Moving from Industry 4.0 to Industry 5.0: What Are the Implications for Smart Logistics?

Abstract

1. Introduction

2. Literature Review

2.1. Industry 4.0

2.2. Industry 5.0

2.3. Literature Gaps and Contributions of This Research

3. Research Method

- Problem Formulation: Entails the identification of the research goals and scopes by defining relevant research questions. It is worthy to note that, for studies including more than one reviewer, there should be a consensus over the questions to avoid evaluation bias.

- Literature Search and Screening: This stage commences with a precise search within the selected databases according to the identified keywords for each research question. The resulted papers are to be filtered out through the inclusion and exclusion of relevant criteria, which are further narrowed down by the screening procedure.

- Bibliometric Analysis: According to the meta-data associated with the extracted papers, a quantitative analysis is conducted to reveal the relations between various characteristics of the research articles, i.e., publication trend, keywords focus, involved journals, etc.

- Content Analysis: Qualitative analysis that aims at a thorough evaluation of the selected papers to explore the current status of the research area and to highlight the future research agenda.

4. Problem Formulation and Literature Search

- Research Question 1 (RQ1): What are the connection and differences in smart logistics between Industry 4.0 and Industry 5.0?

- Research Question 2 (RQ2): What are the main characteristics and enabling technologies of smart logistics in Industry 5.0?

- Research Question 3 (RQ3): What is the research agenda of smart logistics in Industry 5.0?

- Keyword Search. This step employs two search techniques: (1) using a double quotation for an exact match with regard to phrase search; and (2) taking advantage of Boolean operators (OR/AND) to combine various taxonomies of keywords. To thoroughly reveal the connection and differences in smart logistics between Industry 4.0 and Industry 5.0, we searched the respective literature in two groups. The first group emphasized the connection between Industry 4.0 and smart logistics, which primarily yielded two contextual categories connected with “OR”, as shown in Table 1. The second group was to explore the literature that discussed the characteristics, implications, driving factors, and definitions of Industry 5.0-enabled smart logistics. The primary database for the literature search was Web of Science (WoS), which is the most extensively used platform [52]. However, due to the limited number of papers related to smart logistics and Industry 5.0 in WoS, Scopus was also used to yield a reasonable sample for analysis. The literature search was conducted in late December 2021, and the initial search for the first group yielded 288 papers, while it resulted in 247 for the second group (91 and 156 in WoS and Scopus, respectively).

- 2.

- Inclusion/Exclusion of Search Criteria. This procedure attempts to narrow down the collected papers from the previous step by either including or excluding particular criteria. Primarily, the language of the research items was selected as ‘English’ to emphasize the international contributions. To ensure the quality of analysis, the papers were restricted to journal articles and conference proceedings. As also outlined, the introduction of Industry 4.0 was traced back to 2011 [22,23], while the literature had recorded 2017 for Industry 5.0 despite its initial introduction being in 2015 [2,53]. Thus, the next criterion was to set the publication years of the two groups of papers to be after 2011 and 2017, respectively. Another key filter that remarkably impacts the search results is the publication categories, which seeks to eliminate articles with the least correspondence in terms of their scientific fields. Based on the applied filters, there were 114 and 146 in the two groups. Ultimately, a duplicate check for the second group was essential due to the use of two databases, which, in turn, decreased the results to 110.

- 3.

- First Screening (investigation of titles, abstracts, and keywords). The initial consideration in this stage was to exclude review articles, which were respectively recorded as 6 and 9 papers for the two groups. This was followed by a thematic investigation that aimed at filtering out the papers with weak conceptual relevance associated with the research questions. Throughout this process, the titles, abstracts, and keywords of the articles were investigated. This process led to the exclusion of 49 and 59 papers in the two groups.

- 4.

- Second Screening (full-text investigation). During this process, the selected papers from the previous step were entirely read to filter out the ones that were incapable of addressing the research questions directly. After the full-text investigation, 12 papers were eliminated from the first group, and 10 papers were eliminated from the second group.

5. Comparative Bibliometric Analysis

5.1. Publication Trend

5.2. Sources Contributions, Interactions, and Co-Citation Analysis

5.2.1. Source Contributions

5.2.2. Interaction and Co-Citation Analysis

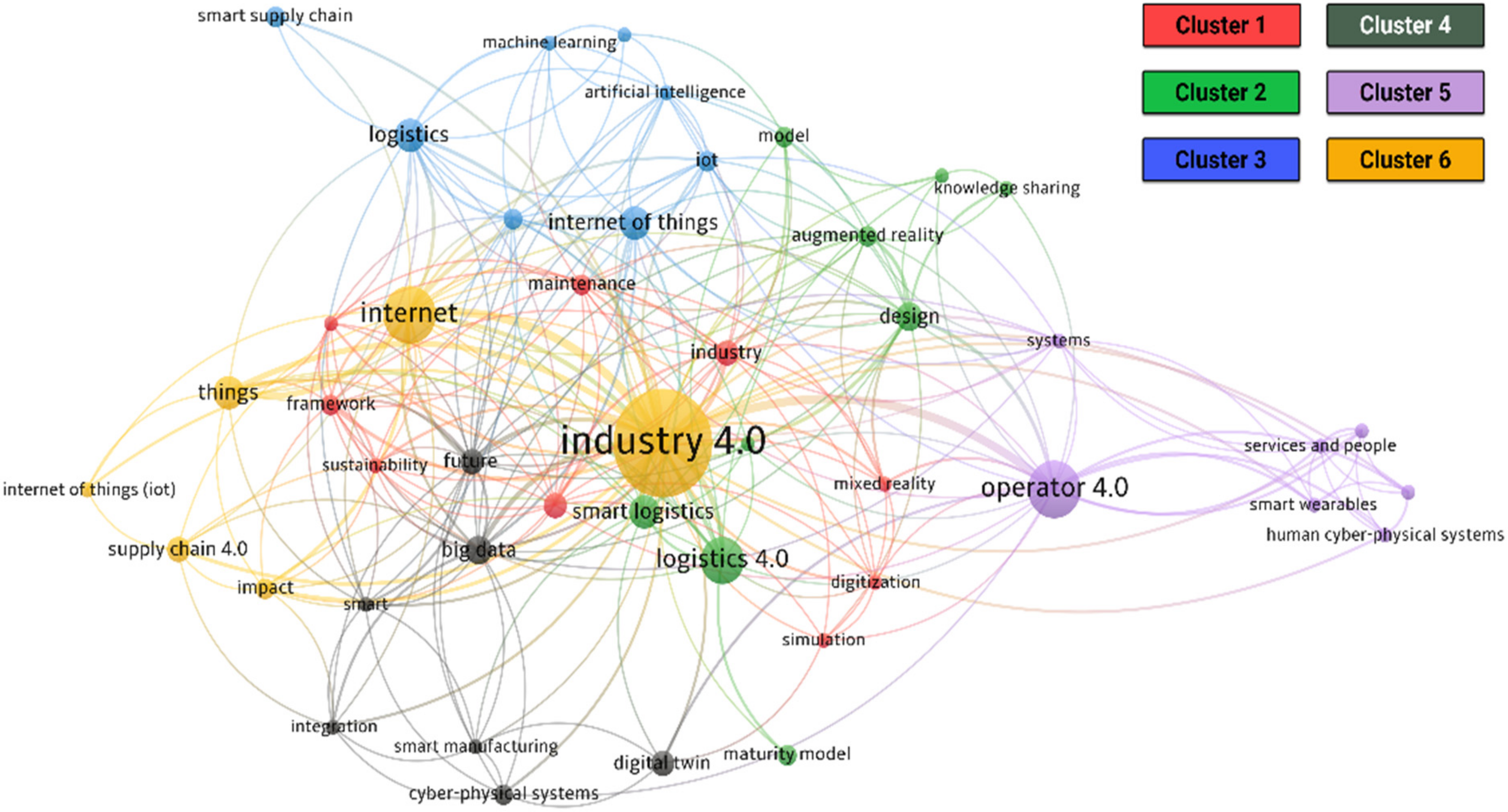

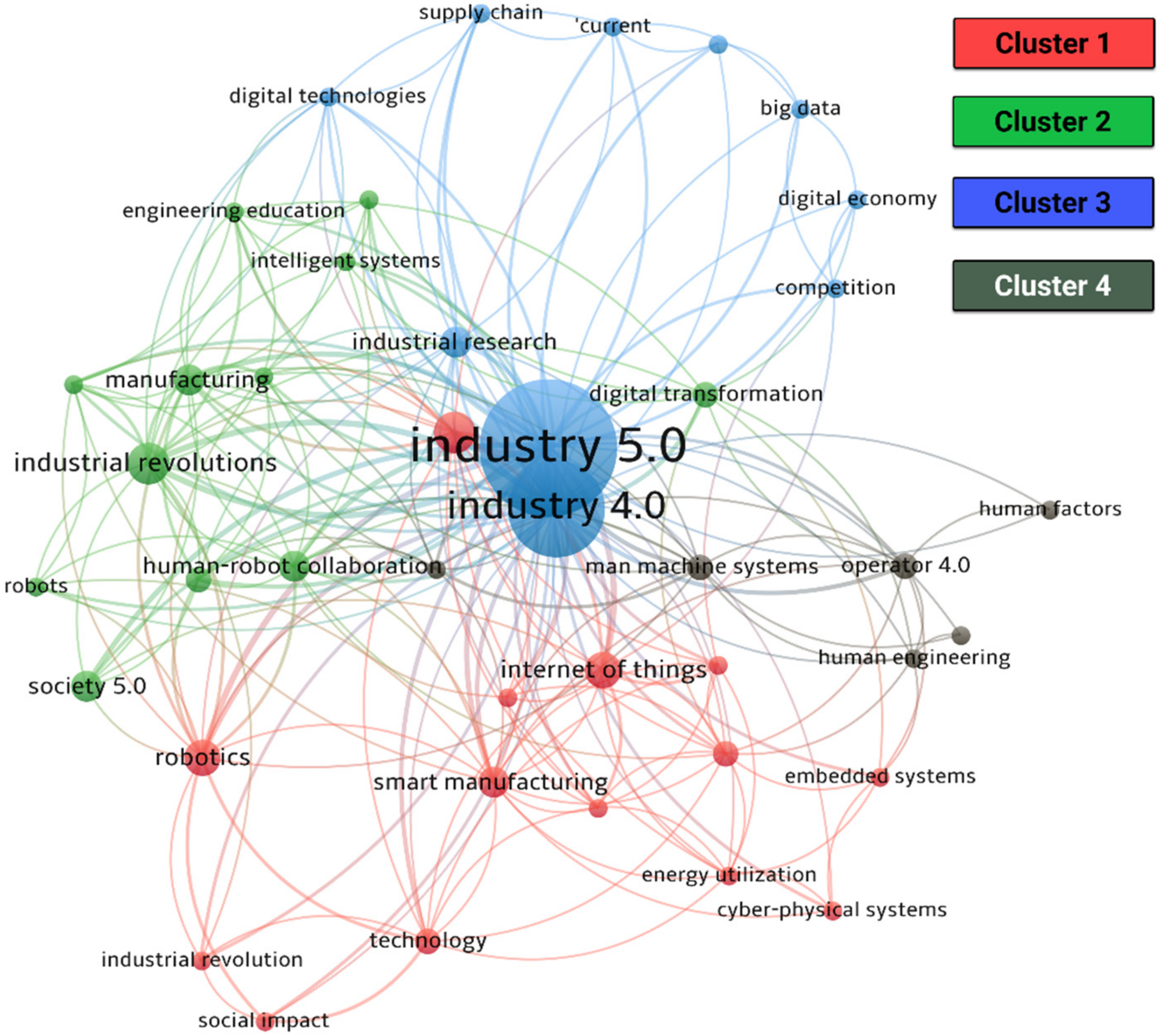

5.3. Keyword Co-Occurrence Analysis

6. Content Analysis and Discussion

6.1. The Three Key Elements of Industry 5.0

- Human-Centricity. Conveys the fact the production and logistics system must be improved with solid attention to human benefits and needs, by which the human is transformed from ‘cost’ to ‘investment’ [2]. From the operational aspect, this urges the promotion of hybrid alternatives in response to the industrial challenges, where the human power and human brain are involved not only in maintaining the surveillance but also in incorporating more intelligence and innovation and, to some extent, making decisions [3,35]. Industry 5.0 emphasizes research and development (R&D) activities to translate information into knowledge and meet sustainable social goals by upskilling humans through formal education or training schemes [2,6,36,56,57]. From the social and economic point of view, Industry 5.0 shapes the ground to not only prevent the elimination of human labor engaged in the manufacturing industry but also create more job opportunities in the supportive industries, which provide technological solutions, i.e., robot manufacturing, sensor manufacturing, etc. [3,34,36]. Hence, based on these objectives, Industry 5.0 is a human-centric paradigm that transfers the human back to the center of production cycles.

- Resilience. Represents the flexibility and agility that a production plant needs to maintain in response to market change [36,58]. Today, customers are strikingly bombarded with high-tech innovations and products, and according to the constant changing in the market, personalized demands are one of the most significant challenges to the manufacturing industry [35]. To a larger extent, manufacturing systems are expected to transform from mass customization to mass personalization [36]. From a tactical perspective, this is realized by incorporating the customers into the design phase to build up the personalized product from scratch [34,59]. To improve the operational flexibility in this regard, human–robot collaboration has significant potential, which conducts versatility of fabrication in a more efficient time [36,37]. It is worthwhile to highlight that while the main task is accomplished by the robot, human collaboration facilitates the problem solving of the work and process flows, and improves intelligence and innovation [35,37].

- Sustainability. The concept of sustainable development was initially introduced by Brundtland in 1987 and defined as the “development that meets the needs of the present without compromising the ability of future generations to meet their own needs” [60]. While the social- and human-related issues are an integral part of this concept, they are merely discussed within human-centricity in the context of Industry 5.0. This approach emphasizes reverse logistics [61,62], circular economy [2], value chains, and so forth [63]. Sustainable development seeks the protection of the environment through sustainable products and logistics systems to approach the zero waste objective [34]. In addition to waste prevention, the manufacturing processes must be environmentally friendly—for example, by using renewable resources and green computing [37].

6.2. Smart Logistics in Industry 5.0

6.2.1. Intelligent Automation

6.2.2. Intelligent Devices

6.2.3. Intelligent Systems

6.2.4. Intelligent Materials

6.3. Discussions and Research Agenda

6.3.1. Analysis of Enabling Technologies

6.3.2. Similarities and Differences between Industry 4.0 and Industry 5.0 for Smart Logistics

6.3.3. Research Agenda

- Smart and sustainable logistics network design. Logistics network design is one of the most important strategic decisions. The human-centric and technology-driven paradigm shift will largely affect the smart logistics operations in Industry 5.0; however, this leads to more challenges in strategic logistics network design to accommodate these configurational and operational changes within the whole planning horizon. Thus, research focus needs to be given to smart and sustainable logistics network design considering both human and technological factors in Industry 5.0.

- Mobile transportation. Intralogistics operations and material handling systems are some of the most significant challenges related to manufacturing logistics, which significantly impact the system’s flexibility and agility. In this regard, smart mobile transportation means, i.e., UAVs, AGVs, have shown significant capabilities with intelligence and connectivity utilities. These pave the way for a smart collaboration with the operator, which not only satisfies the resilience goal but also takes human centricity into account. Given the least attention from the literature, it is of significance to devote more effort in this direction.

- Additive manufacturing. Due to its high adaptability and flexibility, additive manufacturing would significantly influence the sustainable supply chain and logistics operations compared with other techniques in Industry 5.0. Various logistics operations and supply chain activities can benefit. For example, in warehouse management, digital inventories of a large variety of products with low and irregular demands can be held with the help of additive manufacturing, which reduces both costs and environmental impacts. Thus, research attention needs to be given to AM in smart logistics of Industry 5.0 to improve both economic and environmental performance while maintaining a high service level.

- Intelligent materials and supply chain. Biotechnologies and intelligent materials are among the primary technologies for Industry 5.0. Given its low rate of attention from scholars, it is of significance to invest more research effort in this direction. In addition, it is highly beneficial to study the impact of intelligent material on smart and sustainable logistics systems, i.e., green logistics, reverse logistics, circular economy, etc.

- Warehouse and inventory operations. Although plenty of technological discussions exist within the context of manufacturing industries, some other logistics activities are neglected in the agenda. Warehouse and inventory operations could be investigated from various aspects considering both new technologies and human-centric operations—for instance, the use of virtual technologies to improve the information transparency and cognitive skills of warehousing or inventory activities. In addition, innovative human–robot solutions along with advances in sensing technologies potentially serve as valuable topics to be studied further in this context.

- Human-centric manufacturing and logistics. On the one hand, the human operator, supported by technologies, is the most important element in an Industry 5.0-enabled manufacturing and logistics system. On the other hand, the diversified human demands drive the way of technological breakthroughs and paradigm changes in manufacturing and logistics. Hence, it is substantially important to understand the interplay between humans and technologies in the transition by, for example, studying the impact of cobots and other human-centric technologies on manufacturing and logistics.

- Smart logistics solutions for unexpected events and disasters. Recently, the world witnessed several catastrophic events and humanitarian disasters, e.g., the COVID-19 pandemic, the war between Russia and Ukraine, etc., which require more smart and responsive logistics solutions. For example, satisfying the rapidly increasing demand for personal protective equipment (PPE) [129] and properly dealing with infectious medical waste are among the most critical logistics challenges during the pandemic [130]. In this regard, Industry 5.0 may play an important role by providing innovative solutions through autonomous logistics solutions, human–robot collaboration, etc. Thus, future research in this direction is suggested.

7. Conclusions

- RQ1: We conduct a comparative bibliometric analysis to thoroughly present the connection and differences in smart logistics between industry 4.0 and Industry 5.0.

- RQ2: We thoroughly evaluate the characteristics and key enabling technologies of smart logistics in Industry 5.0.

- RQ3: We propose a research agenda with seven directions to inspire future research on smart logistics in Industry 5.0.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Correction Statement

Appendix A

| Author [Ref. No] | AI a | Cobot | Sim. and DT b | Sensor Tech | Cloud. Comp c | Big Data | ML/DL d | VR/AR e | UAV/AGV f | Bio-Tech. | IoT | AM g | Block. h |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Callaghan [6] | √ | ||||||||||||

| Nahavandi [3] | √ | √ | √ | √ | √ | √ | |||||||

| Xu, Lu [2] | √ | √ | √ | √ | |||||||||

| Patera, Garbugli [63] | √ | √ | √ | √ | |||||||||

| Pathak, Pal [37] | √ | √ | √ | ||||||||||

| Gaiardelli, Spellini [35] | √ | √ | |||||||||||

| Duggal, Malik [131] | √ | √ | √ | √ | √ | ||||||||

| Kumar, Gupta [56] | √ | √ | √ | √ | √ | ||||||||

| Javaid and Haleem [36] | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||

| Saptaningtyas and Rahayu [34] | √ | √ | √ | √ | √ | √ | |||||||

| Demir, Döven [38] | √ | √ | √ | √ | √ | ||||||||

| Doyle-Kent and Kopacek [75] | √ | ||||||||||||

| Gürdür Broo, Kaynak [132] | √ | √ | |||||||||||

| Rega, Di Marino [76] | √ | √ | √ | ||||||||||

| Brunzini, Peruzzini [91] | √ | √ | √ | √ | |||||||||

| Thakur and Kumar Sehgal [110] | √ | ||||||||||||

| Fraga-Lamas, Lopes [113] | √ | √ | √ | ||||||||||

| Zhang, Hu [133] | √ | √ | |||||||||||

| Golov, Palamarchuk [111] | √ | √ | √ | ||||||||||

| Resende, Cerqueira [71] | √ | ||||||||||||

| Ávila-Gutiérrez, Aguayo-González [92] | √ | √ | √ | √ | |||||||||

| Doyle-Kent and Kopacek [80] | √ | ||||||||||||

| Bathla, Singh [119] | √ | √ | √ | ||||||||||

| Romero and Stahre [70] | √ | √ | √ | √ | √ | √ | |||||||

| Jabrane and Bousmah [81] | √ | √ | √ | √ | |||||||||

| Fraga-Lamas, Varela-Barbeito [100] | √ | √ | √ | ||||||||||

| Fornasiero and Zangiacomi [78] | √ | √ | √ | ||||||||||

| Carayannis, Dezi [59] | √ | √ | |||||||||||

| Carayannis, Christodoulou [117] | √ | √ | √ | ||||||||||

| Hol [73] | √ | √ | √ | √ | √ | ||||||||

| Doyle Kent and Kopacek [79] | |||||||||||||

| Longo, Padovano [93] | √ | √ | |||||||||||

| Doyle-Kent and Kopacek [31] | √ | √ | |||||||||||

| Martynov, Shiryaev [57] | √ | ||||||||||||

| Martynov, Shavaleeva [53] | √ | √ | √ | ||||||||||

| Mihardjo, Sasmoko [58] | √ | ||||||||||||

| Welfare, Hallowell [72] | √ | ||||||||||||

| Rahman, Muda [118] | √ | √ | √ | √ | √ |

References

- Qin, J.; Liu, Y.; Grosvenor, R. A categorical framework of manufacturing for industry 4.0 and beyond. Procedia CIRP 2016, 52, 173–178. [Google Scholar] [CrossRef]

- Xu, X.; Lu, Y.; Vogel-Heuser, B.; Wang, L. Industry 4.0 and Industry 5.0-Inception, conception and perception. J. Manuf. Syst. 2021, 61, 530–535. [Google Scholar] [CrossRef]

- Nahavandi, S. Industry 5.0-A Human-Centric Solution. Sustainability 2019, 11, 4371. [Google Scholar] [CrossRef]

- Frederico, G.F. From supply chain 4.0 to supply chain 5.0: Findings from a systematic literature review and research directions. Logistics 2021, 5, 49. [Google Scholar] [CrossRef]

- Alexa, L.; Pîslaru, M.; Avasilcăi, S. From Industry 4.0 to Industry 5.0—An Overview of European Union Enterprises. In Sustainability and Innovation in Manufacturing Enterprises; Springer Nature: Cham, Switzerland, 2022; pp. 221–231. [Google Scholar]

- Callaghan, C.W. Transcending the threshold limitation: A fifth industrial revolution? Manag. Res. Rev. 2019, 43, 447–461. [Google Scholar] [CrossRef]

- Ghobakhloo, M. Industry 4.0, digitization, and opportunities for sustainability. J. Clean. Prod. 2020, 252, 119869. [Google Scholar] [CrossRef]

- Romero, C.A.T.; Castro, D.F.; Ortiz, J.H.; Khalaf, O.I.; Vargas, M.A. Synergy between circular economy and industry 4.0: A literature review. Sustainability 2021, 13, 4331. [Google Scholar] [CrossRef]

- Sun, X.; Yu, H.; Solvang, W.D. Industry 4.0 and Sustainable Supply Chain Management. In International Workshop of Advanced Manufacturing and Automation; Lecture Notes in Electrical Engineering; Springer: Singapore, 2021; Volume 737. [Google Scholar]

- Saniuk, S.; Grabowska, S.; Straka, M. Identification of Social and Economic Expectations: Contextual Reasons for the Transformation Process of Industry 4.0 into the Industry 5.0 Concept. Sustainability 2022, 14, 1391. [Google Scholar] [CrossRef]

- Madsen, D.Ø.; Berg, T. An exploratory bibliometric analysis of the birth and emergence of industry 5.0. Appl. Syst. Innov. 2021, 4, 87. [Google Scholar] [CrossRef]

- Sindhwani, R.; Afridi, S.; Kumar, A.; Banaitis, A.; Luthra, S.; Singh, P.L. Can industry 5.0 revolutionize the wave of resilience and social value creation? A multi-criteria framework to analyze enablers. Technol. Soc. 2022, 68, 101887. [Google Scholar] [CrossRef]

- Di Nardo, M.; Yu, H. Special issue “industry 5.0: The prelude to the sixth industrial revolution”. Appl. Syst. Innov. 2021, 4, 45. [Google Scholar] [CrossRef]

- Elangovan, U. Industry 5.0: The Future of the Industrial Economy; CRC Press: Boca Raton, FL, USA, 2022. [Google Scholar]

- Sun, X.; Yu, H.; Solvang, W.; Wang, Y.; Wang, K. The application of Industry 4.0 technologies in sustainable logistics: A systematic literature review (2012–2020) to explore future research opportunities. Environ. Sci. Pollut. Res. 2021, 29, 9560–9591. [Google Scholar] [CrossRef] [PubMed]

- Ali, I.; Phan, H.M. Industry 4.0 technologies and sustainable warehousing: A systematic literature review and future research agenda. Int. J. Logist. Manag. 2022. [Google Scholar] [CrossRef]

- Efthymiou, O.K.; Ponis, S.T. Industry 4.0 Technologies and Their Impact in Contemporary Logistics: A Systematic Literature Review. Sustainability 2021, 13, 11643. [Google Scholar] [CrossRef]

- Ivanov, D.; Dolgui, A. A digital supply chain twin for managing the disruption risks and resilience in the era of Industry 4.0. Prod. Plan. Control 2020, 32, 775–788. [Google Scholar] [CrossRef]

- Wang, K. Logistics 4.0 Solution-New Challenges and Opportunities. In 6th International Workshop of Advanced Manufacturing and Automation; Atlantis Press: Manchester, UK, 2016. [Google Scholar]

- Jagtap, S.; Bader, F.; Garcia-Garcia, G.; Trollman, H.; Fadiji, T.; Salonitis, K. Food logistics 4.0: Opportunities and challenges. Logistics 2021, 5, 2. [Google Scholar] [CrossRef]

- He, Z.; Turner, P. A Systematic Review on Technologies and Industry 4.0 in the Forest Supply Chain: A Framework Identifying Challenges and Opportunities. Logistics 2021, 5, 88. [Google Scholar] [CrossRef]

- Lee, J. Industry 4.0 in big data environment. Ger. Harting Mag. 2013, 1, 8–10. [Google Scholar]

- Kagermann, H.; Wahlster, W. Recommendations for Implementing the Strategic Initiative INDUSTRIE 4.0: Securing the Future of German Manufacturing Industry. Final Report of the Industrie 4.0 Working Group; Forschungsunion: Frankfurt, Germany, 2013. [Google Scholar]

- Rahman, H.; Rahmani, R. Enabling distributed intelligence assisted Future Internet of Things Controller (FITC). Appl. Comput. Inform. 2018, 14, 73–87. [Google Scholar] [CrossRef]

- Erboz, G. How To Define Industry 4.0: Main Pillars of Industry 4.0. In Proceedings of the 7th International Conference on Management (ICoM 2017), At Nitra, Slovakia, 1–2 June 2017. [Google Scholar]

- Huang, T.; Solvang, W.D.; Yu, H. An Introduction of Small-Scale Intelligent Manufacturing System. In 2016 International Symposium On Small-Scale Intelligent Manufacturing Systems (SIMS); IEEE: Narvik, Norway, 2016. [Google Scholar]

- Rüßmann, M.; Lorenz, M.; Gerbert, P.; Waldner, M.; Engel, P.; Harnisch, M.; Justus, J. Industry 4.0: The future of productivity and growth in manufacturing industries. Boston Consult. Group 2015, 9, 54–89. [Google Scholar]

- Azarian, M.; Yu, H.; Solvang, W.D.; Shu, B. An Introduction of the Role of Virtual Technologies and Digital Twin in Industry 4.0. In International Workshop of Advanced Manufacturing and Automation; Lecture Notes in Electrical Engineering; Springer: Singapore, 2020; Volume 634. [Google Scholar]

- Chen, D.; Heyer, S.; Ibbotson, S.; Salonitis, K.; Steingrímsson, J.G.; Thiede, S. Direct digital manufacturing: Definition, evolution, and sustainability implications. J. Clean. Prod. 2015, 107, 615–625. [Google Scholar] [CrossRef]

- Azarian, M.; Yu, H.; Solvang, W.D. Integrating Additive Manufacturing into a Virtual Industry 4.0 Factory. In International Workshop of Advanced Manufacturing and Automation; Lecture Notes in Electrical Engineering; Springer: Singapore, 2021; Volume 737. [Google Scholar]

- Doyle-Kent, M.; Kopacek, P. Industry 5.0: Is the manufacturing industry on the cusp of a new revolution? In Proceedings of the International Symposium for Production Research; Springer: Berlin/Heidelberg, Germany, 2019. [Google Scholar]

- Rada, M. INDUSTRY 5.0—From Virtual to Physical. 2015. Available online: https://www.linkedin.com/pulse/industry-50-from-virtual-physical-michael-rada/ (accessed on 25 February 2022).

- European Commission. Industry 5.0: Towards A Sustainable, Human-Centric and Resilient European Industry; Publications Office: Luxembourg, 2021. [Google Scholar]

- Saptaningtyas, W.W.E.; Rahayu, D.K. A proposed model for food manufacturing in smes: Facing industry 5.0. In Proceedings of the International Conference on Industrial Engineering and Operations Management, Dubai, UAE, 10–12 March 2020. [Google Scholar]

- Gaiardelli, S.; Spellini, S.; Lora, M.; Fummi, F. Modeling in Industry 5.0. In 2021 Forum on Specification & Design Languages (FDL); IEEE: Piscataway, NJ, USA, 2021. [Google Scholar]

- Javaid, M.; Haleem, A. Critical components of industry 5.0 towards a successful adoption in the field of manufacturing. J. Ind. Integr. Manag. 2020, 5, 327–348. [Google Scholar] [CrossRef]

- Pathak, P.; Pal, P.R.; Shrivastava, M.; Ora, M.S. Fifth revolution: Applied AI and human intelligence with cyber physical systems. Int. J. Eng. Adv. Technol. 2019, 8, 23–27. [Google Scholar]

- Demir, K.A.; Döven, G.; Sezen, B. Industry 5.0 and Human-Robot Co-working. Procedia Comput. Sci. 2019, 158, 688–695. [Google Scholar] [CrossRef]

- Barreto, L.; Amaral, A.; Pereira, T. Industry 4.0 implications in logistics: An overview. Procedia Manuf. 2017, 13, 1245–1252. [Google Scholar] [CrossRef]

- Strandhagen, j.; Vallandingham, L.R.; Fragapane, G.; Strandhagen, J.W.; Stangeland, A.B.H.; Sharma, N. Logistics 4.0 and emerging sustainable business models. Adv. Manuf. 2017, 5, 359–369. [Google Scholar] [CrossRef]

- Sutawijaya, A.H.; Nawangsari, L.C. What is the impact of industry 4.0 to green supply chain. J. Environ. Treat. Tech. 2020, 8, 207–213. [Google Scholar]

- Tjahjono, B.; Esplugues, C.; Ares, E.; Pelaez, G. What does industry 4.0 mean to supply chain? Procedia Manuf. 2017, 13, 1175–1182. [Google Scholar] [CrossRef]

- Yu, H. Enhancing the competitiveness of manufacturers through Small-scale Intelligent Manufacturing System (SIMS): A supply chain perspective. In 2017 6th International Conference on Industrial Technology and Management (ICITM); IEEE: Piscataway, NJ, USA, 2017. [Google Scholar]

- Liu, X.; Cao, J.; Yang, Y.; Jiang, S. CPS-based smart warehouse for industry 4.0: A survey of the underlying technologies. Computers 2018, 7, 13. [Google Scholar] [CrossRef]

- Okoli, C.; Schabram, K. A Guide to Conducting A Systematic Literature Review of Information Systems Research. SSRN Electron. J. 2010. [Google Scholar] [CrossRef]

- Templier, M.; Paré, G. A framework for guiding and evaluating literature reviews. Commun. Assoc. Inf. Syst. 2015, 37, 6. [Google Scholar] [CrossRef]

- Fink, A. Conducting Research Literature Reviews: From the Internet to Paper; Sage Publications: Thousand Oaks, CA, USA, 2019. [Google Scholar]

- Evangelista, P.; Durst, S. Knowledge management in environmental sustainability practices of third-party logistics service providers. Vine 2015, 45, 509–529. [Google Scholar] [CrossRef]

- Xiao, Y.; Watson, M. Guidance on conducting a systematic literature review. J. Plan. Educ. Res. 2019, 39, 93–112. [Google Scholar] [CrossRef]

- Kazemi, N.; Modak, N.M.; Govindan, K. A review of reverse logistics and closed loop supply chain management studies published in IJPR: A bibliometric and content analysis. Int. J. Prod. Res. 2019, 57, 4937–4960. [Google Scholar] [CrossRef]

- Ren, R.; Hu, W.; Dong, J.; Sun, B.; Chen, Y.; Chen, Z. A systematic literature review of green and sustainable logistics: Bibliometric analysis, research trend and knowledge taxonomy. Int. J. Environ. Res. Public Health 2020, 17, 261. [Google Scholar] [CrossRef]

- Gusenbauer, M.; Haddaway, N.R. Which academic search systems are suitable for systematic reviews or meta–analyses? Evaluating retrieval qualities of Google Scholar, PubMed, and 26 other resources. Res. Synth. Methods 2020, 11, 181–217. [Google Scholar] [CrossRef]

- Martynov, V.V.; Shavaleeva, D.N.; Zaytseva, A.A. Information Technology as the Basis for Transformation into a Digital Society and Industry 5.0. In Proceedings of the 2019 IEEE International Conference Quality Management, Transport and Information Security, Information Technologies IT and QM and IS 2019, Sochy, Russia, 22–23 September 2019. [Google Scholar]

- Donthu, N.; Kumar, S.; Mukherjee, D.; Pandey, N.; Lim, W.M. How to conduct a bibliometric analysis: An overview and guidelines. J. Bus. Res. 2021, 133, 285–296. [Google Scholar] [CrossRef]

- Van Eck, N.; Waltman, L. Software survey: VOSviewer, a computer program for bibliometric mapping. Scientometrics 2010, 84, 523–538. [Google Scholar] [CrossRef]

- Kumar, R.; Gupta, P.; Singh, S.; Jain, D. Human Empowerment by Industry 5.0 in Digital Era: Analysis of Enablers. In Lecture Notes in Mechanical Engineering; Springer: Singapore, 2021; pp. 401–410. [Google Scholar]

- Martynov, V.; Shiryaev, O.; Zaytseva, A.; Filosova, E.; Baikov, R. The Use of Artificial Intelligence in Modern Educational Technologies in the Transition to a Smart Society. In Proceedings of the 2019 21st International Conference “Complex Systems: Control and Modeling Problems”, CSCMP 2019, Samara, Russia, 3–6 September 2019. [Google Scholar]

- Mihardjo, L.W.W.; Sasmoko, S.; Alamsjah, F.; Djap, E. Boosting the firm transformation in industry 5.0: Experience-agility innovation model. Int. J. Recent Technol. Eng. 2019, 8, 735–742. [Google Scholar]

- Carayannis, E.G.; Dezi, L.; Gregori, G.; Calò, E. Smart Environments and Techno-centric and Human-Centric Innovations for Industry and Society 5.0: A Quintuple Helix Innovation System View Towards Smart, Sustainable, and Inclusive Solutions. J. Knowl. Econ. 2021. [Google Scholar] [CrossRef]

- Imperatives, S. Report of the World Commission on Environment and Development: Our Common Future. 1987. Available online: https://sustainabledevelopment.un.org/content/documents/5987our-common-future.pdf (accessed on 25 February 2022).

- Yu, H.; Solvang, W.D. A general reverse logistics network design model for product reuse and recycling with environmental considerations. Int. J. Adv. Manuf. Technol. 2016, 87, 2693–2711. [Google Scholar] [CrossRef]

- Yu, H.; Solvang, W. A Stochastic Programming Approach with Improved Multi-Criteria Scenario-Based Solution Method for Sustainable Reverse Logistics Design of Waste Electrical and Electronic Equipment (WEEE). Sustainability 2016, 8, 1331. [Google Scholar] [CrossRef]

- Patera, L.; Garbugli, A.; Bujari, A.; Scotece, D.; Corradi, A. A layered middleware for ot/it convergence to empower industry 5.0 applications. Sensors 2022, 22, 190. [Google Scholar] [CrossRef] [PubMed]

- Butner, K.; Ho, G. How the human-machine interchange will transform business operations. Strategy Leadersh. 2019, 47, 25–33. [Google Scholar] [CrossRef]

- Mekid, S.; Schlegel, T.; Aspragathos, N.; Teti, R. Foresight formulation in innovative production, automation and control systems. Foresight 2007, 9, 35–47. [Google Scholar] [CrossRef]

- Pagliosa, M.; Tortorella, G.; Ferreira, J.C.E. Industry 4.0 and Lean Manufacturing: A systematic literature review and future research directions. J. Manuf. Technol. Manag. 2019, 32, 543–569. [Google Scholar] [CrossRef]

- Romero, D.; Bernus, P.; Noran, O.; Stahre, J.; Fast-Berglund, Å. The operator 4.0: Human cyber-physical systems. In IFIP International Conference on Advances in Production Management Systems; Springer: Berlin/Heidelberg, Germany, 2016. [Google Scholar]

- David, R.; Stahre, J.; Wuest, T.; Noran, O.; Bernus, P.; Berglund, Å.F.; Gorecky, D. Towards an operator 4.0 typology: A human-centric perspective on the fourth industrial revolution technologies. In Proceedings of the international conference on computers and industrial engineering (CIE46), Tianjin, China, 29–31 October 2016. [Google Scholar]

- Cimini, C.; Lagorio, A.; Romero, D.; Cavalieri, S.; Stahre, J. Smart Logistics and The Logistics Operator 4.0. IFAC PapersOnLine 2020, 53, 10615–10620. [Google Scholar] [CrossRef]

- Romero, D.; Stahre, J. Towards the Resilient Operator 5.0: The Future of Work in Smart Resilient Manufacturing Systems. Procedia CIRP 2021, 104, 1089–1094. [Google Scholar] [CrossRef]

- Resende, A.; Cerqueira, S.; Barbosa, J.; Damásio, E.; Pombeiro, A.; Silva, A.; Santos, C. Ergowear: An ambulatory, non-intrusive, and interoperable system towards a Human-Aware Human-robot Collaborative framework. In Proceedings of the 2021 IEEE International Conference on Autonomous Robot Systems and Competitions, ICARSC, Santa Maria da Feira, Portugal, 28–29 April 2021. [Google Scholar]

- Welfare, K.S.; Hallowell, M.R.; Shah, J.A.; Riek, L.D. Consider the human work experience when integrating robotics in the workplace. In 2019 14th ACM/IEEE International Conference on Human-Robot Interaction (HRI); IEEE: Piscataway, NJ, USA, 2019. [Google Scholar]

- Hol, A. Business Transformations Within Intelligent Eco-Systems. Lect. Notes Netw. Syst. 2021, 149, 275–284. [Google Scholar] [CrossRef]

- Inagaki, T. Adaptive automation: Sharing and trading of control. Handb. Cogn. Task Des. 2003, 8, 147–169. [Google Scholar]

- Doyle-Kent, M.; Kopacek, P. Collaborative Robotics Making a Difference in the Global Pandemic. Lect. Notes Mech. Eng. 2022, 161–169. [Google Scholar] [CrossRef]

- Rega, A.; Di Marino, C.; Pasquariello, A.; Vitolo, F.; Patalano, S.; Zanella, A.; Lanzotti, A. Collaborative workplace design: A knowledge-based approach to promote human–robot collaboration and multi-objective layout optimization. Appl. Sci. 2021, 11, 12147. [Google Scholar] [CrossRef]

- Nagyova, A.; Kotianova, Z.; Glatz, J.; Sinay, J. Human Failures on Production Line as a Source of Risk of Non-conformity Occurrence. In Advances in Intelligent Systems and Computing; IEEE: Piscataway, NJ, USA, 2020; pp. 97–103. [Google Scholar]

- Fornasiero, R.; Zangiacomi, A. Reshaping the Supply Chain for Society 5.0. In IFIP Advances in Information and Communication Technology; Springer International Publishing: Cham, Switzerland, 2021; pp. 663–670. [Google Scholar]

- Doyle Kent, M.; Kopacek, P. Do We Need Synchronization of the Human and Robotics to Make Industry 5.0 a Success Story. In Digital Conversion on the Way to Industry 4.0; Springer International Publishing: Cham, Switzerland, 2021. [Google Scholar]

- Doyle-Kent, M.; Kopacek, P. Adoption of collaborative robotics in industry 5.0. An Irish industry case study. IFAC-PapersOnLine 2021, 54, 413–418. [Google Scholar] [CrossRef]

- Jabrane, K.; Bousmah, M. A New Approach for Training Cobots from Small Amount of Data in Industry 5.0. Int. J. Adv. Comput. Sci. Appl. 2021, 12, 634–646. [Google Scholar] [CrossRef]

- Kavousi-Fard, A.; Khosravi, A.; Nahavandi, S. A new fuzzy-based combined prediction interval for wind power forecasting. IEEE Trans. Power Syst. 2015, 31, 18–26. [Google Scholar] [CrossRef]

- Khosravi, A.; Nahavandi, S.; Creighton, D. Prediction interval construction and optimization for adaptive neurofuzzy inference systems. IEEE Trans. Fuzzy Syst. 2011, 19, 983–988. [Google Scholar] [CrossRef]

- Khosravi, A.; Nahavandi, S.; Creighton, D. Prediction intervals for short-term wind farm power generation forecasts. IEEE Trans. Sustain. Energy 2013, 4, 602–610. [Google Scholar] [CrossRef]

- Nguyen, T.; Khosravi, A.; Creighton, D.; Nahavandi, S. Spike sorting using locality preserving projection with gap statistics and landmark-based spectral clustering. J. Neurosci. Methods 2014, 238, 43–53. [Google Scholar] [CrossRef]

- Zhou, H.; Kong, H.; Wei, L.; Creighton, D.; Nahavandi, S. Efficient road detection and tracking for unmanned aerial vehicle. IEEE Trans. Intell. Transp. Syst. 2014, 16, 297–309. [Google Scholar] [CrossRef]

- Crutzen, C.K. Intelligent Ambience between Heaven and Hell: A Salvation? J. Inf. Commun. Ethics Soc. 2005, 3, 219–232. [Google Scholar] [CrossRef]

- Matindoust, S.; Nejad, M.B.; Zou, Z.; Zheng, L.R. Food quality and safety monitoring using gas sensor array in intelligent packaging. Sens. Rev. 2016, 36, 169–183. [Google Scholar] [CrossRef]

- Shammar, E.A.; Zahary, A.T. The Internet of Things (IoT): A survey of techniques, operating systems, and trends. Library Hi Tech 2019, 38, 5–66. [Google Scholar] [CrossRef]

- Sreekumar, M.; Nagarajan, T.; Singaperumal, M.; Zoppi, M.; Molfino, R. Critical review of current trends in shape memory alloy actuators for intelligent robots. Ind. Robot. Int. J. 2007, 34, 285–294. [Google Scholar] [CrossRef]

- Brunzini, A.; Brunzini, A.; Grandi, F.; Khamaisi, R.K.; Pellicciari, M. A preliminary experimental study on the workers’ workload assessment to design industrial products and processes. Appl. Sci. 2021, 11, 12066. [Google Scholar] [CrossRef]

- Ávila-Gutiérrez, M.J.; Aguayo-González, F.; Lama-Ruiz, J.R. Framework for the development of affective and smart manufacturing systems using sensorised surrogate models. Sensors 2021, 21, 2274. [Google Scholar] [CrossRef] [PubMed]

- Longo, F.; Padovano, A.; Umbrello, S. Value-oriented and ethical technology engineering in industry 5.0: A human-centric perspective for the design of the factory of the future. Appl. Sci. 2020, 10, 4182. [Google Scholar] [CrossRef]

- Puvvada, Y.S.; Vankayalapati, S.; Sukhavasi, S. Extraction of chitin from chitosan from exoskeleton of shrimp for application in the pharmaceutical industry. Int. Curr. Pharm. J. 2012, 1, 258–263. [Google Scholar] [CrossRef]

- Spada, S.; Ghibaudo, L.; Gilotta, S.; Gastaldi, L.; Cavatorta, M. Analysis of exoskeleton introduction in industrial reality: Main issues and EAWS risk assessment. In International Conference on Applied Human Factors and Ergonomics; Springer: Berlin/Heidelberg, Germany, 2017. [Google Scholar]

- Sung, T.K. Industry 4.0: A Korea perspective. Technol. Forecast. Soc. Change 2018, 132, 40–45. [Google Scholar] [CrossRef]

- Sylla, N.; Bonnet, V.; Colledani, F.; Fraisse, P. Ergonomic contribution of ABLE exoskeleton in automotive industry. Int. J. Ind. Ergon. 2014, 44, 475–481. [Google Scholar] [CrossRef]

- Coelho, J.F.; Ferreira, P.C.; Alves, P.; Cordeiro, R.; Fonseca, A.C.; Góis, J.R.; Gil, M.H. Drug delivery systems: Advanced technologies potentially applicable in personalized treatments. EPMA J. 2010, 1, 164–209. [Google Scholar] [CrossRef]

- Goole, J.; Amighi, K. 3D printing in pharmaceutics: A new tool for designing customized drug delivery systems. Int. J. Pharm. 2016, 499, 376–394. [Google Scholar] [CrossRef] [PubMed]

- Fraga-Lamas, P.; Varela-Barbeito, J.; Fernandez-Carames, T.M. Next Generation Auto-Identification and Traceability Technologies for Industry 5.0: A Methodology and Practical Use Case for the Shipbuilding Industry. IEEE Access 2021, 9, 140700–140730. [Google Scholar] [CrossRef]

- Cao, Y.; You, J.; Shi, Y.; Hu, W. The obstacles of China’s intelligent automobile manufacturing industry development: A structural equation modeling study. Chin. Manag. Stud. 2020, 14, 159–183. [Google Scholar] [CrossRef]

- Rogale, S.F.; Rogale, D.; Dragčević, Z.; Nikolić, G.; Bartoš, M. Technical systems in intelligent clothing with active thermal protection. Int. J. Cloth. Sci. Technol. 2007, 19, 222–233. [Google Scholar] [CrossRef]

- Sakamoto, S.; Barolli, A.; Barolli, L.; Okamoto, S. Implementation of a Web interface for hybrid intelligent systems: A comparison study of two hybrid intelligent systems. Int. J. Web Inf. Syst. 2019, 15, 420–431. [Google Scholar] [CrossRef]

- Sykora, M. Engineering social media driven intelligent systems through crowdsourcing: Insights from a financial news summarisation system. J. Syst. Inf. Technol. 2016, 18, 255–276. [Google Scholar] [CrossRef]

- Xie, K.; Liu, Z.; Fu, L.; Liang, B. Internet of Things-based intelligent evacuation protocol in libraries. Library Hi Tech 2019, 38, 145–163. [Google Scholar] [CrossRef]

- Kumar, R. Sustainable supply chain management in the era of digitialization: Issues and challenges. In Handbook of Research on Social and Organizational Dynamics in the Digital Era; IGI Global: Hershey, PA, USA, 2020; pp. 446–460. [Google Scholar]

- Kumar, R. Espousal of Industry 4.0 in Indian manufacturing organizations: Analysis of enablers. In Research Anthology on Cross-Industry Challenges of Industry 4.0; IGI Global: Hershey, PA, USA, 2021; pp. 1244–1251. [Google Scholar]

- Paschek, D.; Mocan, A.; Draghici, A. Industry 5.0—The expected impact of next industrial revolution. In Proceedings of the Thriving on Future Education, Industry, Business, and Society, Proceedings of the MakeLearn and TIIM International Conference, Piran, Slovenia, 15–17 May 2019. [Google Scholar]

- Skobelev, P.; Borovik, S.Y. On the way from Industry 4.0 to Industry 5.0: From digital manufacturing to digital society. Industry 4.0 2017, 2, 307–311. [Google Scholar]

- Thakur, P.; Kumar Sehgal, V. Emerging architecture for heterogeneous smart cyber-physical systems for industry 5.0. Comput. Ind. Eng. 2021, 162, 107750. [Google Scholar] [CrossRef]

- Golov, R.S.; Palamarchuk, A.G.; Anisimov, K.V.; Andrianov, A.M. Cluster Policy in a Digital Economy. Russ. Eng. Res. 2021, 41, 631–633. [Google Scholar] [CrossRef]

- Zhu, C.; Leung, V.C.M.; Shu, L.; Ngai, E.C.-H. Green Internet of Things for Smart World. IEEE Access 2015, 3, 2151–2162. [Google Scholar] [CrossRef]

- Fraga-Lamas, P.; Lopes, S.I.; Fernández-Caramés, T.M. Green iot and edge AI as key technological enablers for a sustainable digital transition towards a smart circular economy: An industry 5.0 use case. Sensors 2021, 21, 5745. [Google Scholar] [CrossRef] [PubMed]

- Pramanik, P.K.D.; Mukherjee, B.; Pal, S.; Upadhyaya, B.K.; Dutta, S. Ubiquitous manufacturing in the age of industry 4.0: A state-of-the-art primer. In A Roadmap to Industry 4.0: Smart Production, Sharp Business and Sustainable Development; Springer: Berlin/Heidelberg, Germany, 2020; pp. 73–112. [Google Scholar]

- Puthal, D.; Malik, N.; Mohanty, S.P.; Kougianos, E.; Das, G. Everything you wanted to know about the blockchain: Its promise, components, processes, and problems. IEEE Consum. Electron. Mag. 2018, 7, 6–14. [Google Scholar] [CrossRef]

- Samaniego, M.; Deters, R. Virtual Resources & Blockchain for Configuration Management in IoT. J. Ubiquitous Syst. Pervasive Netw. 2018, 9, 1–13. [Google Scholar]

- Carayannis, E.G.; Christodoulou, K.; Christodoulou, P.; Chatzichristofis, S.A.; Zinonos, Z. Known Unknowns in an Era of Technological and Viral Disruptions—Implications for Theory, Policy, and Practice. J. Knowl. Econ. 2021, 2021, 1–24. [Google Scholar] [CrossRef]

- Rahman, N.A.A.; Muda, J.; Mohammad, M.F.; Ahmad, M.F.; Rahim, S.A.; Mayor-Vitoria, F. Digitalization and leap frogging strategy among the supply chain member: Facing GIG economy and why should logistics players care? Int. J. Supply Chain. Manag. 2019, 8, 1042–1048. [Google Scholar]

- Bathla, G.; Singh, P.; Kumar, S.; Verma, M.; Garg, D.; Kotecha, K. Recop: Fine-grained opinions and sentiments-based recommender system for industry 5.0. Soft Comput. 2021. [Google Scholar] [CrossRef]

- Matsuda, M.; Nishi, T.; Hasegawa, M.; Matsumoto, S. Virtualization of a supply chain from the manufacturing enterprise view using e-catalogues. Procedia CIRP 2019, 81, 932–937. [Google Scholar] [CrossRef]

- Nahavandi, S.; Preece, C. A virtual manufacturing environment with an element of reality. Proceedings of Fourth International Conference on Factory 2000—Advanced Factory Automation, York, UK, 3–5 October 1994. [Google Scholar]

- Sulema, Y. ASAMPL: Programming language for mulsemedia data processing based on algebraic system of aggregates. In Interactive Mobile Communication, Technologies and Learning; Springer: Berlin/Heidelberg, Germany, 2017. [Google Scholar]

- Hakanen, E.; Rajala, R. Material intelligence as a driver for value creation in IoT-enabled business ecosystems. J. Bus. Ind. Mark. 2018, 33, 857–867. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A. Industry 4.0 applications in medical field: A brief review. Curr. Med. Res. Pract. 2019, 9, 102–109. [Google Scholar] [CrossRef]

- Li, X.; Shang, J.; Wang, Z. Intelligent materials: A review of applications in 4D printing. Assem. Autom. 2017, 37, 170–185. [Google Scholar] [CrossRef]

- Yang, X.; Ma, C.; Zhu, C.; Qi, B.; Pan, F.; Zhu, C. Design of hazardous materials transportation safety management system under the vehicle-infrastructure connected environment. J. Intell. Connect. Veh. 2019, 2, 14–24. [Google Scholar] [CrossRef]

- Pei, E. 4D Printing: Dawn of an emerging technology cycle. Assem. Autom. 2014, 34, 310–314. [Google Scholar] [CrossRef]

- Pei, E.; Loh, G.H.; Harrison, D.; De Almeida, H.; Verona, M.D.M.; Paz, R. A study of 4D printing and functionally graded additive manufacturing. Assem. Autom. 2017, 37, 147–153. [Google Scholar] [CrossRef]

- Ranney, M.L.; Griffeth, V.; Jha, A.K. Critical supply shortages—The need for ventilators and personal protective equipment during the Covid-19 pandemic. N. Engl. J. Med. 2020, 382, e41. [Google Scholar] [CrossRef]

- Yu, H.; Sun, X.; Solvang, W.D.; Zhao, X. Reverse logistics network design for effective management of medical waste in epidemic outbreaks: Insights from the coronavirus disease 2019 (COVID-19) outbreak in Wuhan (China). Int. J. Environ. Res. Public Health 2020, 17, 1770. [Google Scholar] [CrossRef]

- Duggal, A.S.; Malik, P.K.; Gehlot, A.; Singh, R.; Gaba, G.S.; Masud, M.; Al-Amri, J. A sequential roadmap to Industry 6.0: Exploring future manufacturing trends. IET Commun. 2021, 16, 1751–8628. [Google Scholar] [CrossRef]

- Gürdür Broo, D.; Kaynak, O.; Sait, S.M. Rethinking engineering education at the age of industry 5.0. J. Ind. Inf. Integr. 2022, 25, 100311. [Google Scholar] [CrossRef]

- Zhang, X.; Hu, B.; Xiong, G.; Liu, X.; Dong, X.; Li, D. Research and practice of lightweight digital twin speeding up the implementation of flexible manufacturing systems. In Proceedings of the 2021 IEEE 1st International Conference on Digital Twins and Parallel Intelligence, DTPI, Beijing, China, 15 July–15 August 2021. [Google Scholar]

| Main Category (‘AND’ Boolean Operator) | Sub-Keywords (‘OR’ Boolean Operator) |

|---|---|

| Smart Logistics | smart logistics; logistics 4.0; smart supply chain; supply chain 4.0; operator 4.0 |

| Industry 4.0 | industry 4.0; i4.0; fourth industrial revolution; cyber-physical system; internet of things; cloud computing; augmented reality; big data analytics; artificial intelligence; virtual technology; simulation; additive manufacturing; autonomous robots; cyber security; digital twin |

| Technological Enabler of Smart Logistics | Source Title | No. Items |

|---|---|---|

| Industry 4.0 | IFIP Advances in Information and Communication Technology | 7 |

| Computers & Industrial Engineering | 5 | |

| IFAC-PapersOnline | 5 | |

| Procedia Manufacturing | 3 | |

| Industry 5.0 | Lecture Notes in Mechanical Engineering | 4 |

| Applied Sciences Switzerland | 3 | |

| Sensors | 3 | |

| Journal of The Knowledge Economy | 2 |

| Cluster | Source Title | TLS | Features |

|---|---|---|---|

| Cluster 1 | International Journal of Production Research | 1176 | The application of computerized technologies in manufacturing and operation research |

| Computers in Industry | 641 | ||

| International Journal of Production Economics | 625 | ||

| Cluster 2 | Computers & Industrial Engineering | 541 | Role of technology in manufacturing and logistics |

| International Journal of Advanced Manufacturing Technology | 390 | ||

| Cluster 3 | Procedia Manufacturing | 780 | Manufacturing engineering, processes, and automation |

| Procedia CIRP | 671 | ||

| IFAC-PapersOnline | 544 |

| Cluster | Source Title | TLS | Features |

|---|---|---|---|

| Cluster 1 | Assembly Automation | 241 | An inter-disciplinary combination of manufacturing technologies and information management |

| Journal of Industrial Information Integration | 224 | ||

| Journal of Industrial Integration and Management | 217 | ||

| Industrial Robot | 192 | ||

| Cluster 2 | Sensors | 195 | An inter-disciplinary readership with a focus on engineering, social, human, economic, and environmental aspects |

| IEEE Access | 184 | ||

| Sustainability (Switzerland) | 171 | ||

| Cluster 3 | Applied Sciences Switzerland | 102 | Manufacturing engineering and technology management |

| Procedia CIRP | 69 | ||

| Computers & Industrial Engineering | 66 |

| No. | Industry 4.0 | Industry 5.0 | ||||

|---|---|---|---|---|---|---|

| Keyword | Occur. | TLS | Keyword | Occur. | TLS | |

| 1 | Industry 4.0 | 32 | 123 | Industry 5.0 | 33 | 116 |

| 2 | Internet | 13 | 58 | Industry 4.0 | 20 | 84 |

| 3 | Operator 4.0 | 13 | 42 | Industrial Revolutions | 6 | 30 |

| 4 | Big Data | 5 | 31 | Robotics | 5 | 29 |

| 5 | Future | 4 | 30 | Artificial Intelligence | 6 | 25 |

| 6 | Design | 5 | 27 | Manufacturing | 4 | 25 |

| 7 | Industry | 4 | 27 | Smart Manufacturing | 4 | 23 |

| 8 | Logistics 4.0 | 10 | 26 | Internet of Things | 5 | 22 |

| 9 | Internet of things | 6 | 24 | Human–Robot Collaboration | 4 | 21 |

| 10 | Things | 6 | 24 | Industrial Research | 4 | 18 |

| 11 | Logistics | 6 | 23 | Collaborative Robots | 3 | 16 |

| 12 | Framework | 3 | 21 | Design and Development | 3 | 16 |

| 13 | Performance | 4 | 21 | Man–Machine Systems | 3 | 16 |

| 14 | Smart Logistics | 6 | 19 | Manufacture | 2 | 16 |

| 15 | Augmented Reality | 3 | 17 | Technology | 3 | 16 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jefroy, N.; Azarian, M.; Yu, H. Moving from Industry 4.0 to Industry 5.0: What Are the Implications for Smart Logistics? Logistics 2022, 6, 26. https://doi.org/10.3390/logistics6020026

Jefroy N, Azarian M, Yu H. Moving from Industry 4.0 to Industry 5.0: What Are the Implications for Smart Logistics? Logistics. 2022; 6(2):26. https://doi.org/10.3390/logistics6020026

Chicago/Turabian StyleJefroy, Niloofar, Mathew Azarian, and Hao Yu. 2022. "Moving from Industry 4.0 to Industry 5.0: What Are the Implications for Smart Logistics?" Logistics 6, no. 2: 26. https://doi.org/10.3390/logistics6020026

APA StyleJefroy, N., Azarian, M., & Yu, H. (2022). Moving from Industry 4.0 to Industry 5.0: What Are the Implications for Smart Logistics? Logistics, 6(2), 26. https://doi.org/10.3390/logistics6020026