Progress of Research into Preformed Particle Gels for Profile Control and Water Shutoff Techniques

Abstract

1. Introduction

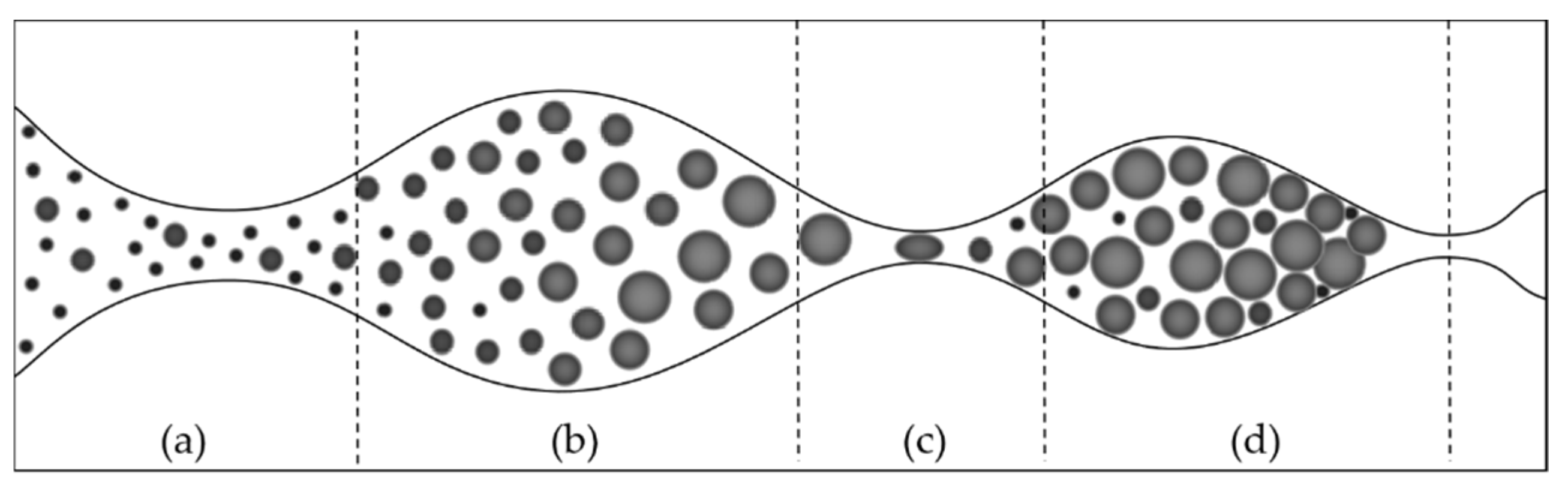

2. The Plugging Mechanism of PPGs

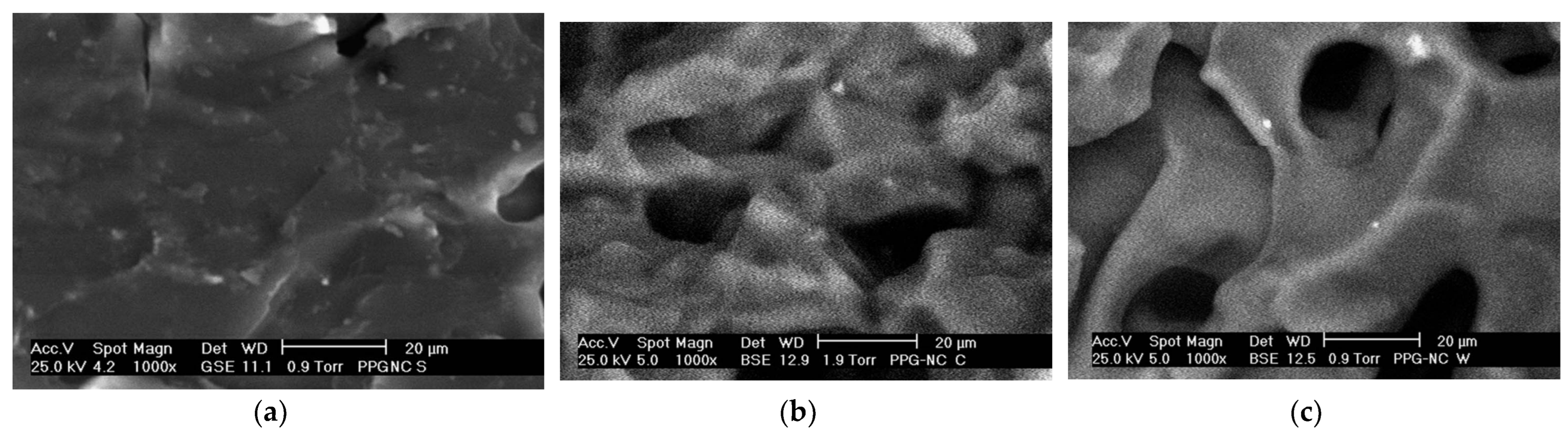

3. Application Example

4. The Current Research Status

4.1. High-Temperature-Resistant PPGs

4.2. Re-Crosslinkable PPG

4.3. Delayed-Swelling PPGs

4.4. Augmented PPGs

4.5. Degradable PPG

5. Discussion

6. Conclusions and Foresight

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- He, J.; Wang, H. Design and Effect of Fracture-flooding in Class III Oil Reservoirs. J. Southwest Pet. Univ. (Sci. Technol. Ed.) 2018, 40, 95–104. [Google Scholar] [CrossRef]

- Khormali, A.; Ahmadi, S. Experimental and modeling analysis on the performance of 2-mercaptobenzimidazole corrosion inhibitor in hydrochloric acid solution during acidizing in the petroleum industry. J. Pet. Explor. Prod. Technol. 2023, 13, 2217–2235. [Google Scholar] [CrossRef]

- Cottin, C.; Al-Amrie, O.; Barrois, E.; Templier, A.; Salehi, N.; Zaitoun, A. Chemical water shutoff pilot in a mature offshore carbonate field. In Proceedings of the Abu Dhabi International Petroleum Exhibition and Conference, Abu Dhabi, United Arab Emirates, 13 November 2017. [Google Scholar] [CrossRef]

- Guo, P.; Tian, Z.; Zhou, R.; Chen, F.; Du, J.; Wang, Z.; Hu, S. Chemical water shutoff agents and their plugging mechanism for gas reservoirs: A review and prospects. J. Nat. Gas Sci. Eng. 2022, 104, 104658. [Google Scholar] [CrossRef]

- Bai, B.; Wei, M.; Liu, Y. Field and Lab Experience with a Successful Preformed Particle Gel Conformance Control Technology. In Proceedings of the SPE Production and Operations Symposium, Oklahoma City, OK, USA, 23–26 March 2013. [Google Scholar] [CrossRef]

- Bai, B.; Liu, W.; Li, L.; Liu, G.; Tang, X. An analysis on intrinsie factors influencing the propertiesof pre-crosslinking gelled particles. Pet. Explor. Dev. 2002, 29, 3. [Google Scholar] [CrossRef]

- Zhao, G.; You, Q.; Gu, C.; Lv, Y.; Dai, C. Preparation mechanism of multiscale dispersed particle gel. Acta Pet. Sin. 2017, 38, 821–829. [Google Scholar] [CrossRef]

- Feng, Y.; Tabary, R.; Renard, M.; Le Bon, C.; Omari, A.; Chauveteau, G. Characteristics of Microgels Designed for Water Shutoff and Profile Control. In Proceedings of the International Symposium on Oilfield Chemistry, Houston, TX, USA, 5 February 2003. [Google Scholar] [CrossRef]

- Seright, R.S.; Lane, R.H.; Sydansk, R.D. A Strategy for Attacking Excess Water Production. SPE Prod. Facil. 2003, 18, 158–169. [Google Scholar] [CrossRef]

- Goudarzi, A.; Zhang, H.; Varavei, A.; Hu, Y.; Delshad, M.; Bai, B.; Sepehrnoori, K. Water Management in Mature Oil Fields using Preformed Particle Gels. In Proceedings of the SPE Western Regional & AAPG Pacific Section Meeting 2013 Joint Technical Conference, Monterey, CA, USA, 19 April 2013. [Google Scholar] [CrossRef]

- Saghafi, H.R.; Naderifar, A.; Gerami, S.; Emadi, M.A. Improvement in thermo-chemical stability of nanocomposite preformed particle gels for conformance control in harsh oil reservoir conditions. Can. J. Chem. Eng. 2016, 94, 1880–1890. [Google Scholar] [CrossRef]

- Tongwa, P.; Nygaard, R.; Bai, B. Evaluation of a Nanocomposite Hydrogel for Water Shut-Off in Enhanced Oil Recovery Applications: Design, Synthesis, and Characterization. J. Appl. Polym. Sci. 2012, 128, 787–794. [Google Scholar] [CrossRef]

- Kang, W.; Xu, H.; Yang, H.; Zhao, W.; Du, S.; Gong, X.; Liu, X. Study on expansion property of pre-crosslinked particle gel with low elasticity and high viscosity. Chem. Eng. Oil Gas 2014, 43, 662–665+674. [Google Scholar] [CrossRef]

- Imqam, A.; Bai, B. Optimizing the strength and size of preformed particle gels for better conformance control treatment. Fuel 2015, 148, 178–185. [Google Scholar] [CrossRef]

- Qiu, Y.; Wu, F.; Wei, M.; Kang, W.; Li, B. Lessons Learned from Applying Particle Gels in Mature Oilfields. In Proceedings of the SPE Improved Oil Recovery Symposium, Tulsa, OK, USA, 12 April 2014. [Google Scholar] [CrossRef]

- Al Brahim, A.; Eriyagama, Y.; Bai, B.; Schuman, T. Feasibility Study of Recrosslinkable Preformed Particle Gels for Natural Gas Injection Profile Control. SPE J. 2023, 28, 1829–1841. [Google Scholar] [CrossRef]

- Alhuraishawy, A.K.; Bai, B.; Imqam, A.; Wei, M. Experimental study of combining low salinity water flooding and preformed particle gel to enhance oil recovery for fractured carbonate reservoirs. Fuel 2018, 214, 342–350. [Google Scholar] [CrossRef]

- Alhuraishawy, A.K.; Sun, X.; Bai, B.; Wei, M.; Imqam, A. Areal sweep efficiency improvement by integrating preformed particle gel and low salinity water flooding in fractured reservoirs. Fuel 2018, 221, 380–392. [Google Scholar] [CrossRef]

- Kang, W.; Shao, S.; Yang, H.; Chen, C.; Gabdullin, M. The effect of stepwise increasing of water injection rates on enhanced oil recovery after preformed particle gel treatment. J. Pet. Sci. Eng. 2019, 182, 106239. [Google Scholar] [CrossRef]

- Sun, X.; Alhuraishawy, A.K.; Bai, B.; Wei, M. Combining preformed particle gel and low salinity waterflooding to improve conformance control in fractured reservoirs. Fuel 2018, 221, 501–512. [Google Scholar] [CrossRef]

- Zhao, Y.; Leng, J.; Lin, B.; Wei, M.; Bai, B. Experimental Study of Microgel Conformance-Control Treatment for a Polymer-Flooding Reservoir Containing Superpermeable Channels. SPE J. 2021, 26, 2305–2317. [Google Scholar] [CrossRef]

- Bai, B.; Liu, Y.; Coste, J.-P.; Li, L. Preformed Particle Gel for Conformance Control: Transport Mechanism Through Porous Media. SPE Reserv. Eval. Eng. 2007, 10, 176–184. [Google Scholar] [CrossRef]

- Yao, C.; Lei, G.; Cathles, L.M.; Steenhuis, T.S. Pore-Scale Investigation of Micron-Size Polyacrylamide Elastic Microspheres (MPEMs) Transport and Retention in Saturated Porous Media. Environ. Sci. Technol. 2014, 48, 5329–5335. [Google Scholar] [CrossRef]

- Imqam, A.; Bai, B.; Delshad, M. Micro-particle gel transport performance through unconsolidated sandstone and its blocking to water flow during conformance control treatments. Fuel 2018, 231, 479–488. [Google Scholar] [CrossRef]

- Li, Y.; Sarıyer, O.S.; Ramachandran, A.; Panyukov, S.; Rubinstein, M.; Kumacheva, E. Universal behavior of hydrogels confined to narrow capillaries. Sci. Rep. 2015, 5, 17017. [Google Scholar] [CrossRef]

- Saghafi; Reza, H. Retention characteristics of enhanced preformed particle gels (PPGs) in porous media: Conformance control implications. J. Pet. Sci. Eng. 2018, 166, 962–968. [Google Scholar] [CrossRef]

- Zhao, Y.; Bai, B. Selective penetration behavior of microgels in superpermeable channels and reservoir matrices. J. Pet. Sci. Eng. 2022, 210, 109897. [Google Scholar] [CrossRef]

- Zhao, Y.; Bai, B. Laboratory Evaluation of Placement Behavior of Microgels for Conformance Control in Reservoirs Containing Superpermeable Channels. Energy Fuels 2022, 36, 1374–1387. [Google Scholar] [CrossRef]

- Dai, C.; Zou, C.; Liu, Y.; You, Q.; Tong, Y.; Wu, C.; Shan, C. Matching principle and in-depth profile control mechanism between elastic dispersed particle gel and pore throat. Acta Pet. Sin. 2018, 39, 427–434. [Google Scholar] [CrossRef]

- Seright, R.S. Gel Placement in Fractured Systems. SPE Prod. Facil. 1995, 10, 241–248. [Google Scholar] [CrossRef]

- Seright, R.S. Gel Propagation Through Fractures. SPE Prod. Facil. 2001, 16, 225–231. [Google Scholar] [CrossRef]

- Coste, J.-P.; Liu, Y.; Bai, B.; LI, Y.; Shen, P.; Wang, Z.; Zhu, G. In-Depth Fluid Diversion by Pre-Gelled Particles. Laboratory Study and Pilot Testing. In Proceedings of the SPE/DOE Improved Oil Recovery Symposium, Tulsa, OK, USA, 3 April 2000. [Google Scholar] [CrossRef]

- Elsharafi, M.O.; Bai, B. Effect of weak preformed particle gel on unswept oil zones/areas during conformance control treatments. Ind. Eng. Chem. Res. 2012, 51, 11547–11554. [Google Scholar] [CrossRef]

- Elsharafi, M.O.; Bai, B. Effect of Strong Preformed Particle Gel on Unswept Oil Zones/Areas During Conformance Control Treatments. In Proceedings of the EAGE Annual Conference & Exhibition incorporating SPE Europec, London, UK, 10 June 2013. [Google Scholar] [CrossRef]

- Li, M.; Guo, J.; Zhou, F.; Cao, L.; Li, B. Investigating the effect of preformed particle gel on conformance control of naturally fractured tight sandstone reservoirs: An experimental study using pressure transfer test method. Fuel 2023, 347, 128479. [Google Scholar] [CrossRef]

- Li, Y.; Liu, Y.; Bai, B.; Liu, G. Research of expansion grain chemical for water shutoff and profile control. Oil Drill. Prod. Technol. 1999, 3, 65–68+114. [Google Scholar] [CrossRef]

- Bai, B.; Li, L.; Liu, Y.; Liu, H.; Wang, Z.; You, C. Preformed Particle Gel for Conformance Control: Factors Affecting Its Properties and Applications. SPE Reserv. Eval. Eng. 2007, 10, 415–422. [Google Scholar] [CrossRef]

- Bai, B.; Huang, F.; Liu, Y.; Seright, R.S.; Wang, Y. Case study on preformed particle gel for in-depth fluid diversion. In Proceedings of the SPE Improved Oil Recovery Conference, Tulsa, OK, USA, 20 April 2008. [Google Scholar] [CrossRef]

- Ma, H.; Xu, Y.; Wei, J.; Liu, M.; Yao, C. Profile control technology in Luo1 Chang8 oilfield and its effect. Petrochem. Ind. Appl. 2013, 32, 57–59+71. [Google Scholar] [CrossRef]

- Pu, J.; Bai, B.; Alhuraishawy, A.; Schuman, T.; Chen, Y.; Sun, X. A Recrosslinkable Preformed Particle Gel for Conformance Control in Heterogeneous Reservoirs Containing Linear-Flow Features. SPE J. 2019, 24, 1714–1725. [Google Scholar] [CrossRef]

- Targac, G.; Gallo, C.; Smith, D.; Huang, C.-K.; Autry, S.; Peirce, J.; Baohong, L. Case History of Conformance Solutions for West Sak Wormhole/Void Space Conduit with a New Reassembling Pre-formed Particle Gel RPPG. In Proceedings of the SPE Annual Technical Conference and Exhibition, Virtual, 19 October 2020. [Google Scholar] [CrossRef]

- Xiong, B.; Loss, R.D.; Shields, D.; Pawlik, T.; Hochreiter, R.; Zydney, A.L.; Kumar, M. Polyacrylamide degradation and its implications in environmental systems. NPJ Clean Water 2018, 1, 17. [Google Scholar] [CrossRef]

- Magzoub, M.I.; Salehi, S.; Hussein, I.A.; Nasser, M.S. Loss circulation in drilling and well construction: The significance of applications of crosslinked polymers in wellbore strengthening: A review. J. Pet. Sci. Eng. 2020, 185, 106653. [Google Scholar] [CrossRef]

- Negi, H.; Verma, P.; Singh, R.K. A comprehensive review on the applications of functionalized chitosan in petroleum industry. Carbohydr. Polym. 2021, 266, 118125. [Google Scholar] [CrossRef] [PubMed]

- Elaf, R.; Ben Ali, A.; Saad, M.; Hussein, I.A.; Nimir, H.; Bai, B.J. Biodegradable Preformed Particle Gel (PPG) Made of Natural Chitosan Material for Water Shut-Off Application. Polymers 2023, 15, 1961. [Google Scholar] [CrossRef] [PubMed]

- Elaf, R.; Ben Ali, A.; Saad, M.; Hussein, I.A.; Bai, B.J. Development of eco-friendly chitosan-g-polyacrylamide preformed particle gel for conformance control in high-temperature and high-salinity reservoirs. Geoenergy Sci. Eng. 2023, 230, 212136. [Google Scholar] [CrossRef]

- Zhu, D.Y.; Hou, J.R.; Wei, Q.; Wu, X.; Bai, B.J. Terpolymer Gel System Formed by Resorcinol Hexamethylenetetramine for Water Management in Extremely High Temperature Reservoirs. Energy Fuels 2017, 31, 1519–1528. [Google Scholar] [CrossRef]

- Ahdaya, M.; Al Brahim, A.; Song, T.; Bai, B.J.; Eriyagama, Y.; Schuman, T.; Zhang, Y. Impact of different additives on low-temperature recrosslinkable preformed particle gel to mitigate fluid losses in fractured formations. Geoenergy Sci. Eng. 2023, 224, 211597. [Google Scholar] [CrossRef]

- Durán-Valencia, C.; Bai, B.; Reyes, H.; Fajardo-López, R.; Barragán-Aroche, F.; López-Ramírez, S. Development of enhanced nanocomposite preformed particle gels for conformance control in high-temperature and high-salinity oil reservoirs. Polym. J. 2014, 46, 277–284. [Google Scholar] [CrossRef]

- Salunkhe, B.; Schuman, T.; Al Brahim, A.; Bai, B.J. Ultra-high temperature resistant preformed particle gels for enhanced oil recovery. Chem. Eng. J. 2021, 426, 130712. [Google Scholar] [CrossRef]

- Schuman, T.; Salunkhe, B.; Al Brahim, A.; Bai, B. Evaluation of Ultrahigh-Temperature-Resistant Preformed Particle Gels for Conformance Control in North Sea Reservoirs. SPE J. 2022, 27, 3660–3673. [Google Scholar] [CrossRef]

- Song, T.; Ahdaya, M.; Zhao, S.; Zhao, Y.; Schuman, T.; Bai, B. Evaluation of a Novel Recrosslinkable Hyperbranched Preformed Particle Gel for the Conformance Control of High-Temperature Reservoirs with Fractures. SPE J. 2022, 27, 3598–3610. [Google Scholar] [CrossRef]

- An, Z.B.; Zhou, K.; Wu, D.J.; Hou, J. Production characteristics and displacement mechanisms of infilling polymer-surfactant-preformed particle gel flooding in post-polymer flooding reservoirs: A review of practice in Ng3 block of Gudao Oilfield. Pet. Sci. 2023, 20, 2354–2371. [Google Scholar] [CrossRef]

- Cui, X.-h.; Li, Z.-q.; Cao, X.-I.; Song, X.-w.; Zhang, X. A Novel PPG Enhanced Surfactant-Polymer System for EOR. In Proceedings of the SPE Enhanced Oil Recovery Conference, Kuala Lumpur, Malaysia, 19 July 2011. [Google Scholar] [CrossRef]

- Sang, Q.; Li, Y.J.; Yu, L.; Li, Z.Q.; Dong, M.Z. Enhanced oil recovery by branched-preformed particle gel injection in parallel-sandpack models. Fuel 2014, 136, 295–306. [Google Scholar] [CrossRef]

- Chen, X. Method study for application of heterogeneous oil displacement agent. Oil Drill. Prod. Technol. 2009, 31, 85–88. [Google Scholar] [CrossRef]

- Gong, H.J.; Zhang, H.; Xu, L.; Li, K.N.; Yu, L.; Li, Y.J.; Dong, M.Z. Further enhanced oil recovery by branched-preformed particle gel/HPAM/surfactant mixed solutions after polymer flooding in parallel-sandpack models. Rsc Adv. 2017, 7, 39564–39575. [Google Scholar] [CrossRef]

- Xu, L.; Qiu, Z.; Gong, H.J.; Zhu, C.F.; Sang, Q.; Li, Y.J.; Dong, M.Z. Synergy of microbial polysaccharides and branched-preformed particle gel on thickening and enhanced oil recovery. Chem. Eng. Sci. 2019, 208, 115138. [Google Scholar] [CrossRef]

- Zhai, Y.; Fang, Z.; Feng, J.; Sun, C.; Deng, W.; Wen, Y. Development and performance evaluation of re-crosslinkable preformed particle gel under high temperature and high salt conditions. Polymer 2024, 296, 126824. [Google Scholar] [CrossRef]

- Song, T.; Ahdaya, M.; Zhai, Z.M.; Schuman, T.; Bai, B.J. Comprehensive evaluation of a novel re-crosslinkable preformed particle gel for the water management of reservoir with concentrated divalent ions. Fuel 2023, 331, 125974. [Google Scholar] [CrossRef]

- Guo, H.; Ge, J.; Xu, Y.; Lv, Q.; Li, Z.; Zhou, D.; Tao, Z. Preparation and Mechanism of Stability for High-Temperature and High-Salinity Gels. SPE J. 2022, 27, 3565–3578. [Google Scholar] [CrossRef]

- Jia, H.; Kang, Z.; Li, Z.; Zhao, J. The Potential of Ultrahigh Strength Gel through Novel Multistage Reinforcement Method for Sealing Operations in Medium to Ultralow Temperature Reservoirs. SPE J. 2022, 27, 2145–2160. [Google Scholar] [CrossRef]

- Qin, Y.; Zhang, D.; Liu, Y.; Cheng, L. Synthesis and performance evaluation of nanocomposite gel particle with salt tolerance andretarding swelling. Mod. Chem. Ind. 2018, 38, 171–174. [Google Scholar] [CrossRef]

- Wu, Y.; Zhang, H.; Zhang, L.; Huang, Y.; Zhao, M.; Dai, C. Development of Novel Delayed Swelling Polymer Gel Particles with Salt Resistance for Enhanced In-Depth Permeability Control. SPE J. 2024, 29, 2060–2075. [Google Scholar] [CrossRef]

- Bai, B.; Sun, X. Development of Swelling-Rate Controllable Particle Gels to Control the Conformance of CO2 Flooding. In Proceedings of the SPE Improved Oil Recovery Conference, Virtual, 30 August 2020. [Google Scholar] [CrossRef]

- Zhou, B.B.; Kang, W.L.; Jiang, H.Z.; Yang, H.B.; Li, Z.; Lv, Z.Q.; Xu, Z.; Ning, C.Y.; Wang, H.Z.; Xie, S.T. Preparation and crosslinking mechanism of delayed swelling double-crosslinking nano polymer gel microsphere for anti-CO2 gas channeling. J. Pet. Sci. Eng. 2022, 219, 111122. [Google Scholar] [CrossRef]

- Pereira, K.A.B.; Pereira, K.A.B.; Oliveira, P.F.; Mansur, C.R.E. Behavior of partially hydrolyzed polyacrylamide/polyethyleneimine reinforced with coal fly ash for preformed particle hydrogels. J. Appl. Polym. Sci. 2020, 137, 49423. [Google Scholar] [CrossRef]

- Khoshkar, P.A.; Fatemi, M.; Ghazanfari, M.H. Static and dynamic evaluation of the effect of nanomaterials on the performance of a novel synthesized PPG for water shut-off and improved oil recovery in fractured reservoirs. J. Pet. Sci. Eng. 2020, 189, 107019. [Google Scholar] [CrossRef]

- Kumar, A.; Mahto, V.; Sharma, V.P. Reinforced preformed particle gel: Synthesis, characterization and performance evaluation for water shut-off jobs in heterogeneous reservoir. J. Pet. Sci. Eng. 2020, 193, 107408. [Google Scholar] [CrossRef]

- Paprouschi, A.; Fatemi, M.; Ghazanfari, M.H. Effect of silicate sodium and graphene nanoplatelets on morphology and rheology characteristics of new synthesized preformed particle gel (PPG) for water shut-off treatment. J. Pet. Sci. Eng. 2021, 204, 108736. [Google Scholar] [CrossRef]

- Do Amparo, S.Z.S.; de Vasconcelos, C.K.B.; Almeida, A.; Sena, L.E.B.; Lima, M.; Medeiros, F.S.; Caliman, V.; Silva, G.G.; Viana, M.M. Microwave-assisted synthesis of PAM preformed particle gels reinforced with carbon nanomaterials for conformance control in oil recovery. Fuel 2022, 330, 125650. [Google Scholar] [CrossRef]

- Cheng, L.; Qin, Y.; Gao, K.J.; Zhang, L.Y.; Zhou, J.S.; Zhang, D.X.; Liao, R.Q.; Li, Z. Experimental Investigation of a Novel Nanocomposite Particle Gel for Water Shutoff Treatment in Mature Oilfields. Acs Omega 2022, 7, 8887–8895. [Google Scholar] [CrossRef]

- Kang, W.L.; Wang, J.Q.; Ye, Z.Q.; Gu, G.J.; Li, W.M.; Yang, H.B.; Li, Z.; Xu, H.X.; Lv, Z.Q.; Sarsenbekuly, B. Study on preparation and plugging effect of sawdust gel particle in fractured reservoir. J. Pet. Sci. Eng. 2022, 212, 110358. [Google Scholar] [CrossRef]

- Kumar, A.; Mahto, V.; Sharma, V.P. A systematic multi-scale experimental investigation of a newly developed halloysite nanotubes reinforced preformed particle gel for improving oil recovery from heterogeneous reservoir: Synthesis, characterization, optimization and performance assessment. Geoenergy Sci. Eng. 2023, 226, 211786. [Google Scholar] [CrossRef]

- Pandit, Y.K.; Mahto, V.; Udayabhanu, G.; Ravishankar, B.; Dhandi, M. Preparation, characterization, and evaluation of a nanomaterial reinforced particle gel system for the control of excessive water production in the mature oil fields. Geoenergy Sci. Eng. 2024, 235, 212707. [Google Scholar] [CrossRef]

- Ai, L.Q.; Yang, H.; Wang, S.W.; Zheng, L.J.; Yuan, H.Y.; Yu, X.R.; Su, G.S. Acrylamide preformed particle gels with movable-crosslinking for conformance control. J. Mol. Liq. 2023, 384, 122217. [Google Scholar] [CrossRef]

- Hao, J.; Fan, H.; Kang, W.; Li, Z.; Yang, H.; Sarsenbekuly, B. Preparation and Property Evaluation of Host-guest Inclusion Supramolecular Gel Particles Profile Pontrol Agent. Oilfield Chem. 2023, 40, 650–655. [Google Scholar] [CrossRef]

- Deng, J.A.; Lian, H.Y.; Zhuang, Y.; Zhao, H.H.; Wang, Z.Y.; Tian, Y.J.; Lin, C.; Yuan, H.Z.; Han, M.; Lu, G.W.; et al. Synthesis and performance evaluation of multi-crosslinked preformed particle gels with ultra-high strength and high-temperature and high-salinity resistance for conformance control. Fuel 2024, 357, 130027. [Google Scholar] [CrossRef]

- Khormali, A.; Ahmadi, S.; Kazemzadeh, Y. Inhibition of Barium Sulfate Precipitation During Water Injection into Oil Reservoirs Using Various Scale Inhibitors. Arab. J. Sci. Eng. 2023, 48, 9383–9399. [Google Scholar] [CrossRef]

- Zhao, S.D.; Zhu, D.Y.; Bai, B.J. Experimental study of degradable preformed particle gel (DPPG) as temporary plugging agent for carbonate reservoir matrix acidizing to improve oil recovery. J. Pet. Sci. Eng. 2021, 205, 108760. [Google Scholar] [CrossRef]

- Zhu, D.Y.; Xu, Z.H.; Sun, R.X.; Fang, X.Y.; Gao, D.W.; Jia, X.B.; Hu, J.R.; Weng, J.T. Laboratory evaluation on temporary plugging performance of degradable preformed particle gels (DPPGs). Fuel 2021, 289, 119743. [Google Scholar] [CrossRef]

- Zhang, X.; Deng, J.N.; Yang, K.; Li, Q.; Meng, S.Y.; Sun, X.X.; Song, Z.Z.; Tian, Y.D.; Zhang, S.A.; Liu, X.J.; et al. High-strength and self-degradable sodium alginate/polyacrylamide preformed particle gels for conformance control to enhance oil recovery. Pet. Sci. 2022, 19, 3149–3158. [Google Scholar] [CrossRef]

| Researcher | Study on PPGs | Improvement |

|---|---|---|

| Kaio A. B. Pereira [67] | The Influence of Fly Ash (CFA) on Polyacrylamide Systems. | Viscoelasticity and temperature resistance are improved. |

| Peyman Abbasi Khoshkar [68] | The effect of nano-clay and nano-silica on AM-AMPS system. | The equilibrium swelling ratio and temperature resistance were improved, the pH and CO2 tolerance were improved, and the synaeresis of PPG was inhibited. |

| Abhinav Kumar [69] | The Reinforcing Effect of Nanomontmorillonite on Polyacrylamide Systems. | The swelling performance, thermal stability and strength are improved, and the water shutoff performance in sandstone is enhanced. |

| Aminsadegh Paprouschi [70] | The effect of Sodium silicate and graphene nanosheets on AM-AMPS system. | The storage modulus is greatly improved, and the strength, thermal stability, and dehydration tolerance are improved. |

| Sthéfany Z.S. do Amparo [71] | Graphene oxide- and carbon nanotube-reinforced polyacrylamide PPGs. | The shear deformation resistance and swelling performance are improved. |

| Li [72] | The effect of laponite on AM-AMPS system. | The swelling rate and mechanical properties are enhanced, and the thermal stability is also slightly improved. |

| Kang [73] | Effect of sawdust on acrylamide/acrylic acid system. | Viscoelasticity, shear resistance, and yield stress are improved, and the plugging rate in cracks is improved. |

| Abhinav Kumar [74] | Effect of halloysite nanotubes on polyacrylamide PPGs. | The swelling capacity, elastic modulus and temperature resistance are improved, and the plugging effect of permeability in the 2-6 D sand pack plugging test is enhanced. |

| Yugal Kishor Pandit [75] | Effect of bentonite and silica on AM-NVP-AMPS system. | Long-term thermal stability, elastic modulus and plugging performance are enhanced. |

| Conventional Polymer Gels | Conventional PPGs | High-Temperature Resistant PPGs | Re-Crosslinkable PPGs | Delayed Swelling PPGs | Augmented PPGs | Degradable PPGs | |

|---|---|---|---|---|---|---|---|

| Temperature tolerance | × | √ | √√ | √ | √ | √ | √ |

| Salt tolerance | × | √ | √ | √ | √ | √ | √ |

| Selective water plugging | √ | √ | √ | √ | √ | √ | √ |

| Long-term stability | × | √ | √ | √ | √ | √√ | × |

| Migration capability | × | √ | √ | √ | √√ | √ | √ |

| Convenient construction | × | √ | √ | √ | √ | √ | √ |

| Applicability of large fractures | × | × | × | √ | × | × | × |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, W.; Li, Y.; Liu, P.; Liu, Z.; Song, T. Progress of Research into Preformed Particle Gels for Profile Control and Water Shutoff Techniques. Gels 2024, 10, 372. https://doi.org/10.3390/gels10060372

Ma W, Li Y, Liu P, Liu Z, Song T. Progress of Research into Preformed Particle Gels for Profile Control and Water Shutoff Techniques. Gels. 2024; 10(6):372. https://doi.org/10.3390/gels10060372

Chicago/Turabian StyleMa, Wei, Yikun Li, Pingde Liu, Zhichang Liu, and Tao Song. 2024. "Progress of Research into Preformed Particle Gels for Profile Control and Water Shutoff Techniques" Gels 10, no. 6: 372. https://doi.org/10.3390/gels10060372

APA StyleMa, W., Li, Y., Liu, P., Liu, Z., & Song, T. (2024). Progress of Research into Preformed Particle Gels for Profile Control and Water Shutoff Techniques. Gels, 10(6), 372. https://doi.org/10.3390/gels10060372