Environmental Risk Assessment Using Neural Network in Liquefied Petroleum Gas Terminal

Abstract

:1. Introduction

2. Materials and Methods

2.1. LPG Terminal

2.2. HAZID Methodology

2.3. Hazard Identification and the Scenario Selection

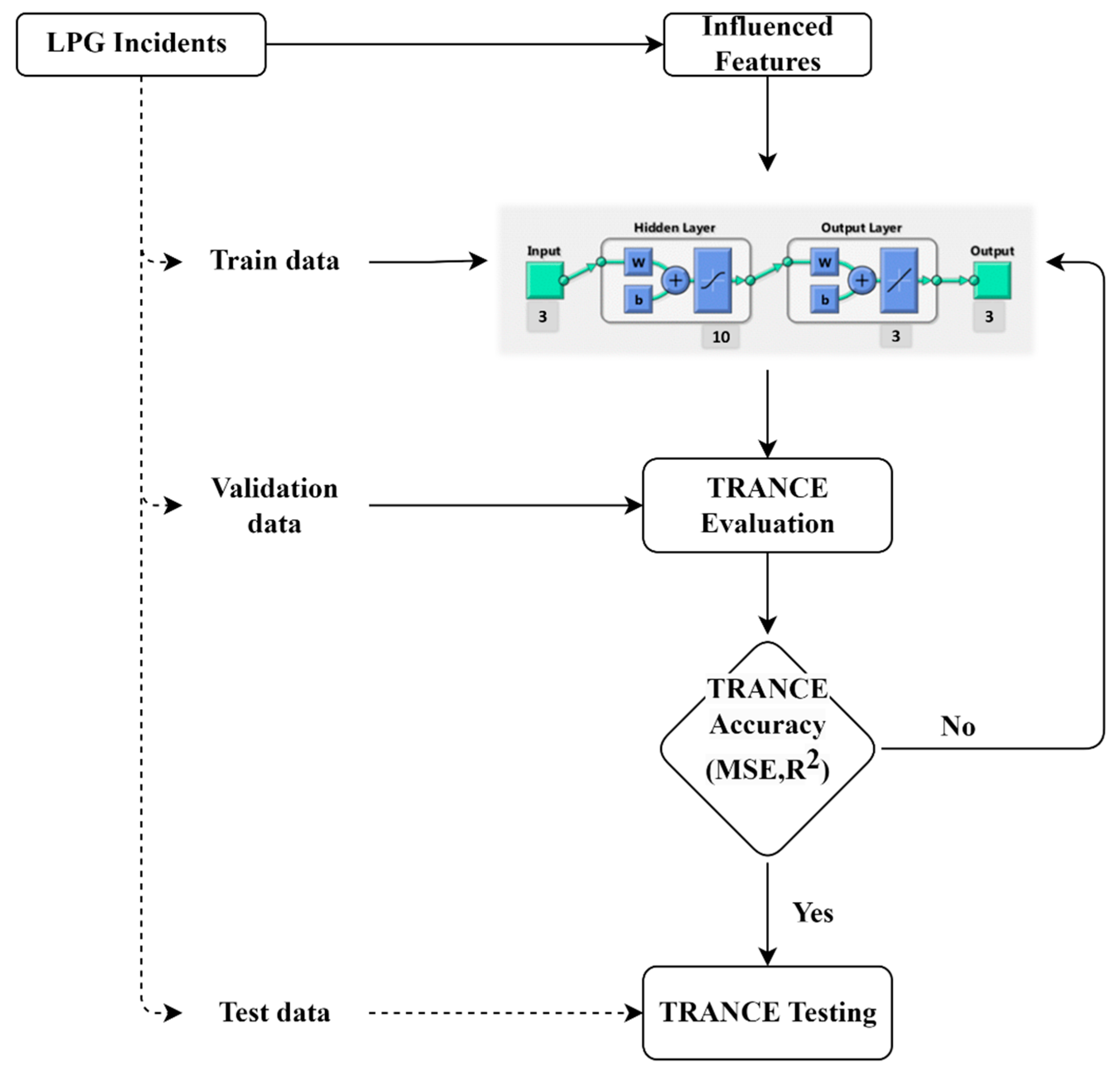

2.4. ANN Topology

3. Results and Discussion

3.1. Modelling Flammable Area of Vapour Cloud

3.2. Jet Fire Radiations

3.3. Fireball Radiations

3.4. Blast Force

3.5. Risk Assessment for Catastrophic Ruptures of LPG Horton Sphere

3.6. Performance of ANN Model

3.7. Limitations of the Study and ANN Model

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hanif, M.A.; Nadeem, F.; Tariq, R.; Rashid, U. Renewable and Alternative Energy Resources; Elsevier: Amsterdam, The Netherlands, 2021; ISBN 9780128181508. [Google Scholar]

- Dormohammadi, A.; Zarei, E.; Delkhosh, M.B.; Gholami, A. Risk Analysis by Means of a QRA Approach on a LPG Cylinder Filling Installation. Process Saf. Prog. 2014, 33, 77–84. [Google Scholar] [CrossRef]

- Rasbash, D.J. Review of Explosion and Fire Hazard of Liquefied Petroleum Gas. Fire Saf. J. 1980, 2, 223–236. [Google Scholar] [CrossRef]

- Roberts, A.F. Thermal Radiation Hazards from Releases of LPG from Pressurised Storage. Fire Saf. J. 1981, 4, 197–212. [Google Scholar] [CrossRef]

- Bariha, N.; Mishra, I.M.; Srivastava, V.C. Fire and Explosion Hazard Analysis during Surface Transport of Liquefied Petroleum Gas (LPG): A Case Study of LPG Truck Tanker Accident in Kannur, Kerala, India. J. Loss Prev. Process Ind. 2016, 40, 449–460. [Google Scholar] [CrossRef]

- Kartal, F. Evaluation of Explosion Pressure of Portable Small Liquefied Petroleum Gas Cylinder. Process Saf. Prog. 2020, 39, e12081. [Google Scholar] [CrossRef]

- Sonwani, N.S.; Ateriya, N.; Kumar, A.; Kohli, A. Two Deaths Due to Explosion of Cylinders of Liquid Petroleum Gas. Egypt J. Forensic. Sci. 2021, 11, 6. [Google Scholar] [CrossRef]

- Landucci, G.; Tugnoli, A.; Busini, V.; Derudi, M.; Rota, R.; Cozzani, V. The Viareggio LPG Accident: Lessons Learnt. J. Loss Prev. Process Ind. 2011, 24, 466–476. [Google Scholar] [CrossRef]

- Brambilla, S.; Manca, D. The Viareggio LPG Railway Accident: Event Reconstruction and Modeling. J. Hazard Mater. 2010, 182, 346–357. [Google Scholar] [CrossRef]

- Chang, J.I.; Lin, C.C. A Study of Storage Tank Accidents. J. Loss Prev. Process Ind. 2006, 19, 51–59. [Google Scholar] [CrossRef]

- Timbang, A.; Prasad, D.M.R.; bin Azri, M.H.; Sofri, S. Addressing Process Safety Challenges in Downstream Industries in Brunei Darussalam. Int. J. Occup. Saf. Ergon. 2021, 28, 2284–2292. [Google Scholar] [CrossRef]

- Sofri, S.; Reddy Prasad, D.M.; Bin Azri, M.H.; Timbang, A. Analysis of Chemical Engineering Curriculum to Improve Process Safety Competency. Int. J. Occup. Saf. Ergon. 2022, 161, 106069. [Google Scholar] [CrossRef]

- Jayakumar, C.; Isac, S.; Prasad, D.M.R. Emergency Response Plan for Methane and Chlorine with Dispersion Modelling Using CAMEO. Int. J. Occup. Saf. Ergon. 2021, 28, 1802–1810. [Google Scholar] [CrossRef]

- Terzioglu, L.; Iskender, H. Modeling the Consequences of Gas Leakage and Explosion Fire in Liquefied Petroleum Gas Storage Tank in Istanbul Technical University, Maslak Campus. Process Saf. Prog. 2021, 40, 319–326. [Google Scholar] [CrossRef]

- Barjoee, S.S.; Elmi, M.R.; Varaoon, V.T.; Keykhosravi, S.S.; Karimi, F. Hazards of Toluene Storage Tanks in a Petrochemical Plant: Modeling Effects, Consequence Analysis, and Comparison of Two Modeling Programs. Environ. Sci. Pollut. Res. 2021, 29, 4587–4615. [Google Scholar] [CrossRef]

- Haghnazarloo, H.; Parvini, M.; Lotfollahi, M.N. Consequence Modeling of a Real Rupture of Toluene Storage Tank. J. Loss Prev. Process Ind. 2015, 37, 11–18. [Google Scholar] [CrossRef]

- Shojaee Barjoee, S.; Dashtian, A.H.; Keykhosravi, S.S.; Abbasi Saryazdi, M.J.; Afrough, M.J. Modeling the Environmental, Health, and Safety Aspects of Xylene Isomer Emission from Storage Tanks in Petrochemical Industries, Iran. Environ. Monit. Assess. 2021, 193, 783. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.E.; Sohn, J.R.; Byeon, S.H.; Yoon, S.J.; Moon, K.W. Alternative Risk Assessment for Dangerous Chemicals in South Korea Regulation: Comparing Three Modeling Programs. Int. J. Environ. Res. Public Health 2018, 15, 1600. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Naemnezhad, A.; Isari, A.A.; Khayer, E.; Esfandiari Birak Olya, M. Consequence Assessment of Separator Explosion for an Oil Production Platform in South of Iran with PHAST Software. Model Earth Syst. Env. 2017, 3, 43. [Google Scholar] [CrossRef] [Green Version]

- Saloua, B.; Mounira, R.; Salah, M.M. Fire and Explosion Risks in Petrochemical Plant: Assessment, Modeling and Consequences Analysis. J. Fail. Anal. Prev. 2019, 19, 903–916. [Google Scholar] [CrossRef]

- Tamascelli, N.; Solini, R.; Paltrinieri, N.; Cozzani, V. Learning from Major Accidents: A Machine Learning Approach. Comput. Chem. Eng. 2022, 162, 107786. [Google Scholar] [CrossRef]

- Carter, A.; Imtiaz, S.; Naterer, G.F. Review of Interpretable Machine Learning for Process Industries. Process Saf. Environ. Prot. 2023, 170, 647–659. [Google Scholar] [CrossRef]

- Harhara, A.; Arora, A.; Faruque Hasan, M.M. Process Safety Consequence Modeling Using Artificial Neural Networks for Approximating Heat Exchanger Overpressure Severity. Comput. Chem. Eng. 2023, 170, 108098. [Google Scholar] [CrossRef]

- Elshaboury, N.; Al-Sakkaf, A.; Alfalah, G.; Abdelkader, E.M. Data-Driven Models for Forecasting Failure Modes in Oil and Gas Pipes. Processes 2022, 10, 400. [Google Scholar] [CrossRef]

- Zakikhani, K.; Nasiri, F.; Zayed, T. A Review of Failure Prediction Models for Oil and Gas Pipelines. J. Pipeline Syst. Eng. Pract. 2020, 11, 03119001. [Google Scholar] [CrossRef]

- Li, J.; Li, Q.; Hao, H.; Li, L. Prediction of BLEVE Blast Loading Using CFD and Artificial Neural Network. Process Saf. Environ. Prot. 2021, 149, 711–723. [Google Scholar] [CrossRef]

- Kumari, P.; Halim, S.Z.; Kwon, J.S., II; Quddus, N. An Integrated Risk Prediction Model for Corrosion-Induced Pipeline Incidents Using Artificial Neural Network and Bayesian Analysis. Process Saf. Environ. Prot. 2022, 167, 34–44. [Google Scholar] [CrossRef]

- Kumari, P.; Wang, Q.; Khan, F.; Kwon, J.S., II. A Unified Causation Prediction Model for Aboveground Onshore Oil and Refined Product Pipeline Incidents Using Artificial Neural Network. Chem. Eng. Res. Des. 2022, 187, 529–540. [Google Scholar] [CrossRef]

- Bhadriraju, B.; Kwon, J.S., II; Khan, F. OASIS-P: Operable Adaptive Sparse Identification of Systems for Fault Prognosis of Chemical Processes. J. Process Control 2021, 107, 114–126. [Google Scholar] [CrossRef]

- Samanipour, S.; Kaserzon, S.; Vijayasarathy, S.; Jiang, H.; Choi, P.; Reid, M.J.; Mueller, J.F.; Thomas, K.V. Machine Learning Combined with Non-Targeted LC-HRMS Analysis for a Risk Warning System of Chemical Hazards in Drinking Water: A Proof of Concept. Talanta 2019, 195, 426–432. [Google Scholar] [CrossRef]

- Kim, K.; Lim, S.; Lee, C.H.; Lee, W.J.; Jeon, H.; Jung, J.; Jung, D. Forecasting Liquefied Natural Gas Bunker Prices Using Artificial Neural Network for Procurement Management. J. Mar. Sci. Eng. 2022, 10, 1814. [Google Scholar] [CrossRef]

- Bariha, N.; Srivastava, V.C.; Mishra, I.M. Incident Analysis of Various Sections of a Liquefied Petroleum Gas (LPG) Bottling Plant. Indian Chem. Eng. 2019, 63, 50–61. [Google Scholar] [CrossRef]

- Arendt, J.S.; Lorenzo, D.K. Evaluating Process Safety in the Chemical Industry. In Evaluating Process Safety in the Chemical Industry; American Chemistry Council: Arlington, VA, USA, 2000. [Google Scholar] [CrossRef]

- Khan, F.I.; Amyotte, P.R. Modeling of BP Texas City Refinery Incident. J. Loss Prev. Process Ind. 2007, 20, 387–395. [Google Scholar] [CrossRef]

- Isimite, J.; Rubini, P. A Dynamic HAZOP Case Study Using the Texas City Refinery Explosion. J. Loss Prev. Process Ind. 2016, 40, 496–501. [Google Scholar] [CrossRef]

- Lees, F.P. Lee’s Loss Prevention in the Process Industries: Hazard Identification, Assessment, and Control; Butterworth-Heinemann: Oxford, UK, 2012; p. 3642. [Google Scholar]

- Rivera Domínguez, C.; Pozos Mares, J.I.; Zambrano Hernández, R.G. Hazard Identification and Analysis in Work Areas within the Manufacturing Sector through the HAZID Methodology. Process Saf. Environ. Prot. 2021, 145, 23–38. [Google Scholar] [CrossRef]

- Barry, T.F. Risk-Informed Industrial Fire Protection Engineering. In SFPE Handbook of Fire Protection Engineering, 5th ed.; SFPE: Washington, DC, USA, 2016; pp. 3183–3210. [Google Scholar] [CrossRef]

- Osage, D.A.; Rodery, C.D.; Pastor, T.P.; Brown, R.G.; Henry, P.A.; Sowinski, J.C. Section VIII: Division 2—Alternative Rules. In Online Companion Guide to the ASME Boiler & Pressure Vessel Codes; ASME: New York, NY, USA, 2020. [Google Scholar] [CrossRef]

- Salamonowicz, Z.; Krauze, A.; Majder-Lopatka, M.; Dmochowska, A.; Piechota-Polanczyk, A.; Polanczyk, A. Numerical Reconstruction of Hazardous Zones after the Release of Flammable Gases during Industrial Processes. Processes 2021, 9, 307. [Google Scholar] [CrossRef]

- Chakraverty, S.; Sahoo, D.M.; Mahato, N.R. Concepts of Soft Computing Fuzzy and ANN with Programming; Springer: Berlin/Heidelberg, Germany, 2019; pp. 1–195. [Google Scholar] [CrossRef]

- Ghaboussi, J. Soft Computing in Engineering; CRC Press: Boca Raton, FL, USA, 2020; ISBN 9780367657260. [Google Scholar]

- El-Abbasy, M.S.; Senouci, A.; Zayed, T.; Mirahadi, F.; Parvizsedghy, L. Artificial Neural Network Models for Predicting Condition of Offshore Oil and Gas Pipelines. Autom Constr. 2014, 45, 50–65. [Google Scholar] [CrossRef]

- Ghatak, M.D.; Ghatak, A. Artificial Neural Network Model to Predict Behavior of Biogas Production Curve from Mixed Lignocellulosic Co-Substrates. Fuel 2018, 232, 178–189. [Google Scholar] [CrossRef]

- Kang, Z.; Catal, C.; Tekinerdogan, B. Machine Learning Applications in Production Lines: A Systematic Literature Review. Comput. Ind. Eng. 2020, 149, 106773. [Google Scholar] [CrossRef]

- Bhadriraju, B.; Narasingam, A.; Kwon, J.S., II. Machine Learning-Based Adaptive Model Identification of Systems: Application to a Chemical Process. Chem. Eng. Res. Des. 2019, 152, 372–383. [Google Scholar] [CrossRef]

- Gavrilov, A.D.; Jordache, A.; Vasdani, M.; Deng, J. Preventing Model Overfitting and Underfitting in Convolutional Neural Networks. Int. J. Softw. Sci. Comput. Intell. 2018, 10, 19–28. [Google Scholar] [CrossRef]

- Gollangi, R.; Nagamalleswara Rao, K. Energetic, Exergetic Analysis and Machine Learning of Methane Chlorination Process for Methyl Chloride Production. Energy Environ. 2022, 0958305X221109604. [Google Scholar] [CrossRef]

| Scenario Name | Scenario Description | Leak Sizes in m |

|---|---|---|

| S1 | A leak from 19 kg capacity LPG cylinder in filling shed in summer daytime (5D condition) | 0.02 |

| S2 | A leak from 19 kg capacity LPG cylinder in filling shed in winter night (2F condition) | 0.02 |

| S3 | Leak from 21 Tons capacity LPG Tank Truck in Loading gantry in summer daytime (5D condition) | Full bore rupture (0.15) |

| S4 | A leak from 21 Tons capacity LPG Tank Truck in Loading gantry in wintertime (2F condition) | Full bore rupture (0.15) |

| S5 | A leak from 21 Tons capacity LPG Tank Truck in Loading gantry in summer Day time (5D condition) | 0.1 |

| S6 | Leak from 21 Tons capacity LPG Tank Truck in Loading gantry in wintertime (2F condition) | 0.1 |

| S7 | A leak at 600 MT Mounded LPG Bullet in summer daytime (5D condition) | 0.1 |

| S8 | A leak at 600 MT Mounded LPG Bullet in winter night-time (2F condition) | 0.1 |

| S9 | A leak from 1350 Tons capacity LPG Horton Sphere in summer daytime (5D condition) | Full bore rupture (0.15) |

| S10 | A leak from 1350 Tons capacity LPG Horton Sphere in winter night-time (2F condition) | Full bore rupture (0.15) |

| S11 | A leak from 1350 Tons capacity LPG Horton Sphere in summer daytime (5D condition) | 0.1 |

| S12 | A leak from 1350 Tons capacity LPG Horton Sphere in winter night-time (2F condition) | 0.1 |

| S13 | Catastrophic rupture of 1350 Tons LPG Horton Sphere of 1350 MT in summer daytime (5D) | Catastrophic rupture |

| S14 | Catastrophic rupture of 1350 Tons LPG Horton Sphere of 1350 MT in winter night-time (2F) | Catastrophic rupture |

| Particulars | Specifications |

|---|---|

| Number of neurons | 10 (First layer), 3 (Second layer) |

| Number of features in input and output | 3, 3 |

| Training algorithm | Feed-Forward Backpropagation |

| Optimization algorithm | Trainlm (Levenberg–Marquardt) |

| Activation function | Sigmoid (hidden layer), Linear (output layer) |

| Performance evaluation index | MSE, R2 |

| Number of epochs | 17 |

| Number of attributes | 160 |

| Observations | MSE | R2 | |

|---|---|---|---|

| Training | 113 | 26.9212 | 0.9994 |

| Validation | 24 | 93.6288 | 0.998 |

| Testing | 24 | 202.9061 | 0.9958 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gabhane, L.R.; Kanidarapu, N. Environmental Risk Assessment Using Neural Network in Liquefied Petroleum Gas Terminal. Toxics 2023, 11, 348. https://doi.org/10.3390/toxics11040348

Gabhane LR, Kanidarapu N. Environmental Risk Assessment Using Neural Network in Liquefied Petroleum Gas Terminal. Toxics. 2023; 11(4):348. https://doi.org/10.3390/toxics11040348

Chicago/Turabian StyleGabhane, Lalit Rajaramji, and NagamalleswaraRao Kanidarapu. 2023. "Environmental Risk Assessment Using Neural Network in Liquefied Petroleum Gas Terminal" Toxics 11, no. 4: 348. https://doi.org/10.3390/toxics11040348

APA StyleGabhane, L. R., & Kanidarapu, N. (2023). Environmental Risk Assessment Using Neural Network in Liquefied Petroleum Gas Terminal. Toxics, 11(4), 348. https://doi.org/10.3390/toxics11040348