Preparation and Characterization of Fe3O4/Poly(HEMA-co-IA) Magnetic Hydrogels for Removal of Methylene Blue from Aqueous Solution

Abstract

:1. Introduction

2. Results and Discussion

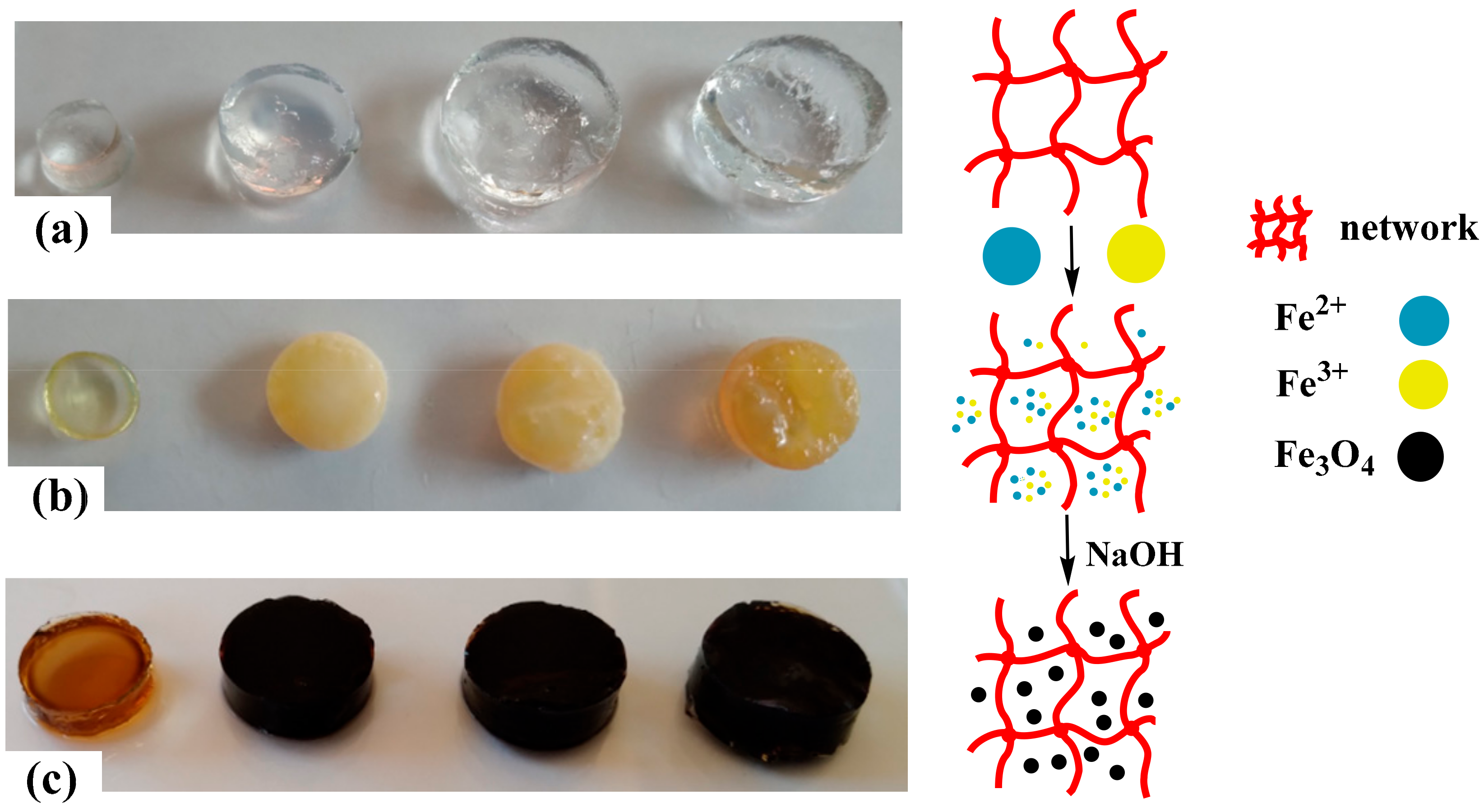

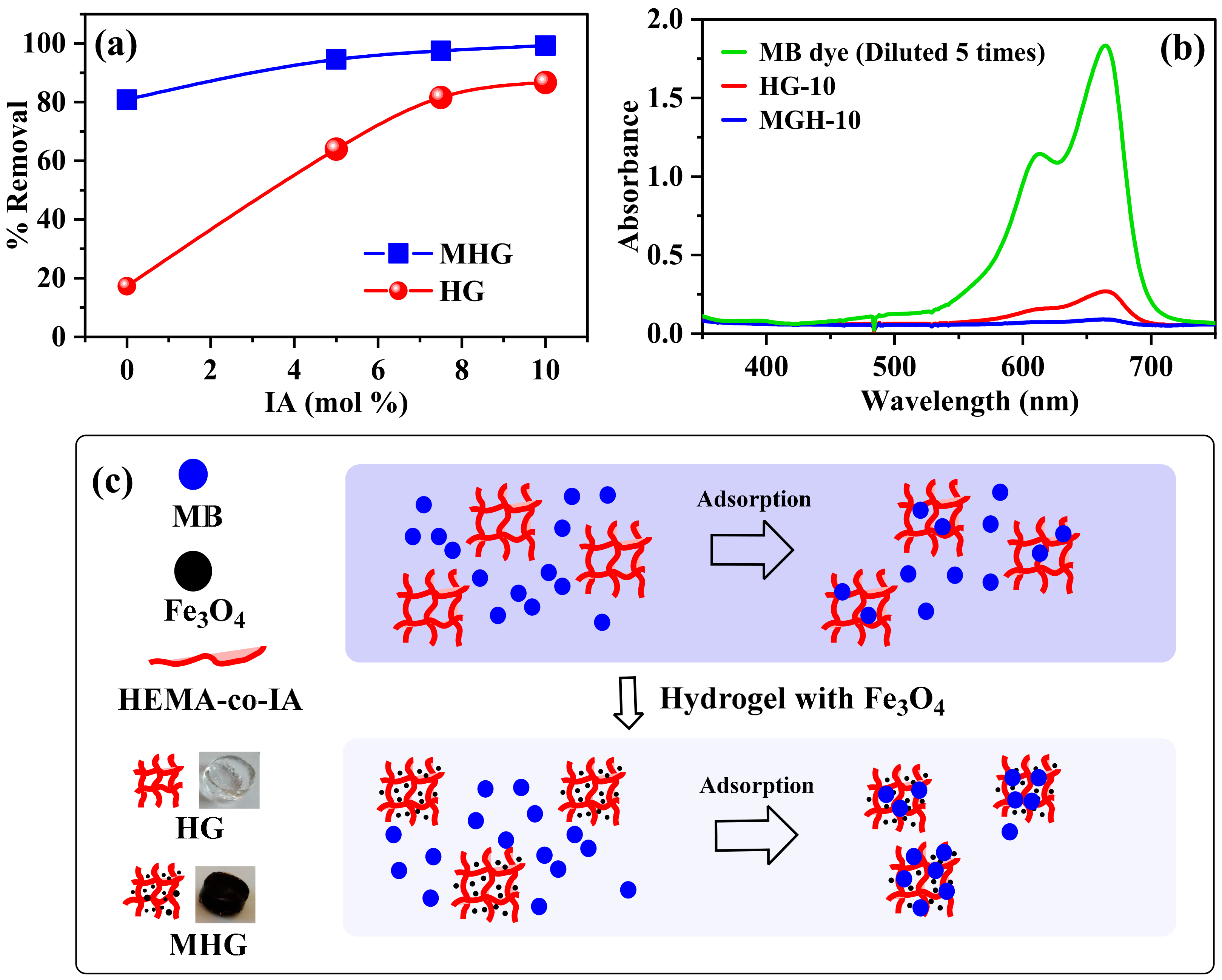

2.1. Synthesis

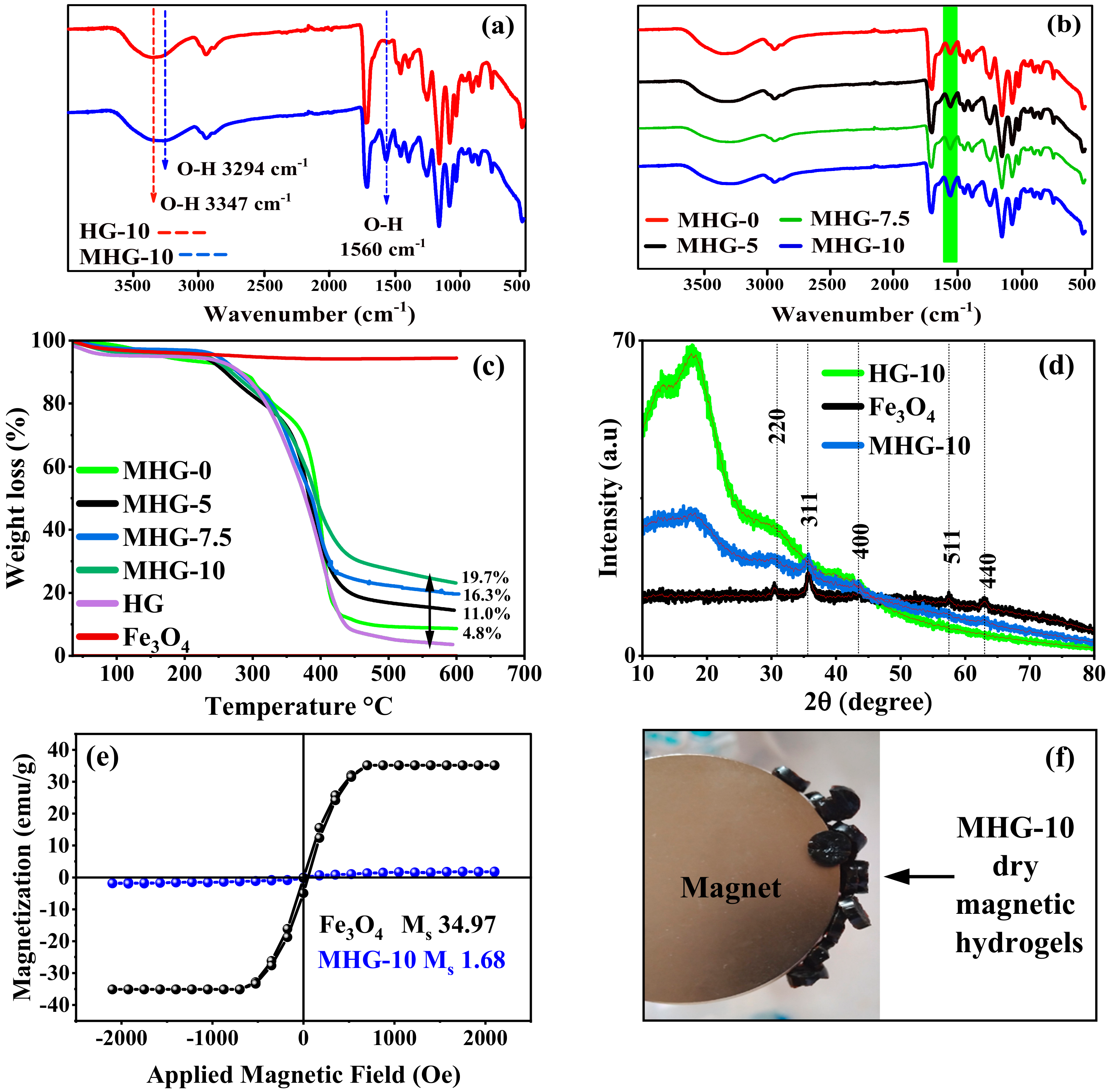

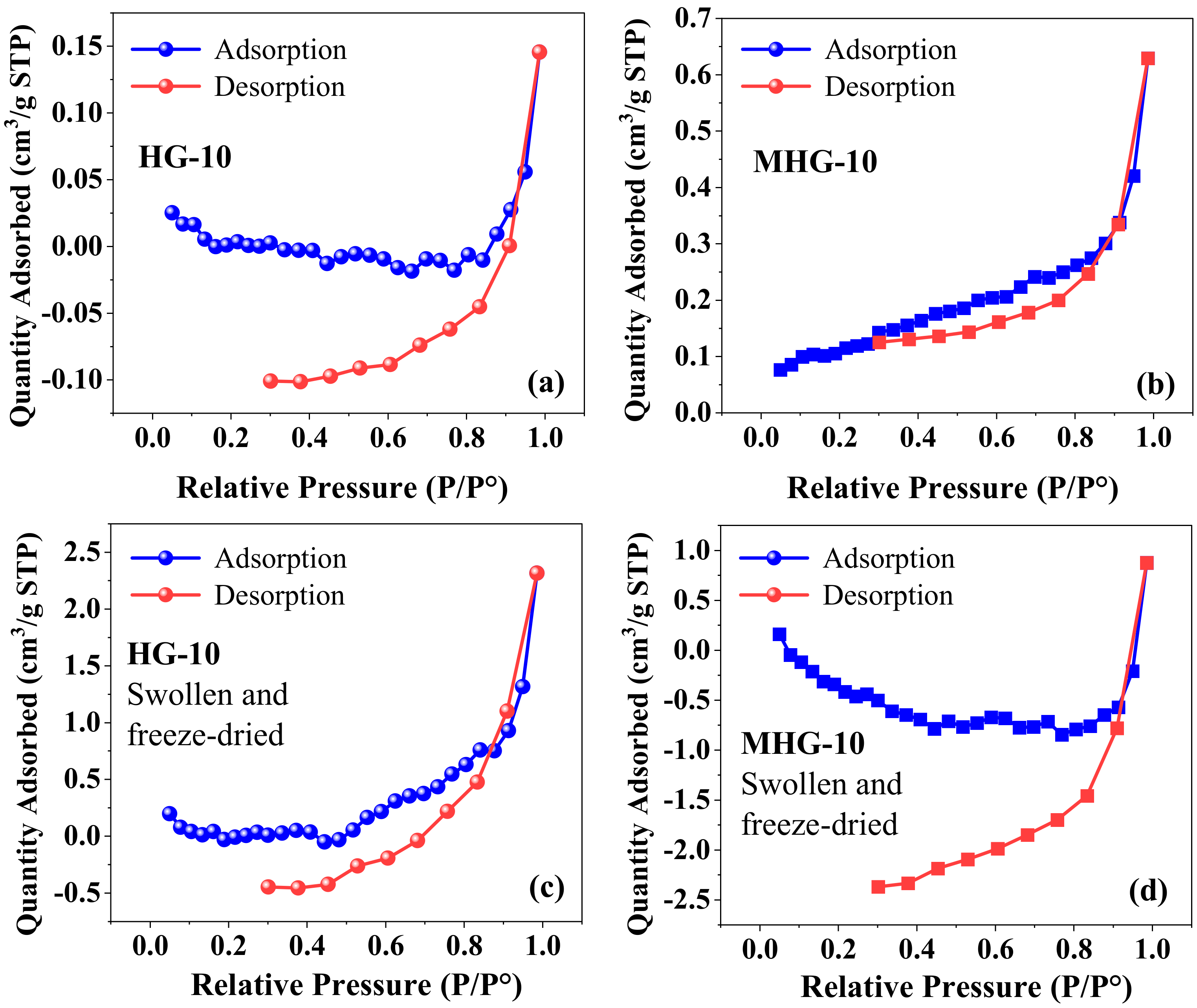

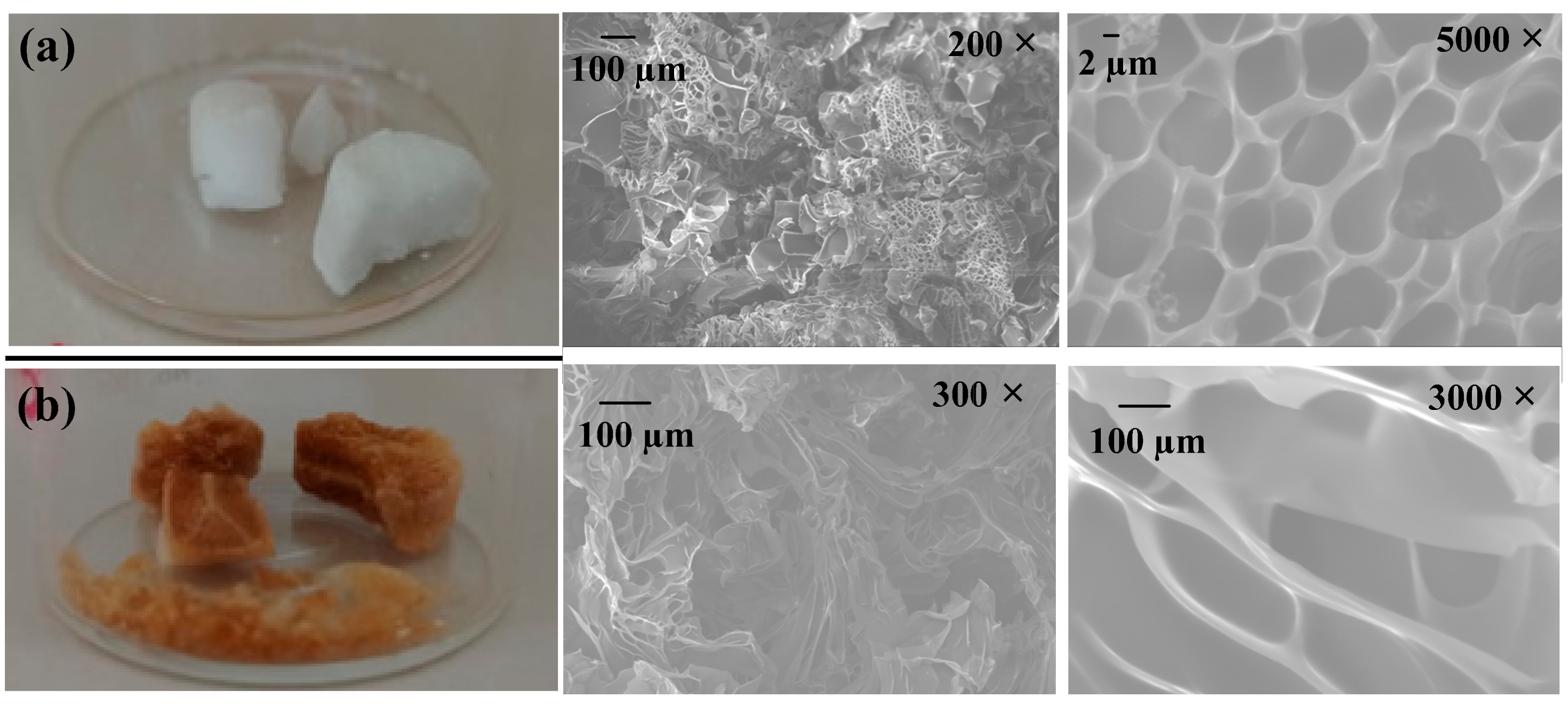

2.2. The Characterization of the Adsorbents

2.3. Degree of Swelling of the HGs and MHGs

2.4. Methyl Blue Adsorption

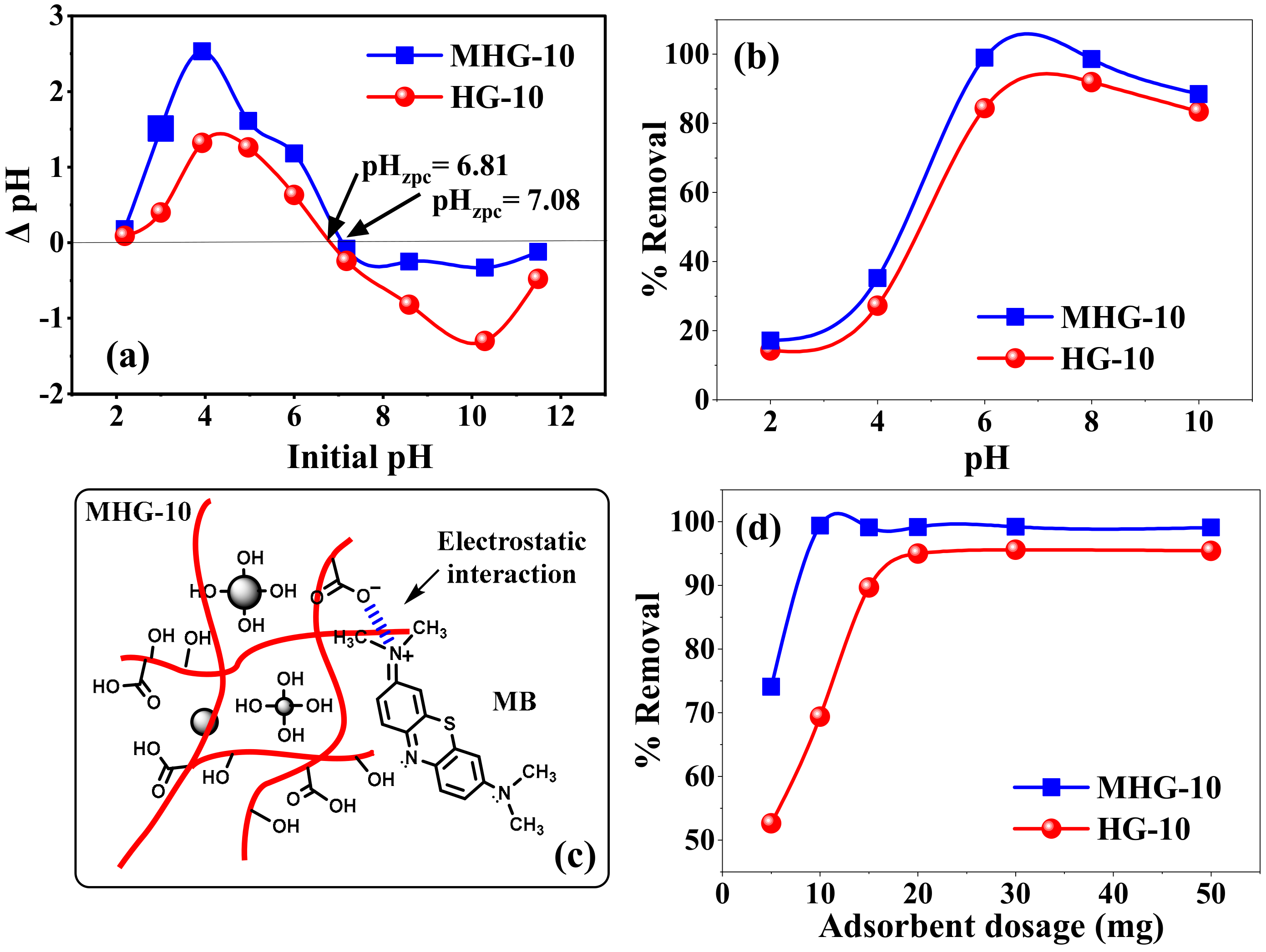

2.4.1. Effect of pH

2.4.2. Effect of the Adsorbent Dose

2.4.3. Effect of Contact Time

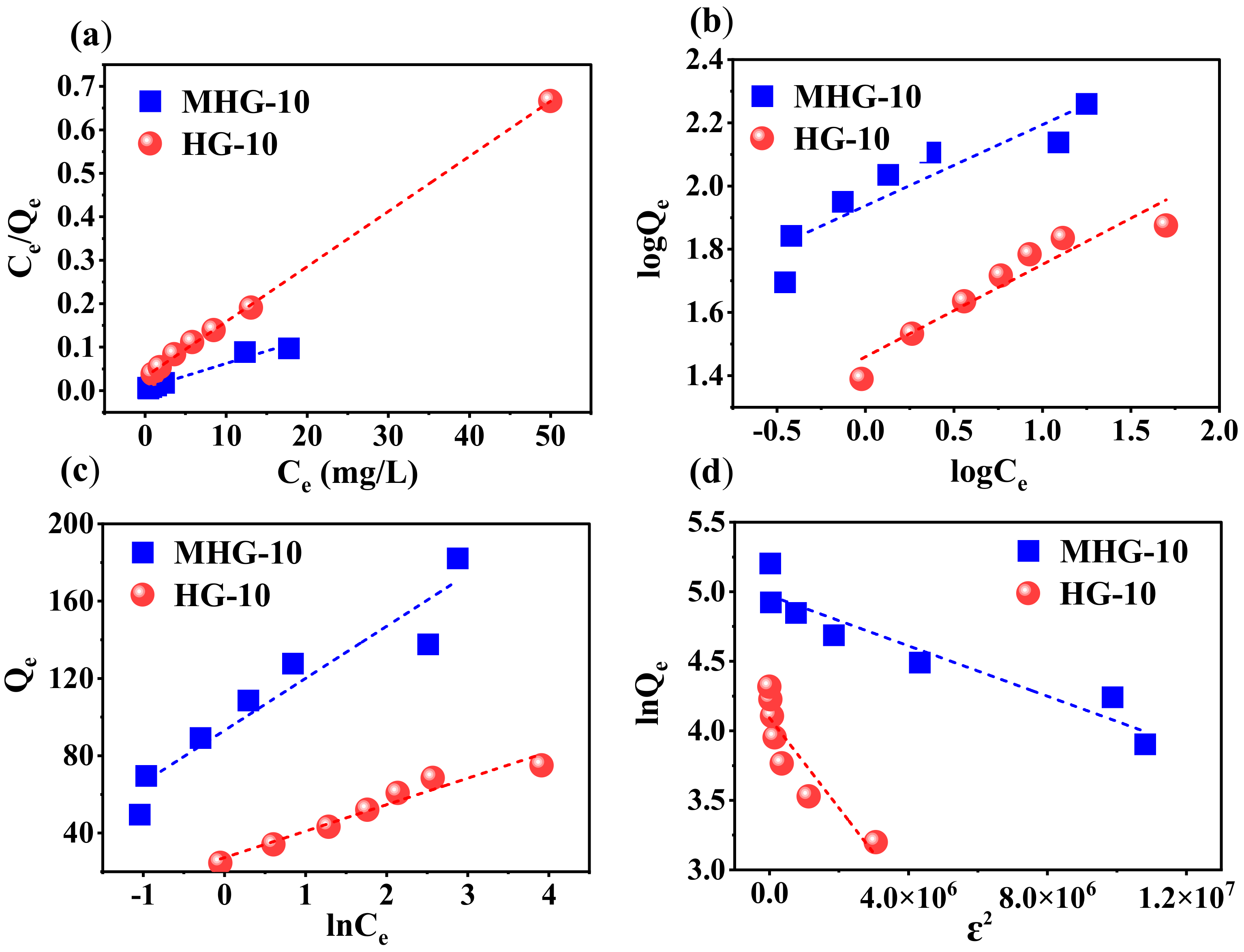

2.4.4. Effect of MB Initial Concentration

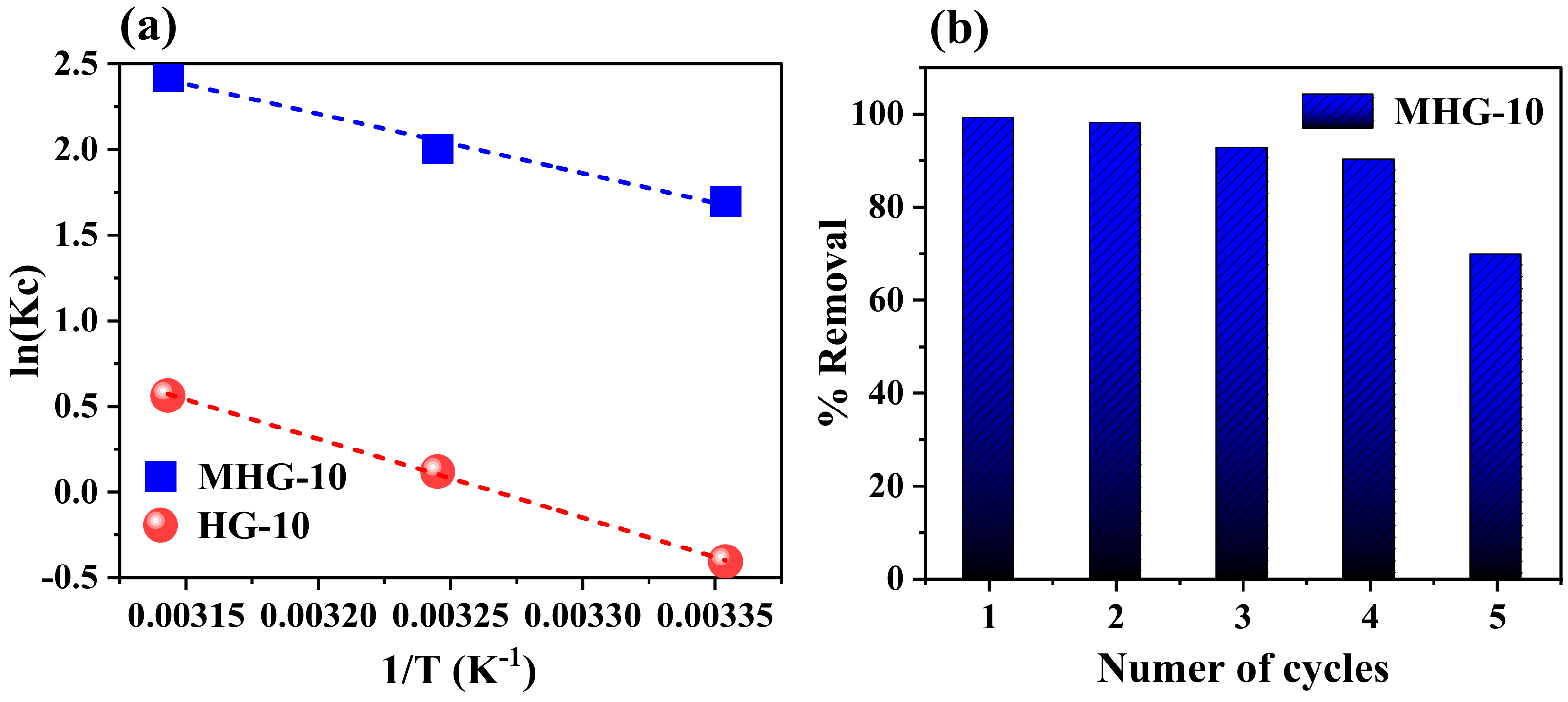

2.5. Thermodynamic Parameters

2.6. Reusability of Adsorbent

3. Conclusions

4. Materials and Methods

4.1. Chemicals

4.2. Synthesis of the Hydrogels (HG)

4.3. Synthesis of the Magnetic Hydrogels (MHGs)

4.4. Instrumental Characterization

4.5. Study of Swelling

4.6. Point of Zero Charge (PZC)

4.7. Adsorption of MB

4.8. Reuse Studies

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Anzules, Í.d.C.P.; Castro, D.W.M. Contaminación ambiental. Recimundo 2022, 6, 93–103. [Google Scholar] [CrossRef]

- Karapanagioti, H.K.; Kalavrouziotis, I.K. Microplastics in Water Bodies and in the Environment. Water 2022, 14, 1324. [Google Scholar] [CrossRef]

- Zhou, Q.; Yang, N.; Li, Y.; Ren, B.; Ding, X.; Bian, H.; Yao, X. Total concentrations and sources of heavy metal pollution in global river and lake water bodies from 1972 to 2017. Glob. Ecol. Conserv. 2020, 22, e00925. [Google Scholar] [CrossRef]

- Islam, T.; Repon, M.R.; Islam, T.; Sarwar, Z.; Rahman, M.M. Impact of textile dyes on health and ecosystem: A review of structure, causes, and potential solutions. Environ. Sci. Pollut. Res. 2022, 30, 9207–9242. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Memon, H.A.; Wang, Y.; Marriam, I.; Tebyetekerwa, M. Circular Economy and Sustainability of the Clothing and Textile Industry. Mater. Circ. Econ. 2021, 3, 12. [Google Scholar] [CrossRef]

- Khattab, T.A.; Abdelrahman, M.S.; Rehan, M. Textile dyeing industry: Environmental impacts and remediation. Environ. Sci. Pollut. Res. 2020, 27, 3803–3818. [Google Scholar] [CrossRef] [PubMed]

- Naushad, M.; Alqadami, A.A.; AlOthman, Z.A.; Alsohaimi, I.H.; Algamdi, M.S.; Aldawsari, A.M. Adsorption kinetics, isotherm and reusability studies for the removal of cationic dye from aqueous medium using arginine modified activated carbon. J. Mol. Liq. 2019, 293, 111442. [Google Scholar] [CrossRef]

- Khan, I.; Saeed, K.; Zekker, I.; Zhang, B.; Hendi, A.H.; Ahmad, A.; Ahmad, S.; Zada, N.; Ahmad, H.; Shah, L.A.; et al. Review on Methylene Blue: Its Properties, Uses, Toxicity and Photodegradation. Water 2022, 14, 242. [Google Scholar] [CrossRef]

- Oladoye, P.O.; Ajiboye, T.O.; Omotola, E.O.; Oyewola, O.J. Methylene blue dye: Toxicity and potential elimination technology from wastewater. Results Eng. 2022, 16, 100678. [Google Scholar] [CrossRef]

- Ihaddaden, S.; Aberkane, D.; Boukerroui, A.; Robert, D. Removal of methylene blue (basic dye) by coagulation-flocculation with biomaterials (bentonite and Opuntia ficus indica). J. Water Process Eng. 2022, 49, 102952. [Google Scholar] [CrossRef]

- Moradihamedani, P. Recent advances in dye removal from wastewater by membrane technology: A review. Polym. Bull. 2022, 79, 2603–2631. [Google Scholar] [CrossRef]

- Saeed, M.; Muneer, M.; Haq, A.U.; Akram, N. Photocatalysis: An effective tool for photodegradation of dyes—A review. Environ. Sci. Pollut. Res. 2021, 29, 293–311. [Google Scholar] [CrossRef] [PubMed]

- Goswami, K.; Ulaganambi, M.; Sukumaran, L.K.; Tetala, K.K.R. Synthesis and application of iron based metal organic framework for efficient adsorption of azo dyes from textile industry samples. Adv. Sample Prep. 2023, 7, 100080. [Google Scholar] [CrossRef]

- Mittal, H.; Al Alili, A.; Morajkar, P.P.; Alhassan, S.M. Graphene oxide crosslinked hydrogel nanocomposites of xanthan gum for the adsorption of crystal violet dye. J. Mol. Liq. 2021, 323, 115034. [Google Scholar] [CrossRef]

- Sultana, M.; Rownok, M.H.; Sabrin, M.; Rahaman, M.H.; Alam, S.M.N. A review on experimental chemically modified activated carbon to enhance dye and heavy metals adsorption. Clean. Eng. Technol. 2022, 6, 100382. [Google Scholar] [CrossRef]

- Harja, M.; Lupu, N.; Chiriac, H.; Herea, D.D.; Buema, G. Studies on the Removal of Congo Red Dye by an Adsorbent Based on Fly-Ash@Fe3O4 Mixture. Magnetochemistry 2022, 8, 125. [Google Scholar] [CrossRef]

- Wang, G.; Li, G.; Huan, Y.; Hao, C.; Chen, W. Acrylic acid functionalized graphene oxide: High-efficient removal of cationic dyes from wastewater and exploration on adsorption mechanism. Chemosphere 2020, 261, 127736. [Google Scholar] [CrossRef] [PubMed]

- Subhan, F.; Aslam, S.; Yan, Z.; Yaseen, M.; Naeem, M.; Ikram, M.; Ali, A.; Bibi, S. Adsorption and reusability performance of hierarchically porous silica (MMZ) for the removal of MB dye from water. Inorg. Chem. Commun. 2022, 139, 109380. [Google Scholar] [CrossRef]

- Guo, S.; Xu, H.; Zhang, F.; Zhu, X.; Li, X. Preparation and adsorption properties of nano magnetite silica gel for methylene blue from aqueous solution. Colloids Surf. A Physicochem. Eng. Asp. 2018, 546, 244–253. [Google Scholar] [CrossRef]

- Andolsi, A.; Chaari, I.; Hamzaoui, A.H. Surface Modification of Magnetite Using Silica Coating: Spectroscopic, Structural, Morphological Characterization and Interaction with Crystal Violet Dye. Silicon 2023, 15, 6257–6268. [Google Scholar] [CrossRef]

- Imessaoudene, A.; Cheikh, S.; Hadadi, A.; Hamri, N.; Bollinger, J.C.; Amrane, A.; Tahraoui, H.; Manseri, A.; Mouni, L. Adsorption Performance of Zeolite for the Removal of Congo Red Dye: Factorial Design Experiments, Kinetic, and Equilibrium Studies. Separations 2023, 10, 57. [Google Scholar] [CrossRef]

- Rakanović, M.; Vukojević, A.; Savanović, M.M.; Armaković, S.; Pelemiš, S.; Živić, F.; Sladojević, S.; Armaković, S.J. Zeolites as Adsorbents and Photocatalysts for Removal of Dyes from the Aqueous Environment. Molecules 2022, 27, 6582. [Google Scholar] [CrossRef]

- Shi, T.; Xie, Z.; Mo, X.; Feng, Y.; Peng, T.; Song, D. Highly Efficient Adsorption of Heavy Metals and Cationic Dyes by Smart Functionalized Sodium Alginate Hydrogels. Gels 2022, 8, 343. [Google Scholar] [CrossRef]

- Mouhtady, O.; Obeid, E.; Abu-samha, M.; Younes, K.; Murshid, N. Evaluation of the Adsorption Efficiency of Graphene Oxide Hydrogels in Wastewater Dye Removal: Application of Principal Component Analysis. Gels 2022, 8, 447. [Google Scholar] [CrossRef] [PubMed]

- Darban, Z.; Shahabuddin, S.; Gaur, R.; Ahmad, I.; Sridewi, N. Hydrogel-Based Adsorbent Material for the Effective Removal of Heavy Metals from Wastewater: A Comprehensive Review. Gels 2022, 8, 263. [Google Scholar] [CrossRef] [PubMed]

- Kaniewska, K.; Karbarz, M.; Katz, E. Nanocomposite hydrogel films and coatings—Features and applications. Appl. Mater. Today 2020, 20, 100776. [Google Scholar] [CrossRef]

- Yao, G.; Bi, W.; Liu, H. pH-responsive magnetic graphene oxide/poly(NVI-co-AA) hydrogel as an easily recyclable adsorbent for cationic and anionic dyes. Colloids Surf. A Physicochem. Eng. Asp. 2020, 588, 124393. [Google Scholar] [CrossRef]

- Zhang, C.; Dai, Y.; Wu, Y.; Lu, G.; Cao, Z.; Cheng, J.; Wang, K.; Yang, H.; Xia, Y.; Wen, X.; et al. Facile preparation of polyacrylamide/chitosan/Fe3O4 composite hydrogels for effective removal of methylene blue from aqueous solution. Carbohydr. Polym. 2020, 234, 115882. [Google Scholar] [CrossRef] [PubMed]

- Hosseini, S.S.; Hamadi, A.; Foroutan, R.; Peighambardoust, S.J.; Ramavandi, B. Decontamination of Cd2+ and Pb2+ from aqueous solution using a magnetic nanocomposite of eggshell/starch/Fe3O4. J. Water Process Eng. 2022, 48, 102911. [Google Scholar] [CrossRef]

- Mehdizadeh, A.; Moghadam, P.N.; Ehsanimehr, S.; Fareghi, A.R. Preparation of a New Magnetic Nanocomposite for the Removal of Dye Pollutions from Aqueous Solutions: Synthesis and Characterization. Mater. Chem. Horiz. 2022, 1, 23–34. [Google Scholar] [CrossRef]

- Beigi, P.; Ganjali, F.; Hassanzadeh-Afruzi, F.; Salehi, M.M.; Maleki, A. Enhancement of adsorption efficiency of crystal violet and chlorpyrifos onto pectin hydrogel@Fe3O4-bentonite as a versatile nanoadsorbent. Sci. Rep. 2023, 13, 10764. [Google Scholar] [CrossRef] [PubMed]

- Singh, N.; Yadav, S.; Mehta, S.K.; Dan, A. In situ incorporation of magnetic nanoparticles within the carboxymethyl cellulose hydrogels enables dye removal. J. Macromol. Sci. Part A 2022, 59, 271–284. [Google Scholar] [CrossRef]

- Filho, E.; Brito, E.; Silva, R.; Streck, L.; Bohn, F.; Fonseca, J. Superparamagnetic polyacrylamide/magnetite composite gels. J. Dispers. Sci. Technol. 2021, 42, 1504–1512. [Google Scholar] [CrossRef]

- Sivudu, K.S.; Rhee, K.Y. Preparation and characterization of pH-responsive hydrogel magnetite nanocomposite. Colloids Surf. A Physicochem. Eng. Asp. 2009, 349, 29–34. [Google Scholar] [CrossRef]

- Shen, X.C.; Fang, X.Z.; Zhou, Y.H.; Liang, H. Synthesis and Characterization of 3-Aminopropyltriethoxysilane-Modified Superparamagnetic Magnetite Nanoparticles. Chem. Lett. 2004, 33, 1468–1469. [Google Scholar] [CrossRef]

- Petcharoen, K.; Sirivat, A. Synthesis and characterization of magnetite nanoparticles via the chemical co-precipitation method. Mater. Sci. Eng. B 2012, 177, 421–427. [Google Scholar] [CrossRef]

- Samrot, A.V.; Ali, H.H.; Selvarani, A.J.; Faradjeva, E.; Raji, P.; Prakash, P.; Kumar, S.S. Adsorption efficiency of chemically synthesized Superparamagnetic Iron Oxide Nanoparticles (SPIONs) on crystal violet dye. Curr. Res. Green. Sustain. Chem. 2021, 4, 100066. [Google Scholar] [CrossRef]

- Taleb, M.F.A.; El Fadl, F.I.A.; Albalwi, H. Adsorption of toxic dye in wastewater onto magnetic NVP/CS nanocomposite hydrogels synthesized using gamma radiation. Sep. Purif. Technol. 2021, 266, 118551. [Google Scholar] [CrossRef]

- Cai, J.; Guo, J.; Ji, M.; Yang, W.; Wang, C.; Fu, S. Preparation and characterization of multiresponsive polymer composite microspheres with core-shell structure. Colloid. Polym. Sci. 2007, 285, 1607–1615. [Google Scholar] [CrossRef]

- Jiang, Y.; Cai, W.; Tu, W.; Zhu, M. Facile Cross-Link Method to Synthesize Magnetic Fe3O4@SiO2-Chitosan with High Adsorption Capacity toward Hexavalent Chromium. J. Chem. Eng. Data 2019, 64, 226–233. [Google Scholar] [CrossRef]

- Thommes, M.; Kaneko, K.; Neimark, A.V.; Olivier, J.P.; Rodriguez-Reinoso, F.; Rouquerol, J.; Sing, K.S.W. Physisorption of gases, with special reference to the evaluation of surface area and pore size distribution (IUPAC Technical Report). Pure Appl. Chem. 2015, 87, 1051–1069. [Google Scholar] [CrossRef]

- Zhang, W.; Lan, Y.; Ma, M.; Chai, S.; Zuo, Q.; Kim, K.H.; Gao, Y. A novel chitosan–vanadium-titanium-magnetite composite as a superior adsorbent for organic dyes in wastewater. Environ. Int. 2020, 142, 105798. [Google Scholar] [CrossRef] [PubMed]

- Yue, J.; Wang, Z.; Chen, J.; Zheng, M.; Wang, Q.; Lou, X. Investigation of pore structure characteristics and adsorption characteristics of coals with different destruction types. Adsorpt. Sci. Technol. 2019, 37, 623–648. [Google Scholar] [CrossRef]

- Li, X.; Gao, Z.; Fang, S.; Ren, C.; Yang, K.; Wang, F. Fractal Characterization of Nanopore Structure in Shale, Tight Sandstone and Mudstone from the Ordos Basin of China Using Nitrogen Adsorption. Energies 2019, 12, 583. [Google Scholar] [CrossRef]

- Qi, L.; Tang, X.; Wang, Z.; Peng, X. Pore characterization of different types of coal from coal and gas outburst disaster sites using low temperature nitrogen adsorption approach. Int. J. Min. Sci. Technol. 2017, 27, 371–377. [Google Scholar] [CrossRef]

- Ozay, O.; Ekici, S.; Baran, Y.; Aktas, N.; Sahiner, N. Removal of toxic metal ions with magnetic hydrogels. Water Res. 2009, 43, 4403–4411. [Google Scholar] [CrossRef] [PubMed]

- Santillán, F.; Rueda, J.C. Removal of Methylene Blue by Hydrogels based on N, N-Dimethylacrylamide and 2-Oxazoline macromonomer. J. Polym. Res. 2020, 27, 263. [Google Scholar] [CrossRef]

- Panda, S.K.; Aggarwal, I.; Kumar, H.; Prasad, L.; Kumar, A.; Sharma, A.; Vo, D.V.N.; Van Thuan, D.; Mishra, V. Magnetite nanoparticles as sorbents for dye removal: A review. Environ. Chem. Lett. 2021, 19, 2487–2525. [Google Scholar] [CrossRef]

- Zhao, L.X.; Xiao, H.; Li, M.H.; Xie, M.; Li, N.; Zhao, R.S. Effectively removing indole-3-butyric acid from aqueous solution with magnetic layered double hydroxide-based adsorbents. J. Hazard. Mater. 2021, 408, 124446. [Google Scholar] [CrossRef]

- Foroutan, R.; Mohammadi, R.; Ahmadi, A.; Bikhabar, G.; Babaei, F.; Ramavandi, B. Impact of ZnO and Fe3O4 magnetic nanoscale on the methyl violet 2B removal efficiency of the activated carbon oak wood. Chemosphere 2022, 286, 131632. [Google Scholar] [CrossRef]

- Chen, L.; Zhu, Y.; Cui, Y.; Dai, R.; Shan, Z.; Chen, H. Fabrication of starch-based high-performance adsorptive hydrogels using a novel effective pretreatment and adsorption for cationic methylene blue dye: Behavior and mechanism. Chem. Eng. J. 2021, 405, 126953. [Google Scholar] [CrossRef]

- Bharathiraja, B.; Selvakumari, I.A.E.; Iyyappan, J.; Varjani, S. Itaconic acid: An effective sorbent for removal of pollutants from dye industry effluents. Curr. Opin. Environ. Sci. Health 2019, 12, 6–17. [Google Scholar] [CrossRef]

- Onder, A.; Ilgin, P.; Ozay, H.; Ozay, O. Removal of dye from aqueous medium with pH-sensitive poly[(2-(acryloyloxy)ethyl]trimethylammonium chloride-co-1-vinyl-2-pyrrolidone] cationic hydrogel. J. Environ. Chem. Eng. 2020, 8, 104436. [Google Scholar] [CrossRef]

- Noori, M.; Tahmasebpoor, M.; Foroutan, R. Enhanced adsorption capacity of low-cost magnetic clinoptilolite powders/beads for the effective removal of methylene blue: Adsorption and desorption studies. Mater. Chem. Phys. 2022, 278, 125655. [Google Scholar] [CrossRef]

- Hu, X.S.; Liang, R.; Sun, G. Super-adsorbent hydrogel for removal of methylene blue dye from aqueous solution. J. Mater. Chem. A Mater. 2018, 6, 17612–17624. [Google Scholar] [CrossRef]

- Safarzadeh, H.; Peighambardoust, S.J.; Mousavi, S.H.; Foroutan, R.; Mohammadi, R.; Peighambardoust, S.H. Adsorption ability evaluation of the poly(methacrylic acid-co-acrylamide)/cloisite 30B nanocomposite hydrogel as a new adsorbent for cationic dye removal. Environ. Res. 2022, 212, 113349. [Google Scholar] [CrossRef] [PubMed]

- Wu, Z.; Wu, J.; Huang, M.; Liang, H.; Sun, B. Preparation of reusable hydrogel spheres based on sodium alginate/Fe3O4 modified with carboxymethyl Huangshui polysaccharide and the efficient adsorption performance for methylene blue. Food Chem. 2024, 438, 138064. [Google Scholar] [CrossRef]

- Ghaedi, M.; Hajjati, S.; Mahmudi, Z.; Tyagi, I.; Agarwal, S.; Maity, A.; Gupta, V.K. Modeling of competitive ultrasonic assisted removal of the dyes—Methylene blue and Safranin-O using Fe3O4 nanoparticles. Chem. Eng. J. 2015, 268, 28–37. [Google Scholar] [CrossRef]

- Li, S.; Liu, X.; Huang, W.; Li, W.; Xia, X.; Yan, S.; Yu, J. Magnetically assisted removal and separation of cationic dyes from aqueous solution by magnetic nanocomposite hydrogels. Polym. Adv. Technol. 2011, 22, 2439–2447. [Google Scholar] [CrossRef]

- Yu, S.; Cui, J.; Jiang, H.; Zhong, C.; Meng, J. Facile fabrication of functional chitosan microspheres and study on their effective cationic/anionic dyes removal from aqueous solution. Int. J. Biol. Macromol. 2019, 134, 830–837. [Google Scholar] [CrossRef]

- Lei, Y.; Zhang, X.; Meng, X.; Wang, Z. The preparation of core–shell Fe3O4@SiO2 magnetic nanoparticles with different surface carboxyl densities and their application in the removal of methylene blue. Inorg. Chem. Commun. 2022, 139, 109381. [Google Scholar] [CrossRef]

- Ahamad, T.; Naushad, M.; Eldesoky, G.E.; Al-Saeedi, S.I.; Nafady, A.; Al-Kadhi, N.S.; Al-Muhtaseb, A.H.; Khan, A.A.; Khan, A. Effective and fast adsorptive removal of toxic cationic dye (MB) from aqueous medium using amino-functionalized magnetic multiwall carbon nanotubes. J. Mol. Liq. 2019, 282, 154–161. [Google Scholar] [CrossRef]

- Taşdelen, B.; Çifçi, D.İ.; Meriç, S. Preparation of N-isopropylacrylamide/itaconic acid/Pumice highly swollen composite hydrogels to explore their removal capacity of methylene blue. Colloids Surf. A Physicochem. Eng. Asp. 2017, 519, 245–253. [Google Scholar] [CrossRef]

- Huaman, M.A.L.; Vega-Chacón, J.; Quispe, R.I.H.; Negrón, A.C.V. Synthesis and swelling behaviors of poly(2-hydroxyethyl methacrylate-co-itaconic acid) and poly(2-hydroxyethyl methacrylate-co-sodium itaconate) hydrogels as potential drug carriers. Results Chem. 2023, 5, 100917. [Google Scholar] [CrossRef]

- Ahmadi, A.; Foroutan, R.; Esmaeili, H.; Peighambardoust, S.J.; Hemmati, S.; Ramavandi, B. Montmorillonite clay/starch/CoFe2O4 nanocomposite as a superior functional material for uptake of cationic dye molecules from water and wastewater. Mater. Chem. Phys. 2022, 284, 126088. [Google Scholar] [CrossRef]

| Amount of IA (mol%) | Water q (g/g) | NaOH 0.01 mol/L q (g/g) | HCl 0.01 mol/L q (g/g) | |||

|---|---|---|---|---|---|---|

| HG | MHG | HG | MHG | HG | MHG | |

| 0 | 0.723 | 24.587 | 0.940 | 15.024 | 0.812 | 0.801 |

| 5 | 10.524 | 52.937 | 18.290 | 27.459 | 0.732 | 0.766 |

| 7.5 | 14.290 | 54.631 | 23.037 | 28.406 | 0.824 | 0.969 |

| 10 | 12.915 | 42.310 | 31.535 | 31.307 | 0.870 | 0.846 |

| Adsorbent | |||

|---|---|---|---|

| Kinetic Models | Parameters | HG-10 | MHG-10 |

| Qe (cal) (mg/g) | 0.529 | 0.171 | |

| Pseudo-first-order | K1 (1/min) | 0.035 | 0.024 |

| R2 | 0.984 | 0.978 | |

| Qe (exp) (mg/g) | 24.626 | 49.709 | |

| Pseudo-second-order | Qe (cal) (mg/g) | 24.652 | 49.718 |

| K2 (g/(mg·min)) | 0.181 | 0.412 | |

| R2 | 0.999 | 0.999 | |

| Qe (exp) (mg/g) | 24.626 | 49.709 | |

| Intraparticle diffusion | KD | 0.0411 | 0.0153 |

| c | 24.188 | 49.536 | |

| R2 | 0.7928 | 0.8987 | |

| Adsorbent | |||

|---|---|---|---|

| Isotherm | Parameters | HG-10 | MHG-10 |

| Qmax (mg/g) | 78.850 | 174.997 | |

| Langmuir | KL (L/mg) | 0.399 | 1.082 |

| R2 | 0.999 | 0.972 | |

| RL | 0.0477–0.0124 | 0.0182–0.0046 | |

| Freundlich | KF (mg/g) | 28.826 | 86.605 |

| 1/n | 0.292 | 0.256 | |

| R2 | 0.906 | 0.845 | |

| Temkin | KT (L/g) | 7.295 | 31.467 |

| bT (J/mol) | 177.815 | 90.335 | |

| R2 | 0.952 | 0.907 | |

| D–R | qs (mg/g) | 59.969 | 144.510 |

| E (kJ/mol) | 1.242 | 2.350 | |

| R2 | 0.818 | 0.900 | |

| Adsorbent | Q (mg/g) | Reference |

|---|---|---|

| Hydrogel sodium alginate/Fe3O4 | 186.57 | [57] |

| Fe3O4 nanoparticles | 91.9 | [58] |

| Poly(AAB) magnetic hydrogel | 12.64 | [59] |

| Magnetic chitosan microspheres (TETA-MCTSms) | 211.22 | [60] |

| Fe3O4@SiO2 magnetic nanoparticles | 37.52 | [61] |

| NH2-MWCNTs@Fe3O4 | 178.5 | [62] |

| P(NIPAAm/IA/pumice) hydrogel | 22.62 | [63] |

| Poly(HEMA-co-IA) magnetic hydrogel (MHG-10) | 174.99 | This work |

| Adsorbent | T °C | ΔG0 (kJ/mol) | ΔH0 (kJ/mol) | ΔS0 (J/mol·K) |

|---|---|---|---|---|

| MHG-10 | 25 | −2.764 | 30.195 | 110.544 |

| 35 | −3.869 | |||

| 45 | −4.974 | |||

| HG-10 | 25 | −3.124 | 34.131 | 124.954 |

| 35 | −4.373 | |||

| 45 | −5.623 |

| Hydrogels HG a Poly(HEMA-co-IA) * | ||||

|---|---|---|---|---|

| HEMA g (mol%) | IA g (mol%) | MBA g (mol%) | APS g (mol%) | |

| HG-0 b | 4.00 (100) | 0.00 (0) | 0.24 (5) | 0.07 (1) |

| HG-5 | 3.80 (95) | 0.20 (5) | 0.24 (5) | 0.07 (1) |

| HG-7.5 | 3.70 (92.5) | 0.30 (7.5) | 0.24 (5) | 0.07 (1) |

| HG-10 | 3.60 (90) | 0.40 (10) | 0.24 (5) | 0.07 (1) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ludeña, M.A.; Meza, F.d.L.; Huamán, R.I.; Lechuga, A.M.; Valderrama, A.C. Preparation and Characterization of Fe3O4/Poly(HEMA-co-IA) Magnetic Hydrogels for Removal of Methylene Blue from Aqueous Solution. Gels 2024, 10, 15. https://doi.org/10.3390/gels10010015

Ludeña MA, Meza FdL, Huamán RI, Lechuga AM, Valderrama AC. Preparation and Characterization of Fe3O4/Poly(HEMA-co-IA) Magnetic Hydrogels for Removal of Methylene Blue from Aqueous Solution. Gels. 2024; 10(1):15. https://doi.org/10.3390/gels10010015

Chicago/Turabian StyleLudeña, Michael A., Flor de L. Meza, Reneé I. Huamán, Ana M. Lechuga, and Ana C. Valderrama. 2024. "Preparation and Characterization of Fe3O4/Poly(HEMA-co-IA) Magnetic Hydrogels for Removal of Methylene Blue from Aqueous Solution" Gels 10, no. 1: 15. https://doi.org/10.3390/gels10010015