Industrially Important Fungal Carotenoids: Advancements in Biotechnological Production and Extraction

Abstract

1. Introduction

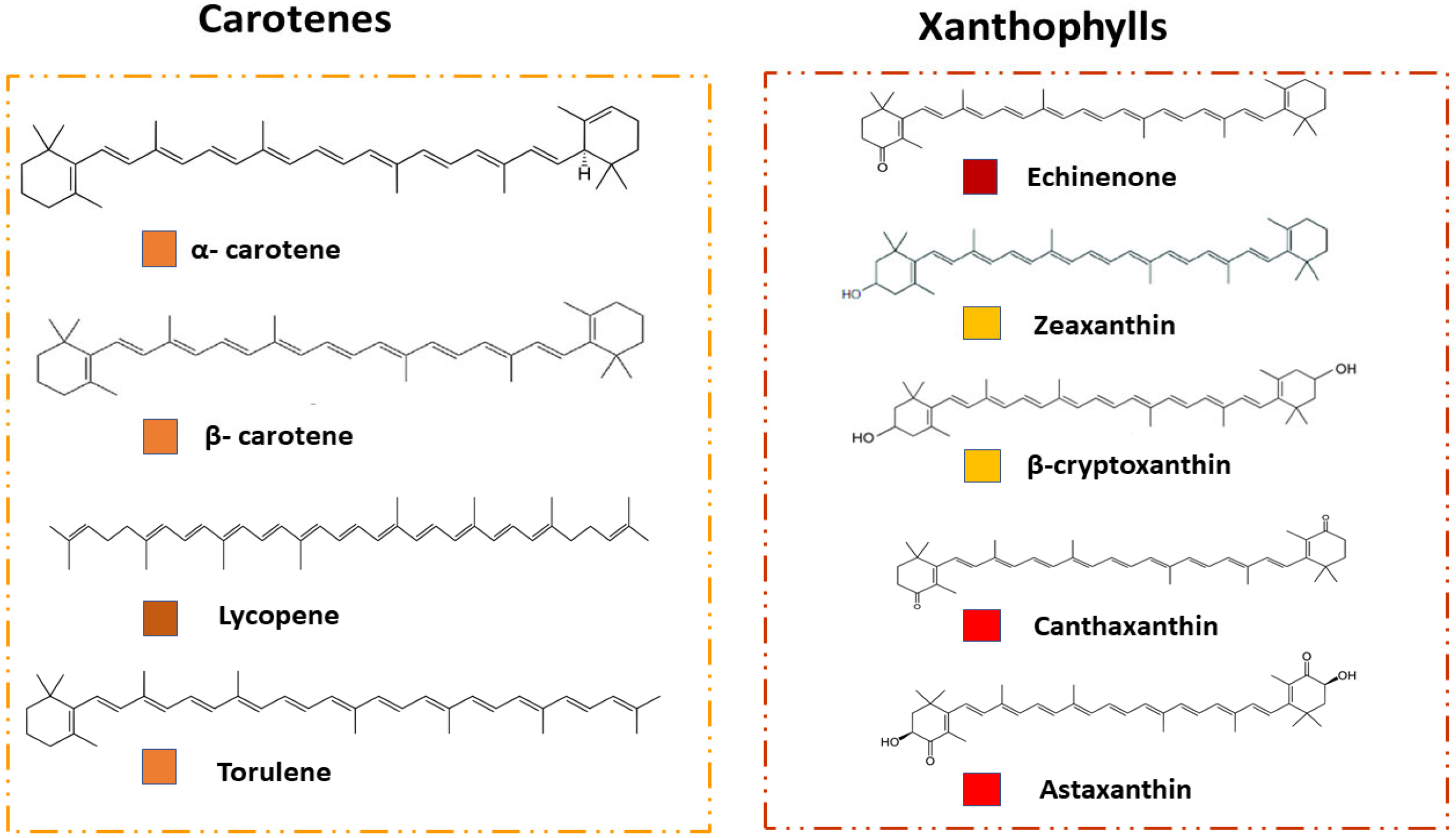

Carotenoids Classification

2. Potential Applications and Biological Functions of Carotenoids

| Carotenoids | Application | Activity | Reference |

|---|---|---|---|

| Astaxanthin | Fish feed and cosmetic industry | Antioxidant, photo-protectant, anti-inflammatory and anticancer. | [22] |

| β-carotene | Animal feed, Nutraceutical and cosmetics industries | Antioxidant, anticancer, and vitamin A precursor | [23] |

| Canthaxanthin | Cosmetic, Poultry and fish feed | Antioxidant and anticancer | [24] |

| Lutein | Poultry feed, functional nutrient | Antioxidant | [25] |

| Lycopene | Supplements in functional food, additives in cosmetics | Antioxidant and anticancer | [26] |

| Neurosporaxanthin | Feed or food additive | Antioxidant | [27] |

| Torulene and torularhodin | Feedstock, food, and cosmetic additives | Antioxidant, and anticancer | [28] |

3. Industrially Important Fungal Carotenoids

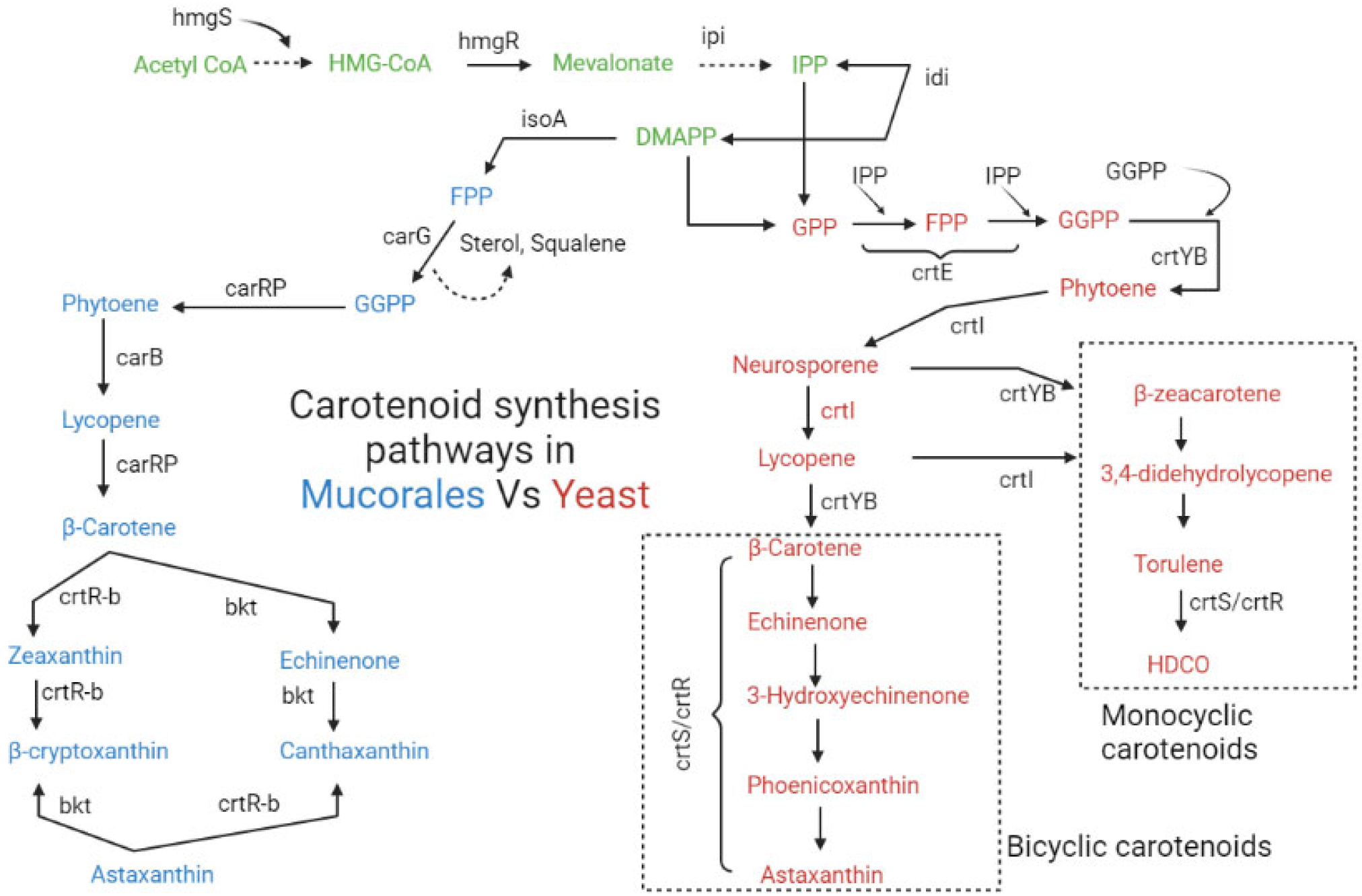

4. Carotenoid Biosynthesis Pathway in Fungi

5. Cultivation Condition Affecting Biotechnological Production of Carotenoids

5.1. pH

5.2. Light

5.3. Temperature

5.4. Carbon and Nitrogen (C/N) Ratio

5.5. Chemical Stressors

6. Recent Trends in Biotechnological Production of Fungal Carotenoid

6.1. Carotenoid Production in Carotenogenic Fungi

6.2. Carotenoid Production in Non-Carotenogenic Fungi

6.2.1. Y. Lipolytica

6.2.2. S. cerevisiae

6.2.3. M. circinelloides

| Microorganism | Carotenoid | Genotype | Fermentation | Productivity | Reference |

|---|---|---|---|---|---|

| B. trispora | β-carotene | Wild type | Shake flask | 39 mg/g DW | [108] |

| optimized culture and development conditions | 78.0 mg/g | [109] | |||

| R. glutinis | β-carotene | Wild type | Shake flask using molasses | 14 mg/L | [110] |

| X. dendrorhous | Astaxanthin | Random mutagenesis, overexpression of crtYB and asy | Optimal growth medium Bioreactor | 9.7 mg/g DCW | [117] |

| Astaxanthin | CYP61 deletion | Sakaguchi flask | 1.65 mg/L | [115] | |

| Astaxanthin | Cre-loxP, overexpressing crtS and crtE | Liquid YM medium | 0.6 mg/g | [121] | |

| Astaxanthin | UV-radiated mutant, NTG | Liquid YM medium | 1.07 mg/g, 1.45 mg/g | [155] | |

| Y. lipolytica | Lycopene | Bacterial crtB and crtI integration | YPD, Shake flask | 3.4 mg/g | [130] |

| β-carotene | Fungal crtBY and crtI | YPD, Shake flask | 12.5 mg/g | [131] | |

| β-carotene | Multiple gene integration | Fed-batch fermentation | 4 g/L | [63] | |

| β-carotene | Golden Gate DNA assembly | Single fed-batch experiment | 6.5 g/L (90 mg/g DCW | [132] | |

| β-carotene | Integrating multiple copies of 13 genes | Fed-batch fermentation. | 7.6 g/L (159 mg/g) | [133] | |

| β-carotene | Yeast crtI, crtE, and crtYB, overexpression of key genes of MVA and FAS pathway | Fed-batch fermentation by using 5 L fermenter | 2695.5 mg/L | [134] | |

| β-carotene | Structure-guided protein engineering | 5 L fermenter | 39.5 g/L | [135] | |

| Astaxanthin | Algal β-ketolase genes | Controlled bioreactor with glucose | 285.19 mg/L | [67] | |

| Astaxanthin | β-ketolase and hydroxylase genes | Fed-batch fermentation | 858 mg/L | [136] | |

| Astaxanthin | Modular enzyme assembly of CrtW and CrtZ | Fed-batch fermentation | 3.3 g/L | [137] | |

| Zeaxanthin | Bacterial multiple copies of copies of crtZ | Wheat straw hemicellulose hydrolysate | 5.2 mg/g DCW | [138] | |

| Zeaxanthin | Bacterial crtZ | Synthetic YNB medium | 3.20 mg/g | [139] | |

| S. cerevisiae | Lycopene | Over expression of OLE1. | Fed-batch fermentation | 73.3 mg/g (2.37 g/L) | [140] |

| β-carotene | Adaptive laboratory evolution of β-carotene synthase gene | Oxidative stress | 16.4 mg/g DCW | [141]. | |

| β-carotene | Modification of extracellular and cell-bound lipases | Grown on olive mill waste oil | 46.5 mg/g DCW (477.9 mg/L) | [142] | |

| β-carotene | Overexpression ARE1 and ARE2 and deletion of (PAH1, DPP1, and LPP1). | Shake flask fermentation | 8.98 mg/g DCW | [143]. | |

| β-carotene | Yeast genes crtYB, crtI, and crtE | Xylose as substrate in fed-batch fermentation | 772.8 mg/L | [144] | |

| Astaxanthin | Overexpression of algal crtZ) and bkt) | Shake flask fermentation | 4.7 mg/g DCW | [145] | |

| Astaxanthin | Over expression of tHMG1(truncated), crtI, and crtYB along with a positive mutant of GGPP synthase | Shake flask fermentation | 8.10 mg/g (47.18 mg/L) | [146] | |

| Astaxanthin | crtW and crtZ along with mutagenesis using ARTP | Batch fermentation in 5 L fermenter. | 13.8 mg/g DCW (217.9 mg/L) | [147] | |

| Astaxanthin | Directed evolution of β-carotene hydroxylase and ketolase | 2 stage high density fermentation | 235 mg/L | [148] | |

| Astaxanthin | Upregulation of opi3 and hrd1 using trifunctional CRISPR Balancing expression of bkt and crtZ | Fed-batch fermentation. | 9.79 mg/g DCW 10.21 mg/g DCW | [150] | |

| M. circinelloides | β-carotene | Disruption of crgA | Shake flask fermentation | 4 mg/g DCW | [45] |

| Canthaxanthin, Astaxanthin | Bacterial crtZ gene | Shake flask fermentation | 443 ±71 μg/g 35 μg/g DCW | [32] | |

| Canthaxanthin | Yeast crtR and crtS | Solid media cultivation | 190 μg/g DCW | [31] | |

| Canthaxanthin | Algal bkt | 1.5 L bioreactor | 576 ± 28 μg/g DCW | [69] |

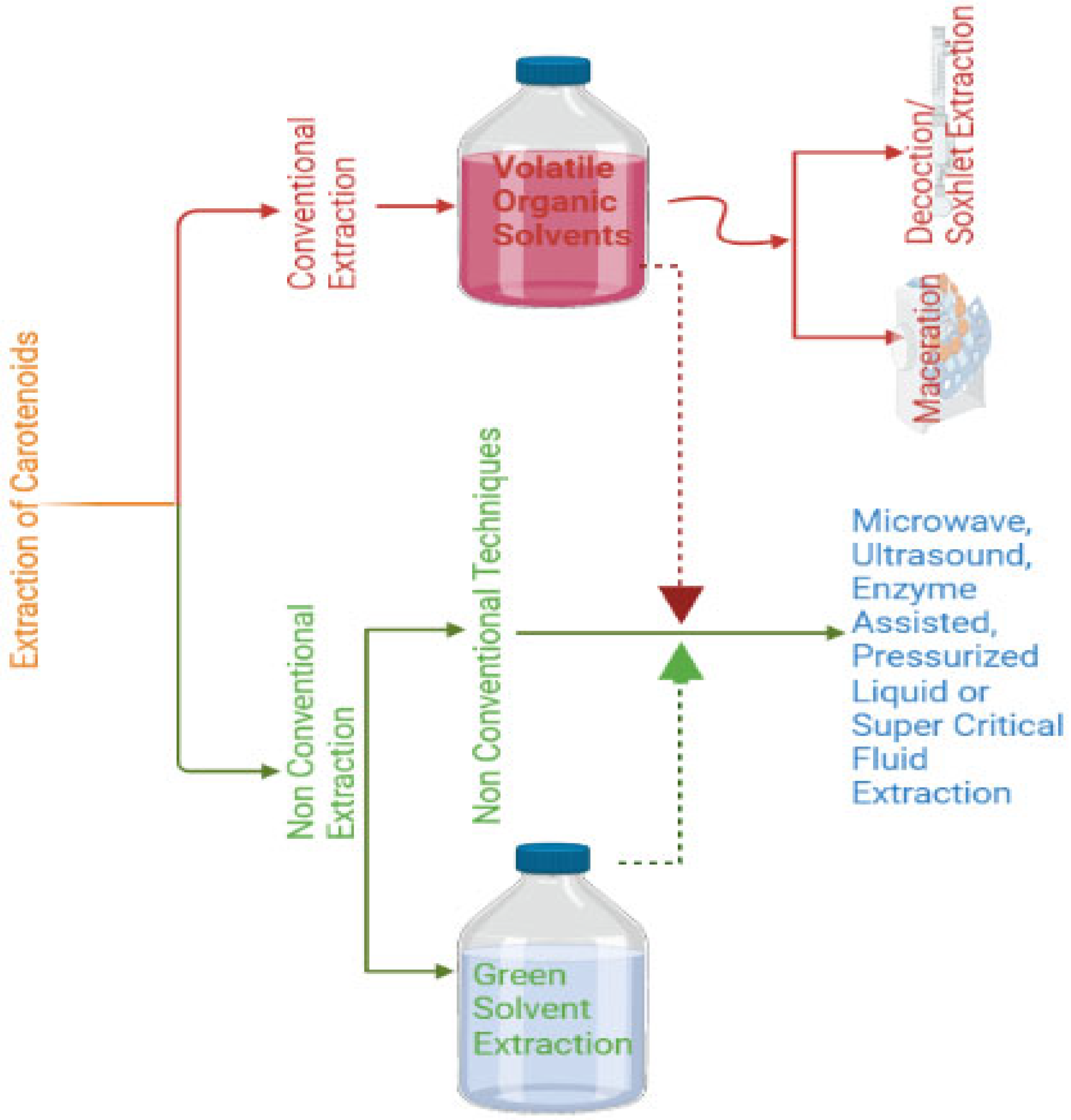

7. Carotenoid Extraction: Methods, Considerations, and Downstream Impacts on Cost

7.1. Conventional Carotenoid Extraction and the Impact of VOCs

7.2. Greener Solvent Extraction

7.3. Non-Conventional Techniques for Carotenoid Extraction

7.3.1. Super Critical Fluid Extraction

7.3.2. Pressurized Liquid Extraction (PLE)

7.3.3. Enzyme, Ultrasound, Microwave, and Electric Field Assisted Extraction of Carotenoids

8. Exploring the Potential of Fungal Pigments for Industrial Applications: Challenges in Commercialization

9. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Igreja, W.S.; de Maia, F.A.; Lopes, A.S.; Chisté, R.C. Biotechnological Production of Carotenoids Using Low Cost-Substrates Is Influenced by Cultivation Parameters: A Review. Int. J. Mol. Sci. 2021, 22, 8819. [Google Scholar] [CrossRef]

- Maoka, T. Carotenoids as Natural Functional Pigments. J. Nat. Med. 2020, 74, 1–16. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Li, Q.R.; Zhang, M.H.; You, Y.; Wang, Y.; Wang, Y.H. Enhancement of Carotenoid Biosynthesis in Phaffia rhodozyma PR106 under Stress Conditions. Biosci. Biotechnol. Biochem. 2019, 83, 2375–2385. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.S.; Wu, J.Y. Optimization of Cell Growth and Carotenoid Production of Xanthophyllomyces dendrorhous through Statistical Experiment Design. Biochem. Eng. J. 2007, 36, 182–189. [Google Scholar] [CrossRef]

- Sandmann, G. Carotenoids and Their Biosynthesis in Fungi. Molecules 2022, 27, 1431. [Google Scholar] [CrossRef]

- Cataldo, V.; Arenas, N.; López, J.; Camilo, C.; Agosin, E. Sustainable Production of β-Xanthophylls in Saccharomyces cerevisiae; University College London: London, UK, 2018. [Google Scholar]

- Maldonade, I.R.; Scamparini, A.R.P.; Rodriguez-Amaya, D.B. Selection and Characterization of Carotenoid-Producing Yeasts from Campinas Region, Brazil. Braz. J. Microbiol. 2007, 38, 65–70. [Google Scholar] [CrossRef]

- Toti, E.; Oliver Chen, C.Y.; Palmery, M.; Valencia, D.V.; Peluso, I. Non-Provitamin A and Provitamin A Carotenoids as Immunomodulators: Recommended Dietary Allowance, Therapeutic Index, or Personalized Nutrition? Oxid. Med. Cell. Longev. 2018, 1–20. [Google Scholar] [CrossRef]

- Jayaraj, J.; Devlin, R.; Punja, Z. Metabolic Engineering of Novel Ketocarotenoid Production in Carrot Plants. Transgenic Res. 2008, 17, 489–501. [Google Scholar] [CrossRef]

- Córdova, P.; Baeza, M.; Cifuentes, V.; Alcaíno, J. Microbiological Synthesis of Carotenoids: Pathways and Regulation. In Progress in Carotenoid Research; Intechopen: London, UK, 2018. [Google Scholar]

- Eliassen, A.H.; Hendrickson, S.J.; Brinton, L.A.; Buring, J.E.; Campos, H.; Dai, Q.; Dorgan, J.F.; Franke, A.A.; Gao, Y.T.; Goodman, M.T.; et al. Circulating Carotenoids and Risk of Breast Cancer: Pooled Analysis of Eight Prospective Studies. J. Natl. Cancer Inst. 2012, 104, 1905–1916. [Google Scholar] [CrossRef] [PubMed]

- Woodside, J.V.; McGrath, A.J.; Lyner, N.; McKinley, M.C. Carotenoids and Health in Older People. Maturitas 2015, 80, 63–68. [Google Scholar] [CrossRef] [PubMed]

- Naz, T.; Nosheen, S.; Li, S.; Nazir, Y.; Mustafa, K.; Liu, Q.; Garre, V.; Song, Y. Comparative Analysis of β-Carotene Production by Mucor Circinelloides Strains CBS 277.49 and WJ11 under Light and Dark Conditions. Metabolites 2020, 10, 38. [Google Scholar] [CrossRef] [PubMed]

- Chew, B.P.; Park, J.S. Carotenoid Action on the Immune Response. J. Nutr. 2004, 134, 257s–261s. [Google Scholar] [CrossRef]

- Mata-Gómez, L.C.; Montañez, J.C.; Méndez-Zavala, A.; Aguilar, C.N. Biotechnological Production of Carotenoids by Yeasts: An Overview. Microb. Cell Fact. 2014, 13, 12. [Google Scholar] [CrossRef]

- Berman, J.; Zorrilla-López, U.; Farré, G.; Zhu, C.; Sandmann, G.; Twyman, R.M.; Capell, T.; Christou, P. Nutritionally Important Carotenoids as Consumer Products. Phytochem. Rev. 2015, 14, 727–743. [Google Scholar] [CrossRef]

- Jampani, C.; Raghavarao, K.S.M.S. Process Integration for Purification and Concentration of Red Cabbage (Brassica Oleracea L.) Anthocyanins. Sep. Purif. Technol. 2015, 141, 10–16. [Google Scholar] [CrossRef]

- Castro-Puyana, M.; Pérez-Sánchez, A.; Valdés, A.; Ibrahim, O.H.M.; Suarez-Álvarez, S.; Ferragut, J.A.; Micol, V.; Cifuentes, A.; Ibáñez, E.; García-Cañas, V. Pressurized Liquid Extraction of Neochloris Oleoabundans for the Recovery of Bioactive Carotenoids with Anti-Proliferative Activity against Human Colon Cancer Cells. Food Res. Int. 2017, 99, 1048–1055. [Google Scholar] [CrossRef]

- Zhang, X.; Zhao, W.E.; Hu, L.; Zhao, L.; Huang, J. Carotenoids Inhibit Proliferation and Regulate Expression of Peroxisome Proliferators-Activated Receptor Gamma (PPARγ) in K562 Cancer Cells. Arch. Biochem. Biophys. 2011, 512, 96–106. [Google Scholar] [CrossRef]

- Hughes, D.A. Effects of Carotenoids on Human Immune Function. In Proceedings of the Nutrition Society; Cambridge University Press: Cambridge, UK, 1999; Volume 58, pp. 713–718. [Google Scholar]

- Cardoso, L.A.C.; Karp, S.G.; Vendruscolo, F.; Kanno, K.Y.F.; Zoz, L.I.C.; Carvalho, J.C. Biotechnological Production of Carotenoids and Their Applications in Food and Pharmaceutical Products. Carotenoids 2017, 8, 125–141. [Google Scholar]

- Panis, G.; Carreon, J.R. Commercial Astaxanthin Production Derived by Green Alga Haematococcus Pluvialis: A Microalgae Process Model and a Techno-Economic Assessment All through Production Line. Algal Res. 2016, 18, 175–190. [Google Scholar] [CrossRef]

- Jing, K.; He, S.; Chen, T.; Lu, Y.; Ng, I.S. Enhancing Beta-Carotene Biosynthesis and Gene Transcriptional Regulation in Blakeslea trispora with Sodium Acetate. Biochem. Eng. J. 2016, 114, 10–17. [Google Scholar] [CrossRef]

- Ravaghi, M.; Razavi, S.H.; Mousavi, S.M.; Sinico, C.; Fadda, A.M. Stabilization of Natural Canthaxanthin Produced by Dietzia Natronolimnaea HS-1 by Encapsulation in Niosomes. LWT—Food Sci. Technol. 2016, 73, 498–504. [Google Scholar] [CrossRef]

- Lin, J.H.; Lee, D.J.; Chang, J.S. Lutein Production from Biomass: Marigold Flowers versus Microalgae. Bioresour. Technol. 2015, 184, 421–428. [Google Scholar] [CrossRef]

- Hernández-Almanza, A.; Montañez, J.; Martínez, G.; Aguilar-Jiménez, A.; Contreras-Esquivel, J.C.; Aguilar, C.N. Lycopene: Progress in Microbial Production. Trends Food Sci. Technol. 2016, 56, 142–148. [Google Scholar] [CrossRef]

- Parra-Rivero, O.; de Barros, M.P.; Del Mar Prado, M.; Gil, J.V.; Hornero-Méndez, D.; Zacarías, L.; Rodrigo, M.J.; Limón, M.C.; Avalos, J. Neurosporaxanthin Overproduction by Fusarium Fujikuroi and Evaluation of Its Antioxidant Properties. Antioxidants 2020, 6, 528. [Google Scholar] [CrossRef] [PubMed]

- Kot, A.M.; Błazejak, S.; Gientka, I.; Kieliszek, M.; Bryś, J. Torulene and Torularhodin: “New” Fungal Carotenoids for Industry? Microb. Cell Fact. 2018, 17, 1–14. [Google Scholar] [CrossRef]

- Avalos, J.; Carmen Limón, M. Biological Roles of Fungal Carotenoids. Curr. Genet. 2015, 61, 309–324. [Google Scholar] [CrossRef] [PubMed]

- Schimek, C.; Wöstemeyer, J. Carotene Derivatives in Sexual Communication of Zygomycete Fungi. Phytochemistry 2009, 70, 1867–1875. [Google Scholar] [CrossRef]

- Csernetics, Á.; Tóth, E.; Farkas, A.; Nagy, G.; Bencsik, O.; Vágvölgyi, C.; Papp, T. Expression of Xanthophyllomyces dendrorhous Cytochrome-P450 Hydroxylase and Reductase in Mucor Circinelloides. World J. Microbiol. Biotechnol. 2015, 31, 321–336. [Google Scholar] [CrossRef]

- Csernetics, Á.; Tóth, E.; Farkas, A.; Nagy, G.; Bencsik, O.; Manikandan, P.; Vágvölgyi, C.; Papp, T. Expression of a Bacterial β-Carotene Hydroxylase in Canthaxanthin Producing Mutant Mucor Circinelloides Strains. Acta Biol. Szeged. 2014, 58, 139–146. [Google Scholar]

- Afroz Toma, M.; Rahman, M.H.; Rahman, M.S.; Arif, M.; Nazir, K.H.M.N.H.; Dufossé, L. Fungal Pigments: Carotenoids, Riboflavin, and Polyketides with Diverse Applications. J. Fungi 2023, 9, 454. [Google Scholar] [CrossRef] [PubMed]

- Velayos, A.; Blasco, J.L.; Alvarez, M.I.; Iturriaga, E.A.; Eslava, A.P. Blue-Light Regulation of Phytoene Dehydrogenase (CarB) Gene Expression in Mucor Circinelloides. Planta 2000, 210, 938–946. [Google Scholar] [CrossRef] [PubMed]

- Avalos, J.; Pardo-Medina, J.; Parra-Rivero, O.; Ruger-Herreros, M.; Rodríguez-Ortiz, R.; Hornero-Méndez, D.; Limón, M.C. Carotenoid Biosynthesis in Fusarium. J. Fungi 2017, 3, 39. [Google Scholar] [CrossRef] [PubMed]

- Rivera Vélez, S.M. Guide for Carotenoid Identification in Biological Samples. J. Nat. Prod. 2016, 79, 1473–1484. [Google Scholar] [CrossRef]

- De Rosso, V.V.; Mercadante, A.Z. Identification and Quantification of Carotenoids, by HPLC-PDA-MS/MS, from Amazonian Fruits. J. Agric. Food Chem. 2007, 55, 5062–5072. [Google Scholar] [CrossRef] [PubMed]

- Domínguez-Bocanegra, A.R.; Ponce-Noyola, T.; Torres-Muñoz, J.A. Astaxanthin Production by Phaffia rhodozyma and Haematococcus Pluvialis: A Comparative Study. Appl. Microbiol. Biotechnol. 2007, 75, 783–791. [Google Scholar] [CrossRef] [PubMed]

- Elwan, H.A.M.; Elnesr, S.S.; Abdallah, Y.; Hamdy, A.; El-Bogdady, A.H. Red Yeast (Phaffia rhodozyma) as a Source of Astaxanthin and Its Impacts on Productive Performance and Physiological Responses of Poultry. Worlds. Poult. Sci. J. 2019, 75, 273–284. [Google Scholar] [CrossRef]

- Kot, A.M.; Błażejak, S.; Kieliszek, M.; Gientka, I.; Bryś, J. Simultaneous Production of Lipids and Carotenoids by the Red Yeast Rhodotorula from Waste Glycerol Fraction and Potato Wastewater. Appl. Biochem. Biotechnol. 2019, 189, 589–607. [Google Scholar] [CrossRef] [PubMed]

- Haxo, F. Carotenoids of the Mushroom Cantharellus Cinnabarinus. Bot. Gaz. 1950, 112, 228–232. [Google Scholar] [CrossRef]

- Davoli, P.; Mierau, V.; Weber, R.W.S. Carotenoids and Fatty Acids in Red Yeasts Sporobolomyces Roseus and Rhodotorula glutinis. Appl. Biochem. Microbiol. 2004, 40, 392–397. [Google Scholar] [CrossRef]

- Pegklidou, K.; Mantzouridou, F.; Tsimidou, M.Z. Lycopene Production Using Blakeslea trispora in the Presence of 2-Methyl Imidazole: Yield, Selectivity, and Safety Aspects. J. Agric. Food Chem. 2008, 56, 4482–4490. [Google Scholar] [CrossRef]

- Goodwin, T.W. The Biochemistry of the Carotenoids; Springer: Berlin, Germany, 1980. [Google Scholar]

- Zhang, Y.; Navarro, E.; Cánovas-Márquez, J.T.; Almagro, L.; Chen, H.; Chen, Y.Q.; Zhang, H.; Torres-Martínez, S.; Chen, W.; Garre, V. A New Regulatory Mechanism Controlling Carotenogenesis in the Fungus Mucor Circinelloides as a Target to Generate β-Carotene over-Producing Strains by Genetic Engineering. Microb. Cell Fact. 2016, 15, 1–14. [Google Scholar] [CrossRef] [PubMed]

- Gómez, M.; Campusano, S.; Gutiérrez, M.S.; Sepúlveda, D.; Barahona, S.; Baeza, M.; Cifuentes, V.; Alcaíno, J. Sterol Regulatory Element-Binding Protein Sre1 Regulates Carotenogenesis in the Red Yeast Xanthophyllomyces dendrorhous. J. Lipid Res. 2020, 61, 1658–1674. [Google Scholar] [CrossRef] [PubMed]

- Papadaki, E.; Mantzouridou, F.T. Natural β-Carotene Production by Blakeslea trispora Cultivated in Spanish-Style Green Olive Processing Wastewaters. Foods 2021, 10, 327. [Google Scholar] [CrossRef]

- Guy Valadon, L.R.; Osman, M.; Mummery, R.S.; Jerebzoff-Quintin, S.; Jerebzoff, S. The Effect of Monochromatic Radiation in the Range 350 to 750 Nm on the Carotenogenesis in Verticillium Agaricinum. Physiol. Plant. 1982, 56, 199–203. [Google Scholar] [CrossRef]

- Strobel, I.; Breitenbach, J.; Scheckhuber, C.Q.; Osiewacz, H.D.; Sandmann, G. Carotenoids and Carotenogenic Genes in Podospora Anserina: Engineering of the Carotenoid Composition Extends the Life Span of the Mycelium. Curr. Genet. 2009, 55, 175–184. [Google Scholar] [CrossRef]

- Iigusa, H.; Yoshida, Y.; Hasunuma, K. Oxygen and Hydrogen Peroxide Enhance Light-Induced Carotenoid Synthesis in Neurospora Crassa. FEBS Lett. 2005, 579, 4012–4016. [Google Scholar] [CrossRef] [PubMed]

- Naguib, Y. Pioneering Astaxanthin. Nutr. Sci. News 2001, 6, 58. [Google Scholar]

- Perera, C.O.; Yen, G.M. Functional Properties of Carotenoids in Human Health. Int. J. Food Prop. 2007, 10, 201–230. [Google Scholar] [CrossRef]

- Esatbeyoglu, T.; Rimbach, G. Canthaxanthin: From Molecule to Function. Mol. Nutr. Food Res. 2017, 61, 1600469. [Google Scholar] [CrossRef]

- Torres-Haro, A.; Verdín, J.; Kirchmayr, M.R.; Arellano-Plaza, M. Metabolic Engineering for High Yield Synthesis of Astaxanthin in Xanthophyllomyces dendrorhous. Microb. Cell Fact. 2021, 20, 1–17. [Google Scholar] [CrossRef]

- Alcaíno, J.; Fuentealba, M.; Cabrera, R.; Baeza, M.; Cifuentes, V. Modeling the Interfacial Interactions between CrtS and CrtR from Xanthophyllomyces dendrorhous, a P450 System Involved in Astaxanthin Production. J. Agric. Food Chem. 2012, 60, 8640–8647. [Google Scholar] [CrossRef] [PubMed]

- Schmidt, I.; Schewe, H.; Gassel, S.; Jin, C.; Buckingham, J.; Hümbelin, M.; Sandmann, G.; Schrader, J. Biotechnological Production of Astaxanthin with Phaffia rhodozyma/Xanthophyllomyces dendrorhous. Appl. Microbiol. Biotechnol. 2011, 89, 555–571. [Google Scholar] [CrossRef]

- Ambati, R.R.; Moi, P.S.; Ravi, S.; Aswathanarayana, R.G. Astaxanthin: Sources, Extraction, Stability, Biological Activities and Its Commercial Applications—A Review. Mar. Drugs 2014, 12, 128–152. [Google Scholar] [CrossRef] [PubMed]

- Silva, F.; Torres-Martínez, S.; Garre, V. Distinct White Collar-1 Genes Control Specific Light Responses in Mucor Circinelloides. Mol. Microbiol. 2006, 61, 1023–1037. [Google Scholar] [CrossRef]

- Barredo, J.L.; García-Estrada, C.; Kosalkova, K.; Barreiro, C. Biosynthesis of Astaxanthin as a Main Carotenoid in the Heterobasidiomycetous Yeast Xanthophyllomyces dendrorhous. J. Fungi 2017, 3, 44. [Google Scholar] [CrossRef]

- Zoz, L.; Carvalho, J.C.; Soccol, V.T.; Casagrande, T.C.; Cardoso, L. Torularhodin and Torulene: Bioproduction, Properties and Prospective Applications in Food and Cosmetics—A Review. Braz. Arch. Biol. Technol. 2015, 58, 278–288. [Google Scholar] [CrossRef]

- Velayos, A.; Eslava, A.P.; Iturriaga, E.A. A Bifunctional Enzyme with Lycopene Cydase and Phytoene Synthase Activities Is Encoded by the CarRP Gene of Mucor Circinelloides. Eur. J. Biochem. 2000, 267, 5509–5519. [Google Scholar] [CrossRef]

- Czajka, J.J.; Nathenson, J.A.; Benites, V.T.; Baidoo, E.E.K.; Cheng, Q.; Wang, Y.; Tang, Y.J. Engineering the Oleaginous Yeast Yarrowia lipolytica to Produce the Aroma Compound β-Ionone. Microb. Cell Fact. 2018, 17, 1–13. [Google Scholar] [CrossRef] [PubMed]

- Gao, S.; Tong, Y.; Zhu, L.; Ge, M.; Zhang, Y.; Chen, D.; Jiang, Y.; Yang, S. Iterative Integration of Multiple-Copy Pathway Genes in Yarrowia lipolytica for Heterologous β-Carotene Production. Metab. Eng. 2017, 41, 192–201. [Google Scholar] [CrossRef] [PubMed]

- Sanz, C.; Velayos, A.; Álvarez, M.I.; Benito, E.P.; Eslava, A.P. Functional Analysis of the Phycomyces CarRA Gene Encoding the Enzymes Phytoene Synthase and Lycopene Cyclase. PLoS ONE 2011, 6, e23102. [Google Scholar] [CrossRef] [PubMed]

- Ootaki, T.; Lighty, A.C.; Delbrück, M.; Hsu, W.J. Complementation between Mutants of Phycomyces Deficient with Respect to Carotenogenesis. MGG Mol. Gen. Genet. 1973, 121, 57–70. [Google Scholar] [CrossRef]

- Sun, T. An Alternative Route for Astaxanthin Biosynthesis in Green Algae. Plant Physiol. 2020, 183, 812–813. [Google Scholar] [CrossRef]

- Tramontin, L.R.R.; Kildegaard, K.R.; Sudarsan, S.; Borodina, I. Enhancement of Astaxanthin Biosynthesis in Oleaginous Yeast Yarrowia lipolytica via Microalgal Pathway. Microorganisms 2019, 71, 472. [Google Scholar] [CrossRef] [PubMed]

- Tian, L.; Musetti, V.; Kim, J.; Magallanes-Lundback, M.; DellaPenna, D. The Arabidopsis LUT1 Locus Encodes a Member of the Cytochrome P450 Family That Is Required for Carotenoid ε-Ring Hydroxylation Activity. Proc. Natl. Acad. Sci. USA 2004, 101, 402–407. [Google Scholar] [CrossRef] [PubMed]

- Naz, T.; Yang, J.; Nosheen, S.; Sun, C.; Nazir, Y.; Mohamed, H.; Fazili, A.B.A.; Ullah, S.; Li, S.; Yang, W.; et al. Genetic Modification of Mucor Circinelloides for Canthaxanthin Production by Heterologous Expression of β-Carotene Ketolase Gene. Front. Nutr. 2021, 8, 756218. [Google Scholar] [CrossRef]

- Verdoes, J.C.; Krubasik, P.; Sandmann, G.; Van Ooyen, A.J.J. Isolation and Functional Characterisation of a Novel Type of Carotenoid Biosynthetic Gene from Xanthophyllomyces dendrorhous. Mol. Gen. Genet. 1999, 262, 453–461. [Google Scholar] [CrossRef]

- Alcaíno, J.; Barahona, S.; Carmona, M.; Lozano, C.; Marcoleta, A.; Niklitschek, M.; Sepúlveda, D.; Baeza, M.; Cifuentes, V. Cloning of the Cytochrome P450 Reductase (CrtR) Gene and Its Involvement in the Astaxanthin Biosynthesis of Xanthophyllomyces dendrorhous. BMC Microbiol. 2008, 8, 169. [Google Scholar] [CrossRef]

- Chi, S.; He, Y.; Ren, J.; Su, Q.; Liu, X.; Chen, Z.; Wang, M.; Li, Y.; Li, J. Overexpression of a Bifunctional Enzyme, CrtS, Enhances Astaxanthin Synthesis through Two Pathways in Phaffia rhodozyma. Microb. Cell Fact. 2015, 14, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Álvarez, V.; Rodríguez-Sáiz, M.; de la Fuente, J.L.; Gudiña, E.J.; Godio, R.P.; Martín, J.F.; Barredo, J.L. The CrtS Gene of Xanthophyllomyces dendrorhous Encodes a Novel Cytochrome-P450 Hydroxylase Involved in the Conversion of β-Carotene into Astaxanthin and Other Xanthophylls. Fungal Genet. Biol. 2006, 43, 261–272. [Google Scholar] [CrossRef]

- Pagels, F.; Vasconcelos, V.; Guedes, A.C. Carotenoids from Cyanobacteria: Biotechnological Potential and Optimization Strategies. Biomolecules 2021, 11, 735. [Google Scholar] [CrossRef] [PubMed]

- Amr, A.E.-B.; Abd, A.M.; Ahmed, R.E.-M. Some Factors Affecting the Production of Carotenoids by Rhodotorula glutinis Var. Glutinis. Food Nutr. Sci. 2012, 2012, 17082. [Google Scholar]

- Hernández-Almanza, A.; Montañez-Sáenz, J.; Martínez-Ávila, C.; Rodríguez-Herrera, R.; Aguilar, C.N. Carotenoid Production by Rhodotorula glutinis YB-252 in Solid-State Fermentation. Food Biosci. 2014, 7, 31–36. [Google Scholar] [CrossRef]

- Korumilli, T.; Mishra, S.; Korukonda, J.R. Production of Astaxanthin by Xanthophyllomyces dendrorhous on Fruit Waste Extract and Optimization of Key Parameters Using Taguchi Method. J. Biochem. Technol. 2020, 11, 25. [Google Scholar]

- Tinoi, J.; Rakariyatham, N.; Deming, R.L. Simplex Optimization of Carotenoid Production by Rhodotorula glutinis Using Hydrolyzed Mung Bean Waste Flour as Substrate. Process Biochem. 2005, 40, 2551–2557. [Google Scholar] [CrossRef]

- Olson, M.L.; Johnson, J.; Carswell, W.F.; Reyes, L.H.; Senger, R.S.; Kao, K.C. Characterization of an Evolved Carotenoids Hyper-Producer of Saccharomyces cerevisiae through Bioreactor Parameter Optimization and Raman Spectroscopy. J. Ind. Microbiol. Biotechnol. 2016, 43, 1355–1363. [Google Scholar] [CrossRef] [PubMed]

- Shih, C.T.; Hang, Y.D. Production of Carotenoids By Rhodotorula Rubrafrom Sauerkraut Brine. LWT-Food Sci. Technol. 1996, 29, 570–572. [Google Scholar] [CrossRef]

- Mihalcea, A.; Ungureanu, C.; Ferdes, M.; Chirvase, A.A.; Tanase, C. The Influence of Operating Conditions on the Growth of the Yeast Rhodotorula Rubra ICCF 209 and on Torularhodin Formation. Culture 2011, 11, 12. [Google Scholar]

- Nasrabadi, M.R.N.; Razavi, S.H. Optimization of β-Carotene Production by a Mutant of the Lactose-Positive Yeast Rhodotorula Acheniorum from Whey Ultrafiltrate. Food Sci. Biotechnol. 2011, 20, 445–454. [Google Scholar] [CrossRef]

- Isaac, S. Mycology Answers: Many Fungi Are Brightly Coloured; Does Pigmentation Provide Any Advantage to Those Species? Mycologist 1994, 8, 178–179. [Google Scholar] [CrossRef]

- Li, C.; Zhang, N.; Li, B.; Xu, Q.; Song, J.; Wei, N.; Wang, W.; Zou, H. Increased Torulene Accumulation in Red Yeast Sporidiobolus Pararoseus NGR as Stress Response to High Salt Conditions. Food Chem. 2017, 237, 1041–1047. [Google Scholar] [CrossRef]

- Zhang, Z.; Ji, H.; Gong, G.; Zhang, X.; Tan, T. Synergistic Effects of Oleaginous Yeast Rhodotorula glutinis and Microalga Chlorella Vulgaris for Enhancement of Biomass and Lipid Yields. Bioresour. Technol. 2014, 164, 93–99. [Google Scholar] [CrossRef] [PubMed]

- Tropea, A.; Gervasi, T.; Melito, M.R.; lo Curto, A.; Lo Curto, R. Does the Light Influence Astaxanthin Production in Xanthophyllomyces dendrorhous? Nat. Prod. Res. 2013, 27, 648–654. [Google Scholar] [CrossRef]

- Dzurendova, S.; Losada, C.B.; Dupuy-Galet, B.X.; Fjær, K.; Shapaval, V. Mucoromycota Fungi as Powerful Cell Factories for Modern Biorefinery. Appl. Microbiol. Biotechnol. 2022, 106, 101–115. [Google Scholar] [CrossRef]

- Aksu, Z.; Eren, A.T. Production of Carotenoids by the Isolated Yeast of Rhodotorula glutinis. Biochem. Eng. J. 2007, 35, 107–113. [Google Scholar] [CrossRef]

- Naghavi, F.; Hanachi, P.; Saboora, A. Effect of Temperature, PH and Salinity on Carotenoid Production in Rodotorula mucilaginosa. Res. Biotechnol. 2014, 5, 1–4. [Google Scholar]

- Nasirian, N.; Mirzaie, M.; Cicek, N.; Levin, D.B. Lipid and Carotenoid Synthesis by Rhodosporidium Diobovatum, Grown on Glucose versus Glycerol, and Its Biodiesel Properties. Can. J. Microbiol. 2018, 64, 277–289. [Google Scholar] [CrossRef]

- Shi, F.; Zhan, W.; Li, Y.; Wang, X. Temperature Influences β-Carotene Production in Recombinant Saccharomyces cerevisiae Expressing Carotenogenic Genes from Phaffia rhodozyma. World J. Microbiol. Biotechnol. 2014, 30, 125–133. [Google Scholar] [CrossRef]

- Zheng, S.; Yang, M.; Yang, Z. Biomass Production of Yeast Isolate from Salad Oil Manufacturing Wastewater. Bioresour. Technol. 2005, 96, 1183–1187. [Google Scholar] [CrossRef]

- Sinha, S.; Singh, G.; Arora, A.; Paul, D. Carotenoid Production by Red Yeast Isolates Grown in Agricultural and “Mandi” Waste. Waste Biomass Valorization 2021, 12, 3939–3949. [Google Scholar] [CrossRef]

- Tkáčová, J.; Čaplová, J.; Klempová, T.; Čertík, M. Correlation between Lipid and Carotenoid Synthesis in Torularhodin-Producing Rhodotorula glutinis. Ann. Microbiol. 2017, 67, 541–551. [Google Scholar] [CrossRef]

- Braunwald, T.; Schwemmlein, L.; Graeff-Hönninger, S.; French, W.T.; Hernandez, R.; Holmes, W.E.; Claupein, W. Effect of Different C/N Ratios on Carotenoid and Lipid Production by Rhodotorula glutinis. Appl. Microbiol. Biotechnol. 2013, 97, 6581–6588. [Google Scholar] [CrossRef]

- Shariati, S.; Zare, D.; Mirdamadi, S. Screening of Carbon and Nitrogen Sources Using Mixture Analysis Designs for Carotenoid Production by Blakeslea trispora. Food Sci. Biotechnol. 2019, 28, 469–479. [Google Scholar] [CrossRef] [PubMed]

- Naz, T.; Nazir, Y.; Nosheen, S.; Ullah, S.; Halim, H.; Fazili, A.B.A.; Li, S.; Mustafa, K.; Mohamed, H.; Yang, W.; et al. Redirecting Metabolic Flux towards the Mevalonate Pathway for Enhanced β-Carotene Production in M. Circinelloides CBS 277.49. Biomed Res. Int. 2020, 2020, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Guan, X.; Lu, Y.; Liu, Y.; Xu, N.; Cai, C.; Li, Q.; Liu, J.; Wang, Y.; Liu, J. Titanium Dioxide-Mediated Fatty Acids Promoted Carotenoid Synthesis in Phaffia rhodozyma PR106 Analyzed Whole Genome. Bioresour. Technol. 2022, 347, 126699. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Li, Q.; Liu, J.; Lu, Y.; Wang, Y.; Wang, Y. Astaxanthin Overproduction and Proteomic Analysis of Phaffia rhodozyma under the Oxidative Stress Induced by TiO2. Bioresour. Technol. 2020, 311, 123525. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.S.; Wu, J.Y. Hydrogen Peroxide-Induced Astaxanthin Biosynthesis and Catalase Activity in Xanthophyllomyces dendrorhous. Appl. Microbiol. Biotechnol. 2006, 73, 663–668. [Google Scholar] [CrossRef]

- Azizi, M.; Zare, D.; Akhavan Sepahy, A.; Azin, M. Evaluating the Effect of Microbial Stimulation and Oxidative Stress on Increasing β-Carotene Production in Blakeslea trispora. Microbiol. Metab. Biotechnol. 2021, 4, 1–11. [Google Scholar]

- Dzurendova, S.; Zimmermann, B.; Kohler, A.; Reitzel, K.; Nielsen, U.G.; Dupuy--Galet, B.X.; Leivers, S.; Horn, S.J.; Shapaval, V. Calcium Affects Polyphosphate and Lipid Accumulation in Mucoromycota Fungi. J. Fungi 2021, 7, 300. [Google Scholar] [CrossRef] [PubMed]

- Gmoser, R.; Ferreira, J.A.; Lundin, M.; Taherzadeh, M.J.; Lennartsson, P.R. Pigment Production by the Edible Filamentous Fungus Neurospora Intermedia. Fermentation 2018, 4, 11. [Google Scholar] [CrossRef]

- Kuzina, V.; Cerdá-Olmedo, E. Ubiquinone and Carotene Production in the Mucorales Blakeslea and Phycomyces. Appl. Microbiol. Biotechnol. 2007, 76, 991–999. [Google Scholar] [CrossRef]

- Wang, C.; Zhao, S.; Shao, X.; Park, J.-B.; Jeong, S.H.; Park, H.J.; Kwak, W.J.; Wei, G.; Kim, S.W. Challenges and Tackles in Metabolic Engineering for Microbial Production of Carotenoids. Microb. Cell Fact. 2019, 18, 55. [Google Scholar] [CrossRef]

- Kanamoto, H.; Nakamura, K.; Misawa, N. Carotenoid Production in Oleaginous Yeasts. Adv. Exp. Med. Biol. 2021, 1261, 153–163. [Google Scholar] [PubMed]

- Sandmann, G. Carotenoids of Biotechnological Importance. Adv. Biochem. Eng. Biotechnol. 2015, 148, 449–467. [Google Scholar] [CrossRef] [PubMed]

- Mehta, B.J.; Obraztsova, I.N.; Cerdá-Olmedo, E. Mutants and Intersexual Heterokaryons of Blakeslea trispora for Production of β-Carotene and Lycopene. Appl. Environ. Microbiol. 2003, 69, 4043–4048. [Google Scholar] [CrossRef]

- Nanou, K.; Roukas, T.; Papadakis, E. Improved Production of Carotenes from Synthetic Medium by Blakeslea trispora in a Bubble Column Reactor. Biochem. Eng. J. 2012, 67, 203–207. [Google Scholar] [CrossRef]

- Bhosale, P.; Gadre, R. V β-Carotene Production in Sugarcane Molasses by a Rhodotorula glutinis Mutant. J. Ind. Microbiol. Biotechnol. 2001, 26, 327–332. [Google Scholar] [CrossRef]

- Zhou, D.; Yang, X.; Wang, H.; Jiang, Y.; Jiang, W.; Zhang, W.; Jiang, M.; Xin, F. Biosynthesis of Astaxanthin by Using Industrial Yeast. Biofuels Bioprod. Biorefining. 2022, 17, 602–615. [Google Scholar] [CrossRef]

- Hu, Z.C.; Zheng, Y.G.; Wang, Z.; Shen, Y.C. PH Control Strategy in Astaxanthin Fermentation Bioprocess by Xanthophyllomyces dendrorhous. Enzyme Microb. Technol. 2006, 39, 586–590. [Google Scholar] [CrossRef]

- Fang, T.J.; Cheng, Y.S. Improvement of Astaxanthin Production by Phaffia rhodozyma through Mutation and Optimization of Culture Conditions. J. Ferment. Bioeng. 1993, 75, 466–469. [Google Scholar] [CrossRef]

- Loto, I.; Gutiérrez, M.S.; Barahona, S.; Sepúlveda, D.; Martínez-Moya, P.; Baeza, M.; Cifuentes, V.; Alcaíno, J. Enhancement of Carotenoid Production by Disrupting the C22-Sterol Desaturase Gene (CYP61) in Xanthophyllomyces dendrorhous. BMC Microbiol. 2012, 12, 1–16. [Google Scholar] [CrossRef] [PubMed]

- Yamamoto, K.; Hara, K.Y.; Morita, T.; Nishimura, A.; Sasaki, D.; Ishii, J.; Ogino, C.; Kizaki, N.; Kondo, A. Enhancement of Astaxanthin Production in Xanthophyllomyces dendrorhous by Efficient Method for the Complete Deletion of Genes. Microb. Cell Fact. 2016, 15, 155. [Google Scholar] [CrossRef]

- Venegas, M.; Barahona, S.; González, A.M.; Sepúlveda, D.; Zúñiga, G.E.; Baeza, M.; Cifuentes, V.; Alcaíno, J. Phenotypic Analysis of Mutants of Ergosterol Biosynthesis Genes (ERG3 and ERG4) in the Red Yeast Xanthophyllomyces dendrorhous. Front. Microbiol. 2020, 11, 1312. [Google Scholar] [CrossRef]

- Gassel, S.; Schewe, H.; Schmidt, I.; Schrader, J.; Sandmann, G. Multiple Improvement of Astaxanthin Biosynthesis in Xanthophyllomyces dendrorhous by a Combination of Conventional Mutagenesis and Metabolic Pathway Engineering. Biotechnol. Lett. 2013, 35, 565–569. [Google Scholar] [CrossRef] [PubMed]

- Gassel, S.; Breitenbach, J.; Sandmann, G. Genetic Engineering of the Complete Carotenoid Pathway towards Enhanced Astaxanthin Formation in Xanthophyllomyces dendrorhous Starting from a High-Yield Mutant. Appl. Microbiol. Biotechnol. 2014, 98, 345–350. [Google Scholar] [CrossRef]

- Pan, X.; Wang, B.; Duan, R.; Jia, J.; Li, J.; Xiong, W.; Ling, X.; Chen, C.; Huang, X.; Zhang, G.; et al. Enhancing Astaxanthin Accumulation in Xanthophyllomyces dendrorhous by a Phytohormone: Metabolomic and Gene Expression Profiles. Microb. Biotechnol. 2020, 13, 1446–1460. [Google Scholar] [CrossRef] [PubMed]

- Visser, H.; Van Ooyen, A.J.J.; Verdoes, J.C. Metabolic Engineering of the Astaxanthin-Biosynthetic Pathway of Xanthophyllomyces dendrorhous. FEMS Yeast Res. 2003, 4, 221–231. [Google Scholar] [CrossRef]

- Zhang, N.; Li, J.; Li, F.; Wang, S. Selectable Marker Recycling in the Nonconventional Yeast Xanthophyllomyces dendrorhous by Transient Expression of Cre on a Genetically Unstable Vector. Appl. Microbiol. Biotechnol. 2019, 103, 963–971. [Google Scholar] [CrossRef] [PubMed]

- Fujisawa, M.; Takita, E.; Harada, H.; Sakurai, N.; Suzuki, H.; Ohyama, K.; Shibata, D.; Misawa, N. Pathway Engineering of Brassica Napus Seeds Using Multiple Key Enzyme Genes Involved in Ketocarotenoid Formation. J. Exp. Bot. 2009, 60, 1319–1332. [Google Scholar] [CrossRef] [PubMed]

- Hasunuma, T.; Miyazawa, S.I.; Yoshimura, S.; Shinzaki, Y.; Tomizawa, K.I.; Shindo, K.; Choi, S.K.; Misawa, N.; Miyake, C. Biosynthesis of Astaxanthin in Tobacco Leaves by Transplastomic Engineering. Plant J. 2008, 55, 857–868. [Google Scholar] [CrossRef]

- Papp, T.; Breum, J.; Arnau, J. Strain and Culture Conditions Improvement for β-Carotene Production with Mucor. Microb. Process. Prod. 2009, 18, 239–256. [Google Scholar]

- Ranga Rao, A.; Raghunath Reddy, R.L.; Baskaran, V.; Sarada, R.; Ravishankar, G.A. Characterization of Microalgal Carotenoids by Mass Spectrometry and Their Bioavailability and Antioxidant Properties Elucidated in Rat Model. J. Agric. Food Chem. 2010, 58, 8553–8559. [Google Scholar] [CrossRef] [PubMed]

- Do, T.T.; Ong, B.N.; Tran, M.L.N.; Nguyen, D.; Melkonian, M.; Tran, H.D. Biomass and Astaxanthin Productivities of Haematococcus Pluvialis in an Angled Twin-Layer Porous Substrate Photobioreactor: Effect of Inoculum Density and Storage Time. Biology 2019, 8, 68. [Google Scholar] [CrossRef]

- Han, D.; Li, Y.; Hu, Q. Astaxanthin in Microalgae: Pathways, Functions and Biotechnological Implications. Algae 2013, 28, 131–147. [Google Scholar] [CrossRef]

- Zhang, W.; Wang, J.; Wang, J.; Liu, T. Attached Cultivation of Haematococcus Pluvialis for Astaxanthin Production. Bioresour. Technol. 2014, 158, 329–335. [Google Scholar] [CrossRef] [PubMed]

- Cifuentes, A.S.; González, M.A.; Vargas, S.; Hoeneisen, M.; González, N. Optimization of Biomass, Total Carotenoids and Astaxanthin Production in Haematococcus Pluvialis Flotow Strain Steptoe (Nevada, USA) under Laboratory Conditions. Biol. Res. 2003, 36, 343–357. [Google Scholar] [CrossRef]

- Schwartz, C.; Shabbir-Hussain, M.; Frogue, K.; Blenner, M.; Wheeldon, I. Standardized Markerless Gene Integration for Pathway Engineering in Yarrowia lipolytica. ACS Synth. Biol. 2017, 6, 402–409. [Google Scholar] [CrossRef]

- Liu, L.; Qu, Y.L.; Dong, G.R.; Wang, J.; Hu, C.Y.; Meng, Y.H. Elevated β-Carotene Production Using Codon-Adapted CarRA&B and Metabolic Balance in Engineered Yarrowia lipolytica. Front. Microbiol. 2021, 12, 627150. [Google Scholar] [CrossRef] [PubMed]

- Larroude, M.; Celinska, E.; Back, A.; Thomas, S.; Nicaud, J.M.; Ledesma-Amaro, R. A Synthetic Biology Approach to Transform Yarrowia lipolytica into a Competitive Biotechnological Producer of β-Carotene. Biotechnol. Bioeng. 2018, 115, 464–472. [Google Scholar] [CrossRef]

- Liu, M.; Zhang, J.; Ye, J.; Qi, Q.; Hou, J. Morphological and Metabolic Engineering of Yarrowia lipolytica to Increase β-Carotene Production. ACS Synth. Biol. 2021, 10, 3551–3560. [Google Scholar] [CrossRef] [PubMed]

- Jing, Y.; Wang, J.; Gao, H.; Jiang, Y.; Jiang, W.; Jiang, M.; Xin, F.; Zhang, W. Enhanced β-Carotene Production in Yarrowia lipolytica through the Metabolic and Fermentation Engineering. J. Ind. Microbiol. Biotechnol. 2023, 50, kuad009. [Google Scholar] [CrossRef] [PubMed]

- Ma, Y.; Liu, N.; Greisen, P.; Li, J.; Qiao, K.; Huang, S.; Stephanopoulos, G. Removal of Lycopene Substrate Inhibition Enables High Carotenoid Productivity in Yarrowia lipolytica. Nat. Commun. 2022, 13, 1–11. [Google Scholar] [CrossRef]

- Ma, Y.; Li, J.; Huang, S.; Stephanopoulos, G. Targeting Pathway Expression to Subcellular Organelles Improves Astaxanthin Synthesis in Yarrowia lipolytica. Metab. Eng. 2021, 68, 152–161. [Google Scholar] [CrossRef]

- Zhu, H.Z.; Jiang, S.; Wu, J.J.; Zhou, X.R.; Liu, P.Y.; Huang, F.H.; Wan, X. Production of High Levels of 3S,3′S-Astaxanthin in Yarrowia lipolytica via Iterative Metabolic Engineering. J. Agric. Food Chem. 2022, 70, 2673–2683. [Google Scholar] [CrossRef] [PubMed]

- Breitenbach, J.; Pollmann, H.; Sandmann, G. Genetic Modification of the Carotenoid Pathway in the Red Yeast Xanthophyllomyces dendrorhous: Engineering of a High-Yield Zeaxanthin Strain. J. Biotechnol. 2019, 289, 112–117. [Google Scholar] [CrossRef] [PubMed]

- Xie, Y.; Chen, S.; Xiong, X. Metabolic Engineering of Non-Carotenoid-Producing Yeast Yarrowia lipolytica for the Biosynthesis of Zeaxanthin. Front. Microbiol. 2021, 12, 699235. [Google Scholar] [CrossRef] [PubMed]

- Ma, T.; Shi, B.; Ye, Z.; Li, X.; Liu, M.; Chen, Y.; Xia, J.; Nielsen, J.; Deng, Z.; Liu, T. Lipid Engineering Combined with Systematic Metabolic Engineering of Saccharomyces cerevisiae for High-Yield Production of Lycopene. Metab. Eng. 2019, 52, 134–142. [Google Scholar] [CrossRef] [PubMed]

- Godara, A.; Rodriguez, M.A.G.; Weatherston, J.D.; Peabody, G.L.; Wu, H.J.; Kao, K.C. Beneficial Mutations for Carotenoid Production Identified from Laboratory-Evolved Saccharomyces cerevisiae. J. Ind. Microbiol. Biotechnol. 2019, 46, 1793–1804. [Google Scholar] [CrossRef]

- Fathi, Z.; Tramontin, L.R.R.; Ebrahimipour, G.; Borodina, I.; Darvishi, F. Metabolic Engineering of Saccharomyces cerevisiae for Production of β-Carotene from Hydrophobic Substrates. FEMS Yeast Res. 2021, 21, foaa068. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhang, Y.; Nielsen, J.; Liu, Z. Production of β-Carotene in Saccharomyces cerevisiae through Altering Yeast Lipid Metabolism. Biotechnol. Bioeng. 2021, 118, 2043–2052. [Google Scholar] [CrossRef]

- Sun, L.; Atkinson, C.A.; Lee, Y.G.; Jin, Y.S. High-Level β-Carotene Production from Xylose by Engineered Saccharomyces cerevisiae without Overexpression of a Truncated HMG1 (THMG1). Biotechnol. Bioeng. 2020, 117, 3522–3532. [Google Scholar] [CrossRef]

- Zhou, P.; Ye, L.; Xie, W.; Lv, X.; Yu, H. Highly Efficient Biosynthesis of Astaxanthin in Saccharomyces cerevisiae by Integration and Tuning of Algal CrtZ and Bkt. Appl. Microbiol. Biotechnol. 2015, 99, 8419–8428. [Google Scholar] [CrossRef] [PubMed]

- Zhou, P.; Xie, W.; Li, A.; Wang, F.; Yao, Z.; Bian, Q.; Zhu, Y.; Yu, H.; Ye, L. Alleviation of Metabolic Bottleneck by Combinatorial Engineering Enhanced Astaxanthin Synthesis in Saccharomyces cerevisiae. Enzyme Microb. Technol. 2017, 100, 28–36. [Google Scholar] [CrossRef]

- Jin, J.; Wang, Y.; Yao, M.; Gu, X.; Li, B.; Liu, H.; Ding, M.; Xiao, W.; Yuan, Y. Astaxanthin Overproduction in Yeast by Strain Engineering and New Gene Target Uncovering. Biotechnol. Biofuels 2018, 11, 230. [Google Scholar] [CrossRef]

- Zhou, P.; Li, M.; Shen, B.; Yao, Z.; Bian, Q.; Ye, L.; Yu, H. Directed Coevolution of β-Carotene Ketolase and Hydroxylase and Its Application in Temperature-Regulated Biosynthesis of Astaxanthin. J. Agric. Food Chem. 2019, 67, 1072–1080. [Google Scholar] [CrossRef] [PubMed]

- Jiang, G.; Yang, Z.; Wang, Y.; Yao, M.; Chen, Y.; Xiao, W.; Yuan, Y. Enhanced Astaxanthin Production in Yeast via Combined Mutagenesis and Evolution. Biochem. Eng. J. 2020, 156, 107519. [Google Scholar] [CrossRef]

- Li, M.; Zhou, P.; Chen, M.; Yu, H.; Ye, L. Spatiotemporal Regulation of Astaxanthin Synthesis in S. cerevisiae. ACS Synth. Biol. 2022, 11, 2636–2649. [Google Scholar] [CrossRef] [PubMed]

- McIntyre, M.; Breum, J.; Arnau, J.; Nielsen, J. Growth Physiology and Dimorphism of Mucor Circinelloides (Syn. Racemosus) during Submerged Batch Cultivation. Appl. Microbiol. Biotechnol. 2002, 58, 495–502. [Google Scholar] [CrossRef]

- Papp, T.; Velayos, A.; Bartók, T.; Eslava, A.P.; Vágvölgyi, C.; Iturriaga, E.A. Heterologous Expression of Astaxanthin Biosynthesis Genes in Mucor Circinelloides. Appl. Microbiol. Biotechnol. 2006, 69, 526–531. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.; Khan, M.A.K.; López-García, S.; Nosheen, S.; Nazir, Y.; Zhang, H.; Garre, V.; Song, Y. Improved SDA Production in High Lipid Accumulating Strain of Mucor Circinelloides WJ11 by Genetic Modification. Am. J. Biochem. Biotechnol. 2020, 16, 138–147. [Google Scholar] [CrossRef]

- Nagy, G.; Szebenyi, C.; Csernetics, Á.; Vaz, A.G.; Tóth, E.J.; Vágvölgyi, C.; Papp, T. Development of a Plasmid Free CRISPR-Cas9 System for the Genetic Modification of Mucor Circinelloides. Sci. Rep. 2017, 7, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Kothari, D.; Lee, J.H.; Chon, J.W.; Seo, K.H.; Kim, S.K. Improved Astaxanthin Production by Xanthophyllomyces dendrorhous SK984 with Oak Leaf Extract and Inorganic Phosphate Supplementation. Food Sci. Biotechnol. 2019, 28, 1171–1176. [Google Scholar] [CrossRef]

- Saini, R.K.; Keum, Y.S. Progress in Microbial Carotenoids Production. Indian J. Microbiol. 2017, 57, 129–130. [Google Scholar] [CrossRef] [PubMed]

- Saini, R.K.; Keum, Y.-S. Carotenoid Extraction Methods: A Review of Recent Developments. Food Chem. 2018, 240, 90–103. [Google Scholar] [CrossRef]

- Salar-García, M.J.; Ortiz-Martínez, V.M.; Hernández-Fernández, F.J.; de Los Ríos, A.P.; Quesada-Medina, J. Ionic Liquid Technology to Recover Volatile Organic Compounds (VOCs). J. Hazard. Mater. 2017, 321, 484–499. [Google Scholar] [CrossRef] [PubMed]

- Yara-Varón, E.; Fabiano-Tixier, A.S.; Balcells, M.; Canela-Garayoa, R.; Bily, A.; Chemat, F. Is It Possible to Substitute Hexane with Green Solvents for Extraction of Carotenoids? A Theoretical versus Experimental Solubility Study. RSC Adv. 2016, 6, 27750–27759. [Google Scholar] [CrossRef]

- Valduga, E.; Tatsch, P.O.; Tiggemann, L.; Treichel, H.; Toniazzo, G.; Zeni, J.; Di Luccio, M.; Fúrigo Júnior, A. Carotenoids Production: Microorganisms as Source of Natural Dyes. Quim. Nova 2009, 32, 2429–2436. [Google Scholar]

- Park, P.K.; Kim, E.Y.; Chu, K.H. Chemical Disruption of Yeast Cells for the Isolation of Carotenoid Pigments. Sep. Purif. Technol. 2007, 53, 148–152. [Google Scholar] [CrossRef]

- Cardenas-Toro, F.P.; Alcázar-Alay, S.C.; Coutinho, J.P.; Godoy, H.T.; Forster-Carneiro, T.; Meireles, M.A.A. Pressurized Liquid Extraction and Low-Pressure Solvent Extraction of Carotenoids from Pressed Palm Fiber: Experimental and Economical Evaluation. Food Bioprod. Process. 2015, 94, 90–100. [Google Scholar] [CrossRef]

- Khataei, M.M.; Epi, S.B.H.; Lood, R.; Spégel, P.; Yamini, Y.; Turner, C. A Review of Green Solvent Extraction Techniques and Their Use in Antibiotic Residue Analysis. J. Pharm. Biomed. Anal. 2022, 209, 114487. [Google Scholar] [CrossRef]

- Choi, Y.H.; Verpoorte, R. Green Solvents for the Extraction of Bioactive Compounds from Natural Products Using Ionic Liquids and Deep Eutectic Solvents. Curr. Opin. Food Sci. 2019, 26, 87–93. [Google Scholar] [CrossRef]

- Khataei, M.M.; Yamini, Y.; Nazaripour, A.; Karimi, M. Novel Generation of Deep Eutectic Solvent as an Acceptor Phase in Three-Phase Hollow Fiber Liquid Phase Microextraction for Extraction and Preconcentration of Steroidal Hormones from Biological Fluids. Talanta 2018, 178, 473–480. [Google Scholar] [CrossRef]

- Gogate, P.R.; Nadar, S.G. Ultrasound-Assisted Intensification of Extraction of Astaxanthin from Phaffia rhodozyma. Indian Chem. Eng. 2015, 57, 240–255. [Google Scholar] [CrossRef]

- Routray, W.; Dave, D.; Cheema, S.K.; Ramakrishnan, V.V.; Pohling, J. Biorefinery Approach and Environment-Friendly Extraction for Sustainable Production of Astaxanthin from Marine Wastes. Crit. Rev. Biotechnol. 2019, 39, 469–488. [Google Scholar] [CrossRef]

- Liu, Z.W.; Zeng, X.A.; Cheng, J.H.; Liu, D.B.; Aadil, R.M. The Efficiency and Comparison of Novel Techniques for Cell Wall Disruption in Astaxanthin Extraction from Haematococcus pluvialis. Int. J. Food Sci. Technol. 2018, 53, 2212–2219. [Google Scholar] [CrossRef]

- Khoo, K.S.; Chong, Y.M.; Chang, W.S.; Yap, J.M.; Foo, S.C.; Khoiroh, I.; Lau, P.L.; Chew, K.W.; Ooi, C.W.; Show, P.L. Permeabilization of Chlorella Sorokiniana and Extraction of Lutein by Distillable CO2-Based Alkyl Carbamate Ionic Liquids. Sep. Purif. Technol. 2021, 256, 117471. [Google Scholar] [CrossRef]

- Mussagy, C.U.; Farias, F.O.; Bila, N.M.; Giannini, M.J.S.M.; Pereira, J.F.B.; Santos-Ebinuma, V.C.; Pessoa, A. Recovery of β-Carotene and Astaxanthin from Phaffia rhodozyma Biomass Using Aqueous Solutions of Cholinium-Based Ionic Liquids. Sep. Purif. Technol. 2022, 290, 120852. [Google Scholar] [CrossRef]

- Yousefi, M.; Rahimi-Nasrabadi, M.; Pourmortazavi, S.M.; Wysokowski, M.; Jesionowski, T.; Ehrlich, H.; Mirsadeghi, S. Supercritical Fluid Extraction of Essential Oils. TrAC Trends Anal. Chem. 2019, 118, 182–193. [Google Scholar] [CrossRef]

- Lim, G.-B.; Lee, S.Y.; Lee, E.K.; Haam, S.J.; Kim, W.S. Separation of Astaxanthin from Red Yeast Phaffia rhodozyma by Supercritical Carbon Dioxide Extraction. Biochem. Eng. J. 2002, 11, 181–187. [Google Scholar] [CrossRef]

- Vafaei, N.; Rempel, C.B.; Scanlon, M.G.; Jones, P.J.H.; Eskin, M.N.A. Application of Supercritical Fluid Extraction (SFE) of Tocopherols and Carotenoids (Hydrophobic Antioxidants) Compared to Non-SFE Methods. AppliedChem 2022, 2, 68–92. [Google Scholar] [CrossRef]

- Machmudah, S.; Shotipruk, A.; Goto, M.; Sasaki, M.; Hirose, T. Extraction of Astaxanthin from Haematococcus p Luvialis Using Supercritical CO2 and Ethanol as Entrainer. Ind. Eng. Chem. Res. 2006, 45, 3652–3657. [Google Scholar] [CrossRef]

- Mezzomo, N.; Martínez, J.; Maraschin, M.; Ferreira, S.R.S. Pink Shrimp (P. Brasiliensis and P. Paulensis) Residue: Supercritical Fluid Extraction of Carotenoid Fraction. J. Supercrit. Fluids. 2013, 74, 22–33. [Google Scholar] [CrossRef]

- Zhao, T.; Yan, X.; Sun, L.; Yang, T.; Hu, X.; He, Z.; Liu, F.; Liu, X. Research Progress on Extraction, Biological Activities and Delivery Systems of Natural Astaxanthin. Trends Food Sci. Technol. 2019, 91, 354–361. [Google Scholar] [CrossRef]

- Liu, C.; Cheng, Y.; Du, C.; Lv, T.; Guo, Y.; Han, M.; Pi, F.; Zhang, W.; Qian, H. Study on the Wall-Breaking Method of Carotenoids Producing Yeast Sporidiobolus Pararoseus and the Antioxidant Effect of Four Carotenoids on SK-HEP-1 Cells. Prep. Biochem. Biotechnol. 2019, 49, 767–774. [Google Scholar] [CrossRef] [PubMed]

- Martínez, J.M.; Delso, C.; Aguilar, D.E.; Álvarez, I.; Raso, J. Organic-Solvent-Free Extraction of Carotenoids from Yeast Rhodotorula glutinis by Application of Ultrasound under Pressure. Ultrason. Sonochem. 2020, 61, 104833. [Google Scholar] [CrossRef]

- Castro-Puyana, M.; Herrero, M.; Urreta, I.; Mendiola, J.A.; Cifuentes, A.; Ibáñez, E.; Suárez-Alvarez, S. Optimization of Clean Extraction Methods to Isolate Carotenoids from the Microalga Neochloris Oleoabundans and Subsequent Chemical Characterization Using Liquid Chromatography Tandem Mass Spectrometry. Anal. Bioanal. Chem. 2013, 405, 4607–4616. [Google Scholar] [CrossRef] [PubMed]

- Strati, I.F.; Gogou, E.; Oreopoulou, V. Enzyme and High Pressure Assisted Extraction of Carotenoids from Tomato Waste. Food Bioprod. Process. 2015, 94, 668–674. [Google Scholar] [CrossRef]

- Nadar, S.S.; Rao, P.; Rathod, V.K. Enzyme Assisted Extraction of Biomolecules as an Approach to Novel Extraction Technology: A Review. Food Res. Int. 2018, 108, 309–330. [Google Scholar] [CrossRef]

- Cheng, X.Y.; Xiong, Y.J.; Yang, M.M.; Zhu, M.J. Preparation of Astaxanthin Mask from Phaffia rhodozyma and Its Evaluation. Process Biochem. 2019, 79, 195–202. [Google Scholar] [CrossRef]

- Khoo, K.S.; Chew, K.W.; Yew, G.Y.; Manickam, S.; Ooi, C.W.; Show, P.L. Integrated Ultrasound-Assisted Liquid Biphasic Flotation for Efficient Extraction of Astaxanthin from Haematococcus Pluvialis. Ultrason. Sonochem. 2020, 67, 105052. [Google Scholar] [CrossRef]

- Aguilar-Machado, D.; Delso, C.; Martinez, J.M.; Morales-Oyervides, L.; Montañez, J.; Raso, J. Enzymatic Processes Triggered by PEF for Astaxanthin Extraction from Xanthophyllomyces dendrorhous. Front. Bioeng. Biotechnol. 2020, 8, 857. [Google Scholar] [CrossRef]

- De Vito, F.; Ferrari, G.; Lebovka, I.N.; Shynkaryk, V.N.; Vorobiev, E. Pulse Duration and Efficiency of Soft Cellular Tissue Disintegration by Pulsed Electric Fields. Food Bioprocess Technol. 2008, 1, 307–313. [Google Scholar] [CrossRef]

- Rebelo, B.A.; Farrona, S.; Ventura, M.R.; Abranches, R. Canthaxanthin, a Red-Hot Carotenoid: Applications, Synthesis, and Biosynthetic Evolution. Plants 2020, 9, 1039. [Google Scholar] [CrossRef] [PubMed]

- Martínez-Cámara, S.; Ibañez, A.; Rubio, S.; Barreiro, C.; Barredo, J.-L. Main Carotenoids Produced by Microorganisms. Encyclopedia 2021, 1, 1223–1245. [Google Scholar] [CrossRef]

- Liu, X.; Xie, J.; Zhou, L.; Zhang, J.; Chen, Z.; Xiao, J.; Cao, Y.; Xiao, H. Recent Advances in Health Benefits and Bioavailability of Dietary Astaxanthin and Its Isomers. Food Chem. 2022, 404, 134605. [Google Scholar] [CrossRef]

- Tamaki, S.; Ozasa, K.; Nomura, T.; Ishikawa, M.; Yamada, K.; Suzuki, K.; Mochida, K. Zeaxanthin Is Required for Eyespot Formation and Phototaxis in Euglena gracilis. Plant Physiol. 2023, 191, 2414–2426. [Google Scholar] [CrossRef] [PubMed]

- Joshi, K.; Kumar, P.; Kataria, R. Microbial Carotenoid Production and Their Potential Applications as Antioxidants: A Current Update. Process Biochem. 2023, 128, 190–205. [Google Scholar] [CrossRef]

- Saejung, C.; Lomthaisong, K.; Kotthale, P. Alternative Microbial-Based Functional Ingredient Source for Lycopene, Beta-Carotene, and Polyunsaturated Fatty Acids. Heliyon 2023, 9, e13828. [Google Scholar] [CrossRef]

| Fungal Species | Carotenoids | Reference |

|---|---|---|

| Ascomycota: | ||

| Fusarium species | Neurosporaxanthin and torulene | [35,36,37] |

| Neurospora crassa | ||

| Basidiomycota: | ||

| Xanthophyllomyce dendrorhous | Astaxanthin and β-carotene | [38,39] |

| Rhodotorula glutinis | Torulene, torularhodin and β-carotene | [40] |

| Cantharellus species | Canthaxanthin | [41] |

| Rhodotorula and Sporobolomyces roseus | Torulene, torularhodin, and β-carotene | [42] |

| Mucoromycota: | ||

| Blakeslea trispora, Phycomyces blakesleanus | Lycopene and β-carotene | [43,44] |

| Mucor circinelloides | β-carotene | [13] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Naz, T.; Ullah, S.; Nazir, Y.; Li, S.; Iqbal, B.; Liu, Q.; Mohamed, H.; Song, Y. Industrially Important Fungal Carotenoids: Advancements in Biotechnological Production and Extraction. J. Fungi 2023, 9, 578. https://doi.org/10.3390/jof9050578

Naz T, Ullah S, Nazir Y, Li S, Iqbal B, Liu Q, Mohamed H, Song Y. Industrially Important Fungal Carotenoids: Advancements in Biotechnological Production and Extraction. Journal of Fungi. 2023; 9(5):578. https://doi.org/10.3390/jof9050578

Chicago/Turabian StyleNaz, Tahira, Samee Ullah, Yusuf Nazir, Shaoqi Li, Bushra Iqbal, Qing Liu, Hassan Mohamed, and Yuanda Song. 2023. "Industrially Important Fungal Carotenoids: Advancements in Biotechnological Production and Extraction" Journal of Fungi 9, no. 5: 578. https://doi.org/10.3390/jof9050578

APA StyleNaz, T., Ullah, S., Nazir, Y., Li, S., Iqbal, B., Liu, Q., Mohamed, H., & Song, Y. (2023). Industrially Important Fungal Carotenoids: Advancements in Biotechnological Production and Extraction. Journal of Fungi, 9(5), 578. https://doi.org/10.3390/jof9050578