1. Introduction

The four major departments of the manufacturing industry are engineering (research, design, and development), operations (production planning and control, manufacturing, quality control, maintenance, supply chain, logistics, packaging, and dispatch), information technology and finance (information technology, financial control, human relations, and administration), and sales and marketing. However, the supply chain is considered the heart of businesses, as a seamless flow of commodities across various manufacturing functions until it reaches the customer is essential to achieve the goals of the business. The term “supply chain” in a broader connotation refers to the complete cross-functional coordination within an organization, and the backward and forward integration with its suppliers and customers, respectively [

1]. In simple words, it can refer to all the activities (such as demand and supply planning, forecasting, production, and transportation of products) involved in processing and transforming the raw material into a value-added finished product, including post-sales support, logistics, and reverse logistics [

2].

Although many large-scale organizations have long ago moved from the conventional methods of tracking their products using physical ledgers, emails, and excel sheets to an IT-based technology infrastructure such as EDI and SAP (Enterprise Resource Planning systems), the real challenge in tackling the seamless flow of products and achieving the visibility of products at every stage is still unaddressed [

3,

4]. Additionally, as these technologies are centralized database management technologies, they are vulnerable to manipulation and security threats. The problem with these technologies also lies in the lack of interconnection and visibility of information across the entire supply chain participants. For instance, the higher number of intermediaries between the manufacturer and consumer, and globalization have increased the length of the supply chain network which resulted in lack of visibility to product origins and shipment details [

5]. The challenge is both quantitative and qualitative. Studies have also shown that gaps in sharing information between the supply chain participants result in sub-optimal business performance [

6]. In a nutshell, the current challenges in supply chain and logistics can be termed as the lack of trustworthy data and data visibility, which is primarily due to the participation of many intermediaries. As multiple individual collaborators such as suppliers, manufacturers, dealers, and resellers are an integral part of a supply chain, effective management of information flow between the parties with the required transparency and trustworthiness is critical. In addition, the data are crucial for accurate forecasting of demand and inventory records, schedule material and production planning, and better inventory management [

7].

The onset of the COVID-19 pandemic and its impact on the supply chain is a well-known issue that exposed the vulnerability of the current practices. Originally thought of as a minor disruption, the semiconductor shortage has become a global crisis impacting consumer electronics, automotive, medical equipment, power, and almost all the sectors. It has put the existing supply chain network of many large-scale and well-established industries in the spotlight and exposed their fragile infrastructure. Any such major disruption in the supply chain has the potential to derail the functioning of an organization and can severely impact its sales and profitability. Organizations irrespective of their size, sector, and geographical diversity were affected by the collective failure of their supply chain network, clearly showing the inefficient processes that they currently follow. The real problem lies in the lack of trustworthy supply chain-related data that even reputed firms have visibility to [

8]. Additionally, as many large-scale organizations rely on their multiple vendors and suppliers throughout the globe to reduce manufacturing costs, the visibility of data at every level and its integrity and reliability is highly critical. The increase in the number of products and global supplier network has added several complex interlinked layers to the supply chain and lengthened logistics chain which means that there are multiple places where something can go wrong. This made the industries realize the importance of further digitizing their supply chain and logistics facilities and the need to adopt emerging technologies such as blockchain to improve the integrity and visibility of data.

The arrival of “Industry 4.0” technologies, a term used to refer to the advanced digital, computing, and networking technologies have revolutionized how different functions of an enterprise communicate and collaborate to operate efficiently. The technologies such as automation, artificial intelligence, blockchain, cloud computing, Internet of Things (IoT), and big data analytics have the potential to modernize traditional supply chain practices by transforming them into a digitally managed and connected infrastructure. In particular, blockchain with its unique characteristics such as reliable real-time sharing of information, security, traceability, and immutability would make it a strong tool in the integration of the entire supply chain infrastructure [

9]. However, as the technology is relatively new and probably immature in handling complex real-world problems, it is critical to know the fundamental working principle of the technology in order to set a realistic expectation. Additionally, in the context of supply chain and logistics operations, it is imperative to understand the complexities and challenges that manufacturing industries face to estimate the possible benefits of the technology, which leads to the following questions:

- (1)

What is blockchain technology and what are its characteristics, and benefits?

- (2)

What are the complexities and challenges in manufacturing supply chain and logistics?

- (3)

How blockchain technology can help address supply chain and logistics challenges?

- (4)

How blockchain technology can provide provenance and traceability to critical products and what are the potential applications of blockchain in other sectors?

- (5)

What are the challenges in adopting blockchain technology that must be addressed before widespread adoption?

Hence, this paper aims to provide a comprehensive overview of the role of blockchain technology in addressing supply chain and logistics-related challenges and answering the critical questions through various sections by analyzing, organizing, and reviewing the literature. The research question 1 is answered through

Section 2, and the questions 2, 3, 4, and 5 are answered through

Section 3,

Section 4,

Section 5 and

Section 6, respectively. Finally, the consolidated overview, key takeaways, and future directions are explained in

Section 7. The study would emphasize businesses to question their current practices and make them think about the integration of data-oriented transaction-driven technology such as blockchain into their supply chain.

2. Blockchain Technology

Bitcoin was the first direct application of blockchain technology. Satoshi Nakamoto [

10] published a blueprint of blockchain technology in 2008 to avoid the double-spending problem, over which cryptocurrencies such as Bitcoin and Ethereum were developed. However, the roots of the idea can be traced back to 1991 during which the concept of using a signed chain of information as a tamper-proof electronic ledger, and a consensus model to reach an agreement were discussed [

11,

12]. Later, the technology has evolved to be used in maintaining smart digital contracts [

13]. Currently, the researchers are focusing on optimizing the technology to make it work in sync with Industry 4.0 technologies such as IoT in handling the digital data storage requirements [

14]. The terms bitcoin and blockchain are often used interchangeably and even few papers have used the term blockchain to refer to the public type of distributed ledger, such as bitcoin. Although blockchain is a type of distributed ledger that uses a sequence of blocks linked to a chain, not all distributed ledger is blockchain and bitcoin uses blockchain technology for transactions [

15].

Currently, all the financial transactions between two persons or entities are carried out through a trusted centralized third party such as banks or financial institutions. However, blockchain technology is used to create a decentralized mechanism in which the transactions can happen between two users without a central intermediatory. Basically, blockchain is a distributed ledger in which a block containing the details of records and transactions is encrypted and stored permanently in a chain. Whenever a new transaction is performed it is added as a new block, hence maintaining the history of all transactions in an immutable form [

16]. In other words, it is a technology for storing information in a way that is impossible to alter, manipulate, or hack. Although the users are anonymous in a blockchain network, their identifiers and all transactions are publicly available to all the nodes (a node is an individual system or a computer within a blockchain network) [

17]. Full nodes and light nodes are the two major blockchain nodes. Full nodes have the complete transaction history of the blockchain and are responsible for validating new blocks. Light nodes do not have a copy of the complete blockchain but only have the headers of blocks and they connect to full nodes to validate the information stored in the blockchain.

Additionally, the blockchain network can have private, public, and permissioned networks based on the access level provided to the participants. The type of blockchain decides if all or only a few of the participants can be a part of the consensus for a block. A public blockchain (such as Bitcoin) is a fully open and distributed network that allows all the participants to access, maintain, and validate transactions, whereas in a private blockchain, the transactions are accessed and validated only by a set of authorized participant nodes. A centralized authority grants access to the participant nodes in a private blockchain. Data privacy and the ability to select network participants make a private blockchain an attractive option for industrial applications [

18]. A permissioned network is a hybrid system (e.g., Ripple and Stellar) in which generally all the users have read-only access to the blockchain while the permission to publish a new block is restricted only to a few key users through the access granted by a centralized authority [

19]. The recently launched IBM Food Trust is a cloud-based hybrid blockchain solution that brings farmers, suppliers, and retailers into an ecosystem to improve the traceability, transparency, and efficiency of the food supply chain. It allows participants to set custom access levels and collaborate securely. The typical flow of transactions in a blockchain network is shown in

Figure 1.

The major difference between a ledger or transaction stored in a conventional database such as MySQL and a blockchain network lies in the distributed, decentralized, and immutable nature of blockchain technology. For instance, as a conventional database is centralized, an administrator has the authority to control or manipulate the data. In addition, the entire database itself is vulnerable to cyberattacks. However, as a blockchain network is decentralized, all the transaction details are distributed across all the participating nodes of the chain. Hence, all the participating nodes (based on public or private blockchain) are responsible for validating the transaction and broadcasting the timestamped data to the blockchain network in the form of blocks. So, any data manipulation must be performed in all the nodes, which is practically impossible. Additionally, as the transaction is timestamped, any manipulation in a block would be added as a new transaction only to that node. So invariably the transaction details cannot be hacked or faked, which makes the system trustable.

2.1. Layers of Blockchain Architecture

As the scope of the paper is to explain the fundamentals of blockchain technology and how it can help in streamlining the manufacturing supply chain, only an overview of blockchain architecture is discussed in this section.

In principle, blockchain technology is a combination of various technologies such as computing, networking, cryptography, and mathematics [

20]. The previous section explains what does blockchain technology does. Now, to understand how it is done and how blockchain technology is different from other conventional digital data storage, it is imperative to know the various layers of a blockchain, individual components of a block, and the way data is stored in it. The various layers of a blockchain architecture are shown in

Figure 2. The hardware layer comprises of physical mediums such as servers, nodes, cables, connectors, and all the basic infrastructure required to support and maintain the functioning of a blockchain network [

21]. The data layer is the core of a blockchain which contains a linked list of data blocks that contains all the details of a transaction. The contents of a block and its functionality are explained separately in the following paragraph. Blockchain is a peer-to-peer network, and a peer is used to compute, validate, and store transactions. The network layer contains the data transmission protocol and verification system. In addition, privacy and security are a part of the network layer itself [

22]. A consensus layer is responsible for the generation and validation of the blocks and enforces the rules to reach consensus within the decentralized system. Proof of Work (PoW), Proof of Stake (PoS), Practical Byzantine Fault Tolerance (PBFT), Proof of Elapsed Time (PoET), Proof of Capacity, Proof of Burn (PoB), and Delegated Proof of Stake (DPoS) are a few of the consensus algorithms that can be used based on the individual business need [

23]. Each consensus algorithm works on a different principle and with an increase in the complexity of the algorithm, the time taken to process each transaction increases. The application layer provides the user interface that acts as the liaison between the user and the blockchain network. Smart contracts, chaincode, and decentralized applications (DApps) are a few examples of an application layer.

2.2. Strucutre of a Block

A blockchain can be visualized as a write-once and read-only database that stores data in the form of a block, and a few key data stored in a block are shown in

Figure 3. A block is divided into header and body, and each block is identified using a hash. As shown in

Figure 3, a block header is used to store the metadata and is composed of timestamp, version, hash value, difficulty, nonce, and Merkel root [

24]. The timestamp is used to identify the chronological position of a block in the blockchain and as proof to know when that block is added. Version denotes the blockchain version used. While version 1.0 was predominantly used for cryptocurrency transactions, versions 2.0 and 3.0 are used for smart contracts and decentralized applications, respectively. The yet-to-arrive version 4.0 is expected to provide interoperability and play a key role in industrial applications, and may overcome the challenges in the previous three versions such as scalability, adaptability, and affordability [

25]. Hashing is a technique of applying a cryptographic hash function to data. A hash function is considered the backbone of a blockchain network, which is used to convert input data into a string of bytes with a fixed length and structure. It is generated using the SHA256 cryptographic hash algorithm which acts like a fingerprint or DNA that can be used to identify a transaction [

26]. Every block contains a hash that links it to the previous block and adding new blocks is the responsibility of the miners. Difficulty is a number that denotes the time it would take to add a new block of the transaction to the blockchain [

27], and it depends on the number of mining nodes and the hash rate of the network. The higher the difficulty, the greater the computing power to verify transactions and the more secure the network. In the blockchain, mining is a process to validate a transaction and add it to the existing blockchain network. A miner solves a complex puzzle (termed Proof of Work or PoW) that requires hashing the transaction and information from the previous block using a hash algorithm to create a new block and obtain bitcoin rewards. In simple terms, hashing refers to transforming data into a digitally encoded token that acts as a digital fingerprint of the underlying assets that can be traced or traded using a private key. A nonce is an abbreviation for “number only used once” and is a 32-bit random number that is used for authentication, hashing, identification, or electronic signatures [

28]. In short, mining is about guessing the nonce as fast as possible. A Merkle root is a mathematical technique that summarizes the transaction in a block. It validates data in a Merkel tree (or binary hash tree) and is used to verify whether the data is corrupted, hacked, or manipulated [

29]. The body of the block contains the business data such as the transaction counter and the transaction details.

2.3. Characteristics of Blockchain

Bitcoin is considered as the most popular and successful application which brought attention to blockchain technology. However, over the years, the technology sector has realized the true potential of blockchain beyond bitcoins and financial sectors. Hence, the unique characteristics and features of blockchain technology that make it stand out from the existing database management system are discussed in this section.

2.3.1. Immutability

Any transaction that is added to a blockchain network is immutable, which means it cannot be altered or tampered with. The common misconceptions in maintaining digital records such as data manipulation, deletion, or tampering of records are eliminated with this unique characteristic of blockchain. Hence, even if a transaction is added with errors, it cannot be overwritten or deleted, but a new transaction with correct details must be added again as a new block. Additionally, both the original transaction with error and the newly added transaction would be visible to the participants in chronological order with an appropriate timestamp [

30].

2.3.2. Decentralization

Decentralization is a core characteristic of blockchain, which means it neither has a single authority to control nor a centralized server to manage or store data in the framework; instead, it relies on a group of nodes. Hence, all the participant nodes of a blockchain network act as a server that can store anything, such as cryptocurrencies, financial transactions, contracts, or any important digital data which can be accessed using a private key [

31].

2.3.3. Distributed Ledger

A distributed ledger is a database in which the data is shared, duplicated, and synchronized among the participants of the network. Unlike traditional banking and financial transactions which are controlled by a centralized authority, blockchain relies on decentralized and distributed nodes. As all the participant nodes of the network (based on public or private blockchain) have a copy of the transaction and require majority consensus to add the details of a new transaction, this creates enhanced trust and integrity. Additionally, in a shared ledger, as a transaction can be logged only once, it eliminates duplication. Although blockchain is a distributed ledger, not all distributed ledger is blockchain [

32].

2.3.4. Consensus Mechanism

The consensus algorithm is another core characteristic of distributed or multi-agent systems such as blockchain technology. As there is no centralized agency to validate or verify a transaction, blockchain uses a consensus mechanism in which the participants of the network reach an agreement to accept or reject the transaction. In simple terms, consensus refers to voting or an agreement between the active nodes of a blockchain network to validate a transaction. This is essential in creating an environment of trust in a distributed system and ensures that only legitimate data is added as a new block, especially in a public blockchain [

33]. However, with an increase in the complexity of the consensus algorithm, the speed at which new blocks can be added is reduced. Hence, for a large industrial application such as a supply chain, a private or permissioned blockchain with a relatively simpler consensus mechanism can be used since the right to add new blocks are with fewer known participants. The consensus algorithm also helps to ensure consistency of data in the presence of several failure nodes. The two types of failure nodes are crash fault and Byzantine fault nodes. A crash fault tolerance guarantees to reach consensus even if certain components fail, whereas Byzantine fault tolerance helps the network to function even in the presence of malicious nodes [

34]. Although trust is built on the data based on distributed ledger technology, blockchain is referred to as a “trustless system”, as the transactions are executed by the participants of the network based on the consensus achieved between them (especially in a public blockchain in which the participants do not know each other), and not by a trusted centralized agency. The various consensus algorithms used in blockchain are briefly discussed in

Section 2.1.

2.4. Benefits of Blockchain

Trust, security, efficiency, and transaction speed are the key benefits of blockchain technology. Although traditional financial consortia are a highly tested and proven solution for making transactions, they are slow and expensive. The downside is primarily due to the involvement of a centralized agency and third parties that receive multiple requests at a time to verify and approve transactions which can lead to delays and poor performance. However, as blockchain technology is a peer-to-peer network that does not have an administrator or middlemen between the sender and receiver, it can provide a more secure, quicker, and more cost-efficient alternative, especially for cross-border transactions. The immutability feature ensures users that any data once added to a blockchain stays as it is forever. Furthermore, the possibility to automate transactions through self-executing “smart contracts” can highly reduce the overall time taken to execute transactions. These features of blockchain make it a highly suitable technology infrastructure for multi-organizational businesses such as supply chain, logistics, and financial entities [

35].

Although blockchain technology has the potential in providing disruptive benefits to various functions of the manufacturing industry, the involvement of a large number of internal and external intermediaries makes the supply chain and logistics highly vulnerable to manipulation of data, lack of trust, lack of visibility to information, and data breaches. However, blockchain, by its inherent nature, can address all these issues and empower the users who would like to see more information about their products. Hence, the application of blockchain technology in the manufacturing supply chain and logistics is explained in the following sections.

3. Complexities and Challenges in Manufacturing Supply Chain and Logistics

The raw material is an integral part of all products which takes a tour across various manufacturing stages to gain value addition before reaching the customer as a finished product, and the supply chain and logistics facilitate the movement of raw material. Although the terms “supply chain” and “logistics” are often interchanged, there is a profound difference between them. The supply chain refers to the complete network of planning, sourcing, manufacturing, distribution, and delivery of products to the customers, while logistics refers to the activities in moving and storing goods efficiently between two functions within a supply chain. Hence, logistics is an integral or subset of the supply chain. Managing the supply chain and logistics is regarded as one of the critical aspects of the product life cycle, as highly efficient management is required to reduce cost and time with minimal or no waste. Supply chain management involves streamlining both upstream and downstream activities and ensuring the uninterrupted flow of goods and services. For the manufacturing industry, the activities that involve the flow of material into the organization right from the raw material stage until the product is manufactured are the upstream supply chain, while all the activities that involve the flow of material post-manufacturing until it reaches the customer are the downstream supply chain.

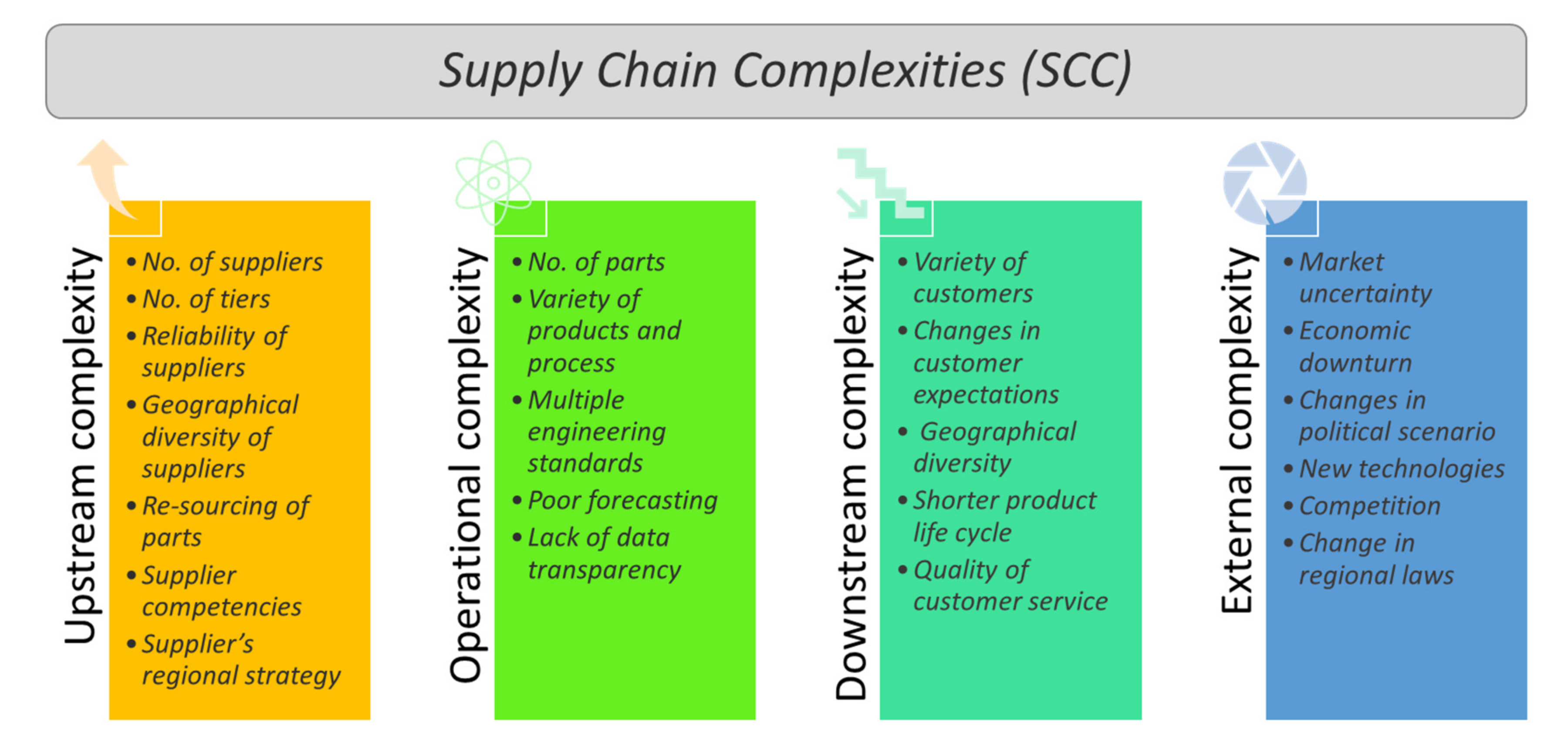

The term supply chain complexity (SCC) is used to describe the interdependencies of the system wherein a change in one element affects the other elements of the network. For instance, variables such as changes in the customer requirement, changes in industrial standards, adoption of new technologies, competition, and changes in process, products, suppliers, vendors, or distributors can act as the drivers of complexity [

36]. Chand et al. [

37] have categorized the complexities into upstream, operational, downstream, and external, based on their drivers. The activities related to the material flow into the organization are upstream supply chain and the complexities that an organization faces while organizing the material flow into the organization. It predominantly revolves around the suppliers, including the number of suppliers involved, reliability of product quality and lead time, geographical limitations, development of alternate suppliers, and building competencies are a few examples of upstream complexity. The complexities that are a part of internal manufacturing such as the large variety of parts, products, processes, multiple engineering standards, poor forecasting, and lack of data transparency across functions are classified as operational complexity. The activities related to the material flow away from the organization are the downstream supply chain, which revolves around the distribution channels and customers. Hence, customer-related complexities such as a vast variety of customers, change in customer expectations in terms of product quality and lead time, geographical diversity, shorter product life cycle, and quality of customer service are some drivers of downstream complexity, while the complexity that is outside the control of an organization such as economic downturn, changes in the political scenario, new technologies, competition, and change in regional laws are few examples of external complexities. The various drivers of the supply chain complexities are shown in

Figure 4.

Currently, most industries do not have a robust system to track the life cycle of a product from the raw material stage till it reaches the customers. Until a few decades ago, a life cycle of a product ends once a product is sold to the consumer. However, as a measure to improve customer satisfaction and maintain their reputation, many automotive and manufacturing companies have started recalling their products if they find that their products were not meeting the required quality or regulatory requirements. Additionally, the environmental laws in a few countries encourage manufacturers with tax sops and incentives to collect the used products from the customers for recycling. In addition, by adopting a suitable framework for sustainable practices and promoting a circular economy, even businesses across the world have started focusing on how the profit is made rather than how much profit is made. A circular economy is an alternate model to the linear economy (take–make–waste economy), which is focused to maximize the value by reducing, recovering, and recycling the resources to reduce pressure on the environment. This new-age requirement for processes such as product recalls, recycling, returns, repairs, and replacements, which are called “reverse logistics”, needs a modern solution to efficiently track the products even many years after it has been sold.

In addition, the other modern supply chain challenges such as the presence of multiple channels to reach customers (like eCommerce, traditional retailers, drop shipping, and third-party marketplaces), heavy fluctuation in demand, cross-border sourcing of raw materials and spares, just-in-time manufacturing, and customers’ need for highly customized products increases the vulnerability of the system to collapse. In a nutshell, challenges in the manufacturing supply chain and logistics can be boiled down to “lack of data” or in other words, not having access to timely and trustworthy data. However, most of the challenges can be brought under one umbrella and addressed using data-focused technology such as blockchain at every stage of the product’s life cycle.

4. Blockchain Technology in Manufacturing Supply Chain and Logistics

While the traditional supply chain was all about focusing on the “where” and “when” of a physical product, the modern supply chain is about the management of data, services, and products bundled into solutions [

38]. Although blockchain technology is not a panacea that can fix all the supply chain-related challenges, it can play a vital role in addressing most of the data-related challenges that a manufacturing supply chain faces, such as the lack of a traceability mechanism for products, identifying counterfeit/grey market products, improving visibility of products, and eliminating paperwork and administrative difficulties throughout the product life cycle. For instance, the pandemic-driven surge in demand for medical personal protective equipment such as masks and protective gear has flooded the market with fake products. Hence, VeChain, a blockchain-powered platform, has applied shipment boxes that bear a VeChain non-fungible token chip, and a two-factor authentication QR code to assure the legitimacy of the products [

39].

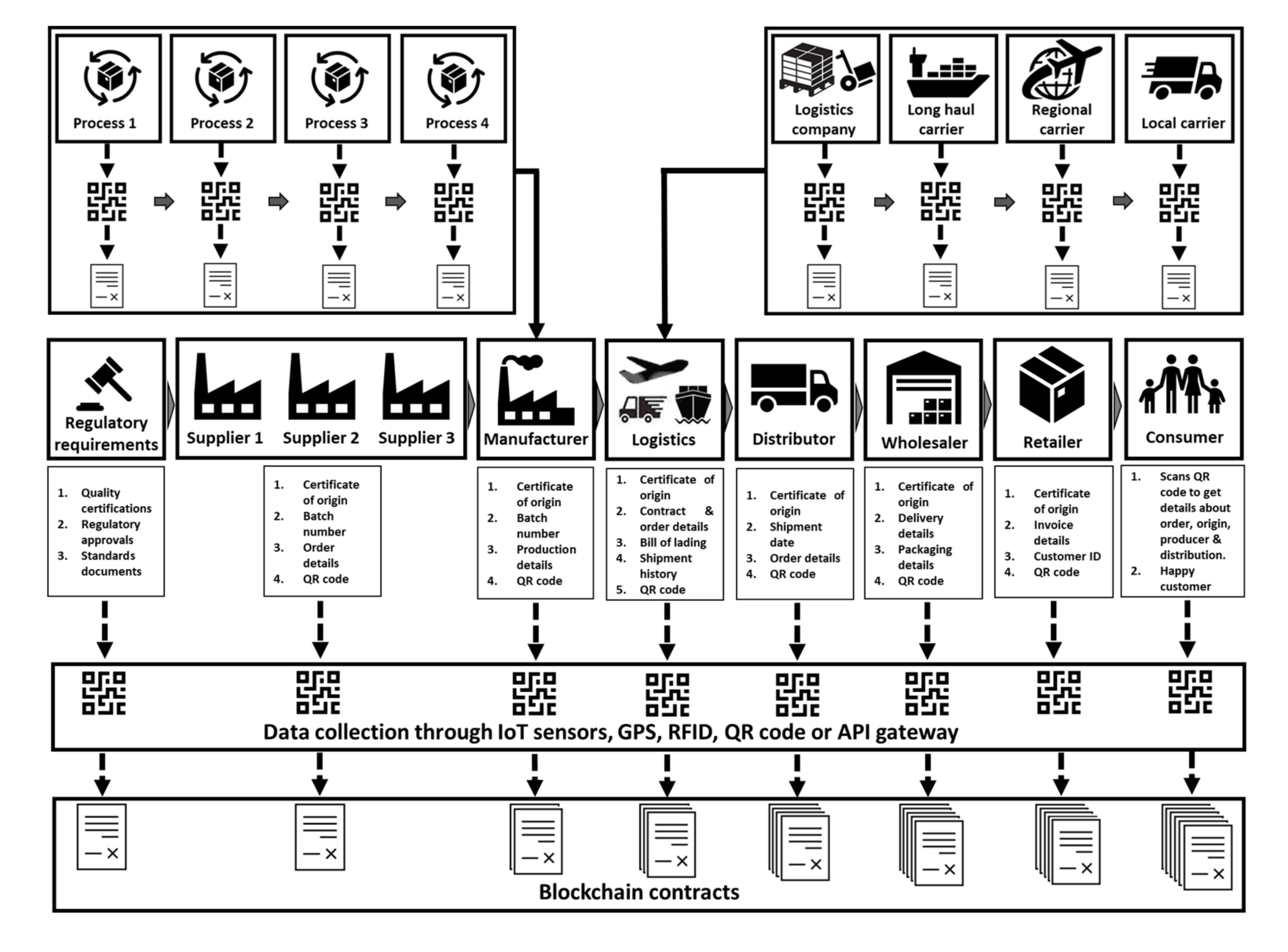

To provide a best-in-class user experience to their customers, manufacturers often diversify their supply chain network to all parts of the globe. In addition, to leverage the benefits of low-cost labor, availability of raw materials, favorable government policies, and a large consumer base, manufacturing industries stretch their boundaries beyond continents. In such a highly competitive market scenario, even a single broken link in the network could lead to disruptions and delays that can affect the customer experience, which, in turn, can heavily influence the top line and bottom line of a company. A typical data flow in a manufacturing supply chain and logistics supported by various data collection systems and blockchain technology is shown in

Figure 5.

In a manufacturing supply chain, the information, or data, from the various participants such as suppliers, manufacturers, logistics providers, distributors, wholesalers, and retailers are collected through various advanced data collection technologies such as IoT sensors, GPS, RFID, QR codes, and APIs. At every stage, the real-time data is pushed in the form of blocks into a blockchain network. As a blockchain system acts as a single data source that stores all the information in an immutable and digitally distributed ledger, it is visible to all the participants of the network. However, a permissioned system can be used to ensure that only the key users have access to add new blocks into the system and the other participants can only track the status of an order through their view-only access. In addition, various third-party applications can be used to retrieve end-to-end product traceability data from a blockchain network using an approved token in any required format for visualization. The product label with a barcode or QR code can be used by the customer to trace the origin of the product and the various value addition stages it went through at a granular level, to obtain supply chain provenance. The transparent and immutable data would lead to increased customer trust and satisfaction. Additionally, the tracking system also helps the manufacturers in reducing the overhead charges involved during recalls and validating the authenticity of the product. A few of the supply chain-specific applications of blockchain technology are elaborated in the following section.

4.1. Building Trust in Supply Chain

As the data in a blockchain is immutable and tamperproof, it increases the trust and traceability of the underlying product. In particular, in the modern industrial era, corporations often do business with numerous small-scale supplier and vendor networks, over which they have limited or no control. The supplier network that is spread throughout the globe further reduces trust. In such a low-trust scenario, the business partners tend to see the other as a competing entity rather than a partner [

40]. Hence, building trust between them is necessary to ensure the success of the supply chain network. However, hesitation in sharing trade secrets and IP details, the need to ensure the compliance and regulatory standards are being followed and verify the quality of raw materials used, and poor communication, lead to friction between the manufacturer and the supplier. Digitization of all the physical assets used in a supply chain using IoT and linking the data collection process to an immutable decentralized network improves the reliability of data and fool-proof asset tracking [

41]. As any data added to a blockchain cannot be altered and needs to be validated by all the participant nodes, this enhances the trustworthiness of the data. Additionally, it helps businesses in avoiding losses incurred due to counterfeit and gray market parts, especially in critical and high-value products such as consumer electronics, jewelry, pharmaceutical, automotive, defense, and aerospace components. In a supply chain and logistics system that is integrated with a blockchain network, all the transactions are non-editable and timestamped, meaning that it provides a very high level of security, transparency, traceability, and trust among the participants.

Another feature of blockchain that provides trust in a blockchain-backed supply chain is “smart contracts” that can be executed with suppliers and contractors. A smart contract is a digital contract that is stored in a blockchain network that is automatically executed when predefined contractual obligations are satisfied [

42]. It is primarily used to automate the execution of agreement quickly between the participants without involving an intermediatory. The agreement can also be a workflow that triggers the next action in the process when certain requirements are fulfilled, or a milestone is achieved. In simple terms, it can be visualized in the same way as the “condition statement” (if-else or if-then statements) of a programming language. In a supply chain, a smart contract can be used to automatically verify and execute contracts, track inventory, process payments to intermediaries, send notifications, and issue tickets without manual intervention or cumbersome paperwork.

4.2. Supply Chain Transparency and Traceability

A transparent supply chain refers to the practice that provides easy availability and visibility of required information always to all the participant stakeholders. Typically, a supply chain transaction involves the flow of information, inventory, and financials arising out of orders, shipments, and payments which must synchronize with each other. Although current ERP systems are capable of tracking the details, they need significant manual intervention, and the data are not visible to all the participants. However, blockchain technology can help manufacturing industries to permanently record and track all the information related to quotations, order details, compliance certificates, manufacturing cost breakups, dates, completed and pending processes, the current location of the product, quality details, and other relevant particulars in one place. It helps in achieving end-to-end product tracking from procurement of raw materials until the product reaches customers. The availability of reliable and tamperproof information in one place increases the traceability of products in the supply chain, which, in turn, helps the business and customers to ensure that their products meet all the required standards. Additionally, manufacturers can have better control over their suppliers and outsourced contractors. The precise data on time taken and cost incurred at every value addition stage help to optimize the process. This can also help B2B businesses to provide a real-time update to their customers about order status and delivery commitments [

43].

Asset tracking refers to tracking products throughout the supply chain using blockchain technology that can help fight counterfeit products [

44]. An asset can be a physical product (tracked using IoT) or a digital document (using the smart contract) that can be tracked in real-time and stored in a blockchain network which makes the journey of the asset highly transparent and agile. It provides up-to-date details about the assets and ensures that all the relevant data about an asset are transparent, accurate, and reliable. Blockchain technology allows the requestor to track the origin of both tangible and intangible assets which can eliminate fraudulent transactions [

45].

4.3. Supply Chain Flexibility

Flexibility refers to the ability to quickly adapt and meet changing customer requirements and retain competitive advantage [

46]. While the traditional manufacturing industries rely on mass production to reduce the overall cost of products, the new-age customers’ preferences for customization and personalization made the industries upgrade themselves with Industry 4.0 technologies such as Internet of Things (IoT), Artificial Intelligence (AI), cloud computing, and collaborative robots. The complex and dynamic nature of the business requires a supporting technology that is flexible to adapt and simplify the process. Businesses that quickly respond to the changes in external factors such as fluctuating demand, dynamic market conditions, and changes in customer preferences can quickly react to the change and maintain the service quality to the customers. For a supply chain to be flexible, a transparent, trustable, seamless, and real-time flow of information between various internal and external stakeholders is necessary. By combining blockchain technology with IoT and AI, a manufacturing supply chain and logistics can become more flexible and agile [

47]. The technology can integrate all the stakeholders of a supply chain and provide data that can be used to improve predictions and manage real-time demand. This helps to make quick decisions and reduce losses incurred from both surplus and low inventory.

In general, improved data quality, data integrity, data-based decision making, demand forecasting, flexibility to adapt to changes, visibility across the entire supply chain, product traceability, automated approvals, improved sustainability, reduced risk, superior inventory management, and higher customer confidence are the few benefits that a firm can earn by adopting blockchain technology to their supply chain network.

5. Application Scenario in Cutting Tool Manufacturing Industry

In this section, a real-life application scenario of blockchain technology from the aspects of a metal cutting tool manufacturer is conceptualized. Typically, cutting tool manufacturers supply tools to crucial industries such as automotive, aerospace, transportation, general engineering, and defense sectors that have stringent quality and compliance requirements. These tools are dual-use products that can be used in civil applications such as machining agricultural pump components [

48] but are also capable of manufacturing aerospace, ballistic, or fighter jet parts [

49]. In addition, most countries rely on importing essential industrial raw materials such as tungsten carbide and cobalt [

50] to manufacture the tools. Hence, to adhere to the export ban on such products to rogue nations, it is critical to build a supply chain ecosystem using digital technologies such as blockchain and IoT that is transparent and traceable. The component shown in

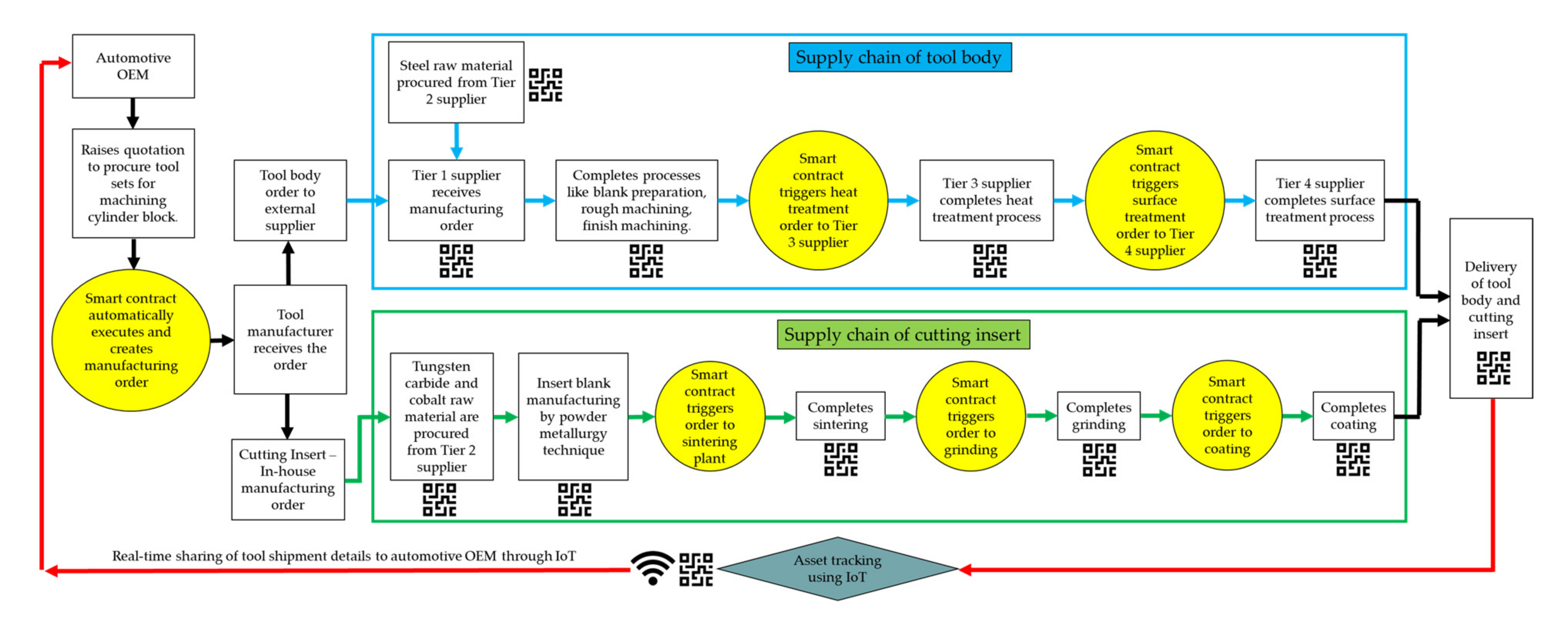

Figure 6 corresponds to an automotive cylinder block machining application that requires numerous tools such as indexable milling cutters, slotting cutters, end mills, drills, reamers, taps, and so on. In this scenario, the application of blockchain technology to provide provenance and traceability of an indexable milling cutter is hypothesized, and the logic can also be extended to other tools and products. The tool has two major assembly parts, a tool body made of steel and cutting inserts made of tungsten carbide. It is hypothesized that the tool manufacturer outsources the tool body manufacturing to an external supplier, while the cutting inserts are manufactured in-house. The clamping screw is neglected, as the process flow discussed for the tool body is applicable for the screws as well.

The automotive OEM creates a quotation to purchase all the tools required to machine a cylinder block. After the tool manufacturer accepts the quotation, an order is placed. The preliminary process of raising a quotation and placing a purchase order can be automated using smart contracts and stored in the blockchain network. The purchase order is automatically executed if pre-defined conditions such as delivery lead time and cost commitments are satisfied. Once the conditions are met, it triggers the manufacturing order on its own. Based on the order, the tool manufacturer creates the required CAD drawings for the tool body and places a manufacturing order with a tier-1 supplier. The blockchain network, which is extended to all the participants of the supply chain, enables the supplier to add blocks of information on the sourcing and processing stages of the steel raw material from the time the ore is mined and formed into a billet, that is obtained from the raw material supplier (named as the tier-2 supplier for the sake of discussion). This provides provenance details and ensures that the raw material is sourced from a conflict-free ethical source. The composition of the steel, mechanical and metallurgical properties such as hardness, toughness, tensile strength, and other relevant details are permanently stored in the network in the form of blocks by the tier-1 supplier for future requirements. Subsequently, the value additions performed at various stages such as blank preparation, rough machining, finish machining, heat treatment, and surface treatment (such as nickel plating, chrome plating, etc.) are also added to ensure that the tool has undergone all the required processes. If the supplier further outsources the processes such as heat treatment (to an external party named as the tier-3 supplier) and surface treatment (to an external party named as the tier-4 supplier), the relevant supplier and process details are also added to the blockchain. The smart contracts can be implemented to automatically trigger orders to the tier-3 and tier-4 suppliers. In a conventional supply chain, the comprehensive overview of the sourcing and process details of the multi-layered supplier network has very reduced or no visibility to the tool manufacturer and the automotive OEM who are at the top of the supply chain. However, adopting blockchain provides visibility to these data transparently to the entire supply chain from top to bottom. Additionally, by using smart contracts to automatically trigger the succeeding processes, the tool manufacturer also obtains additional real-time visibility to the accurate delivery date of the tool without manual intervention which can be used to automatically schedule subsequent interdependent activities. The entire flow of information between the automotive OEM, tool manufacturer, and multi-tier suppliers is shown in

Figure 7. Additionally, the entire flow of order data and the required documentation right from quotation, customer service, purchase, manufacturing, quality, and shipping can be automated and stored permanently in a blockchain network.

Simultaneously, an in-house manufacturing order is also placed to manufacture the cutting insert. The sourcing and provenance details of tungsten carbide and cobalt raw materials, the two key materials used in the manufacturing of cutting insert [

50] are added as a block. The subsequent processes such as pressing of blanks, sintering, grinding, and coating, equipment used, process parameters, date of completion of various activities, and quality details can be added to the blockchain network for future reference. This can also help the tool manufacturer to verify the missing processes or validate the process parameters if there is a performance complaint in the future. In addition, tracking the end customer details, application, service life of the tools, and reverse logistics to support replacements or recycling can also be automated by marrying blockchain with other supporting digital technologies such as IoT. In both the tool and cutting insert manufacturing processes, the documentation requirement such as ISO/ANSI standard guidelines, EHS (Environment, Health, and Safety) compliance, export and import documents, quality certifications, and operating guidelines can be linked to the blockchain to have a permanent record of all the documents that can be verified by the automotive OEM at any time. Thus, by adopting blockchain technology to all the parts of their products, the automotive OEM can obtain comprehensive traceability, transparency, and trust in the data and add value to their supply chain.

5.1. Successful Industrial Use Cases

An exhaustive list of successful industrial use cases, from almost all the sectors, is currently available, which demonstrate the extent to which blockchain has transformed their businesses. However, only a few of the examples that are in line with the scope of the article are discussed in this section.

The eXtended Compliance End-to-End Distributed (XCEED) blockchain project developed by IBM using IBM Blockchain and Hyperledger Fabric has helped Renault, an automotive manufacturer, to share and overlook compliance standards transparently, accurately, and automatically to the entire supplier network. As an average automotive supply chain deals with hundreds of suppliers all around the world to produce tens and thousands of spare parts that go into various vehicle models, sharing millions of documents related to standards and compliance is cumbersome. The automaker has ascertained that the traditional way of exchanging these files through mails, trading files, and phone calls to the hundreds of suppliers with whom they make business is time-consuming. However, the distributed ledger characteristics of blockchain have enabled them to distribute and track data across the entire network with ease, while maintaining the confidentiality of the information using a permissioned network [

51].

German automaker BMW worked together with DHL, a leader in the logistics industry, to develop a blockchain-based proof-of-concept to improve the visibility of parts shipped. To avoid the long manual process, a private blockchain network that can show the supply chain-related data to the participants was created. The various access level ensured that the participants could access only the data that are of interest to them. Additionally, the system’s capability to provide real-time shipment data to their dealers from the time an order is placed until it is delivered has helped them in reducing manual reports and gave better visibility to real-time data [

52].

The miles clocked by the automobile odometer is a critical assessment used for the valuation of vehicles and approving warranty claims. However, the cost of illegal tampering with data is a common threat in the used-car market, the value of which is estimated to be around USD 7.5 billion every year, in Germany alone. To solve the issue, Bosch, an engineering technology company, and TÜV Rheinland, a German certification agency collaborated to develop a blockchain-based system to prevent data manipulation in the odometer of automobiles. The system collects the distance clocked by the odometer in real-time using IoT sensors, timestamped, and automatically transfers it to a tamperproof blockchain network which ensures the authenticity of the data. The technique can be extended to logistics providers to maintain records of their fleets and assist used-vehicle dealers [

53].

Maersk, a global shipping company, has collaborated with IBM and developed a blockchain-based trade platform to digitize the supply chain that can track end-to-end details of shipments. The details related to the progress of goods in the supply chain, the current location of the container, custom clearance documents, bills of lading, and all other relevant data are made visible to all the participants of the network in a tamperproof database. The platform provides greater visibility to goods-in-transit, eliminates cumbersome paperwork, and improves transparency and trust among the participants. In addition, it has the potential in avoiding delays and offer enormous cost benefits [

54].

RCS Global, a leader in delivering responsible sourcing of raw materials, has partnered with IBM and developed the Responsible Sourcing Blockchain Network. Originally developed to trace the origin of Li-ion metal used in manufacturing batteries, the technology can support end-to-end tracking of all raw materials from mine to customer. The granular details of the process flow from the time the metal is mined and moved to various stages, such as smelter, cathode unit, battery unit, manufacturing plants, until it reaches an electric vehicle or a consumer electronic can be traced. This ensures customers that the minerals used in the product were sourced from a responsible sourcing site that is free from conflicts and unethical practices [

55].

5.2. Other Applications

Due to the various unique characteristics (that are discussed in

Section 2), blockchain technology has quickly gained popularity beyond cryptocurrencies. Apart from supply chain management, some of the sectors that have the potential to embrace the benefits of blockchain technology are briefly discussed in this section.

5.2.1. Banking and Finance

Blockchain is fundamentally a distributed ledger and as ledger maintenance is the core business of banking and finance, it is the first sector to embrace the technology. As for the traditional banking system, all the transactions were originally stored in physical format. Later, the physical ledgers were replaced by managing the details of transactions in a digital database. However, due to the ever-increasing online threats, a traditional centralized database is still susceptible to manipulation and the entire system is vulnerable to hacking. As the banking and financial sector is considered a key pillar for the economic development of a country, any disruption to the sectors would be catastrophic. However, the unique characteristics of blockchain that were discussed throughout the paper can help the sector to manage its processes efficiently. Auditing financial results, which usually takes days and weeks, can be considerably reduced to hours due to the availability of trustworthy data. Automated clearance, payments and settlements, tokenizing securities such as shares and bonds, elimination of third parties for quicker and efficient processing of loans and credits, fool-proof asset management, decentralized database to maintain customer records, secure and cost-effective international money transfers, and immutable nature of transactions are a few of the benefits which a traditional banking system can gain by adopting blockchain [

56].

5.2.2. Insurance

Insurance is another key sector that involves numerous contracts in the form of physical paperwork between multiple parties that results in delayed processing and a lengthy settlement cycle [

57]. The contracts involve cumbersome record-keeping of various details such as customers’ personal details, nominations, premiums, renewals, claims, investigations, and settlements. However, all the transaction details can be easily and efficiently stored in a blockchain network which can be used to support quick claims, automate the claim settlement, and prevent fraudulent claims. This can lead to increased customer satisfaction and reduce the administrative cost to the insurance provider.

5.2.3. Healthcare

Currently, the health records of individuals are stored in a physical format and most of them are lost over a period. However, blockchain can act as an interoperable and comprehensive system to record and manage the details of individuals by automatically pulling patient details from physicians and hospital records and storing them in a secure network in the form of electronic medical records or health records (EMR/EHR). It also assists physicians in understanding a patient’s medical history, which can lead to improved diagnosis and can be used to prevent future illness. The records can also be used to buy or renew insurance policies and initiate claims or settlements automatically. In addition, the technology can also support maintaining a larger public health management initiative and eliminate the circulation of counterfeit drugs and pharma products [

58].

5.2.4. Intellectual Property (IP) and Copyright Management

Blockchain technology can act as a digital repository to maintain IP ownership and copyright certificates of individuals and corporates. Through smart contracts, the IP rights can be licensed to interested parties automatically and royalty details can be tracked easily. The other potential use cases include maintaining the different versions of an IP in one decentralized secure location, digital rights management, proof of ownership and provenance authentication, distribution, tracking and automatic approval of IP rights, and implementing IP contracts [

59].

5.2.5. Education

The education institutes can make use of the immutable nature of the blockchain technology to store and track the entire transcripts digitally, such as student and staff records, frame syllabus, and issue certificates [

60]. The certificates would become a tamperproof permanent record in the university’s blockchain network that can be easily viewed or verified by the other participating agencies such as higher education universities, employment firms, and immigration agencies.

5.2.6. Real Estate

All the property records, the history of previous ownership details, details of taxes paid to the government, property approval documents, rental and mortgage details can be efficiently tracked by maintaining all the records in a blockchain network. The technology can help all property-related transactions to become transparent and trustable, as they can otherwise be influenced by shady practices. In addition, it can also help governments to eliminate undervaluation issues in the property transactions that lead to revenue loss and reduce the cost involved in record keeping. Removing middlemen, improved transparency, liquidity, fractional ownership, fraudulent transactions, use of unaccounted money, and other illegal activities that are common in the real estate sector, can be eliminated through blockchain [

61].

The potential application of blockchain technology is exhaustive, and in general, can be used in all the sectors where transparency and trust in data are required. In line with that context, the few other sectors that can realize the benefits of blockchain technology include retail, eCommerce, media, stock market, transportation, food, pharma, fashion, jewelry, and governance.

6. Challenges in Adopting Blockchain Technology

Although blockchain technology provides numerous benefits to the users, the technology has not yet received widespread adaptation due to various challenges and limitations. Scalability, high energy and computational power, throughput, latency, high setup cost, and lack of standardization are some of the major challenges [

62]. For instance, the consensus protocols used to maintain the integrity of the blockchain must be executed every time to add new blocks. However, with the new blocks added to the chain continuously, it grows larger, which consumes more energy and requires enormous computational power. It renders integrating the technology with smaller and low-powered IoT devices extremely difficult, and firms could face challenges in attaining sustainability targets. As the required computational power increases it can also lead to longer processing time which makes the system inefficient. To maintain the core characteristics of decentralization, many participant nodes are required, which leads to scalability problems, especially in a public blockchain.

In the blockchain, throughput refers to the rate at which the transactions are processed. In other words, it can be termed as the number of transactions per second [

63]. According to a stress test conducted in 2014, the VISA network has the capability to handle 56,582 transactions per second at its peak (although on average it only handles around 2000 transactions per second), while bitcoin takes around 10 min to confirm a transaction and can only handle three to seven transactions per second, which exposes the network’s scalability and throughput issue [

64]. Although blockchain technology is considered highly secure, exploiting the technology by gaining a majority consensus (also known as a 51% attack or majority attack) is possible in a network with a small number of participants [

65].

In the blockchain, “latency”, which is also denoted as “block time” refers to the time taken to generate the next block of transaction in the chain, and the current latency is roughly around 10 min, which is much higher than the traditional systems [

66]. Additionally, having many confirmation blocks in the network compounds the issue. In particular, the presence of a large number of nodes, each spread across the world with different networking and computational capabilities in a public blockchain, increases the latency as each node requires access to the blockchain to reach consensus. As a full node has an entire copy of the blockchain, it takes a huge toll on the hardware, software, and network infrastructure. Low transaction processing throughput and high latency are commonly reported issues in the deployment of IoT devices to blockchain [

67]. Additionally, as each node in the blockchain basically performs the same task, the lack of sharding makes it impossible to execute parallel tasks. Blockchain trilemma is another common notion used to denote the challenges associated with all decentralized networks. According to the consistency, availability, and partition (CAP) tolerance theorem, a decentralized network can achieve only two of the benefits between decentralization, security, and scalability at a given time, while compromising the other. Hence, achieving scalability without compromising decentralization or security is highly difficult. Similarly, achieving security and scalability together is a challenge, as they oppose each other. As security and decentralization cannot be compromised, scalability is often seen as the highest risk for the growth of blockchain technology. However, some scholars believe that all three can be achieved without a compromise in the future [

68].

However, most of the discussed challenges were related to having a public blockchain, and they can be tackled by adopting a private blockchain which is suitable for industrial applications such as supply chain and logistics. However, few studies that have tested the performance of private Ethereum blockchains have also highlighted block frequency, block size, node configuration, computational power, and consensus costs that limit the scalability [

69,

70]. In addition, the cost involved in setting up a private blockchain network for the entire supply chain would be high, complex, and unknown in many cases. To address the challenge, a few service providers such as IBM have developed a cloud-based blockchain network as a service for easy deployment, which can ease the setup cost to a certain extent. With every service provider developing their blockchain protocols and architecture, the lack of standardization could lead to blockchain applications facing interoperability issues. The other common challenges include lack of budget, unfamiliar technology architecture, lack of enough successful use cases, regulatory and compliance issues, lack of awareness, and some companies seeing no significant value addition to their current practices.

7. Key Takeaways and Future Directions

Unlike other sectors, the challenges of a supply chain are unique, due to the complicated and multi-tiered network, which involves several parties who operate from different parts of the world with various compliance and ethical standards. Hence, the unique challenge of bringing the entire supply chain under one roof requires a unique technology such as blockchain that can provide a very high level of traceability, transparency, immutability, and security to data. However, when it comes to businesses adopting any new technology, the first and foremost question that is asked is, “Can the technology add value to their supply chain and improve profitability?” The answer is, “yes”, and the three potential areas where it can add value are summarized below:

Improve the speed and reduce manual processes in the current practices, especially among suppliers and vendors that are at the bottom-most tier of the supply chain who often go unnoticed or are difficult to track.

Improve traceability and provenance of the entire supply chain to mitigate costs arising out of using inferior quality, counterfeit, or grey market parts, facilitate easy reverse logistics, support circular economy, and adhere to reputation, compliance, and ethics.

Provide transparent, trustable, and secure information to all the participants of the supply chain in real-time by eliminating errors in inventory records, missing shipments, and duplicate payments.

The study clearly shows that blockchain is not just another technology that would fade out once the buzz around digital technology settles, but its tremendous benefits clearly show that it is a technology that is here to stay. At the InFinity forum 2021 organized by the International Financial Services Centres Authority (IFSCA), Mukesh Ambani, one of the richest men in the world and chairman of Reliance Industries Ltd., has asserted his faith in blockchain technology and highlighted the unique features of the technology such as security, trust, automation, and efficiency that can modernize the supply chain, which is the lifeline of a country’s economy. Although there is no doubt that the technology would be a real game-changer, it could take time to evolve to address various real-world challenges and show significant value propositions before receiving universal acceptance. What follows is the summary of challenges and future directions of blockchain technology:

Currently, not all the trading partners are participants in the blockchain. Extending the network across all the supply chain partners would be expensive, consume more energy, and require enormous networking and computational power.

As interoperability between two different networks is a challenge, selecting a specific blockchain technology ties the users to it. For instance, blockchain interoperability currently works for the different blockchains of the same network, but between different networks (also called cross-chain or cross-blockchain interoperability) such as Ethereum and Ripple is difficult.

Reducing the size of the blockchain without losing information, block size optimization, a lightweight blockchain to reduce transaction latency and computing power, a new standard to represent transactions in a block, and new governing rules to suit industrial needs, are a few potential future studies.

The integration of IoT-enabled devices with private blockchain could open the doors of new possibilities if scalability and cost issues are addressed as each IoT device generates gigabytes of data in a short time.

Blockchain-enabled automatically executable digital contracts also called “smart contracts” have the potential to become the future of all digital transactions by providing secure and transparent transactions.

Many participant nodes increase challenges such as scalability, latency, throughput, networking, data privacy, cost, and high energy consumption. Hence, a private blockchain is suitable for multi-organizational businesses such as supply chain and logistics. However, hybrid blockchain, an amalgamation of a public and private blockchain that provides flexibility on data visibility without compromising security also shows immense potential.

8. Conclusions

For a consumer, as the supply chain is the face of a business, organizations across various sectors race to build an efficient and reliable management technique to protect their business. Despite the advancement in integrating information technologies with the traditional supply chain, challenges such as time, trust, transparency, traceability, and security of data are unaddressed. Although most organizations have “digitalized” their supply chain and logistics, there is currently a need for “data-driven” practices. So, the supply chain of the future must be connected, collaborative, secure, intelligent, and scalable. Hence, the use of modern Industry 4.0 technologies that are often called “smart factory technologies” such as automation, artificial intelligence, blockchain, IoT, cloud computing, and big data analytics are the compelling necessities for a smart supply chain network. Together, the technologies can assist industries to develop a transparent and trustable supply chain ecosystem that can ease operational challenges and improve financials.

However, despite having a rosy outlook and abundant capabilities, even after a decade, blockchain technology is still in a very nascent stage, and firms are wary of upgrading their traditional database with blockchain. Perhaps, a novel technology does not always mean it guarantees superior performance and successful widespread acceptance. Nevertheless, supply chain management is the one area in which the technology would become a real game-changer due to the involvement of multiple stakeholders, and a complex process that demands the availability of transparent, trustable, and real-time data. However, to achieve a mainstream adaptation, the technology must suitably address critical challenges such as scalability, interoperability, high energy and computational power, throughput, and high cost. Further research on the technology to overcome the challenges would completely revolutionize the way information flow is managed in a supply chain and logistics network. However, the success of the technology would highly depend on various stakeholders coming together to transform their legacy practices into data-oriented digital technology such as blockchain. Hence, based on the literature survey, it can be concluded that blockchain technology can provide significant benefits to the supply chain and logistics network of manufacturing companies in terms of trust, transparency, traceability, security, and flexibility.