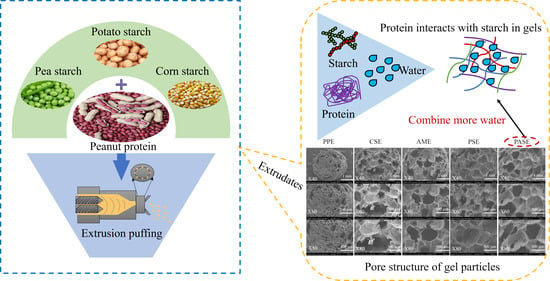

Effect of Starch Types on the Textural and Rehydration Properties of Extruded Peanut Protein Pore Gel Particles

Abstract

1. Introduction

2. Results and Discussion

2.1. Thermal Properties of Starch

2.2. Expansion Property Analysis

2.3. Color and Textural Property Analysis

2.4. Rehydration Properties of Extrudates

2.5. Macro and Micro Structures

2.6. Protein Secondary Structures

2.7. Rheological Properties of Extrudates

3. Conclusions

4. Materials and Methods

4.1. Materials

4.2. Extrusion Puffing

4.3. Expansion Properties of Extrudates

4.3.1. Expansion Ratio (ER)

4.3.2. Density

4.4. Textural Properties of Extrudates

4.4.1. Surface Color Analysis

4.4.2. Hardness and Brittleness

4.5. Water Absorption Index (WAI) and Water Solubility Index (WSI)

4.6. Analysis of Structure

4.7. Fourier-Transform Infrared Spectroscopy (FTIR)

4.8. Rheological Properties

4.9. Statistical Analysis

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- He, X.H.; Liu, H.Z.; Liu, L.; Zhao, G.L.; Wang, Q.; Chen, Q.L. Effects of high pressure on the physicochemical and functional properties of peanut protein isolates. Food Hydrocoll. 2014, 36, 123–129. [Google Scholar] [CrossRef]

- Wild, F.; Czerny, M.; Janssen, A.M.; Kole, A.P.W.; Zunabovic, M.; Domig, K.J. The evolution of a plant-based alternative to meat from niche markets to widely accepted meat alternatives. Agro Food Ind. Hi-Tech 2014, 25, 45–49. [Google Scholar]

- Seth, K.; Kochhar, A. Formulation and nutritional evaluation of baked products supplemented with partially defatted peanut flour. Nutr. Food Sci. 2017, 47, 808–816. [Google Scholar] [CrossRef]

- Phongthai, S.; Singsaeng, N.; Nhoo-ied, R.; Suwannatrai, T.; Schonlechner, R.; Unban, K.; Klunklin, W.; Laokuldilok, T.; Phimolsiripol, Y.; Rawdkuen, S. Properties of Peanut (KAC431) Protein Hydrolysates and Their Impact on the Quality of Gluten-Free Rice Bread. Foods 2020, 9, 942. [Google Scholar] [CrossRef] [PubMed]

- Luo, S.W.; Koksel, F. Application of physical blowing agents in extrusion cooking of protein enriched snacks: Effects on product expansion, microstructure, and texture. Trends Food Sci. Technol. 2023, 133, 49–64. [Google Scholar] [CrossRef]

- Song, J.X.; Shao, Y.; Chen, X.X.; Li, X.H. Release of characteristic phenolics of quinoa based on extrusion technique. Food Chem. 2022, 374, 128780. [Google Scholar] [CrossRef]

- Alam, S.A.; Jarvinen, J.; Kokkonen, H.; Jurvelin, J.; Poutanen, K.; Sozer, N. Factors affecting structural properties and invitro starch digestibility of extruded starchy foams containing bran. J. Cereal Sci. 2016, 71, 190–197. [Google Scholar] [CrossRef]

- Lyu, J.S.; Lee, J.-S.; Chae, T.Y.; Yoon, C.S.; Han, J. Effect of screw speed and die temperature on physicochemical, textural, and morphological properties of soy protein isolate-based textured vegetable protein produced via a low-moisture extrusion. Food Sci. Biotechnol. 2022, 32, 659–669. [Google Scholar] [CrossRef] [PubMed]

- Beck, S.M.; Knoerzer, K.; Foerster, M.; Mayo, S.; Philipp, C.; Arcot, J. Low moisture extrusion of pea protein and pea fibre fortified rice starch blends. J. Food Eng. 2018, 231, 61–71. [Google Scholar] [CrossRef]

- Philipp, C.; Oey, I.; Silcock, P.; Beck, S.M.; Buckow, R. Impact of protein content on physical and microstructural properties of extruded rice starch-pea protein snacks. J. Food Eng. 2017, 212, 156–173. [Google Scholar] [CrossRef]

- Kristiawan, M.; Micard, V.; Maladira, P.; Alchamieh, C.; Maigret, J.E.; Réguerre, A.L.; Emin, M.A.; Della Valle, G. Multi-scale structural changes of starch and proteins during pea flour extrusion. Food Res. Int. 2018, 108, 203–215. [Google Scholar] [CrossRef] [PubMed]

- Arora, B.; Rizvi, S.S.H. In-mouth, self-disintegrating milk protein puffs-I. Process development. J. Food Process Eng. 2022, 45, 11. [Google Scholar] [CrossRef]

- Yu, X.; Wang, L.; Zhang, J.; Wang, Z.; Wang, K.; Duan, Y.; Xiao, Z.; Wang, P. Understanding effects of glutelin on physicochemical and structural properties of extruded starch and the underlying mechanism. Carbohydr. Polym. 2022, 304, 120513. [Google Scholar] [CrossRef] [PubMed]

- Zambrano, Y.; Contardo, I.; Moreno, M.C.; Bouchon, P. Effect of Extrusion Temperature and Feed Moisture Content on the Microstructural Properties of Rice-Flour Pellets and Their Impact on the Expanded Product. Foods 2022, 11, 198. [Google Scholar] [CrossRef] [PubMed]

- Kowalski, R.J.; Morrow, C.D.; McDonald, A.G.; Ganjyal, G.M. A new technique for cross-sectional density profiling of extruded foods by X-ray scanning. Food Struct. 2016, 8, 1–7. [Google Scholar] [CrossRef]

- Wang, S.Y.; Kowalski, R.J.; Kang, Y.F.; Kiszonas, A.M.; Zhu, M.J.; Ganjyal, G.M. Impacts of the Particle Sizes and Levels of Inclusions of Cherry Pomace on the Physical and Structural Properties of Direct Expanded Corn Starch. Food Bioprocess Technol. 2017, 10, 394–406. [Google Scholar] [CrossRef]

- Kumar, R.; Xavier, K.A.M.; Lekshmi, M.; Balange, A.; Gudipati, V. Fortification of extruded snacks with chitosan: Effects on techno functional and sensory quality. Carbohydr. Polym. 2018, 194, 267–673. [Google Scholar] [CrossRef]

- Beech, D.; Beech, J.; Gould, J.; Hill, S. Effect of amylose/amylopectin ratio and extent of processing on the physical properties of expanded maize starches. Int. J. Food Sci. Technol. 2022, 57, 2298–2309. [Google Scholar] [CrossRef]

- Geetha, R.; Mishra, H.N.; Srivastav, P.P. Twin screw extrusion of kodo millet-chickpea blend: Process parameter optimization, physico-chemical and functional properties. J. Food Sci. Technol. 2014, 51, 3144–3153. [Google Scholar] [CrossRef]

- Amaya-Llano, S.L.; Hernández, N.M.; Tostado, E.C.; Martínez-Bustos, F. Functional characteristics of extruded blends of whey protein concentrate and corn starch. Cereal Chem. 2007, 84, 195–201. [Google Scholar] [CrossRef]

- Zhang, Y.L.; Shao, F.; Wan, X.; Zhang, H.H.; Cai, M.H.; Hu, K.; Duan, Y.Q. Effects of rapeseed protein addition on soybean protein-based textured protein produced by low-moisture extrusion: Changes in physicochemical attributes, structural properties and barrel flow behaviors. Food Hydrocoll. 2024, 149, 109631. [Google Scholar] [CrossRef]

- Yağci, S.; Göğüs, F. Development of extruded snack from food by-products: A response surface analysis. J. Food Process Eng. 2009, 32, 565–586. [Google Scholar] [CrossRef]

- Xu, M.J.; Zhang, X.R.; Zhang, Y.Y.; Wang, J.R.; Li, J.Y.; Hu, Y.Y.; Cao, S.; Luan, G.Z. Effect of screw speed, temperature and moisture on physicochemical properties of corn gluten meal extrudate. J. Sci. Food Agric. 2023, 103, 5782–5790. [Google Scholar] [CrossRef]

- Li, X.; Guillermic, R.M.; Nadimi, M.; Paliwal, J.; Koksel, F. Physical and microstructural quality of extruded snacks made from blends of barley and green lentil flours. Cereal Chem. 2022, 99, 1112–1123. [Google Scholar] [CrossRef]

- Li, M.F.; Liu, C.; Hong, J.; Zheng, X.L.; Lu, Y.J.; Bian, K. Influence of wheat starch on rheological, structural and physico-chemical properties gluten-starch dough during mixing. Int. J. Food Sci. Technol. 2022, 57, 2069–2079. [Google Scholar] [CrossRef]

- Leonard, W.; Zhang, P.Z.; Ying, D.Y.; Fang, Z.X. Application of extrusion technology in plant food processing byproducts: An overview. Compr. Rev. Food Sci. Food Saf. 2020, 19, 218–246. [Google Scholar] [CrossRef] [PubMed]

- Shen, H.S.; Yan, M.T.; Liu, X.Y.; Ge, X.Z.; Zeng, J.; Gao, H.Y.; Zhang, G.Q.; Li, W.H. Wheat starch particle size distribution regulates the dynamic transition behavior of gluten at different stages of dough mixing. Int. J. Biol. Macromol. 2023, 24, 125371. [Google Scholar] [CrossRef]

- Han, W.; Ma, S.; Li, L.; Zheng, X.L.; Wang, X.X. Gluten aggregation behavior in gluten and gluten-starch doughs after wheat bran dietary fiber addition. LWT-Food Sci. Technol. 2019, 106, 1–6. [Google Scholar] [CrossRef]

- Orisaleye, J.I.; Adefuye, O.A.; Ogundare, A.A.; Fadipe, O.L. Parametric analysis and design screw extruder for slightly non-Newtonian (pseudoplastic) materials. Eng. Sci. Technol. Int. J. 2018, 21, 229–237. [Google Scholar] [CrossRef]

- Liu, Q.; Wang, Y.H.; Yang, Y.Y.; Yu, X.P.; Xu, L.L.; Jiao, A.Q.; Jin, Z.Y. Structure, physicochemical properties and in vitro digestibility of extruded starch-lauric acid complexes with different amylose contents. Food Hydrocoll. 2023, 136, 108239. [Google Scholar] [CrossRef]

- Dobosz, A.; Sikora, M.; Krystyjan, M.; Lach, R.; Borczak, B. Influence of xanthan gum on the short- and long-term retrogradation of potato starches of various amylose content. Food Hydrocoll. 2020, 102, 105618. [Google Scholar] [CrossRef]

- Qiao, D.; Huang, Y.; Zhao, G.; Zhang, Y.; Hou, X.; Zhang, B.; Jiang, F. Small and large oscillatory shear behaviors of gelatin/starch system regulated by amylose/amylopectin ratio. Food Hydrocoll. 2023, 142, 108780. [Google Scholar] [CrossRef]

- Chen, Q.L.; Zhang, J.C.; Zhang, Y.J.; Kaplan, D.L.; Wang, Q. Protein-amylose/amylopectin molecular interactions during high-moisture extruded texturization toward plant-based meat substitutes applications. Food Hydrocoll. 2022, 127, 107559. [Google Scholar] [CrossRef]

- Hu, A.; Li, T.; Zhou, H.; Guo, F.; Wang, Q.; Zhang, J. Water binding ability changes of different proteins during high-moisture extrusion. Food Hydrocoll. 2024, 152, 109935. [Google Scholar] [CrossRef]

- Martin, A.; Osen, R.; Karbstein, H.P.; Emin, M.A. Linking Expansion Behaviour of Extruded Potato Starch/Rapeseed Press Cake Blends to Rheological and Technofunctional Properties. Polymers 2021, 13, 215. [Google Scholar] [CrossRef]

- Chen, Q.L.; Zhang, J.C.; Zhang, Y.J.; Meng, S.; Wang, Q. Rheological properties of pea protein isolate-amylose/amylopectin mixtures and the application in the high-moisture extruded meat substitutes. Food Hydrocoll. 2021, 117, 106732. [Google Scholar] [CrossRef]

| Starch Types | T0 (°C) | TP (°C) | ΔH (J/g) | ΔT1/2 (°C) |

|---|---|---|---|---|

| AM | 68.02 ± 0.31 a | 73.68 ± 0.28 a | 14.19 ± 1.07 a | 4.80 ± 4.66 b |

| PS | 66.27 ± 0.01 b | 70.87 ± 0.04 c | 12.00 ± 0.09 b | 0.58 ± 0.44 c |

| PAS | 61.89 ± 0.44 c | 68.18 ± 0.45 d | 7.31 ± 0.10 c | 0.14 ± 0.16 c |

| CS | 67.00 ± 0.63 ab | 72.13 ± 0.71 b | 10.44 ± 0.33 b | 6.66 ± 0.09 a |

| Color | PPE | CSE | AME | PSE | PASE |

|---|---|---|---|---|---|

| L | 57.04 ± 1.73 b | 66.70 ± 0.58 ab | 65.16 ± 0.18 b | 66.38 ± 0.49 ab | 67.69 ± 0.96 a |

| a | 1.93 ± 0.11 a | 0.40 ± 0.12 c | 1.08 ± 0.31 b | 0.72 ± 0.33 bc | 0.53 ± 0.18 c |

| b | 9.99 ± 0.57 b | 10.81 ± 0.27 ab | 11.89 ± 1.16 a | 11.13 ± 0.62 ab | 10.75 ± 0.90 ab |

| ΔE | 33.79 ± 1.53 a | 24.73 ± 0.63 c | 26.61 ± 0.61 b | 25.16 ± 0.68 bc | 23.81 ± 0.55 c |

| Appearances |  |  |  |  |  |

| Types | β-Sheet | Random Coil | α-Helix | β-Turn |

|---|---|---|---|---|

| PP | 37.82 ± 1.82 a | 25.51 ± 0.86 a | 22.98 ± 0.67 b | 13.29 ± 0.28 b |

| PASE | 28.24 ± 0.20 b | 19.84 ± 2.26 a | 24.51 ± 1.03 b | 22.03 ± 3.30 a |

| PSE | 26.30 ± 0.41 b | 25.43 ± 0.88 a | 24.10 ± 0.71 b | 16.24 ± 0.49 b |

| AME | 27.61 ± 3.68 b | 14.52 ± 1.74 a | 39.39 ± 2.52 a | 15.19 ± 0.20 b |

| CSE | 27.54 ± 1.51 b | 21.09 ± 10.56 a | 26.05 ± 2.36 b | 15.87 ± 2.59 b |

| PPE | 32.45 ± 3.95 a | 14.75 ± 1.24 a | 26.37 ± 1.26 b | 24.21 ± 1.58 a |

| Extrudates | K (Pa·sn) | n | R2 |

|---|---|---|---|

| PPE | 373.4 ± 39.00 b | 0.23 ± 0.02 b | 0.99 |

| CSE | 292.47 ± 1.12 c | 0.31 ± 0.00 a | 0.98 |

| AME | 207.64 ± 6.75 d | 0.35 ± 0.00 a | 0.97 |

| PAE | 230.26 ± 1.06 d | 0.34 ± 0.00 a | 0.98 |

| PASE | 466.19 ± 28.16 a | 0.26 ± 0.03 b | 0.98 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, F.; Hu, A.; Zhou, H.; Hu, H.; Li, T.; Wang, Q.; Zhang, J. Effect of Starch Types on the Textural and Rehydration Properties of Extruded Peanut Protein Pore Gel Particles. Gels 2024, 10, 250. https://doi.org/10.3390/gels10040250

Guo F, Hu A, Zhou H, Hu H, Li T, Wang Q, Zhang J. Effect of Starch Types on the Textural and Rehydration Properties of Extruded Peanut Protein Pore Gel Particles. Gels. 2024; 10(4):250. https://doi.org/10.3390/gels10040250

Chicago/Turabian StyleGuo, Feng, Anna Hu, Huan Zhou, Hui Hu, Tongqing Li, Qiang Wang, and Jinchuang Zhang. 2024. "Effect of Starch Types on the Textural and Rehydration Properties of Extruded Peanut Protein Pore Gel Particles" Gels 10, no. 4: 250. https://doi.org/10.3390/gels10040250

APA StyleGuo, F., Hu, A., Zhou, H., Hu, H., Li, T., Wang, Q., & Zhang, J. (2024). Effect of Starch Types on the Textural and Rehydration Properties of Extruded Peanut Protein Pore Gel Particles. Gels, 10(4), 250. https://doi.org/10.3390/gels10040250