Exploring Spatial Patterns in Sensor Data for Humidity, Temperature, and RSSI Measurements

Abstract

:1. Introduction

2. Materials and Methods

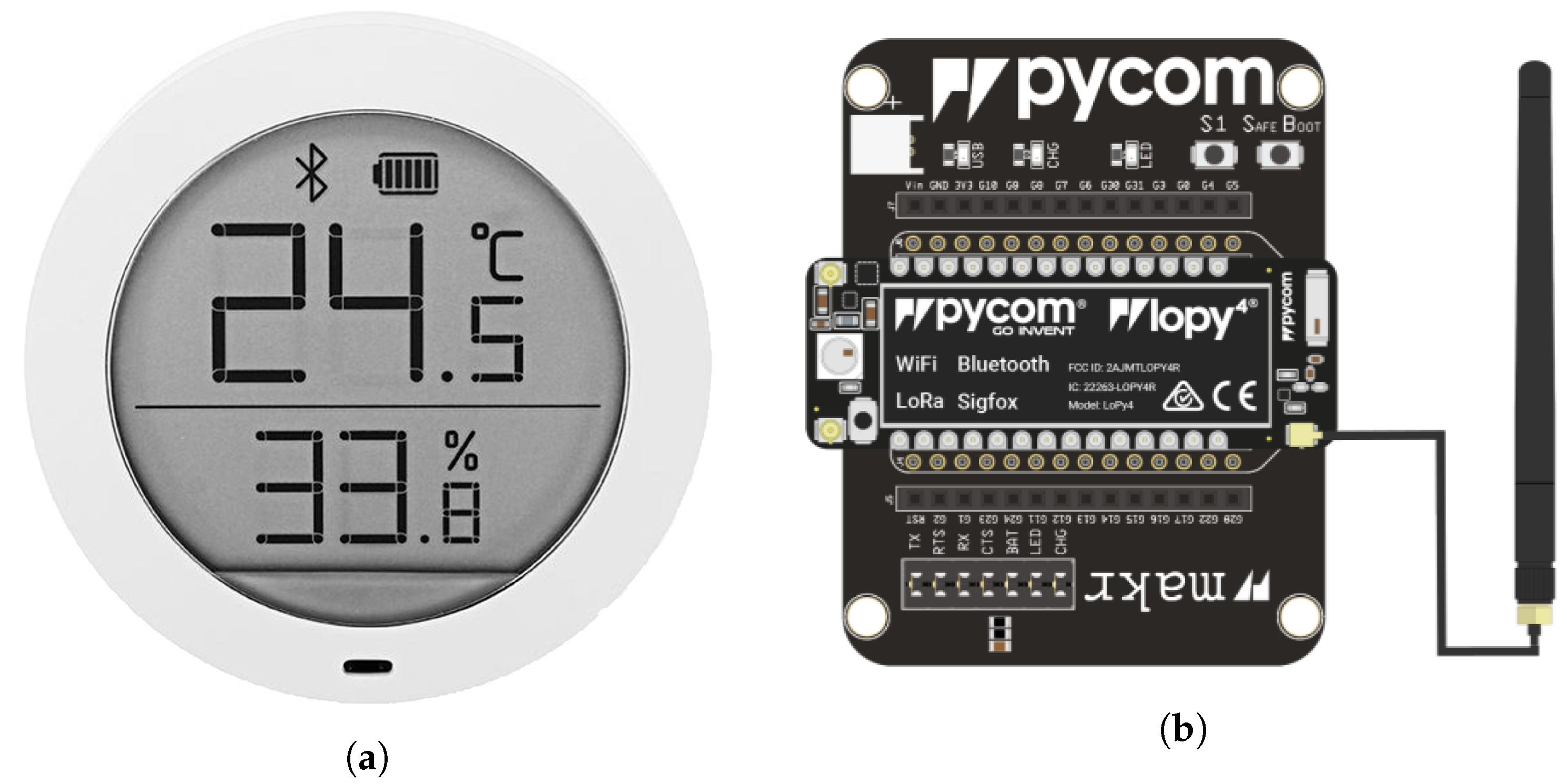

2.1. Acquisition Devices

2.2. Description of Areas

2.3. Dataset Organization

2.4. Value of the Data

3. Data Samples

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| IoT | Internet of Things |

| WSN | Wireless Sensor Networks |

| RSSI | Received Signal Strength Indicator |

| BLE | Bluetooth Low Energy |

References

- Wolkoff, P.; Azuma, K.; Carrer, P. Health, work performance, and risk of infection in office-like environments: The role of indoor temperature, air humidity, and ventilation. Int. J. Hyg. Environ. Health 2021, 233, 113709. [Google Scholar] [CrossRef] [PubMed]

- Díaz-González, C.d.l.M.; Mateos-López, N.; De la Rosa-Hormiga, M.; Carballo-Hernández, G. Influence of Hospital Environmental Variables on Thermometric Measurements and Level of Concordance: A Cross-Sectional Descriptive Study. Int. J. Environ. Res. Public Health 2023, 20, 4665. [Google Scholar] [CrossRef] [PubMed]

- Shetty, S. An Intelligent and Secure Real-Time Environment Monitoring System for Healthcare Using IoT and Cloud Computing with the Mobile Application Support. In Image Based Computing for Food and Health Analytics: Requirements, Challenges, Solutions and Practices: IBCFHA; Springer: Berlin/Heidelberg, Germany, 2023; pp. 83–95. [Google Scholar]

- Vallan, A.; Fissore, D.; Pisano, R.; Barresi, A.A. On the Use of Temperature Measurements as a Process Analytical Technology (PAT) for the Monitoring of a Pharmaceutical Freeze-Drying Process. Pharmaceutics 2023, 15, 861. [Google Scholar] [CrossRef] [PubMed]

- Marques, G.C.; von Seggern, F.; Dehm, S.; Breitung, B.; Hahn, H.; Dasgupta, S.; Tahoori, M.B.; Aghassi-Hagmann, J. Influence of humidity on the performance of composite polymer electrolyte-gated field-effect transistors and circuits. IEEE Trans. Electron Devices 2019, 66, 2202–2207. [Google Scholar] [CrossRef]

- Boddu, R.D.; Ragam, P.; Pendhota, S.P.; Goni, M.; Indrala, S.; Badavath, U.R. IoT-Based Smart Agricultural Monitoring System. In Proceedings of the Fourth International Conference on Computer and Communication Technologies, Online, 26–28 July 2023; pp. 377–385. [Google Scholar]

- García, L.; Parra, L.; Jimenez, J.M.; Parra, M.; Lloret, J.; Mauri, P.V.; Lorenz, P. Deployment strategies of soil monitoring WSN for precision agriculture irrigation scheduling in rural areas. Sensors 2021, 21, 1693. [Google Scholar] [CrossRef]

- Popa, A.; Hnatiuc, M.; Paun, M.; Geman, O.; Hemanth, D.J.; Dorcea, D.; Son, L.H.; Ghita, S. An intelligent IoT-based food quality monitoring approach using low-cost sensors. Symmetry 2019, 11, 374. [Google Scholar] [CrossRef]

- Bradford, K.J.; Dahal, P.; Van Asbrouck, J.; Kunusoth, K.; Bello, P.; Thompson, J.; Wu, F. The dry chain: Reducing postharvest losses and improving food safety in humid climates. In Food Industry Wastes; Elsevier: Amsterdam, The Netherlands, 2020; pp. 375–389. [Google Scholar]

- Gaur, A.; Lacasse, M. Climate Data to Support the Adaptation of Buildings to Climate Change in Canada. Data 2022, 7, 42. [Google Scholar] [CrossRef]

- Chang, S.J.; Kang, Y.; Yun, B.Y.; Yang, S.; Kim, S. Assessment of effect of climate change on hygrothermal performance of cross-laminated timber building envelope with modular construction. Case Stud. Therm. Eng. 2021, 28, 101703. [Google Scholar] [CrossRef]

- Ma, N.; Aviv, D.; Guo, H.; Braham, W.W. Measuring the right factors: A review of variables and models for thermal comfort and indoor air quality. Renew. Sustain. Energy Rev. 2021, 135, 110436. [Google Scholar] [CrossRef]

- Shahmirzadi, M.R.; Gholampour, A.; Kashani, A.; Ngo, T.D. Shrinkage behavior of cementitious 3D printing materials: Effect of temperature and relative humidity. Cem. Concr. Compos. 2021, 124, 104238. [Google Scholar] [CrossRef]

- Tham, S.; Thompson, R.; Landeg, O.; Murray, K.; Waite, T. Indoor temperature and health: A global systematic review. Public Health 2020, 179, 9–17. [Google Scholar] [CrossRef] [PubMed]

- Amaripadath, D.; Rahif, R.; Velickovic, M.; Attia, S. A systematic review on role of humidity as an indoor thermal comfort parameter in humid climates. J. Build. Eng. 2023, 68, 106039. [Google Scholar] [CrossRef]

- Yang, L.; Deng, S.; Fang, G.; Li, W. Improved indoor air temperature and humidity control using a novel direct-expansion-based air conditioning system. J. Build. Eng. 2021, 43, 102920. [Google Scholar] [CrossRef]

- Xu, X.; Zhong, Z.; Deng, S.; Zhang, X. A review on temperature and humidity control methods focusing on air-conditioning equipment and control algorithms applied in small-to-medium-sized buildings. Energy Build. 2018, 162, 163–176. [Google Scholar] [CrossRef]

- Kowli, A.; Rani, V.; Sanap, M. Data-driven virtual sensing for spatial distribution of temperature and humidity. J. Build. Eng. 2023, 67, 105726. [Google Scholar] [CrossRef]

- Furze, J.N.; Mayad, E.H. Emergent horizons and biodynamic interactions. Environ. Sci. Pollut. Res. 2021, 28, 64137–64139. [Google Scholar] [CrossRef]

- Guzmán, C.H.; Carrera, J.L.; Durán, H.A.; Berumen, J.; Ortiz, A.A.; Guirette, O.A.; Arroyo, A.; Brizuela, J.A.; Gómez, F.; Blanco, A.; et al. Implementation of virtual sensors for monitoring temperature in greenhouses using CFD and control. Sensors 2018, 19, 60. [Google Scholar] [CrossRef]

- Ganesh, G.A.; Sinha, S.L.; Verma, T.N.; Dewangan, S.K. Investigation of indoor environment quality and factors affecting human comfort: A critical review. Build. Environ. 2021, 204, 108146. [Google Scholar] [CrossRef]

- Bakry, M.S.; Hamdy, M.; Mohamed, A.; Elsayed, K. Energy saving potential in open museum spaces: A comparative hygrothermal microclimates analysis. Build. Environ. 2022, 225, 109639. [Google Scholar] [CrossRef]

- Ganguly, S.; Ahmed, A.; Wang, F. Optimised building energy and indoor microclimatic predictions using knowledge-based system identification in a historical art gallery. Neural Comput. Appl. 2020, 32, 3349–3366. [Google Scholar] [CrossRef]

- He, J.; Li, Y.; Zhang, X.; Li, J. Missing and Corrupted Data Recovery in Wireless Sensor Networks Based on Weighted Robust Principal Component Analysis. Sensors 2022, 22, 1992. [Google Scholar] [CrossRef]

- Hussein, M.; Marghescu, I.; Alduais, N.A. Performance of Data Reduction Algorithms for Wireless Sensor Network (WSN) using Different Real-Time Datasets: Analysis Study. Int. J. Adv. Comput. Sci. Appl. 2022, 13, 649–661. [Google Scholar] [CrossRef]

- Al-Shabi, M.; Abuhamdah, A. Using deep learning to detecting abnormal behavior in internet of things. Int. J. Electr. Comput. Eng. 2022, 12, 2108. [Google Scholar] [CrossRef]

- Esmaeili, H.; Bidgoli, B.M.; Hakami, V. CMML: Combined metaheuristic-machine learning for adaptable routing in clustered wireless sensor networks. Appl. Soft Comput. 2022, 118, 108477. [Google Scholar] [CrossRef]

- Alghanmi, N.; Alotaibi, R.; Buhari, S.M. Machine learning approaches for anomaly detection in IoT: An overview and future research directions. Wirel. Pers. Commun. 2022, 122, 2309–2324. [Google Scholar] [CrossRef]

- Dash, L.; Pattanayak, B.K.; Mishra, S.K.; Sahoo, K.S.; Jhanjhi, N.Z.; Baz, M.; Masud, M. A Data Aggregation Approach Exploiting Spatial and Temporal Correlation among Sensor Data in Wireless Sensor Networks. Electronics 2022, 11, 989. [Google Scholar] [CrossRef]

- Fotue, D.; Labiod, H. Efficient Tree Aggregation and Processing Time for Wireless Sensor Networks. Mob. Networks Appl. 2023, 2023, 1–8. [Google Scholar] [CrossRef]

- Srivastava, A.; Bharti, M.R. Hybrid Machine Learning Model for Anomaly Detection in Unlabelled Data of Wireless Sensor Networks. Wirel. Pers. Commun. 2023, 129, 2693–2710. [Google Scholar] [CrossRef]

- Intel Berkeley Research Lab Dataset. Available online: http://db.csail.mit.edu/labdata/labdata.html (accessed on 7 April 2023).

- Botero-Valencia, J.; Castano-Londono, L.; Marquez-Viloria, D. Indoor Temperature and Relative Humidity Dataset of Controlled and Uncontrolled Environments. Data 2022, 7, 81. [Google Scholar] [CrossRef]

- Ramli, N.A.M.; Rahiman, M.H.F.; Malik, M.F.A.; Kamarudin, L.M.; Mohamed, L.; Zakaria, A.; Abdullah, M.S.M. A design and development of a wireless sensor network for potential monitoring and localization. J. Electr. Eng. Technol. 2020, 15, 2735–2743. [Google Scholar] [CrossRef]

- Guidara, A.; Fersi, G.; Derbel, F.; Jemaa, M.B. Impacts of Temperature and Humidity variations on RSSI in indoor Wireless Sensor Networks. Procedia Comput. Sci. 2018, 126, 1072–1081. [Google Scholar] [CrossRef]

- Lavdas, S.; Zacharioudakis, L.; Khalifeh, A.; Zinonos, Z. The effect of temperature and humidity on indoor LoRa propagation model. In Proceedings of the 2021 17th International Conference on Distributed Computing in Sensor Systems (DCOSS), Pafos, Cyprus, 14–16 July 2021; pp. 374–379. [Google Scholar]

- Goldoni, E.; Savazzi, P.; Favalli, L.; Vizziello, A. Correlation between weather and signal strength in Lorawan Networks: An extensive dataset. Comput. Networks 2022, 202, 108627. [Google Scholar] [CrossRef]

- Jain, C.; Sashank, G.V.S.; Venkateswaran, N.; Markkandan, S. Low-cost BLE based indoor localization using RSSI fingerprinting and machine learning. In Proceedings of the 2021 Sixth International Conference on Wireless Communications, Signal Processing and Networking (WiSPNET), Chennai, India, 25–27 March 2021; pp. 363–367. [Google Scholar]

- Singh, N.; Choe, S.; Punmiya, R. Machine learning based indoor localization using Wi-Fi RSSI fingerprints: An overview. IEEE Access 2021, 9, 127150–127174. [Google Scholar] [CrossRef]

- Ramirez, R.; Huang, C.Y.; Liao, C.A.; Lin, P.T.; Lin, H.W.; Liang, S.H. A practice of BLE RSSI measurement for indoor positioning. Sensors 2021, 21, 5181. [Google Scholar] [CrossRef]

| Specification | Value |

|---|---|

| Temperature range | −9.9 C–60 C |

| Temperature accuracy | 0.1 C |

| Humidity range | 0–99.9 |

| humidity accuracy | 0.1 |

| Rated power | 0.18 mW |

| Power supply | Batteries (AAA) × 1 |

| Battery life | 1 year |

| Specification | Value |

|---|---|

| Microcontroller | ESP32 |

| RAM | 520 KB + 4 MB |

| External flash | 8 MB |

| Bluetooth | BLE 4.2 and 2.0 |

| Working voltage | 3.3 V to 5 V |

| LAB1 | LAB2 | |||

|---|---|---|---|---|

| Sensor | X | Y | X | Y |

| 1 | 7.21 | 0.60 | 5.70 | 7.54 |

| 2 | 3.88 | 5.88 | 5.70 | 10.17 |

| 3 | 5.85 | 5.88 | 3.30 | 11.60 |

| 4 | 0.60 | 0.60 | 3.30 | 9.12 |

| 5 | 1.92 | 1.94 | 3.30 | 6.34 |

| 6 | 3.88 | 3.91 | 3.30 | 3.86 |

| 7 | 1.92 | 3.91 | 3.30 | 1.38 |

| 8 | 5.85 | 3.91 | 5.70 | 4.91 |

| 9 | 7.21 | 7.22 | 5.70 | 2.43 |

| 10 | 1.92 | 5.88 | 0.90 | 2.43 |

| 11 | 0.60 | 7.22 | 0.90 | 10.17 |

| 12 | 5.85 | 1.94 | 0.90 | 4.91 |

| 13 | 3.88 | 1.94 | 0.90 | 7.54 |

| Gateway | 1.63 | 7.73 | 0.00 | 5.93 |

| Place | Start Date | End Date | Elapsed Time | Size | File | Link |

|---|---|---|---|---|---|---|

| LAB1 | 06/08/2022 10:44:00 | 07/19/2022 11:59:00 | 985:15:00 | 354,695 | Sample00.mat | https://osf.io/ra73v |

| Humidity00.xlsx | https://osf.io/prke9 | |||||

| RSSI00.xlsx | https://osf.io/vbphj | |||||

| Temperature00.xlsx | https://osf.io/ywv52 | |||||

| Time00.xlsx | https://osf.io/3ygax | |||||

| LAB1 | 07/27/2022 11:05:21 | 09/19/2022 12:00:40 | 1296:55:19 | 466,892 | Sample01.mat | https://osf.io/te24d |

| Humidity01.xlsx | https://osf.io/qycu8 | |||||

| RSSI01.xlsx | https://osf.io/f4ce6 | |||||

| Temperature01.xlsx | https://osf.io/vzqr5 | |||||

| Time01.xlsx | https://osf.io/x4p27 | |||||

| LAB2 | 10/24/2022 11:00:00 | 10/26/2022 19:00:00 | 56:00:00 | 20,161 | Sample02.mat | https://osf.io/qg2ku |

| Humidity02.xlsx | https://osf.io/3efmz | |||||

| RSSI02.xlsx | https://osf.io/qvabh | |||||

| Temperature02.xlsx | https://osf.io/a632n | |||||

| Time02.xlsx | https://osf.io/sed6z | |||||

| LAB2 | 11/03/2022 12:05:00 | 11/27/2022 05:00:00 | 568:55:00 | 204,811 | Sample03.mat | https://osf.io/ub8k4 |

| Humidity03.xlsx | https://osf.io/m8e4q | |||||

| RSSI03.xlsx | https://osf.io/vrjs7 | |||||

| Temperature03.xlsx | https://osf.io/t8wng | |||||

| Time03.xlsx | https://osf.io/hgrbu | |||||

| LAB2 | 11/27/2022 18:30:00 | 11/30/2022 11:20:00 | 64:50:00 | 23,341 | Sample04.mat | https://osf.io/s9byf |

| Humidity04.xlsx | https://osf.io/r8qys | |||||

| RSSI04.xlsx | https://osf.io/7dbf6 | |||||

| Temperature04.xlsx | https://osf.io/w2vkf | |||||

| Time04.xlsx | https://osf.io/f92eq | |||||

| LAB2 | 12/06/2022 15:15:00 | 01/11/2023 06:46:00 | 855:31:00 | 307,987 | Sample05.mat | https://osf.io/cax4m |

| Humidity05.xlsx | https://osf.io/2pc78 | |||||

| RSSI05.xlsx | https://osf.io/w3x47 | |||||

| Temperature05.xlsx | https://osf.io/h7qkn | |||||

| Time05.xlsx | https://osf.io/undy7 | |||||

| REF | 02/16/2023 15:38:06 | 02/20/2023 07:31:57 | 87:53:51 | 31,644 | Sample06.mat | https://osf.io/76zpb |

| Humidity06.xlsx | https://osf.io/5zrmt | |||||

| RSSI06.xlsx | https://osf.io/bm6ek | |||||

| Temperature06.xlsx | https://osf.io/5xz24 | |||||

| Time06.xlsx | https://osf.io/8n3bh | |||||

| EXT | 06/08/2022 00:00:00 | 02/20/2023 23:56:00 | 6191:56:00 | 92,880 | Sample07.mat | https://osf.io/mz3nd |

| Humidity07.xlsx | https://osf.io/dnj4z | |||||

| Temperature07.xlsx | https://osf.io/fq4h9 | |||||

| Time07.xlsx | https://osf.io/v6jxu | |||||

| Total | 3915:20:10 | 1,409,531 |

| Sensor | T01 | T02 | T03 | T04 | T05 | T06 | T07 | T08 | T09 | T10 | T11 | T12 | T13 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| T01 | 100.00 | 98.97 | 98.20 | 99.10 | 99.49 | 99.30 | 98.74 | 99.20 | 99.35 | 99.51 | 98.11 | 99.30 | 99.49 |

| T02 | 98.97 | 100.00 | 99.29 | 99.38 | 99.15 | 99.41 | 99.40 | 99.48 | 99.37 | 98.86 | 98.73 | 99.41 | 98.88 |

| T03 | 98.20 | 99.29 | 100.00 | 99.15 | 98.46 | 98.97 | 99.43 | 99.05 | 98.89 | 98.10 | 99.09 | 98.94 | 98.18 |

| T04 | 99.10 | 99.38 | 99.15 | 100.00 | 99.18 | 99.45 | 99.30 | 99.41 | 99.30 | 99.07 | 99.03 | 99.41 | 99.12 |

| T05 | 99.49 | 99.15 | 98.46 | 99.18 | 100.00 | 99.37 | 98.96 | 99.32 | 99.46 | 99.46 | 98.23 | 99.38 | 99.43 |

| T06 | 99.30 | 99.41 | 98.97 | 99.45 | 99.37 | 100.00 | 99.21 | 99.50 | 99.43 | 99.25 | 98.65 | 99.51 | 99.25 |

| T07 | 98.74 | 99.40 | 99.43 | 99.30 | 98.96 | 99.21 | 100.00 | 99.26 | 99.25 | 98.68 | 99.10 | 99.19 | 98.73 |

| T08 | 99.20 | 99.48 | 99.05 | 99.41 | 99.32 | 99.50 | 99.26 | 100.00 | 99.44 | 99.12 | 98.54 | 99.51 | 99.11 |

| T09 | 99.35 | 99.37 | 98.89 | 99.30 | 99.46 | 99.43 | 99.25 | 99.44 | 100.00 | 99.29 | 98.52 | 99.45 | 99.27 |

| T10 | 99.51 | 98.86 | 98.10 | 99.07 | 99.46 | 99.25 | 98.68 | 99.12 | 99.29 | 100.00 | 98.15 | 99.23 | 99.51 |

| T11 | 98.11 | 98.73 | 99.09 | 99.03 | 98.23 | 98.65 | 99.10 | 98.54 | 98.52 | 98.15 | 100.00 | 98.53 | 98.30 |

| T12 | 99.30 | 99.41 | 98.94 | 99.41 | 99.38 | 99.51 | 99.19 | 99.51 | 99.45 | 99.23 | 98.53 | 100.00 | 99.23 |

| T13 | 99.49 | 98.88 | 98.18 | 99.12 | 99.43 | 99.25 | 98.73 | 99.11 | 99.27 | 99.51 | 98.30 | 99.23 | 100.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Botero-Valencia, J.; Martinez-Perez, A.; Hernández-García, R.; Castano-Londono, L. Exploring Spatial Patterns in Sensor Data for Humidity, Temperature, and RSSI Measurements. Data 2023, 8, 82. https://doi.org/10.3390/data8050082

Botero-Valencia J, Martinez-Perez A, Hernández-García R, Castano-Londono L. Exploring Spatial Patterns in Sensor Data for Humidity, Temperature, and RSSI Measurements. Data. 2023; 8(5):82. https://doi.org/10.3390/data8050082

Chicago/Turabian StyleBotero-Valencia, Juan, Adrian Martinez-Perez, Ruber Hernández-García, and Luis Castano-Londono. 2023. "Exploring Spatial Patterns in Sensor Data for Humidity, Temperature, and RSSI Measurements" Data 8, no. 5: 82. https://doi.org/10.3390/data8050082

APA StyleBotero-Valencia, J., Martinez-Perez, A., Hernández-García, R., & Castano-Londono, L. (2023). Exploring Spatial Patterns in Sensor Data for Humidity, Temperature, and RSSI Measurements. Data, 8(5), 82. https://doi.org/10.3390/data8050082