A New Wave of Industrialization of PHA Biopolyesters

Abstract

:1. Introduction

2. Industrializing Poly(3-hydroxybutyrate) (P(3HB) or PHB)

2.1. Challenges of Processing and Commercializing P(3HB)

2.2. Biomer

2.3. PHB Industrial S.A.

2.4. Tianan Biologic Materials Co.

2.5. Nafigate Corporation–Hydal

2.6. Newlight Technologies LLC

2.7. COFCO Cooperation Ltd.

2.8. Mango Materials

2.9. Bio-On

3. Industrializing P(3HB-co-3HV) Copolyesters

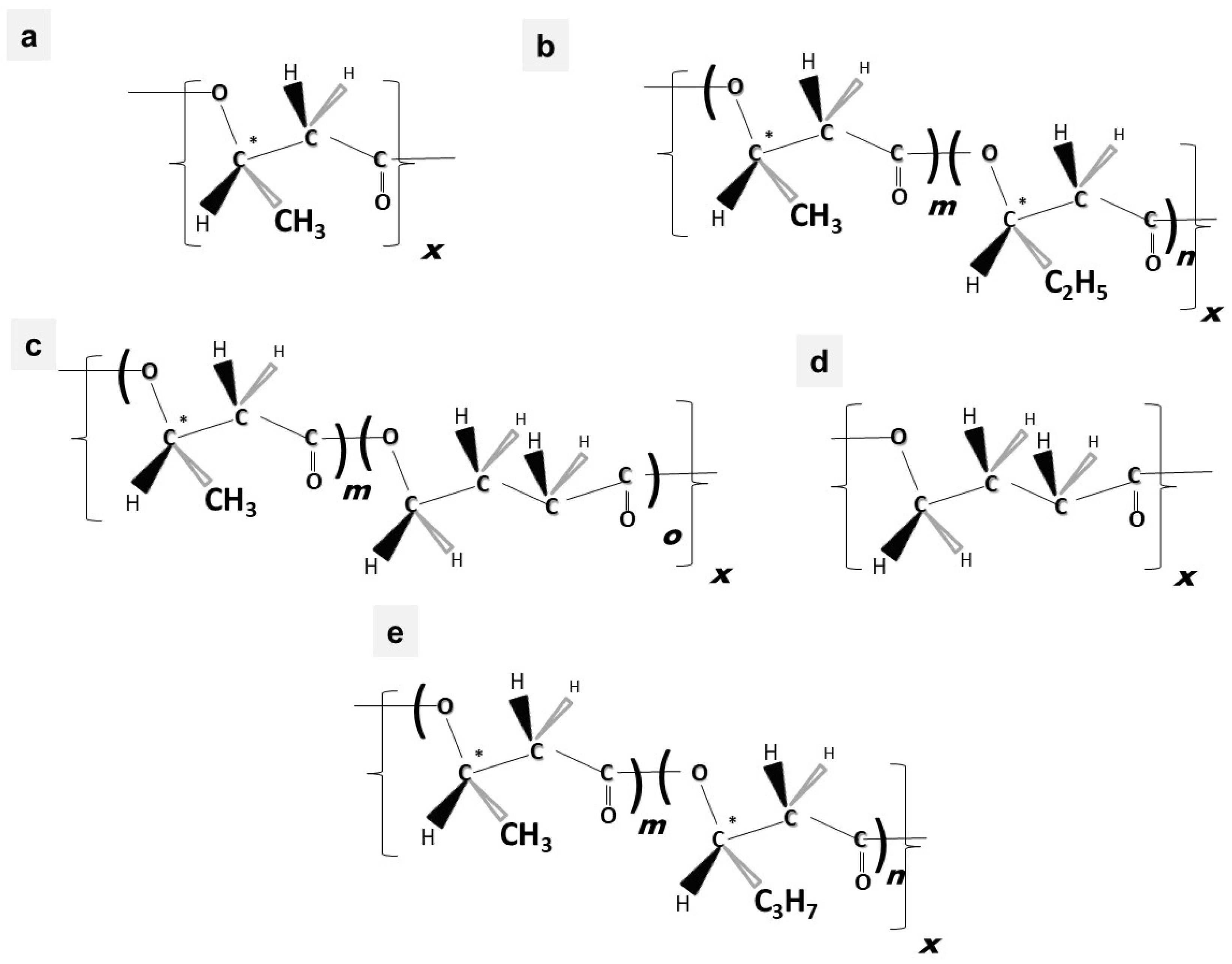

3.1. PHA Heteropolyesters and Their Advantages in Processing and Commercialization

3.2. ICI–Zeneca–Metabolix–Telles

3.3. PHB Industrial S.A., Brazil

3.4. Tianan Biologic Materials Co.

3.5. Genecis Bioindustries Inc.

3.6. Bioextrax

4. Industrializing P(3HB-co-4HB) Copolyesters

4.1. 4-Hydroxybutyrate: An Achiral Building Block as Game Changer for PHA Properties

4.2. Tianjin GreenBio Materials Co. Ltd.

4.3. Shenzhen Ecomann Biotechnology Co. Ltd.

4.4. Metabolix and Cheiljedang Corporation

4.5. PhaBuilder and Medpha

4.6. Tepha Medical Devices Inc.

5. Industrializing P(3HB-co-3HHx) Copolyesters

5.1. Hybrid-Type PHA Copolyesters Consisting of Scl- and Mcl-PHA Building Blocks

5.2. Danimer Scientific

5.3. Kanegafuchi Chemical Industry Co. Ltd. (Kaneka)

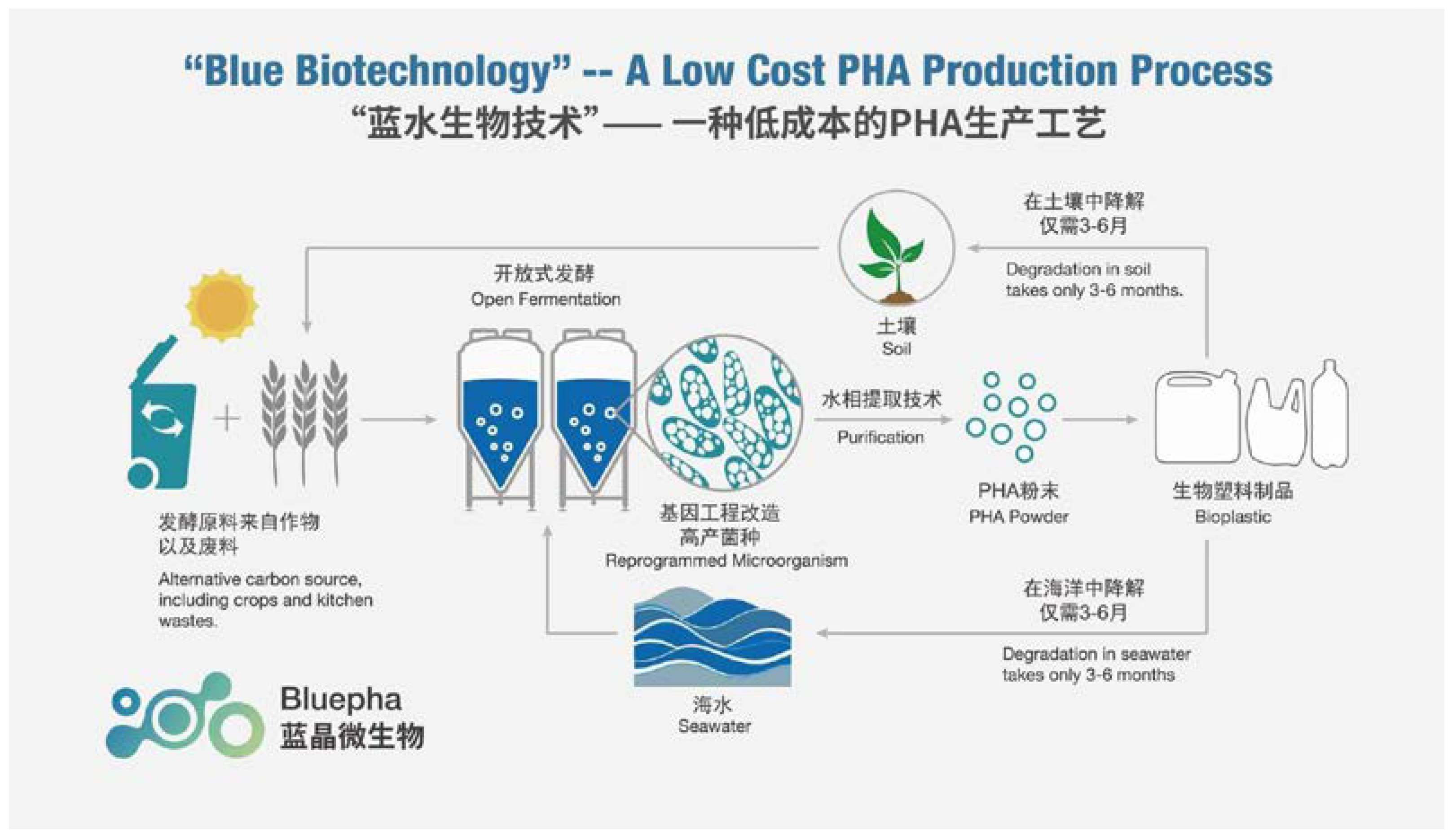

5.4. Bluepha

5.5. RWDC Industries Ltd.

6. Industrializing Mcl-PHA Copolyesters

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Koller, M. Switching from petro-plastics to microbial polyhydroxyalkanoates (PHA): The biotechnological escape route of choice out of the plastic predicament. EuroBiotech J. 2019, 3, 32–44. [Google Scholar] [CrossRef] [Green Version]

- UN General Assembly. Resolution A/60/L.22–Oceans and the Law of the Sea. Available online: https://www.un.org/en/development/desa/population/migration/generalassembly/docs/globalcompact/A_RES_60_30.pdf (accessed on 15 September 2021).

- Dilkes-Hoffman, L.S.; Lant, P.A.; Laycock, B.; Pratt, S. The rate of biodegradation of PHA bioplastics in the marine environment: A meta-study. Mar. Pollut. Bull. 2019, 142, 15–24. [Google Scholar] [CrossRef] [PubMed]

- Sharma, V.; Sehgal, R.; Gupta, R. Polyhydroxyalkanoate (PHA): Properties and modifications. Polymer 2021, 212, 123161. [Google Scholar] [CrossRef]

- Braunegg, G.; Lefebvre, G.; Genser, K.F. Polyhydroxyalkanoates, biopolyesters from renewable resources: Physiological and engineering aspects. J. Biotechnol. 1998, 65, 127–161. [Google Scholar] [CrossRef]

- Saratale, R.G.; Cho, S.K.; Saratale, G.D.; Kadam, A.A.; Ghodake, G.S.; Kumar, M.; Kim, D.S.; Mulla, S.I.; Shin, H.S. A comprehensive overview and recent advances on polyhydroxyalkanoates (PHA) production using various organic waste streams. Bioresour. Technol. 2021, 325, 124685. [Google Scholar] [CrossRef] [PubMed]

- de Donno, M.L.; Moreno, S.; Rene, E.R. Polyhydroxyalkanoate (PHA) production via resource recovery from industrial waste streams: A review of techniques and perspectives. Bioresour. Technol. 2021, 331, 124985. [Google Scholar] [CrossRef] [PubMed]

- Kourmentza, C.; Plácido, J.; Venetsaneas, N.; Burniol-Figols, A.; Varrone, C.; Gavala, H.N.; Reis, M.A. Recent advances and challenges towards sustainable polyhydroxyalkanoate (PHA) production. Bioengineering 2017, 4, 55. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, X.; Lin, Y.; Wu, Q.; Wang, Y.; Chen, G.Q. Synthetic biology and genome-editing tools for improving PHA metabolic engineering. Trends Biotechnol. 2020, 38, 689–700. [Google Scholar] [CrossRef]

- Zheng, Y.; Chen, J.C.; Ma, Y.M.; Chen, G.Q. Engineering biosynthesis of polyhydroxyalkanoates (PHA) for diversity and cost reduction. Metab. Eng. 2020, 58, 82–93. [Google Scholar] [CrossRef]

- Chen, G.Q.; Chen, X.Y.; Wu, F.Q.; Chen, J.C. Polyhydroxyalkanoates (PHA) toward cost competitiveness and functionality. Adv. Ind. Eng. Polym. Res. 2020, 3, 1–7. [Google Scholar] [CrossRef]

- Koller, M. Established and advanced approaches for recovery of microbial polyhydroxyalkanoate (PHA) biopolyesters from surrounding microbial biomass. EuroBiotech. J. 2020, 4, 113–126. [Google Scholar] [CrossRef]

- Park, S.J.; Kim, T.W.; Kim, M.K.; Lee, S.Y.; Lim, S.C. Advanced bacterial polyhydroxyalkanoates: Towards a versatile and sustainable platform for unnatural tailor-made polyesters. Biotechnol. Adv. 2012, 30, 1196–1206. [Google Scholar] [CrossRef] [PubMed]

- Meereboer, K.W.; Misra, M.; Mohanty, A.K. Review of recent advances in the biodegradability of polyhydroxyalkanoate (PHA) bioplastics and their composites. Green Chem. 2020, 22, 5519–5558. [Google Scholar] [CrossRef]

- Gigante, V.; Cinelli, P.; Seggiani, M.; Alavarez, V.A.; Lazzeri, A. Processing and Thermomechanical Properties of PHA. In The Handbook of Polyhydroxyalkanoates; Koller, M., Ed.; CRC Press: Boca Raton, FL, USA, 2020; Volume 3, pp. 91–118. [Google Scholar]

- Puppi, D.; Chiellini, F. Additive manufacturing of PHA. In The Handbook of Polyhydroxyalkanoates; Koller, M., Ed.; CRC Press: Boca Raton, FL, USA, 2020; Volume 3, pp. 119–136. [Google Scholar]

- European Commission. A European Green Deal. Available online: https://ec.europa.eu/info/strategy/priorities-2019-2024/european-green-deal_en (accessed on 7 September 2021).

- Essel, R.; Carus, M. Meta analysis of 30 LCAs. Bio-Plast. Mag. 2012, 7, 46–49. [Google Scholar]

- Koller, M. Chemical and biochemical engineering approaches in manufacturing polyhydroxyalkanoate (PHA) biopolyesters of tailored structure with focus on the diversity of building blocks. Chem. Biochem. Eng. Q. 2018, 32, 413–438. [Google Scholar] [CrossRef]

- da Cruz Pradella, J.G. Economics and Industrial Aspects of PHA Production. In The Handbook of Polyhydroxyalkanoates; Koller, M., Ed.; CRC Press: Boca Raton, FL, USA, 2020; Volume 3, pp. 389–404. [Google Scholar]

- Koller, M.; Maršálek, L.; Miranda de Sousa Dias, M.; Braunegg, G. Producing microbial polyhydroxyalkanoate (PHA) biopolyesters in a sustainable manner. N. Biotechnol. 2017, 37, 24–38. [Google Scholar] [CrossRef]

- Hänggi, U. Virgin PHB Has Thermoplastic Properties, but is not a Thermoplast. Available online: http://www.biomer.de/K%C3%96LN2018.pdf (accessed on 15 September 2021).

- BASF. ecoflex®: Das Original Seit 1998–Zertifiziert Kompostierbarer Kunststoff. Available online: https://plastics-rubber.basf.com/global/de/performance_polymers/products/ecoflex.html (accessed on 10 September 2021).

- Gregorova, A.; Wimmer, R.; Hrabalova, M.; Koller, M.; Ters, T.; Mundigler, N. Effect of surface modification of beech wood flour on mechanical and thermal properties of poly(3-hydroxybutyrate)/wood flour composites. Holzforschung 2009, 63, 565–570. [Google Scholar] [CrossRef]

- Biomer. Injection Molded Articles Made of Renewable Raw Materials. Available online: https://www.biomer.de/IndexE.html (accessed on 13 September 2021).

- Hänggi, U.; (Biomer, Schwalbach, Germany). Personal communication, 2021.

- Arrieta, M.P.; López, J.; Hernández, A.; Rayón, E. Ternary PLA–PHB–Limonene blends intended for biodegradable food packaging applications. Eur. Polym. J. 2014, 50, 255–270. [Google Scholar] [CrossRef]

- Smith, M.K.; Paleri, D.M.; Abdelwahab, M.; Mielewski, D.F.; Misra, M.; Mohanty, A.K. Sustainable composites from poly(3-hydroxybutyrate) (PHB) bioplastic and agave natural fibre. Green Chem. 2020, 22, 3906–3916. [Google Scholar] [CrossRef]

- Nonato, R.; Mantelatto, P.; Rossell, C. Integrated production of biodegradable plastic, sugar and ethanol. Appl. Microbiol. Biotechnol. 2011, 57, 1–5. [Google Scholar]

- Biocycle. BIOCYCLE 1000–Properties. Available online: http://www.biocycle.com.br/images/propriedades_1000_ing.pdf (accessed on 10 September 2021).

- The Industry Gives Its First Steps. Available online: http://www.biocycle.com.br/imprensa_ing_01.htm (accessed on 10 September 2021).

- TianAn Biopolymer. Available online: http://www.tianan-enmat.com/index.html (accessed on 14 September 2021).

- TianAn. Available online: http://www.tianan-enmat.com/product.html# (accessed on 15 September 2021).

- Nafigate. Bacteria Are the Key. Available online: https://www.nafigate.com/hydal-biotechnology/ (accessed on 14 September 2021).

- Nafigate. Naturetics: Cosmetics with PHA. Available online: https://www.nafigate.com/portfolio/naturetics/ (accessed on 11 September 2021).

- Newlight. Available online: https://www.newlight.com/aircarbon (accessed on 12 September 2021).

- Newlight. Available online: https://www.newlight.com/products (accessed on 9 September 2021).

- Covalent. Available online: https://covalentfashion.com/ (accessed on 10 September 2021).

- BioPlastics. Thyssenkrupp Commissions First Commercial Bioplastics Plant for COFCO in China. Available online: https://www.bioplasticsmagazine.com/en/news/meldungen/20181018thyssenkrupp-commissions-first-commercial-bioplastics-plant-for-COFCO-in-China.php (accessed on 10 September 2021).

- Chen, G.-Q.; Jiang, X.-R. Next generation industrial biotechnology based on extremophilic bacteria. Curr. Opin. Biotechnol. 2018, 50, 94–100. [Google Scholar] [CrossRef]

- Wu, F.; Chen, G.-Q. Next generation industrial biotechnology. In The Handbook of Polyhydroxyalkanoates; Koller, M., Ed.; CRC Press: Boca Raton, FL, USA, 2021; Volume 2, pp. 405–415. [Google Scholar]

- Tan, D.; Wang, Y.; Tong, Y.; Chen, G.Q. Grand Challenges for Industrializing Polyhydroxyalkanoates (PHAs). Trends Biotechnol. 2021, 39, 953–963. [Google Scholar] [CrossRef]

- Chen, G.Q.; (Tsinghua University, Beijing, China). Personal communication, 2021.

- Tsinghua University; COFCO Nutrition and Health Research Institute Co., Ltd., Jilin; COFCO Biochemical Co., Ltd.; COFCO Biotechnology Co., Ltd. Chinese Patent 202010358327, 30 June 2020.

- MangoMaterials. Available online: https://www.mangomaterials.com/ (accessed on 10 September 2021).

- Kovalcik, A. Recent advances in 3D printing of polyhydroxyalkanoates: A review. EuroBiotech. J. 2021, 5, 48–55. [Google Scholar] [CrossRef]

- Bio-On. Available online: http://www.bio-on.it/ (accessed on 10 September 2021).

- Kunststoff Web. Bio-On: Krisengeschüttelter Biopolymer-Hersteller ist Pleite. Available online: https://www.kunststoffweb.de/branchen-news/bio-on_krisengeschuettelter_biopolymer-hersteller_ist_pleite_t244145 (accessed on 10 September 2021).

- Bio-On. Available online: http://www.bio-on.it/biomeds.php?lin=inglese (accessed on 10 September 2021).

- GlobeNewswire. Bio-On Presents a Revolutionary New Technology to Eliminate Oil Pollution in the Sea within 3 Weeks. Available online: https://www.globenewswire.com/news-release/2017/06/05/1008187/0/en/Bio-on-presents-a-revolutionary-new-technology-to-eliminate-oil-pollution-in-the-sea-within-3-weeks.html (accessed on 10 September 2021).

- Bio-On. Minerv Bio Cosmetics Formulation Type C1 Worldwide New Patent. Available online: http://www.bio-on.it/minerv-cosmetics.php?lin=inglese (accessed on 10 September 2021).

- Bioplastics News. Bio-On and Unilever Revolutionise Sun Cream Industry with MyKai. Available online: https://bioplasticsnews.com/2019/04/09/bio-on-and-unilever-revolutionise-sun-cream-industry-with-mykai/ (accessed on 10 September 2021).

- Bio-On. Available online: http://www.bio-on.it/minerv-supertoys.php?lin=inglese (accessed on 10 September 2021).

- Bio-On. Available online: https://www.bioplasticsmagazine.com/en/news/meldungen/20191106Bio-on-patents-new-cigarette-filter-material-.php (accessed on 10 September 2021).

- Bio-On. Available online: http://www.bio-on.it/immagini/comunicati-finanziari/CS_82_BIO-ON_KARTELL_presenta_BIO (accessed on 10 September 2021).

- Lemoigne, M. Études sur l’autolyse microbienne origine de l’acide β-oxybutyrique formé par autolyse. Ann. Inst. Pasteur 1927, 41, 148. [Google Scholar]

- Wallen, L.L.; Davis, E.N. Biopolymers of activated sludge. Environ. Sci. Technol. 1972, 6, 161–164. [Google Scholar] [CrossRef]

- Wallen, L.L.; Rohwedder, W.K. Poly-beta-hydroxyalkanoate from activated sludge. Environ. Sci. Technol. 1974, 8, 576–579. [Google Scholar] [CrossRef]

- Findlay, R.H.; White, D.C. Polymeric beta-hydroxyalkanoates from environmental samples and Bacillus megaterium. Appl. Environ. Microbiol. 1983, 45, 71–78. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Morikawa, H.; Marchessault, R.H. Pyrolysis of bacterial polyalkanoates. Can. J. Chem. 1981, 59, 2306–2313. [Google Scholar] [CrossRef] [Green Version]

- Holmes, P.A.; Wright, L.F.; Collins, S.H. Beta-Hydroxybutyrate Polymers. European Patent EP0052459A1, 30 October 1981. [Google Scholar]

- Luzier, W.D. Materials derived from biomass/biodegradable materials. Proc. Nat. Acad. Sci. USA 1982, 89, 839–842. [Google Scholar] [CrossRef] [Green Version]

- Liggat, J. ICI´s BIOPOL Cautionary Tales. Available online: https://www.scotchem.ac.uk/wp-content/uploads/2019/02/Biopol-IBioIC-compressed.pdf (accessed on 10 September 2021).

- Mirelplastics. Available online: http://www.mirelplastics.com/ (accessed on 10 September 2021).

- Lu, H.; Madbouly, S.A.; Schrader, J.A.; Kessler, M.R.; Grewell, D.; Graves, W.R. Novel bio-based composites of polyhydroxyalkanoate (PHA)/distillers dried grains with solubles (DDGS). RSC Adv. 2014, 4, 39802–39808. [Google Scholar] [CrossRef] [Green Version]

- Mirelplastics. Available online: http://www.mirelplastics.com/wp-content/uploads/2017/03/011212-MBLXAnnoucesTerminationTellesJV-1.pdf (accessed on 10 September 2021).

- Biokunststoffe.de. Available online: http://www.biokunststoffe.de/index.php?option=com_content&view=article&id=1598%3A009metabolixarticle&lang=de (accessed on 10 September 2021).

- BIOCYCLE–Sustainable Polymer from Sugar Cane. Available online: https://dc.engconfintl.org/cgi/viewcontent.cgi?article=1015&context=bioenergy_ii (accessed on 10 September 2021).

- Rocha, R.C.; da Silva, L.F.; Taciro, M.K.; Pradella, J.G. Production of poly(3-hydroxybutyrate-co-3-hydroxyvalerate) P(3HB-co-3HV) with a broad range of 3HV content at high yields by Burkholderia sacchari IPT 189. World J. Microb. Biot. 2008, 24, 427–431. [Google Scholar] [CrossRef]

- Ashby, R.D.; Solaiman, D.K.; Nuñez, A.; Strahan, G.D.; Johnston, D.B. Burkholderia sacchari DSM 17165: A source of compositionally-tunable block-copolymeric short-chain poly(hydroxyalkanoates) from xylose and levulinic acid. Bioresource Technol. 2018, 253, 333–342. [Google Scholar] [CrossRef] [PubMed]

- Kovalcik, A.; Machovsky, M.; Kozakova, Z.; Koller, M. Designing packaging materials with viscoelastic and gas barrier properties by optimized processing of poly(3-hydroxybutyrate-co-3-hydroxyvalerate) with lignin. React. Funct. Polym. 2015, 94, 25–34. [Google Scholar] [CrossRef]

- Modi, S.; Koelling, K.; Vodovotz, Y. Assessing the mechanical, phase inversion, and rheological properties of poly-[(R)-3-hydroxybutyrate-co-(R)-3-hydroxyvalerate] (PHBV) blended with poly-(L-lactic acid) (PLA). Eur. Polym. J. 2013, 49, 3681–3690. [Google Scholar] [CrossRef]

- Montano-Herrera, L.; Pratt, S.; Arcos-Hernandez, M.V.; Halley, P.J.; Lant, P.A.; Werker, A.; Laycock, B. In-line monitoring of thermal degradation of PHA during melt-processing by Near-Infrared spectroscopy. New Biotechnol. 2014, 31, 357–363. [Google Scholar] [CrossRef]

- Luo, S.; Cao, J.; McDonald, A.G. Esterification of industrial lignin and its effect on the resulting poly(3-hydroxybutyrate-co-3-hydroxyvalerate) or polypropylene blends. Ind. Crops Prod. 2017, 97, 281–291. [Google Scholar] [CrossRef] [Green Version]

- Larsson, M.; Markbo, O.; Jannasch, P. Melt processability and thermomechanical properties of blends based on polyhydroxyalkanoates and poly(butylene adipate-co-terephthalate). RSC Adv. 2016, 6, 44354–44363. [Google Scholar] [CrossRef] [Green Version]

- HelianPolymers. Available online: https://helianpolymers.com/enmat-y3000p-phb-polymer-for-injection-molding-thermoforming.html (accessed on 10 September 2021).

- Meereboer, K.W.; Pal, A.K.; Cisneros-López, E.O.; Misra, M.; Mohanty, A.K. The effect of natural fillers on the marine biodegradation behaviour of poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBV). Sci. Rep. 2021, 11, 911. [Google Scholar] [CrossRef]

- Genecis. Available online: https://genecis.co/ (accessed on 10 September 2021).

- Bioextrax. Available online: https://bioextrax.com/wp-content/uploads/2020/04/Bioextrax-PHA-one-pager-April-20.pdf (accessed on 10 September 2021).

- Hall, E.; (CEO Bioextrax AB, Lund, Sweden). Personal communication, 2021.

- Doi, Y.; Kunioka, M.; Nakamura, Y.; Soga, K. Nuclear magnetic resonance studies on unusual bacterial copolyesters of 3-hydroxybutyrate and 4-hydroxybutyrate. Macromolecules 1988, 21, 2722–2727. [Google Scholar] [CrossRef]

- Utsunomia, C.; Ren, Q.; Zinn, M. Poly(4-hydroxybutyrate): Current state and perspectives. Front. Bioeng. Biotechnol. 2020, 8, 257. [Google Scholar] [CrossRef] [Green Version]

- Kunioka, M.; Kawaguchi, Y.; Doi, Y. Production of biodegradable copolyesters of 3-hydroxybutyrate and 4-hydroxybutyrate by Alcaligenes eutrophus. Appl. Microbial. Biotechnol. 1989, 30, 569–573. [Google Scholar] [CrossRef]

- Cong, C.; Zhang, S.; Xu, R.; Lu, W.; Yu, D. The influence of 4HB content on the properties of poly(3-hydroxylbutyrate-co-4-hydroxylbutyrate) based on melt molded sheets. J. Appl. Polym. Sci. 2008, 109, 1962. [Google Scholar] [CrossRef]

- Tjgreenbio. Available online: http://www.tjgreenbio.com (accessed on 10 September 2021).

- Larsson, M.; Hetherington, C.J.; Wallenberg, R.; Jannasch, P. Effect of hydrophobically modified graphene oxide on the properties of poly(3-hydroxybutyrate-co-4-hydroxybutyrate). Polymer 2017, 108, 66–77. [Google Scholar] [CrossRef]

- Khandal, D.; Pollet, E.; Averous, L. Elaboration and behavior of poly(3-hydroxybutyrate-co-4-hydroxybutyrate)-nano-biocomposites based on montmorillonite or sepiolite nanoclays. Eur. Polym. J. 2016, 81, 64–76. [Google Scholar] [CrossRef]

- Made-in-China. Available online: https://ecomann.en.made-in-china.com/ (accessed on 10 September 2021).

- Coltelli, M.B.; Panariello, L.; Morganti, P.; Danti, S.; Baroni, A.; Lazzeri, A.; Fusco, A.; Donnarumma, G. Skin-compatible biobased beauty masks prepared by extrusion. J. Funct. Biomater. 2020, 11, 23. [Google Scholar] [CrossRef] [Green Version]

- Wu, C.S.; Hsu, Y.C.; Liao, H.T.; Cai, Y.X. Antibacterial activity and in vitro evaluation of the biocompatibility of chitosan-based polysaccharide/polyester membranes. Carbohyd. Polym. 2015, 134, 438–447. [Google Scholar] [CrossRef]

- CJ Bio. Available online: https://www.cjbio.net/en/products/cjPha.do (accessed on 10 September 2021).

- ABC News. What to Know about PHA Biodegradable Plastic and How It Could Help Southeast Asia. Available online: https://abcnews.go.com/Business/pha-biodegradable-plastic-southeast-asia/story?id=78859058 (accessed on 10 September 2021).

- Yeld10 Bioscience. Yield10 Bioscience Announces Achievement of Proof-of-Concept Milestone for Producing PHA Bioplastic in Field Grown Camelina Plants. Available online: https://www.globenewswire.com/news-release/2021/01/19/2160613/0/en/Yield10-Bioscience-Announces-Achievement-of-Proof-of-Concept-Milestone-for-Producing-PHA-Bioplastic-in-Field-Grown-Camelina-Plants.html (accessed on 10 September 2021).

- Tan, D.; Wu, Q.; Chen, J.C.; Chen, G.Q. Engineering Halomonas TD01 for the low-cost production of polyhydroxyalkanoates. Metab. Eng. 2014, 26, 34–47. [Google Scholar] [CrossRef]

- Ye, J.; Hu, D.; Che, X.; Jiang, X.; Li, T.; Chen, J.; Zhang, H.M.; Chen, G.Q. Engineering of Halomonas bluephagenesis for low cost production of poly (3-hydroxybutyrate-co-4-hydroxybutyrate) from glucose. Metab. Eng. 2018, 47, 143–152. [Google Scholar] [CrossRef]

- PHABuilder. Available online: http://www.phabuilder.cn/ (accessed on 10 September 2021).

- Chen, B.K.; Shen, C.H.; Chen, S.C.; Chen, A.F. Ductile PLA modified with methacryloyloxyalkyl isocyanate improves mechanical properties. Polymer 2010, 51, 4667–4672. [Google Scholar] [CrossRef]

- Jun, C.L. Reactive blending of biodegradable polymers: PLA and starch. J. Polym. Environ. 2000, 8, 33–37. [Google Scholar] [CrossRef]

- Rosa, D.S.; Guedes, C.G.F.; Bardi, M.A.G. Evaluation of thermal, mechanical and morphological properties of PCL/CA and PCL/CA/PE-g-GMA blends. Polym. Test. 2007, 26, 209–215. [Google Scholar] [CrossRef]

- Martin, D.P.; Williams, S.F. Medical applications of poly-4-hydroxybutyrate: A strong flexible absorbable biomaterial. Biochem. Eng. J. 2003, 16, 97–105. [Google Scholar] [CrossRef]

- Brigham, C.J.; Sinskey, A.J. Applications of polyhydroxyalkanoates in the medical industry. Int. J. Biotechnol. Wellness Ind. 2012, 1, 52–60. [Google Scholar] [CrossRef]

- Tepha Medical Devices. Available online: https://www.tepha.com/technology/overview/ (accessed on 10 September 2021).

- Chen, G.; Zhang, G.; Park, S.; Lee, S. Industrial scale production of poly(3-hydroxybutyrate-co-3-hydroxyhexanoate). Appl. Microbiol. Biotechnol. 2001, 57, 50–55. [Google Scholar] [PubMed]

- Kobayashi, G.; Shiotani, T.; Shima, Y.; Doi, Y. Biosynthesis and characterization of poly(3-hydroxybutyrate-co-3-hydroxy-hexanoate) from oils and fats by Aeromonas sp. OL-338 and Aeromonas sp. FA440. In Biodegradable Plastics and Polymers; Doi, Y., Fukuda, K., Eds.; Elsevier: Amsterdam, The Netherlands, 1994; pp. 410–416. [Google Scholar]

- Lee, S.H.; Oh, D.H.; Ahn, W.S.; Lee, Y.; Choi, J.I.; Lee, S.Y. Production of poly(3-hydroxybutyrate-co-3-hydroxyhexanoate) by high-cell-density cultivation of Aeromonas hydrophila. Biotechnol. Bioeng. 2000, 67, 240–244. [Google Scholar] [CrossRef]

- Noda, I.; Green, P.R.; Satkowski, M.M.; Schechtman, L.A. Preparation and properties of a novel class of polyhydroxyalkanoate copolymers. Biomacromolecules 2005, 6, 580–586. [Google Scholar] [CrossRef]

- Danimer Scientific. Available online: https://danimerscientific.com/pha-beginning-of-life/ (accessed on 15 September 2021).

- Bacardi Limited. Available online: https://www.bacardilimited.com/media/news-archive/bacardi-first-in-fight-against-plastic-pollution-with-100-biodegradable-spirits-bottle/ (accessed on 15 September 2021).

- Danimer Scientific. Kemira Announces Partnership with Danimer Scientific to Develop Biodegradable Coating for Paper and Board Industry. Available online: https://danimerscientific.com/2020/12/09/kemira-announces-partnership-with-danimer-scientific-to-develop-biodegradable-coating-for-paper-and-board-industry/ (accessed on 15 September 2021).

- Kaneka Biopolymers. Available online: https://kanekabiopolymers.com/ (accessed on 15 September 2021).

- Kaneka. Kaneka Biodegradable Polymer PHBH™ Applied to Straws for Seven Café’s New Lineup. Available online: https://www.kaneka.co.jp/en/topics/news/2020/ennr2005291.html (accessed on 15 September 2021).

- Kaneka. Kaneka Biodegradable Polymer PHBH™ Used in Shiseido’s Cosmetics Packages. Available online: https://www.kaneka.co.jp/en/topics/news/2020/ennr2008061.html (accessed on 15 September 2021).

- Global Bioeconomy Summit 2018. Marketing of Kaneka Biodegradable Polymer PHBHTM as a Solution to Plastic Waste Issues. Available online: https://cupdf.com/document/marketing-of-kaneka-biodegradable-polymer-phbhtm-kaneka-biodegradable-polymer.html (accessed on 15 September 2021).

- Steinbüchel, A. Foreword. In The Handbook of Polyhydroxyalkanoates; Koller, M., Ed.; CRC Press: Boca Raton, FL, USA, 2020; Volume 1, pp. 13–15. [Google Scholar]

- Bluepha. PHA Bioplastic. Available online: http://en.bluepha.com/pha-bioplastic (accessed on 15 September 2021).

- RWDC Industries. Available online: https://www.rwdc-industries.com/technology (accessed on 15 September 2021).

- TechInAsia. Does this $133m Bet on Biodegradable ‘Plastic’ Hold Water? Available online: https://www.techinasia.com/133m-bet-biodegradable-plastic-hold-water (accessed on 15 September 2021).

- Solon. Products & Applications. Available online: https://www.solon.eco/products-and-applications (accessed on 15 September 2021).

- PolyFerm Canada. VersaMerTM PHAs. Available online: https://www.polyfermcanada.com/versamer_phas.html (accessed on 15 September 2021).

- The Free Library. TerraVerdae Expands Elastomeric PHA Biomaterials Portfolio via PolyFerm Canada Partnership. Available online: https://www.thefreelibrary.com/TerraVerdae+Expands+Elastomeric+PHA+Biomaterials+Portfolio+via...-a0439704651 (accessed on 15 September 2021).

- Ramsay, B.; (Polyferm Canada, Kingston, ON, Canada). Personal communication, 2021.

| Type of PHA | Production Strains (Origin) | Substrates | Manufacturer | Logo | PHA Brand Name (Trade Mark) | Capacity (t/year) | Certifications/Approvals |

|---|---|---|---|---|---|---|---|

Poly(3-hydroxybutyrate) | Cupriavidus necator (soil bacterium) | Glucose | ICI, London, UK (technology transferred to Zeneca, Monsanto, and finally Metabolix) |  | BIOPOL | Stopped (was about 800 in 1996) | - |

| Hydrolyzed cane sugar | PHB Industrial S.A. (PHB/ISA), Serrana, Brazil |  | BIOCYCLE | ~100 (entire PHA production capacity) | Compostable according to DIN CERTO and Vinçotte | ||

| Beet sucrose and by-products of sugar beet industry (molasses) plus additional surplus products from agriculture | Bio-On, Bologna, Italy |  | Minerv-PHA | 2000 (current situation unclear!) | “Biodegradable”: according to USDA (“certified biobased product”) and TÜV Austria “OK biodegradable”; according to company: “MINERV-PHA™ dissolves in normal river or sea water leaving no residue in just a few days.” | ||

| Azohydromonas australica (Azohydromomas lata) (soil bacterium) | Sucrose | Biomer, Schwalbach, Germany |  | Biomer | 900 (capacity) | “Fully biodegradable and compostable” | |

| Paraburkholderia sacchari (soil bacterium) | Sucrose | PHB Industrial S.A. (PHB/ISA), Serrana, Brazil |  | BIOCYCLE | ~100 (entire PHA production capacity) | Compostable according to DIN CERTO and Vinçotte | |

| Halomonas sp. (Halomonas bluephagenesis ssp.) (salt lake isolate) | Presumably glucose | COFCO, Beijing, PR China |  | COFCO PHA | 1000 (capacity) | n.r. | |

| Not disclosed Methanotroph (“robust strain”; origin n.r.) | Crude biogas (CH4, CO2, H2S) | Mango Materials, Redwood City, CA, USA |  | YOOP | 0.25 (pilot scale; long-term goal: about 5 t per year) | “Fully biodegradable and compostable” | |

| “Newlight´s biocatalyst 9X” (marine isolate) | CH4 and CO2 from greenhouse gases | Newlight Technologies LLC, Huntington Beach, CA, USA |  | AirCarbon | n.r. | “Fully biodegradable”; “readily compostable” | |

| “Own microbiological collection”; wild-type organisms (origin not disclosed) | Waste cooking oil (Hydal technology) | Nafigate Corporation, Prague, Czech Republic |  | Hydal PHA | n.r. | FDA approved for food contact (FCN 1754), “carbon-negative” certified (ISO 14046-3 and specification for the assessment of the life cycle greenhouse gas emissions of goods and services (PAS 2050: 2008/2011)), “ocean degradable” (ASTM D6691 and D7081), “industrially compostable” (ASTM D6400) | |

Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) | Cupriavidus necator (soil bacterium) | Glucose plus 3HV precursor | ICI, London, UK (technology transferred to Zeneca, Monsanto, and finally Metabolix) |  | BIOPOL | Stopped (was about 600–800 in 1996) | - |

| Glucose plus 3HV precursor | Telles (joint venture of Metabolix and ADM from 2009 to 2012) |  | Mirel | 50,000 (capacity in 2009; stopped in 2012) | n.r. | ||

| Glucose plus 3HV precursor (glucose deriving from cassava starch) | Tianan Biologic Materials Co., Ningbo, PR China |  | ENMAT | 2000 | “Compostable” according to US Biodegradable Products Institute (BPI) Food Contact Material (“FCM”) substance No. 744 in Table 1 of Annex I of the Plastics Regulation of the EU (REACH) | ||

| Hydrolyzed cane sucrose plus propionate | PHB Industrial S.A. (PHB/ISA), Serrana, Brazil |  | BIOCYCLE | ~100 (entire PHA production capacity) | n.r. | ||

| Beet sucrose and by-products of sugar beet industry (molasses) plus additional surplus products from agriculture plus 3HV precursors | Bio-On, Bologna, Italy |  | Minerv-PHA | 2000 (current situation unclear!) | “Biodegradable”: according to USDA (“certified biobased product”) and TÜV Austria “OK biodegradable”; according to company: “MINERV-PHA™ dissolves in normal river or sea water leaving no residue in just a few days.” | ||

| Halomonas sp. (Halomonas bluephagenesis ssp.) (salt lake isolate; genetically engineered) | Presumably glucose plus 3HV precursor | PhaBuilder, Beijing, PR China |  | - | n.r. | n.r. | |

| Haloferax mediterranei (marine salt brine at Spanish coast) | Sugars, starch, glycerol (no 3HV-related precursors needed) | Not commercially produced yet, but high industrial potential supposed | - | - | - | - | |

Poly(3-hydroxybutyrate-co-4-hydroxybutyrate) | Rec. Escherichia coli (Enterobacterium) | Glucose plus 1,4-butanediole (4HB precursor) | Tianjin GreenBio Materials Co. Ltd., Tianjin, PR China |  | SoGreen | 10,000 | n.r. |

| CJ, Seoul, Republic of Korea (technology from Metabolix) |  | Yield10 | n.r. | n.r. | |||

| Not disclosed | Tepha Medical Devices Inc., Lexington, MA, USA |  | TephaELAST | n.r. | FDA approved for biomedical use as implant material; the entire production process is ISO 13485 compliant | ||

| Not disclosed | Sugar plus 4HB-related precursor | Shenzhen Ecomann Biotechnology Co. Ltd., Guangdong, PR China |  | AmBio | 10,000 (planned: 75,000 capacity) | “OK compost” “OK compost HOME” FDA approved | |

| Halomonas sp. TD40 (salt lake isolate) | Glucose, corn steep liquor, and GBL | PhaBuilder, Beijing, PR China |  | mP34HB 10 | 1000–10,000 (entire PHA production capacity) | Biodegradable according to ASTM 6400 and EN13432 | |

| Halomonas sp. (Halomonas bluephagenesis ssp.; presumably strain TD40) | Glucose, corn steep liquor, and GBL | Medpha, Beijing, PR China | n.r. | Medpha PHA | 100 | n.r. | |

Poly(3-hydroxybutyrate-co-3-hydroxyhexanoate) | Presumably Aeromonas caviae or Aeromonas hydrophila; other sources (Tan et al., 2021) assume rec. C. necator (soil bacteria) | “Inexpensive oils derived from the seeds of plants such as canola and soy” | Danimer Scientific, Bainbridge, GA, USA (formerly Meredian Holdings Group Inc. and MHG; technology originally from Proctor & Gamble, Cincinatti, OH, USA) |  | Nodax | 10,000 | Biobased (ASTM D6866; “OK biobased”); anaerobic and aerobic digestion in soil freshwater (“OK biodegradable SOIL”), freshwater (“OK biodegradable WATER”), marine environment (ASTM D6691), industrial and home composting (according to TÜV Austria and EN and ASTM norms). FDA approved for food contact |

| Rec. C. necator | Vegetable oils | Kanegafuchi Chemical Industry Co. Ltd. (Kaneka), Tokyo, Japan |  | “OK compost INDUSTRIAL”, “OK compost HOME”, “OK biodegradable SOIL” (certification in progress), and “OK biobased” according to TÜV Austria; the “Biobased” certification for Japan; and the “Industrial Compostable” certification for Japan and USA | |||

| Waste cooking oil | RWDC Industries Ltd., Athens, GA, USA |  | Solon® | 4000 (expected to be expanded) | n.r. | ||

| Rec. C. necator (“reprogrammed microorganism”) (salt lake isolate) | “Alternative carbon source, including crops and kitchen waste”, seawater | Bluepha Co. Ltd., Beijing, PR China |  | Bluepha PHA | 1000 | Readily degraded both in seawater and soil within 3–6 months | |

Poly(4-hydroxybutyrate) | Rec. Escherichia coli (Enterobacterium) | 4HB-related precursor | Tepha Medical Devices Inc., Lexington, MA, USA |  | TephaFLEX | n.r. | FDA approved for biomedical use as implant material; the entire production process is ISO 13485 compliant |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Koller, M.; Mukherjee, A. A New Wave of Industrialization of PHA Biopolyesters. Bioengineering 2022, 9, 74. https://doi.org/10.3390/bioengineering9020074

Koller M, Mukherjee A. A New Wave of Industrialization of PHA Biopolyesters. Bioengineering. 2022; 9(2):74. https://doi.org/10.3390/bioengineering9020074

Chicago/Turabian StyleKoller, Martin, and Anindya Mukherjee. 2022. "A New Wave of Industrialization of PHA Biopolyesters" Bioengineering 9, no. 2: 74. https://doi.org/10.3390/bioengineering9020074

APA StyleKoller, M., & Mukherjee, A. (2022). A New Wave of Industrialization of PHA Biopolyesters. Bioengineering, 9(2), 74. https://doi.org/10.3390/bioengineering9020074