Biocorrosion and Cytotoxicity Studies on Biodegradable Mg-Based Multicomponent Alloys

Abstract

1. Introduction

2. Experimental Details

2.1. Fabrication and Sample Preparation

2.2. Electrochemical Characterization

2.3. SEM–EDS Analysis

2.4. In Vitro Studies: Cytotoxicity Assay Using MTT (3-(4,5-Dimethylthiazol-2-yl)-2,5-Diphenyltetrazolium Bromide)

3. Results and Discussion

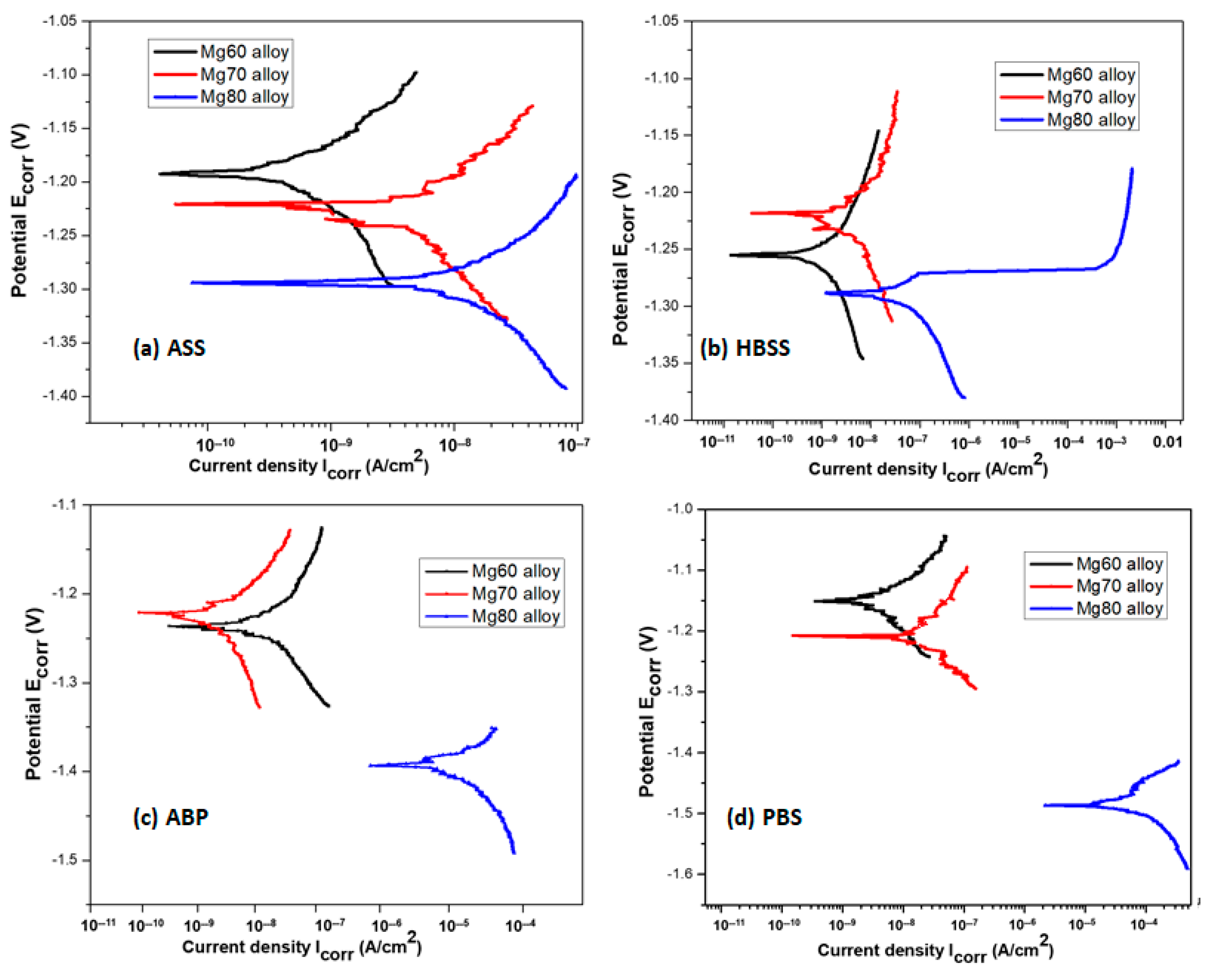

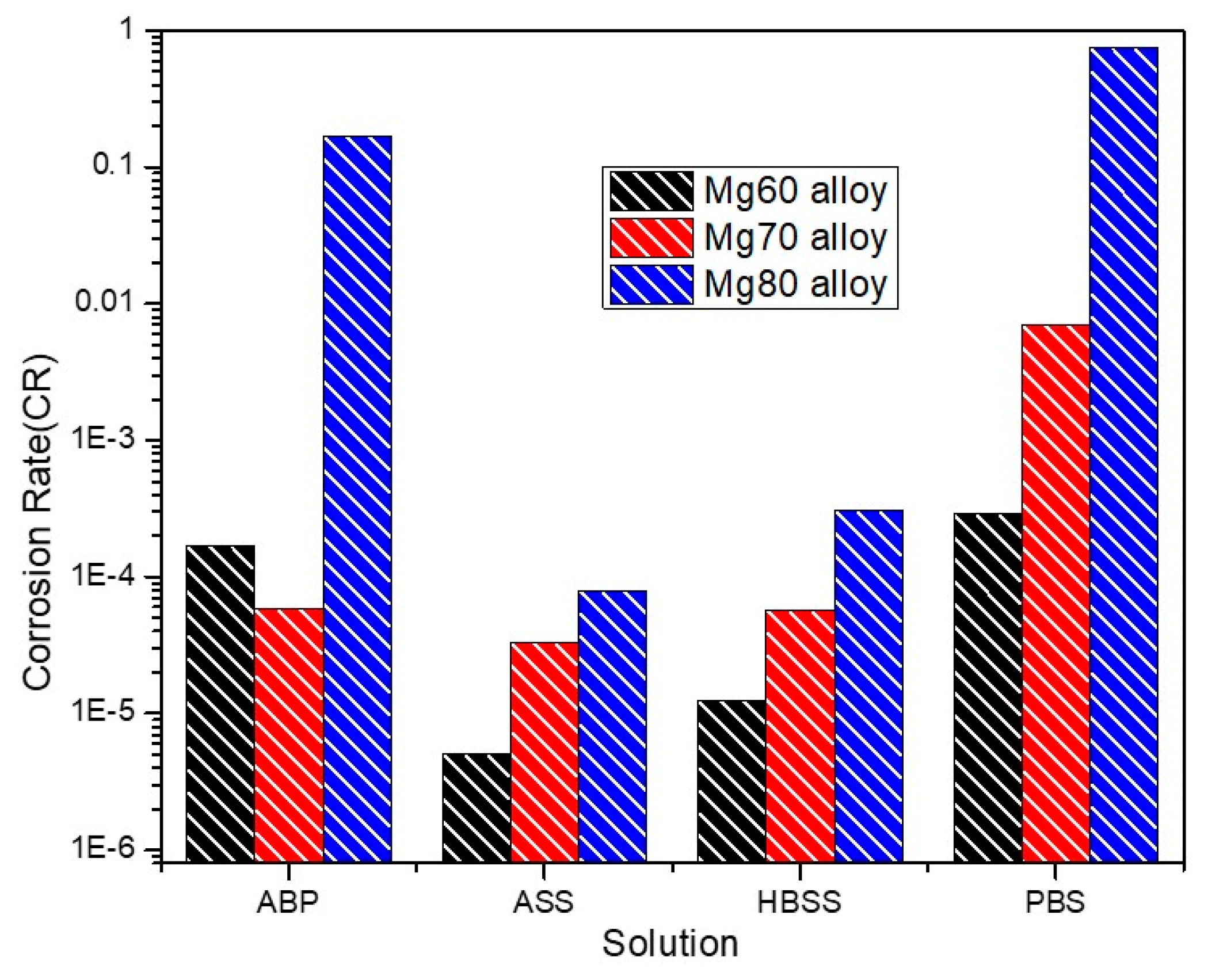

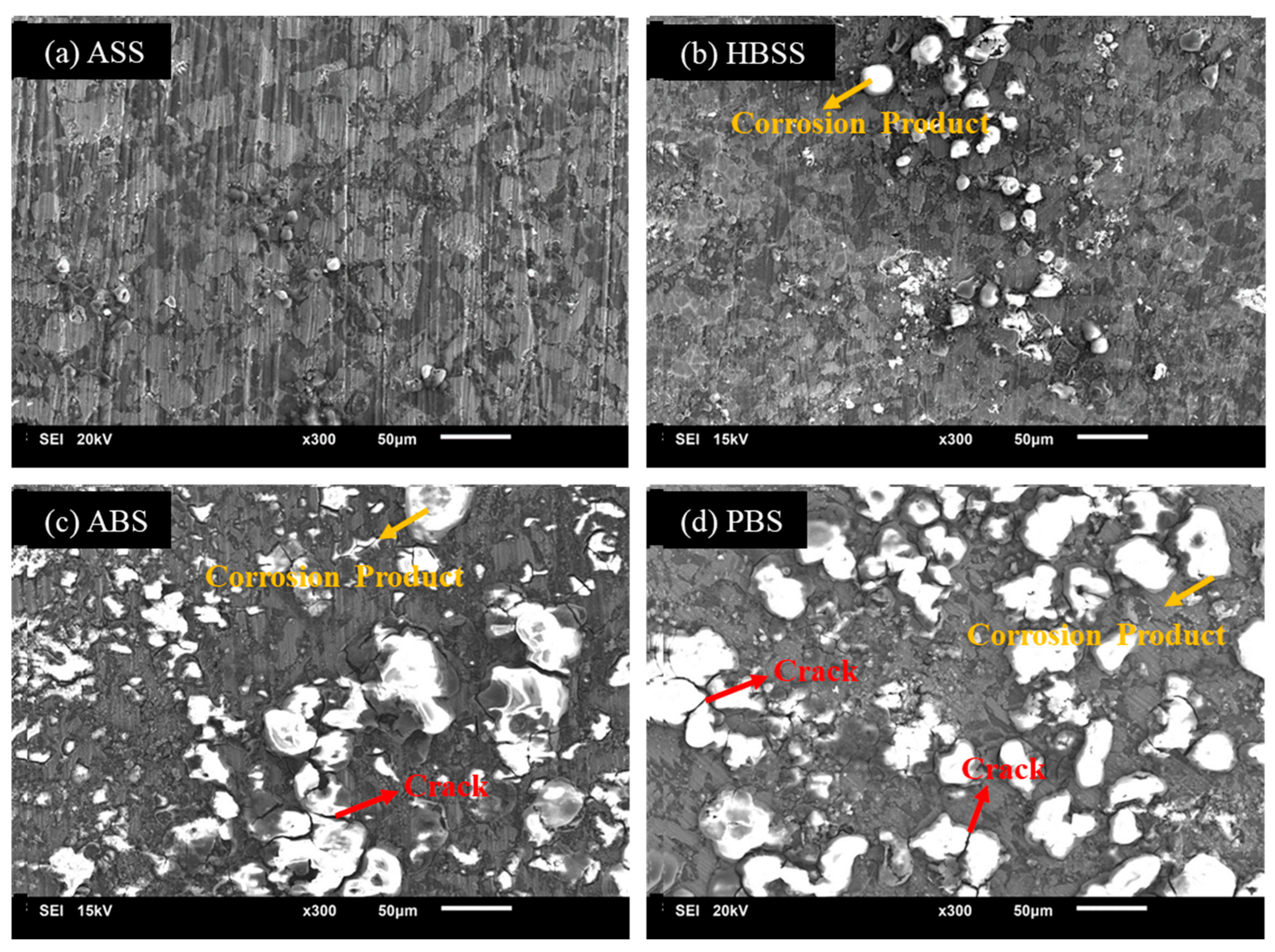

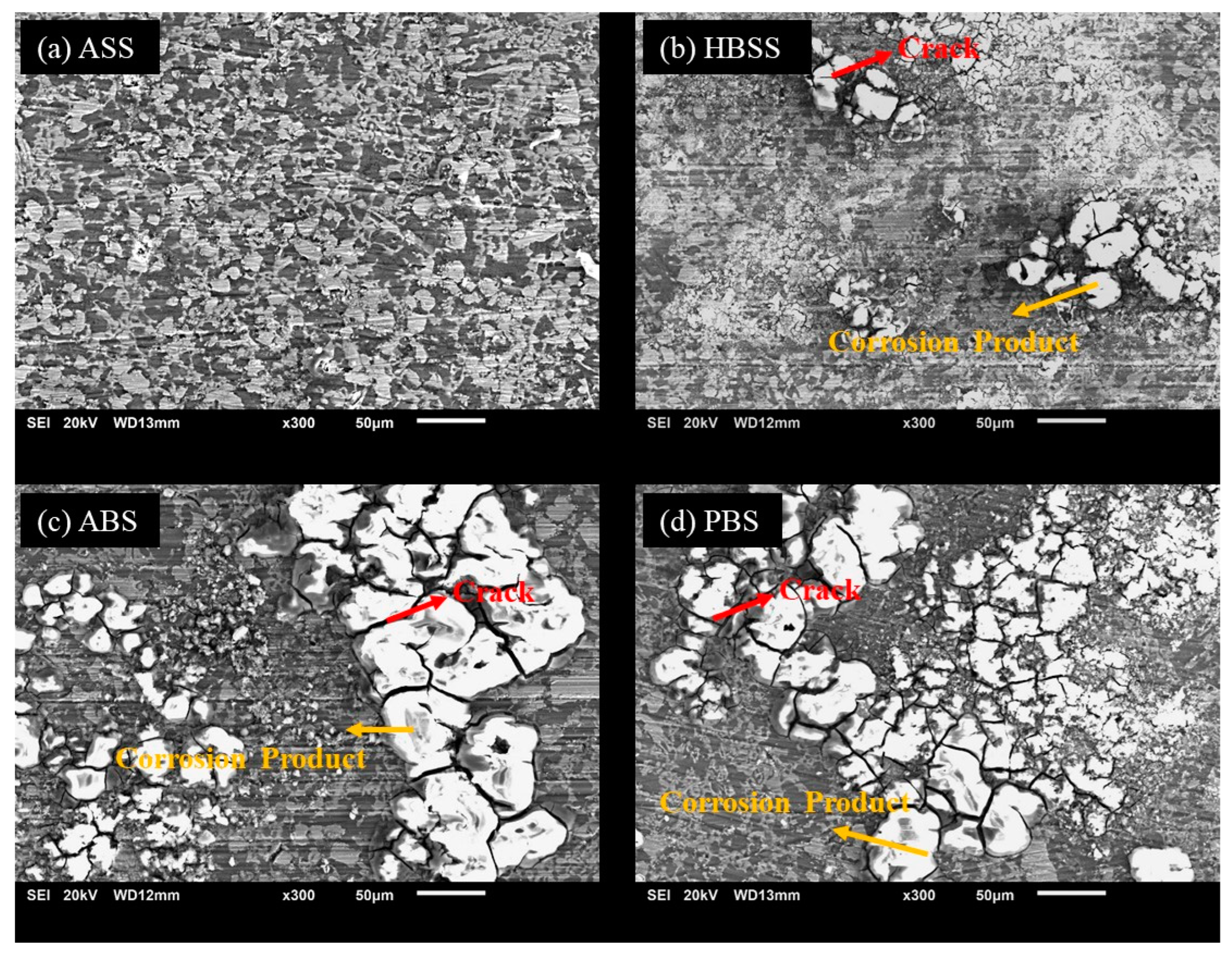

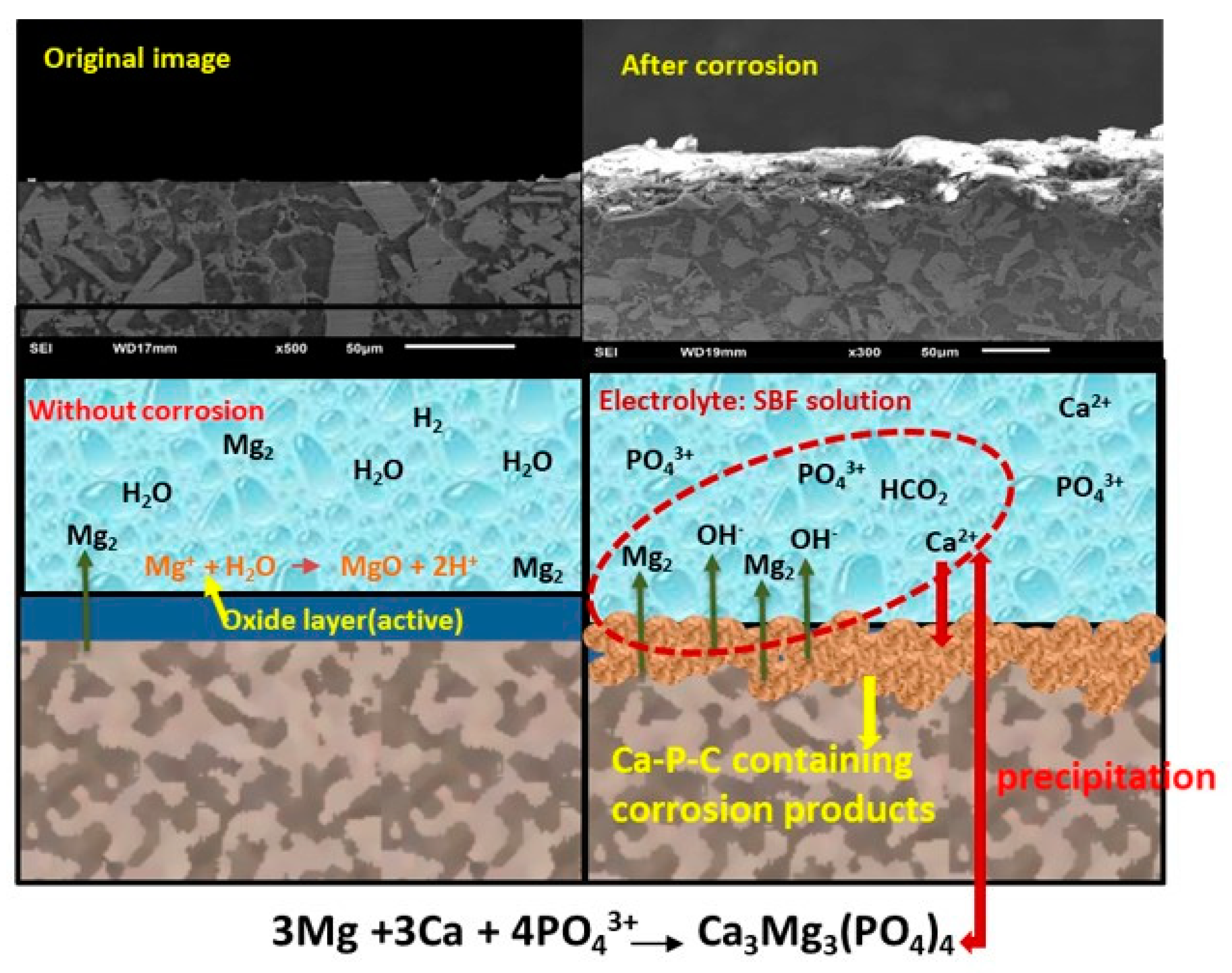

3.1. Potentiodynamic Polarization Measurements and Surface Morphologies

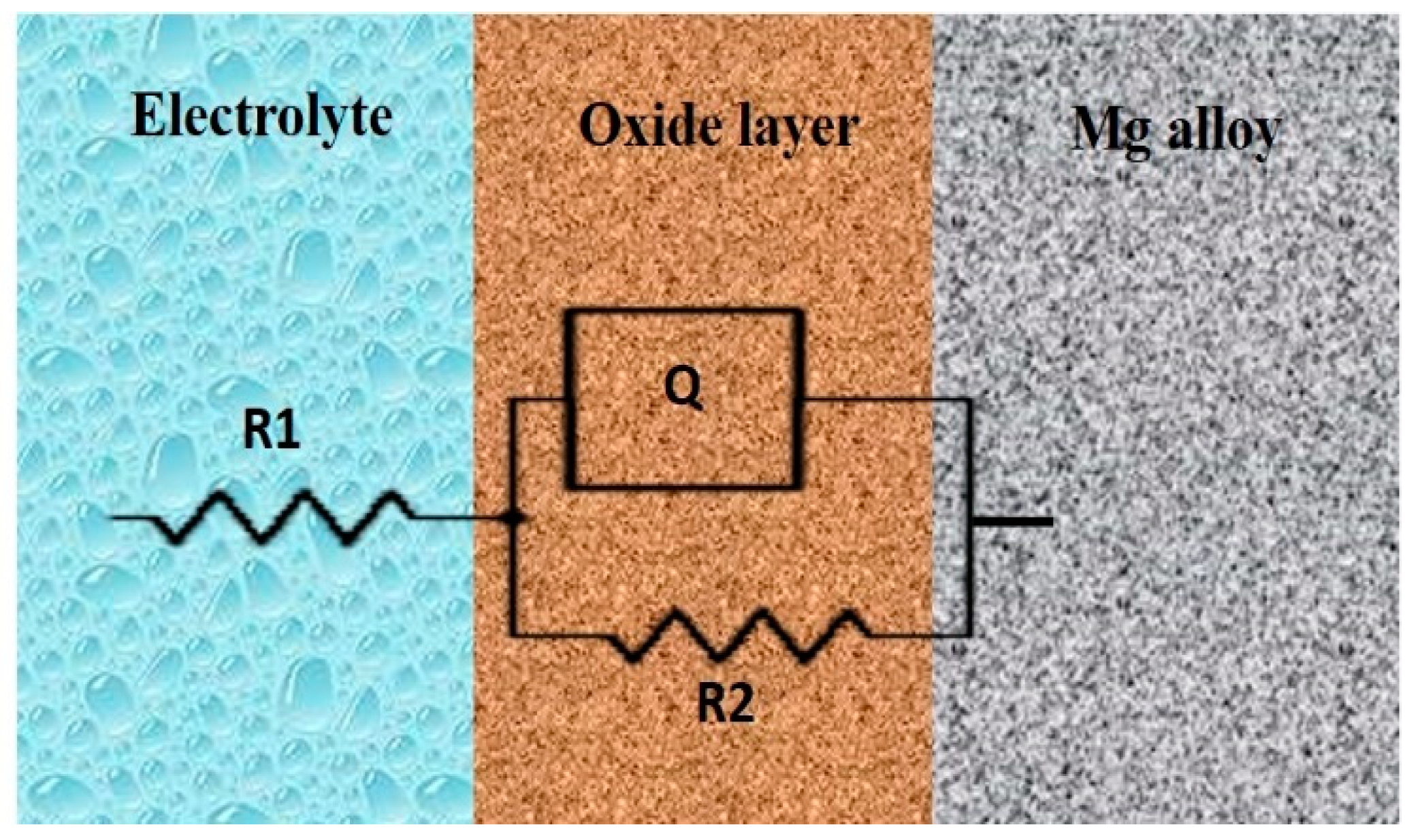

3.2. Electrochemical Impedance Spectroscopy (EIS) Measurement

3.3. Energy-Dispersion X-ray Spectroscopy

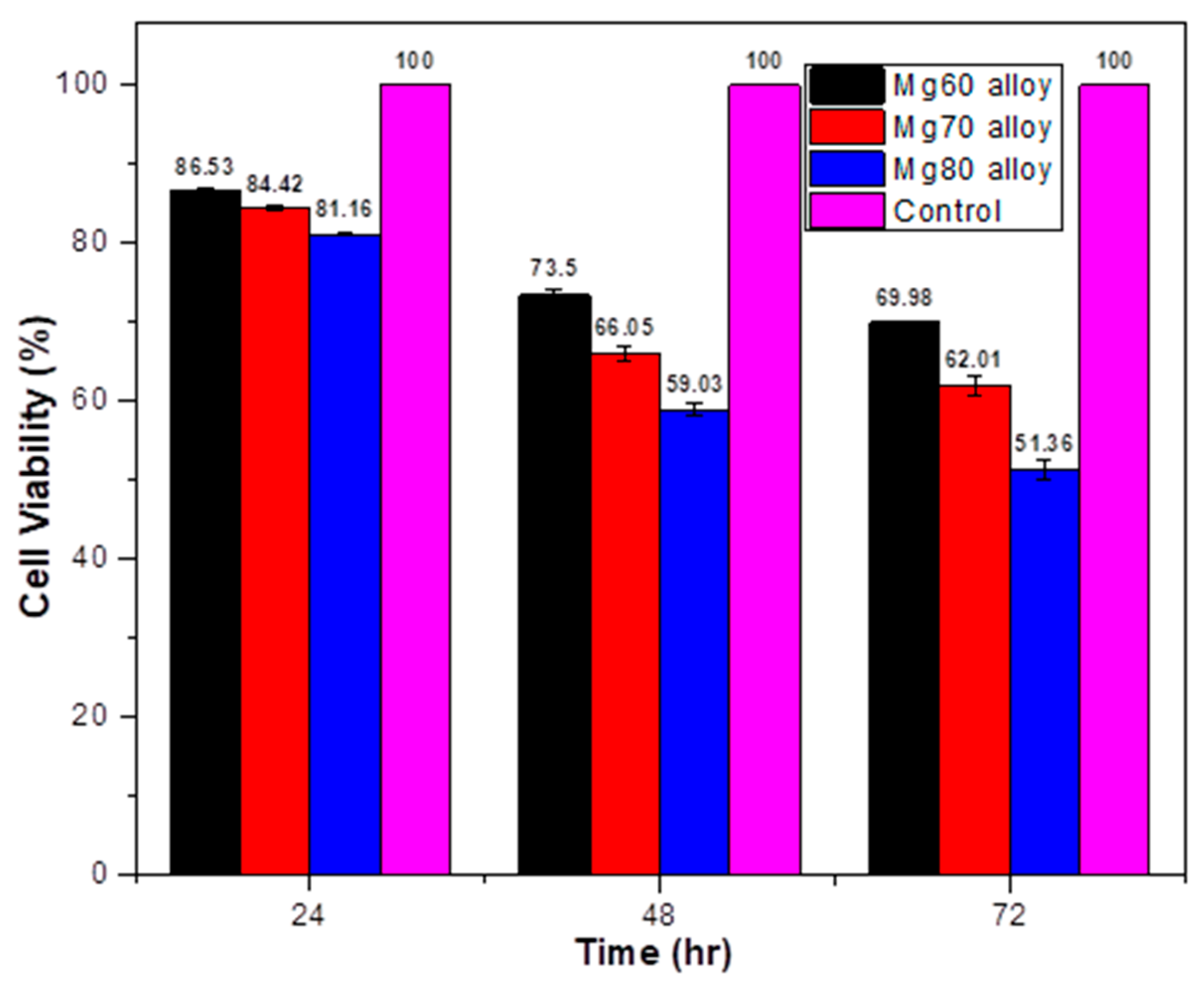

4. Cytotoxicity Behavior of Mg–MCA Alloys

5. Conclusions

- The electrochemical corrosion behavior of the Mg–MCA alloys were tested in various simulated body fluids, and the corrosion resistance order for the Mg–MCA alloys is as follows: ASS > HBSS > ABP > PBS;

- Among all the three alloys, the Mg60 alloy exhibited low corrosion rates (~× 10−5 mm/year), with negligible surface defects observed on the alloy surface in all solutions. This can be attributed to the formation of Mg32(AlZn)49 and Mg–Zn–Cu phases and a lower Mg content, with a high atomic percentage of alloying elements. This stable nature contributes to excellent corrosion resistance;

- The Mg80 alloy displayed high corrosion rates (range from 7.97 × 10−5 to 0.74 mm/year) and severe surface degradation, with deeper cracks observed on the alloy surface when immersed in all four solutions, leading to higher metal dissolution. This can be attributed to the high Mg content and the formation of intermetallic phases, such as Al6Mn, Al2CuMg, and Al2Cu phases;

- It is interesting to note that in the ABP solution, the Mg70 alloy displayed a high corrosion resistance value (5.84 × 10−5 mm/year) compared to the Mg60 alloy (1.68 × 10−4 mm/year);

- According to the EDS analysis, which further validates the polarization, SEM, and impedance data parameters, all three Mg–MCA alloys in the ASS solution exhibited superior corrosion resistance. This strongly indicates that the current alloys are exceptionally well-suited for dental applications;

- In vitro studies revealed that the novel Mg–MCA alloys demonstrate cytotoxicity activity against tumor cells;

- Analysis of the live/dead morphologies in the occurrence of MDA-MB-231 cells showed an increased presence of dead cells in regard to the Mg80 alloy, with majority of live cells observed in regard to the Mg60 alloy;

- In conclusion, the results indicate that, concerning proliferation and vitality, the Mg80 alloy can be deemed a promising material with potential antitumor activity for implants.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Aidin, B.K.; Benyamin, Y.; Masoud, M. Emerging Magnesium-Based Biomaterials for Orthopedic Implantation. Emerg. Mater. Res. 2019, 8, 1–13. [Google Scholar]

- Yang, Y.; Qiao, L.; Gao, Z.; Yan, Y. Study of wear-corrosion resistance of Co-based biomaterial. Emerg. Mater. Res. 2016, 5, 194–200. [Google Scholar] [CrossRef]

- Joshi, M.G.; Advani, S.G.; Miller, F.; Santare, M.H. Analysis of a femoral hip prosthesis designed to reduce stress shielding. J. Biomech. 2000, 33, 1655–1662. [Google Scholar] [CrossRef]

- Shomali, A.A.; Guillory, R.J.; Seguin, D.; Goldman, J.; Drelich, J.W. Effect of PLLA coating on corrosion and biocompatibility of zinc in vascular environment. Surf. Innov. 2017, 5, 211–220. [Google Scholar] [CrossRef]

- Drelich, A.J.; Bowen, P.K.; LaLonde, L.; Goldman, J.; Drelich, J.W. Importance of oxide film in endovascular biodegradable zinc stents. Surf. Innov. 2017, 4, 133–140. [Google Scholar] [CrossRef]

- Esmaily, M.; Svensson, J.E.; Fajardo, S.; Birbilis, N.; Frankel, G.S.; Virtanen, S.; Arrabal, R.; Thomas, S.; Johansson, L.G. Fundamentals and advances in magnesium alloy corrosion. Prog. Mater. Sci. 2017, 89, 92–193. [Google Scholar] [CrossRef]

- Manivasagam, G.; Suwas, S. Biodegradable Mg and Mg based alloys for biomedical implants. Mater. Sci. Technol. 2014, 30, 515–520. [Google Scholar] [CrossRef]

- Yunfei, D.; Cuie, W.; Peter, H.; Yuncang, L. Effects of alloying elements on the corrosion behavior and biocompatibility of biodegradable magnesium alloys: A review. J. Mater. Chem. B 2014, 2, 1912–1933. [Google Scholar]

- Staiger, M.P.; Pietak, A.M.; Huadmai, J.; Dias, G. Magnesium and its alloys as orthopedic biomaterials: A review. Biomaterials 2006, 27, 1728–1734. [Google Scholar] [CrossRef]

- Moravej, M.; Mantovani, D. Biodegradable metals for cardiovascular stent application: Interests and new opportunities. Int. J. Mol. Sci. 2011, 12, 4250–4270. [Google Scholar] [CrossRef]

- Sezer, N.; Evis, Z.; Kayhan, S.M.; Tahmasebifar, A.; Koç, M. Review of magnesium-based biomaterials and their applications. J. Magnes. Alloys 2018, 6, 23–43. [Google Scholar] [CrossRef]

- Riaz, U.; Shabib, I.; Haider, W. The current trends of Mg alloys in biomedical applications-A review. J. Biomed. Mater. Res. B Appl. Biomater. 2019, 107, 1970–1996. [Google Scholar] [CrossRef]

- Wen, Z.; Wu, C.; Dai, C.; Yang, F. Corrosion behaviors of Mg and its alloys with different Al contents in a modified simulated body fluid. J. Alloys Compd. 2009, 488, 392–399. [Google Scholar] [CrossRef]

- Bobby Kannan, M.; Singh Raman, R.K.; Witte, F.; Blawert, C.; Dietzel, W. Influence of circumferential notch and fatigue crack on the mechanical. J. Biomed. Mater. Res. Part B Appl. Biomater. 2011, 96, 303–309. [Google Scholar] [CrossRef]

- Thomaz, T.R.; Weber, C.R.; Pelegrini, T.; Dick, L.F.P.; Kncornschild, D. The negative difference effect of magnesium and of the AZ91 alloy in chloride and stannate-containing solutions. Corr. Sci. 2010, 52, 2235–2243. [Google Scholar] [CrossRef]

- Song, G. Control of biodegradation of biocompatable magnesium alloys. Corr. Sci. 2007, 49, 1696–1701. [Google Scholar] [CrossRef]

- Trivedi, P. Process-Structure-Property Relationship in Magnesium-Based Biodegradable Alloy for Biomedical Applications; The University of Texas: El Paso, TX, USA, 2017. [Google Scholar]

- Du, H.; Wei, Z.; Liu, Z.; Zhang, E. Effects of Zn on the microstructure, mechanical property and bio-corrosion property of Mg–3Ca alloys for biomedical application. Mater. Chem. Phys. 2011, 125, 568–575. [Google Scholar] [CrossRef]

- Tun, K.S.; Kumar, A.; Gupta, M. Introducing a High-Performance Mg-Based Multicomponent Alloy as an Alternative to Al-Alloys. Front. Mater. 2019, 6, 1–6. [Google Scholar] [CrossRef]

- Song, L.; Lu, Y.; Zhang, Y.; Li, X.; Cong, M.; Xu, W. The effect of Ca addition on microstructure and mechanical properties of extruded AZ31 alloys. Vacuum 2019, 168, 108822. [Google Scholar] [CrossRef]

- Srivatsan, T.S.; Ibrahim, I.A.; Mohamed, F.A.; Lavernia, E.J. Processing techniques for particulate-reinforced metal aluminium matrix composites. J. Mater. Sci. 1991, 26, 5965–5978. [Google Scholar] [CrossRef]

- Song, G.L.; Atrens, A. Corrosion Mechanisms of Magnesium Alloys. Adv. Eng. Mater. 1999, 1, 11–33. [Google Scholar] [CrossRef]

- Abd El-Rahman, S.S. Neuropathology of aluminum toxicity in rats (glutamate and GABA impairment). Pharmacol. Res. 2003, 47, 189–194. [Google Scholar] [CrossRef]

- Razavi, M.; Huang, Y. Assessment of magnesium-based biomaterials: From bench to clinic. Biomater. Sci. 2019, 7, 2241–2263. [Google Scholar] [CrossRef]

- Xu, D.; He, J.; Wen, J.; Shi, H. Effect of immersion time on corrosion behavior of Mg-2Nd-0.5Zn-0.4Zr-1Y alloy in simulated body fluid. Mater. Res. Express. 2019, 6, 125414. [Google Scholar] [CrossRef]

- Aghion, E.; Bronfin, B. Magnesium alloys development towards the 21st century. Mater. Sci. Technol. 2011, 17, 631–642. [Google Scholar]

- Song, G. Recent progress in corrosion and protection of magnesium alloys. Adv. Eng. Mater. 2007, 9, 177–183. [Google Scholar] [CrossRef]

- Bordbar-Khiabani, A.; Yarmand, B.; Sharifi-Asl, S.; Mozafari, M. Improved corrosion performance of biodegradable magnesium in simulated inflammatory condition via drug-loaded plasma electrolytic oxidation coatings. Mater. Chem. Phys. 2020, 239, 1–14. [Google Scholar] [CrossRef]

- Wang, S.; Yang, C.; Ren, L.; Shen, M.; Yang, K. Study on antibacterial performance of Cu-bearing cobalt-based alloy. Mater. Lett. 2014, 129, 88–90. [Google Scholar] [CrossRef]

- Kainer, K.U.; Bala Srinivasan, P.; Blawert, C.; Dietzel, W. Corrosion of Magnesium and its Alloys. Corrosion 2010, 51, 2011–2041. [Google Scholar]

- Ardelean, M.; Wang, J.; Thompson, G.E. Influence of copper content on the corrosion of magnesium alloy AM50. Corros. Sci. 2018, 137, 181–195. [Google Scholar]

- Atrens, A.; Johnston, S. The role of intermetallic compounds in enhancing the corrosion resistance of magnesium alloys. Corros. Sci. 2005, 47, 973–977. [Google Scholar]

- Parthiban, G.T.; Palaniswamy, N.; Sivan, V. Effect of manganese addition on anode characteristics of electrolytic magnesium. Anti-Corros. Methods Mater. 2009, 56, 79–83. [Google Scholar] [CrossRef]

- Radha, R.; Sreekanth, D. Insight of magnesium alloys and composites for orthopedic implant applications—A review. J. Mg. Alloys 2017, 5, 286–312. [Google Scholar] [CrossRef]

- Makar, G.L.; Kruger, J. Corrosion of magnesium. Int. Mater. Rev. 2013, 38, 138–153. [Google Scholar] [CrossRef]

- Shivkumar, R. Synergistic and Antagonistic Effects in Metal Alloys. J. Mater. Sci. 1993, 28, 6241–6253. [Google Scholar]

- Somayajulu, S.N.R. Effect of Alloying Elements on the Corrosion Behavior of Mg-Al-Zn-Mn Alloys. Corros. Sci. 2007, 49, 2976–2993. [Google Scholar]

- Huang, J.H. Effects of Alloying Elements on the Microstructure, Mechanical Properties and Corrosion Behavior of Mg-Al-Zn Alloys. Mater. Sci. Eng. A 2009, 524, 1–10. [Google Scholar]

- Park, N.H. Effect of Alloying Elements on the Microstructure and Mechanical Properties of Mg-Al-Cu-Mn Alloys. Mater. Sci. Eng. A 2008, 485, 446–453. [Google Scholar]

- Gururaj, P.; Vyasaraj, M.; Saif, W.; Milli, S.K.; Manoj, G. Enhancing Mechanical Response of Monolithic Magnesium Using Nano-NiTi (Nitinol) Particles. Metals 2018, 8, 1014. [Google Scholar] [CrossRef]

- Chunhong, Z.; Xiaomei, H.; Milin, Z.; Lili, G.; Reizhi, W. Electrochemical characterization of the corrosion of a Mg–Li Alloy. Mater. Lett. 2008, 62, 2177–2180. [Google Scholar]

- Sudha, P.; Tun, K.S.; Anchal, N.; Gupta, M.; Vincent, S. Electrochemical characterization of a Novel Mg70Al18Zn6Ca4Y2 low entropy alloy in different aqueous environments. Metall. Mater. Trans. A 2021, 52, 2549–2563. [Google Scholar] [CrossRef]

- Xiaoxiao, G.; Chenghu, L.; Guowei, W.; Yang, Q.; Chunguang, F.; Jia, L.; Yanping, S. A novel method for evaluating the dynamic biocompatibility of degradable biomaterials based on real-time cell analysis. Regen. Biomater. 2020, 1, 321–329. [Google Scholar]

- Zeng, R.C.; Hu, Y.; Guan, H.K.; Cui, H.Z.; Han, E.H. Corrosion of magnesium alloy AZ31: The influence of bicarbonate, sulphate, hydrogen phosphate and dihydrogen phosphate ions in saline solution. Corros. Sci. 2014, 86, 171–182. [Google Scholar] [CrossRef]

- Johnston, S.; Shi, Z.; Atrens, A. The influence of pH on the corrosion rate of high-purity Mg, AZ91 and ZE41 in bicarbonate buffered Hanks’ solution. Corros. Sci. 2015, 101, 182–192. [Google Scholar] [CrossRef]

- Ison, H.C.K. Handbook on Corrosion Testing and Evaluation. Br. Corros. J. 1971, 7, 171. [Google Scholar] [CrossRef]

- Bao, L.; Le, Q.; Zhang, Z.; Esling, C. Novel degradation rate controlling mechanism of biocompatible Mg-Zn-Y-Zr alloys. Mater. Lett. 2019, 235, 189–192. [Google Scholar] [CrossRef]

- Fakiha, E.H.; Amany, M.F.; Mohammed, Z.F. Electrochemical behavior of AZ91D magnesium alloy in phosphate medium—Part I. Effect of Ph. J. Appl. Electrochem. 2009, 39, 583–591. [Google Scholar]

- Liping, X.; Erlin, Z.; Dongsong, Y.; Songyan, Z.; Ke, Y. In vitro corrosion behaviour of Mg alloys in a phosphate buffered solution for bone implant application. J. Mater. Sci. Mater. Med. 2008, 19, 1017–1025. [Google Scholar]

- Zhang, C.Y.; Zeng, R.; Liu, C.L.; Gao, J.C. Comparison of calcium phosphate coatings on Mg–Al and Mg–Ca alloys and their corrosion behavior in Hank’s solution. Surf. Coat. Technol. 2010, 204, 3636–3640. [Google Scholar]

- BakhsheshiRad, H.R.; Idris, M.H.; Abdul-Kadir, M.R.; Ourdjini, A.; Medraj, M.; Daroonparvar, M.; Hamzah, E. Mechanical and bio-corrosion properties of quaternary Mg–Ca–Mn–Zn alloys compared with binary Mg–Ca alloys. Mater. Des. 2014, 53, 283–292. [Google Scholar] [CrossRef]

- Badawy, W.A.; Hilal, N.H.; Rabiee, M.; Nady, H. Electrochemical behavior of Mg and some Mg alloys in aqueous solutions of different Ph. Electrochim. Acta 2010, 55, 1880–1887. [Google Scholar] [CrossRef]

- Liang, j.; Bala Srinivasan, P.; Blawert, C.; Dietzel, W. Influence of chloride ion concentration on the electrochemical corrosion behaviour of plasma electrolytic oxidation coated AM50 magnesium alloy. Electrochim. Acta 2010, 55, 6802–6811. [Google Scholar] [CrossRef]

- Wang, Y.B.; Li, H.F.; Cheng, Y.; Wei, S.C.; Zheng, Y.F. Corrosion performances of a Nickel-free Fe-based bulk metallic glass in simulated body fluids. Electrochem. Commun. 2009, 11, 2187–2190. [Google Scholar] [CrossRef]

- Shukla, A.K.; Balasubramaniam, R.; Bhargava, S. Properties of passive film formed on CP titanium, Ti–6Al–4V and Ti–13.4 Al–29Nb alloys in simulated human body conditions. Intermetallics 2005, 13, 631–637. [Google Scholar] [CrossRef]

- Hodgson, W.E.; Mueller, Y.; Forster, D.C.; Virtanen, S. Electrochemical characterisation of passive films on Ti alloys under simulated biological conditions. Electrochim. Acta 2002, 47, 1913–1923. [Google Scholar] [CrossRef]

- El-Taib Heakal, F.; Shehata, O.S.; Tantawy, N.S. Degradation behaviour of AZ80E magnesium alloy exposed to phosphate buffer saline medium. Corros. Sci. 2014, 86, 285–294. [Google Scholar] [CrossRef]

- Weiwei, H.; Erlin, Z.; Ke, Y. Effect of Y on the bio-corrosion behavior of extruded Mg–Zn–Mn alloy in Hank’s solution. Mater. Sci. Eng. C 2010, 30, 167–174. [Google Scholar]

- Moutarlier, V.; Viennet, R.; Gigandet, M.P.; Hihn, J.Y. Use of ultrasound irradiation during acid etching of the 2024 aluminum alloy: Effect on corrosion resistance after anodization. Ultrason. Sonochem. 2020, 18, 31470–31476. [Google Scholar] [CrossRef] [PubMed]

- Natalia, A.; Mikhail, K.; Natalia, M.; Boris, S.; Regine, W.R.; Sergey, D.; Yuri, E. Cytotoxicity of biodegradable magnesium alloy WE43 to tumor cells in vitro: Bioresorbable implants with antitumor activity? J. Biomed. Mater. Res. 2020, 108, 167–173. [Google Scholar]

- Hu, Y.; Dong, D.; Wang, X.; Chen, H.; Qiao, Y. Synthesis and Properties of Mg-Mn-Zn Alloys for Medical Applications. Materials 2021, 14, 1855. [Google Scholar]

- Bahrampour, S.; Bordbar-Khiabani, A.; Siadati, M.H.; Gasik, M.; Mozafari, M. Improving the inflammatory-associated corrosion behavior of magnesium alloys by Mn3O4 incorporated plasma electrolytic oxidation coatings. Chem. Eng. J. 2024, 483, 149016. [Google Scholar]

- Yuanhao, W.; Guanping, H.; Yu, Z.; Yang, L.; Mei, L.; Xiaolan, W.; Nan, L.; Kang, L.; Guan, Z.; Yufeng, Z.; et al. Unique antitumor property of the Mg-Ca-Sr alloys with addition of Zn. Sci. Rep. 2016, 6, 21736. [Google Scholar]

- Chen, Y.M.; Xiao, M.; Zhao, H.; Yang, B.C. On the antitumor properties of biomedical magnesium metal. J. Mater. Chem. B 2015, 3, 849–858. [Google Scholar] [CrossRef] [PubMed]

- Hakimi, O.; Ventura, Y.; Goldman, J.; Vago, R.; Aghion, E. Porous biodegradable EW62 medical implants resist tumor cell growth. Mater. Sci. Eng. C Mater. Biol. Appl. 2016, 61, 516–525. [Google Scholar] [CrossRef] [PubMed]

| Contents (g/L) | ABP (pH 7.4) | HBSS (pH 7.4) | PBS (pH 7.4) | ASS (pH 6.2) |

|---|---|---|---|---|

| NaCl | 8.036 | 8.0 | 8.0 | 1.5 |

| NaHCO3 | 0.352 | 0.35 | - | 1.5 |

| NaH2PO4 | - | - | 1.15 | 0.5 |

| KCl | 0.225 | 0.4 | 0.2 | - |

| KSCN | - | - | - | 0.5 |

| KH2PO4 | - | 0.06 | 0.2 | - |

| Lactic Acid | - | - | - | 0.9 |

| Na2HPO4·3H2O | 0.238 | - | - | - |

| MgCl2·6H2O | 0.311 | - | - | - |

| CaCl2 | 0.293 | - | - | - |

| Na2SO4 | 0.0072 | - | - | - |

| CaCl2·2H2O | - | 0.19 | - | - |

| MgSO4·7H2O | - | 0.2 | - | - |

| Na2HPO4·7H2O | - | 0.09 | - | - |

| Glucose | - | 1.0 | - | - |

| Type of Solution | Material | Icorr (A/cm2) | Ecorr (V vs. SCE) |

|---|---|---|---|

| ASS | Mg60 alloy | 3.48 × 10−10 | −1.19 |

| Mg70 alloy | 2.03 × 10−9 | −1.22 | |

| Mg80 alloy | 4.68 × 10−9 | −1.29 | |

| PBS | Mg60 alloy | 4.30 × 10−9 | −1.15 |

| Mg70 alloy | 1.97 × 10−8 | −1.20 | |

| Mg80 alloy | 4.40 × 10−5 | −1.48 | |

| ABP | Mg60 alloy | 1.15 × 10−8 | −1.23 |

| Mg70 alloy | 3.57 × 10−9 | −1.21 | |

| Mg80 alloy | 9.99 × 10−6 | −1.39 | |

| HBSS | Mg60 alloy | 8.55 × 10−10 | −1.25 |

| Mg70 alloy | 3.52 × 10−9 | −1.23 | |

| Mg80 alloy | 1.81 × 10−8 | −1.29 |

| Composition | Solution | pH Level | Icorr (A/cm2) |

|---|---|---|---|

| Mg–Mn–Zn alloy | PBS | 7.4 | 7.917 × 10−5 |

| AZ31 alloy | HBSS | 7.4 | 2.74 × 10−4 |

| Mg–2Ca–0.5Mn–2Zn alloy | Kokubo (c–SBF) | 7.6 | 78.3 × 10−6 |

| Mg–2Ca–0.5Mn–4Zn alloy | 7.6 | 99.6 × 10−6 | |

| Mg–2Ca–0.5Mn–7Zn alloy | 7.6 | 174.1 |

| Solution | Alloy | R1 (Ω) | R2 (Ω) | Q1 (F) | n |

|---|---|---|---|---|---|

| ASS | Mg60 | 0.01 | 0.06 | 0.27 | 0.7 |

| Mg70 | 9.66 × 10−3 | 0.04 | 0.67 | 0.7 | |

| Mg80 | 8.61 × 10−3 | 0.035 | 0.46 | 0.7 | |

| HBSS | Mg60 | 3.42 × 10−3 | 0.019 | 0.078 | 0.8 |

| Mg70 | 3.49 × 10−3 | 0.01 | 0.22 | 0.8 | |

| Mg80 | 4.23 × 10−3 | 7.21 × 10−3 | 0.63 | 0.7 | |

| ABP | Mg60 | 2.63 × 10−3 | 8.42 × 10−3 | 0.124 | 0.9 |

| Mg70 | 2.57 × 10−3 | 9.10 × 10−3 | 0.13 | 0.8 | |

| Mg80 | 4.01 × 10−3 | 5.72 × 10−3 | 0.65 | 0.7 | |

| PBS | Mg60 | 2.71 × 10−3 | 0.03 | 0.38 | 0.7 |

| Mg70 | 2.62 × 10−3 | 0.01 | 0.28 | 0.8 | |

| Mg80 | 2.49 × 10−3 | 8.65 × 10−3 | 0.55 | 0.8 |

| Solution | Alloy | O (%.at) | Mg (%.at) | Al (%.at) | Zn (%.at) | Cu (%.at) | Mn (%.at) | P (%.at) | Cl (%.at) |

|---|---|---|---|---|---|---|---|---|---|

| ASS | Mg60 | 14.04 | 60.49 | 12.71 | 5.35 | 4.12 | 2.84 | 0.46 | - |

| Mg70 | 17.10 | 59.64 | 13.07 | 3.46 | 6.18 | 0.55 | - | - | |

| Mg80 | 36.65 | 52.34 | 1.89 | 3.79 | 4.11 | 0.31 | 0.90 | - | |

| HBSS | Mg60 | 40.41 | 38.64 | 9.58 | 3.42 | 6.22 | 1.13 | 0.59 | - |

| Mg70 | 44.73 | 43.05 | 5.64 | 3.00 | 2.32 | 0.58 | 0.68 | - | |

| Mg80 | 71.56 | 28.33 | 0.11 | 0.00 | 0.00 | 0.00 | 0.00 | - | |

| ABP | Mg60 | 60.71 | 29.78 | 3.79 | 1.45 | 2.41 | 0.94 | 0.94 | - |

| Mg70 | 30.61 | 48.44 | 8.75 | 4.05 | 2.76 | 1.09 | 4.29 | - | |

| Mg80 | 70.80 | 28.48 | 0.19 | 0.25 | 0.22 | 0.04 | 0.03 | - | |

| PBS | Mg60 | 53.32 | 36.46 | 4.01 | 2.36 | 1.50 | 0.55 | 2.12 | - |

| Mg70 | 61.27 | 29.06 | 3.97 | 1.28 | 2.89 | 0.97 | - | 0.55 | |

| Mg80 | 70.53 | 28.80 | 0.19 | 0.12 | 0.08 | 0.04 | 0.25 | - |

| Time | Alloy | Cell Viability (%) | Standard Deviation % CV |

|---|---|---|---|

| 24 h | Mg60 | 86.24 | 0.37 |

| Mg70 | 84.4 | 0.37 | |

| Mg80 | 81.21 | 0.12 | |

| 48 h | Mg60 | 72.91 | 0.69 |

| Mg70 | 65.72 | 0.80 | |

| Mg80 | 59.29 | 0.77 | |

| 72 h | Mg60 | 70.14 | 0.17 |

| Mg70 | 61.16 | 1.36 | |

| Mg80 | 51.64 | 1.16 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sudha, P.; Tun, K.S.; Pillai, J.; Dutta, M.; Gupta, M.; Kumar, V.S. Biocorrosion and Cytotoxicity Studies on Biodegradable Mg-Based Multicomponent Alloys. Bioengineering 2024, 11, 621. https://doi.org/10.3390/bioengineering11060621

Sudha P, Tun KS, Pillai J, Dutta M, Gupta M, Kumar VS. Biocorrosion and Cytotoxicity Studies on Biodegradable Mg-Based Multicomponent Alloys. Bioengineering. 2024; 11(6):621. https://doi.org/10.3390/bioengineering11060621

Chicago/Turabian StyleSudha, Priya, Khin Sandar Tun, Jisha Pillai, Mainak Dutta, Manoj Gupta, and Vincent Shantha Kumar. 2024. "Biocorrosion and Cytotoxicity Studies on Biodegradable Mg-Based Multicomponent Alloys" Bioengineering 11, no. 6: 621. https://doi.org/10.3390/bioengineering11060621

APA StyleSudha, P., Tun, K. S., Pillai, J., Dutta, M., Gupta, M., & Kumar, V. S. (2024). Biocorrosion and Cytotoxicity Studies on Biodegradable Mg-Based Multicomponent Alloys. Bioengineering, 11(6), 621. https://doi.org/10.3390/bioengineering11060621