Functional Gels and Chemicals Used in Oil and Gas Drilling Engineering: A Status and Prospective

Abstract

:1. Introduction

2. Functional Drilling Fluid Chemicals

2.1. Drilling Fluid Flow Regulator

2.2. Filter Loss Reducer for Drilling Fluids

2.3. Drilling Fluid Plugging Materials

3. Functional Cementing Fluids

3.1. Self-Healing Cementing Material

3.2. Nanoparticle Cementing Material

4. Functional Hydraulic Fracturing Fluids

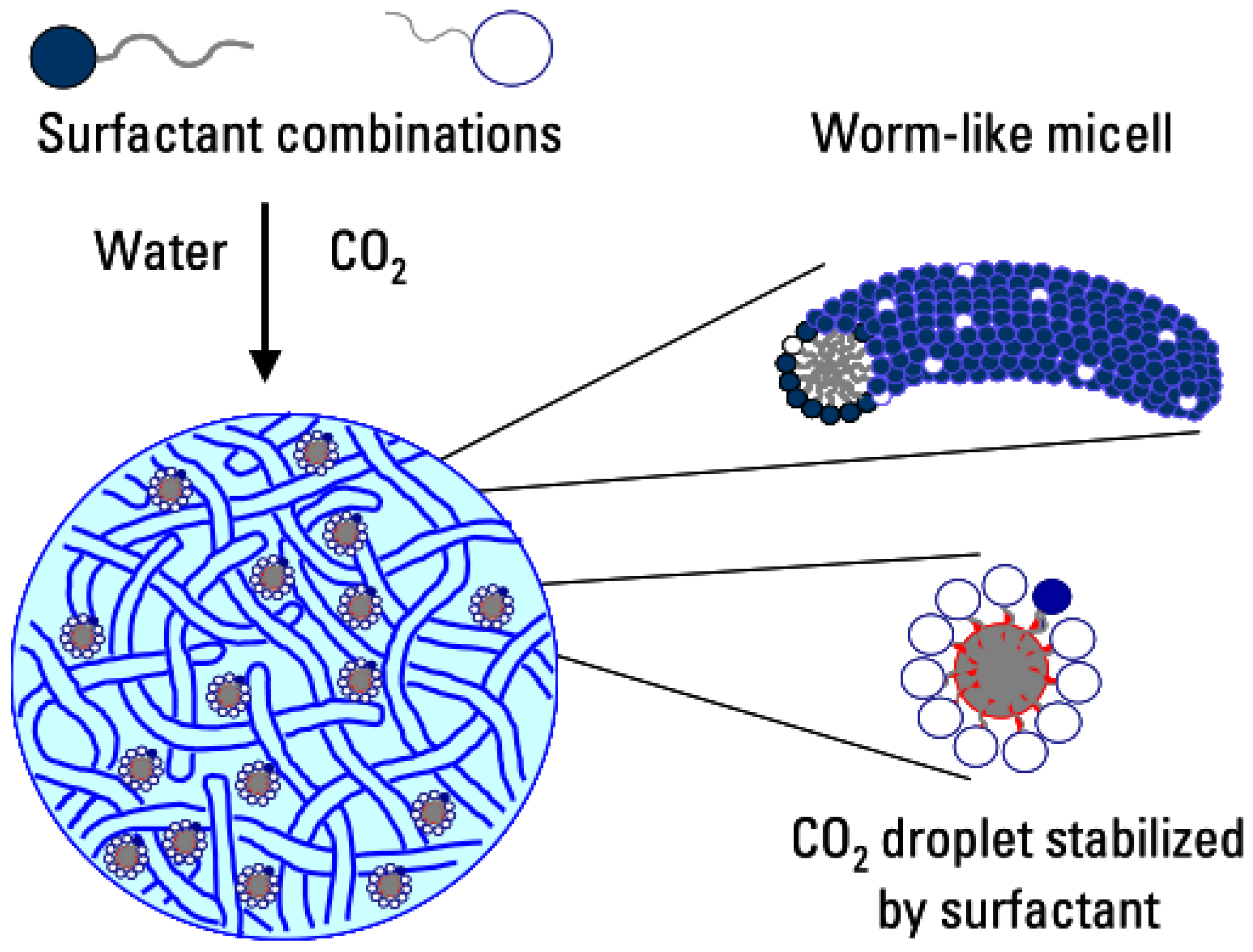

4.1. Clean Hydraulic Fracturing Fluids

4.2. Nanoscale Hydraulic Fracturing Fluids

4.3. High-Temperature-Resistant Hydraulic Fracturing Fluids

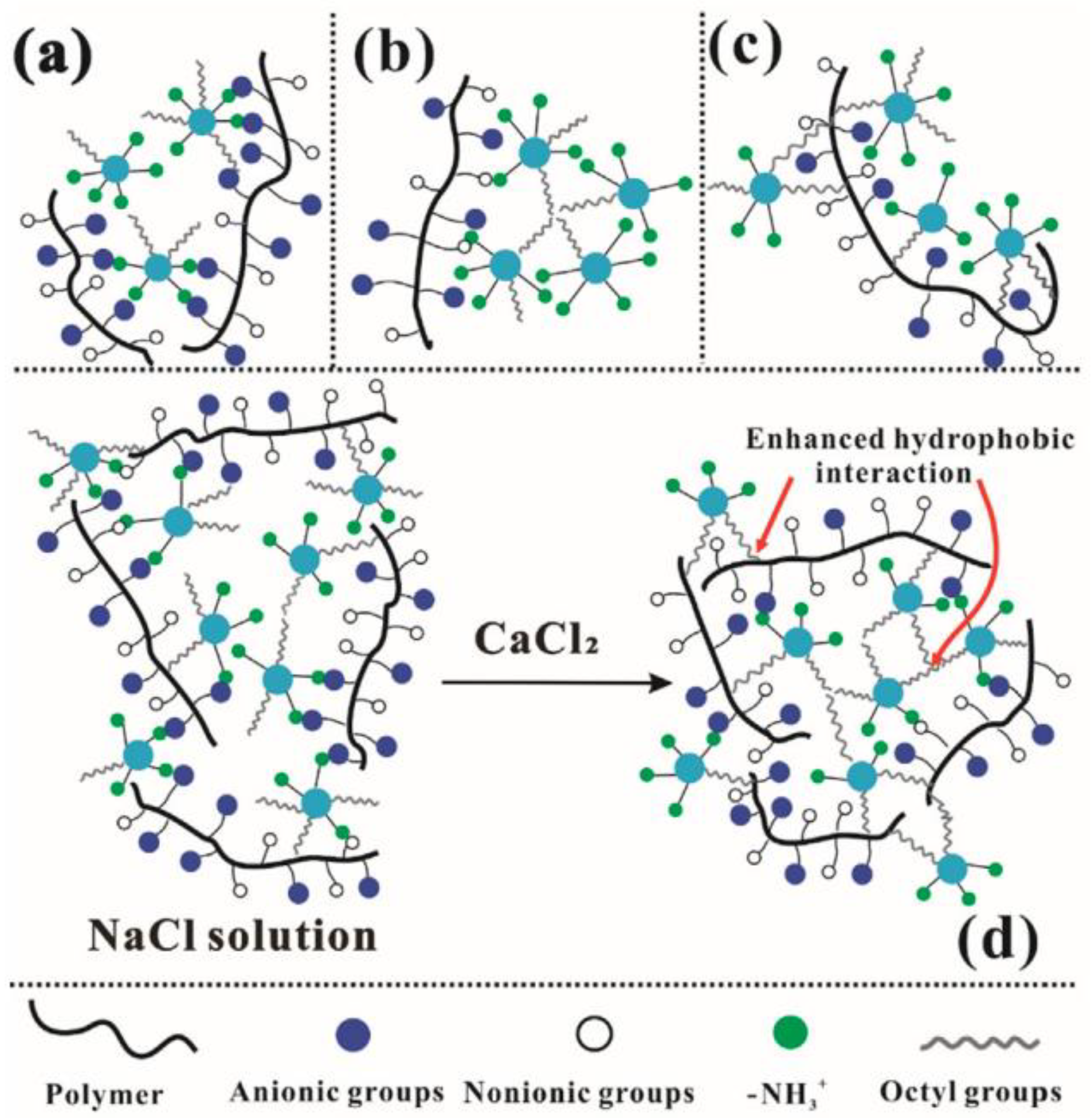

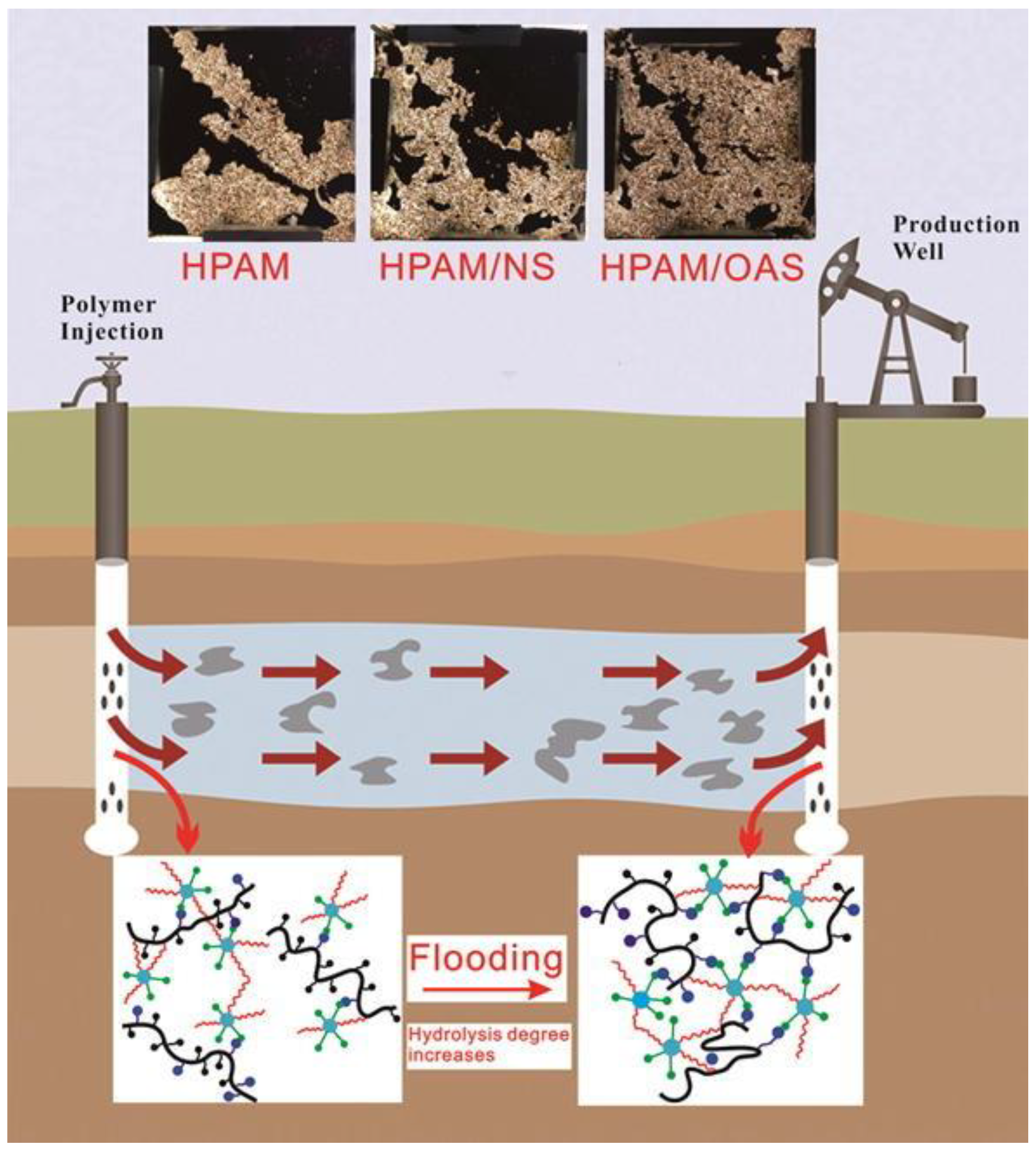

5. Functional Oil Displacement Agents

5.1. Nanoparticle Polymer Displacement Agents

5.2. Nanoparticle Surfactant Displacement Agents

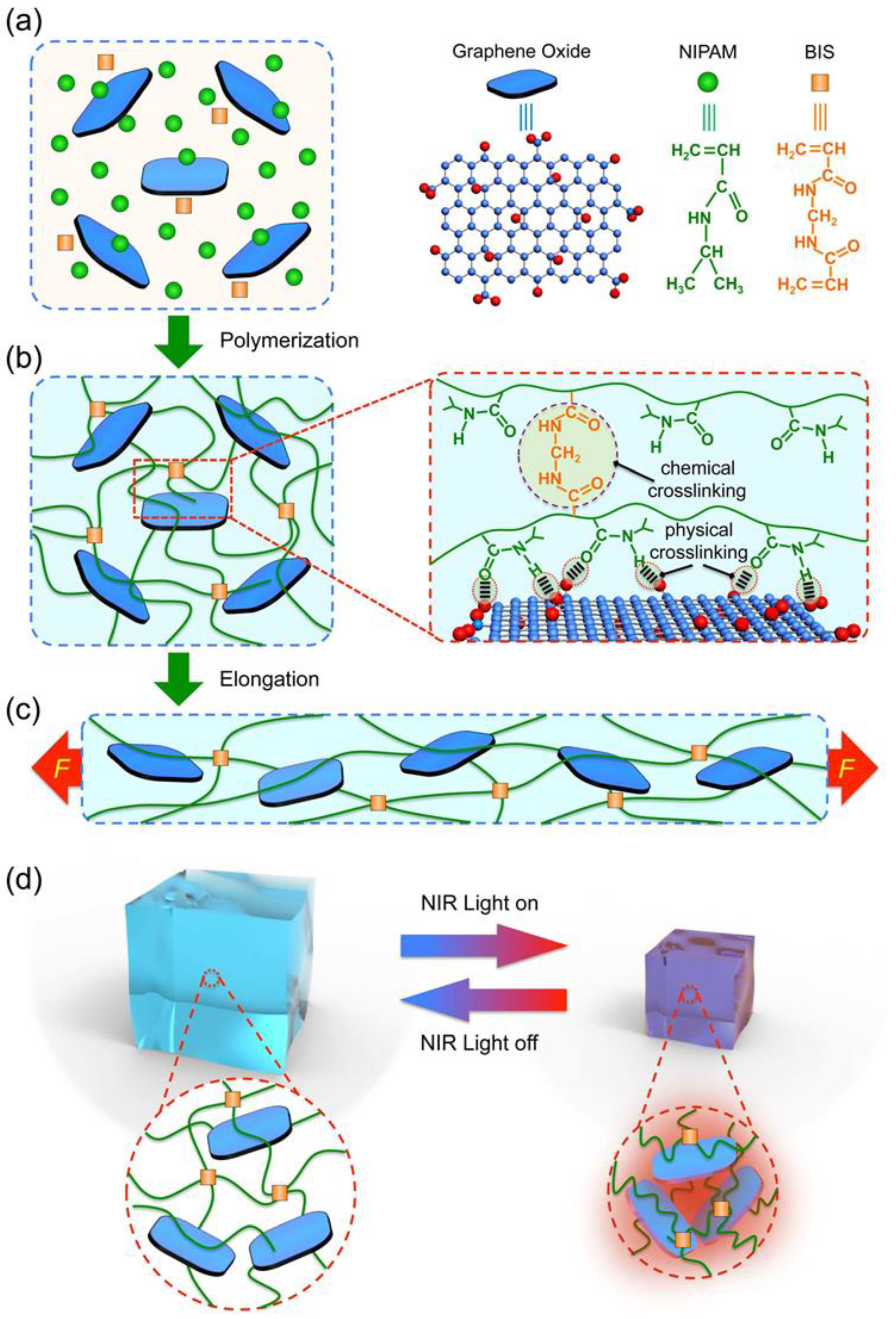

6. Functional Conformance Control and Water-Plugging Agents

6.1. Smart Gel Agents

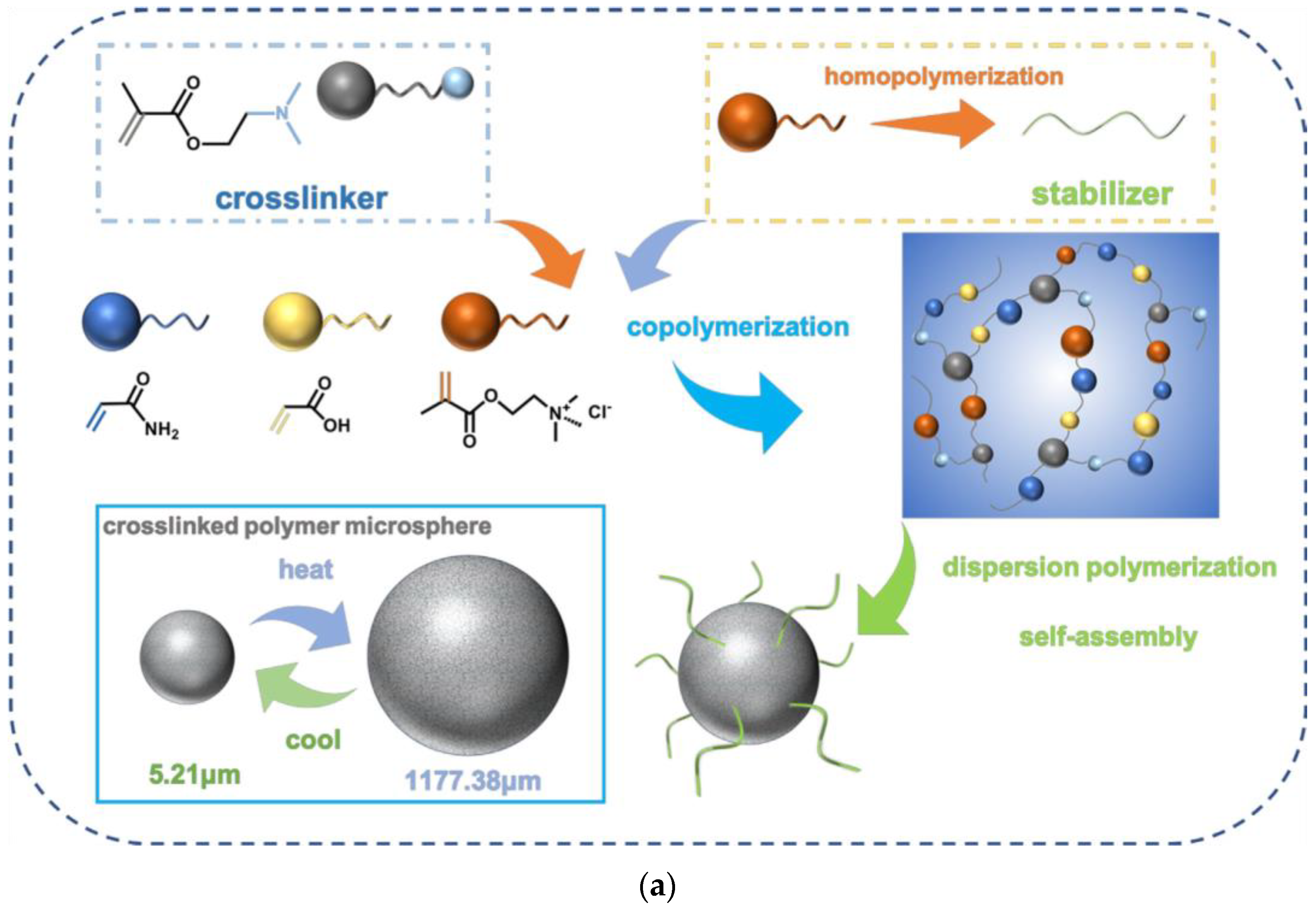

6.2. Polymer Microsphere Agents

7. Prospectives of Functional Chemical Used in Oil and Gas Drilling Engineering

7.1. Drilling Fluid Loss Control

7.2. Cementing

7.3. Hydraulic Fracturing

7.4. Enhanced Oil Recovery

7.5. Conformance Control and Water Plugging

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bag, D.S.; Rao, K.U.B. Smart polymers and their applications. J. Polym. Mater. 2014, 23, 225–248. [Google Scholar]

- Hollingshead, S.; Lin, C.Y.; Liu, J.C. Designing Smart Materials with Recombinant Proteins. Macromol. Biosci. 2017, 17, 1600554. [Google Scholar] [CrossRef] [PubMed]

- Lei, M.; Huang, W.; Li, N.; Jia, J.; Li, J.; Wang, Y.; Li, J. The damage mechanism of oil-based drilling fluid for tight sandstone gas reservoir and its optimization. J. Pet. Sci. Eng. 2017, 158, 616–625. [Google Scholar] [CrossRef]

- Guo, M. A zwitterionic copolymer as rheology modifier and fluid loss agents for water-based drilling fluids. Polymers 2021, 13, 3120. [Google Scholar]

- Faisal, R.; Kamal, I.; Salih, N.; Préat, A. Optimum formulation design and properties of drilling fluids incorporated with green uncoated and polymer-coated magnetite nanoparticles. Arab. J. Chem. 2024, 17, 105492. [Google Scholar] [CrossRef]

- Bao, D.; Liu, S.; Zhang, X.; Li, F.; Wang, J.; Jia, H.; Zhang, P. Preparation and Degradation Performance Study of P(AM/GG/PEGDA) Nanocomposite Self-Degradation Gel Plugging Material. Gels 2023, 9, 735. [Google Scholar] [CrossRef]

- Davoodi, S.; Al-Shargabi, M.; David, A.; Rukavishnikov, S. Recent advances in polymers as additives for wellbore cementing applications: A review. Fuel 2024, 357, 129692. [Google Scholar] [CrossRef]

- Qureshi, T.; Kanellopoulos, A.; Al-Tabbaa, A. Autogenous self-healing of cement with expansive minerals-I: Impact in early age crack healing. Constr. Build. Mater. 2018, 10, 768–784. [Google Scholar] [CrossRef]

- Meng, T.; Hong, Y.; Wei, H.; Xu, Q. Effect of Nano-SiO2 with Different Particle Size on the Hydration Kinetics of Cement. Thermochim. Acta 2019, 675, 127–133. [Google Scholar] [CrossRef]

- Samuel, M.; Card, R.J.; Nelson, E.B.; Brown, J.E.; Fu, D.K. Polymer-free fluid for hydraulic fracturing. In SPE Annual Technical Conference and Exhibition; SPE: Kuala Lumpur, Malaysia, 2001; p. 38622. [Google Scholar]

- Samuel, M.; Polson, D.; Graham, D.; Kordziel, W.; Waite, T. Viscoelastic Surfactant Fracturing Fluids: Applications in Low Permeability Reservoirs; SPE: Kuala Lumpur, Malaysia, 2000; p. 60322. [Google Scholar]

- Baruah, A.; Shekhawat, D.S.; Pathak, A.K.; Ojha, K. Experimental investigation of rheological properties in zwitterionic-anionic mixed-surfactant based fracturing fluids. J. Pet. Sci. Eng. 2016, 146, 340–349. [Google Scholar] [CrossRef]

- Fletcher, A.; Davis, J. How EOR Can be Transformed by Nanotechnology. In Spe Improved Oil Recovery Symposium; OnePetro: Richardson, TX, USA, 2010; p. 129531. [Google Scholar]

- Zhang, Y.; Qi, J.; Wang, N.; Wang, L.; Lu, H. Pseudo gemini surfactant fracturing fluid with dual function of fracturing and oil flooding for enhanced oil recovery. J. Mol. Liq. 2024, 393, 123562. [Google Scholar] [CrossRef]

- Kim, Y.S.; Liu, M.J.; Ishida, Y.; Ebina, Y.; Osada, M.; Sasaki, T.; Hikima, T.; Takata, M.; Aida, T. The responsive actuation enabled by permittivity switching in an electrostatically anisotropic hydrogel. Nat. Mater. 2015, 14, 1002. [Google Scholar] [CrossRef] [PubMed]

- Hamed, S.B.; Belhadri, M. Rheological properties of biopolymers drilling fluids. J. Pet. Sci. Eng. 2009, 67, 84–90. [Google Scholar] [CrossRef]

- Jiang, G.C.; Sun, J.S.; He, Y.B.; Cui, K.X.; Dong, T.F.; Yang, L.L.; Yang, X.K.; Wang, X.X. Novel water-based drilling and completion fluid technology to improve wellbore quality during drilling and protect unconventional reservoirs. Engineering 2022, 18, 129–142. [Google Scholar] [CrossRef]

- Davison, J.M.; Clary, S.; Saasen, A.; Allouche, M.; Nguyen, V.A. Rheology of Various Drilling Fluid Systems under Deepwater Drilling Conditions and the Importance of Accurate Predictions of Downhole Fluid Hydraulics. Drill. Fluid 1999, 214, 89–94. [Google Scholar]

- Hongping, Q.; Yang, W.U.; Zhiyu, H.; Tailiang, Z. Synthesis and performance evaluation of fluid loss additive for high temperature resistant and salt tolerant drilling fluid. Chem. Ind. Eng. Progress. 2015, 84, 23–32. [Google Scholar]

- Van Oort, E.; Lee, J.; Friedheim, J.; Toups, B. New flat-rheology synthetic-based mud for improved deepwater drilling. In Spe Technical Conference & Exhibition; SPE: Kuala Lumpur, Malaysia, 2004; p. 90987. [Google Scholar]

- Said, M.M.; El-Sayed, A.-A.H. The use of palm oil fatty acid methyl ester as a base fluid for a flat rheology high-performance drilling fluid. J. Pet. Sci. Eng. 2018, 3, 101. [Google Scholar] [CrossRef]

- Young, S.; Friedheim, J.E.; Lee, J.; Prebensen, O.I. A new generation of flat rheology invert drilling fluids. In SPE Oil and Gas India Conference and Exhibition; SPE: Kuala Lumpur, Malaysia, 2012; p. 154682. [Google Scholar]

- Bajpai, A.K.; Shukla, S.K.; Bhanu, S.; Kankane, S. Responsive polymers in controlled drug delivery. Prog. Polym. Sci. 2008, 33, 1088–1118. [Google Scholar] [CrossRef]

- Salamone, J.C.; Volksen, W.; Olson, A.P.; Israel, S.C. Aqueous solution properties of a poly (vinyl imidazolium sulfobetaine). Polymer 1978, 19, 1157–1162. [Google Scholar] [CrossRef]

- Morales-Cruz, M.; Flores-Fernandez, G.M.; Morales-Cruz, M.; Orellano, E.A.; Rodriguez-Martinez, J.A.; Ruiz, M.; Griebenow, K. Two-step nanoprecipitation for the production of protein loaded PLGA nanospheres. Results Pharma Sci. 2012, 2, 79–85. [Google Scholar] [CrossRef]

- Shakeri, S.; Roghanian, R.; Emtiazi, G.; Errico, C.; Chiellini, F. Preparation of protein-loaded PLGA-PVP blend nanoparticles by nanoprecipitation method: Entrapment, Initial burst and drug release kinetic studies. Nanomed. J. 2015, 12, 176–190. [Google Scholar]

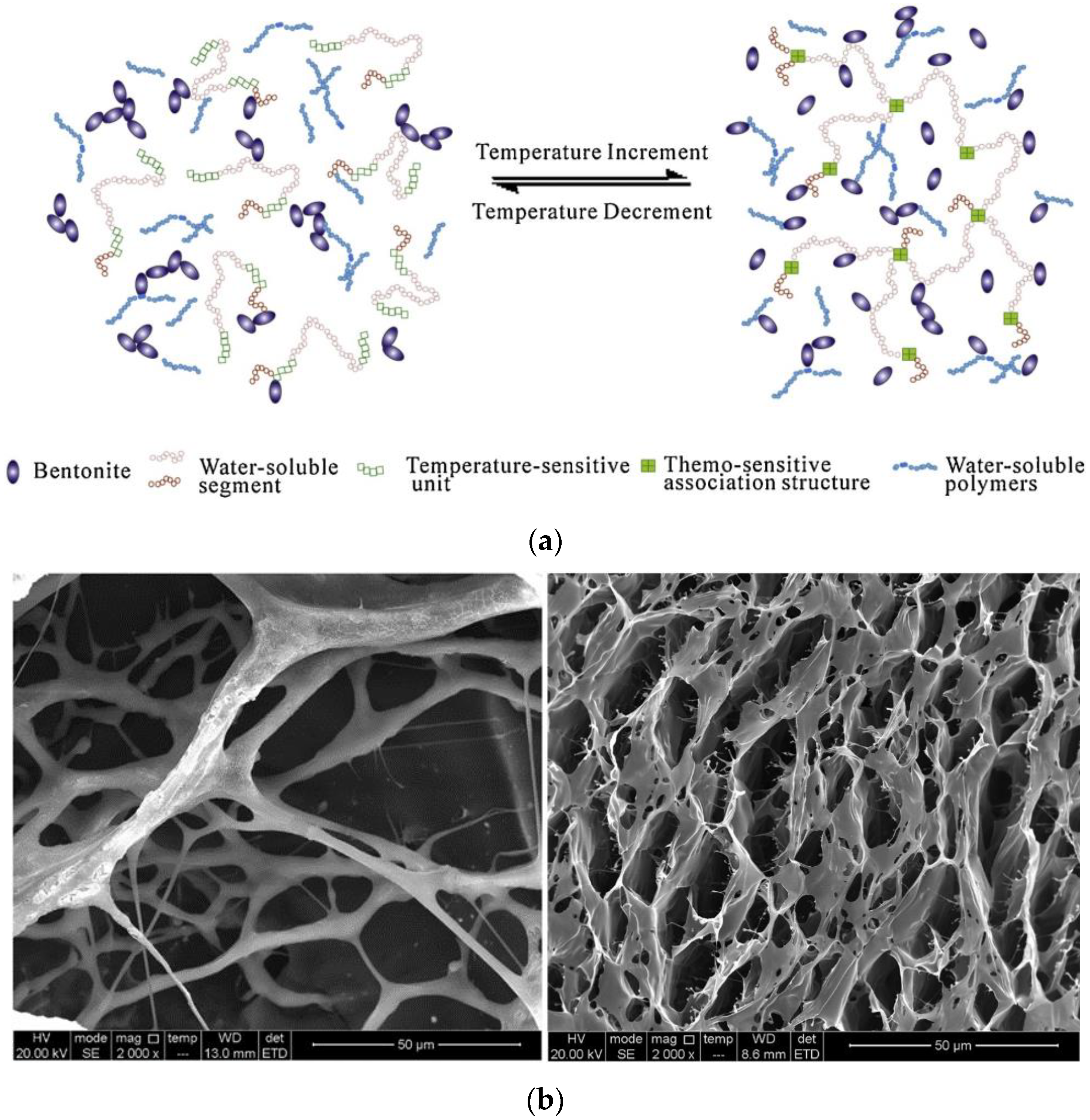

- Xie, B.; Zhang, X.; Li, Y.; Liu, W.; Luo, M. Application of a novel thermo-sensitive copolymer as a potential rheological modifier for deepwater water-based drilling fluids. Colloids Surf. A. Physicochem. Eng. Asp. 2019, 581, 123848. [Google Scholar] [CrossRef]

- Zhang, X.; Jiang, G.; Xuan, Y.; Wang, L.; Huang, X. Associating copolymer acrylamide/diallyl dimethylammonium chloride/butyl acrylate/ 2-acrylamido-2-methylpropanesulfonic acid as a tackifier in clay-free and water-based drilling fluids. Energy Fuels 2017, 31, 4655–4662. [Google Scholar] [CrossRef]

- Sun, J.; Chang, X.; Lv, K.; Wang, J.; Zhao, J. Salt-responsive zwitterionic copolymer as a tackifier in brine drilling fluids. J. Mol. Liq. 2020, 319, 114345. [Google Scholar] [CrossRef]

- Thaemlitz, C.J.; Patel, A.D.; Coffin, G.; Conn, L. New environmentally safe high-temperature water-based drilling-fluid system. Spe Drill. Complet. 1999, 14, 185–189. [Google Scholar] [CrossRef]

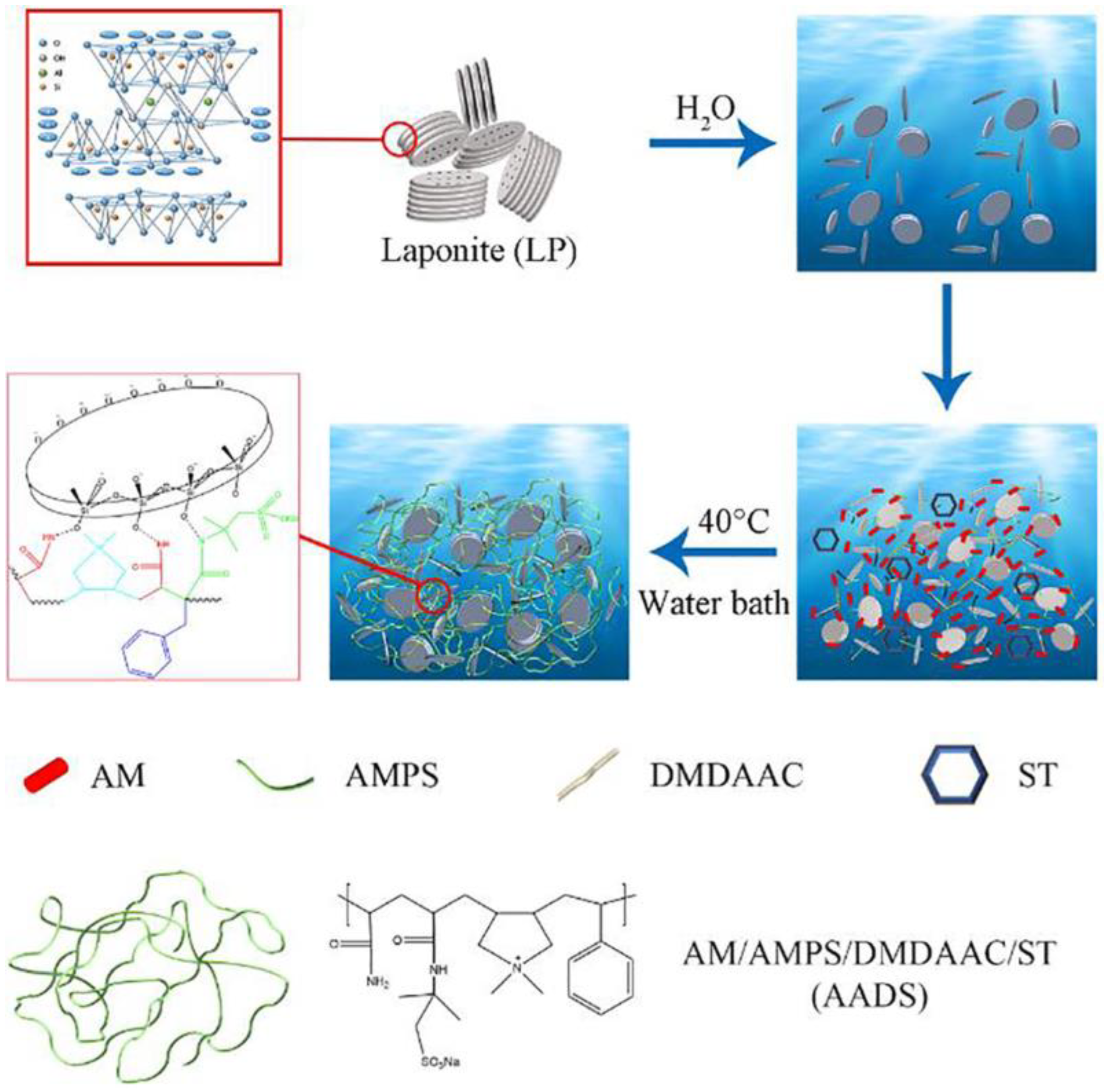

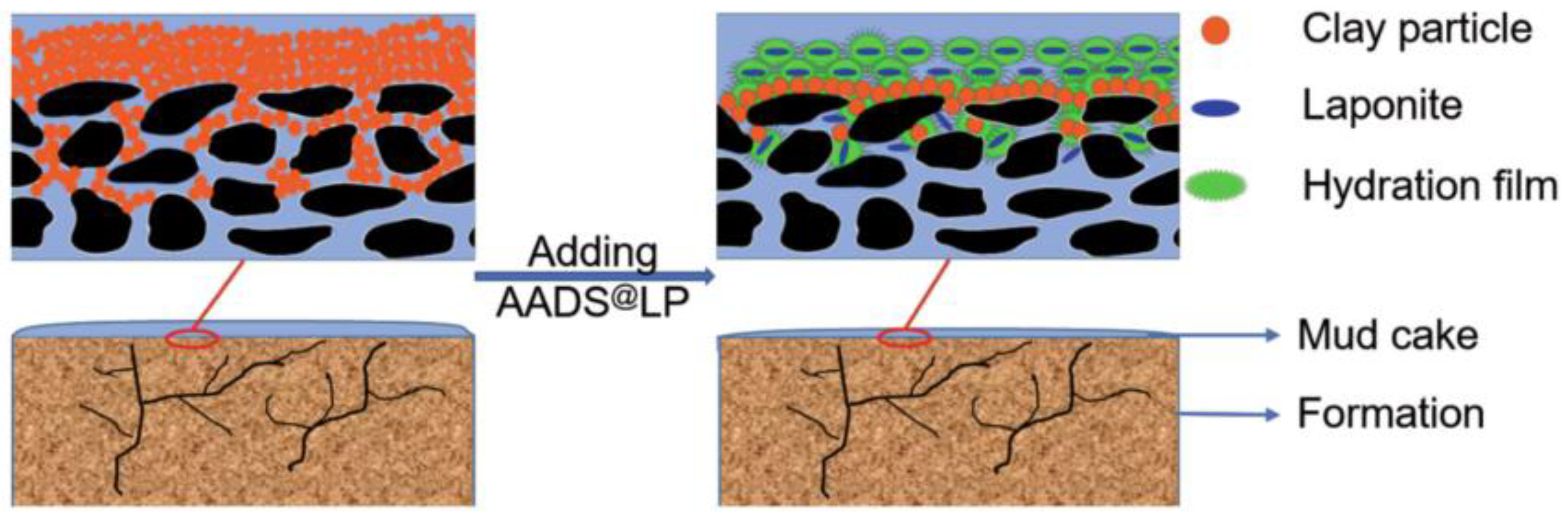

- Shen, H.K.; Lv, K.H.; Huang, X.B.; Liu, J.P. Hydrophobic-associated polymer-based laponite nanolayered silicate composite as filtrate reducer for water-based drilling fluid at high temperature. J. Appl. Polym. Sci. 2019, 137, 48608. [Google Scholar] [CrossRef]

- Tomislav, S.; Robert, H.; Pavel, M. Uniquely engineered water-base high temperature drill-in fluid increases production, cuts costs in Croatia campaign. In Spe/iadc Drilling Conference; SPE: Kuala Lumpur, Malaysia, 2003; p. 79839. [Google Scholar]

- Alsaba, M.T.; Nygaard, R.; Hareland, G.; Contreras, O. Review of lost circulation materials and treatments with an updated classification. In Proceedings of the AADE Fluids Technical Conference and Exhibition, Houston, TX, USA, 15–16 April 2014. [Google Scholar]

- Abrams, A. Mud design to minimize rock impairment due to particle invasion. J. Pet. Technol. 1977, 29, 586–592. [Google Scholar] [CrossRef]

- Angelos, S.; Yang, Y.W.; Patel, K. p H-responsive supramolecular nanovalves based on cucurbit uril pseudorotaxanes. Angew. Chem. Int. Ed. 2008, 47, 2222–2226. [Google Scholar] [CrossRef]

- Zhang, S.Y.; Bellinger, A.M.; Glettig, D.L.; Barman, R. A pH-responsive supramolecular polymer gel as an enteric elastomer for use in gastric devices. Nat. Mater. 2015, 14, 1065–1071. [Google Scholar] [CrossRef]

- Osada, Y.; Okuzaki, H.; Hori, H. A polymer gel with electrically driven motility. Nature 1992, 355, 242–244. [Google Scholar] [CrossRef]

- Yang, C.; Wang, W.; Yao, C.; Xie, R.; Ju, X.J.; Liu, Z.; Chu, L.Y. Hydrogel walkers with electro-driven motility for cargo transport. Sci. Rep. 2015, 5, 13622–13631. [Google Scholar] [CrossRef]

- Liu, Z.; Liu, L.; Ju, X.J.; Xie, R.; Zhang, B.; Chu, L.Y. K+-recognition capsules with squirting release mechanisms. Chem. Commun. 2011, 47, 12283–12285. [Google Scholar] [CrossRef] [PubMed]

- Ho, J.F.; Tavassoli, S.; Patterson, J.W.; Shafiei, M.; Huh, C.; Bommer, P.M.; Bryant, S.L.; Balhoff, M.T. The Use of a pH-Triggered Polymer Gelant to Seal Cement Fractures in Wells. Spe Drill. Complet. 2015, 31, 225–235. [Google Scholar] [CrossRef]

- Ratna, D.; Karger-Kocsis, J. Recent advances in shape memory polymers and composites: A review. J. Mater. Sci. 2008, 43, 254–269. [Google Scholar] [CrossRef]

- Zhao, Q.; Qi, H.J.; Xie, T. Recent progress in shape memory polymer: New behavior, enabling materials, and mechanistic understanding. Prog. Polym. Sci. 2015, 49–50, 79–120. [Google Scholar] [CrossRef]

- Lendlein, A.; Kelch, S. Shape-Memory Polymers. ChemInform 2010, 33, 251. [Google Scholar] [CrossRef]

- Mansour, A.; Taleghani, A.D.; Li, G. Smart Lost Circulation Materials for Wellbore Strengthening. In Proceedings of the 51st U.S. Rock Mechanics/Geomechanics Symposium, San Francisco, CA, USA, 25–28 June 2017. [Google Scholar]

- Mansour, A.K. Experimental Study and Modeling of Smart Loss Circulation Materials: Advantages and Promises. Master’s Thesis, Louisiana State University, Baton Rouge, LA, USA, 2017. [Google Scholar]

- Mansour, A.; Dahi Taleghani, A.; Salehi, S.; Li, G.; Ezeakacha, C. Smart lost circulation materials for productive zones. J. Pet. Explor. Prod. Technol. 2018, 9, 281–296. [Google Scholar] [CrossRef]

- Bekas, D.G.; Tsirka, K.; Baltzis, D.; Paipetis, A.S. Self-healing materials: A review of advances in materials, evaluation, characterization and monitoring techniques. Composites, Part B. Engineering 2016, 87B, 92–119. [Google Scholar] [CrossRef]

- Nguyen, H.; Choi, J.; Song, K.; Song, J.; Huh, J.; Lee, B. Self-healing properties of cement-based and alkali-activated slag-based fiber-reinforced composites. Constr. Build. Mater. 2018, 165, 801–811. [Google Scholar] [CrossRef]

- Fang, G.; Liu, Y.; Qin, S.; Ding, W.; Dong, B. Visualized tracing of crack self-healing features in cement/microcapsule system with X-ray microcomputed tomography. Constr. Build. Mater. 2018, 179, 336–347. [Google Scholar] [CrossRef]

- Zhang, R.; Mao, X.; Zhao, Z. Synthesis of oil-swelling material and evaluation of its self-healing effect in cement paste. Polym. -Plast. Technol. Eng. 2018, 11, 618–629. [Google Scholar] [CrossRef]

- Zyganitidis, I.; Stefanidou, M.; Kalfagiannis, N.; Logothetidis, S. Nanomechanical characterization of cement-based pastes enriched with SiO2 nanoparticles. Mater. Sci. Eng. B 2011, 176, 1580–1584. [Google Scholar] [CrossRef]

- Cheraghian, G. Effects of nanoparticles on wettability: A review on applications of nanotechnology in the enhanced oil recovery. Islam. Azad Univ.-Tonekabon Branch 2015, 26, 443–452. [Google Scholar]

- Lee, S.W.; Minki, J.M.; Kim, J.W. Application of Ca-doped mesoporous silica to well-grouting cement for enhancement of self-healing capacity. Mater. Des. 2016, 29, 362–368. [Google Scholar] [CrossRef]

- Cavanagh, P.; Johnson, C.; Roy-Delage, S.L.; Debruijn, G.; Dargaud, B. Self-healing cement-novel to achieve leak-free wells. In Spe/iadc Drilling Conference; SPE: Kuala Lumpur, Malaysia, 2007; p. 105781. [Google Scholar]

- Sadrmomtazi, A.; Fasihi, A.; Balalaei, F.; Haghi, A.K. Investigation of mechanical and physical properties of mortars containing silica fume and nano-SiO2. Acta Mater. 2009, 56, 3558–3567. [Google Scholar]

- Valipour, M.; Mirdamadi, A.; Shekarchi, M. Comparative study of nano-SiO2 and silica fume on gas permeability of concrete. In Proceedings of the International Conference on Durability of Building Materials and Components, Porto, Portugal, 12 April 2011. [Google Scholar]

- Land, G.; Stephan, D. The influence of nano-silica on the hydration of ordinary Portland cement. J. Mater. Sci. 2012, 47, 1011–1017. [Google Scholar] [CrossRef]

- Wu, X.P.; Zhang, Y.; Sun, X.; Huang, Y.P. A novel CO2 and pressure-responsive viscoelastic surfactant fluid for fracturing. Fuel 2018, 04, 79–87. [Google Scholar] [CrossRef]

- Chen, Y.; Pope, T.L. Novel CO2-emulsified viscoelastic surfactant fracturing fluid system. In SPE European Formation Damage Conference and Exhibition; SPE: Kuala Lumpur, Malaysia, 2005; p. 94603. [Google Scholar]

- Saien, J.; Shahrezaei, F. Organic pollutants removal from petroleum refinery wastewater with nano titania photocatalyst and UV light emission. Int. J. Photoenergy 2012, 2012, 91–93. [Google Scholar] [CrossRef]

- Huang, T.; Crews, J.B.; Agrawal, G. Nanoparticle pseudo crosslinked micellar fluids: Optimal solution for fluid-loss control with internal breaking. In SPE International Symposium and Exhibition on Formation Damage Control; SPE: Kuala Lumpur, Malaysia, 2010; p. 128067. [Google Scholar]

- Crews, J.B.; Gomaa, A.M. Nanoparticle-associated surfactant micellar fluids: An alternative to crosslinked polymer systems. In SPE International Oilfield Nanotechnology Conference and Exhibition; OnePetro: Richardson, TX, USA, 2012; p. 157055. [Google Scholar]

- Gurluk, M.R.; Nasreldin, H.A.; Crews, J.B. Enhancing the performance of viscoelastic surfactant fluids using nanoparticles. In SPE Europec featured at EAGE Conference and Exhibition; SPE: Kuala Lumpur, Malaysia, 2013; p. 164900. [Google Scholar]

- Fakoya, M.F.; Shah, S.N. Rheological Properties of Surfactant-Based and Polymeric Nano-Fluids. In Society of Petroleum Engineers; OnePetro: Richardson, TX, USA, 2013; p. 163921. [Google Scholar]

- Liu, J.W.; Wang, S.B.; Wang, C.; Zhao, F.; Shi Lei, S.; Yi, H.Y.; Guo, J.C. Influence of nanomaterial morphology of guar-gum fracturing fluid physical and mechanical properties. Carbohydr. Polym. 2020, 234, 115915. [Google Scholar] [CrossRef]

- Mitchell, T.O.; Parris, M.D. High Temperature Hydraulic Fracturing Fluid. U.S. Patent 6,227,295, 8 May 2001. [Google Scholar]

- Yan, S.; Tang, J.; Yan, S.; Wang, Y.; Han, J.; Shi, S. Preparation and performance of novel temperature-resistant thickening agent. Polym. Adv. Technol. 2017, 29, 1022–1029. [Google Scholar] [CrossRef]

- Funkhouser, G.P.; Holtsclaw, J.; Blevins, J. Hydraulic fracturing under extreme HPHT conditions: Successful application of a new synthetic fluid in south Texas gas wells. In SPE Deep Gas Conference and Exhibition; SPE: Kuala Lumpur, Malaysia, 2010; p. 132173. [Google Scholar]

- Williams, D.A. Crosslinker Composition for High Temperature Hydraulic Fracturing Fluids. U.S. Patent 4,534,870A, 13 August 1985. [Google Scholar]

- Liang, F.; Reddy, B.R.; Li, L.; Al-Muntasheri, G.A. High Temperature Crosslinked Fracturing Fluids. WO 2017096055 A1, 8 June 2017. [Google Scholar]

- Carman, S.; Gupta, D. Method of Fracturing with Phenothiazine Stabilizer. U.S. Patent No. 8,691,734, 8 April 2014. [Google Scholar]

- Cheraghian, G.; Tardasti, S. Improved Oil Recovery by the Efficiency of Nanoparticle in Imbibition Mechanism. In Proceedings of the 74th EAGE Conference and Exhibition Incorporating EUROPEC, Copenhagen, Denmark, 4–7 June 2012. [Google Scholar]

- Madhan, A.; Guo, K.; Yu, Z.X. A state-of-the-artrevicw of nanoparticle application in petroleum with a focus on advanced oil recovery. Appl. Sci. 2018, 8, 871. [Google Scholar]

- Norhasri, M.S.M.; Hamidah, M.S.; Fadzil, A.M. Appli cations of using nano material in concrete: A review. Constr. Build. Mater. 2017, 133, 91–97. [Google Scholar] [CrossRef]

- Chen, J.; Wang, Y.; Liu, W.; Ma, Y. Nano-engineered mate rials for transparent supercapacitors. ChemNanoMat 2019, 6, 42–52. [Google Scholar] [CrossRef]

- Du, L.; Zhang, R.; Yang, H.; Tang, S.; Hou, Z.; Jing, J.; Xue, P. Synthesis, characteristics and medical applications of plant nanomaterials. Planta 2020, 252, 108–115. [Google Scholar] [CrossRef] [PubMed]

- Tian, Q.Y.; Wang, L.; Tang, Y.; Liu, C.; Ma, C.; Wang, T. Research and Application of Nano Polymer Microspheres Diversion Technique of Deep Fluid. Soc. Pet. Eng. 2012. [CrossRef]

- Yao, C.; Lei, G.; Li, L.; Gao, X. Selectivity of pore-scale elastic microspheres as a novel profile control and oil displacement agent. Energy Fuels 2012, 26, 5092–5101. [Google Scholar] [CrossRef]

- Kanj, M.; Funk, J.; Al-Yousif, Z. Nanofluid Core flood Experiments in the ARAB-D. In SPE Saudi Arabia Section Technical Symposium; Society of Petroleum Engineers, SPE: Kuala Lumpur, Malaysia, 2009. [Google Scholar]

- Kothari, N.; Raina, B.; Chandak, K.; Iyer, V.; Mahajan, H. Application of ferrofluid for enhanced surfactant flooding in IOR. In SPE Europec Featured at EAGE Conference and Exhibition; SPE: Kuala Lumpur, Malaysia, 2010; p. 131272. [Google Scholar]

- Cao, J.; Song, T.; Wang, X.; Zhu, Y.; Wang, S.; Zhao, M.; Miao, Y.; Zhang, J. Studies on the rheological properties of amphiphilic nano silica and a partially hydrolyzed polyacrylamide hybrid for enhanced oil recovery. Chem. Eng. Sci. 2019, 206, 146–155. [Google Scholar] [CrossRef]

- Olayiwola, S.O.; Dejam, M. Comprehensive experimental study on the effect of silica nanoparticles on the oil recovery during alternating injection with low salinity water and surfactant into carbonate reservoirs. J. Mol. Liq. 2021, 325, 115178. [Google Scholar] [CrossRef]

- Philippova, O.E.; Molchanov, V.S. Enhanced rheological properties and performance of viscoelastic surfactant fluids with embedded nanoparticles. Curr. Opin. Colloid Interface Sci. 2019, 43, 52–62. [Google Scholar] [CrossRef]

- Li, S.; Sng, A.; Daniel, D.; Lau, H.C.; Torsæter, O.; Stubbs, L.P. Visualizing and quantifying wettability alteration by silica nanofluids. ACS Appl. Mater. Interfaces 2021, 13, 41182–41189. [Google Scholar] [CrossRef]

- Mahmoudi, S.; Jafari, A.; Javadian, S. Temperature effect on performance of nanoparticle/surfactant flooding in enhanced heavy oil recovery. Pet. Sci. 2019, 16, 1387–1402. [Google Scholar] [CrossRef]

- Abhishek, R.; Kumar, G.S.; Sapru, R.K. Wettability Alteration in Carbonate Reservoirs Using Nanofluids. Pet. Sci. Technol. 2015, 33, 794–801. [Google Scholar] [CrossRef]

- Zhang, A.G.; Fan, Z.F.; Zhao, L.; He, C.G. An investigation on sensitivity analysis and performance prediction of profile control by clay particles for polymer flooded reservoir. J. Pet. Sci. Eng. 2021, 196, 107690. [Google Scholar] [CrossRef]

- Xu, B.; Wang, Y. Profile control performance and field application of preformed particle gel in low-permeability fractured reservoir. J. Pet. Explor. Prod. Technol. 2020, 11, 477–482. [Google Scholar] [CrossRef]

- Liu, L.; Gou, S.H.; Fang, S.W.; Tang, L. Organic-inorganic microspheres of temperature-controlled size for profile control. J. Mol. Liq. 2020, 317, 113993. [Google Scholar] [CrossRef]

- Iskander, G.; Nurxat, N.; Sarkyt, K. Bulk gels for permeability reduction in fractured and matrix reservoirs. Energy Rep. 2019, 5, 733–746. [Google Scholar]

- Sadiya, A.; Pramod, G.; Manohar, V.B. Design and development of trivalent aluminum ions-induced self-healing polyacrylic acid novel hydrogels. Polymer 2017, 8, 196–205. [Google Scholar]

- Lym, J.S.; Nguyen, Q.V.; Ahn, D.W.; Lee, D.S. Sulfamethazine-based pH-sensitive hydrogels with potential application for transcatheter arterial chemoembolization therapy. Acta Biomater. 2016, 41, 253–263. [Google Scholar] [CrossRef]

- Chen, F.; Chen, Q.; Zhu, L.; Tang, Z.Q.; Li, Q.F.; Qin, G.; Zheng, J. General strategy to fabricate strong and tough low-molecular-weight gelator-based supramolecular hydrogels with double network structure. Chem. Mater. 2018, 30, 1743–1754. [Google Scholar] [CrossRef]

- Han, L.; Zhang, Y.N.; Lu, X.; Zhang, H.P. Polydopamine nanoparticles modulating stimuli responsive PNIPAM hydrogels with cell/tissue adhesiveness. ACS Appl. Mater. Interfaces 2016, 8, 29088–29100. [Google Scholar] [CrossRef]

- Shi, K.; Liu, Z.; Wei, Y.Y.; Wang, W.; Ju, X.J.; Xie, R.; Liang, Y.; Chu, L.Y. Near-infrared light-responsive poly(N-isopropyl acrylamide)/ graphene oxide nanocomposite hydrogels with ultrahigh tensibility. ACS Appl. Mater. Interfaces 2015, 7, 27289–27298. [Google Scholar] [CrossRef]

- Guo, A.; Geng, Y.; Zhao, L.; Li, J.; Liu, D.; Li, P. Preparation of cationic polyacrylamide microsphere emulsion and its performance for permeability reduction. Pet. Sci. 2014, 11, 408–416. [Google Scholar] [CrossRef]

- Ji, J.; Ke, Y.; Ji, D.; Zhang, Z.; Shao, M.; Liu, P. Investigation on preparation of poly (AM/SSS/AMPS) microspheres by dispersion polymerization system. IOP Conf. Ser. Earth Environ. Sci. 2018, 170, 022087. [Google Scholar] [CrossRef]

- Du, W.H.; Wu, P.W.; Zhao, Z.X.; Xi, Z. Facile preparation and characterization of temperature-responsive hydrophilic crosslinked polymer microspheres by aqueous dispersion polymerization. Eur. Polym. J. 2020, 128, 109610. [Google Scholar] [CrossRef]

- Shi, F.; Wu, J.; Zhao, B. Preparation and Investigation of Intelligent Polymeric Nanocapsule for Enhanced Oil Recovery. Materials 2019, 12, 1093. [Google Scholar] [CrossRef] [PubMed]

- Bai, Y.Q.; He, S.Q.; Lian, Y.; Yu, T.T.; Dai, C.L.; Zhao, J.; Zhang, H.H. Self-Lubricating Supramolecular Hydrogel for In-Depth Profile Control in Fractured Reservoirs. ACS Omega 2020, 5, 7244–7253. [Google Scholar] [CrossRef] [PubMed]

- Yongqing Bai, Y.Q.; Chaolei Ban, C.L.; He, S.Q.; Zhao, J.; Zhang, H.H. Temperature-responsive self-lubricating hydrogel from dynamic Diels-Alder crosslinking for reservoir in-depth profile control. J. Mol. Liq. 2021, 323, 114595. [Google Scholar]

- Zhang, D.; Zhao, W.; Wu, Y.; Chen, Z.; Li, X. Preparation and properties of multilayer assembled polymer gel microsphere profile control agents. Polym. Eng. Sci. 2019, 59, 1507–1516. [Google Scholar] [CrossRef]

- Li, Z.; Zhou, Y.; Li, T.; Zhang, J.; Tian, H. Stimuli-responsive hydrogels: Fabrication and biomedical applications. VIEW 2021, 3, 20200112. [Google Scholar] [CrossRef]

- Saha, E.; Mitra, J. Multi-Stimuli-Responsive Self-Healable and Moldable Ni(II)-based Gels for Reversible Gas Adsorption and Pd Sequestration via Gel-to-Gel Transformation. ACS Appl. Mater. Interfaces 2019, 11, 10718–10728. [Google Scholar] [CrossRef]

| Classification | Functional Materials | Function Characteristics | References |

|---|---|---|---|

| Drilling fluid flow regulator | Temperature-sensitive copolymer (PANA) | PANA can be a continuous network structure in solution and can change the rheological properties of fluid | (Xie et al., 2019) [27] |

| Salt-responsive zwitterionic polymer (PAMN) | Salt-sensitive polymers can (to a certain extent) increase the ability of drilling fluids to re-sist salinization | (Sun et al., 2020) [29] | |

| Filter loss reducer for drilling fluids | Terpolymer filter loss reducer | The filter loss reducer effectively maintained the rheological stability of the drilling fluid | (Thaemlitz et al., 2012) [30] |

| A nano-lamellar silicate composite (AADS@LP) | The network strength of the polymer was improved, and the clay particles piled up tightly, forming an isolation membrane that reduced the filtration losses | (Shen et al., 2019) [31] | |

| A new generation of high-temperature-resistant filter loss reducers (Hostadrill 4706) | This filter loss reducer had excellent anti-salt properties, and it could significantly improve the rheological properties of drilling fluids | (Tomislav et al., 2003) [32] | |

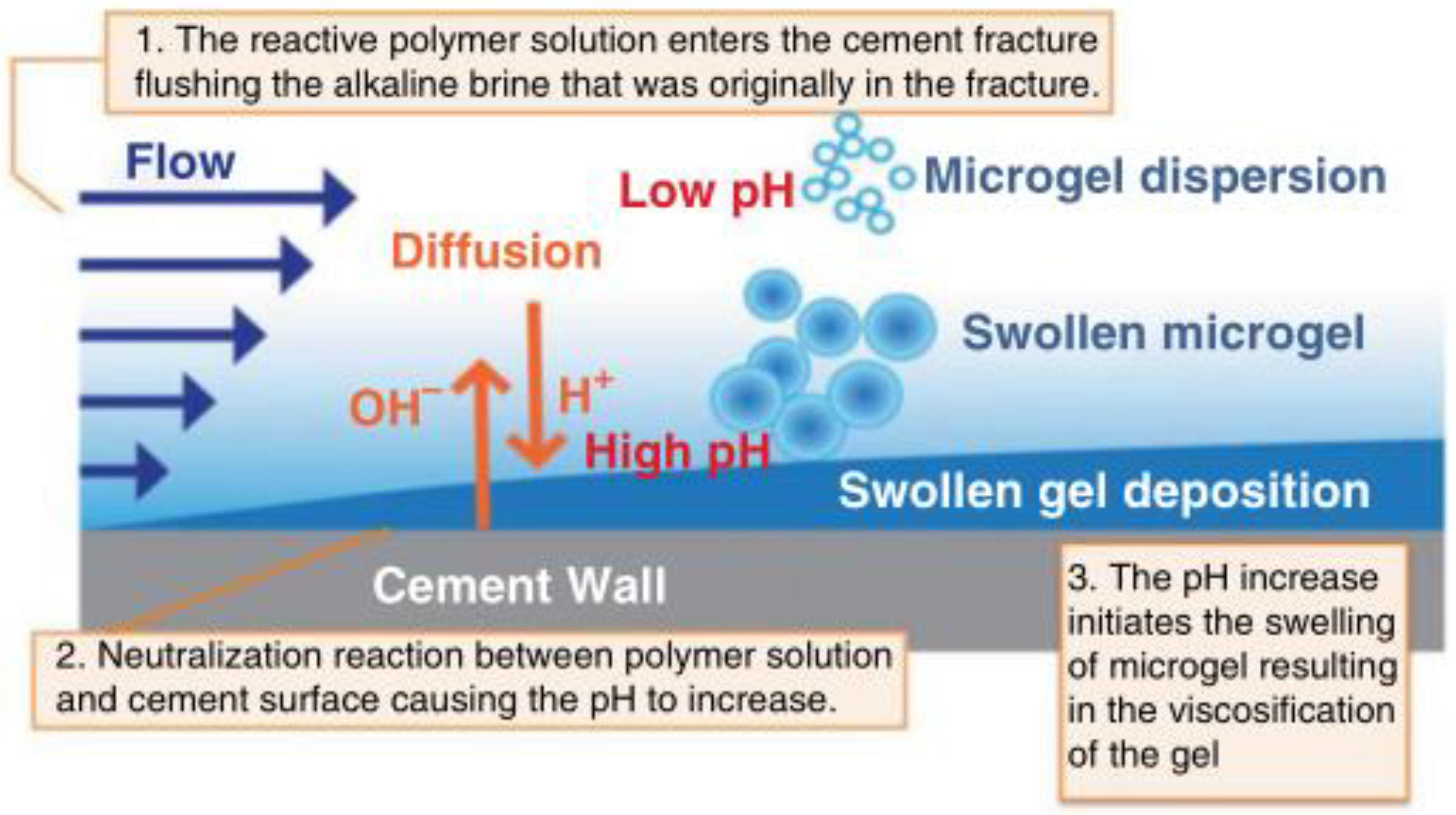

| Drilling fluid plugging materials | An aqueous dispersion of insoluble smart gels | The reaction of the smart gel with the OH- ions leached from the alkaline cement wall causes the gel viscosity to increase | (Ho et al., 2015) [40] |

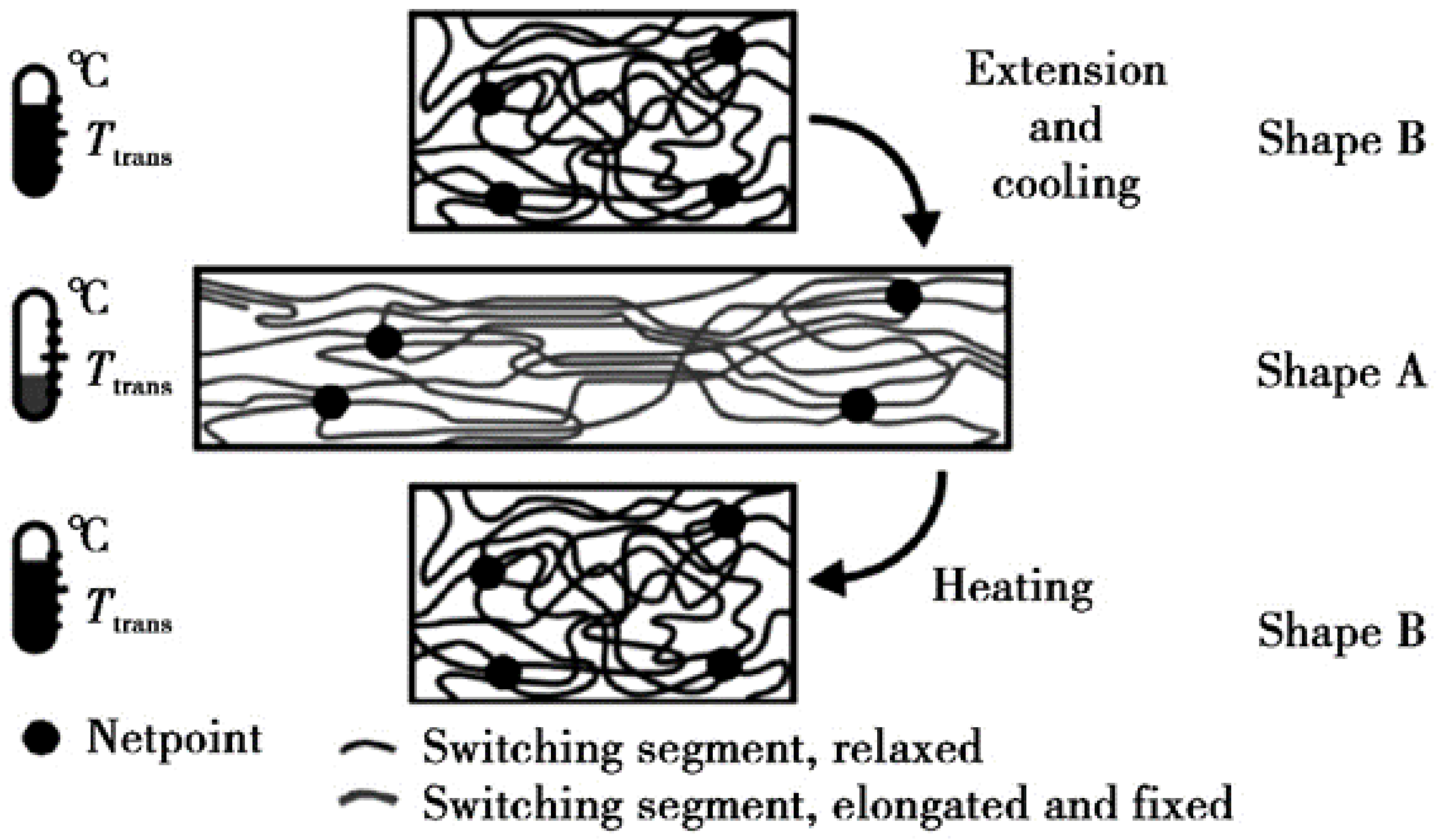

| Shape memory polymer (SMP) | Smart plugging working fluids based on SMP are automatically activated by temperature stimulation and produce deformation changes when they enter formations | (Zhao et al., 2015) (Lendlein and Kelch., 2010) [42,43] | |

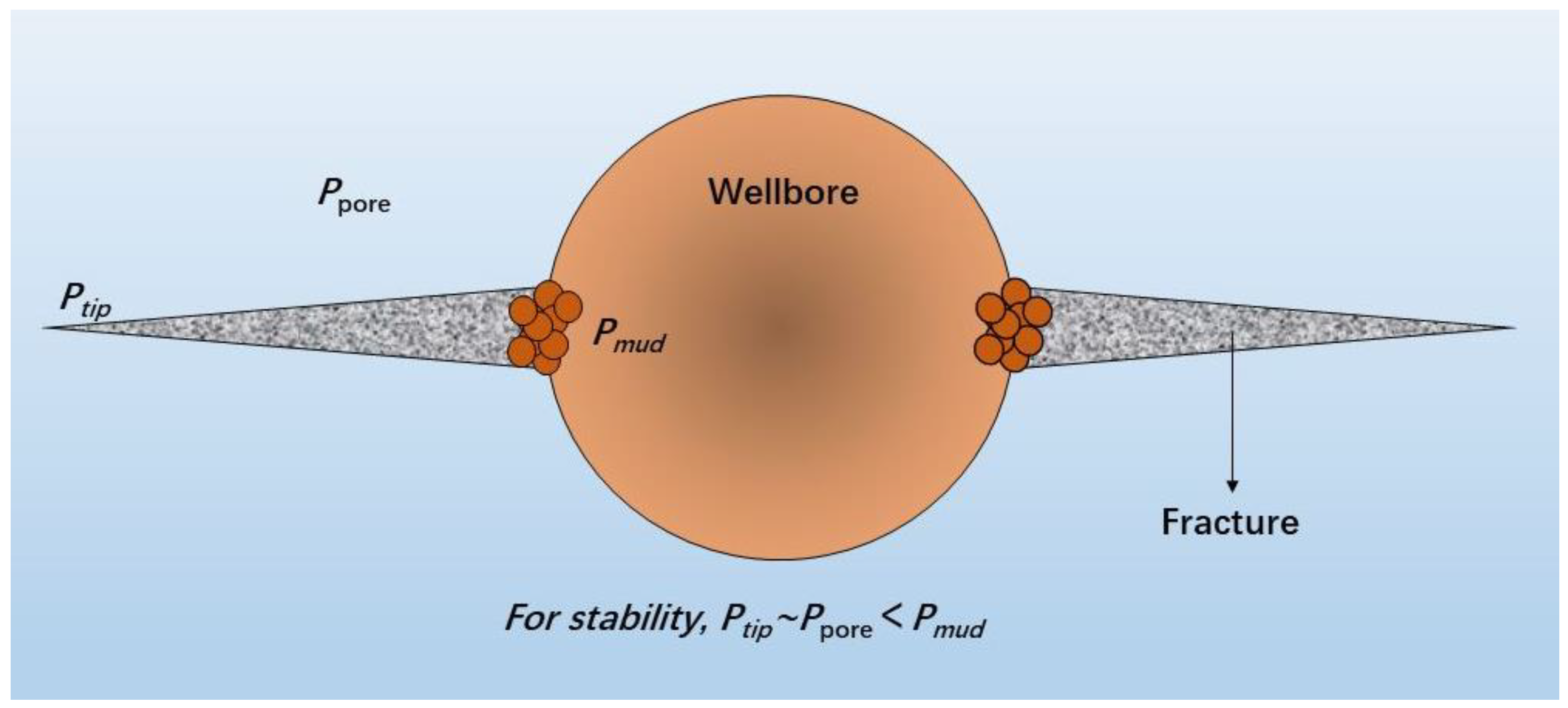

| Lost circulation material (LCM) | The LCM is activated by the temperature of the bottom hole and can successfully seal the fracture’s mouth | (Mansour et al., 2017) [44] |

| Classification | Functional Materials | Function Characteristics | References |

|---|---|---|---|

| Self-healing cementing material | The composite swelling mineral PC90M5B5 | PC90M5B5 can improve the strength recovery rate, plugging efficiency, and self-healing effect of cement | (Qureshi et al., 2018) [8] |

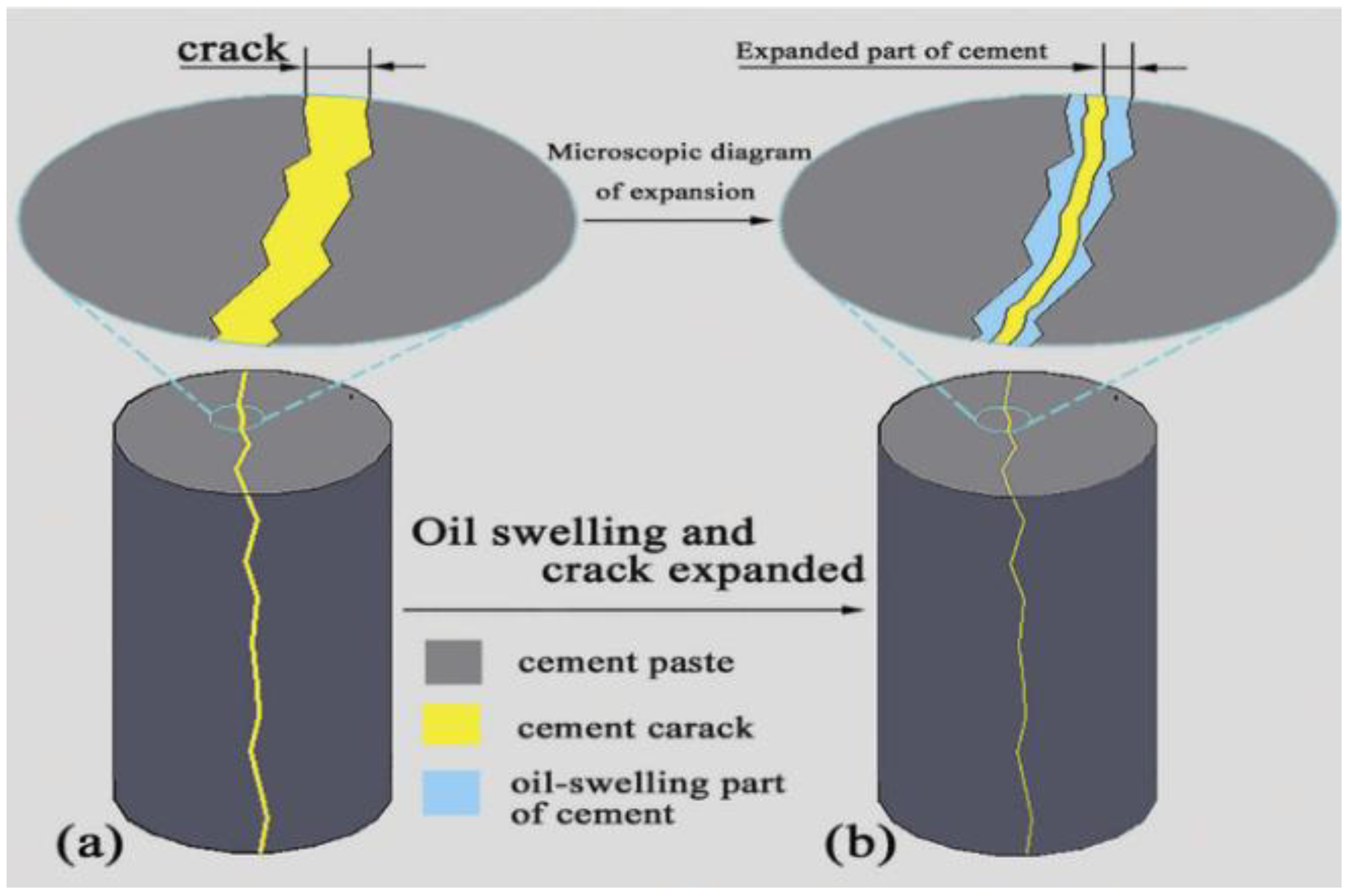

| A new additive oil swelling material (OSM) | Due to the oil-absorbing swelling of OSM, the self-healing cement paste expands and gradually occupies the space of the fracture | (Zhang et al., 2018) [50] | |

| Nanoparticle cementing material | Nano-SiO2 | Nano-SiO2 has a higher surface activity that significantly improves the stability of cement paste, including its compressive, splitting, tensile, and flexural strengths, as well as microstructural density, particularly enhancing the early strength of cement stone | (Sadrmomtazi et al., 2009) (Valipour et al., 2011) (Land and Stephan, 2012) [55,56,57] |

| Classification | Functional Materials | Function Characteristics | References |

|---|---|---|---|

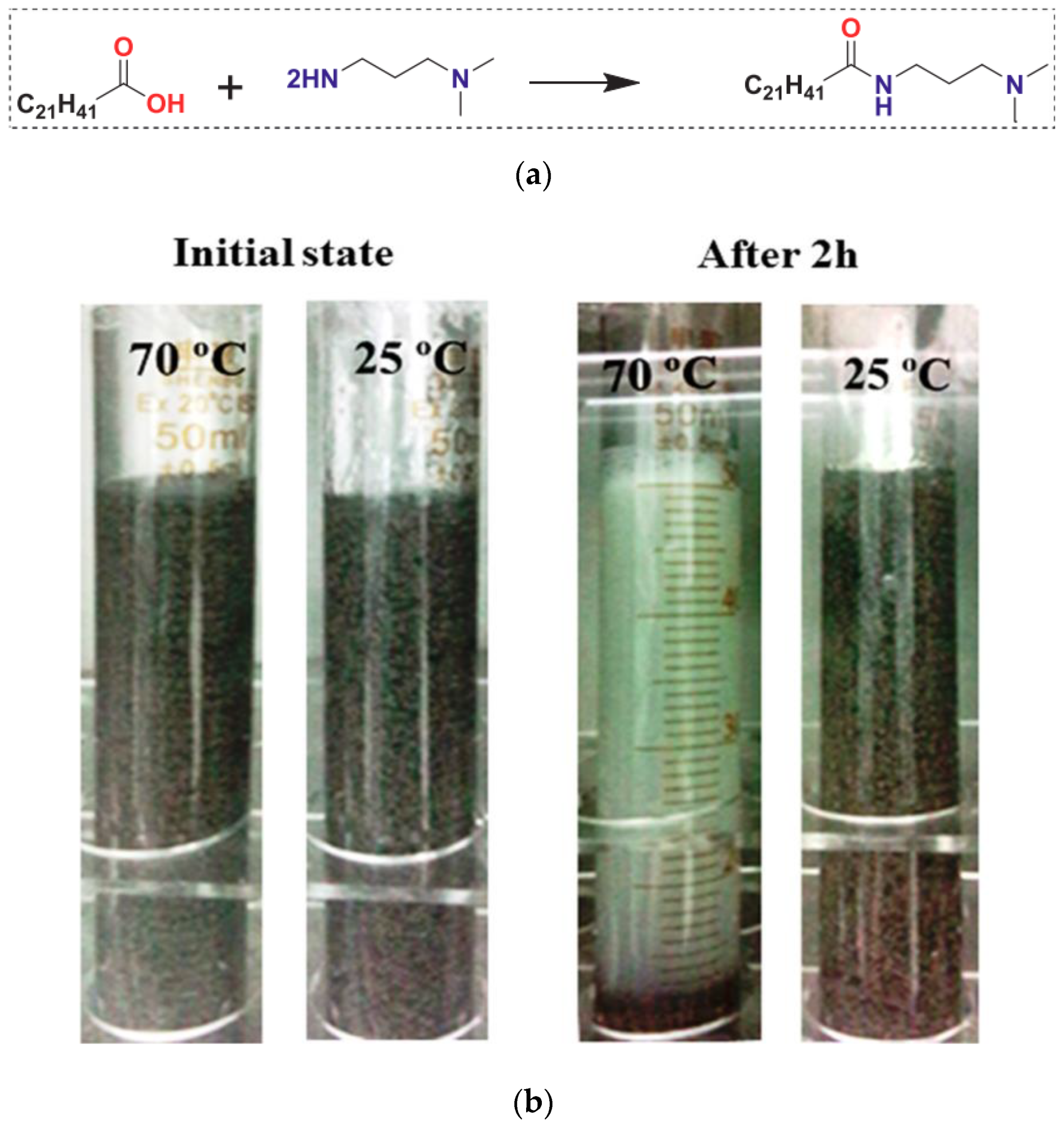

| Clean hydraulic fracturing fluids | A CO2-responsive surfactant isopropyl dimethylamine (EA) | EA was used as a thickener to develop a new viscoelastic surfactant-based fracturing fluid. The viscoelastic properties of this CO2-responsive VES fracturing fluid were excellent. | (Wu et al., 2018) [58] |

| A supercritical CO2-clean foam fracturing fluid | This system can be extended to water-sensitive formations, preventing potential hydro-locking and preventing CO2 from affecting the internal structure of the micelles and altering the viscoelasticity of the fluids. | (Chen et al., 2005) [59] | |

| Nanoscale hydraulic fracturing fluids | MgO and ZnO nanoparticles | The MgO and ZnO nanoparticles improved the thermal stability and the temperature resistance of the VES and exhibited higher viscosity yield. | (Gurluk et al., 2013) [63] |

| Nano-SiO2 | SiO2 nanoparticles increase the apparent viscosity and viscoelasticity of the solution, forming a three-dimensional network structure of the system. | (Fakoya and Shah, 2013) (Liu et al., 2020) [64,65] | |

| High-temperature-resistant hydraulic fracturing fluids | A temperature-resistant thickener | This thickener significantly improves the viscosity and temperature resistance of the fracturing fluid, up to 232 °C. | (Funkhouser et al., 2010) [68] |

| A new high-temperature fracturing fluid stabilizer (phenothiazine) | Phenothiazine was applied as a temperature stabilizer compounded with sodium thiosulfate in a specific polymer fracturing fluid system that could withstand formation temperatures of up to 260 °C. | (Carman and Gupta, 2014) [71] |

| Classification | Functional Materials | Function Characteristics | References |

|---|---|---|---|

| Nanoparticle polymer displacement agents | A composite oil displacement SiO2 NP/HPAM containing nanoparticles | The amine-functionalized SiO2 NPs significantly improved the temperature and salt resistance of the HPAM. The incorporation of amphiphilic SiO2 NPs could solve the contradiction between viscosity enhancement and the injection of polyacrylamide-based polymers. | (Cao et al., 2019) [81] |

| Nanoparticle surfactant displacement agents | Nano-SiO2 | Nanoparticles make the interfacial distribution more uniform, reducing the oil–water interfacial tension more significantly. The change in the wettability of SiO2 nanoparticles can increase the recovery rate by about 8%. | (Li et al., 2021) [84] |

| Silane-coated silica nanoparticles | The silane-coated silica nanofluids could influence the change in wettability to a more water-wet state. In addition, the oil displacement performance was significantly improved. | (Abhishek et al., 2015) [86] |

| Classification | Functional Materials | Function Characteristics | References |

|---|---|---|---|

| Smart gel agents | A near-infrared (NIR) light-responsive poly(N-isopropyl acrylamide)/graphene oxide (PNIPAM-GO) nanocomposite hydrogel | The hydrogen bonding interactions between the GO nanosheets and PNIPAM chains enhanced the degree of freedom of sliding of the polymer chains in the smart gels. The chemical crosslinking effect also ensured that the smart gel had a stable network structure. | (Shi et al., 2015) [95] |

| Polymer microsphere agents | A temperature-responsive crosslinking polymer microsphere (c-PMAD) | Microspheres have high thermal stability. At 66.5 °C, the microspheres exhibit upper critical solution temperature transition (UCST) behavior. The particle size of c-PMAD decreases with the increase in temperature. | (Du et al., 2020) [98] |

| The double crosslinking gel PAM-FA-BGPP (PAFB) | PAFB can be decomposed to form a polymer aqueous lubricant with appropriate viscosity. This reduces the frictional resistance of the polymer microspheres to the microminiature pore throats during their deep migration in the formation. | (Bai et al., 2020) [100] | |

| A smart polymer gel microsphere regulator (P(AA-AM C18DMAAC)@SiO2) | This gel exhibited the property of slowly absorbing water at low temperatures and rapidly absorbing water at high temperatures. | (Zhang et al., 2019) [102] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, K.; Bai, Y.; Ma, J.; Sun, J.; Liu, Y.; Lang, Y. Functional Gels and Chemicals Used in Oil and Gas Drilling Engineering: A Status and Prospective. Gels 2024, 10, 47. https://doi.org/10.3390/gels10010047

Yang K, Bai Y, Ma J, Sun J, Liu Y, Lang Y. Functional Gels and Chemicals Used in Oil and Gas Drilling Engineering: A Status and Prospective. Gels. 2024; 10(1):47. https://doi.org/10.3390/gels10010047

Chicago/Turabian StyleYang, Keqing, Yingrui Bai, Jiayun Ma, Jinsheng Sun, Yuan Liu, and Youming Lang. 2024. "Functional Gels and Chemicals Used in Oil and Gas Drilling Engineering: A Status and Prospective" Gels 10, no. 1: 47. https://doi.org/10.3390/gels10010047

APA StyleYang, K., Bai, Y., Ma, J., Sun, J., Liu, Y., & Lang, Y. (2024). Functional Gels and Chemicals Used in Oil and Gas Drilling Engineering: A Status and Prospective. Gels, 10(1), 47. https://doi.org/10.3390/gels10010047