Carbon Nanotube-Doped 3D-Printed Silicone Electrode for Manufacturing Multilayer Porous Plasticized Polyvinyl Chloride Gel Artificial Muscles

Abstract

1. Introduction

2. Results and Discussion

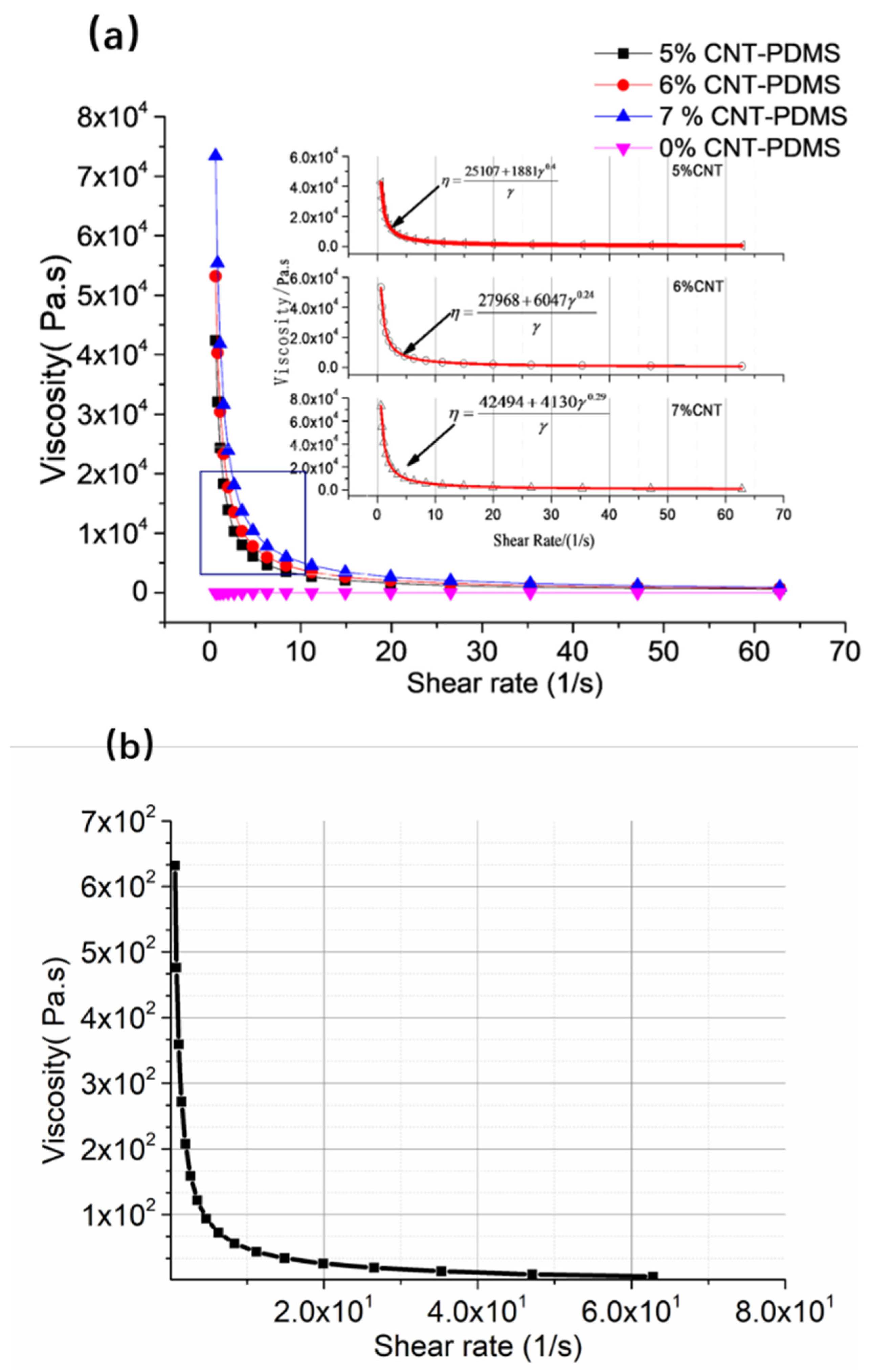

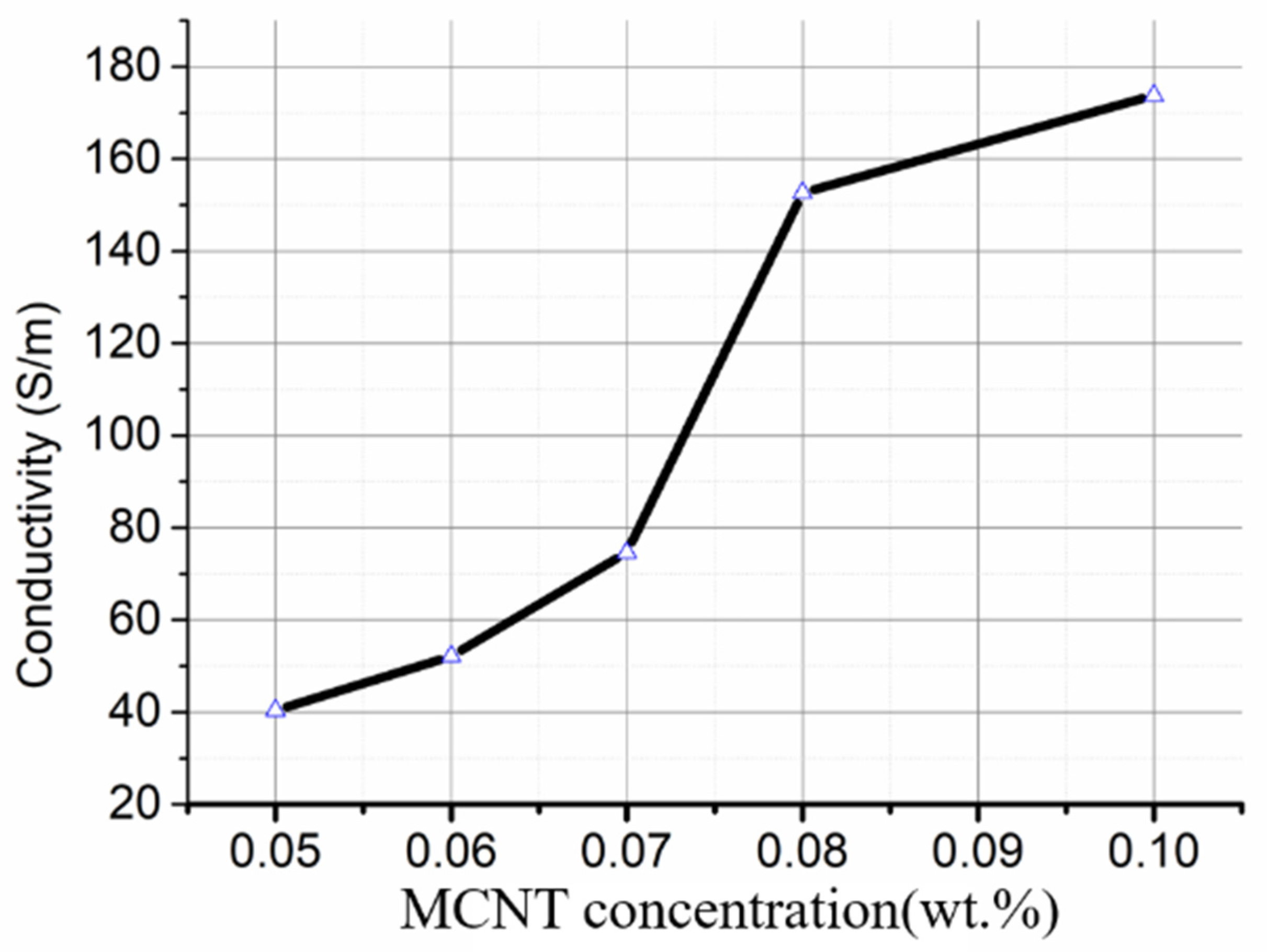

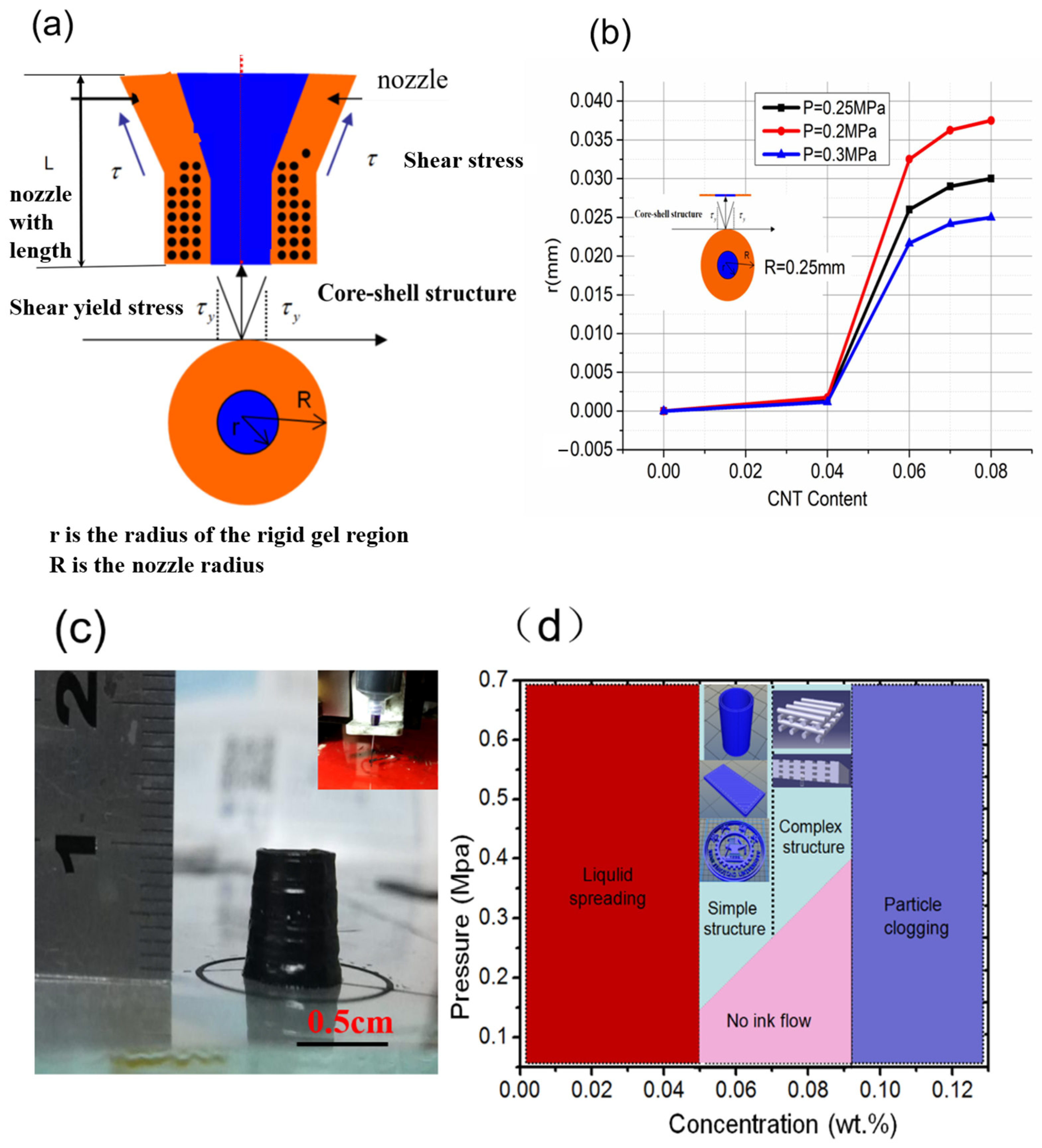

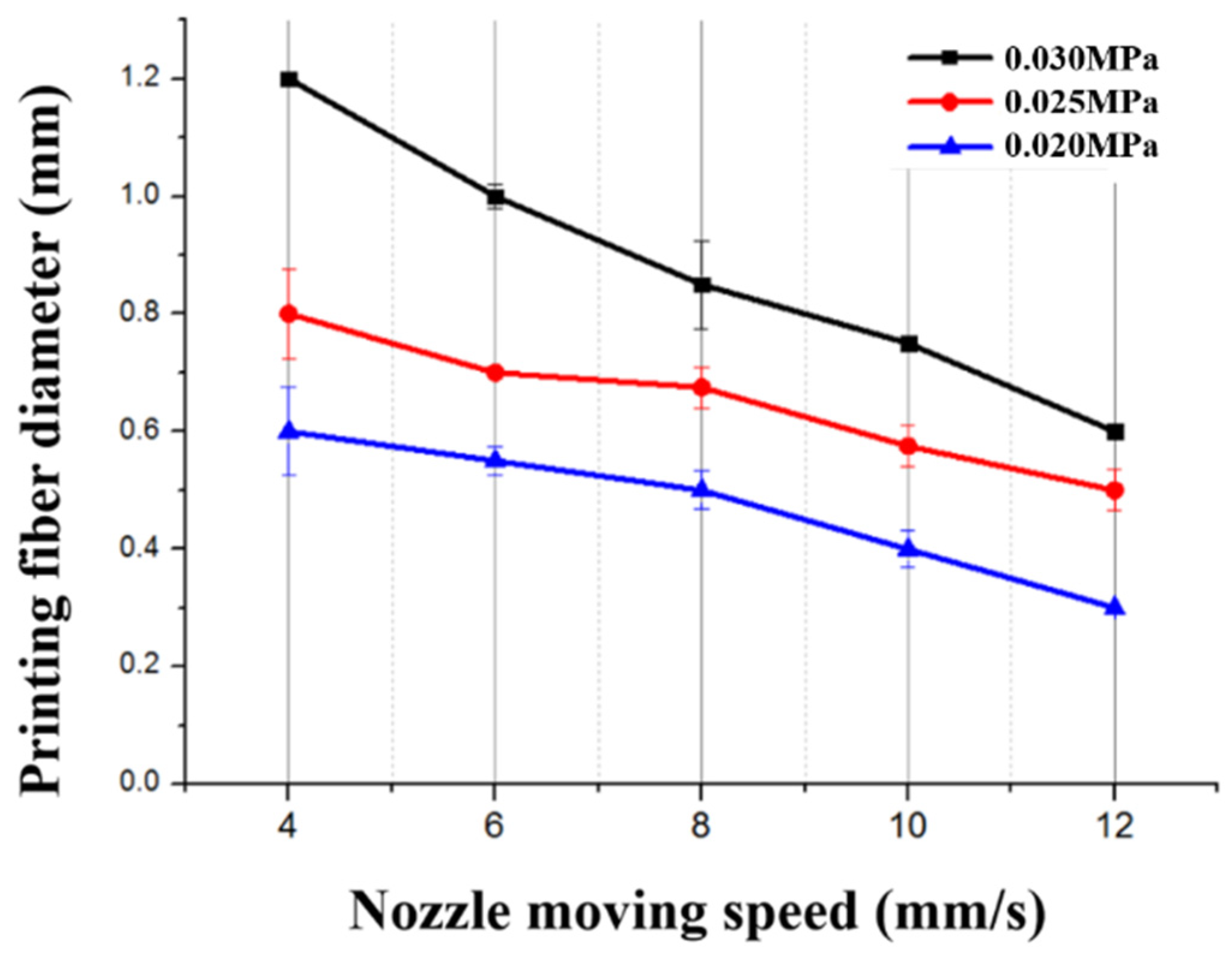

2.1. Printability of CNT-PDMS and PVC Gel Inks

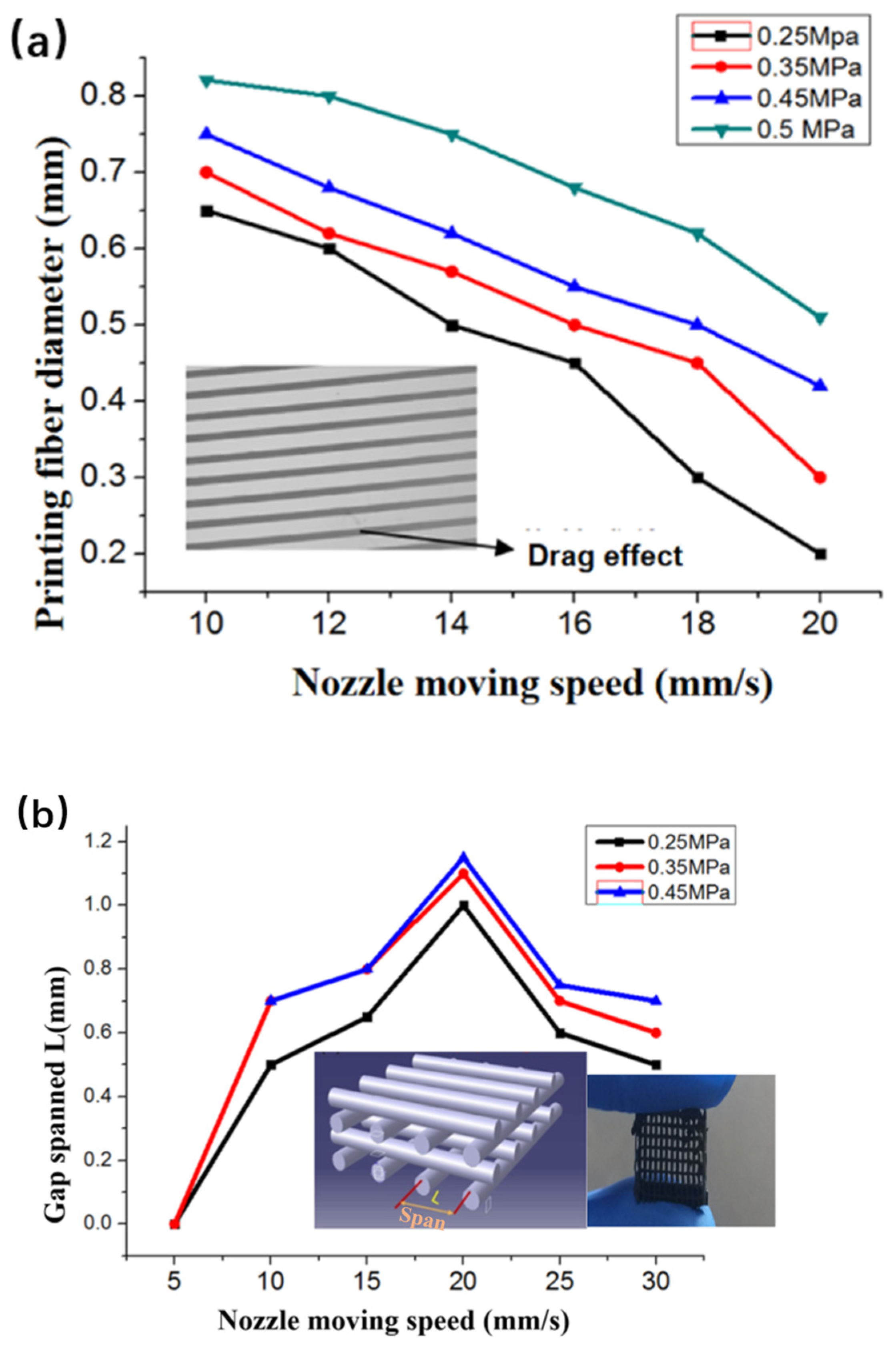

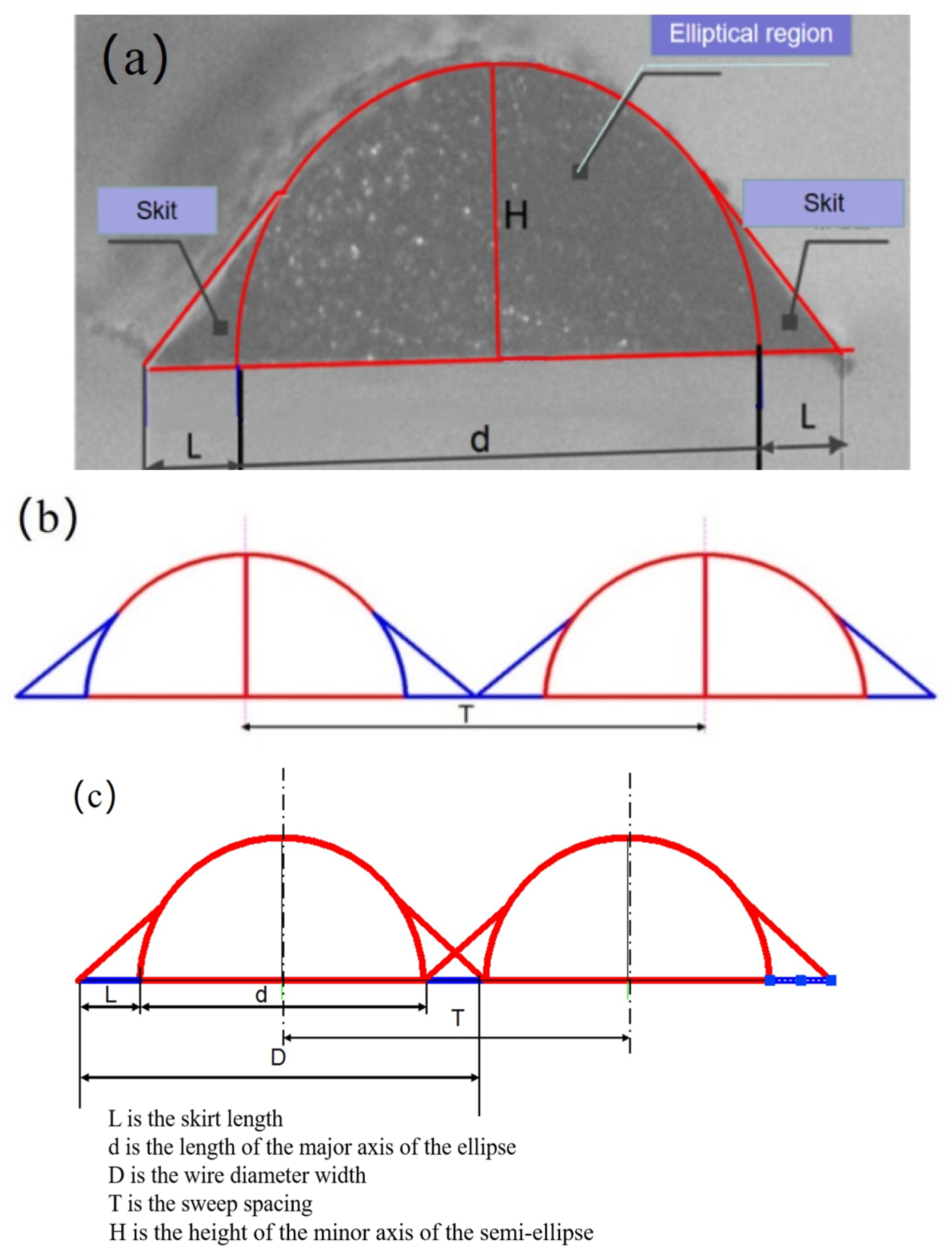

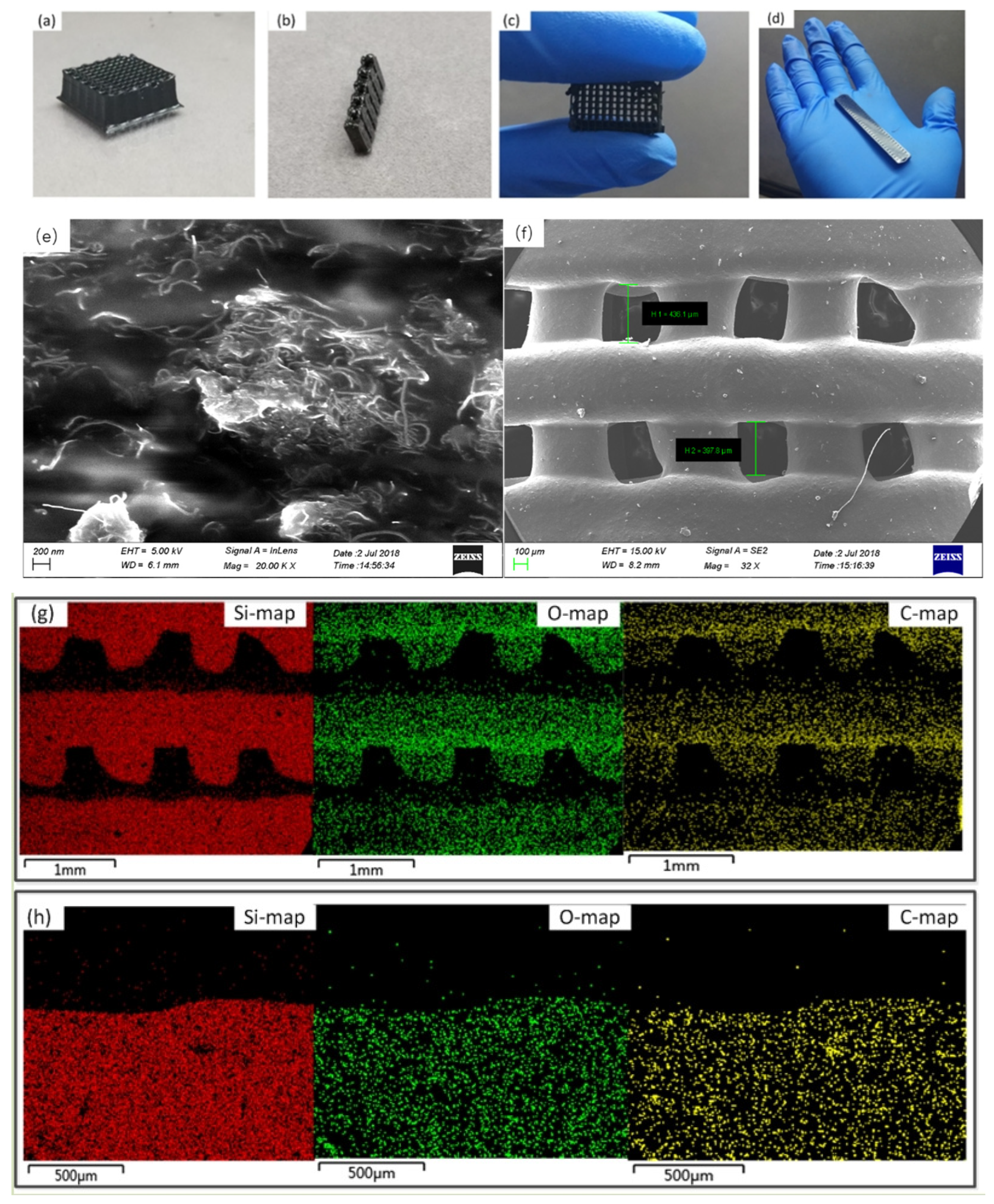

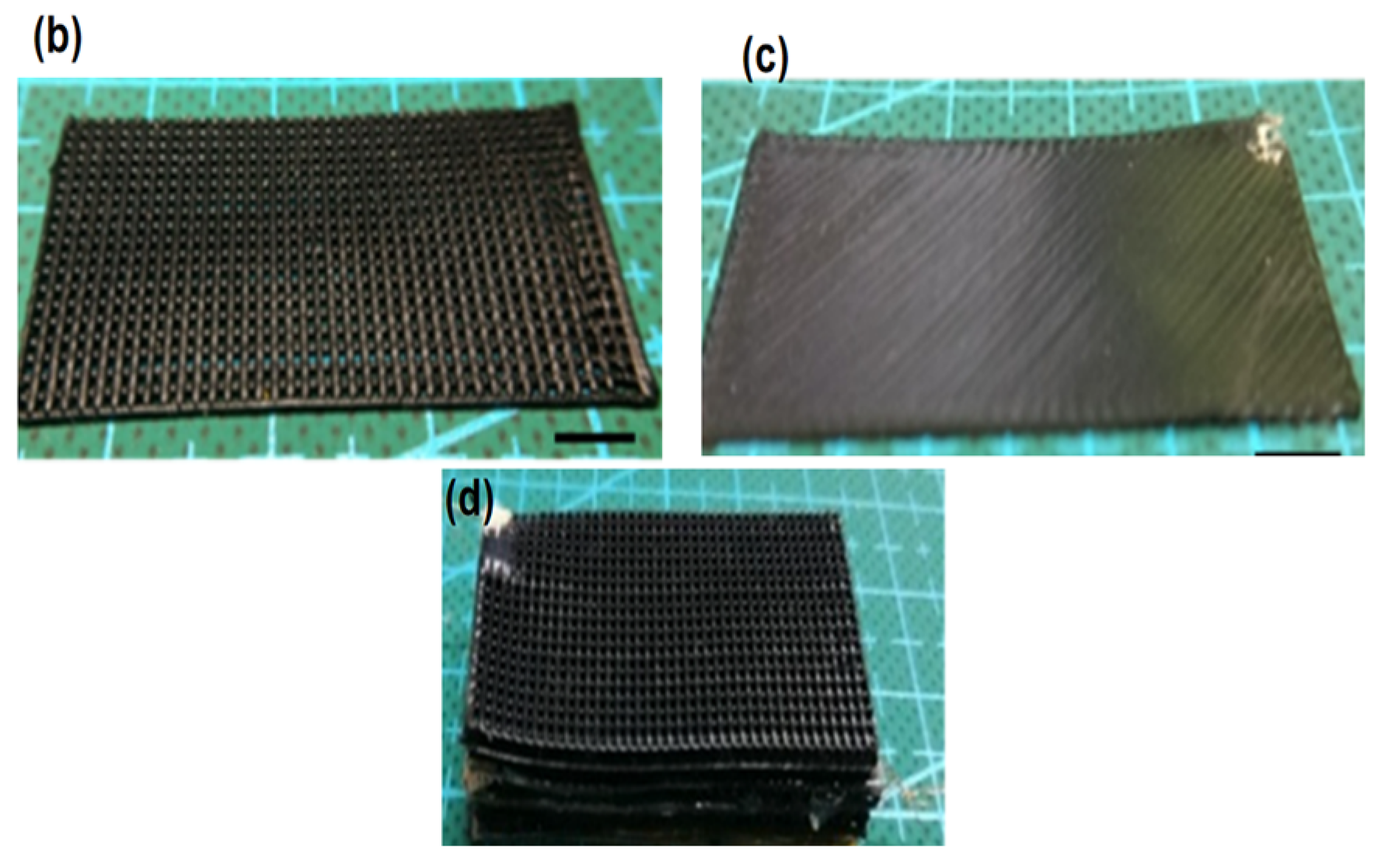

2.2. CNT-PDMS Printed Spanning Structure

2.3. Printed Planar PVC Gel Structure

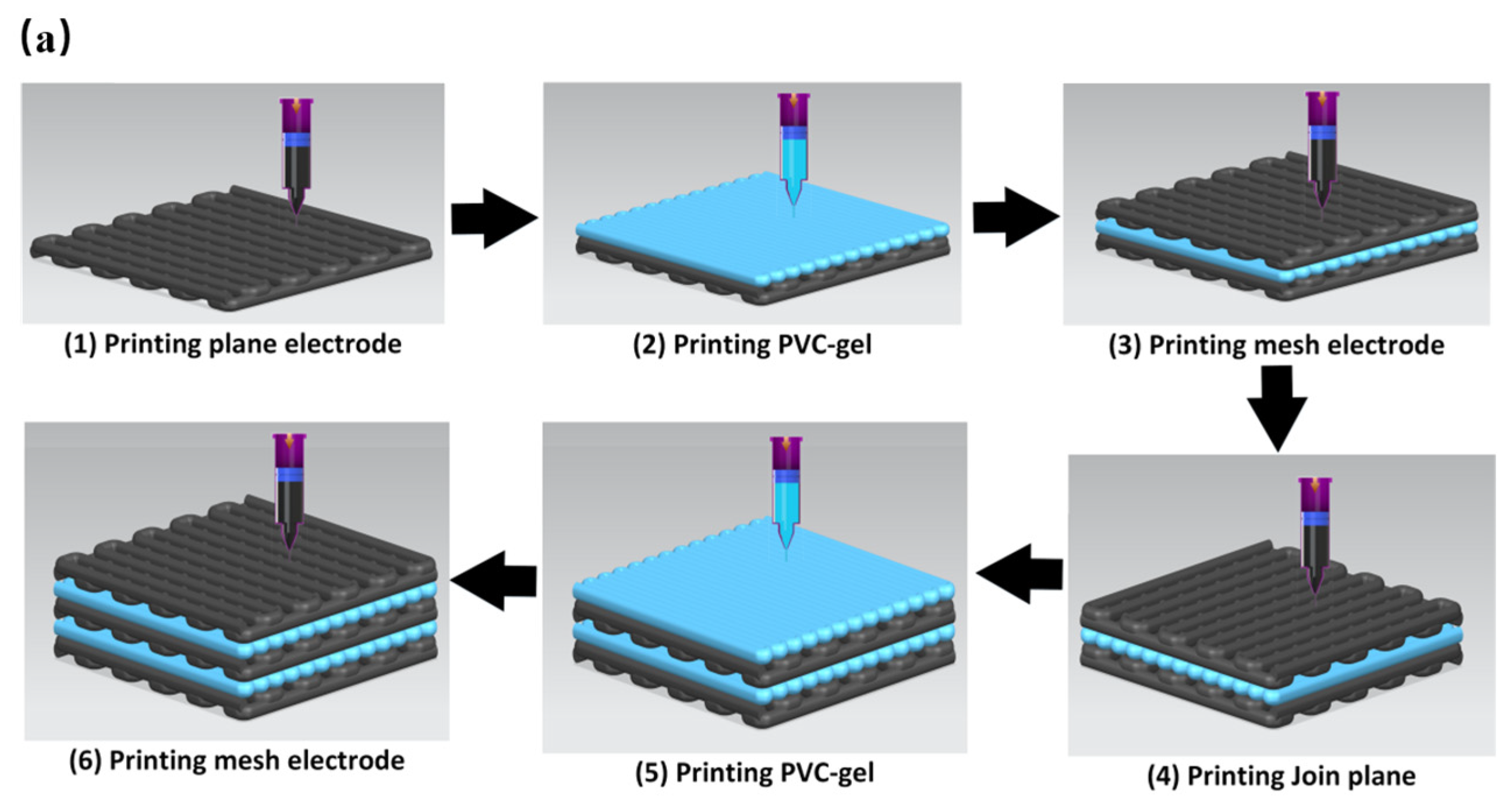

2.4. Integrated Printing of Multilayer Porous PVC Gel

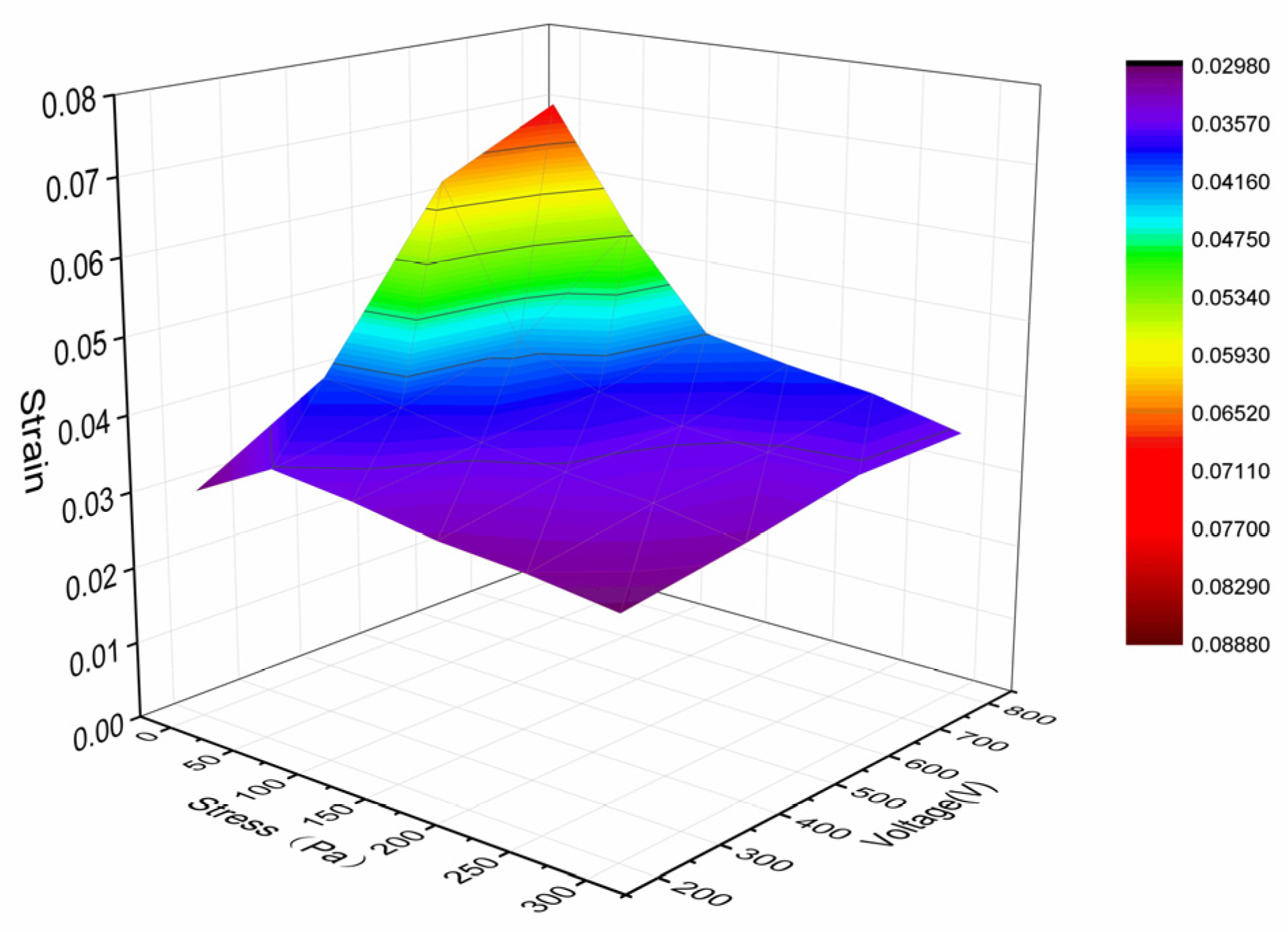

2.5. Performance Testing and Discussion

3. Conclusions

4. Materials and Methods

4.1. Designing and Manufacturing PVC Gel Artificial Muscle

4.2. Material System

4.3. Ink Characterization

4.4. Printing Process

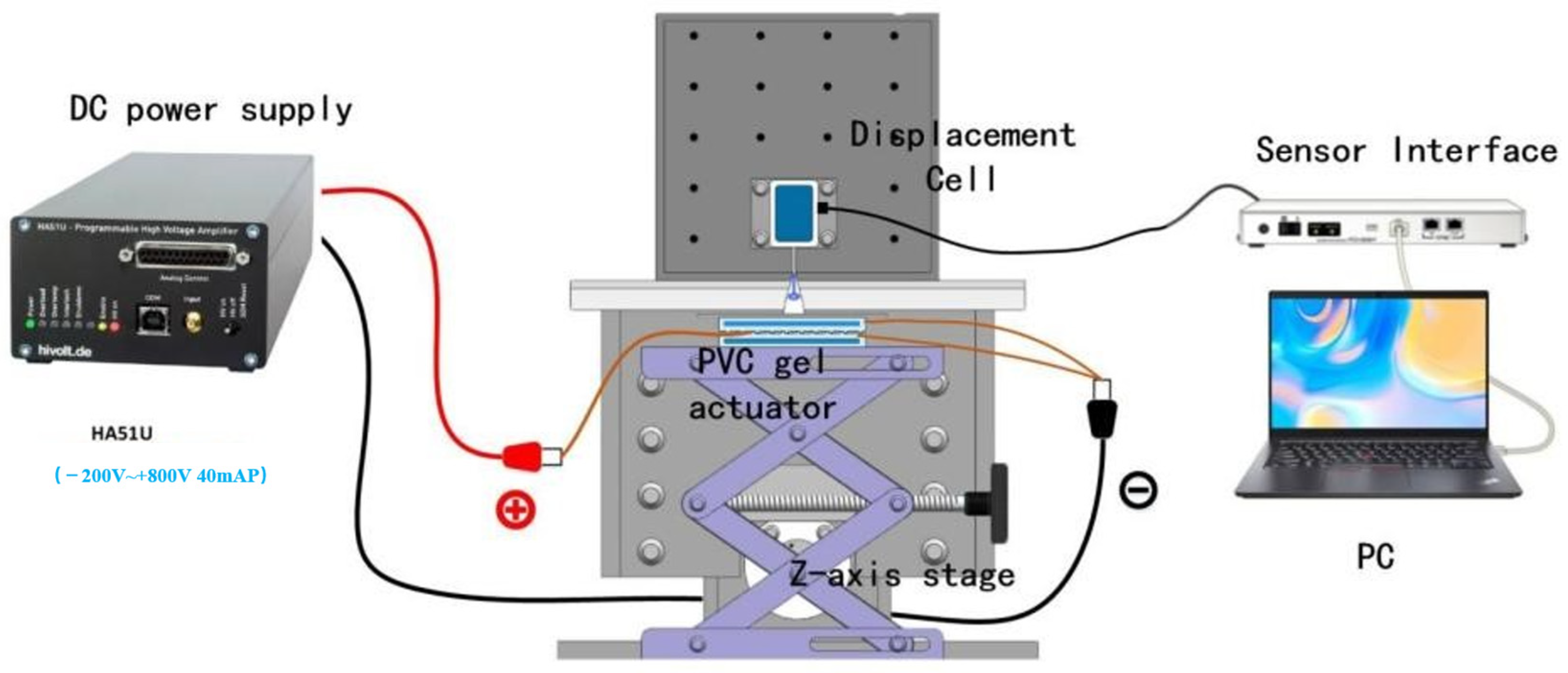

4.5. Performance Test of Artificial Muscles

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Umrao, S.; Tabassian, R.; Kim, J.; Nguyen, V.H.; Zhou, Q.; Nam, S.; Oh, I.K. MXene Artificial Muscles Based on Ionically Cross-Linked Ti3C2Tx Electrode for Kinetic Soft Robotics. Sci. Robot. 2019, 4, 7797. [Google Scholar] [CrossRef] [PubMed]

- Davidson, Z.S.; Shahsavan, H.; Aghakhani, A.; Guo, Y.; Hines, L.; Xia, Y.; Yang, S.; Sitti, M. Monolithic Shape-Programmable Dielectric Liquid Crystal Elastomer Actuators. Sci. Adv. 2019, 5, 0855. [Google Scholar] [CrossRef] [PubMed]

- Acome, E.; Mitchell, S.K.; Morrissey, T.G.; Emmett, M.B.; Benjamin, C.; King, M.; Radakovitz, M.; Keplinger, C. Hydraulically Amplified Self-Healing Electrostatic Actuators with Muscle-like Performance. Science 2018, 359, 61–65. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.; Yim, J.K.; Liang, J.; Shao, Z.; Qi, M.; Zhong, J.; Luo, Z.; Yan, X.; Zhang, M.; Wang, X.; et al. Insect-Scale Fast Moving and Ultrarobust Soft Robot. Sci. Robot. 2019, 4, 1594. [Google Scholar] [CrossRef] [PubMed]

- Wani, O.M.; Zeng, H.; Priimagi, A. A Light-Driven Artificial Flytrap. Nat. Commun. 2017, 8, 15546. [Google Scholar] [CrossRef] [PubMed]

- Gu, G.; Zou, J.; Zhao, R.; Zhao, X.; Zhu, X. Soft Wall-Climbing Robots. Sci. Robot. 2018, 3, 2874. [Google Scholar] [CrossRef] [PubMed]

- Zarek, M.; Layani, M.; Cooperstein, I.; Sachyani, E.; Cohn, D.; Magdassi, S. 3D Printing of Shape Memory Polymers for Flexible Electronic Devices. Adv. Mater. 2015, 28, 4449–4454. [Google Scholar] [CrossRef]

- Thetpraphi, K.; Kanlayakan, W.; Chaipo, S.; Moretto, G.; Kuhn, J.; Audigier, D.; Minh Quyen, L.; Cottinet, P.-J.; Petit, L.; Capsal, J.-F. 3D-Printed Electroactive Polymer Force-Actuator for Large and High Precise Optical Mirror Applications. Addit. Manuf. 2021, 47, 102199. [Google Scholar] [CrossRef]

- Sanchez, V.; Payne, C.J.; Preston, D.J.; Alvarez, J.T.; Weaver, J.C.; Atalay, A.T.; Boyvat, M.; Vogt, D.M.; Wood, R.J.; Whitesides, G.M.; et al. Smart Thermally Actuating Textiles. Adv. Mater. Technol. 2020, 5, 2000383. [Google Scholar] [CrossRef]

- Zhu, M.; Sun, Z.; Zhang, Z.; Shi, Q.; He, T.; Liu, H.; Chen, T.; Lee, C. Haptic-Feedback Smart Glove as a Creative Human-Machine Interface (HMI) for Virtual/Augmented Reality Applications. Sci. Adv. 2020, 6, 8693. [Google Scholar] [CrossRef]

- Byun, J.; Lee, Y.; Yoon, J.; Lee, B.; Oh, E.; Chung, S.; Lee, T.; Cho, K.-J.; Kim, J.; Hong, Y. Electronic Skins for Soft, Compact, Reversible Assembly of Wirelessly Activated Fully Soft Robots. Sci. Robot. 2018, 3, 9020. [Google Scholar] [CrossRef] [PubMed]

- Park, W.-H.; Bae, J.W.; Shin, E.-J.; Kim, S.-Y. Development of a Flexible and Bendable Vibrotactile Actuator Based on Wave-Shaped Poly(Vinyl Chloride)/Acetyl Tributyl Citrate Gels for Wearable Electronic Devices. Smart Mater. Struct. 2016, 25, 115020. [Google Scholar] [CrossRef]

- Hines, L.; Petersen, K.; Lum, G.Z.; Sitti, M. Soft Actuators for Small-Scale Robotics. Adv. Mater. 2016, 29, 1603483. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Hashimoto, M. PVC Gel Soft Actuator-Based Wearable Assist Wear for Hip Joint Support during Walking. Smart Mater. Struct. 2017, 26, 125003. [Google Scholar] [CrossRef]

- Ali, M.; Ueki, T.; Tsurumi, D.; Hirai, T. Influence of Plasticizer Content on the Transition of Electromechanical Behavior of PVC Gel Actuator. Langmuir 2011, 27, 7902–7908. [Google Scholar] [CrossRef] [PubMed]

- Shin, E.-J.; Park, W.-H.; Kim, S.-Y. Fabrication of a High-Performance Bending Actuator Made with a PVC Gel. Appl. Sci. 2018, 8, 1284. [Google Scholar] [CrossRef]

- Helps, T.; Taghavi, M.; Rossiter, J. Thermoplastic Electroactive Gels for 3D-Printable Artificial Muscles. Smart Mater. Struct. 2019, 28, 085001. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, Y.; Wang, Z.; He, Q.; Li, C.; Cai, S. 3D Printing of Electrically Responsive PVC Gel Actuators. ACS Appl. Mater. Interfaces 2021, 13, 24164–24172. [Google Scholar] [CrossRef] [PubMed]

- Luo, B.; Zhong, Y.; Chen, H.; Zhu, Z.; Wang, Y. Direct Writing Corrugated PVC Gel Artificial Muscle via Multi-Material Printing Processes. Polymers 2021, 13, 2734. [Google Scholar] [CrossRef]

- Plog, J.; Jiang, Y.; Pan, Y.; Yarin, A.L. Electrostatically-Assisted Direct Ink Writing for Additive Manufacturing. Addit. Manuf. 2021, 39, 101644. [Google Scholar] [CrossRef]

- Ravichandran, D.; Xu, W.; Kakarla, M.; Jambulkar, S.; Zhu, Y.; Song, K. Multiphase Direct Ink Writing (MDIW) for Multilayered Polymer/Nanoparticle Composites. Addit. Manuf. 2021, 47, 102322. [Google Scholar] [CrossRef]

- Muth, J.T.; Vogt, D.M.; Truby, R.L.; Mengüç, Y.; Kolesky, D.B.; Wood, R.J.; Lewis, J.A. Embedded 3D Printing of Strain Sensors within Highly Stretchable Elastomers. Adv. Mater. 2014, 26, 6307–6312. [Google Scholar] [CrossRef] [PubMed]

- Chausse, V.; Schieber, R.; Raymond, Y.; Ségry, B.; Sabaté, R.; Kolandaivelu, K.; Ginebra, M.-P.; Pegueroles, M. Solvent-Cast Direct-Writing as a Fabrication Strategy for Radiopaque Stents. Addit. Manuf. 2021, 48, 102392. [Google Scholar] [CrossRef]

- Yuk, H.; Lu, B.; Lin, S.; Qu, K.; Xu, J.; Luo, J.; Zhao, X. 3D Printing of Conducting Polymers. Nat. Commun. 2020, 11, 1604. [Google Scholar] [CrossRef] [PubMed]

- Xiong, H.; Chen, H.; Zhao, L.; Huang, Y.; Zhou, K.; Zhang, D. SiCw/SiCp Reinforced 3D-SiC Ceramics Using Direct Ink Writing of Polycarbosilane-Based Solution: Microstructure, Composition and Mechanical Properties. J. Eur. Ceram. Soc. 2019, 39, 2648–2657. [Google Scholar] [CrossRef]

- Franchin, G.; Wahl, L.; Colombo, P. Direct Ink Writing of Ceramic Matrix Composite Structures. J. Am. Ceram. Soc. 2017, 100, 4397–4401. [Google Scholar] [CrossRef]

- Lewis, J.A. Direct Ink Writing of 3D Functional Materials. Adv. Funct. Mater. 2006, 16, 2193–2204. [Google Scholar] [CrossRef]

- Smay, J.E.; Cesarano, J.; Lewis, J.A. Colloidal Inks for Directed Assembly of 3-D Periodic Structures. Langmuir 2002, 18, 5429–5437. [Google Scholar] [CrossRef]

| Moving Speed | Air Pressure | Scanning Spacing | Layer Height | Curing Temperature and Time |

|---|---|---|---|---|

| 20 mm/s | 0.25 MPa | 0.166 mm | 0.155 | 80 °C, 2 h |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luo, B.; Lu, H.; Zhong, Y.; Zhu, K.; Wang, Y. Carbon Nanotube-Doped 3D-Printed Silicone Electrode for Manufacturing Multilayer Porous Plasticized Polyvinyl Chloride Gel Artificial Muscles. Gels 2024, 10, 416. https://doi.org/10.3390/gels10070416

Luo B, Lu H, Zhong Y, Zhu K, Wang Y. Carbon Nanotube-Doped 3D-Printed Silicone Electrode for Manufacturing Multilayer Porous Plasticized Polyvinyl Chloride Gel Artificial Muscles. Gels. 2024; 10(7):416. https://doi.org/10.3390/gels10070416

Chicago/Turabian StyleLuo, Bin, Hanjing Lu, Yiding Zhong, Kejun Zhu, and Yanjie Wang. 2024. "Carbon Nanotube-Doped 3D-Printed Silicone Electrode for Manufacturing Multilayer Porous Plasticized Polyvinyl Chloride Gel Artificial Muscles" Gels 10, no. 7: 416. https://doi.org/10.3390/gels10070416

APA StyleLuo, B., Lu, H., Zhong, Y., Zhu, K., & Wang, Y. (2024). Carbon Nanotube-Doped 3D-Printed Silicone Electrode for Manufacturing Multilayer Porous Plasticized Polyvinyl Chloride Gel Artificial Muscles. Gels, 10(7), 416. https://doi.org/10.3390/gels10070416