Waste Collection Optimisation: A Path to a Green and Sustainable City of Makkah

Abstract

:1. Introduction

2. Literature Review

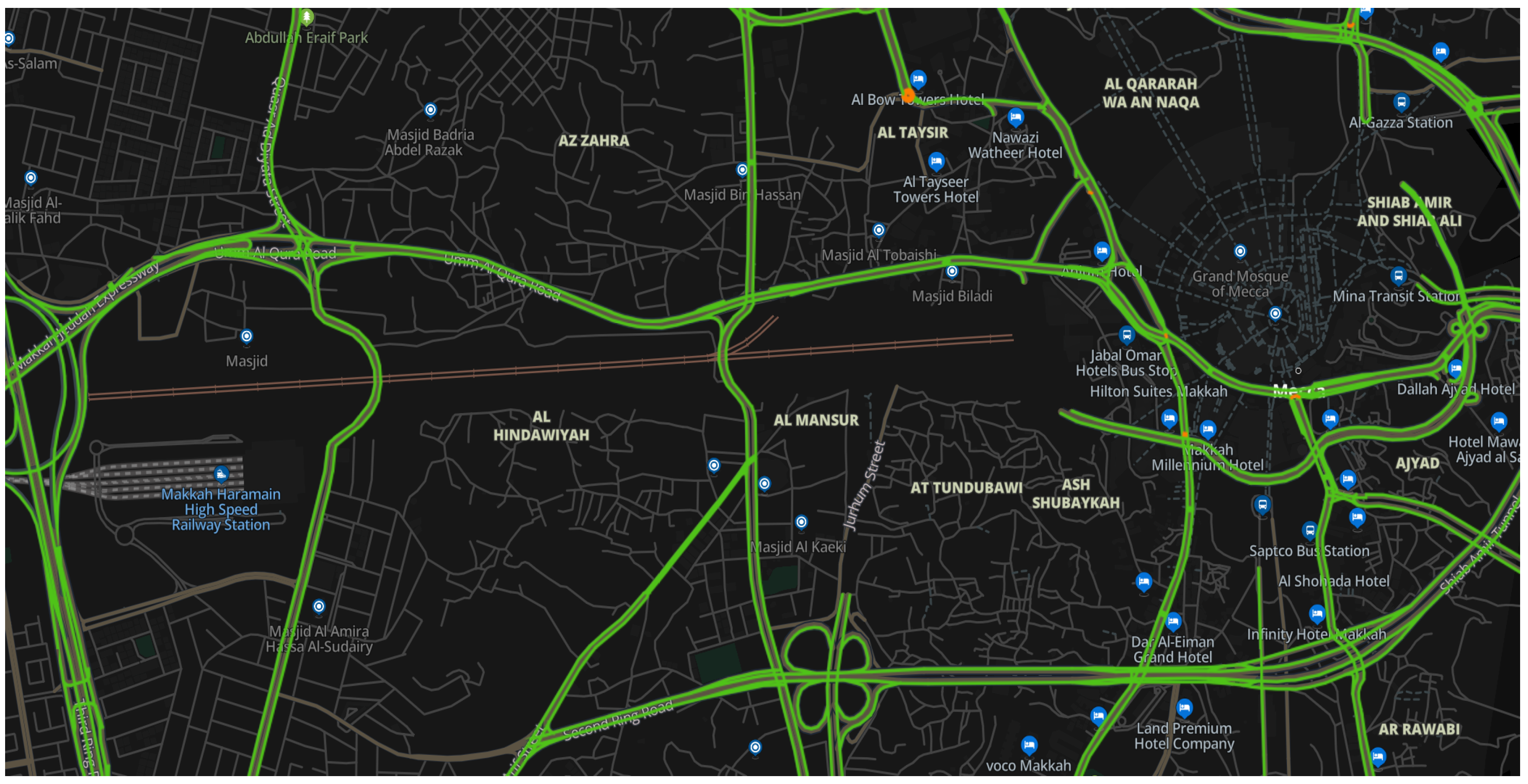

3. Problem Description

Constraints and Objectives

4. Computational Experiments

| Algorithm 1. The time-oriented nearest neighbour heuristic |

|

5. Conclusions

- Investigating different constructive heuristics to better understand how we can employ metaheuristics more effectively to tackle SWCPs [36].

- There could be consideration of more realistic versions of these problem scenarios, such as considering different waste types, container load levels, or various truck capacities.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Saudi and Middle East Green Initiatives. Available online: https://www.saudigreeninitiative.org/ (accessed on 31 January 2022).

- A Sustainable Saudi Vision. Vision 2030. Available online: https://www.vision2030.gov.sa/v2030/a-sustainable-saudi-vision/ (accessed on 31 January 2022).

- Department of Economic and Social Affairs. Goal 7. Available online: https://sdgs.un.org/goals/goal7 (accessed on 31 January 2022).

- Vergara, S.E.; Tchobanoglous, G. Municipal solid waste and the environment: A global perspective. Annu. Rev. Environ. Resour. 2012, 37, 277–309. [Google Scholar] [CrossRef]

- Shukla, S.; Hait, S. Smart waste management practices in smart cities: Current trends and future perspectives. In Advanced Organic Waste Management; Elsevier: Amsterdam, The Netherlands, 2022; pp. 407–424. [Google Scholar]

- Karimi, N.; Ng, K.T.W.; Richter, A. Development of a regional solid waste management framework and its application to a prairie province in central Canada. Sustain. Cities Soc. 2022, 82, 103904. [Google Scholar] [CrossRef]

- Environmental Protection Agency. Available online: https://www.epa.gov/greenvehicles/fast-facts-transportation-greenhouse-gas-emissions (accessed on 31 January 2022).

- Erdem, M. Optimisation of sustainable urban recycling waste collection and routing with heterogeneous electric vehicles. Sustain. Cities Soc. 2022, 80, 103785. [Google Scholar] [CrossRef]

- Ahmad, S.; Imran; Jamil, F.; Iqbal, N.; Kim, D. Optimal route recommendation for waste carrier vehicles for efficient waste collection: A step forward towards sustainable cities. IEEE Access 2020, 8, 77875–77887. [Google Scholar] [CrossRef]

- Febria, J.; Dewi, C.; Mailoa, E. Optimization of capacitated vehicle routing problem using initial route with same size K-means and greedy algorithm for vaccines distribution. Int. J. Appl. Sci. Eng. 2021, 18, 1–9. [Google Scholar] [CrossRef]

- Dotoli, M.; Epicoco, N. A vehicle routing technique for hazardous waste collection. IFAC-PapersOnLine 2017, 50, 9694–9699. [Google Scholar] [CrossRef]

- Wu, H.; Tao, F.; Yang, B. Optimization of vehicle routing for waste collection and transportation. Int. J. Environ. Res. Public Health 2020, 17, 4963. [Google Scholar] [CrossRef]

- Lella, J.; Mandla, V.R.; Zhu, X. Solid waste collection/transport optimization and vegetation land cover estimation using Geographic Information System (GIS): A case study of a proposed smart-city. Sustain. Cities Soc. 2017, 35, 336–349. [Google Scholar] [CrossRef]

- Hannan, M.; Begum, R.; Al-Shetwi, A.Q.; Ker, P.; Al Mamun, M.; Hussain, A.; Basri, H.; Mahlia, T. Waste collection route optimisation model for linking cost saving and emission reduction to achieve sustainable development goals. Sustain. Cities Soc. 2020, 62, 102393. [Google Scholar] [CrossRef]

- Radwan, N.; Khan, N.A.; Elmanfaloty, R.A.G. Optimization of solid waste collection using RSM approach, and strategies delivering sustainable development goals (SDG’s) in Jeddah, Saudi Arabia. Sci. Rep. 2021, 11, 16612. [Google Scholar] [CrossRef]

- Hannan, M.; Lipu, M.H.; Akhtar, M.; Begum, R.; Al Mamun, M.A.; Hussain, A.; Mia, M.; Basri, H. Solid waste collection optimization objectives, constraints, modeling approaches, and their challenges toward achieving sustainable development goals. J. Clean. Prod. 2020, 277, 123557. [Google Scholar] [CrossRef]

- Islam, R.; Rahman, M.S. An ant colony optimization algorithm for waste collection vehicle routing with time windows, driver rest period and multiple disposal facilities. In Proceedings of the 2012 International Conference on Informatics, Electronics & Vision (ICIEV), Dhaka, Bangladesh, 18–19 May 2012; IEEE: Piscatway, NJ, USA, 2012; pp. 774–779. [Google Scholar]

- Agacsapan, B.; Cabuk, S.N. Determination of suitable waste transfer station areas for sustainable territories: Eskisehir case. Sustain. Cities Soc. 2020, 52, 101829. [Google Scholar] [CrossRef]

- Hannan, M.; Akhtar, M.; Begum, R.; Basri, H.; Hussain, A.; Scavino, E. Capacitated vehicle-routing problem model for scheduled solid waste collection and route optimization using PSO algorithm. Waste Manag. 2018, 71, 31–41. [Google Scholar] [CrossRef]

- Samanlioglu, F. A multi-objective mathematical model for the industrial hazardous waste location-routing problem. Eur. J. Oper. Res. 2013, 226, 332–340. [Google Scholar] [CrossRef]

- Abdullahi, H.; Reyes-Rubiano, L.; Ouelhadj, D.; Faulin, J.; Juan, A.A. Modelling and multi-criteria analysis of the sustainability dimensions for the green vehicle routing problem. Eur. J. Oper. Res. 2021, 292, 143–154. [Google Scholar] [CrossRef]

- Guloyan, G.; Aydin, R. Optimization of capacitated vehicle routing problem for recyclable solid waste collection using genetic and seed genetic algorithms hybridized with greedy algorithm. In Proceedings of the 2020 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Singapore, 14–17 December 2020; IEEE: Piscatway, NJ, USA, 2020; pp. 595–599. [Google Scholar]

- Zhao, Z.; Zhou, M.; Liu, S. Iterated greedy algorithms for flow-shop scheduling problems: A tutorial. IEEE Trans. Autom. Sci. Eng. 2021, 19, 1941–1959. [Google Scholar] [CrossRef]

- Mahendran, G.; Sathiskumar, M.; Thiruvenkadam, S.; Lakshminarasimman, L. Multi-objective unbalanced distribution network reconfiguration through hybrid heuristic algorithm. J. Electr. Eng. Technol. 2013, 8, 215–222. [Google Scholar] [CrossRef]

- Mat, N.A.; Benjamin, A.M.; Abdul-Rahman, S.; Wibowo, A. Nearest greedy for solving the waste collection vehicle routing problem: A case study. AIP Conf. Proc. 2017, 1905, 040018. [Google Scholar]

- Elgammal, I.; Alhothali, G.T. Towards Green Pilgrimage: A Framework For Action in Makkah, Saudi Arabia. Int. J. Relig. Tour. Pilgr. 2021, 9, 39–57. [Google Scholar]

- The General Authority for Statistics (GAStat). Population in Makkah Region by Gender, Age Group, and Nationality (Saudi/Non-Saudi). Available online: https://www.stats.gov.sa/en/5723 (accessed on 31 January 2022).

- Alhothali, G.T.; Mavondo, F.; Elgammal, I. Sustainability of religious travel and tourism: A profile deviation perspective. J. Islam. Mark. 2022, 14, 1551–1576. [Google Scholar] [CrossRef]

- Kallehauge, B.; Larsen, J.; Madsen, O.B.; Solomon, M.M. Vehicle Routing Problem with Time Windows; Springer: Berlin, Germany, 2005. [Google Scholar]

- Toth, P.; Vigo, D. The Vehicle Routing Problem; SIAM: Philadelphia, PA, USA, 2002. [Google Scholar]

- Ralphs, T.K.; Kopman, L.; Pulleyblank, W.R.; Trotter, L.E. On the capacitated vehicle routing problem. Math. Program. 2003, 94, 343–359. [Google Scholar] [CrossRef]

- Gurobi Optimization. Gurobi 7.5 User’s Manual; Gurobi: Beaverton, OR, USA, 2017. [Google Scholar]

- Google. Route. Schedule. Plan. Assign. Pack. Solve. OR-Tools is Fast and Portable Software for Combinatorial Optimization. Available online: https://developers.google.com/optimization (accessed on 31 January 2022).

- Gayialis, S.P.; Tatsiopoulos, I.P. Design of an IT-driven decision support system for vehicle routing and scheduling. Eur. J. Oper. Res. 2004, 152, 382–398. [Google Scholar] [CrossRef]

- Solomon, M. Algorithms for the vehicle routing and scheduling problems with time window constraints. Oper. Res. 1987, 35, 254–265. [Google Scholar] [CrossRef]

- Avdoshin, S.; Beresneva, E. Constructive heuristics for Capacitated Vehicle Routing Problem: A comparative study. Proc. Inst. Syst. Program. RAS 2019, 31, 145–156. [Google Scholar] [CrossRef] [PubMed]

- Pasha, J.; Nwodu, A.L.; Fathollahi-Fard, A.M.; Tian, G.; Li, Z.; Wang, H.; Dulebenets, M.A. Exact and metaheuristic algorithms for the vehicle routing problem with a factory-in-a-box in multi-objective settings. Adv. Eng. Inform. 2022, 52, 101623. [Google Scholar] [CrossRef]

- Qi, R.; Li, J.q.; Wang, J.; Jin, H.; Han, Y.y. Qmoea: A q-learning-based multiobjective evolutionary algorithm for solving time-dependent green vehicle routing problems with time windows. Inf. Sci. 2022, 608, 178–201. [Google Scholar] [CrossRef]

| Notations | Description |

|---|---|

| Sets | |

| N | Set of nodes. |

| A | Set of arcs. |

| C | Set of containers. |

| K | Set of waste collection trucks. |

| Parameters | |

| Binary parameter indicates the distance between node i to node j. | |

| Binary parameter indicates the travelling time between node i to node j. | |

| Container i maximum capacity. | |

| Q | Waste collection trucks maximum capacity. |

| Earliest time to visit container i. | |

| latest time to visit container i. | |

| Service time for container i. | |

| Distance cost of travelling | |

| Time cost of travelling | |

| Variables | |

| Decision variable to indicate that a node j is visited right after node i by a waste collection truck k. | |

| Integer variable for the service starting time for each node and truck . | |

| Integer variable for the load of truck k when it arrives at container i. | |

| C | XCOORD. | YCOORD. | Q | |||

|---|---|---|---|---|---|---|

| 0 | ||||||

| 1 | ||||||

| 2 | ||||||

| ⋯ | ⋯ | ⋯ | ⋯ | ⋯ | ⋯ | ⋯ |

| N |

| # Veh | #Cont. | LB | Distance | Time | Veh. Load | Obj | Cpt | % Gap |

|---|---|---|---|---|---|---|---|---|

| 3 | 5 | 152.06 | 125.73 | 150.88 | 34.74 | 152.06 | 0.06 | 0.00% |

| 5 | 10 | 258.10 | 213.63 | 256.35 | 45.76 | 258.10 | 0.11 | 0.00% |

| 5 | 15 | 261.55 | 214.95 | 257.94 | 60.54 | 261.55 | 1.46 | 0.00% |

| 6 | 10 | 310.56 | 256.56 | 307.88 | 49.33 | 310.56 | 0.11 | 0.00% |

| 9 | 15 | 470.10 | 387.91 | 465.49 | 69.25 | 470.10 | 0.45 | 0.00% |

| 9 | 20 | 471.17 | 388.23 | 465.87 | 73.16 | 471.17 | 1.76 | 0.00% |

| 10 | 25 | 512.53 | 422.51 | 507.02 | 75.42 | 512.53 | 63.73 | 0.00% |

| 10 | 35 | 493.23 | 404.07 | 484.88 | 105.51 | 493.23 | 468.41 | 0.00% |

| 15 | 50 | 691.43 | 567.79 | 681.35 | 139.44 | 695.48 | 3200.27 | 0.42% |

| #Veh | #Cont. | LB | Distance | Time | Veh. Load | Obj | Cpt | % Gap |

| 3 | 5 | 152.06 | 125.73 | 150.88 | 34.74 | 152.06 | 0.07 | 0.00% |

| 5 | 10 | 258.10 | 213.63 | 256.35 | 45.76 | 258.10 | 0.08 | 0.00% |

| 5 | 15 | 261.55 | 214.95 | 257.94 | 60.54 | 261.55 | 1.57 | 0.00% |

| 6 | 10 | 310.56 | 256.56 | 307.88 | 49.33 | 310.56 | 0.11 | 0.00% |

| 9 | 15 | 470.10 | 387.91 | 465.49 | 69.25 | 470.10 | 0.40 | 0.00% |

| 9 | 20 | 471.17 | 388.23 | 465.87 | 73.16 | 471.17 | 6.44 | 0.00% |

| 10 | 25 | 512.53 | 422.51 | 507.02 | 79.14 | 512.53 | 15.75 | 0.00% |

| 10 | 35 | 493.23 | 404.07 | 484.88 | 105.51 | 493.23 | 54.29 | 0.00% |

| 15 | 50 | 691.43 | 567.24 | 680.69 | 139.44 | 692.54 | 3200.24 | 0.16% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Algethami, H.; Alhothali, G.T. Waste Collection Optimisation: A Path to a Green and Sustainable City of Makkah. Logistics 2023, 7, 54. https://doi.org/10.3390/logistics7030054

Algethami H, Alhothali GT. Waste Collection Optimisation: A Path to a Green and Sustainable City of Makkah. Logistics. 2023; 7(3):54. https://doi.org/10.3390/logistics7030054

Chicago/Turabian StyleAlgethami, Haneen, and Ghada Talat Alhothali. 2023. "Waste Collection Optimisation: A Path to a Green and Sustainable City of Makkah" Logistics 7, no. 3: 54. https://doi.org/10.3390/logistics7030054

APA StyleAlgethami, H., & Alhothali, G. T. (2023). Waste Collection Optimisation: A Path to a Green and Sustainable City of Makkah. Logistics, 7(3), 54. https://doi.org/10.3390/logistics7030054