Emission Characteristics of Volatile Organic Compounds from Material Extrusion Printers Using Acrylonitrile–Butadiene–Styrene and Polylactic Acid Filaments in Printing Environments and Their Toxicological Concerns

Abstract

1. Introduction

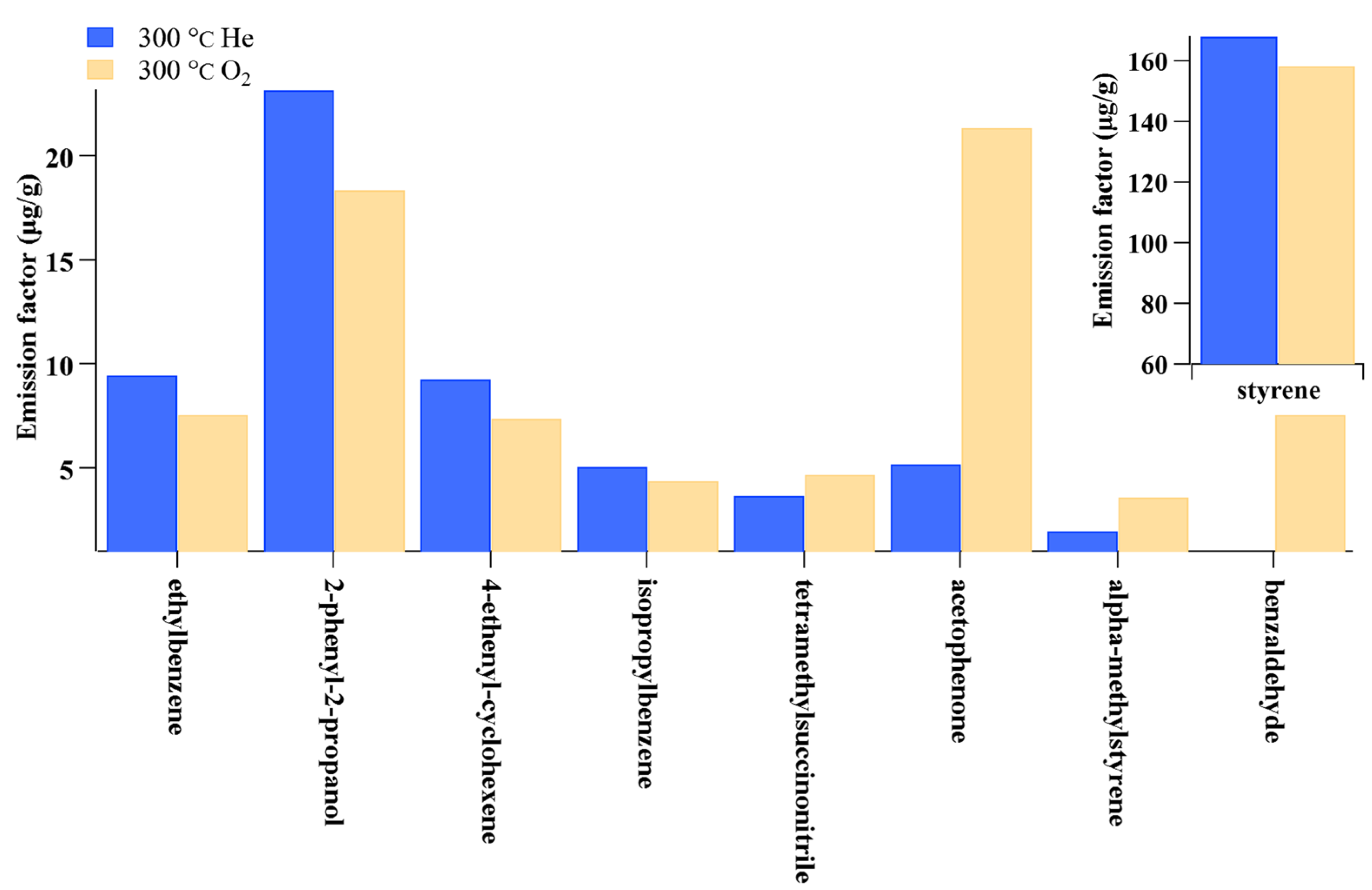

2. VOC Measurement and Emission Characteristics of ABS and PLA Filaments

3. Potential Influences of VOC Emission from ABS and PLA Filaments

4. Toxicological Concerns

5. Summary and Future Perspectives

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jiang, R.; Kleer, R.; Piller, F.T. Predicting the future of additive manufacturing: A Delphi study on economic and societal implications of 3D printing for 2030. Technol. Forecast. Soc. Change 2017, 117, 84–97. [Google Scholar]

- Jipa, A.; Dillenburger, B. 3D Printed Formwork for Concrete: State-of-the-Art, Opportunities, Challenges, and Applications. 3D Print. Addit. Manuf. 2022, 9, 84–107. [Google Scholar] [PubMed]

- Goh, G.D.; Sing, S.L.; Yeong, W.Y. A review on machine learning in 3D printing: Applications, potential, and challenges. Artif. Intell. Rev. 2021, 54, 63–94. [Google Scholar]

- Ramya, A.; Vanapalli, S.L. 3D printing technologies in various applications. Int. J. Mech. Eng. Technol. 2016, 7, 396–409. [Google Scholar]

- Hiemenz, J. Additive Manufacturing Trends in Aerospace; White Paper; Stratasys: Minnetonka, MN, USA, 2014; pp. 1–11. [Google Scholar]

- Ali, M.H.; Batai, S.; Sarbassov, D. 3D printing: A critical review of current development and future prospects. Rapid Prototyp. J. 2019, 25, 1108–1126. [Google Scholar] [CrossRef]

- Nadagouda, M.N.; Ginn, M.; Rastogi, V. A review of 3D printing techniques for environmental applications. Curr. Opin. Chem. Eng. 2020, 28, 173–178. [Google Scholar] [CrossRef]

- Rozsos, R.S.; Buna, Z.L.; Ștefan, B.; Comes, R.; Tompa, V. Design and development of a linear DELTA 3D printer. Acta Tech.-Ser. Appl. Math. Mech. Eng. 2020, 63, 185–190. [Google Scholar]

- Forward. 3D Printer Market Report of China in 2021–2026; Forward Business Informtion Co., Ltd.: Shenzhen, China, 2021. (In Chinese) [Google Scholar]

- Colorado, H.A.; Velasquez, E.I.G.; Monteiro, S.N. Sustainability of additive manufacturing: The circular economy of materials and environmental perspectives. J. Mater. Res. Technol.-Jmr&T 2020, 9, 8221–8234. [Google Scholar] [CrossRef]

- Stabile, L.; Scungio, M.; Buonanno, G.; Arpino, F.; Ficco, G. Airborne particle emission of a commercial 3D printer: The effect of filament material and printing temperature. Indoor Air 2017, 27, 398–408. [Google Scholar] [CrossRef]

- Min, K.; Li, Y.; Wang, D.; Chen, B.; Ma, M.; Hu, L.; Liu, Q.; Jiang, G. 3D Printing-Induced Fine Particle and Volatile Organic Compound Emission: An Emerging Health Risk. Environ. Sci. Technol. Lett. 2021, 8, 616–625. [Google Scholar] [CrossRef]

- Chan, F.L.; House, R.; Kudla, I.; Lipszyc, J.C.; Rajaram, N.; Tarlo, S.M. Health survey of employees regularly using 3D printers. Occup. Med. 2018, 68, 211–214. [Google Scholar] [CrossRef] [PubMed]

- Mohammadian, Y.; Nasirzadeh, N. Toxicity risks of occupational exposure in 3D printing and bioprinting industries: A systematic review. Toxicol. Ind. Health 2021, 37, 573–584. [Google Scholar] [CrossRef] [PubMed]

- Preez, S.d.; Johnson, A.R.; LeBouf, R.F.; Linde, S.J.L.; Stefaniak, A.B.; Plessis, J.d. Exposures during industrial 3-D printing and post-processing tasks. Rapid Prototyp. J. 2018, 24, 865–871. [Google Scholar] [CrossRef]

- Youn, J.-S.; Seo, J.-W.; Han, S.; Jeon, K.-J. Characteristics of nanoparticle formation and hazardous air pollutants emitted by 3D printer operations: From emission to inhalation. RSC Adv. 2019, 9, 19606–19612. [Google Scholar] [CrossRef]

- Bozkurt, Y.; Karayel, E. 3D printing technology; methods, biomedical applications, future opportunities and trends. J. Mater. Res. Technol. 2021, 14, 1430–1450. [Google Scholar] [CrossRef]

- Shahrubudin, N.; Lee, T.C.; Ramlan, R. An overview on 3D printing technology: Technological, materials, and applications. Procedia Manuf. 2019, 35, 1286–1296. [Google Scholar] [CrossRef]

- Irfan Ul Haq, M.; Khuroo, S.; Raina, A.; Khajuria, S.; Javaid, M.; Farhan Ul Haq, M.; Haleem, A. 3D printing for development of medical equipment amidst coronavirus (COVID-19) pandemic—Review and advancements. Res. Biomed. Eng. 2020, 38, 305–315. [Google Scholar] [CrossRef]

- Wojnowski, W.; Kalinowska, K.; Majchrzak, T.; Zabiegala, B. Real-time monitoring of the emission of volatile organic compounds from polylactide 3D printing filaments. Sci. Total Environ. 2022, 805, 150181. [Google Scholar] [CrossRef]

- Davis, A.Y.; Zhang, Q.; Wong, J.P.S.; Weber, R.J.; Black, M.S. vconsumer level material extrusion 3D printers. Build. Environ. 2019, 160, 106209. [Google Scholar] [CrossRef]

- Byrley, P.; Geer Wallace, M.A.; Boyes, W.K.; Rogers, K. Particle and volatile organic compound emissions from a 3D printer filament extruder. Sci. Total Environ. 2020, 736, 139604. [Google Scholar] [CrossRef]

- Jihoon, P.; Haejoon, J.; Oh, Y.; Kyungho, P.; Chungsik, Y. Understanding Three-dimensional Printing Technology, Evaluation, and Control of Hazardous Exposure Agents. J. Korean Soc. Occup. Environ. Hyg. 2018, 28, 241–256. [Google Scholar] [CrossRef]

- Ding, S.; Wan, M.P.; Ng, B.F. Dynamic Analysis of Particle Emissions from FDM 3D Printers through a Comparative Study of Chamber and Flow Tunnel Measurements. Environ. Sci. Technol. 2020, 54, 14568–14577. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; Pardo, M.; Rudich, Y.; Kaplan-Ashiri, I.; Wong, J.P.S.; Davis, A.Y.; Black, M.S.; Weber, R.J. Chemical Composition and Toxicity of Particles Emitted from a Consumer-Level 3D Printer Using Various Materials. Environ. Sci. Technol. 2019, 53, 12054–12061. [Google Scholar] [CrossRef] [PubMed]

- Jensen, A.C.Ø.; Harboe, H.; Brostrøm, A.; Jensen, K.A.; Fonseca, A.S. Nanoparticle Exposure and Workplace Measurements During Processes Related to 3D Printing of a Metal Object. Front. Public Health 2020, 8, 608718. [Google Scholar] [CrossRef]

- Sittichompoo, S.; Kanagalingam, S.; Thomas-Seale, L.E.J.; Tsolakis, A.; Herreros, J.M. Characterization of particle emission from thermoplastic additive manufacturing. Atmos. Environ. 2020, 239, 117765. [Google Scholar] [CrossRef]

- Park, J.; Kwon, O.-h.; Yoon, C.; Park, M. Estimates of particulate matter inhalation doses during three-dimensional printing How many particles can penetrate into our body? Indoor Air 2021, 31, 392–404. [Google Scholar] [CrossRef]

- Zhang, Q.; Black, M.S. Particle and Chemical Emissions from a Vat Photopolymerization 3D Printer. Chem. Insights 2021, 1–6. [Google Scholar]

- Pham, Y.L.; Wojnowski, W.; Beauchamp, J. Online Volatile Compound Emissions Analysis Using a Microchamber/Thermal Extractor Coupled to Proton Transfer Reaction-Mass Spectrometry. Anal. Chem. 2022, 94, 17354–17359. [Google Scholar] [CrossRef]

- Zhang, J.; Chen, D.-R.; Chen, S.-C. A review of emission characteristics and control strategies for particles emitted from 3D fused deposition modeling (FDM) printing. Build. Environ. 2022, 221, 109348. [Google Scholar] [CrossRef]

- Romanowski, H.; Bierkandt, F.S.; Luch, A.; Laux, P. Summary and derived Risk Assessment of 3D printing emission studies. Atmos. Environ. 2023, 294, 119501. [Google Scholar] [CrossRef]

- Beard, J.M.; Royer, B.M.; Hesita, J.M.; Byrley, P.; Lewis, A.; Hadynski, J.; Matheson, J.; Al-Abed, S.R.; Sayes, C.M. Lung cell toxicological effects of 3D printer aerosolized filament byproducts. Environ. Sci. Pollut. Res. 2025, 32, 5078–5090. [Google Scholar] [CrossRef]

- He, X.; Barnett, L.M.; Jeon, J.; Zhang, Q.; Alqahtani, S.; Black, M.; Shannahan, J.; Wright, C. Real-Time Exposure to 3D-Printing Emissions Elicits Metabolic and Pro-Inflammatory Responses in Human Airway Epithelial Cells. Toxics 2024, 12, 67. [Google Scholar] [CrossRef] [PubMed]

- Finnegan, M.; Thach, C.L.; Khaki, S.; Markey, E.; O’Connor, D.J.; Smeaton, A.F.; Morrin, A. Characterization of Volatile and Particulate Emissions from Desktop 3D Printers. Sensors 2023, 23, 9660. [Google Scholar] [CrossRef] [PubMed]

- Mendes, L.; Kangas, A.; Kukko, K.; Mølgaard, B.; Säämänen, A.; Kanerva, T.; Flores Ituarte, I.; Huhtiniemi, M.; Stockmann-Juvala, H.; Partanen, J.; et al. Characterization of Emissions from a Desktop 3D Printer. J. Ind. Ecol. 2017, 21, S94–S106. [Google Scholar] [CrossRef]

- Potter, P.M.; Al-Abed, S.R.; Lay, D.; Lomnicki, S.M. VOC Emissions and Formation Mechanisms from Carbon Nanotube Composites during 3D Printing. Environ. Sci. Technol. 2019, 53, 4364–4370. [Google Scholar] [CrossRef]

- Steinle, P. Characterization of emissions from a desktop 3D printer and indoor air measurements in office settings. J. Occup. Environ. Hyg. 2016, 13, 121–132. [Google Scholar] [CrossRef]

- Väisänen, A.J.K.; Hyttinen, M.; Ylönen, S.; Alonen, L. Occupational exposure to gaseous and particulate contaminants originating from additive manufacturing of liquid, powdered, and filament plastic materials and related post-processes. J. Occup. Environ. Hyg. 2019, 16, 258–271. [Google Scholar] [CrossRef]

- Chan, F.L.; Hon, C.Y.; Tarlo, S.M.; Rajaram, N.; House, R. Emissions and health risks from the use of 3D printers in an occupational setting. J. Toxicol. Environ. Health. Part A 2020, 83, 279–287. [Google Scholar] [CrossRef]

- Stefaniak, A.B.; LeBouf, R.F.; Yi, J.; Ham, J.; Nurkewicz, T.; Schwegler-Berry, D.E.; Chen, B.T.; Wells, J.R.; Duling, M.G.; Lawrence, R.B. Characterization of chemical contaminants generated by a desktop fused deposition modeling 3-dimensional Printer. J. Occup. Environ. Hyg. 2017, 14, 540–550. [Google Scholar]

- Gu, J.; Uhde, E.; Wensing, M.; Xia, F.; Salthammer, T. Emission Control of Desktop 3D Printing: The Effects of a Filter Cover and an Air Purifier. Environ. Sci. Technol. Lett. 2019, 6, 499–503. [Google Scholar] [CrossRef]

- Gu, J.; Wensing, M.; Uhde, E.; Salthammer, T. Characterization of particulate and gaseous pollutants emitted during operation of a desktop 3D printer. Environ. Int. 2019, 123, 476–485. [Google Scholar] [CrossRef]

- Azimi, P.; Zhao, D.; Pouzet, C.; Crain, N.E.; Stephens, B. Emissions of Ultrafine Particles and Volatile Organic Compounds from Commercially Available Desktop Three-Dimensional Printers with Multiple Filaments. Environ. Sci. Technol. 2016, 50, 1260–1268. [Google Scholar] [CrossRef] [PubMed]

- Zisook, R.E.; Simmons, B.D.; Vater, M.; Perez, A.; Donovan, E.P.; Paustenbach, D.J.; Cyrs, W.D. Emissions associated with operations of four different additive manufacturing or 3D printing technologies. J. Occup. Environ. Hyg. 2020, 17, 464–479. [Google Scholar] [CrossRef] [PubMed]

- Wojnowski, W.; Kalinowska, K.; Gebicki, J.; Zabiegala, B. Monitoring the BTEX Volatiles during 3D Printing with Acrylonitrile Butadiene Styrene (ABS) Using Electronic Nose and Proton Transfer Reaction Mass Spectrometry. Sensors 2020, 20, 5531. [Google Scholar] [CrossRef] [PubMed]

- Floyd, E.L.; Wang, J.; Regens, J.L. Fume emissions from a low-cost 3-D printer with various filaments. J. Occup. Environ. Hyg. 2017, 14, 523–533. [Google Scholar]

- Hall, S.; Penegelly, I.; Staff, J. Measuring and Controlling Emissions from Polymer Filament Desktop 3D Printers; Research Reports, RR1146; Health and Safety Executive (HSE): Buxton, UK, 2019. [Google Scholar]

- Zhang, Q.; Black, M.S. Exposure hazards of particles and volatile organic compounds emitted from material extrusion 3D printing: Consolidation of chamber study data. Environ. Int. 2023, 182, 108316. [Google Scholar] [CrossRef]

- Wojtyła, S.; Klama, P.; Baran, T. Is 3D printing safe? Analysis of the thermal treatment of thermoplastics: ABS, PLA, PET, and nylon. J. Occup. Environ. Hyg. 2017, 14, D80–D85. [Google Scholar] [CrossRef]

- Wojtyła, S.; Klama, P.; Śpiewak, K.; Baran, T. 3D printer as a potential source of indoor air pollution. Int. J. Environ. Sci. Technol. 2020, 17, 207–218. [Google Scholar] [CrossRef]

- Henderson, L.; Brusick, D.; Ratpan, F.; Veenstra, G. A review of the genotoxicity of ethylbenzene. Mutat. Res. 2007, 635, 81–89. [Google Scholar] [CrossRef]

- Paul, P.E.V.; Sangeetha, V.; Deepika, R.G. Chapter 9—Emerging Trends in the Industrial Production of Chemical Products by Microorganisms. In Recent Developments in Applied Microbiology and Biochemistry; Buddolla, V., Ed.; Academic Press: Cambridge, MA, USA, 2019; pp. 107–125. [Google Scholar] [CrossRef]

- Karwasz, A.; Osiński, F. Literature review on emissions from additive manufacturing by FDM method and their impact on human health. Manag. Prod. Eng. Rev. 2020, 11, 65–73. [Google Scholar] [CrossRef]

- Bai, X.; Liang, P.; Zhang, M.; Gong, S.; Zhao, L. Effects of Reprocessing on Acrylonitrile–Butadiene–Styrene and Additives. J. Polym. Environ. 2022, 30, 1803–1819. [Google Scholar] [CrossRef]

- Kumar, V.; Ahuja, I.S.; Singh, R. Multi-Factor Optimization for Preparation of Mechanical Blended and Chemical Assisted Mechanical Blended ABS-Graphene Composite for 3D Printing. In Reference Module in Materials Science and Materials Engineering; Elsevier: Amsterdam, The Netherlands, 2021. [Google Scholar] [CrossRef]

- Achanzar, W.E.; Mangipudy, R.S. Acrylonitrile. In Encyclopedia of Toxicology, 3rd ed.; Wexler, P., Ed.; Academic Press: Oxford, UK, 2014; pp. 76–78. [Google Scholar] [CrossRef]

- Vance, M.E.; Pegues, V.; Van Montfrans, S.; Leng, W.; Marr, L.C. Aerosol Emissions from Fuse-Deposition Modeling 3D Printers in a Chamber and in Real Indoor Environments. Environ. Sci. Technol. 2017, 51, 9516–9523. [Google Scholar] [CrossRef] [PubMed]

- Chuang, Y.-S.; Berekute, A.K.; Hsu, H.-Y.; Wei, H.-S.; Gong, W.-C.; Hsu, Y.-Y.; Tsai, C.-J.; Yu, K.-P. Assessment of emissions and exposure in 3D printing workplaces in Taiwan. J. Occup. Environ. Hyg. 2024, 21, 270–286. [Google Scholar] [CrossRef] [PubMed]

- Khaki, S.; Rio, M.; Marin, P. Characterization of Emissions in Fab Labs: An Additive Manufacturing Environment Issue. Sustainability 2022, 14, 2900. [Google Scholar] [CrossRef]

- Dobrzynska, E.; Kondej, D.; Kowalska, J.; Szewczynska, M. Exposure to chemical substances and particles emitted during additive manufacturing. Environ. Sci. Pollut. Res. 2022, 29, 40273–40278. [Google Scholar] [CrossRef]

- Alberts, E.; Ballentine, M.; Barnes, E.; Kennedy, A. Impact of metal additives on particle emission profiles from a fused filament fabrication 3D printer. Atmos. Environ. 2021, 244, 117956. [Google Scholar] [CrossRef]

- Potter, P.M.; Al-Abed, S.R.; Hasan, F.; Lomnicki, S.M. Influence of polymer additives on gas-phase emissions from 3D printer filaments. Chemosphere 2021, 279, 130543. [Google Scholar] [CrossRef]

- Zhang, Q.; Wong, J.P.S.; Davis, A.Y.; Black, M.S.; Weber, R.J. Characterization of particle emissions from consumer fused deposition modeling 3D printers. Aerosol Sci. Technol. 2017, 51, 1275–1286. [Google Scholar] [CrossRef]

- Zhang, Q.; Sharma, G.; Wong, J.P.S.; Davis, A.Y.; Black, M.S.; Biswas, P.; Weber, R.J. Investigating particle emissions and aerosol dynamics from a consumer fused deposition modeling 3D printer with a lognormal moment aerosol model. Aerosol Sci. Technol. 2018, 52, 1099–1111. [Google Scholar] [CrossRef]

- Katz, E.F.; Goetz, J.D.; Wang, C.; Hart, J.L.; Terranova, B.; Taheri, M.L.; Waring, M.S.; DeCarlo, P.F. Chemical and Physical Characterization of 3D Printer Aerosol Emissions with and without a Filter Attachment. Environ. Sci. Technol. 2020, 54, 947–954. [Google Scholar] [CrossRef]

- Dobrzynska, E.; Kondej, D.; Kowalska, J.; Szewczynska, M. State of the art in additive manufacturing and its possible chemical and particle hazards-review. Indoor Air 2021, 31, 1733–1758. [Google Scholar] [CrossRef]

- Viitanen, A.-K.; Kallonen, K.; Kukko, K.; Kanerva, T.; Saukko, E.; Hussein, T.; Hämeri, K.; Säämänen, A. Technical control of nanoparticle emissions from desktop 3D printing. Indoor Air 2021, 31, 1061–1071. [Google Scholar] [CrossRef] [PubMed]

- Rajeshkumar, G.; Seshadri, S.A.; Devnani, G.L.; Sanjay, M.R.; Siengchin, S.; Maran, J.P.; Al-Dhabi, N.A.; Karuppiah, P.; Mariadhas, V.A.; Sivarajasekar, N.; et al. Environment friendly, renewable and sustainable poly lactic acid (PLA) based natural fiber reinforced composites-A comprehensive review. J. Clean. Prod. 2021, 310, 127483. [Google Scholar] [CrossRef]

- Dunn, K.L.; Dunn, K.H.; Hammond, D.; Lo, S. Three-dimensional printer emissions and employee exposures to ultrafine particles during the printing of thermoplastic filaments containing carbon nanotubes or carbon nanofibers. J. Nanoparticle Res. 2020, 22, 46. [Google Scholar] [CrossRef]

- Stefaniak, A.B.; Johnson, A.R.; du Preez, S.; Hammond, D.R.; Wells, J.R.; Ham, J.E.; LeBouf, R.F.; Menchaca, K.W.; Martin, S.B.; Duling, M.G.; et al. Evaluation of emissions and exposures at workplaces using desktop 3-dimensional printers. J. Chem. Health Saf. 2019, 26, 19–30. [Google Scholar] [CrossRef]

- Hossain, S.K.M.; Toledo Vega, A.; Valles-Rosales, D.; Park, Y.H.; Kuravi, S.; Sohn, H. Particulate suspension: A review of studies characterizing particulates and volatile organic compounds emissions during additive manufacturing processes. Part. Sci. Technol. 2023, 41, 350–360. [Google Scholar] [CrossRef]

- Thapa, B.; Hsieh, S.-A.; Bell, D.S.; Anderson, J.L. Monitoring the liberation of volatile organic compounds during fused deposition modeling three dimensional printing using solid-phase microextraction coupled to gas chromatography/mass spectrometry. J. Chromatogr. A 2023, 1693, 463886. [Google Scholar] [CrossRef]

- Inkinen, S.; Hakkarainen, M.; Albertsson, A.-C.; Södergård, A. From Lactic Acid to Poly(lactic acid) (PLA): Characterization and Analysis of PLA and Its Precursors. Biomacromolecules 2011, 12, 523–532. [Google Scholar] [CrossRef]

- Ding, S.; Ng, B.F.; Shang, X.; Liu, H.; Lu, X.; Wan, M.P. The characteristics and formation mechanisms of emissions from thermal decomposition of 3D printer polymer filaments. Sci. Total Environ. 2019, 692, 984–994. [Google Scholar] [CrossRef]

- Kruza, M.; McFiggans, G.; Waring, M.S.; Wells, J.R.; Carslaw, N. Indoor secondary organic aerosols: Towards an improved representation of their formation and composition in models. Atmos. Environ. 2020, 240, 117784. [Google Scholar] [CrossRef]

- Na, K.; Song, C.; Cocker, D.R., III. Formation of secondary organic aerosol from the reaction of styrene with ozone in the presence and absence of ammonia and water. Atmos. Environ. 2006, 40, 1889–1900. [Google Scholar]

- Zhu, B.; Han, Y.; Wang, C.; Huang, X.; Xia, S.; Niu, Y.; Yin, Z.; He, L. Understanding primary and secondary sources of ambient oxygenated volatile organic compounds in Shenzhen utilizing photochemical age-based parameterization method. J. Environ. Sci. 2019, 75, 105–114. [Google Scholar]

- Wypych, G. Handbook of UV Degradation and Stabilization; Elsevier: Amsterdam, The Netherlands, 2020. [Google Scholar]

- Nazaroff, W.W.; Weschler, C.J. Cleaning products and air fresheners: Exposure to primary and secondary air pollutants. Atmos. Environ. 2004, 38, 2841–2865. [Google Scholar] [CrossRef]

- Huang, Y.; Lee, S.C.; Ho, K.F.; Ho, S.S.H.; Cao, N.; Cheng, Y.; Gao, Y. Effect of ammonia on ozone-initiated formation of indoor secondary products with emissions from cleaning products. Atmos. Environ. 2012, 59, 224–231. [Google Scholar] [CrossRef]

- Stefaniak, A.B.; LeBouf, R.F.; Duling, M.G.; Yi, J.; Abukabda, A.B.; McBride, C.R.; Nurkiewicz, T.R. Inhalation exposure to three-dimensional printer emissions stimulates acute hypertension and microvascular dysfunction. Toxicol. Appl. Pharmacol. 2017, 335, 1–5. [Google Scholar] [CrossRef]

- Gümperlein, I.; Fischer, E.; Dietrich-Gümperlein, G.; Karrasch, S.; Nowak, D.; Jörres, R.A.; Schierl, R. Acute health effects of desktop 3D printing (fused deposition modeling) using acrylonitrile butadiene styrene and polylactic acid materials: An experimental exposure study in human volunteers. Indoor Air 2018, 28, 611–623. [Google Scholar] [CrossRef]

- Leso, V.; Ercolano, M.L.; Mazzotta, I.; Romano, M.; Cannavacciuolo, F.; Iavicoli, I. Three-Dimensional (3D) Printing: Implications for Risk Assessment and Management in Occupational Settings. Ann. Work Expo. Health 2021, 65, 617–634. [Google Scholar] [CrossRef]

- Farcas, M.T.; McKinney, W.; Coyle, J.; Orandle, M.; Mandler, W.K.; Stefaniak, A.B.; Bowers, L.; Battelli, L.; Richardson, D.; Hammer, M.A.; et al. Evaluation of Pulmonary Effects of 3-D Printer Emissions From Acrylonitrile Butadiene Styrene Using an Air-Liquid Interface Model of Primary Normal Human-Derived Bronchial Epithelial Cells. Int. J. Toxicol. 2022, 41, 312–328. [Google Scholar] [CrossRef]

- Uribe-Echeverria, T.; Beiras, R. Acute toxicity of bioplastic leachates to Paracentrotus lividus sea urchin larvae. Mar. Environ. Res. 2022, 176, 105605. [Google Scholar] [CrossRef]

- IARC. Evaluation of Carcinogenic Risks to Humans: Some industrial chemicals. 15–22 February 2000, Lyon, France. IARC Monogr. Eval. Carcinog. Risks Hum. 2000, 77, 1–529. [Google Scholar]

- Tu, Y.-J.; Chang, C.-K.; You, C.-F. Combustion of isopropyl alcohol using a green manufactured CuFe2O4. J. Hazard. Mater. 2012, 229–230, 258–264. [Google Scholar] [CrossRef]

- IARC. IARC Monographs on the Evaluation of Carcinogenic Risks to Humans: Styrene, Styrene-7,8-oxide, and Quinoline. In IARC Working Group on the Evaluation of Carcinogenic Risks to Humans; International Agency for Research on Cancer: Lyon, France, 2019. [Google Scholar]

- Storer, M.; Curry, K.; Squire, M.; Kingham, S.; Epton, M. Breath testing and personal exposure—SIFT-MS detection of breath acetonitrile for exposure monitoring. J. Breath Res. 2015, 9, 036006. [Google Scholar] [CrossRef]

- Afshar-Mohajer, N.; Wu, C.-Y.; Ladun, T.; Rajon, D.A.; Huang, Y. Characterization of particulate matters and total VOC emissions from a binder jetting 3D printer. Build. Environ. 2015, 93, 293–301. [Google Scholar] [CrossRef]

- Zontek, T.L.; Scotto, N.; Hollenbeck, S. Controls for University Fabrication Laboratories-Best Practices for Health and Safety. ACS Chem. Health Saf. 2021, 28, 119–128. [Google Scholar] [CrossRef]

- ANSI/CAN/UL 2904; Standard Method for Testing and Assessing Particle and Chemical Emissions from 3D Printers. American National Standards Institute: Washington DC, USA, 2023.

| μg/m3 | Printer 1 a | Printer 2 b | Printer 3 c |

|---|---|---|---|

| styrene | 912.8 | 237.1 | 17.0 |

| ethylbenzene | 59.9 | 6.6 | 13.0 |

| acetophenone | 61.5 | 2.0 | |

| benzene | 0.4 | ||

| acetaldehyde | 7.7 | ||

| isopropyl alcohol | 108.1 | ||

| ethanol | 39.9 | ||

| acetone | 31.5 | ||

| xylene | 3.0 | ||

| benzaldehyde | 6.0 | ||

| c14(tetradecane) | 2.0 | ||

| acetic acid | 3.0 | ||

| phenol | 1.0 | ||

| hexadecane | 2.0 | ||

| toluene | 40.4 | ||

| hexanal | 70.5 | ||

| octanal | 41.4 | ||

| nonanal | 39.7 | ||

| 1-butano | 39.5 | ||

| benzenemethanol, alpha., alpha.-di | 44.8 | ||

| alpha.-pinene | 42.2 |

| Compounds | Classification | Exposure Concentration (EC, μg/m3) | Cancer Risk (CR) | Hazardous Quotient (HQ) |

|---|---|---|---|---|

| benzene | 1 | 0.51 | 3.97 × 10−6 | 0.0170 |

| ethylbenzene | 2B | 84.26 | 2.11 × 10−4 | 0.0842 |

| formaldehyde | 1 | 1.83 | 2.38 × 10−5 | 0.0062 |

| acetaldehyde | 2B | 0.81 | 1.79 × 10−6 | 0.0905 |

| styrene | 2A | 26.46 | 0.0265 | |

| isopropyl alcohol | 3 | 142.47 | 0.7123 | |

| methyl methacrylate | 3 | 1.93 | 0.0028 | |

| phenol | 3 | 0.92 | 0.0000 | |

| toluene | 3 | 0.51 | 0.0001 | |

| o-xylene | / | 29.51 | 0.2951 | |

| p-xylene | / | 0.61 | 0.0204 | |

| acetic acid | / | 1.32 | 0.0001 | |

| butanone | / | 0.81 | 0.0002 | |

| acetone | / | 11.19 | 0.0004 | |

| benzoic acid | / | 1.93 | 0.0010 | |

| Total cancer risk | 2.40 × 10−4 | |||

| Total hazard quotient (HQs) | 1.2567 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, Y.; Xue, Y.; Sun, C.; She, L.; Peng, Y. Emission Characteristics of Volatile Organic Compounds from Material Extrusion Printers Using Acrylonitrile–Butadiene–Styrene and Polylactic Acid Filaments in Printing Environments and Their Toxicological Concerns. Toxics 2025, 13, 276. https://doi.org/10.3390/toxics13040276

Gao Y, Xue Y, Sun C, She L, Peng Y. Emission Characteristics of Volatile Organic Compounds from Material Extrusion Printers Using Acrylonitrile–Butadiene–Styrene and Polylactic Acid Filaments in Printing Environments and Their Toxicological Concerns. Toxics. 2025; 13(4):276. https://doi.org/10.3390/toxics13040276

Chicago/Turabian StyleGao, Yuan, Yawei Xue, Chenyang Sun, Luhang She, and Ying Peng. 2025. "Emission Characteristics of Volatile Organic Compounds from Material Extrusion Printers Using Acrylonitrile–Butadiene–Styrene and Polylactic Acid Filaments in Printing Environments and Their Toxicological Concerns" Toxics 13, no. 4: 276. https://doi.org/10.3390/toxics13040276

APA StyleGao, Y., Xue, Y., Sun, C., She, L., & Peng, Y. (2025). Emission Characteristics of Volatile Organic Compounds from Material Extrusion Printers Using Acrylonitrile–Butadiene–Styrene and Polylactic Acid Filaments in Printing Environments and Their Toxicological Concerns. Toxics, 13(4), 276. https://doi.org/10.3390/toxics13040276