment (TOPM) | [37,39,40,41,42,43,44,45,46,47,48] |

| Organizational Interaction Maturity (ORGM) | [37,49,50,51,52,53,54,55,56] |

| Quality Management (QUAL) | [57,58,59,60,61,62,63,64,65,66,67] |

| Environmental Management (ENVI) | [68,69,70,71,72,73] |

| Customer Relationship Management (CUST) | [61,63,65,67,74,75,76,77,78,79,80] |

| Green Human Resource Management (GHRM) | [56,81,82,83,84,85,86,87,88] |

| Supplier Selection (SUPP) | [8,38,45,48,89,90,91,92,93,94,95,96,97,98] |

| Smart Process and Design (SP&D) | [38,99,100,101,102,103,104] |

| MCDM Applications in GSCM | [38,91,105,106,107,108,109,110,111,112,113] |

| Justifications for the Selected Methods | [106,114,115,116,117,118,119,120,121,122] |

| Outer-Dependence | Inner-Dependence | Fuzzy Triangular Number | The Inverse of the Fuzzy Triangular Number | ||||

|---|---|---|---|---|---|---|---|

| Linguistic Expressions for Comparisons among 5Vs of Bigdata with Respect to “SCF” | Linguistic Expressions for Comparisons Among 5Vs of Bigdata | ||||||

| Similar | (1, | 1, | 1) | (1, | 1, | 1) | |

| Moderately Important | (1, | 3, | 5) | (1/5, | 1/3, | 1) | |

| Important | (3, | 5, | 7) | (1/7, | 1/5, | 1/3) | |

| Very Important | (5, | 7, | 9) | (1/9, | 1/7, | 1/5) | |

| Extremely Important | (7, | 9, | 11) | (1/11, | 1/9, | 1/7) | |

| Inner-Dependence | Outer-Dependence | Overall | |||||

|---|---|---|---|---|---|---|---|

| Veracity | Value | Velocity | Variety | Volume | SCF | ||

| Veracity | __ | 0.31 | 0.10 | 0.53 | 0.10 | 0.44 | 0.30 |

| Value | 0.31 | __ | 0.10 | 0.02 | 0.10 | 0.44 | 0.29 |

| Velocity | 0.06 | 0.06 | __ | 0.43 | 0.40 | 0.03 | 0.07 |

| Variety | 0.31 | 0.31 | 0.40 | __ | 0.40 | 0.04 | 0.17 |

| Volume | 0.31 | 0.31 | 0.40 | 0.02 | __ | 0.05 | 0.17 |

| GSCM Practices | d+ | d− | Fuzzy TOPSIS Score (CCi) | Rank |

|---|---|---|---|---|

| CUST | 4.534 | 0.507 | 0.101 | 4 |

| SUPP | 4.507 | 0.526 | 0.104 | 3 |

| ENVI | 4.626 | 0.406 | 0.081 | 6 |

| QUAL | 4.385 | 0.659 | 0.131 | 2 |

| TOPM | 4.695 | 0.366 | 0.072 | 7 |

| GHRM | 4.728 | 0.323 | 0.064 | 8 |

| SP&D | 4.307 | 0.730 | 0.145 | 1 |

| ORGM | 4.540 | 0.495 | 0.098 | 5 |

| Ranking | GSCM Practices | TOPSIS Score | Basic Readiness Index (BRI) | Relative Readiness Index (RRI) |

|---|---|---|---|---|

| 1 | SP&D | 0.145 | 18.2% | 100% |

| 2 | QUAL | 0.131 | 16.4% | 90.1% |

| 3 | SUPP | 0.104 | 13.1% | 72.0% |

| 4 | CUST | 0.101 | 12.6% | 69.4% |

| 5 | ORGM | 0.098 | 12.3% | 67.8% |

| 6 | ENVI | 0.081 | 10.1% | 55.6% |

| 7 | TOPM | 0.072 | 9.1% | 49.8% |

| 8 | GHRM | 0.064 | 8.0% | 44.1% |

| SUM = 0.796 |

| CUST | SUP | ENV | QUAL | TOPMC | GHRM | SP&D | ORGM | Driving Power | ||

|---|---|---|---|---|---|---|---|---|---|---|

| CUST | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 0 | 5 | |

| SUP | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 0 | 5 | |

| ENV | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 0 | 5 | |

| QUAL | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 0 | 5 | |

| TOPMC | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 8 | |

| GHRM | 1 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 7 | |

| SP&D | 0 | 1 | 1 | 1 | 0 | 0 | 1 | 0 | 4 | |

| ORGM | 1 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 7 | |

| Dependence Power | 7 | 8 | 8 | 8 | 1 | 3 | 8 | 3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alidrisi, H. Measuring the Environmental Maturity of the Supply Chain Finance: A Big Data-Based Multi-Criteria Perspective. Logistics 2021, 5, 22. https://doi.org/10.3390/logistics5020022

Alidrisi H. Measuring the Environmental Maturity of the Supply Chain Finance: A Big Data-Based Multi-Criteria Perspective. Logistics. 2021; 5(2):22. https://doi.org/10.3390/logistics5020022

Chicago/Turabian StyleAlidrisi, Hisham. 2021. "Measuring the Environmental Maturity of the Supply Chain Finance: A Big Data-Based Multi-Criteria Perspective" Logistics 5, no. 2: 22. https://doi.org/10.3390/logistics5020022

APA StyleAlidrisi, H. (2021). Measuring the Environmental Maturity of the Supply Chain Finance: A Big Data-Based Multi-Criteria Perspective. Logistics, 5(2), 22. https://doi.org/10.3390/logistics5020022