Utilization of Infrared Drying as Alternative to Spray- and Freeze-Drying for Low Energy Consumption in the Production of Powdered Gelatin

Abstract

1. Introduction

2. Results and Discussion

2.1. Effect of Different Drying Procedures on the Physical Features of Gelatin

2.2. Electrical and Specific Energy Consumption of Different Drying Procedures

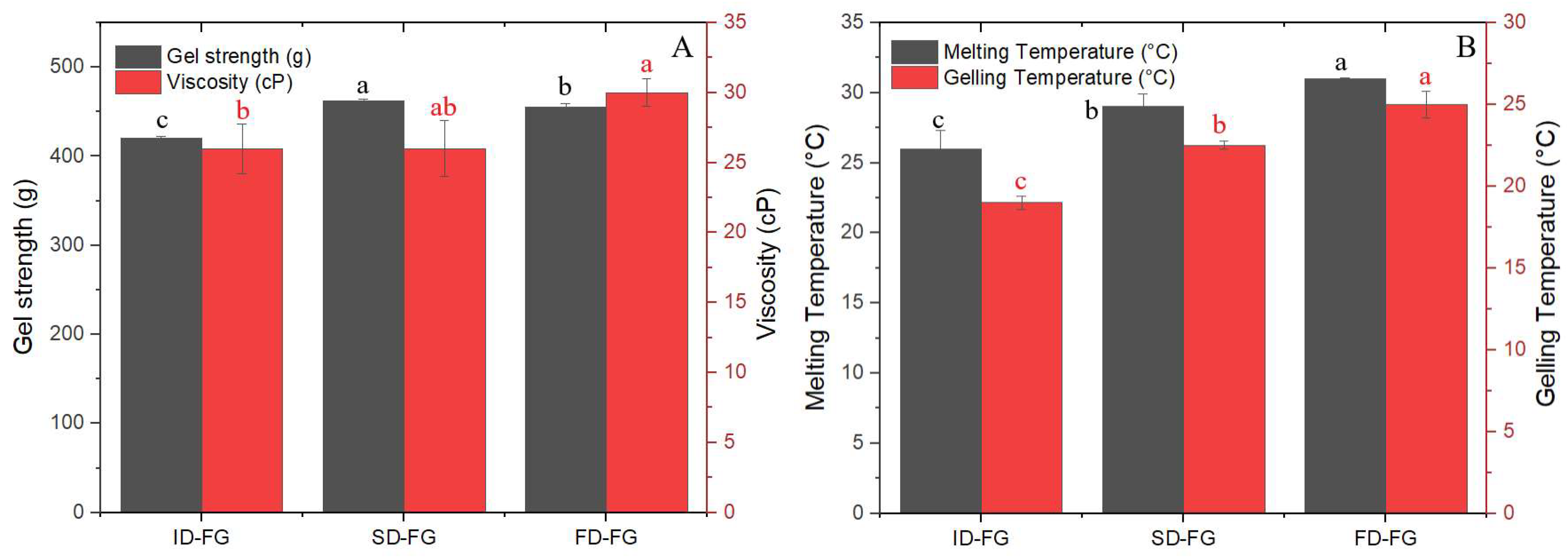

2.3. Effect of Different Drying Procedures on the Quality of Gelatin

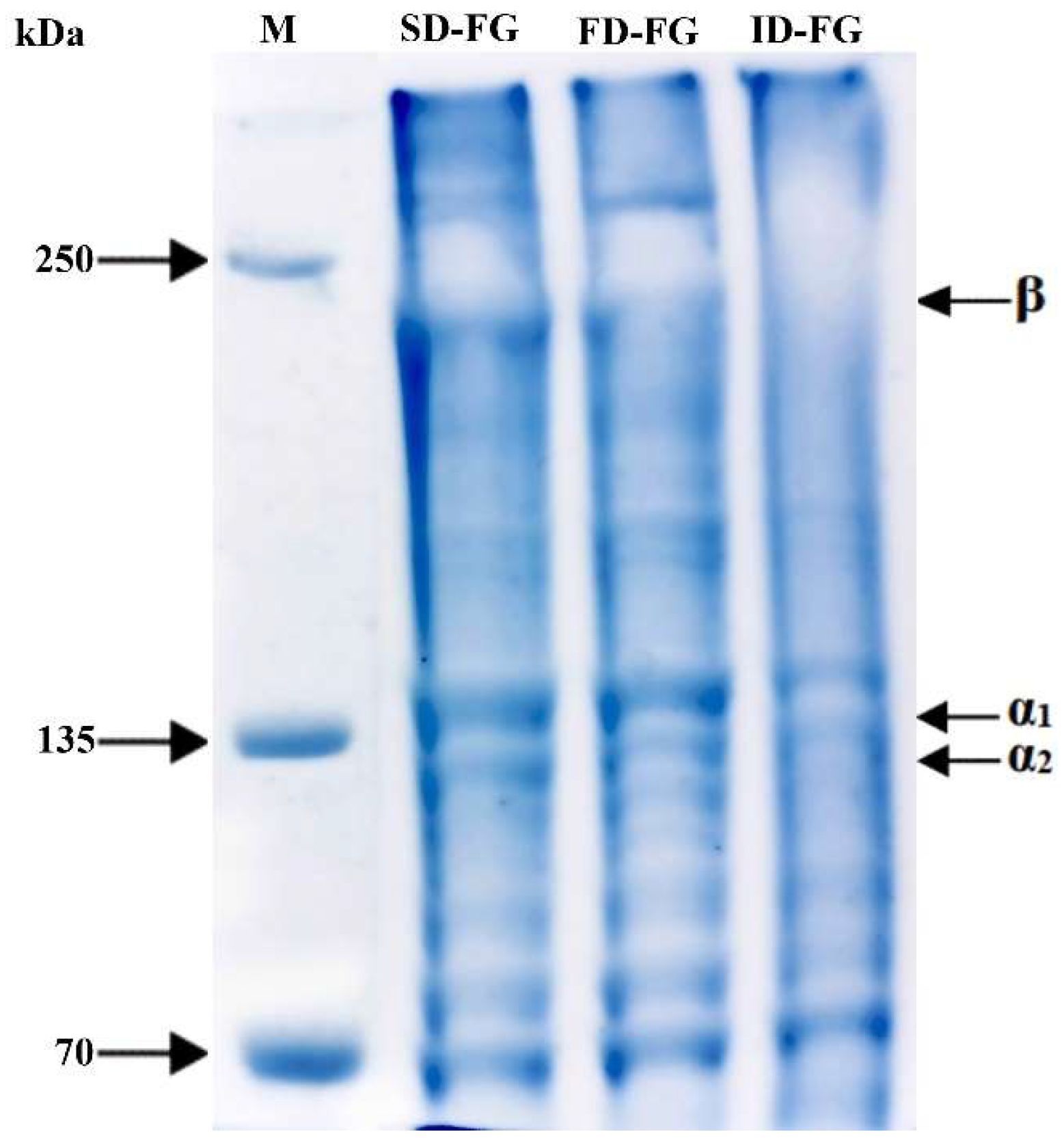

2.4. Effect of Different Drying Procedures on Molecular Weight Distribution of Gelatin

2.5. Effect of Different Drying Procedures on Thermal Behavior of Gelatin

2.6. Effect of Different Drying Procedures on UV–Vis Absorption Spectra of Gelatin

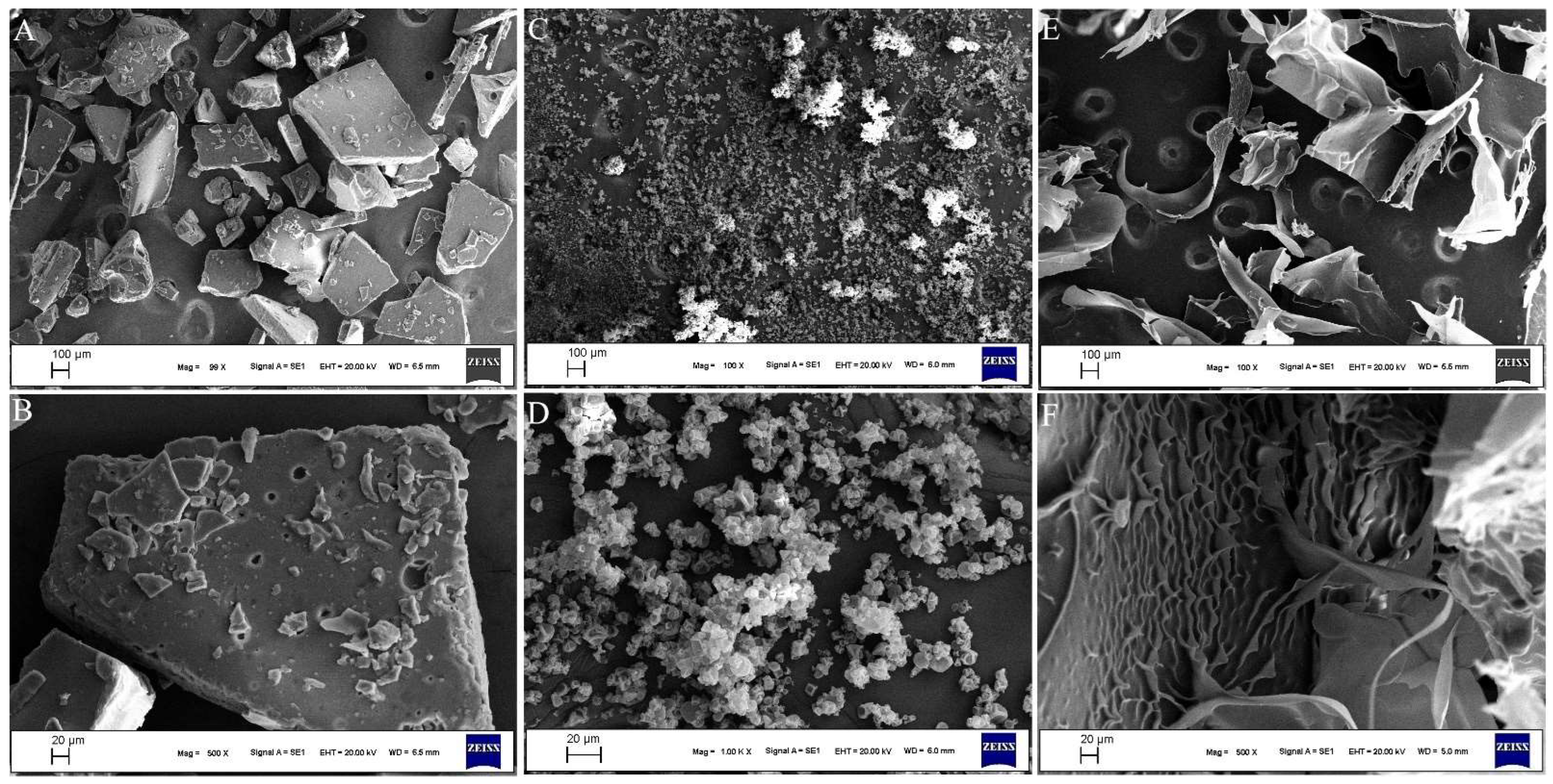

2.7. Effect of Different Drying Procedures on Surface Morphology of Gelatin

3. Conclusions

4. Materials and Methods

4.1. Materials

4.2. Methods

4.2.1. Pretreatment and Gelatin Extraction

4.2.2. Drying Processes

Infrared Drying (ID) of Gelatin Extract

Spray-Drying (SD) of Gelatin Extract

Freeze-Drying (FD) of Gelatin Extract

4.2.3. Electricity and Energy Consumption Values of Drying Systems

4.2.4. Solubility, Color, pH, Conductivity, Carr Index and Hausner Ratio of Dried Gelatins

4.2.5. Water-Holding and Fat-Binding Capacity

4.2.6. Gel Strength, Viscosity, Gelling and Melting Temperature

4.2.7. SDS-Page Pattern of Powdered Gelatins

4.2.8. Thermal Analysis

4.2.9. UV-Vis Absorption Spectrum

4.2.10. Morphological Characterization of Gelatin Powders

4.3. Statistical Analysis

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Siburian, W.Z.; Rochima, E.; Andriani, Y.; Praseptiangga, D. Fish gelatin (defifinition, manufacture, analysis of quality characteristics, and application): A review. Int. J. Fish. Aquat. 2020, 8, 90–95. [Google Scholar]

- Ruan, Q.; Chen, W.; Lv, M.; Zhang, R.; Luo, X.; Yu, E.; Pan, C.; Ma, H. Influences of trypsin pretreatment on the structures, composition, and functional characteristics of skin gelatin of tilapia, grass carp, and sea perch. Mar. Drugs 2023, 21, 423. [Google Scholar] [CrossRef] [PubMed]

- Ding, M.; Zhang, T.; Zhang, H.; Tao, N.; Wang, X.; Zhong, J. Gelatin-stabilized traditional emulsions: Emulsion forms, droplets, and storage stability. Food Sci. Hum. Wellness 2020, 9, 320–327. [Google Scholar] [CrossRef]

- Cansu, Ü. Comparative evaluation of different separation and concentration procedures on some quality and functional properties of fish gelatin. Innov. Food Sci. Emerg. Technol. 2023, 83, 103237. [Google Scholar] [CrossRef]

- Dehnad, D.; Jafari, S.M.; Afrasiabi, M. Influence of drying on functional properties of food biopolymers: From traditional to novel dehydration techniques. Trends Food Sci. Technol. 2016, 57, 116–131. [Google Scholar] [CrossRef]

- Feng, X.; Dai, H.; Ma, L.; Fu, Y.; Yu, Y.; Zhu, H.; Wang, H.; Sun, Y.; Tan, H.; Zhang, Y. Effect of drying methods on the solubility and amphiphilicity of room temperature soluble gelatin extracted by microwave-rapid freezing-thawing coupling. Food Chem. 2021, 351, 129226. [Google Scholar] [CrossRef] [PubMed]

- Kanwate, B.W.; Ballari, R.V.; Kudre, T.G. Influence of spray-drying, freeze-drying and vacuum-drying on physicochemical and functional properties of gelatin from Labeo rohita swim bladder. Int. J. Biol. Macromol. 2019, 121, 135–141. [Google Scholar] [CrossRef] [PubMed]

- Salem, A.; Fakhfakh, N.; Jridi, M.; Abdelhedi, O.; Nasri, M.; Debeaufort, F.; Zouari, N. Microstructure and characteristic properties of dogfish skin gelatin gels prepared by freeze/spray-drying methods. Int. J. Biol. Macromol. 2020, 162, 1–10. [Google Scholar] [CrossRef]

- Mad-Ali, S.; Benjakul, S.; Prodpran, T.; Maqsood, S. Interfacial properties of gelatin from goat skin as influenced by drying methods. LWT 2016, 73, 102–107. [Google Scholar] [CrossRef]

- Sae-Leaw, T.; Benjakul, S.; O’Brien, N.M. Effect of pretreatments and drying methods on the properties and fishy odor/flavor of gelatin from seabass (Lates calcarifer) skin. Dry. Technol. 2016, 34, 53–65. [Google Scholar] [CrossRef]

- Riadh, M.H.; Ahmad, S.A.B.; Marhaban, M.H.; Soh, A.C. Infrared heating in food drying: An overview. Dry. Technol. 2015, 33, 322–335. [Google Scholar] [CrossRef]

- Pawar, S.B.; Pratape, V.M. Fundamentals of infrared heating and its application in drying of food materials: A review. J. Food Process Eng. 2017, 40, e12308. [Google Scholar] [CrossRef]

- Sakare, P.; Prasad, N.; Thombare, N.; Singh, R.; Sharma, S.C. Infrared drying of food materials: Recent advances. Food Eng. Rev. 2020, 12, 381–398. [Google Scholar] [CrossRef]

- Rasli, H.I.; Sarbon, N.M. Effects of different drying methods on the rheological, functional and structural properties of chicken skin gelatin compared to bovine gelatin. Int. Food Res. J. 2015, 22, 584. [Google Scholar]

- Ninan, G.; Zynudheen, A.A.; Joseph, J. Physico-chemical and texture properties of gelatin and water gel desserts prepared from the skin of freshwater carps. Fish. Technol. 2011, 48, 67–74. [Google Scholar]

- Aksun-Tümerkan, E.T.; Cansu, Ü.; Boran, G.; Mac Regenstein, J.; Özoğul, F. Physiochemical and functional properties of gelatin obtained from tuna, frog and chicken skins. Food Chem. 2019, 287, 273–279. [Google Scholar] [CrossRef] [PubMed]

- Zhang, D.; Li, H.; Wang, Z.; Emara, A.M.; Hu, Y.; He, Z. Effects of in vitro oxidation on myofbrillar protein charge, aggregation, and structural characteristics. Food Chem. 2020, 332, 127396. [Google Scholar] [CrossRef]

- Yousaf, A.M.; Kim, D.W.; Kim, J.K.; Kim, J.O.; Yong, C.S.; Choi, H.G. Novel fenofibrate-loaded gelatin microcapsules with enhanced solubility and excellent flowability: Preparation and physicochemical characterization. Powder Technol. 2015, 275, 257–262. [Google Scholar] [CrossRef]

- Hamzeh, A.; Benjakul, S.; Sae-Leaw, T.; Sinthusamran, S. Effect of drying methods on gelatin from splendid squid (Loligo formosana) skins. Food Biosci. 2018, 26, 96–103. [Google Scholar] [CrossRef]

- Pirasteh, G.; Saidur, R.; Rahman, S.M.A.; Rahim, N.A. A review on development of solar drying applications. Renew. Sustain. Energy Rev. 2014, 31, 133–148. [Google Scholar] [CrossRef]

- Lingayat, A.; Balijepalli, R.; Chandramohan, V.P. Applications of solar energy based drying technologies in various industries–A review. Sol. Energy 2021, 229, 52–68. [Google Scholar] [CrossRef]

- Li, N.; Wang, Y.; Gan, Y.; Wang, S.; Wang, Z.; Zhang, C.; Wang, Z. Physicochemical and functional properties of protein isolate recovered from Rana chensinensis ovum based on different drying techniques. Food Chem. 2022, 396, 133632. [Google Scholar] [CrossRef] [PubMed]

- Saifullah, M.; McCullum, R.; McCluskey, A.; Vuong, Q. Effects of different drying methods on extractable phenolic compounds and antioxidant properties from lemon myrtle dried leaves. Heliyon 2019, 5, 12. [Google Scholar] [CrossRef] [PubMed]

- Kaveh, M.; Abbaspour-Gilandeh, Y.; Fatemi, H.; Chen, G. Impact of different drying methods on the drying time, energy, and quality of green peas. J. Food Process. Preserv. 2021, 45, e15503. [Google Scholar] [CrossRef]

- Xu, Y.; Xiao, Y.; Lagnika, C.; Li, D.; Liu, C.; Jiang, N.; Song, J.; Zhang, M. A comparative evaluation of nutritional properties, an-tioxidant capacity and physical characteristics of cabbage (Brassica oleracea var. capitate Var L.) subjected to different drying methods. Food Chem. 2020, 309, 124935. [Google Scholar]

- Mad-Ali, S.; Benjakul, S.; Prodpran, T.; Maqsood, S. Characteristics and gel properties of gelatin from goat skin as affected by spray-drying. Dry. Technol. 2017, 35, 218–226. [Google Scholar] [CrossRef]

- Ahmad, T.; Ismail, A.; Ahmad, S.A.; Khalil, K.A.; Kumar, Y.; Adeyemi, K.D.; Sazili, A.Q. Recent advances on the role of process variables affecting gelatin yield and characteristics with special reference to enzymatic extraction: A review. Food Hydrocoll. 2017, 63, 85–96. [Google Scholar] [CrossRef]

- Chen, X.; Ma, L.; Guo, T.; Yu, Y.; Li, X.; Xia, W.; Zhang, Y. Effects of freezing thawing pretreatment combined with liquid nitrogen and dilute acid on the gelatinization of collagen. Int. J. Biol. Macromol. 2018, 118, 435–441. [Google Scholar] [CrossRef] [PubMed]

- Koli, J.M.; Sagar, B.V.; Kamble, R.S.; Sharangdhar, S.T. Functional properties of gelatin extracted from four different types of fishes: A comparative study. Indian J. Fundam. Appl. Life Sci. 2014, 4, 322–327. [Google Scholar]

- Tkaczewska, J.; Wielgosz, M.; Kulawik, P.; Zając, M. The effect of drying temperature on the properties of gelatin from carps (Cyprinus carpio) skin. Czech J. Food Sci. 2019, 37, 246–251. [Google Scholar] [CrossRef]

- Al-Harrasi, A.; Bhatia, S.; Al-Azri, M.S.; Ullah, S.; Najmi, A.; Albratty, M.; Meraya, A.M.; Mohan, S.; Aldawsari, M.F. Effect of drying temperature on physical, chemical, and antioxidant properties of ginger oil loaded gelatin-sodium alginate edible films. Membranes 2022, 12, 862. [Google Scholar] [CrossRef]

- Mohammed, M.A.P. Functional properties of tilapia’s fish scale gelatin film: Effects of different type of plasticizers. Sains Malays. 2020, 49, 2221–2229. [Google Scholar]

- Xu, M.; Wei, L.; Xiao, Y.; Bi, H.; Yang, H.; Du, Y. Physicochemical and functional properties of gelatin extracted from Yak skin. Int. J. Biol. Macromol. 2017, 95, 1246–1253. [Google Scholar] [CrossRef]

- Wang, H.; Tong, X.; Yuan, Y.; Peng, X.; Zhang, Q.; Zhang, S.; Xie, C.; Zhang, X.; Yan, S.; Xu, J.; et al. Effect of spray-drying and freeze-drying on the properties of soybean hydrolysates. J. Chem. 2020, 2020, 9201457. [Google Scholar] [CrossRef]

- Rudra, S.G.; Sethi, S.; Jha, S.K.; Kumar, R. Physico-chemical and functional properties of cowpea protein isolate as affected by the dehydration technique. Legume Res. -Int. J. 2016, 39, 370–378. [Google Scholar] [CrossRef]

- Cho, S.M.; Kwak, K.S.; Park, D.C.; Gu, Y.S.; Ji, C.I.; Jang, D.H. Processing optimization and functional properties of gelatin from shark (Isurus oxyrinchus) cartilage. Food Hydrocolloids. 2004, 18, 573–579. [Google Scholar] [CrossRef]

- Turchiuli, C.; Eloualia, Z.; El Mansouri, N.; Dumoulin, E. Fluidised bed agglomeration: Agglomerates shape and end-use properties. Powder Technol. 2005, 157, 168–175. [Google Scholar] [CrossRef]

- British Standards Institution (BSI). Methods for Sampling and Testing Gelatin (Physical and Chemical Methods); BSI: London, UK, 1975. [Google Scholar]

- Gelatin Manufacturers Institute of America. GMIA Standard Methods for the Testing of Edible Gelatin; Gelatin Manufacturers Institute of America: New York, NY, USA, 2019; pp. 13–15. [Google Scholar]

- Karim, B.F.; Cansu, Ü.; Boran, G. Quality and functional features of gelatine extracted from chicken skin in comparison with commercial gelatines from porcine, bovine and piscine. Acta Aliment. 2022, 51, 194–203. [Google Scholar] [CrossRef]

- Laemmli, U.K. Cleavage of structural proteins during the assembly of the head of bacterio-phage T4. Nature 1970, 227, 680–685. [Google Scholar] [CrossRef]

- Başyiğit, B.; Görgüç, A.; Gençdağ, E.; Cansu, Ü.; Yılmaz, F.M.; Karaaslan, M. Functional characterization of high-yield plant protein powder valorized from de-oiled sour cherry seed using microwave-assisted enzymatic extraction followed by spray-and freeze-drying. Biomass Convers. Biorefinery 2023, 13, 14657–14671. [Google Scholar] [CrossRef]

| ID-FG | SD-FG | FD-FG | |

|---|---|---|---|

| WHC (g water/g protein) | 5.37 ± 0.7 b | 10.22 ± 1.1 a | 2.11 ± 0.1 c |

| FBA (g oil/g protein) | 0.75 ± 0.0 c | 2.10 ± 0.1 b | 15.39 ± 0.2 a |

| Solubility (%) | 96.36 ± 3.6 a | 96.55 ± 2.5 a | 90.15 ± 3.1 b |

| Hausner ratio | 1.34 ± 0.03 c | 1.56 ± 0.05 b | 1.73 ± 0.03 a |

| Carr index | 25.26 ± 1.50 c | 35.94 ± 2.21 b | 42.09 ± 1.10 a |

| pH | 3.67 ± 0.0 a | 3.68 ± 0.0 a | 3.62 ± 0.0 a |

| Transparency | 39.10 ± 0.5 b | 53.00 ± 0.4 a | 26.80 ± 0.1 c |

| Conductivity (µS/cm) | 670 ± 5.0 a | 670 ± 4.5 a | 693 ± 6.8 a |

| L* | 70.90 ± 2.2 c | 95.40 ± 1.0 a | 80.47 ± 1.2 b |

| a* | 6.10 ± 0.5 a | 3.55 ± 0.3 b | −0.75 ± 0.2 c |

| b* | 30.70 ± 0.8 a | 7.32 ± 0.7 c | 14.85 ± 1.1 b |

| Hue angle | 1.38 ± 0.0 a | 1.12 ± 0.0 b | −1.51 ± 0.0 c |

| Chroma | 31.32 ± 0.9 a | 8.15 ± 0.6 c | 14.90 ± 1.0 b |

| ID-FG | SD-FG | FD-FG | |

|---|---|---|---|

| Electricity consumption (kW*h/g gelatin) | 0.217 ± 0.00 c | 1.784 ± 0.01 a | 1.528 ± 0.03 b |

| Specific Energy Consumption (SEC) (kW*h/kg) | 3.41 ± 0.10 c | 8.46 ± 0.31 b | 25.33 ± 0.24 a |

| Drying time (min/g gelatin) | 45.96 ± 0.11 c | 64.18 ± 0.04 b | 147.16 ± 1.3 a |

| Drying yield (%) | 94.70 ± 0.13 b | 60.31 ± 0.51 c | 96.32 ± 0.20 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cansu, Ü. Utilization of Infrared Drying as Alternative to Spray- and Freeze-Drying for Low Energy Consumption in the Production of Powdered Gelatin. Gels 2024, 10, 522. https://doi.org/10.3390/gels10080522

Cansu Ü. Utilization of Infrared Drying as Alternative to Spray- and Freeze-Drying for Low Energy Consumption in the Production of Powdered Gelatin. Gels. 2024; 10(8):522. https://doi.org/10.3390/gels10080522

Chicago/Turabian StyleCansu, Ümran. 2024. "Utilization of Infrared Drying as Alternative to Spray- and Freeze-Drying for Low Energy Consumption in the Production of Powdered Gelatin" Gels 10, no. 8: 522. https://doi.org/10.3390/gels10080522

APA StyleCansu, Ü. (2024). Utilization of Infrared Drying as Alternative to Spray- and Freeze-Drying for Low Energy Consumption in the Production of Powdered Gelatin. Gels, 10(8), 522. https://doi.org/10.3390/gels10080522