Comparative Analysis of Hydrogel Adsorption/Desorption with and without Surfactants

Abstract

:1. Introduction

2. Results and Discussion

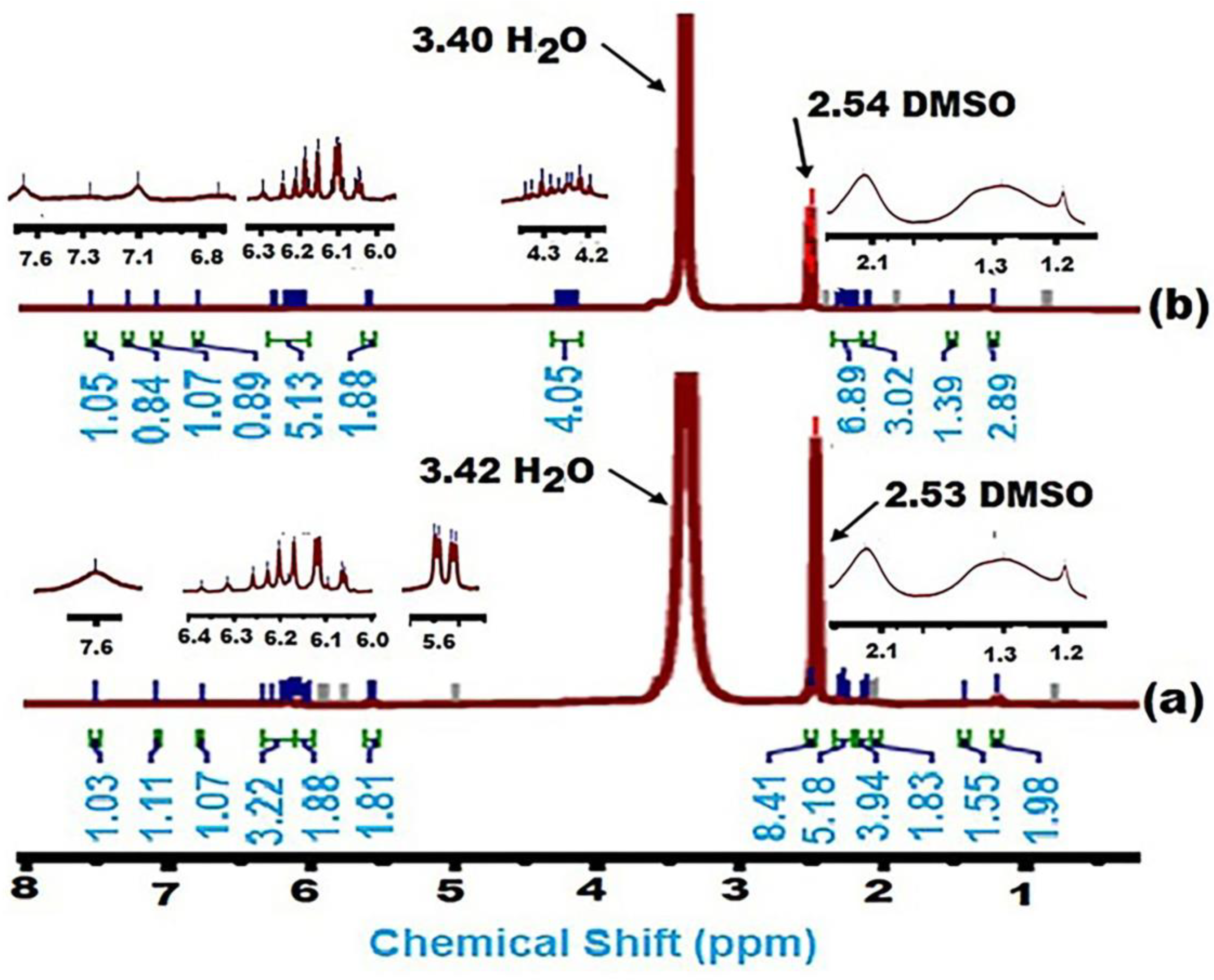

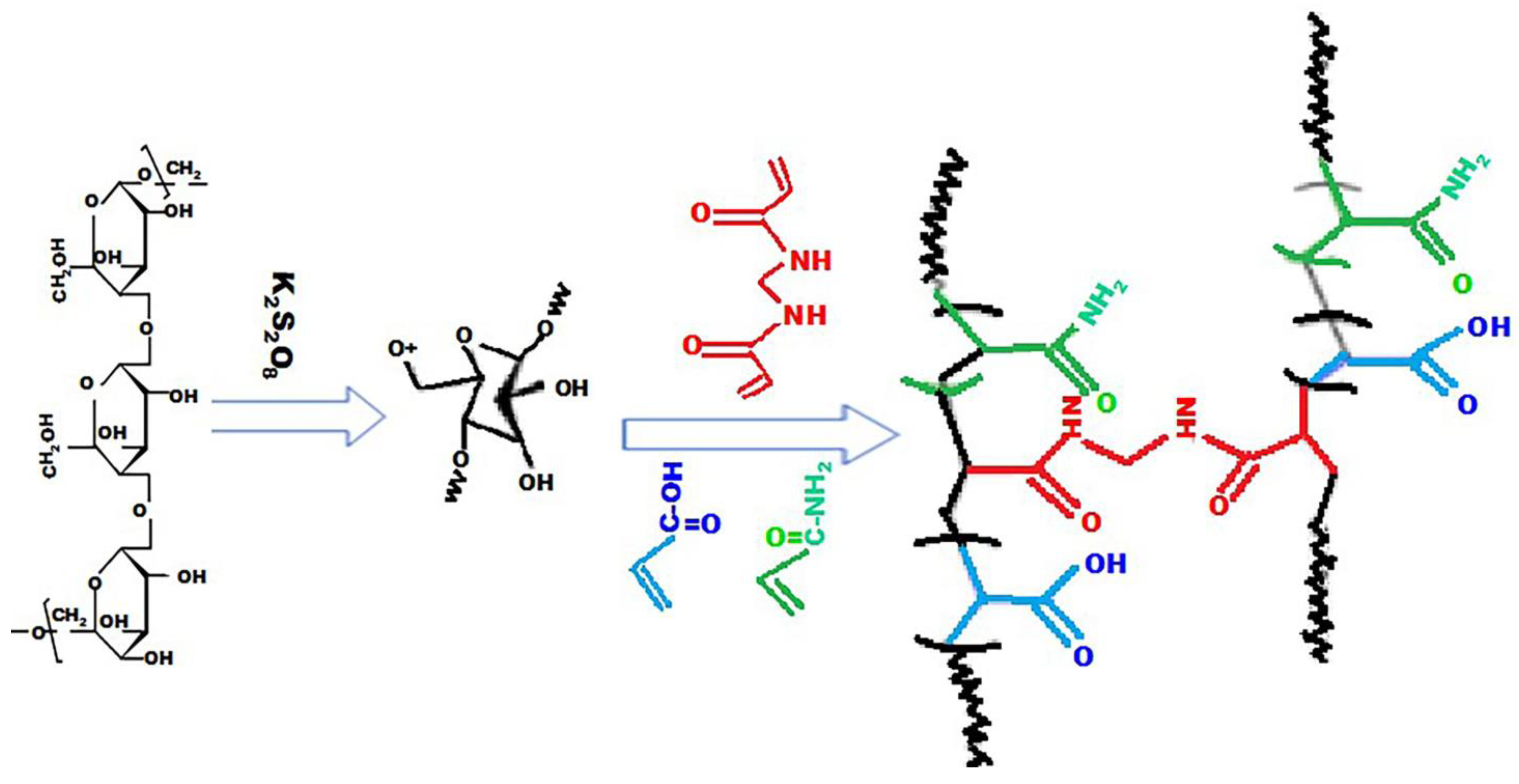

2.1. Chemical Structure Justification

2.2. Adsorption Properties

2.2.1. Adsorption Capacity

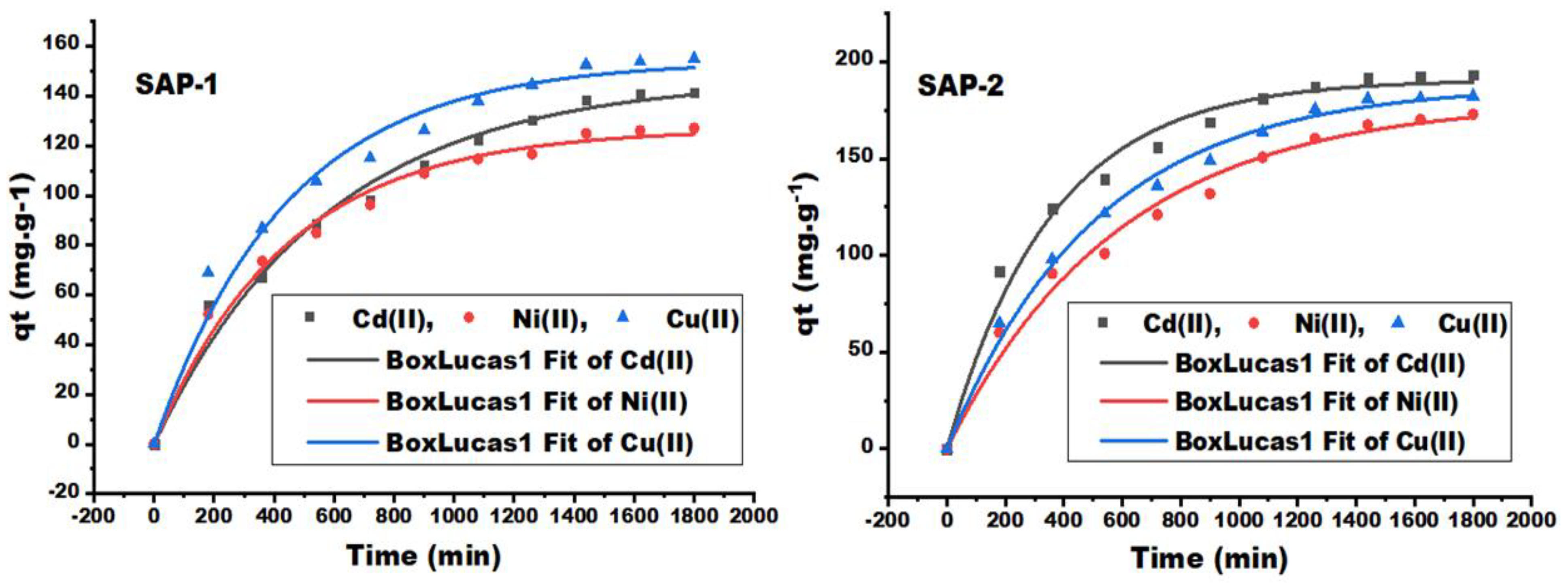

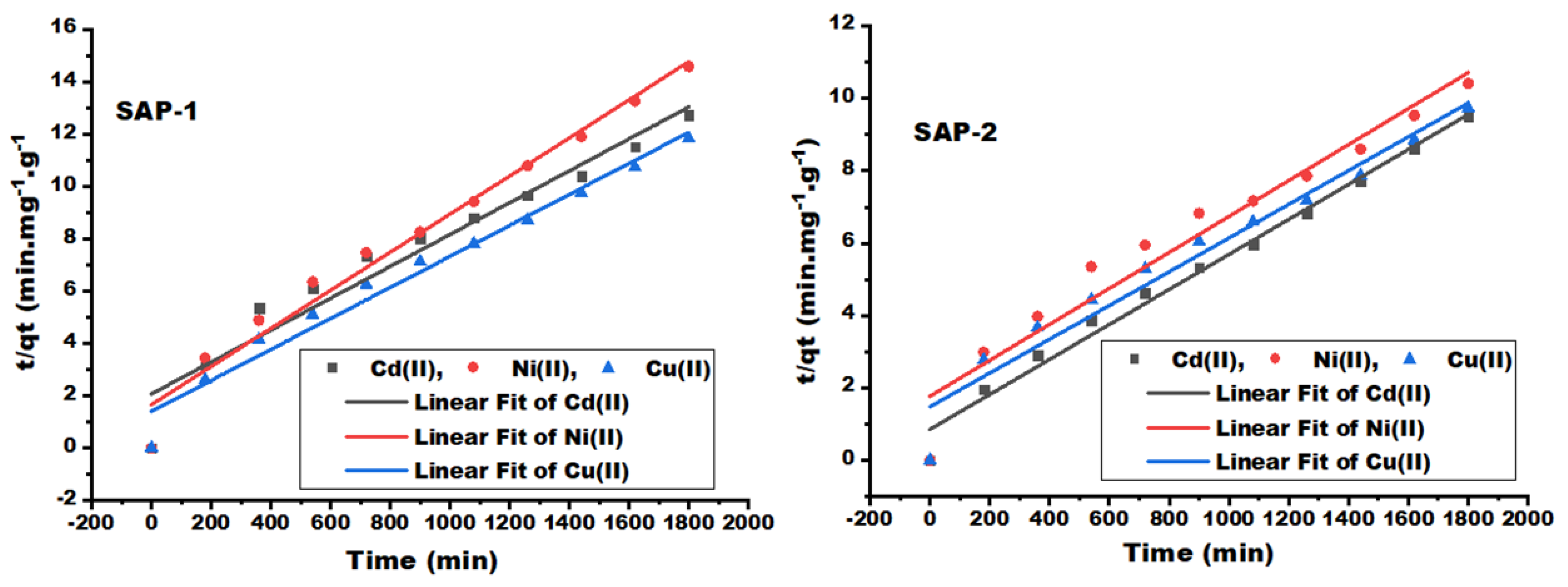

2.2.2. Adsorption Mechanism Models

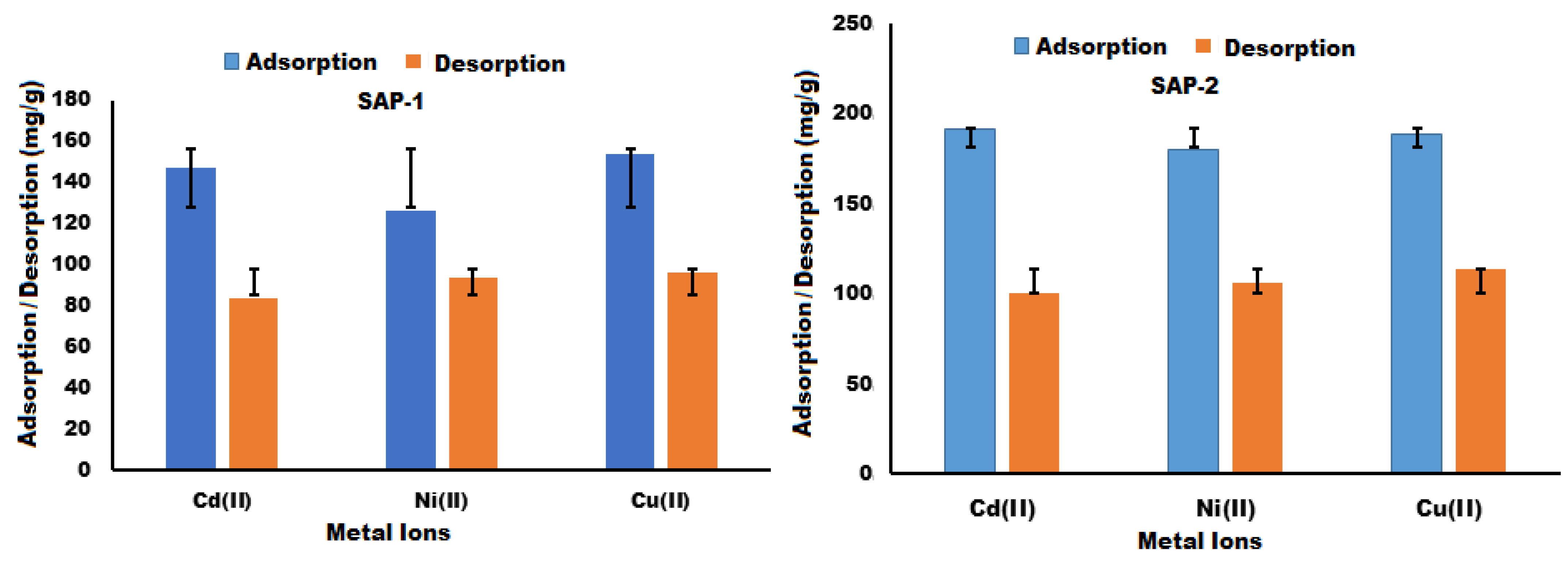

2.3. Adsorption and Desorption Properties

2.3.1. FE-SEM Analysis of Hydrogels

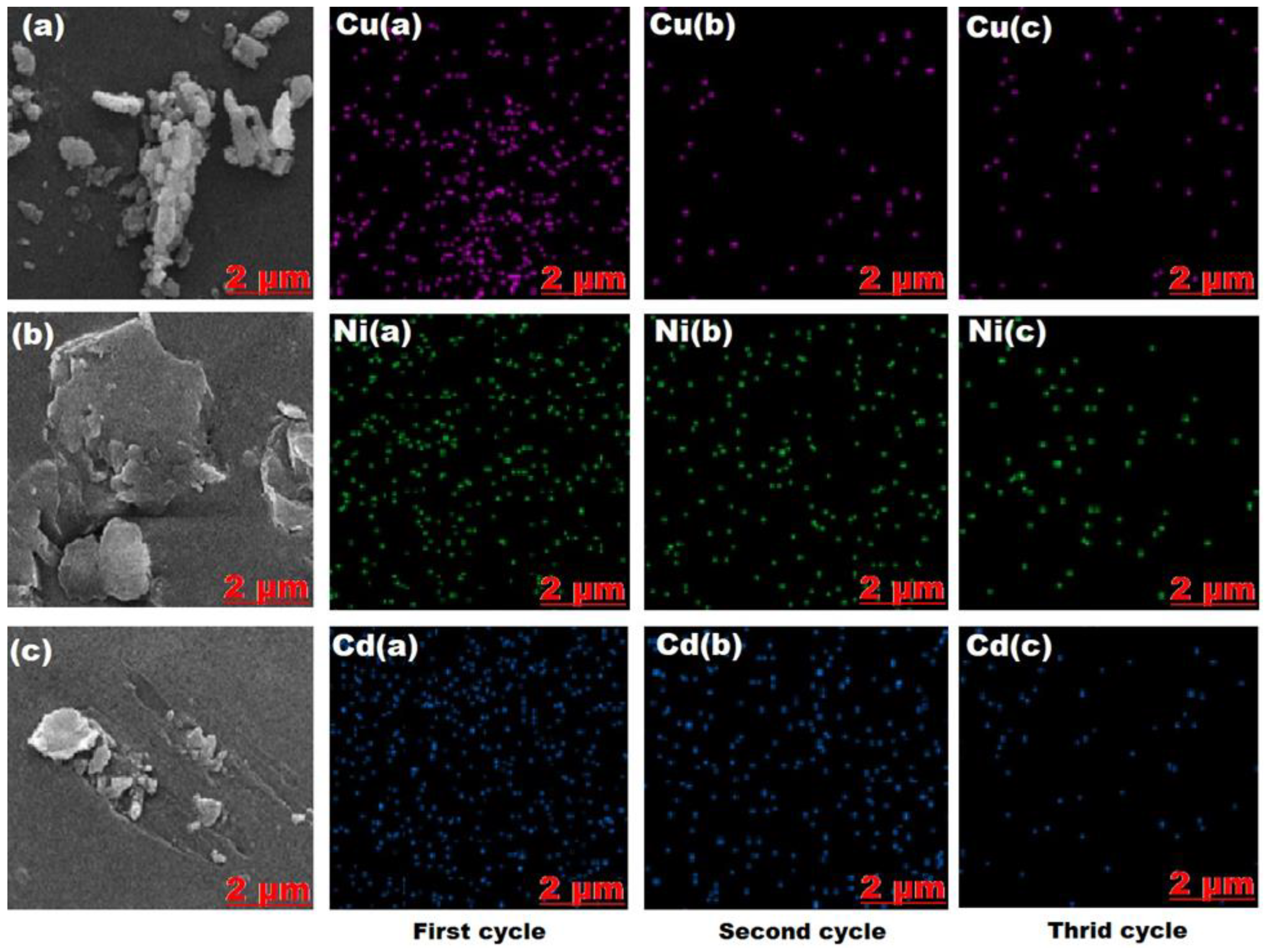

2.3.2. EDS Analysis of Hydrogel after Adsorbing/Desorbing

2.3.3. Adsorption/Desorption Capacity

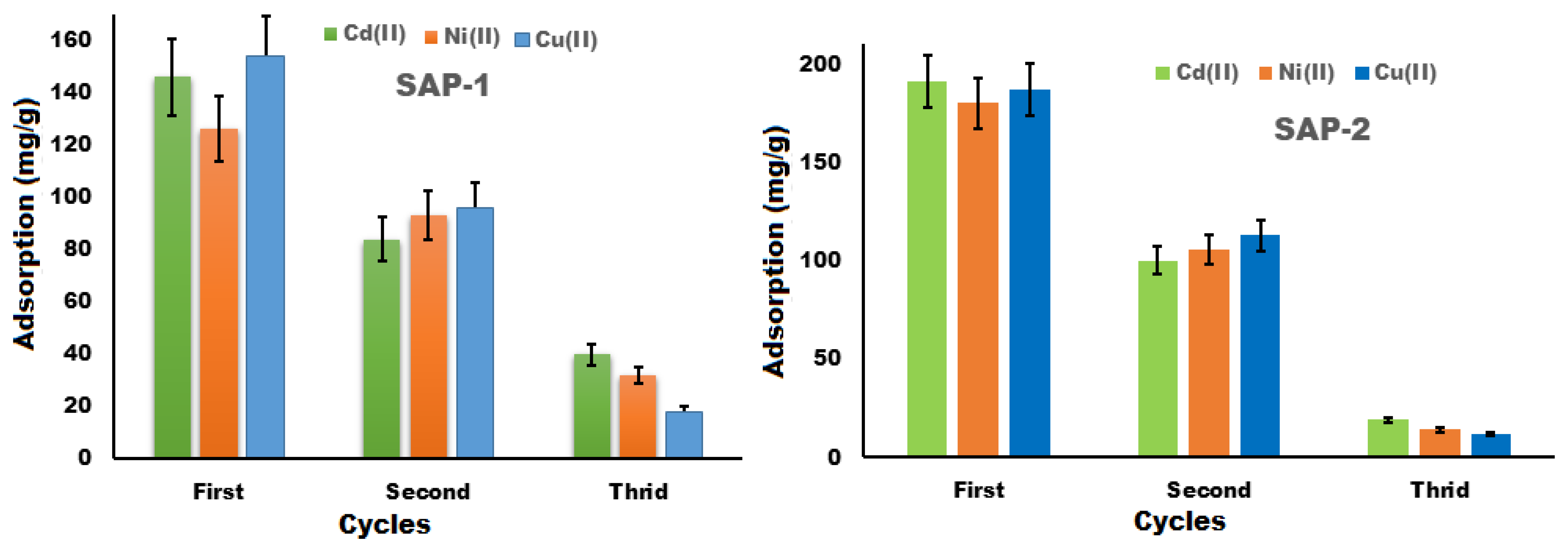

2.3.4. Reusability

3. Conclusions

4. Materials and Methods

4.1. Materials

4.2. Preparation of the Hydrogels

4.3. Characterization Techniques

4.4. Adsorption and Desorption of Metal Ions

4.4.1. Adsorption Experiments

Adsorption Capacity and Removal Efficiency

Kinetics Ions Adsorption

4.4.2. Desorption Experiments

4.4.3. Reusability Experiments

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sinha, V.; Chakma, S. Advances in the preparation of hydrogel for wastewater treatment: A concise review. J. Environ. Chem. Eng. 2019, 7, 103295. [Google Scholar] [CrossRef]

- Sultan, M.; Abdelhakim, A.A.; Nassar, M. Cu2O-mediated assembly of electrodeposition of Au nanoparticles onto 2D metal-organic framework nanosheets for real-time monitoring of hydrogen peroxide released from living cells. Anal. Bioanal. Chem. 2021, 413, 613–624. [Google Scholar] [CrossRef]

- Korde, J.M.; Kandasubramanian, B. Naturally biomimicked smart shape memory hydrogels for biomedical functions. Chem. Eng. J. 2020, 379, 122430. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, H.; Ma, C.; Yin, H.; Gong, L.; Duh, Y.; Feng, R. Durable, cost-effective and superhydrophilic chitosan-alginate hydrogel coated mesh for efficient oil/water separation. Carbohydr. Polym. 2019, 226, 115279. [Google Scholar] [CrossRef] [PubMed]

- Kandry, G.; Aboelmagd, E.I.; Ibrahim, M.M. Cellulosic-based hydrogel from biomass material for removal of metals from waste water. J. Macromol. Sci. Part A Pure Appl. Chem. 2019, 56, 968–981. [Google Scholar] [CrossRef]

- Sugumaran, K.R.; Ponnusami, V. Review on production, downstream processing and characterization of microbial pullulan. Carbohydr. Polym. 2017, 173, 573–591. [Google Scholar] [CrossRef]

- Singh, R.S.; Kaur, N.; Kennedy, J.F. Pullulan production from agro-industrial waste and its applications in food industry: A review. Carbohydr. Polym. 2019, 217, 46–57. [Google Scholar] [CrossRef] [PubMed]

- Abdulkadhim, M.K.; Habeeb, S.A. The possibility of producing uniform nanofibers from blends of natural biopolymers. Mater. Perform. Charact. 2022, 11, 313–323. [Google Scholar] [CrossRef]

- Wan, G.; Cheng, Y.; Song, J.; Chen, Q.; Chen, B.; Liu, Y.; Ji, S.; Chen, H.; Wang, Y. Nucleus-targeting near-infrared nanoparticles based on TAT peptide-conjugated IR780 for photo-chemotherapy of breast cancer. Chem. Eng. J. 2020, 380, 122458. [Google Scholar] [CrossRef]

- Yenchit, S.; Tadokoro, Y.; Iwamori, S. Measuring active oxygen species across a nonwoven fabric using a pullulan-mixed methylene blue thin film and electron spin resonance. IEEJ Trans. Sens. Micromach. 2019, 139, 54–60. [Google Scholar] [CrossRef]

- Tabasum, S.; Noreen, A.; Maqsood, M.F.; Umar, H.; Akram, N.; Nazli, Z.-I.-H.; Chatha, S.A.S. A review on versatile applications of blends and composites of pullulan with natural and synthetic polymers. Int. J. Biol. Macromol. 2018, 120, 603–632. [Google Scholar] [CrossRef] [PubMed]

- Saber-Samandari, S.; Gulcan, H.O.; Saber-Samandari, S.; Gazi, M. Efficient removal of anionic and cationic dyes from an aqueous solution using pullulan-graft-polyacrylamide porous hydrogel. Water Air Soil Pollut. 2014, 225, 2177. [Google Scholar] [CrossRef]

- Singh, R.; Pal, D.; Mathur, A.; Singh, A.; Krishnan, M.A.; Chattopadhyay, S. An efficient pH sensitive hydrogel, with biocompatibility and high reusability for removal of methylene blue dye from aqueous solution. React. Funct. Polym. 2019, 144, 104346. [Google Scholar] [CrossRef]

- Bhadani, B.; Abe, M. Structural diversity, physicochemical properties and application of imidazolium surfactants: Recent advances. Adv. Colloid Interface Sci. 2016, 231, 36–58. [Google Scholar] [CrossRef] [PubMed]

- Siyal, A.A.; Shamsuddin, M.R.; Low, A.; Rabat, N.E. A review on recent developments in the adsorption of surfactants from wastewater. J. Environ. Manag. 2020, 254, 109797. [Google Scholar] [CrossRef] [PubMed]

- Bakshi, M.S.; Kaur, I. Aggregates of cationic surfactants and anionic polyelectrolytes influenced by bulky head group modifications. Colloids Surf. A Physicochem. Eng. Asp. 2003, 224, 185–197. [Google Scholar] [CrossRef]

- Pal, P.; Pal, A. Enhanced Pb2+ removal by anionic surfactant bilayer anchored on chitosan bead surface. J. Mol. Liq. 2017, 248, 713–724. [Google Scholar] [CrossRef]

- Harutyunyan, L.R.; Harutyunyan, R.S.; Gabrielyan, G.A.; Lasareva, E.V. Modification of chitosan and chitosan succinate by surfactants and investigation of their properties. Colloids Surf. A Physicochem. Eng. Asp. 2019, 578, 123622. [Google Scholar] [CrossRef]

- Pal, P.; Pal, A. Surfactant-modified chitosan beads for cadmium ion adsorption. Int. J. Biol. Macromol. 2017, 104, 1548–1555. [Google Scholar] [CrossRef]

- Chatterjee, S.; Lim, S.R.; Woo, S.H. Adsorption of a cationic dye, methylene blue, onto chitosan hydrogel beads generated by anionic surfactant gelation. Environ. Technol. 2011, 32, 1503–1514. [Google Scholar] [CrossRef] [PubMed]

- Kongarapu, R.J.; Nayak, A.K.; Khobragade, M.U.; Pala, A. Surfactant bilayer on chitosan bead surface for enhanced Ni (II) adsorption. Sustain. Mater. Technol. 2018, 18, e00077. [Google Scholar] [CrossRef]

- Vakili, M.; Rafatullah, M.; Ibrahim, M.H.; Abdullah, A.Z.; Salamatinia, B.; Gholami, Z. Chitosan hydrogel beads impregnated with hexadecylamine for improved reactive blue 4 adsorption. Carbohyd. Polym. 2016, 137, 139–146. [Google Scholar] [CrossRef] [PubMed]

- Shaban, S.M.; Aiad, I.; Moustafa, A.H.; Aljoboury, O.H. Some alginates polymeric cationic surfactants; surface study and their evaluation as biocide and corrosion inhibitors. J. Mol. Liq. 2019, 273, 164. [Google Scholar] [CrossRef]

- Das, D.; Pal, A. Adsolubilization phenomenon perceived in chitosan beads leading to a fast and enhanced malachite green removal. Chem. Eng. J. 2016, 290, 371. [Google Scholar] [CrossRef]

- Kumar, V.; Parihar, R.D.; Sharma, A.; Bakshi, P.; Sidhu, G.P.S.; Bali, A.S.; Karaouzas, I.; Bhardwaj, R.; Thukral, A.K.; Gyasi-Agyei, Y.; et al. Global evaluation of heavy metal content in surface water bodies: A meta-analysis using heavy metal pollution indices and multivariate statistical analyses. Chemosphere 2019, 236, 124364. [Google Scholar] [CrossRef] [PubMed]

- Olapido, A.A.; Gazi, M. Nickel removal from aqueous solutions by alginate-based composite beads: Central composite design and artificial neural network modelling. J. Water Process Eng. 2015, 8, e81–e91. [Google Scholar] [CrossRef]

- Zimta, A.-A.; Schitcu, V.; Gurzau, E.; Stavaru, C.; Manda, G.; Szedlacsek, S.; Berindan-Neagoe, I. Biological and molecular modifications induced by cadmium and arsenic during breast and prostate cancer development. Environ. Res. 2019, 178, 108700. [Google Scholar] [CrossRef]

- Li, Y.; Shen, R.; Wu, H.; Yu, L.; Wang, Z.; Wang, D. Liver changes induced by cadmium poisoning distinguished by confocal Raman imaging. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2020, 225, 117483. [Google Scholar] [CrossRef] [PubMed]

- Reyes-Hinojosa, D.; Lozada-Perez, C.A.; Cuevas, Y.Z.; Lopez-Reyes, A.; Martinez-Nava, G.; Fernandez-Torres, J.; Olivos-Meza, A.; Landa-Solis, C.; Guiterrez-Ruiz, M.C.; del Castillo, E.R.; et al. Toxicity of cadmium in musculoskeletal diseases. Environ. Toxicol. Pharmacol. 2019, 72, 103219. [Google Scholar] [CrossRef] [PubMed]

- Araujo, C.V.M.; Pontes, J.R.S.; Blasco, J. Does the previous exposure to copper alter the pattern of avoidance by zebrafish in a copper gradient scenario? Hypothesis of time-delayed avoidance due to pre-acclimation. Sci. Total Environ. 2019, 694, 133703. [Google Scholar] [CrossRef] [PubMed]

- da Costa, J.S.; Bertizzolo, E.G.; Bianchini, D.; Fajardo, A.R. Adsorption of benzene and toluene from aqueous solution using a composite hydrogel of alginate-grafted with mesoporous silica. J. Hazard. Mater. 2021, 418, 126405. [Google Scholar] [CrossRef] [PubMed]

- Ji, Z.; Zhang, H.; Zhang, Y.; Chen, T.; Long, Z.; Li, M.; Pei, Y. Distribution, ecological risk and source identification of heavy metals in sediments from the Baiyangdian Lake, Northern China. Chemosphere 2019, 237, 124425. [Google Scholar] [CrossRef] [PubMed]

- Salimi, A.; Rahimi, H.-R.; Foroontanfar, H.; Jafari, E.; Ameri, A.; Shakibaie, M. Toxicity of microwave-assisted biosynthesized zinc nanoparticles in mice: A preliminary study. Artif. Cells Nanomed. Biotechnol. 2019, 47, 1846–1858. [Google Scholar] [CrossRef] [PubMed]

- Saber-Samandari, S.; Gazi, M. Pullulan based porous semi-IPN hydrogel: Synthesis characterization and its application in the removal of mercury from aqueous solution. J. Taiwan Inst. Chem. Eng. 2015, 51, 143–151. [Google Scholar] [CrossRef]

- Barakat, M.A. New trends in removing heavy metals from industrial wastewater. Arab. J. Chem. 2011, 4, 361–377. [Google Scholar] [CrossRef]

- Efome, J.E.; Rana, D.; Matsuura, T.; Lan, C.Q. Effects of operating parameters and coexisting ions on the efficiency of heavy metal ions removal by nano-fibrous metal-organic framework membrane filtration process. Sci. Total Environ. 2019, 674, 355–362. [Google Scholar] [CrossRef] [PubMed]

- Nemati, M.; Hosseini, S.M.; Shabanian, M. Novel electrodialysis cation exchange membrane prepared y 2-acrylamido-2-methylpropane sulfonic acid; heavy metal ions removal. J. Hazard. Mater. 2017, 337, 90–104. [Google Scholar] [CrossRef] [PubMed]

- Areco, M.M.; Saleh-Medina, L.; Trinello, M.A.; Marco-Brown, J.L.; Alfonso, M.D.S. Adsorption of Cu(II), Zn(II), Cd(II) and Pb(II) by dead Avena fatua biomass and the effect of these metals on their growth. Colloids Surf. B Biointerfaces 2013, 110, 305–312. [Google Scholar] [CrossRef] [PubMed]

- Radi, S.; El Abiad, C.; Moura, N.M.M.; Faustino, M.A.F.; Neves, M.G.P.M.S. New hybrid adsorbent based on porphyrin functionalized silica for heavy metals removal: Synthesis, characterization, isotherms, kinetics and thermodynamics studies. J. Hazard. Mater. 2019, 370, 80–90. [Google Scholar] [CrossRef] [PubMed]

- Ramos-Lara, F.; Ramírez, M.Q.; Flores, M.; Arroyo, R.; Caldiño, U. Optical spectroscopy of Nd3+ ions in poly (acrylic acid). J. Phys. Condens. Matter 2006, 18, 7951. [Google Scholar] [CrossRef]

- Tao, X.; Xie, Y.; Zhang, Q.; Qiu, X.; Yuan, L.; Wen, Y.; Li, M.; Yang, X.; Tao, T.; Xie, M.; et al. Cholesterol-modified amino-pullulan nanoparticles as a drug carrier: Comparative study of cholesterol-modified carboxyethyl pullulan and pullulan nanoparticles. Nanomaterials 2016, 6, 165. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.; Wang, X.; Ji, F.; Wang, Y.B.J.; Wang, X.; Guo, L.; Li, Y. New bifunctional-pullulan-based micelles with good biocompatibility for efficient co-delivery of cancer-suppressing p53 gene and doxorubicin to cancer cells. RSC Adv. 2015, 5, 94719–94731. [Google Scholar] [CrossRef]

- Sonmez, B.; Celikkol, A.N. Pullulan based hydrogels for the removal of various metal ions from aqueous solutions. J. Environ. Chem. Eng. 2021, 9, 106188. [Google Scholar] [CrossRef]

- Chang, H.; Wang, G.; Yang, A.; Tao, X.; Liu, X.; Shen, Y.; Zheng, Z. A transparent, flexible, low-temperature, and solution-processible graphene composite electrode. Adv. Funct. Mater. 2010, 20, 2893–2902. [Google Scholar] [CrossRef]

- Mukwada, L.T.; Mochane, M.J.; Motaung, T.E.; Motloung, S.V.; Koao, L.F. Effect of sodium dodecylbenzene sulphonate modifier and PP-g-MA on the morphology and thermal conductivity of PP/EG composites. Plast. Rubber Compos. 2017, 46, 469–475. [Google Scholar] [CrossRef]

- Tally, M.; Atassi, Y. Synthesis and characterization of pH-sensitive superabsorbent hydrogels based on sodium alginate-g-poly (acrylic acid-co-acrylamide) obtained via an anionic surfactant micelle templating under microwave irradiation. Polym. Bull. 2016, 73, 3183–3208. [Google Scholar] [CrossRef]

- Repo, E.; Warchol, J.K.; Kurniawan, T.A.; Sillanpaa, M.E.T. Adsorption of Co(II) and Ni(II) by EDTA- and/or DTPA-modified chitosan: Kinetic and equilibrium modeling. Chem. Eng. J. 2010, 161, 73–82. [Google Scholar] [CrossRef]

- Kutsevol, N.V.; Zheltonozhskaya, T.B.; Demchenko, O.V.; Kunitskaya, L.R.; Syromyatnikov, V.G. Effect of the structure of poly(vinyl alcohol)-graft-polyacrylamide copolymers on their thermooxidative stability. Polym. Sci. Ser. A 2004, 46, 518–525. [Google Scholar]

- Luo, M.-T.; Li, H.-L.; Huang, C.; Zhang, H.-R.; Xiong, L.; Chen, X.-F.; Chen, X.-D. Cellulose-based absorbent production from bacterial cellulose and acrylic acid: Synthesis and performance. Polymers 2018, 10, 702. [Google Scholar] [CrossRef] [PubMed]

- Bian, Y.; Bian, Z.; Zhang, J.; Ding, A.; Liu, S.; Zheng, L.; Wang, H. Adsorption of cadmium ions from aqueous solutions by activated carbon with oxygen-containing functional groups. Chin. J. Chem. Eng. 2015, 23, 1705–1711. [Google Scholar] [CrossRef]

- Ratnamala, G.H.; Shetty, K.V.; Srinikethan, G. Removal of remazol brilliant blue dye from dyecontaminated water by adsorption using red mud: Equilibrium, kinetic, and thermodynamic studies. Water Air Soil Pollut. 2012, 223, 6187–6199. [Google Scholar] [CrossRef]

- Doshi, B.; Ayati, A.; Tanhaei, B.; Repo, E.; Sillanpää, M. Partially carboxymethylated and partially cross-linked surface of chitosan versus the adsorptive removal of dyes and divalent metal ions. Carbohyd. Polym. 2018, 197, 586. [Google Scholar] [CrossRef] [PubMed]

- Ni, X.; Li, Z.; Wang, Y. Adsorption Characteristics of Anionic Surfactant Sodium Dodecylbenzene Sulfonate on the Surface of Montmorillonite Minerals. Front. Chem. 2018, 6, 390. [Google Scholar] [CrossRef] [PubMed]

- Zeng, L.; Zhou, F.; Hu, R.; Xie, W.; Wang, G.; Yang, C.; Liang, E.; Xu, W.; Van der Bruggen, B. Synthesis of cross-linked carboxyl modified polyvinyl alcohol and its application in selective adsorption separation of Cu(II) from Cd(II) and Ni(II). J. Polym. Environ. 2020, 29, 28–37. [Google Scholar] [CrossRef]

- Lucaci, A.R.; Bulgariu, D.; Popescu, M.-C.; Bulgariu, L. Adsorption of Cu(II) ions on adsorbent materials obtained from marine red algae Callithamnion corymbosum sp. Water 2020, 12, 372. [Google Scholar] [CrossRef]

- Xie, R.; Jin, Y.; Chen, Y.; Jiang, W. The importance of surface functional groups in the adsorption of copper onto walnut shell derived activated carbon. Water Sci. Technol. 2017, 76, 3022–3034. [Google Scholar] [CrossRef] [PubMed]

- Bafrooee, A.A.T.; Panahi, H.A.; Hasani, A.H.; Moniri, E.; Miralinaghi, M. Removal of Hg2+ by carboxyl-terminated hyperbranched poly(amidoamine) dendrimers grafted superparamagnetic nanoparticles as an efficient adsorbent. Environ. Sci. Pollut. Res. 2020, 27, 9547–9567. [Google Scholar] [CrossRef] [PubMed]

- Guo, X.; Li, M.; Liu, A.; Jiang, M.; Niu, X.; Liu, X. Interfacial adhesion of polylactic acid on cellulose surface: A molecular dynamics study. Water 2020, 12, 2105. [Google Scholar] [CrossRef]

- Zhang, L.; Song, F.; Wu, Y.; Cheng, L.; Qian, J.; Wang, S.; Chen, Q.; Li, Y. A novel amino and carboxyl functionalized mesoporous silica as an efficient adsorbent for nickel (II). J. Chem. Eng. Data 2018, 64, 176–188. [Google Scholar] [CrossRef]

- Serra, R.S.; Molina-Mateo, J.; Torregrosa-Cabanilles, C.; Andrio-Balado, A.; Duen, J.M.M.; Serrano-Aroca, Á. Bio-nanocomposite hydrogel based on zinc alginate/graphene oxide: Morphology, structural conformation. Polymers 2020, 12, 702. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Zhou, S.; Zhang, L.; You, T.; Xu, F. Adsorption of heavy metals by graphene oxide/cellulose hydrogel prepared from NaOH/urea aqueous solution. Materials 2016, 9, 582. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Chen, G. Using hydrogel-biochar composites for enhanced cadmium removal from aqueous media. Mater. Sci. Eng. Int. J. 2018, 2, 294–298. [Google Scholar] [CrossRef]

- Teow, Y.H.; Kam, L.M.; Mohammad, A.W. Synthesis of cellulose hydrogel for copper (II) ions adsorption. J. Environ. Chem. Eng. 2018, 6, 4588–4597. [Google Scholar] [CrossRef]

- Song, Q.; Gao, J.; Lin, Y.; Zhang, Z.; Xiang, Y. Synthesis of cross-linking chitosan-PVA composite hydrogel and adsorption of Cu(II) ions. Water Sci. Technol. 2020, 81, 1063–1070. [Google Scholar] [CrossRef] [PubMed]

- Habeeb, S.A.; Nadhim, B.A. Removal of nickel (II) ions, low-level pollutants, and total bacterial colony count from wastewater by composite nanofiber film. Sci. Iran. 2023, 30, 2056–2069. [Google Scholar] [CrossRef]

- Khoshkho, S.M.; Tanhaei, B.; Kazemi, A.A.M. Preparation and characterization of ionic and non-ionic surfactants impregnated κ-carrageenan hydrogel beads for investigation of the adsorptive mechanism of cationic dye to develop for biomedical applications. J. Mol. Liq. 2021, 324, 115118. [Google Scholar] [CrossRef]

| Samples | Metal Ions | A1 (mg/g) a | A | B | C | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| A2 (mg/g) b | K1 (min−1) | R2 | A3 (mg/g) c | K2 (g. mg−1, min−1) | R2 | Ki1 Mg. g−1 min−0.5 | Ki2 Mg. g−1 min−0.5 | Ki3 Mg. g−1 min−0.5 | |||

| SAP-1 | Cd (II) | 146.9 | 156 | 0.0019 | 0.88 | 164.20 | 1.79 × 10−5 | 0.98 | 3.66 | 3.54 | 1.54 |

| Ni (II) | 126.75 | 130.72 | 0.002 | 0.87 | 137.36 | 3.18 × 10−5 | 0.98 | 3.88 | 3.54 | 1.50 | |

| Cu (II) | 154 | 167.01 | 0.0023 | 0.86 | 168.63 | 2.50 × 10−5 | 0.96 | 3.30 | 3.28 | 0.51 | |

| SAP-2 | Cd (II) | 190.722 | 195.68 | 0.0027 | 0.95 | 206.61 | 2.74 × 10−5 | 0.99 | 6.60 | 4.29 | 1.14 |

| Ni (II) | 179.94 | 189.41 | 0.0018 | 0.93 | 201.21 | 1.39 × 10−5 | 0.98 | 4.48 | 3.90 | 1.28 | |

| Cu (II) | 187.978 | 206.03 | 0.0024 | 0.92 | 214.59 | 1.47 × 10−5 | 0.98 | 5.0 | 4.88 | 1.22 | |

| Elements | Desorption of Cd (II) | Desorption of Ni (II) | Desorption of Cu (II) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| A | B | C | A | B | C | A | B | C | |

| C | 40.76 | 42.59 | 45.72 | 54.14 | 45.87 | 44.18 | 48.84 | 51.7 | 49 |

| N | 12.19 | 13.1 | 10.03 | 11.55 | 14.15 | 15.05 | 13 | 14.65 | 14.56 |

| O | 30.36 | 30.92 | 37.09 | 25.36 | 34.55 | 33.05 | 27.11 | 28.04 | 32.76 |

| Si | 2.1 | 1.97 | 1.92 | 0.62 | 0.76 | 0.8 | 1.69 | 0.95 | 1.05 |

| Cl | 1.84 | 1.3 | 2.13 | 2.11 | 0.98 | 4.06 | 1.74 | 1.97 | 0.57 |

| Al | 1.22 | 1.56 | 1.5 | 2.11 | 2.07 | 2 | 1.7 | 1.01 | 1.41 |

| Cu | - | - | - | - | - | - | 5.92 | 1.68 | 0.65 |

| Ni | - | - | - | 4.11 | 1.62 | 0.86 | - | - | - |

| Cd | 11.53 | 8.56 | 1.61 | - | - | - | - | - | - |

| Hydrogel | Metal Ions | Adsorption Capacity (mg/g) | Ref. |

|---|---|---|---|

| Hydrogel–biochar composite | Cd (II) | 63.58 | [62] |

| Cellulose hydrogel | Cu (II) | 52.30 | [63] |

| Chitosan–PVA composite hydrogel | Cu (II) | 62.10 | [64] |

| Pullulan-g-poly(AA-co-Aam) hydrogel | Cd (II) | 169.79 | [43] |

| NaAlg-g-P(AA-co-AM) hydrogel, obtained via SDBS micelle templating | Cd (II) Ni (II) Cu (II) | 31.18 6.720 67.99 | [46] |

| PUL-g-P(AA-co-AM) hydrogel | Cd (II) Ni (II) Cu (II) | 146.90 126.75 154.00 | This study |

| PUL-g-P(AA-co-AM) hydrogel, obtained via SDBS micelle templating | Cd (II) Ni (II) Cu (II) | 190.72 179.94 187.98 | This study |

| Samples | Pullulan | Monomers | MBA (Crosslinker) | K2S2O8 (Initiator) | Surfactant (SDBS) | |

|---|---|---|---|---|---|---|

| Acrylic Acid | Acrylamide | |||||

| SAP-1 | 17% | 35% | 35% | 7% | 6% | - |

| SAP-2 | 17% | 34% | 34% | 7% | 6% | 2% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dhahir, S.A.; Braihi, A.J.; Habeeb, S.A. Comparative Analysis of Hydrogel Adsorption/Desorption with and without Surfactants. Gels 2024, 10, 251. https://doi.org/10.3390/gels10040251

Dhahir SA, Braihi AJ, Habeeb SA. Comparative Analysis of Hydrogel Adsorption/Desorption with and without Surfactants. Gels. 2024; 10(4):251. https://doi.org/10.3390/gels10040251

Chicago/Turabian StyleDhahir, Salam Abdulla, Auda Jabbar Braihi, and Salih Abbas Habeeb. 2024. "Comparative Analysis of Hydrogel Adsorption/Desorption with and without Surfactants" Gels 10, no. 4: 251. https://doi.org/10.3390/gels10040251