Regression Metamodel-Based Digital Twin for an Industrial Dynamic Crossflow Filtration Process

Abstract

:1. Introduction

2. Materials and Methods

2.1. Production Setup and Operation

2.2. Mechanistic–Empirical Process Dynamics Model

2.3. Regression Metamodel

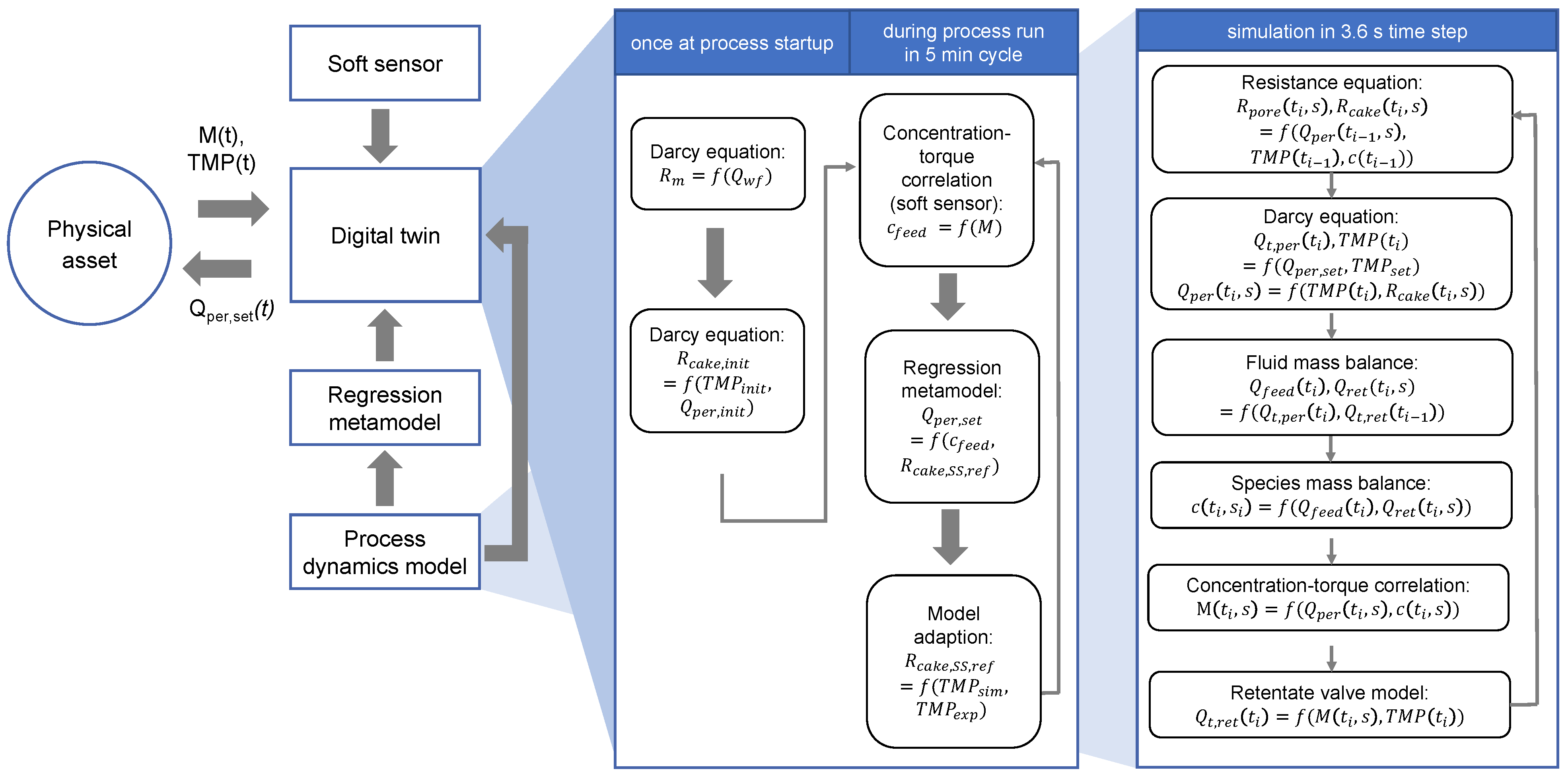

2.4. Digital Twin Framework

3. Results

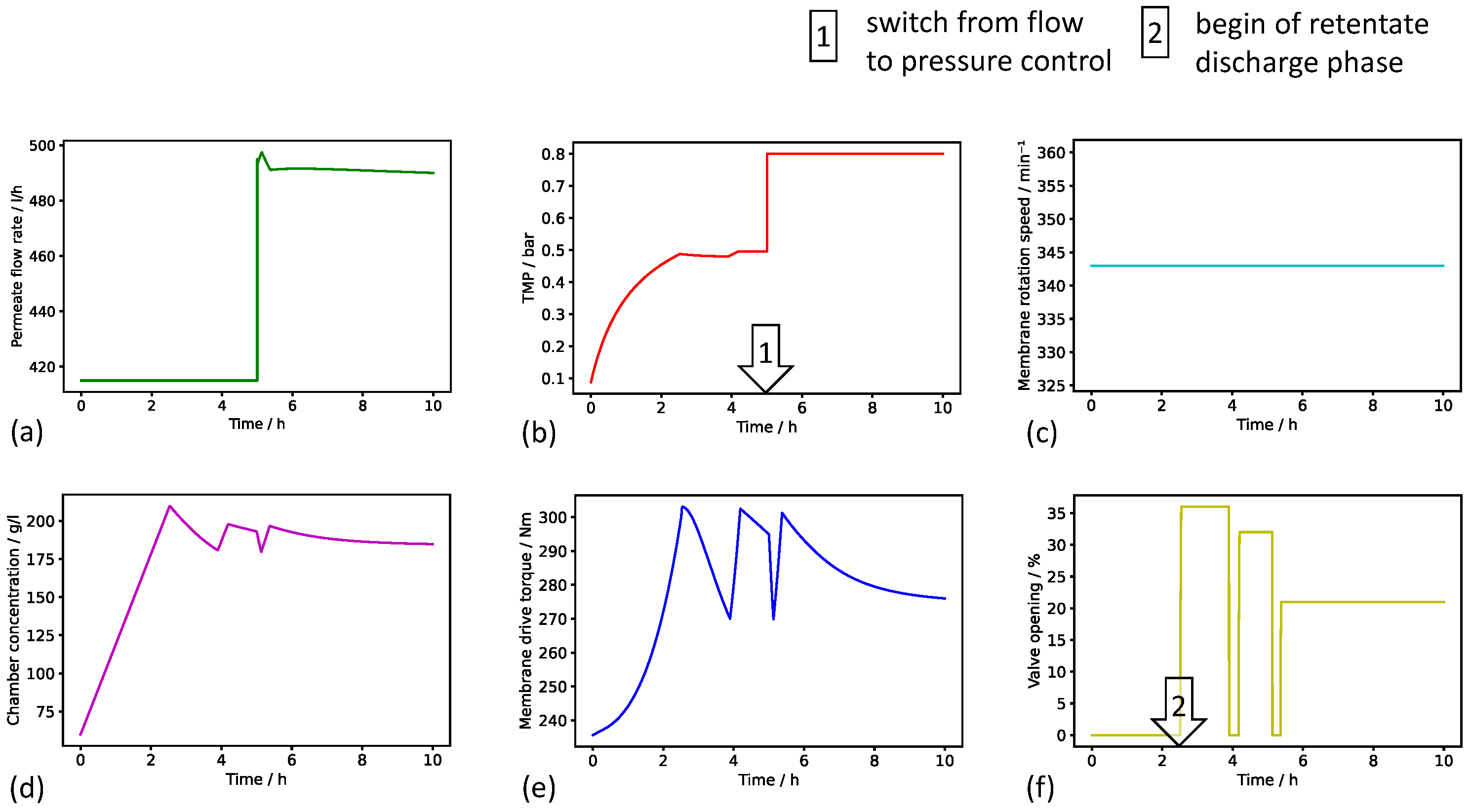

3.1. Mechanistic–Empirical Process Dynamics Model

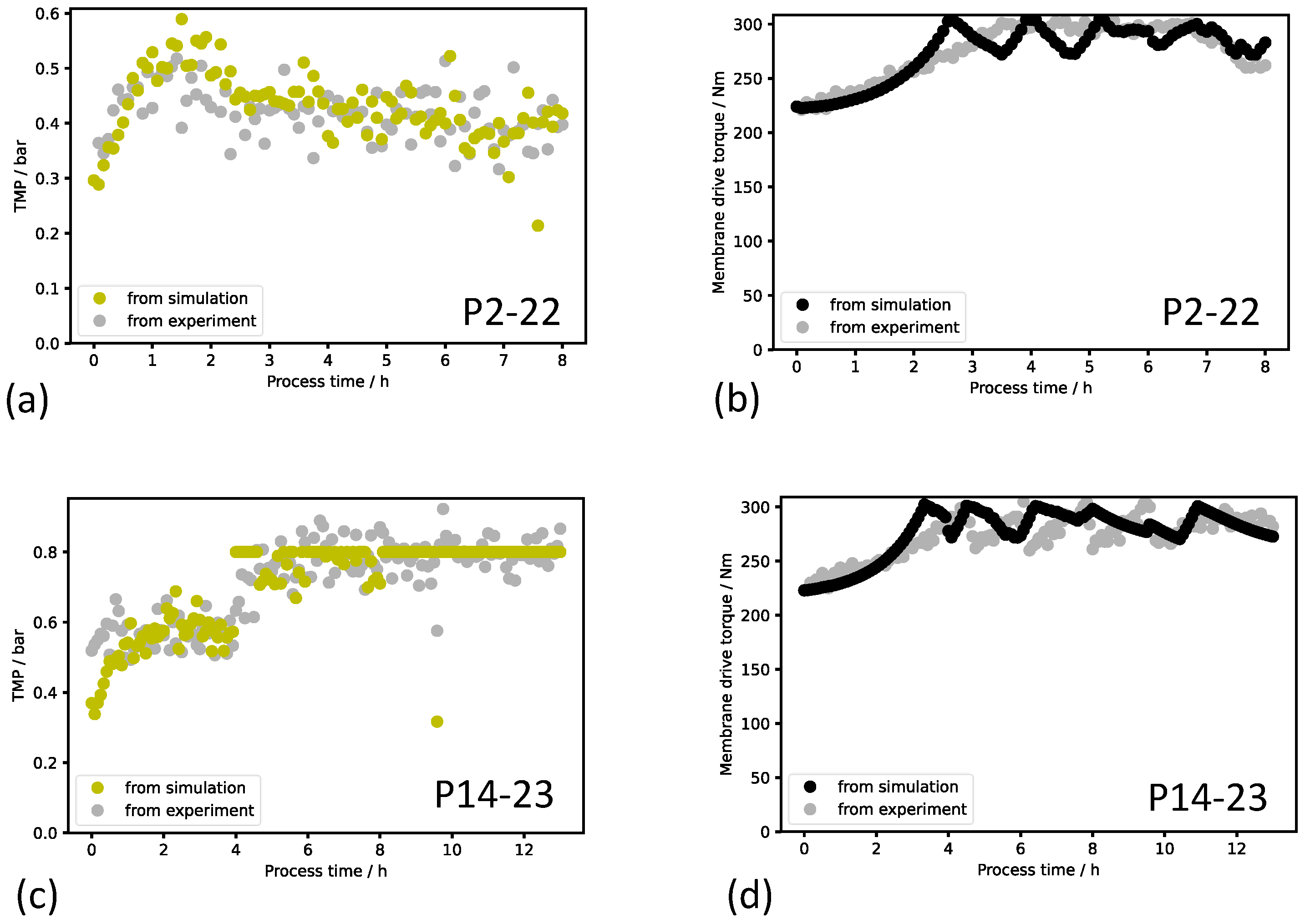

3.2. Process Dynamics Model Validation

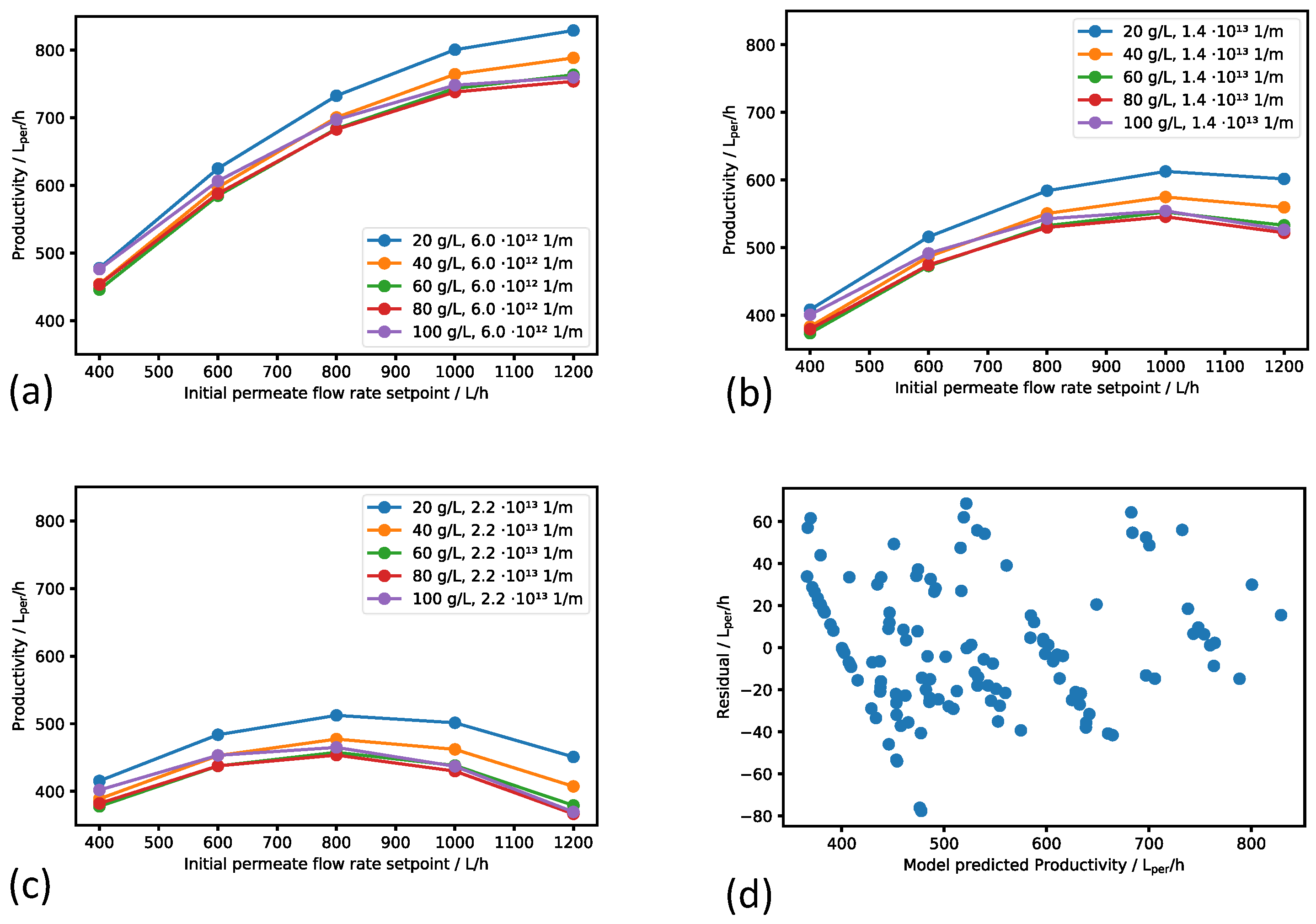

3.3. Regression Metamodel

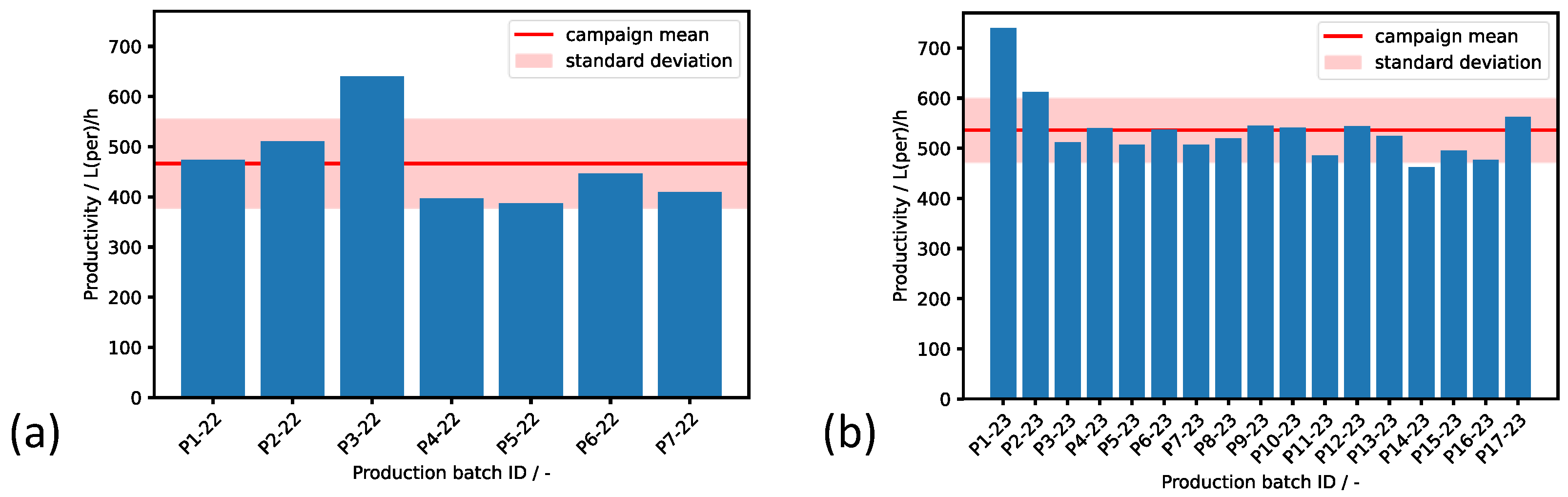

3.4. Effect of the Digital Twin on the Productivity

4. Discussion

4.1. Process Dynamics Model Quality

4.2. Digital Twin Optimization Capability

4.3. Applicability of the Digital Twin Concept beyond the Presented Use Case

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Vogel-Heuser, B.; Hess, D. Guest Editorial Industry 4.0–Prerequisites and Visions. IEEE Trans. Autom. Sci. Eng. 2016, 13, 411–413. [Google Scholar] [CrossRef]

- Negri, E.; Fumagalli, L.; Macchi, M. A Review of the Roles of Digital Twin in CPS-based Production Systems. Procedia Manuf. 2017, 11, 939–948. [Google Scholar] [CrossRef]

- Uhlemann, T.H.J.; Lehmann, C.; Steinhilper, R. The Digital Twin: Realizing the Cyber-Physical Production System for Industry 4.0. Procedia CIRP 2017, 61, 335–340. [Google Scholar] [CrossRef]

- Kritzinger, W.; Karner, M.; Traar, G.; Henjes, J.; Sihn, W. Digital Twin in manufacturing: A categorical literature review and classification. IFAC-PapersOnLine 2018, 51, 1016–1022. [Google Scholar] [CrossRef]

- He, B.; Bai, K.J. Digital twin-based sustainable intelligent manufacturing: A review. Adv. Manuf. 2020, 9, 1–21. [Google Scholar] [CrossRef]

- Rasheed, A.; San, O.; Kvamsdal, T. Digital Twin: Values, Challenges and Enablers From a Modeling Perspective. IEEE Access 2020, 8, 21980–22012. [Google Scholar] [CrossRef]

- Ashtari Talkhestani, B.; Jung, T.; Lindemann, B.; Sahlab, N.; Jazdi, N.; Schloegl, W.; Weyrich, M. An architecture of an Intelligent Digital Twin in a Cyber-Physical Production System. At-Autom. 2019, 67, 762–782. [Google Scholar] [CrossRef]

- Zhang, C.; Xu, W.; Liu, J.; Liu, Z.; Zhou, Z.; Pham, D.T. A Reconfigurable Modeling Approach for Digital Twin-based Manufacturing System. Procedia CIRP 2019, 83, 118–125. [Google Scholar] [CrossRef]

- Malakuti, S.; Grüner, S. Architectural aspects of digital twins in IIoT systems. In Proceedings of the 12th European Conference on Software Architecture: Companion Proceedings (ECSA’18), Madrid, Spain, 24–28 September 2018. [Google Scholar] [CrossRef]

- Chen, Y.; Yang, O.; Sampat, C.; Bhalode, P.; Ramachandran, R.; Ierapetritou, M. Digital Twins in Pharmaceutical and Biopharmaceutical Manufacturing: A Literature Review. Processes 2020, 8, 1088. [Google Scholar] [CrossRef]

- Klein, M.; Maschler, B.; Zeller, A.; Talkhestani, B.A.; Jazdi, N.; Weyrich, M.; Rosen, R. Architektur und Technologiekomponenten eines digitalen Zwillings. In Automation 2019; VDI Verlag: Düsseldorf, Germany, 2019; pp. 89–102. [Google Scholar] [CrossRef]

- Smiatek, J.; Jung, A.; Bluhmki, E. Towards a Digital Bioprocess Replica: Computational Approaches in Biopharmaceutical Development and Manufacturing. Ther. Biomanuf. 2020, 38, 1141–1153. [Google Scholar] [CrossRef]

- Martinez, E.M.; Ponce, P.; Macias, I.; Molina, A. Automation Pyramid as Constructor for a Complete Digital Twin, Case Study: A Didactic Manufacturing System. Sensors 2021, 21, 4656. [Google Scholar] [CrossRef]

- Moyne, J.; Qamsane, Y.; Balta, E.C.; Kovalenko, I.; Faris, J.; Barton, K.; Tilbury, D.M. A Requirements Driven Digital Twin Framework: Specification and Opportunities. IEEE Access 2020, 8, 107781–107801. [Google Scholar] [CrossRef]

- Durão, L.F.C.S.; Haag, S.; Anderl, R.; Schützer, K.; Zancul, E. Digital Twin Requirements in the Context of Industry 4.0. In Product Lifecycle Management to Support Industry 4.0; Springer International Publishing: Berlin/Heidelberg, Germany, 2018; pp. 204–214. [Google Scholar] [CrossRef]

- Lopez, P.C.; Udugama, I.A.; Thomsen, S.T.; Roslander, C.; Junicke, H.; Mauricio-Iglesias, M.; Gernaey, K.V. Towards a digital twin: A hybrid data-driven and mechanistic digital shadow to forecast the evolution of lignocellulosic fermentation. Biofuels Bioprod. Biorefin. 2020, 14, 1046–1060. [Google Scholar] [CrossRef]

- Trunzer, E.; Wu, C.; Guo, K.; Vermum, C.; Vogel-Heuser, B. Data-Driven Approach to Support Experts in the Identification of Operational States in Industrial Process Plants. In Proceedings of the IECON 2018-44th Annual Conference of the IEEE Industrial Electronics Society, Washington, DC, USA, 21–23 October 2018. [Google Scholar] [CrossRef]

- Chew, C.M.; Aroua, M.K.; Hussain, M.A. Advanced process control for ultrafiltration membrane water treatment system. J. Clean. Prod. 2018, 179, 63–80. [Google Scholar] [CrossRef]

- Herwig, C.; Pörtner, R.; Möller, J. (Eds.) Digital Twins; Springer International Publishing: Berlin/Heidelberg, Germany, 2021. [Google Scholar] [CrossRef]

- Narayanan, H.; Luna, M.F.; Stosch, M.; Bournazou, M.N.C.; Polotti, G.; Morbidelli, M.; Butté, A.; Sokolov, M. Bioprocessing in the Digital Age: The Role of Process Models. Biotechnol. J. 2020, 15, 1900172. [Google Scholar] [CrossRef]

- Sokolov, M.; von Stosch, M.; Narayanan, H.; Feidl, F.; Butté, A. Hybrid modeling—A key enabler towards realizing digital twins in biopharma? Biotechnol. J. 2020, 34, 100715. [Google Scholar] [CrossRef]

- Sansana, J.; Joswiak, M.N.; Castillo, I.; Wang, Z.; Rendall, R.; Chiang, L.H.; Reis, M.S. Recent trends on hybrid modeling for Industry 4.0. Curr. Opin. Chem. Eng. 2021, 151, 107365. [Google Scholar] [CrossRef]

- Solle, D.; Hitzmann, B.; Herwig, C.; Pereira Remelhe, M.; Ulonska, S.; Wuerth, L.; Prata, A.; Steckenreiter, T. Between the Poles of Data-Driven and Mechanistic Modeling for Process Operation. Chem. Ing. Tech. 2017, 89, 542–561. [Google Scholar] [CrossRef]

- von Stosch, M.; Oliveira, R.; Peres, J.; de Azevedo, S.F. Hybrid semi-parametric modeling in process systems engineering: Past, present and future. Comput. Chem. Eng. 2014, 60, 86–101. [Google Scholar] [CrossRef]

- Narayanan, H.; von Stosch, M.; Feidl, F.; Sokolov, M.; Morbidelli, M.; Butté, A. Hybrid modeling for biopharmaceutical processes: Advantages, opportunities, and implementation. Front. Chem. Eng. 2023, 5, 1157889. [Google Scholar] [CrossRef]

- Rizki, Z.; Ravesloot, R.; van Beckhoven, R.; Ottens, M. Model-based optimization of multistage ultrafiltration/diafiltration for recovery of canola protein. Food Bioprod. Process. 2023, 140, 212–229. [Google Scholar] [CrossRef]

- Krippl, M.; Dürauer, A.; Duerkop, M. Hybrid modeling of cross-flow filtration: Predicting the flux evolution and duration of ultrafiltration processes. Sep. Purif. Technol. 2020, 248, 117064. [Google Scholar] [CrossRef]

- Piron, E.; Latrille, E.; René, F. Application of artificial neural networks for crossflow microfiltration modelling: “black-box” and semi-physical approaches. Comput. Chem. Eng. 1997, 21, 1021–1030. [Google Scholar] [CrossRef]

- Díaz, V.H.G.; Prado-Rubio, O.A.; Willis, M.J.; von Stosch, M. Dynamic hybrid model for ultrafiltration membrane processes. In Computer Aided Chemical Engineering; Elsevier: Amsterdam, The Netherlands, 2017; pp. 193–198. [Google Scholar] [CrossRef]

- Chew, C.M.; Aroua, M.K.; Hussain, M.A. A practical hybrid modelling approach for the prediction of potential fouling parameters in ultrafiltration membrane water treatment plant. J. Ind. Eng. Chem. 2017, 45, 145–155. [Google Scholar] [CrossRef]

- Jin, R.; Chen, W.; Simpson, T. Comparative studies of metamodelling techniques under multiple modelling criteria. Struct. Multidiscip. Optim. 2001, 23, 1–13. [Google Scholar] [CrossRef]

- Romijn, R.; Özkan, L.; Weiland, S.; Ludlage, J.; Marquardt, W. A grey-box modeling approach for the reduction of nonlinear systems. J. Process. Control 2008, 18, 906–914. [Google Scholar] [CrossRef]

- Franzreb, M.; Muller, E.; Vajda, J. Cost estimation for protein a chromatography: An in silico approach to mab purification strategy. Bioprocess Int. 2014, 12, 9. [Google Scholar]

- Wang, G.; Briskot, T.; Hahn, T.; Baumann, P.; Hubbuch, J. Root cause investigation of deviations in protein chromatography based on mechanistic models and artificial neural networks. J. Chromatogr. A 2017, 1515, 146–153. [Google Scholar] [CrossRef] [PubMed]

- Bott, R.; Langeloh, T.; Ehrfeld, E. Dynamic cross flow filtration. Chem. Eng. J. 2000, 80, 245–249. [Google Scholar] [CrossRef]

- Jaffrin, M.Y. Dynamic Crossflow Filtration. In Encyclopedia of Membrane Science and Technology; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2013. [Google Scholar] [CrossRef]

- Marke, H.S.; Breil, M.P.; Hansen, E.B.; Pinelo, M.; Krühne, U. Cake resistance in rotational dynamic filtration: Determination and modeling. Sep. Purif. Technol. 2020, 250, 117100. [Google Scholar] [CrossRef]

- Marke, H.S.; Breil, M.P.; Hansen, E.B.; Pinelo, M.; Krühne, U. Investigation of the velocity factor in a rotational dynamic microfiltration system. Sep. Purif. Technol. 2019, 220, 69–77. [Google Scholar] [CrossRef]

- Ho, W.S.W.; Sirkar, K.K. (Eds.) Membrane Handbook, 1st ed.; Springer: New York, NY, USA, 1992. [Google Scholar] [CrossRef]

- Schmidt-Traub, H.; Schulte, M.; Seidel-Morgenstern, A. Preparative Chromatography; Wiley-VCH Verlag GmbH: Weinheim, Germany, 2020. [Google Scholar]

- Mezger, T.G. The Rheology Handbook, 4th ed.; Vincentz Network: Hannover, Germany, 2012. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Heusel, M.; Grim, G.; Rauhut, J.; Franzreb, M. Regression Metamodel-Based Digital Twin for an Industrial Dynamic Crossflow Filtration Process. Bioengineering 2024, 11, 212. https://doi.org/10.3390/bioengineering11030212

Heusel M, Grim G, Rauhut J, Franzreb M. Regression Metamodel-Based Digital Twin for an Industrial Dynamic Crossflow Filtration Process. Bioengineering. 2024; 11(3):212. https://doi.org/10.3390/bioengineering11030212

Chicago/Turabian StyleHeusel, Matthias, Gunnar Grim, Joel Rauhut, and Matthias Franzreb. 2024. "Regression Metamodel-Based Digital Twin for an Industrial Dynamic Crossflow Filtration Process" Bioengineering 11, no. 3: 212. https://doi.org/10.3390/bioengineering11030212

APA StyleHeusel, M., Grim, G., Rauhut, J., & Franzreb, M. (2024). Regression Metamodel-Based Digital Twin for an Industrial Dynamic Crossflow Filtration Process. Bioengineering, 11(3), 212. https://doi.org/10.3390/bioengineering11030212