Evaluation of Indigenous Candida oleophila and Candida boidinii in Monoculture and Sequential Fermentations: Impact on Ethanol Reduction and Chemical Profile in Chilean Sauvignon Blanc Wines

Abstract

:1. Introduction

2. Materials and Methods

2.1. Yeasts

2.2. Evaluation of the Fermentation Potential in Glucose/Fructose Medium

2.2.1. Glucose/Fructose Medium

2.2.2. Starter Culture

2.2.3. Fermentation

2.3. Laboratory-Scale Fermentations

2.3.1. Grape Juice

2.3.2. Fermentation

2.3.3. Monoculture Fermentation

2.3.4. Sequential Fermentation

2.3.5. Fermentation Follow-Up and Control

2.4. Microvinifications

2.5. Statistical Analysis

3. Results and Discussions

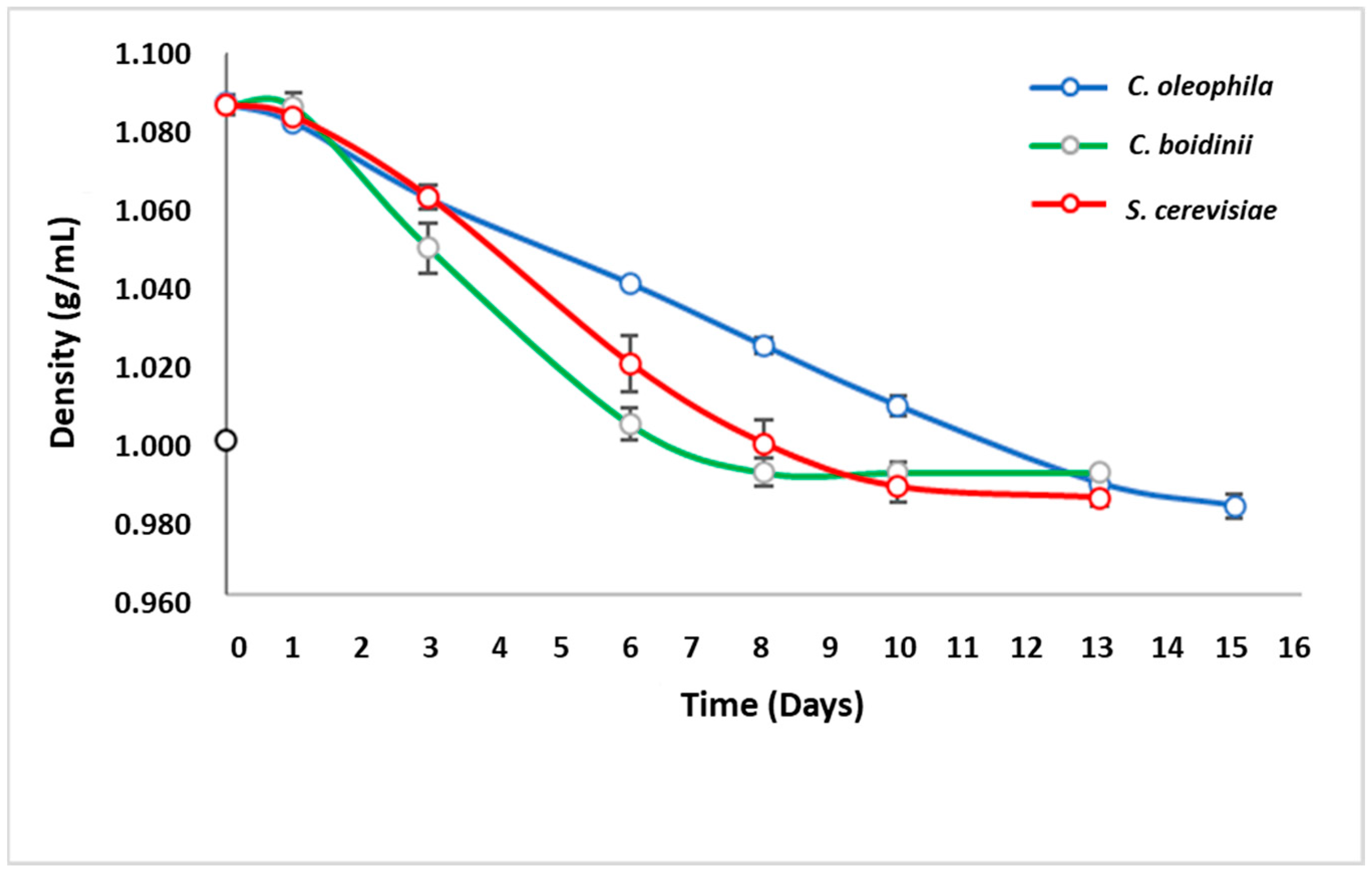

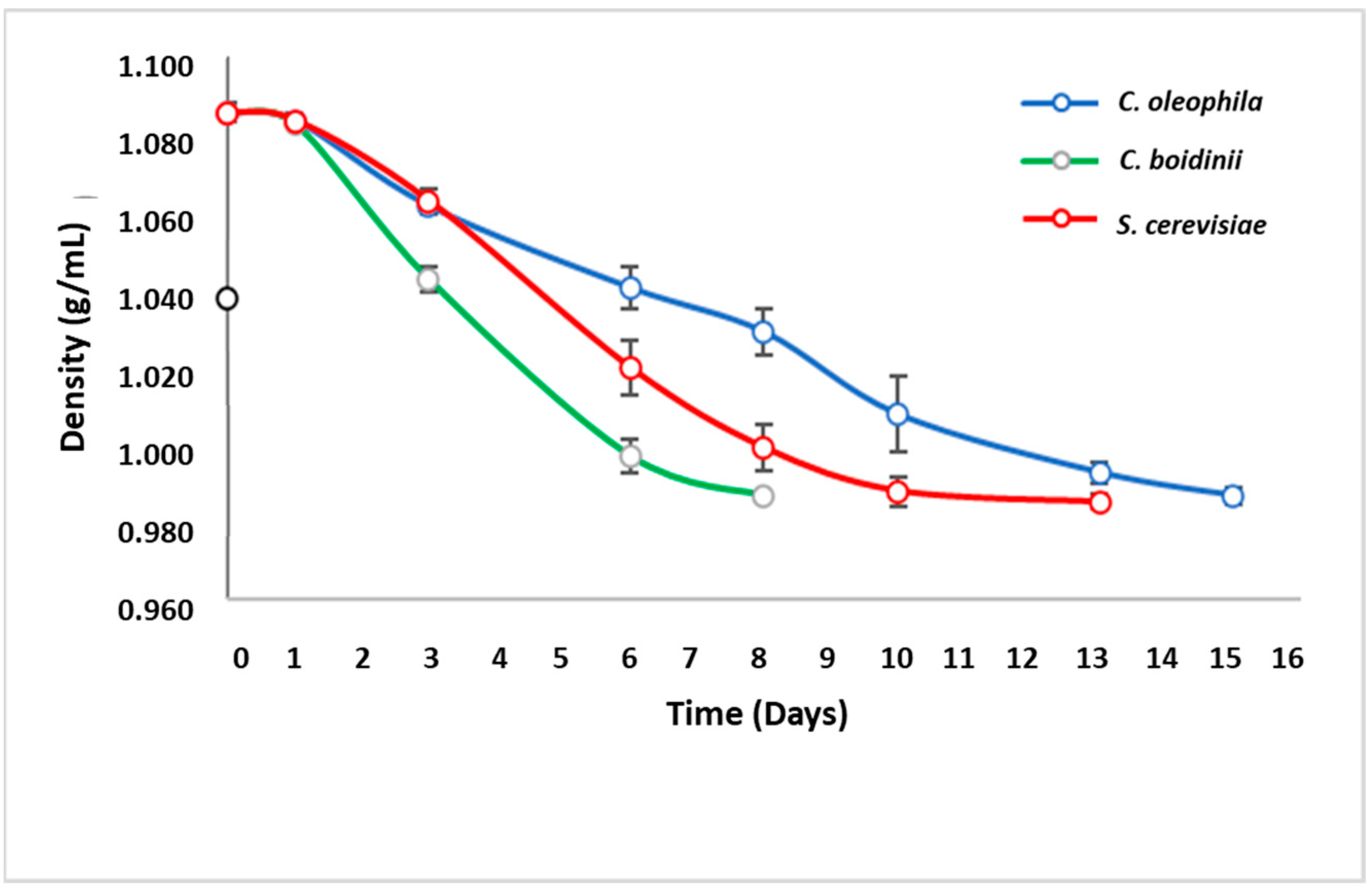

3.1. Fermentation in the Synthetic (Glucose/Fructose) Medium

3.2. Fermentations at Laboratory Scale

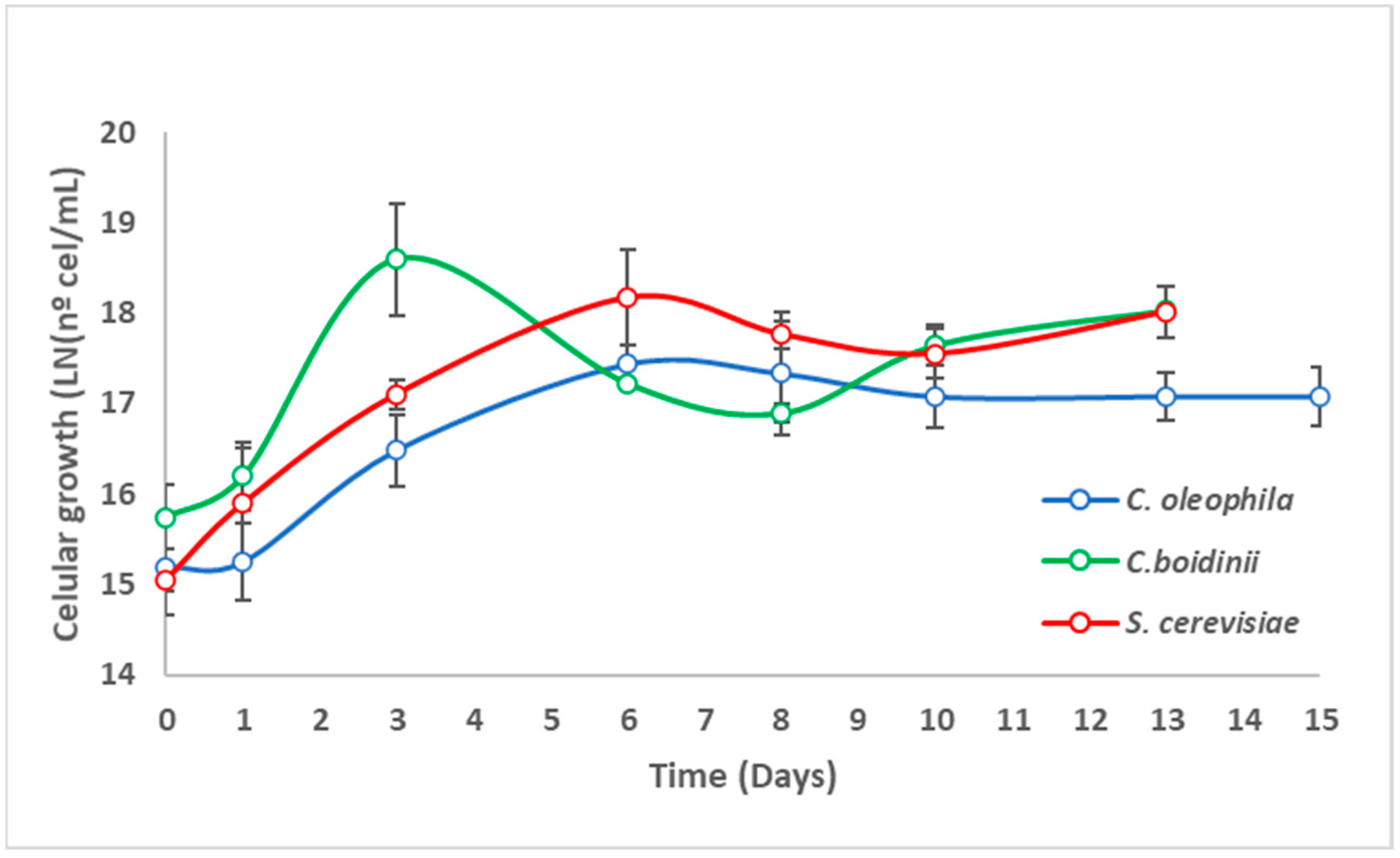

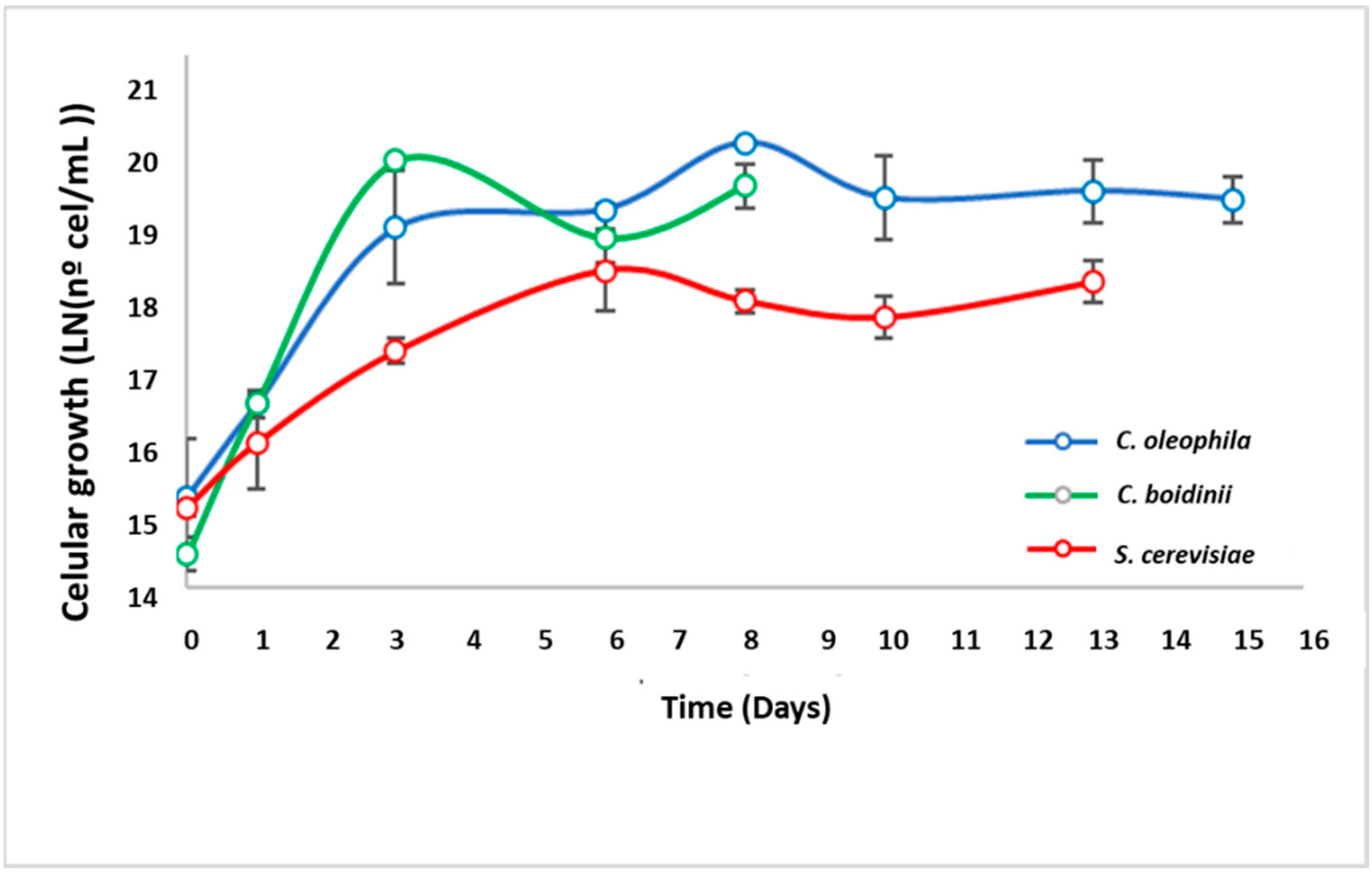

3.2.1. Monoculture Fermentation

3.2.2. Sequential Fermentation

3.3. Microvinifications

3.3.1. Microvinification with Sauvignon Blanc Grape Juice form the Casablanca Valley

3.3.2. Microvinification with Sauvignon Blanc Grape Juice form the Curicó Valley

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, B.; Tang, C.; Yang, D.; Liu, H.; Xue, J.; Duan, C.; Yan, G. Effects of three indigenous non-Saccharomyces yeasts and their pairwise combinations in co-fermentation with Saccharomyces cerevisiae on volatile compounds of Petit Manseng wines. Food Chem. 2022, 368, 130807. [Google Scholar] [CrossRef] [PubMed]

- Chen, K.; Escott, C.; Loira, I.; del Fresno, J.M.; Morata, A.; Tesfaye, W.; Calderon, F.; Suárez-Lepe, J.A.; Han, S.; Benito, S. Use of non-Saccharomyces yeasts and oenological tannin in red winemaking: Influence on colour, aroma and sensorial properties of young wines. Food Microbiol. 2018, 69, 51–63. [Google Scholar] [CrossRef] [PubMed]

- Van Wyk, N.; von Wallbrunn, C.; Swiegers, J.H.; Pretorius, I.S. Biotechnology of Wine Yeasts; Elsevier: Amsterdam, The Netherlands, 2020. [Google Scholar]

- Bokulich, N.A.; Thorngate, J.H.; Richardson, P.M.; Mills, D.A. Microbial biogeography of wine grapes is conditioned by cultivar, vintage, and climate. Proc. Natl. Acad. Sci. USA 2014, 111, 139–148. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gao, F.; Zeng, G.; Wang, B.; Xiao, J.; Zhang, L.; Cheng, W.; Wang, H.; Li, H.; Shi, X. Discrimination of the geographic origins and varieties of wine grapes using high-throughput sequencing assisted by a random forest model. Lwt 2021, 145, 111333. [Google Scholar] [CrossRef]

- Contreras, A.; Hidalgo, C.; Schmidt, S.; Henschke, P.A.; Curtin, C.; Varela, C. The application of non-Saccharomyces yeast in fermentations with limited aeration as a strategy for the production of wine with reduced alcohol content. Int. J. Food Microbiol. 2015, 205, 7–15. [Google Scholar] [CrossRef]

- Han, X.; Qing, X.; Yang, S.; Li, R.; Zhan, J.; You, Y.; Huang, W. Study on the diversity of non-Saccharomyces yeasts in Chinese wine regions and their potential in improving wine aroma by β-glucosidase activity analyses. Food Chem. 2021, 360, 129886. [Google Scholar] [CrossRef]

- Lappa, I.K.; Kachrimanidou, V.; Pateraki, C.; Koulougliotis, D.; Eriotou, E.; Kopsahelis, N. Indigenous yeasts: Emerging trends and challenges in winemaking. Curr. Opin. Food Sci. 2020, 32, 133–143. [Google Scholar] [CrossRef]

- Franco, W.; Benavides, S.; Valencia, P.; Ramírez, C.; Urtubia, A. Native yeasts and lactic acid bacteria isolated from spontaneous fermentation of seven grape cultivars from the maule region (Chile). Foods 2021, 10, 1737. [Google Scholar] [CrossRef]

- Aplin, J.J.; White, K.P.; Edwards, C.G. Growth and metabolism of non-Saccharomyces yeasts isolated from Washington state vineyards in media and high sugar grape musts. Food Microbiol. 2019, 77, 158–165. [Google Scholar] [CrossRef]

- Comitini, F.; Gobbi, M.; Domizio, P.; Romani, C.; Lencioni, L.; Mannazzu, I.; Ciani, M. Selected non-Saccharomyces wine yeasts in controlled multistarter fermentations with Saccharomyces cerevisiae. Food Microbiol. 2011, 28, 873–882. [Google Scholar] [CrossRef]

- Whitener, M.E.B.; Stanstrup, J.; Carlin, S.; Divol, B.; Toit, M.D.; Vrhovsek, U. Effect of non-Saccharomyces yeasts on the volatile chemical profile of Shiraz wine. Aust. J. Grape Wine Res. 2017, 23, 179–192. [Google Scholar] [CrossRef]

- Hong, M.; Li, J.; Chen, Y.; Qi, B.; Huang, Y.; Wu, J.; Yue, H.; Tong, Z.; Liu, Y.; Wang, F. Impact of mixed non-Saccharomyces yeast during fermentation on volatile aroma compounds of Vidal blanc icewine. Lwt 2021, 145, 111342. [Google Scholar] [CrossRef]

- Mančić, S.; Danilović, B.; Malićanin, M.; Stojanović, S.S.; Nikolić, N.; Lazić, M.; Karabegović, I. Fermentative potential of native yeast candida famata for prokupac grape must fermentation. Agriculture 2021, 11, 358. [Google Scholar] [CrossRef]

- Zhang, P.; Zhang, R.; Sirisena, S.; Gan, R.; Fang, Z. Beta-glucosidase activity of wine yeasts and its impacts on wine volatiles and phenolics: A mini-review. Food Microbiol. 2021, 100, 103859. [Google Scholar] [CrossRef]

- Liu, D.; Legras, J.L.; Zhang, P.; Chen, D.; Howell, K. Diversity and dynamics of fungi during spontaneous fermentations and association with unique aroma profiles in wine. Int. J. Food Microbiol. 2021, 338, 108983. [Google Scholar] [CrossRef]

- Contreras, A.; Hidalgo, C.; Henschke, P.A.; Chambers, P.J.; Curtin, C.; Varela, C. Evaluation of non-Saccharomyces yeasts for the reduction of alcohol content in wine. Appl. Environ. Microbiol. 2014, 80, 1670–1678. [Google Scholar] [CrossRef] [Green Version]

- Berthels, N.J.; Otero, R.R.C.; Bauer, F.F.; Pretorius, I.S.; Thevelein, J.M. Correlation between glucose/fructose discrepancy and hexokinase kinetic properties in different Saccharomyces cerevisiae wine yeast strains. Appl. Microbiol. Biotechnol. 2008, 77, 1083–1091. [Google Scholar] [CrossRef]

- Fleet, G.H. Yeast interactions and wine flavour. Int. J. Food Microbiol. 2003, 86, 11–22. [Google Scholar] [CrossRef]

- Tronchoni, J.; Gamero, A.; Arroyo-López, F.N.; Barrio, E.; Querol, A. Differences in the glucose and fructose consumption profiles in diverse Saccharomyces wine species and their hybrids during grape juice fermentation. Int. J. Food Microbiol. 2009, 134, 237–243. [Google Scholar] [CrossRef] [Green Version]

- Azhar, S.H.M.; Abdulla, R.; Jambo, S.A.; Marbawi, H.; Gansau, J.A.; Faik, A.A.M.; Rodrigues, K.F. Yeasts in sustainable bioethanol production: A review. Biochem. Biophys. Rep. 2017, 10, 52–61. [Google Scholar] [CrossRef]

- Fakhruddin, M.; Quayum, M.A.; Ahmed, M.M.; Choudhury, N. Analysis of key factors affecting ethanol production by S. cerevisiae. Biotechnology 2012, 11, 248–252. [Google Scholar] [CrossRef]

- Hranilovic, A.; Gambetta, J.M.; Jeffery, D.W.; Grbin, P.R.; Jiranek, V. Lower-alcohol wines produced by Metschnikowia pulcherrima and Saccharomyces cerevisiae co-fermentations: The effect of sequential inoculation timing. Int. J. Food Microbiol. 2020, 329, 108651. [Google Scholar] [CrossRef] [PubMed]

- García-Fraile, P.; Silva, L.R.; Sánchez-Márquez, S.; Velázquez, E.; Rivas, R. Plums (Prunus domestica L.) are a good source of yeasts producing organic acids of industrial interest from glycerol. Food Chem. 2013, 139, 31–34. [Google Scholar] [CrossRef] [PubMed]

- Junior, W.J.F.L.; Nadai, C.; Crepalde, L.T.; de Oliveira, V.; de Matos, A.D.; Giacomini, A.; Corich, V. Potential use of Starmerella bacillaris as fermentation starter for the production of low-alcohol beverages obtained from unripe grapes. Int. J. Food Microbiol. 2019, 303, 1–8. [Google Scholar] [CrossRef]

- Ciani, M.; Morales, P.; Comitini, F.; Tronchoni, J.; Canonico, L.; Curiel, J.A.; Oro, L.; Rodrigues, A.J.; Gonzalez, R. Non-conventional yeast species for lowering ethanol content of wines. Front. Microbiol. 2016, 7, 642. [Google Scholar] [CrossRef] [Green Version]

- Del Fresno, J.M.; Morata, A.; Loira, I.; Bañuelos, M.A.; Escott, C.; Benito, S.; González Chamorro, C.; Suárez-Lepe, J.A. Use of non-Saccharomyces in single-culture, mixed and sequential fermentation to improve red wine quality. Eur. Food Res. Technol. 2017, 243, 2175–2185. [Google Scholar] [CrossRef]

- Rolle, L.; Englezos, V.; Torchio, F.; Cravero, F.; Segade, S.R.; Rantsiou, K.; Giacosa, S.; Gambuti, A.; Gerbi, V.; Cocolin, L. Alcohol reduction in red wines by technological and microbiological approaches: A comparative study. Aust. J. Grape Wine Res. 2018, 24, 62–74. [Google Scholar] [CrossRef]

- Englezos, V.; Cravero, F.; Torchio, F.; Rantsiou, K.; Ortiz-Julien, A.; Lambri, M.; Gerbi, V.; Rolle, L.; Cocolin, L. Oxygen availability and strain combination modulate yeast growth dynamics in mixed culture fermentations of grape must with Starmerella bacillaris and Saccharomyces cerevisiae. Food Microbiol. 2018, 69, 179–188. [Google Scholar] [CrossRef]

- Cioch-Skoneczny, M.; Satora, P.; Skoneczny, S.; Pater, A. Determination of the oenological properties of yeast strains isolated from spontaneously fermented grape musts obtained from cool climate grape varieties. Eur. Food Res. Technol. 2020, 246, 2299–2307. [Google Scholar] [CrossRef]

- Matraxia, M.; Alfonzo, A.; Prestianni, R.; Francesca, N.; Gaglio, R.; Todaro, A.; Alfeo, V.; Perretti, G.; Columba, P.; Settanni, L.; et al. Non-conventional yeasts from fermented honey by-products: Focus on Hanseniaspora uvarum strains for craft beer production. Food Microbiol. 2021, 99, 103806. [Google Scholar] [CrossRef]

- Santos, M.M.D.; Gombert, A.K.; Christensen, B.; Olsson, L.; Nielsen, J. Identification of in vivo enzyme activities in the cometabolism of glucose and acetate by Saccharomyces cerevisiae by using 13C-labeled substrates. Eukaryot. Cell 2003, 2, 599–608. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liccioli, T.; Tran, T.M.T.; Cozzolino, D.; Jiranek, V.; Chambers, P.J.; Schmidt, S.A. Microvinification—How small can we go? Appl. Microbiol. Biotechnol. 2011, 89, 1621–1628. [Google Scholar] [CrossRef] [PubMed]

- Zoecklein, B.W.; Fugelsang, K.C.; Gump, B.H.; Nury, F.S. Volatile Acidity. Wine Anal. Prod. 1995, 11, 192–198. [Google Scholar] [CrossRef]

| Yeast | Ethanol (% v/v) | Sugar Consumption (%) | Yield (g Ethanol/g Glucose) |

|---|---|---|---|

| C. oleophila | 4.20 ± 0.53 a | 71.77 ± 2.41 a | 0.25 ± 0.02 a |

| C. boidinii | 6.40 ± 0.20 b | 99.89 ± 1.31 b | 0.24 ± 0.04 a |

| S. cerevisiae | 13.90 ± 0.65 c | 99.92 ± 1.11 b | 0.45 ± 0.04 b |

| Yeast | Ethanol (%v/v) | Residual Sugar (g/L) | Yield (g Ethanol/g Glucose) | G/F | Days |

|---|---|---|---|---|---|

| C. oleophila | 12.10 ± 0.10 a | 2.70 ± 0.26 a | 0.347 | 1.074 | 15 |

| C. boidinii | 12.37 ± 0.06 b | 2.17 ± 0.84 a | 0.354 | 1.070 | 10 |

| S. cerevisiae | 12.87 ± 0.16 c | 2.50 ± 0.17 a | 0.368 | 1.072 | 13 |

| Yeast | g/L | |

|---|---|---|

| Acetic Acid | Glycerol | |

| C. oleophila | 0.15 ± 0.15 a | 9.47 ± 1.17 a |

| C. boidinii | 0.14 ± 0.19 a | 10.97 ± 0.84 a |

| S. cerevisiae | 0.07 ± 0.02 a | 11.27 ± 0.46 a |

| Yeast | Ethanol (%v/v) | Residual Sugar (g/L) | Yield (g Ethanol/g Glucose) | G/F | Days |

|---|---|---|---|---|---|

| C. oleophila | 11.37 ± 1.46 a | 2.03 ± 0.25 a | 0.368 | 1.072 | 15 |

| C. boidinii | 12.83 ± 0.55 a | 2.40 ± 0.20 a | 0.368 | 1.071 | 8 |

| S. cerevisiae | 12.87 ± 0.12 a | 2.25 ± 0.17 a | 0.358 | 1.072 | 13 |

| Yeast | g/L | |

|---|---|---|

| Acetic Acid | Glycerol | |

| C. oleophila | 0.03 ± 0.03 a | 5.17 ± 0.76 a |

| C. boidinii | NDL | 6.77 ± 0.45 a |

| S. cerevisiae | 0.07 ± 0.02 a | 11.25 ± 0.46 b |

| Yeast | Fermentation | Ethanol % v/v | g/L | |||||

|---|---|---|---|---|---|---|---|---|

| Fructose | Glucose | Glycerol | Acetic Acid | Malic Acid | Lactic Acid | |||

| S. cerevisiae | Control | 13.74 ± 0.18 a | 1.73 ± 0.20 a | 0.39 ± 0.11 a | 7.26 ± 0.27 a | 0.29 ± 0.12 a | 2.42 ± 0.28 a | 0.09 ± 0.03 a |

| C. boidinii | Monoculture | 13.57 ± 0.66 a | 0.82 ± 0.00 ab | 0.23 ± 0.04 b | 6.14 ± 0.10 c | 0.23 ± 0.03 ab | 2.22 ± 0.03 ab | ND |

| Sequential | 13.20 ± 0.84 a | 1.32 ± 0.40 ab | 0.22 ± 0.02 c | 6.74 ± 0.11 b | 0.21 ± 0.05 ab | 2.23 ± 0.02 ab | 0.10 ± 0.01 a | |

| C. oleophila | Monoculture | 13.90 ± 0.98 a | 1.07 ± 0.26 ab | 0.21 ± 0.06 b | 6.55 ± 0.19 b | 0.29 ± 0.06 a | 2.33 ± 0.14 ab | ND |

| Sequential | 13.12 ± 1.15 a | 0.60 ± 0.15 b | 0.099 ± 0.02 b | 6.71 ± 0.16 b | 0.16 ± 0.02 b | 2.37 ± 0.15 ab | 0.17 ± 0.01 a | |

| Yeast | Ethanol % v/v | g/L | |||||

|---|---|---|---|---|---|---|---|

| Fructose | Glucose | Glycerol | Acetic Acid | Malic Acid | Lactic Acid | ||

| S. cerevisiae | 11.95 ± 0.14 a | 1.79 ± 0.40 a | 0.06 ± 0.03 a | 6.70 ± 0.87 a | NDL | 2.00 ± 0.22 a | 0.18 ± 0.03 ab |

| C. boidinii | 11.51 ± 0.84 a | 2.04 ± 0.29 a | 0.08 ± 0.02 a | 8.51 ± 0.12 c | 0.46 ± 0.29 b | 1.75 ± 0.01 b | 0.05 ± 0.02 a |

| C. oleophila | 11.41 ± 0.55 a | 2.81 ± 0.83 a | 0.11 ± 0.02 a | 5.37 ± 0.19 b | 0.11 ± 0.01 a | 0.11 ± 0.08 c | 0.21 ± 0.14 b |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Benavides, S.; Franco, W.; Ceppi De Lecco, C.; Durán, A.; Urtubia, A. Evaluation of Indigenous Candida oleophila and Candida boidinii in Monoculture and Sequential Fermentations: Impact on Ethanol Reduction and Chemical Profile in Chilean Sauvignon Blanc Wines. J. Fungi 2022, 8, 259. https://doi.org/10.3390/jof8030259

Benavides S, Franco W, Ceppi De Lecco C, Durán A, Urtubia A. Evaluation of Indigenous Candida oleophila and Candida boidinii in Monoculture and Sequential Fermentations: Impact on Ethanol Reduction and Chemical Profile in Chilean Sauvignon Blanc Wines. Journal of Fungi. 2022; 8(3):259. https://doi.org/10.3390/jof8030259

Chicago/Turabian StyleBenavides, Sergio, Wendy Franco, Consuelo Ceppi De Lecco, Angélica Durán, and Alejandra Urtubia. 2022. "Evaluation of Indigenous Candida oleophila and Candida boidinii in Monoculture and Sequential Fermentations: Impact on Ethanol Reduction and Chemical Profile in Chilean Sauvignon Blanc Wines" Journal of Fungi 8, no. 3: 259. https://doi.org/10.3390/jof8030259