Comparative Evaluation of Mechanical and Physical Properties of Mycelium Composite Boards Made from Lentinus sajor-caju with Various Ratios of Corn Husk and Sawdust

Abstract

1. Introduction

2. Materials and Methods

2.1. Fungal Strain

2.2. Sources of Substrate and Preparation

2.3. Preparation of Mycelial Inoculum

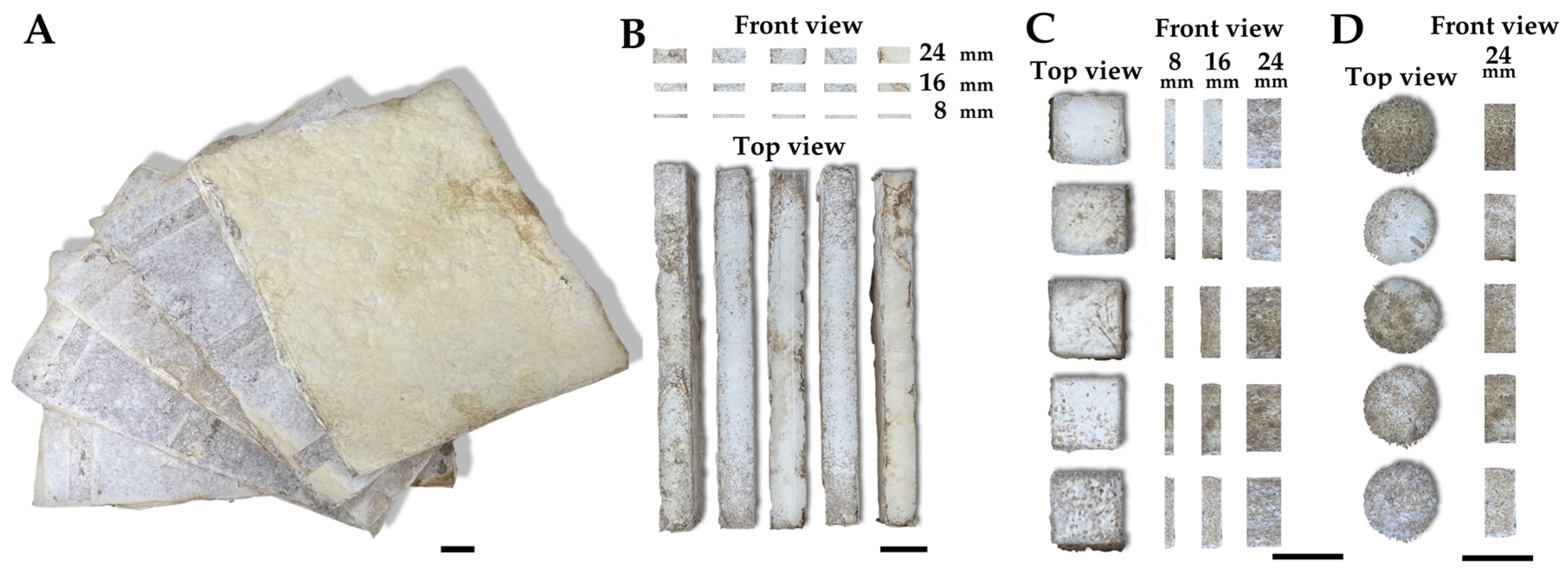

2.4. Preparation of MBCs

2.5. Preparation of MCB Molds

2.6. MCB Production

2.7. Specimen Preparation for Determination of Mechanical and Physical Properties

2.8. Determination of Mechanical Properties

2.8.1. Modulus of Elasticity

2.8.2. Bending Strength

2.9. Determination of Physical Properties

2.9.1. Density

2.9.2. Shrinkage

2.9.3. Water Absorption

2.9.4. Volumetric Swelling

2.9.5. Thermal Conductivity

2.9.6. Sound Absorption Coefficient

2.10. Statistical Analysis

3. Results and Discussion

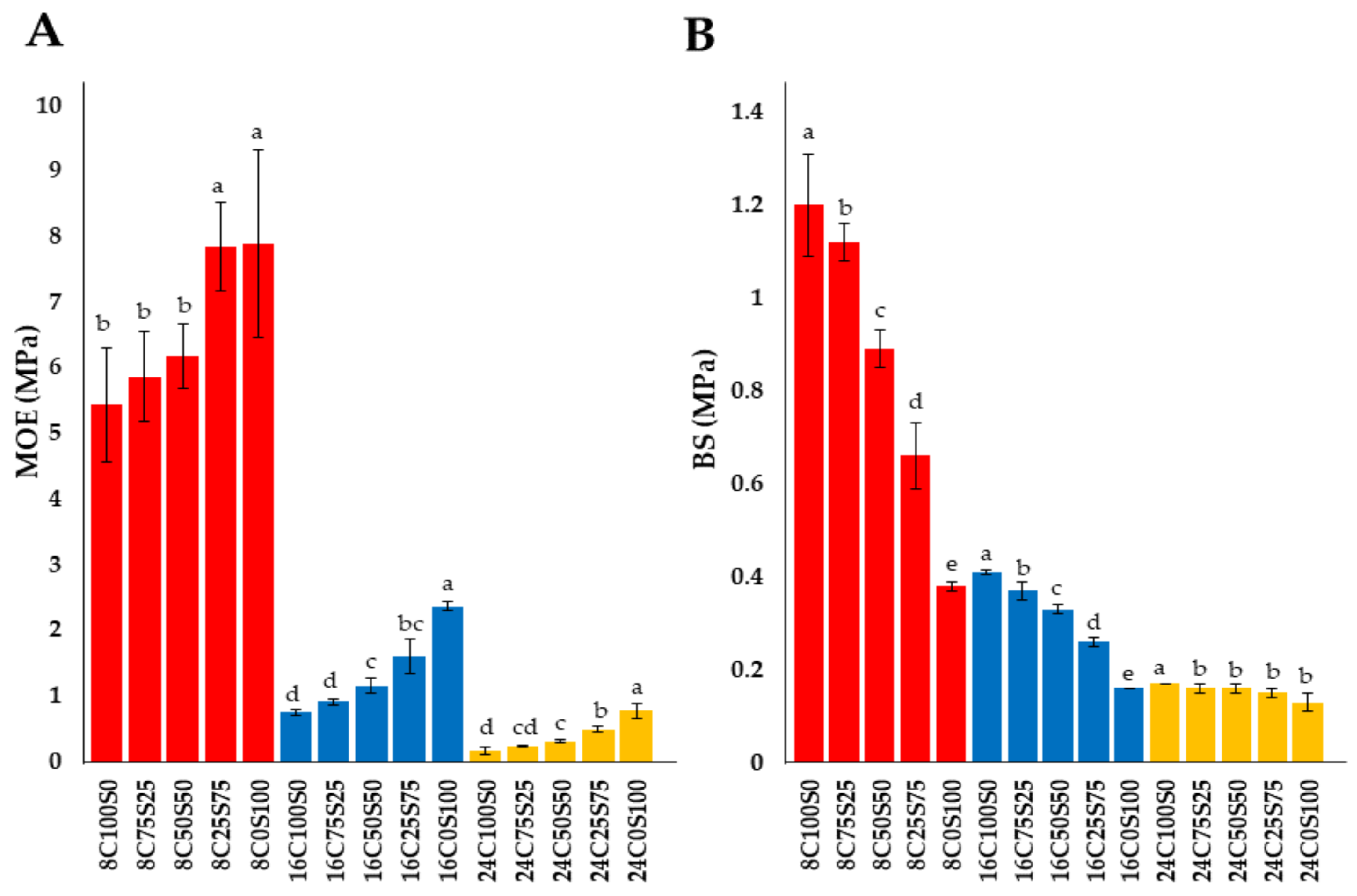

3.1. Mechanical Properties of MCBs

3.1.1. Modulus of Elasticity

3.1.2. Bending Strength

3.2. Physical Properties of MCBs

3.2.1. Density

3.2.2. Shrinkage

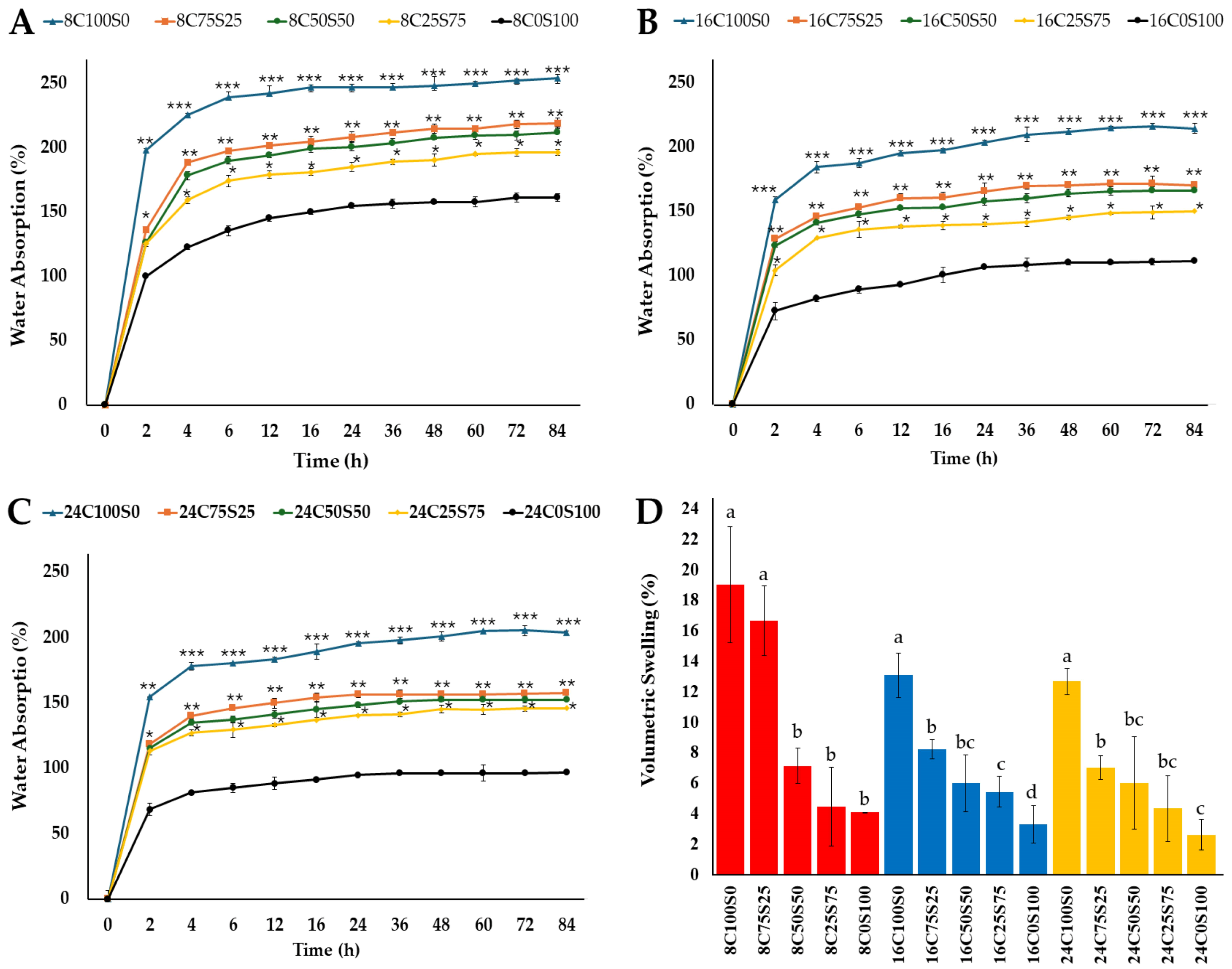

3.2.3. Water Absorption

3.2.4. Volumetric Swelling

3.2.5. Thermal Conductivity Values

3.2.6. Sound Absorption Coefficient

3.3. Comparison of Properties with Commercial Boards

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hammond, G.; Jones, C.; Lowrie, F. Embodied Carbon: The Inventory of Carbon and Energy (ICE) (Version 2.0); University of Bath with BSRIA: Bracknell, UK, 2011. [Google Scholar]

- Symons, K. Book Review: Embodied Carbon: The Inventory of Carbon and Energy (ICE); University of Bath with BSRIA: Bracknell, UK, 2011. [Google Scholar]

- Xanthos, D.; Walker, T.R. International policies to reduce plastic marine pollution from single-use plastics (plastic bags and microbeads): A review. Mar. Pollut. Bull. 2017, 118, 17–26. [Google Scholar] [CrossRef] [PubMed]

- Lambert, S.; Wagner, M. Characterisation of nanoplastics during the degradation of polystyrene. Chemosphere 2016, 145, 265–268. [Google Scholar] [CrossRef] [PubMed]

- Suwanmanee, U.; Varabuntoonvit, V.; Chaiwutthinan, P.; Tajan, M.; Mungcharoen, T.; Leejarkpai, T. Life cycle assessment of single use thermoform boxes made from polystyrene (PS), polylactic acid (PLA), and PLA/starch: Cradle to consumer gate. Int. J. Life Cycle Assess. 2013, 18, 401–417. [Google Scholar] [CrossRef]

- Rendón-Villalobos, R.; Ortíz-Sánchez, A.; Tovar-Sánchez, E.; Flores-Huicochea, E. The Role of Biopolymers in Obtaining Environmentally Friendly Materials; Ghaly, A.A., Ed.; Composites from Renewable and Sustainable Materials; InTech: Vladivostok, Russia, 2016; pp. 151–179. [Google Scholar]

- Teeraphantuvat, T.; Jatuwong, K.; Jinanukul, P.; Thamjaree, W.; Lumyong, S.; Aiduang, W. Improving the physical and mechanical properties of mycelium-based green composites using paper waste. Polymers 2024, 16, e262. [Google Scholar] [CrossRef]

- Garcia-Garcia, D.; Quiles-Carrillo, L.; Balart, R.; Torres-Giner, S.; Arrieta, M.P. Innovative solutions and challenges to increase the use of Poly (3-hydroxybutyrate) in food packaging and disposables. Eur. Polym. J. 2022, 178, e111505. [Google Scholar] [CrossRef]

- Balaeș, T.; Radu, B.-M.; Tănase, C. Mycelium-composite materials—A promising alternative to plastics? J. Fungi 2023, 9, e210. [Google Scholar] [CrossRef] [PubMed]

- Acharjee, S.A.; Bharali, P.; Gogoi, B.; Sorhie, V.; Walling, B.; Alemtoshi. PHA-based bioplastic: A potential alternative to address microplastic pollution. Water Air Soil Pollut. 2023, 234, e21. [Google Scholar] [CrossRef] [PubMed]

- Khalil, H.P.S.A.; Bhat, A.H.; Yusra, A.F.I. Green composites from sustainable cellulose nanofibrils: A review. Carbohydr. Polym. 2012, 87, 963–979. [Google Scholar] [CrossRef]

- Chen, Y.; Dang, B.; Jin, C.; Sun, Q. Processing lignocellulose-based composites into an ultrastrong structural material. ACS Nano 2018, 13, 371–376. [Google Scholar] [CrossRef]

- Ferdosian, F.; Pan, Z.; Gao, G.; Zhao, B. Bio-based adhesives and evaluation for wood composites application. Polymers 2017, 9, e70. [Google Scholar] [CrossRef]

- Hemmilä, V.; Adamopoulos, S.; Karlsson, O.; Kumar, A. Development of sustainable bio-adhesives for engineered wood panels–A review. RSC Adv. 2017, 7, 38604–38630. [Google Scholar] [CrossRef]

- Sun, W.; Tajvidi, M.; Hunt, C.G.; McIntyre, G.; Gardner, D.J. Fully bio-based hybrid composites made of wood, fungal mycelium and cellulose nanofibrils. Sci. Rep. 2019, 9, e3766. [Google Scholar] [CrossRef]

- Arikan, E.B.; Ozsoy, H.D. A review: Investigation of bioplastics. J. Civil. Eng. Archit. 2015, 9, 188–192. [Google Scholar]

- Moshood, T.D.; Nawanir, G.; Mahmud, F.; Mohamad, F.; Ahmad, M.H.; AbdulGhani, A. Biodegradable plastic applications towards sustainability: Recent innovations in the green product. Cleaner Eng. Technol. 2022, 6, e100404. [Google Scholar] [CrossRef]

- Girometta, C.; Picco, A.M.; Baiguera, R.M.; Dondi, D.; Babbini, S.; Cartabia, M.; Pellegrini, M.; Savio, E. Physico-mechanical and thermodynamic properties of mycelium-based biocomposites: A review. Sustainability 2019, 11, e281. [Google Scholar] [CrossRef]

- Ali, G.; Paniz, F.; Fabricio, V.; John, P.; Benay, G. Mycelium-based bio-composites for architecture: Assessing the effects of cultivation factors on compressive strength. Architecture in the Age of the 4th Industrial Revolution. In Proceedings of the 37th eCAADe and 23rd SIGraDi Conference, University of Porto, Porto, Portugal, 11–13 September 2019; pp. 505–514. [Google Scholar]

- Elsacker, E.; Vandelook, S.; Brabcart, J.; Peeters, E.; Laet, L.D. Mechanical, physical and chemical characterisation of mycelium-based composites with different types of lignocellulosic substrates. PLoS ONE 2019, 14, e0213954. [Google Scholar] [CrossRef]

- Attias, N.; Danai, O.; Tarazi, E.; Pereman, I.; Grobman, Y.J. Implementing bio-design tools to develop mycelium-based products. Des. J. 2019, 22, 1647–1657. [Google Scholar] [CrossRef]

- Appels, F.V.W.; Camere, S.; Montalti, M.; Karana, E.; Jansen, K.M.B.; Dijksterhuis, J.; Krijgsheld, P.; Wösten, H.A.B. Fabrication factors influencing mechanical, moisture- and water-related properties of mycelium-based composites. Mater. Des. 2019, 161, 64–71. [Google Scholar] [CrossRef]

- Aiduang, W.; Jatuwong, K.; Jinanukul, P.; Suwannarach, N.; Kumla, J.; Thamjaree, W.; Teeraphantuvat, T.; Waroonkun, T.; Oranratmanee, R.; Lumyong, S. Sustainable innovation: Fabrication and characterization of mycelium-based green composites for modern interior materials using agro-industrial wastes and different species of fungi. Polymers 2024, 16, e550. [Google Scholar] [CrossRef]

- Xing, Y.; Brewer, M.; El-Gharabawy, H.; Griffith, G.; Jones, P. Growing and testing mycelium bricks as building insulation materials. IOP Conf. Ser. Earth Environ. Sci. 2018, 121, e022032. [Google Scholar] [CrossRef]

- Jiang, L.; Walczyk, D.; McIntyre, G.; Chan, W.K. Cost modeling and optimization of a manufacturing system for mycelium-based biocomposite parts. J. Manuf. Syst. 2016, 41, 8–20. [Google Scholar] [CrossRef]

- Pelletier, M.G.; Holt, G.A.; Wanjura, J.D.; Bayer, E.; McIntyre, G. An evaluation study of mycelium based acoustic absorbers grown on agricultural by-product substrates. Ind. Crops Prod. 2013, 51, 480–485. [Google Scholar] [CrossRef]

- Robertson, O.; Høgdal, F.; Mckay, L.; Lenau, T. Fungal future: A review of mycelium biocomposites as an ecological alternative insulation material. In Proceedings of NordDesign; Technical University of Denmark: Lyngby, Denmark, 2020; pp. 1–13. [Google Scholar]

- Ongpeng, J.M.C.; Inciong, E.; Sendo, V.; Soliman, C.; Siggaoat, A. Using waste in producing bio-composite mycelium bricks. Appl. Sci. 2020, 10, e5303. [Google Scholar] [CrossRef]

- Bagheriehnajjar, G.; Yousefpour, H.; Rahimnejad, M. Environmental impacts of mycelium-based bio-composite construction materials. Int. J. Environ. Sci. Technol. 2024, 21, 5437–5458. [Google Scholar] [CrossRef]

- Alaneme, K.K.; Anaele, J.U.; Oke, T.M.; Kareem, S.A.; Adediran, M.; Ajibuwa, O.A.; Anabaranze, Y.O. Mycelium based composites: A review of their bio-fabrication procedures, material properties and potential for green building and construction applications. Alex. Eng. J. 2023, 83, 234–250. [Google Scholar] [CrossRef]

- Yang, L.; Qin, Z. Bioprospects of Macrofungi; Qin, Z., Ed.; Experimental analysis of the mechanics of mycelium-based biocomposites; CRC Press: Boca Raton, FL, USA, 2023; pp. 205–232. [Google Scholar]

- Aiduang, W.; Jatuwong, K.; Luangharn, T.; Jinanukul, P.; Thamjaree, W.; Teeraphantuvat, T.; Waroonkun, T.; Lumyong, S. A Review delving into the factors influencing mycelium-based green composites (MBCS) production and their properties for long-term sustainability targets. Biomimetics 2024, 9, 337. [Google Scholar] [CrossRef]

- Aiduang, W.; Kumla, J.; Srinuanpan, S.; Thamjaree, W.; Lumyong, S.; Suwannarach, N. Mechanical, physical, and chemical properties of mycelium-based composites produced from various lignocellulosic residues and fungal species. J. Fungi 2022, 8, e1076. [Google Scholar] [CrossRef]

- Kadir, Y.A.; Samsi, H.W.; Masseat, K.; Rashid, N.A.A.; Ali, S.Z.; Karim, S.R.A.; Karim, A.A. Physical and mechanical properties of plywood made from Meranti temak nipis (Shorea roxburghii). In Proceedings of the Forest Products Seminar Lignocellulosic Materials Towards a Sustainable Future, FRIM Proceedings No. 25; Forest Research Institute Malaysia: Kuala Lumpur, Malaysia, 2023; pp. 46–49. [Google Scholar]

- BS EN 310:1993; Wood-Based Panels. Determination of Modulus of Elasticity in Bending and of Bending Strength. The British Standards Institution (BSI): London, UK, 1993.

- Gezer, E.D.; Gümüşkaya, E.; Uçar, E.; Ustaömer, E. Mechanical properties of mycelium based MDF. Sigma J. Eng. Nat. Sci. 2020, 11, 135–140. [Google Scholar]

- Espinoza-Herrera, R.; Cloutier, A. Physical and mechanical properties of gypsum particleboard reinforced with portland cement. Eur. J. Wood Wood Prod. 2011, 69, 247–254. [Google Scholar] [CrossRef]

- BS EN 323:1993; Wood-Based Panels. Determination of Density. The British Standards Institution (BSI): London, UK, 1993.

- ASTM D1037:2002; Standard Test Methods for Evaluating Properties of Wood-Base Fiber and Particle Panel Materials. ASTM: West Conshohocken, PA, USA, 2002.

- Dotun, A.O.; Olalekan, O.S.; Olugbenga, A.L.; Emmanuel, M.A. Physical and mechanical properties evaluation of corncob and sawdust cement bonded ceiling boards. Int. J. Eng. Res. Africa 2019, 42, 65–75. [Google Scholar]

- Faouel, J.; Mzali, F.; Jemni, A.; Nasrallah, A.B. Thermal conductivity and thermal diffusivity measurements of wood in the three anatomic directions using the transient hot-bridge method. Spec. Top. Rev. Porous Media Int. J. 2012, 3, 229–237. [Google Scholar] [CrossRef]

- ISO 22007-2:2022; Plastics—Determination of Thermal Conductivity and Thermal Diffusivity—Part 2: Transient Plane Heat Source (Hot Disc) Method. ISO: Geneva, Switzerland, 2022.

- Keawprak, N.; Arkom, P.; Lao-auyporn, P.; Kaewpreak, N.; Wannasut, P.; Watcharapasorn, A. Development of expanded perlite board for thermal insulation. Chiang Mai J. Sci. 2022, 49, 1644–1652. [Google Scholar] [CrossRef]

- ISO 10534-2:2023; Acoustics—Determination of Acoustic Properties in Impedance Tubes—Part 2: Two-Microphone Technique for Normal Sound Absorption Coefficient and Normal Surface Impedance. ISO: Geneva, Switzerland, 2023.

- Yang, W.D.; Li, Y. Sound absorption performance of natural fibers and their composites. Sci. China Technol. Sci. 2012, 55, 2278–2283. [Google Scholar] [CrossRef]

- Siano, D.; Viscardi, M.; Chimenti, M.; Panzaa, M.A.; Molaro, A.; Lanzillo, S. Experimental analysis of innovative acoustic materials for engine noise control in vehicles. In Proceedings of the International Congress on Sound and Vibration. ICSV No. 26, Montreal, France, 7–11 July 2019; pp. 1–8. [Google Scholar]

- Haneef, M.; Ceseracciu, L.; Canale, C.; Bayer, I.S.; Heredia-Guerrero, J.A.; Athanassiou, A. Advanced materials from fungal mycelium: Fabrication and tuning of physical properties. Sci. Rep. 2017, 7, e41292. [Google Scholar] [CrossRef]

- Shi, J.; Peng, J.; Huang, Q.; Cai, L.; Shi, S.Q. Fabrication of densified wood via synergy of chemical pretreatment, hot-pressing and post mechanical fixation. J. Wood Sci. 2020, 66, e5. [Google Scholar] [CrossRef]

- Kuznetsova, I.; Zaitsev, B.; Krasnopolskaya, L.; Teplykh, A.; Semyonov, A.; Avtonomova, A.; Ziangirova, M.; Smirnov, A.; Kolesov, V. Influence of humidity on the acoustic properties of mushroom mycelium films used as sensitive layers for acoustic humidity sensors. Sensors 2020, 20, e2711. [Google Scholar] [CrossRef]

- Johnston, J.C.; Kuczmarski, M.A.; Olszko, G. Development of instrumentation for the measurement of the performance of acoustic absorbers. Open J. Acoust. 2015, 5, 172–192. [Google Scholar] [CrossRef][Green Version]

- Liu, R.; Li, X.; Long, L.; Sheng, Y.; Xu, J.; Wang, Y. Improvement of mechanical properties of mycelium/cotton stalk composites by water immersion. Compos. Interfaces 2020, 27, 953–966. [Google Scholar] [CrossRef]

- Kuribayashi, T.; Lankinen, P.; Hietala, S.; Mikkonen, K.S. Dense and continuous networks of aerial hyphae improve flexibility and shape retention of mycelium composite in the wet state. Compos. Part A Appl. Sci. Manuf. 2022, 152, e106688. [Google Scholar] [CrossRef]

- Jones, M.; Mautner, A.; Luenco, S.; Bismarck, A.; John, S. Engineered mycelium composite construction materials from fungal biorefineries: A critical review. Mater. Des. 2020, 187, e108397. [Google Scholar] [CrossRef]

- Pointner, M.; Kuttner, P.; Obrlik, T.; Jäger, A.; Kahr, H. Composition of corncobs as a substrate for fermentation of biofuels. Agron. Res. 2014, 12, 391–396. [Google Scholar]

- El-Tayeb, T.S.; Abdelhafez, A.A.; Ali, S.H.; Ramadan, E.M. Effect of acid hydrolysis and fungal biotreatment on agro-industrial wastes for obtainment of free sugars for bioethanol production. Braz. J. Microbiol. 2012, 43, 1523–1535. [Google Scholar] [CrossRef] [PubMed]

- Song, S.T.; Saman, N.; Johari, K.; Mat, H.B. Removal of mercury (II) from aqueous solution by using rice residues. J. Teknol. 2013, 63, 67–73. [Google Scholar] [CrossRef]

- Islam, M.R.; Tudryn, G.; Bucinell, R.; Schadler, L.; Picu, R.C. Morphology and mechanics of fungal mycelium. Sci. Rep. 2017, 7, e13070. [Google Scholar] [CrossRef]

- Kokubo, A.; Kuraishi, S.; Sakurai, N. Culm strength of barley 1: Correlation among maximum bending stress, cell wall dimensions, and cellulose content. Plant Physiol. 1989, 91, 876–882. [Google Scholar] [CrossRef]

- Ye, H.; Zhang, Y.; Yu, Z.; Mu, J. Effects of cellulose, hemicellulose, and lignin on the morphology and mechanical properties of metakaolin-based geopolymer. Constr. Build. Mater. 2018, 173, 10–16. [Google Scholar] [CrossRef]

- Kirk, T.K.; Farrell, R.L. Enzymatic “combustion”: The microbial degradation of lignin1, 2. Ann. Rev. Micro. 1987, 41, 465–505. [Google Scholar] [CrossRef]

- Irbe, I.; Loris, G.D.; Filipova, I.; Andze, L.; Skute, M. Characterization of self-growing biomaterials made of fungal mycelium and various lignocellulose-containing ingredients. Materials 2022, 15, e7608. [Google Scholar] [CrossRef]

- Mbabali, H.; Lubwama, M.; Yiga, V.A.; Were, E.; Kasedde, H. Development of rice husk and sawdust mycelium-based bio-composites: Optimization of mechanical, physical and thermal properties. J. Inst. Eng. India Ser. D 2023, 105, 97–117. [Google Scholar] [CrossRef]

- Aiduang, W.; Suwannarach, N.; Kumla, J.; Thamjaree, W.; Lumyong, S. Valorization of agricultural waste to produce myco-composite materials from mushroom mycelia and their physical properties. Agr. Nat. Resour. 2020, 56, 1083–1090. [Google Scholar]

- Butu, A.; Rodino, S.; Miu, B.; Butu, M. Mycelium-based materials for the ecodesign of bioeconomy. Dig. J. Nanomater. Biostruct. 2020, 15, 1129–1140. [Google Scholar] [CrossRef]

- Ascensão, G.; Beersaerts, G.; Marchi, M.; Segata, M.; Faleschini, F.; Pontikes, Y. Shrinkage and mitigation strategies to improve the dimensional stability of CaO-FeOx-Al2O3-SiO2 inorganic polymers. Materials 2019, 12, e3679. [Google Scholar] [CrossRef] [PubMed]

- Holt, G.A.; McIntyre, G.; Flagg, D.; Bayer, E.; Wanjura, J.D.; Pelletier, M.G. Fungal mycelium and cotton plant materials in the manufacture of biodegradable molded packaging material: Evaluation study of select blends of cotton byproducts. J. Biobased Mater. Bioenergy 2012, 6, 431–439. [Google Scholar] [CrossRef]

- Houette, T.; Maurer, C.; Niewiarowski, R.; Gruber, P. Growth and mechanical characterization of mycelium-based composites towards future bioremediation and food production in the material manufacturing cycle. Biomimetics 2022, 7, e103. [Google Scholar] [CrossRef]

- Rigobello, A.; Ayres, P. Compressive behaviour of anisotropic mycelium-based composites. Sci. Rep. 2022, 12, e6846. [Google Scholar] [CrossRef] [PubMed]

- Angelova, G.; Brazkova, M.; Goranov, B. Effect of the lignocellulose substrate type on mycelium growth and biocomposite formation by Ganoderma lucidum GA3P. Food Sci. Appl. Biotechnol. 2022, 5, 211–218. [Google Scholar] [CrossRef]

- Agustiany, E.A.; Ridho, M.R.; Rahmi, M.D.N.; Madyaratri, E.W.; Falah, F.; Lubis, M.A.R.; Solihat, N.N.; Syamani, F.A.; Karungamye, P.; Sohail, A.; et al. Recent developments in lignin modification and its application in lignin-based green composites: A review. Polym. Comp. 2022, 8, 4848–4865. [Google Scholar] [CrossRef]

- Chuayplod, P.; Aht-Ong, D. A study of microcrystalline cellulose prepared from parawood (Hevea brasiliensis) sawdust waste using different acid types. J. Met. Mater. Miner. 2018, 28, 106–114. [Google Scholar]

- Răut, I.; Călin, M.; Vuluga, Z.; Oancea, F.; Paceagiu, J.; Radu, N.; Doni, M.; Alexandrescu, E.; Purcar, V.; Gurban, A.-M.; et al. Fungal based biopolymer composites for construction materials. Materials 2021, 14, e2906. [Google Scholar] [CrossRef]

- Dias, P.P.; Jayasinghe, L.B.; Waldmann, D. Investigation of mycelium-Miscanthus composites as building insulation material. Results Mater. 2021, 10, e100189. [Google Scholar] [CrossRef]

- Vette, J.F.; Böttger, W.O.J. Properties of mycelium-composite biobased insulation materials with local organic waste streams as substrate and after use for mushroom cultivation. RILEM Proceedings Pro 131. In Proceedings of the 3rd International Conference on Bio-Based Building Materials, Belfast, UK, 26–28 June 2019; pp. 649–650. [Google Scholar]

- Rao, S.E.; Ray, L.; Khan, T.; Ravi, G. Thermal conductivity, density and porosity of sedimentary and metamorphic rocks from the Lower and Higher Himalaya, Western Himalaya. India. Geo. J. Inter. 2022, 231, 459–473. [Google Scholar] [CrossRef]

- Liu, H.; Zhao, X. Thermal Conductivity Analysis of High Porosity Structures with Open and Closed Pores. Int. J. Heat Mass Transf. 2022, 183, e122089. [Google Scholar] [CrossRef]

- Olivero, E.; Gawronska, E.; Manimuda, P.; Jivani, D.; Chaggan, F.Z.; Corey, Z.; de Almeida, T.S.; Kaplan-Bie, J.; McIntyre, G.; Wodo, O.; et al. Gradient porous structures of mycelium: A quantitative structure–mechanical property analysis. Sci. Rep. 2023, 13, e19285. [Google Scholar] [CrossRef] [PubMed]

- Cao, L.; Fu, Q.; Si, Y.; Ding, B.; Yu, J. Porous materials for sound absorption. Compos. Commun. 2018, 10, 25–35. [Google Scholar] [CrossRef]

- Kalauni, K.; Pawar, S.J. A review on the taxonomy, factors associated with sound absorption and theoretical modeling of porous sound absorbing materials. J. Porous Mater. 2019, 26, 1795–1819. [Google Scholar] [CrossRef]

- Seddeq, H.S. Factors influencing acoustic performance of sound absorptive materials. Aust. J. Basic Appl. Sci. 2009, 3, 4610–4617. [Google Scholar]

- Walter, N.; Gürsoy, B. Simulating Acoustic Performance of Mycelium-Based Sound Absorption Panels. In Proceedings of the 41st Conference on Education and Research in Computer Aided Architectural Design in Europe, eCAADe 2023, Education and research in Computer Aided Architectural Design in Europe, Graz, Austria, 20–23 September 2023; pp. 277–286. [Google Scholar]

- Castagnède, B.; Aknine, A.; Brouard, B.; Tarnow, V. Effects of compression on the sound absorption of fibrous materials. Appl. Acoust. 2000, 61, 173–182. [Google Scholar] [CrossRef]

- Barta, D.-G.; Simion, I.; Tiuc, A.-E.; Vasile, O. Mycelium-based composites as a sustainable solution for waste management and circular economy. Materials 2024, 17, e404. [Google Scholar] [CrossRef]

- Hsu, T.; Dessi-Olive, J. A design framework for absorption and diffusion panels with sustainable materials. In Proceedings of the 2021 Inter-Noise Conference, Washington, DC, USA, 1–4 August 2021. [Google Scholar]

- Cai, J.; Han, J.; Ge, F.; Lin, Y.; Pan, J.; Ren, A. Development of impact-resistant mycelium-based composites (MBCs) with agricultural waste straws. Constr. Build. Mater. 2023, 389, e131730. [Google Scholar] [CrossRef]

- Ayrilmis, N.; Buyuksari, U.; As, N. Bending strength and modulus of elasticity of wood-based panels at cold and moderate temperatures. Cold Reg. Sci. Technol. 2010, 63, 40–43. [Google Scholar] [CrossRef]

- Ayrilmis, N.; Winandy, J.E. Effects of post heat-treatment on surface characteristics and adhesive bonding performance of medium density fiberboard. Mater. Manuf. Process. 2009, 24, 594–599. [Google Scholar] [CrossRef]

- Ayrilmis, N.; Jarusombuti, S.; Fueangvivat, V.; Bauchongkol, P. Effects of thermal treatment of rubberwood fibres on physical and mechanical properties of medium density fibreboard. J. Trop. For. Sci. 2011, 23, 10–16. [Google Scholar]

- Suchsland, O.; Woodson, G.E. Fiberboard Manufacturing Practices in the United States; United States Department of Agriculture, Forest Service: Washington, DC, USA, 1987.

- Sonderegger, W.; Niemz, P. Thermal conductivity and water vapour transmission properties of wood-based materials. Eur. J. Wood Prod. 2009, 67, 313–321. [Google Scholar] [CrossRef]

- Nemli, G.; Çolakoğlu, G. Effects of mimosa bark usage on some properties of particleboard. Turk. J. Agric. For. 2005, 29, 227–230. [Google Scholar]

- BS EN 622-4:2009; Fibreboards, Specifications, Requirements for Softboards. British Standards Institution (BSI): London, UK, 2009.

- Papadopoulos, A.N.; Hill, C.A.S. The sorption of water vapour by anhydride modified softwood. Wood Sci. Technol. 2003, 37, 221–231. [Google Scholar] [CrossRef]

- Ganev, S.; Cloutier, A.; Beauregard, R.; Gendron, G. Linear expansion and thickness swell of MDF as a function of panel density and sorption state. Wood Fiber Sci. 2005, 37, 327–336. [Google Scholar]

- Berardi, U.; Iannace, G. Acoustic characterization of natural fibers for sound absorption applications. Build. Environ. 2015, 94, 840–852. [Google Scholar] [CrossRef]

- Cramer, S.M.; Friday, O.M.; White, R.H.; Sriprutkiat, G. Mechanical properties of gypsum board at elevated temperatures. In Proceedings of the Fire and Materials 2003: 8th International Conference, San Francisco, CA, USA, 27–28 January 2003; pp. 33–42. [Google Scholar]

- Bénichou, N.; Sultan, M.A. Thermal properties of lightweight-framed construction components at elevated temperatures. Fire Mater. 2005, 29, 165–179. [Google Scholar] [CrossRef]

- Karni, J.; Karni, E.Y. Gypsum in construction: Origin and properties. Mater. Struct. 1995, 28, 92–100. [Google Scholar] [CrossRef]

- Wakili, K.G.; Tanner, C. U-value of a dried wall made of perforated porous clay bricks: Hot box measurement versus numerical analysis. Energy Build. 2003, 35, 675–680. [Google Scholar] [CrossRef]

- Camino, G.; Maffezzoli, A.; Braglia, M.; de Lazzaro, D.; Zammarano, M. Effect of hydroxides and hydroxycarbonate structure on fire retardant effectiveness and mechanical properties in ethylene-vinyl acetate copolymer. Polym. Degrad. Stab. 2001, 74, 457–464. [Google Scholar] [CrossRef]

- Feng, C.; Janssen, H.; Wu, C.; Feng, Y.; Meng, Q. Validating various measures to accelerate the static gravimetric sorption isotherm determination. Build. Environ. 2013, 69, 64–71. [Google Scholar] [CrossRef]

- Warnock, A.C.C. Controlling sound transmission through concrete block walls. J. Acoust. Soc. Am. 1998, 103, 41–47. [Google Scholar]

- Ardanuy, M.; Claramunt, J.; Filho, R.D.T. Cellulosic fiber reinforced cement-based composites: A review of recent research. Constr. Build. Mater. 2015, 79, 115–128. [Google Scholar] [CrossRef]

- Mohr, B.J.; Nanko, H.; Kurtis, K.E. Durability of kraft pulp fiber–cement composites to wet/dry cycling. Cem. Concr. Compos. 2005, 27, 435–448. [Google Scholar] [CrossRef]

- Akers, S.A.S. Cracking in fibre cement products. Constr. Build. Mater. 2010, 4, 202–207. [Google Scholar] [CrossRef]

- Biot, M.A.; Tolstoy, I. Formulation of wave propagation in infinite media by normal coordinates with an application to diffraction. J. Acoust. Soc. Am. 1957, 29, 381–391. [Google Scholar] [CrossRef]

- Jelle, B.P. Traditional, state-of-the-art and future thermal building insulation materials and solutions–Properties, requirements and possibilities. Energy Build. 2011, 43, 2549–2563. [Google Scholar] [CrossRef]

- Papadopoulos, A.M. State of the art in thermal insulation materials and aims for future developments. Energy Build. 2005, 37, 77–86. [Google Scholar] [CrossRef]

- Schiavoni, S.; Alessandro, F.D.; Bianchi, F.; Asdrubali, F. Insulation materials for the building sector: A review and comparative analysis. Renew. Sustain. Energy Rev. 2016, 62, 988–1011. [Google Scholar] [CrossRef]

- Asdrubali, F.; Alessandro, F.D.; Schiavoni, S. A review of unconventional sustainable building insulation materials. Sustain. Mater. Technol. 2015, 4, 1–17. [Google Scholar] [CrossRef]

| Thickness (mm) | Ratio of Substrate Based on Dry Weight (%) | Specimen Name | |

|---|---|---|---|

| Corn Husk | Sawdust | ||

| 8 | 100 | 0 | 8C100S0 |

| 75 | 25 | 8C75S25 | |

| 50 | 50 | 8C50S50 | |

| 25 | 75 | 8C25S75 | |

| 0 | 100 | 8C0S100 | |

| 16 | 100 | 0 | 16C100S0 |

| 75 | 25 | 16C75S25 | |

| 50 | 50 | 16C50S50 | |

| 25 | 75 | 16C25S75 | |

| 0 | 100 | 16C0S100 | |

| 24 | 100 | 0 | 24C100S0 |

| 75 | 25 | 24C75S25 | |

| 50 | 50 | 24C50S50 | |

| 25 | 75 | 24C25S75 | |

| 0 | 100 | 24C0S100 | |

| Properties | Pearson Correlation Coefficients (r/p-Value) | ||

|---|---|---|---|

| 8 mm | 16 mm | 24 mm | |

| MOE | −0.772 */<0.001 | −0.937 */<0.001 | −0.923 */<0.001 |

| BS | 0.977 */<0.001 | 0.967 */<0.001 | 0.764 */<0.001 |

| DS | −0.635 */<0.001 | −0.975 */<0.001 | −0.975 */<0.001 |

| SK | 0.992 */<0.001 | 0.973 */<0.001 | 0.968 */0.007 |

| WA | 0.973 */0.005 | 0.963 */0.009 | 0.937 */0.019 |

| VS | 0.943/0.160 | 0.949/0.140 | 0.944/0.160 |

| TC | ND | ND | −0.921 */0.026 |

| SAC (250 Hz) | ND | ND | 0.281/0.647 |

| SAC (500 Hz) | ND | ND | 0.228/0.712 |

| SAC (1000 Hz) | ND | ND | 0.740/0.153 |

| Properties | Pearson Correlation Coefficients (r/p-Value) | ||||

|---|---|---|---|---|---|

| C100S0 | C75S25 | C50S50 | C25S75 | C0S100 | |

| MOE | −0.898 */<0.001 | −0.908 */<0.001 | −0.921 */<0.001 | −0.922 */<0.001 | −0.929 */<0.001 |

| BS | −0.945 */<0.001 | −0.951 */<0.001 | −0.957 */<0.001 | −0.937 */<0.001 | −0.919 */<0.001 |

| DS | 0.635/0.066 | 0.555/0.120 | 0.929 */<0.001 | 0.898 */<0.001 | 0.949 */<0.001 |

| SK | 0.980/0.125 | 0.752/0.549 | 0.921/0.256 | 0.990/0.089 | 0.958/0.186 |

| WA | −0.946/0.200 | −0.946/0.210 | −0.955/0.193 | −0.896/0.293 | −0.951/0.200 |

| VS | −0.894/0.297 | −0.917/0.262 | −0.850/0.353 | −0.093/0.940 | −0.999/0.220 |

| Specimen Name | Thermal Conductivity (W/m∙K) |

|---|---|

| 24C100S0 | 0.037 |

| 24C75S25 | 0.048 |

| 24C50S50 | 0.052 |

| 24C25S75 | 0.054 |

| 24C0S100 | 0.079 |

| Specimen Name | Sound Absorption Coefficient (%) | ||

|---|---|---|---|

| 250 Hz | 500 Hz | 1000 Hz | |

| 24C100S0 | 40 | 34 | 85 |

| 24C75S25 | 51 | 49 | 94 |

| 24C50S50 | 43 | 45 | 86 |

| 24C25S75 | 43 | 43 | 84 |

| 24C0S100 | 40 | 41 | 61 |

| Properties | MBCs | Commercial Boards * | |||||||

|---|---|---|---|---|---|---|---|---|---|

| This Study | Previous Studies | Medium-Density Fiber Board | Softboard | Gypsum Board | Fiber Cement Board | Insulated Board | Acoustic Board | ||

| MOE (MPa) | 0.17–7.88 | 0.14–97.00 | 2500–4000 | 80–150 | 1500–3000 | 6000–15,000 | 3000–7000 | 20–100 | |

| BS (MPa) | 0.13–1.26 | 0.02–4.40 | 20–40 | 0.70–1.20 | 1.5–3.5 | 10–30 | 0.1–0.3 | 0.5–2.0 | |

| DS (kg/m3) | 209.17–256.28 | 25–954 | 640–800 | 230–400 | 600–800 | 1300–1700 | 15–200 | 60–400 | |

| SK (%) | 8.15–25.78 | 2.78–17 | 0.01–0.30 | 0.2–0.5 | 0.05–0.10 | 0.02–0.05 | 0.015–0.030 | 0.02–0.10 | |

| WA (%) | 96.86–254.11 | 24.45–560 | 5–15 | 30–70 | 30–50 | 10–25 | 1–4 | 5–30 | |

| VS (%) | 2.63–19.03 | 0.28–21 | 10–25 | 15–40 | 0.02–0.10 | 0.1–2.0 | 1.0–2.5 | 0.1–1.0 | |

| TC (W/m·K) | 0.037–0.079 | 0.029–0.124 | 0.10–0.18 | 0.035–0.060 | 0.16–0.25 | 0.20–0.40 | 0.022–0.040 | 0.03–0.05 | |

| SAC (%) | 250 Hz | 40–51 | 16–20 | 10–20 | 15–30 | 5–10 | 10–20 | 30–60 | 50–80 |

| 500 Hz | 34–49 | 50–51 | 8–15 | 30–50 | 5–8 | 8–15 | 65–90 | 80–100 | |

| 1000 Hz | 61–94 | 70–75 | 6–12 | 50–70 | 4–7 | 6–12 | 85–100 | 90–100 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jinanukul, P.; Kumla, J.; Aiduang, W.; Thamjaree, W.; Oranratmanee, R.; Shummadtayar, U.; Tongtuam, Y.; Lumyong, S.; Suwannarach, N.; Waroonkun, T. Comparative Evaluation of Mechanical and Physical Properties of Mycelium Composite Boards Made from Lentinus sajor-caju with Various Ratios of Corn Husk and Sawdust. J. Fungi 2024, 10, 634. https://doi.org/10.3390/jof10090634

Jinanukul P, Kumla J, Aiduang W, Thamjaree W, Oranratmanee R, Shummadtayar U, Tongtuam Y, Lumyong S, Suwannarach N, Waroonkun T. Comparative Evaluation of Mechanical and Physical Properties of Mycelium Composite Boards Made from Lentinus sajor-caju with Various Ratios of Corn Husk and Sawdust. Journal of Fungi. 2024; 10(9):634. https://doi.org/10.3390/jof10090634

Chicago/Turabian StyleJinanukul, Praween, Jaturong Kumla, Worawoot Aiduang, Wandee Thamjaree, Rawiwan Oranratmanee, Umpiga Shummadtayar, Yuttana Tongtuam, Saisamorn Lumyong, Nakarin Suwannarach, and Tanut Waroonkun. 2024. "Comparative Evaluation of Mechanical and Physical Properties of Mycelium Composite Boards Made from Lentinus sajor-caju with Various Ratios of Corn Husk and Sawdust" Journal of Fungi 10, no. 9: 634. https://doi.org/10.3390/jof10090634

APA StyleJinanukul, P., Kumla, J., Aiduang, W., Thamjaree, W., Oranratmanee, R., Shummadtayar, U., Tongtuam, Y., Lumyong, S., Suwannarach, N., & Waroonkun, T. (2024). Comparative Evaluation of Mechanical and Physical Properties of Mycelium Composite Boards Made from Lentinus sajor-caju with Various Ratios of Corn Husk and Sawdust. Journal of Fungi, 10(9), 634. https://doi.org/10.3390/jof10090634