Preparation, Characterization and Formation Mechanism of High Pressure-Induced Whey Protein Isolate/κ-Carrageenan Composite Emulsion Gel Loaded with Curcumin

Abstract

1. Introduction

2. Results and Discussion

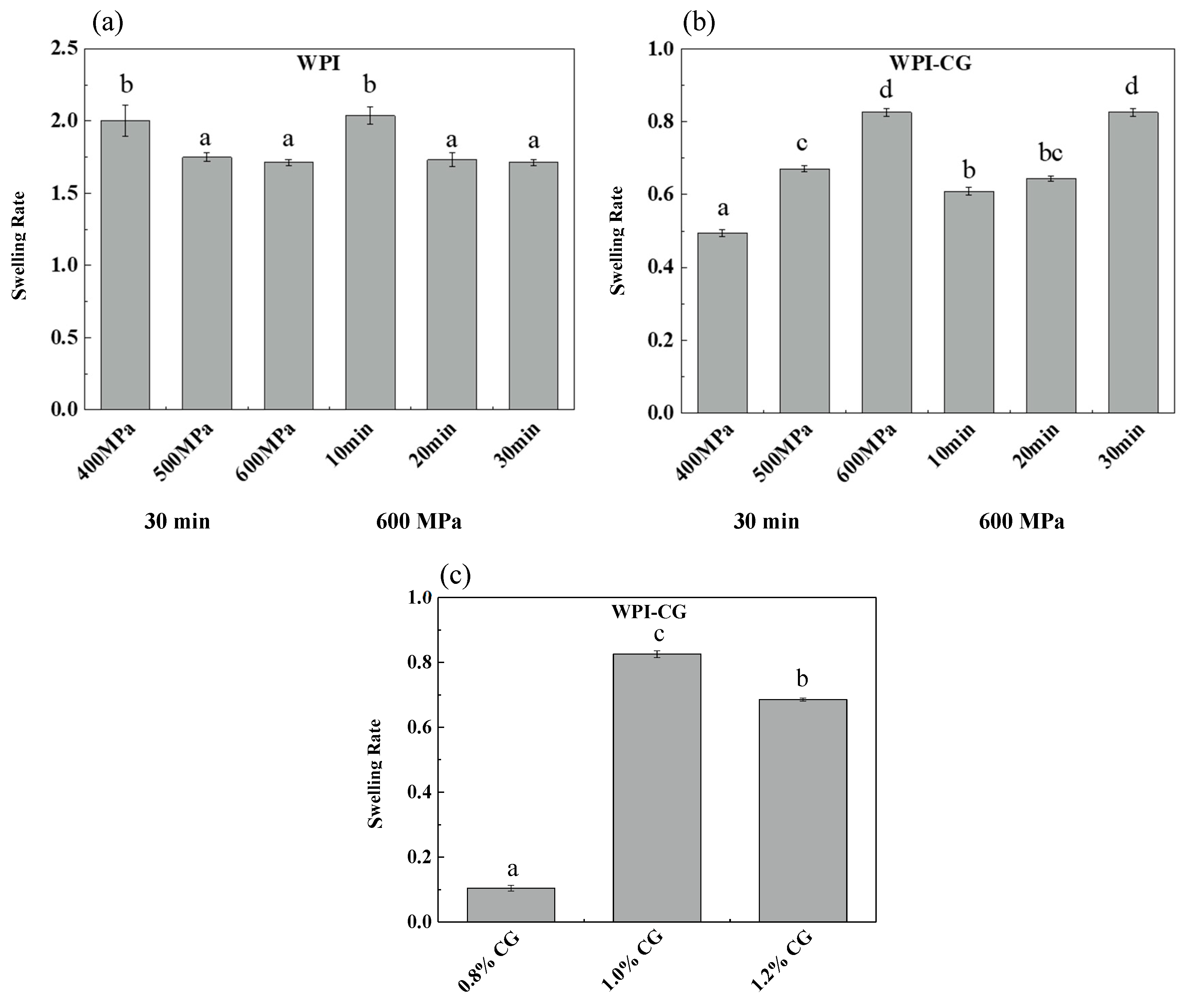

2.1. Swelling Rate

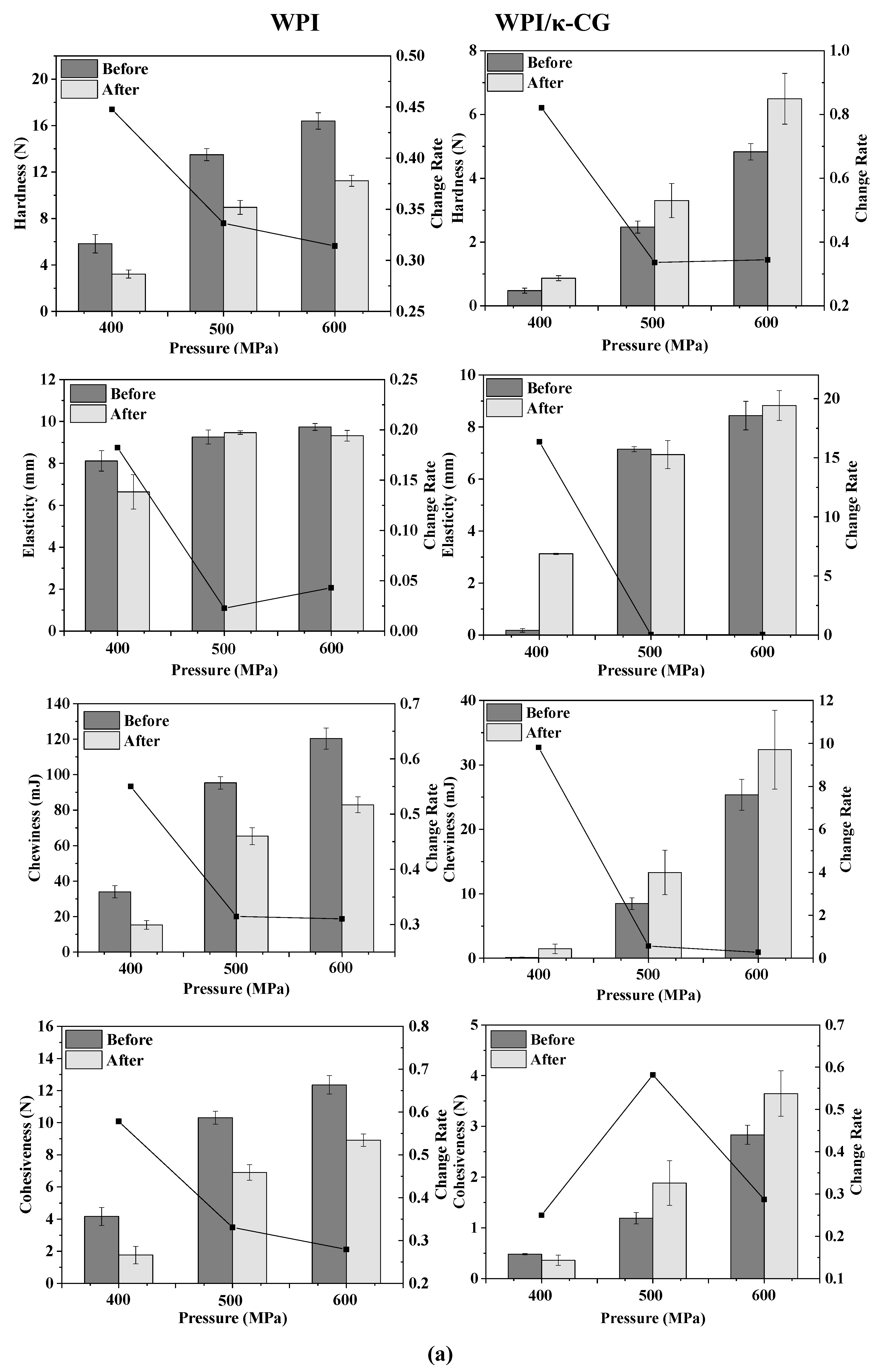

2.2. Texture Profile Analysis (TPA)

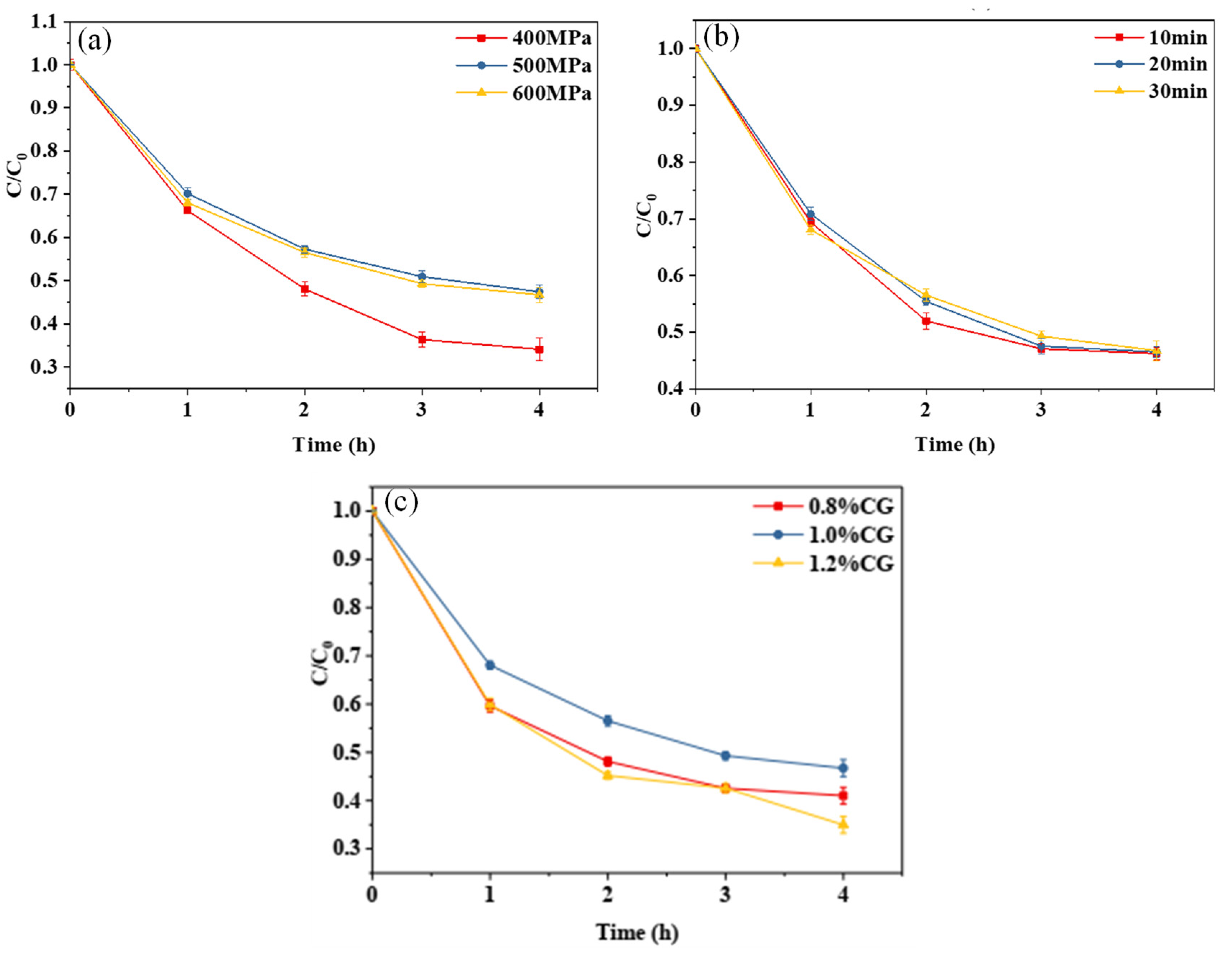

2.3. Stability of Curcumin

2.3.1. Photochemical Stability

2.3.2. Thermal Stability

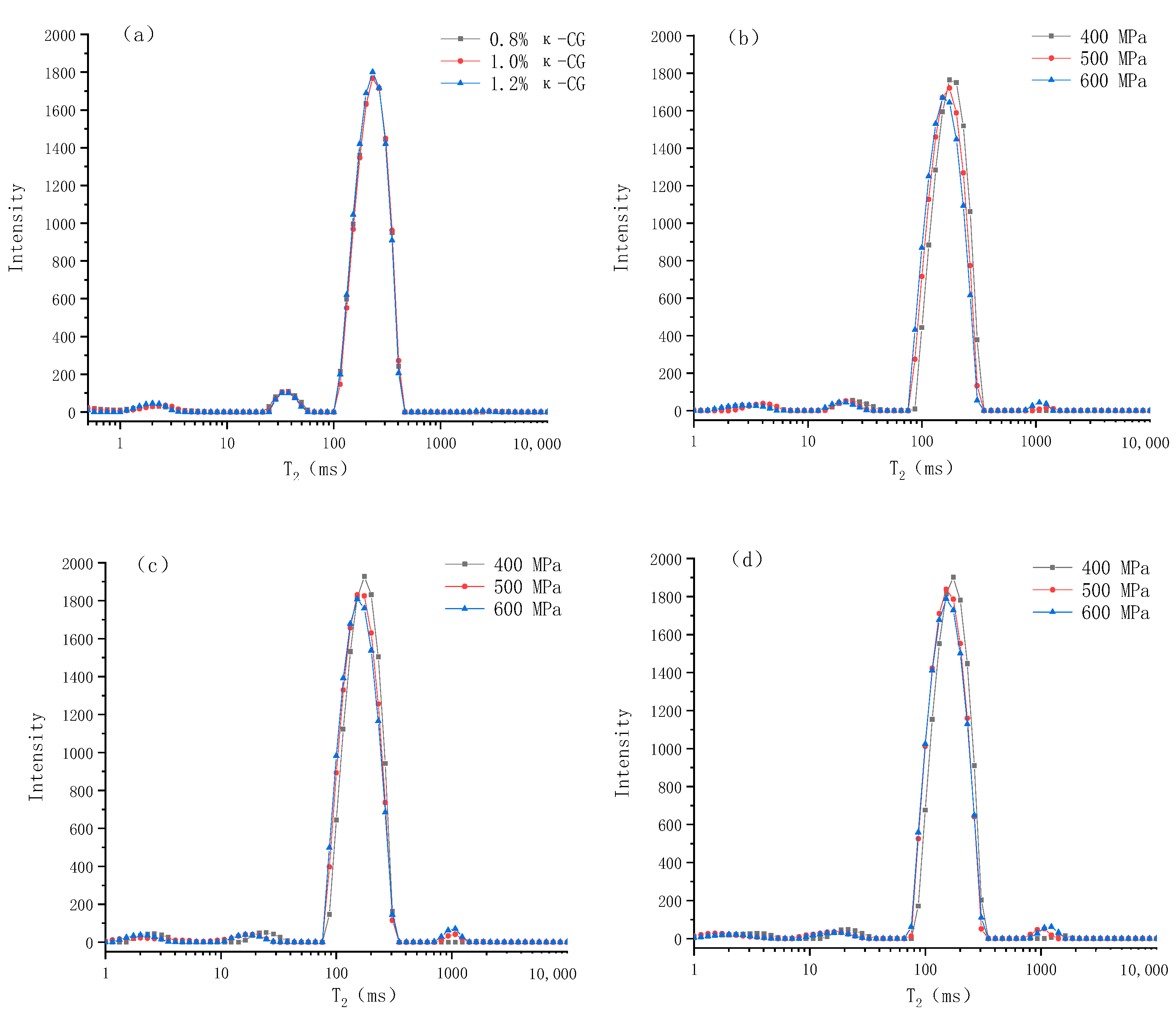

2.4. LF-NMR

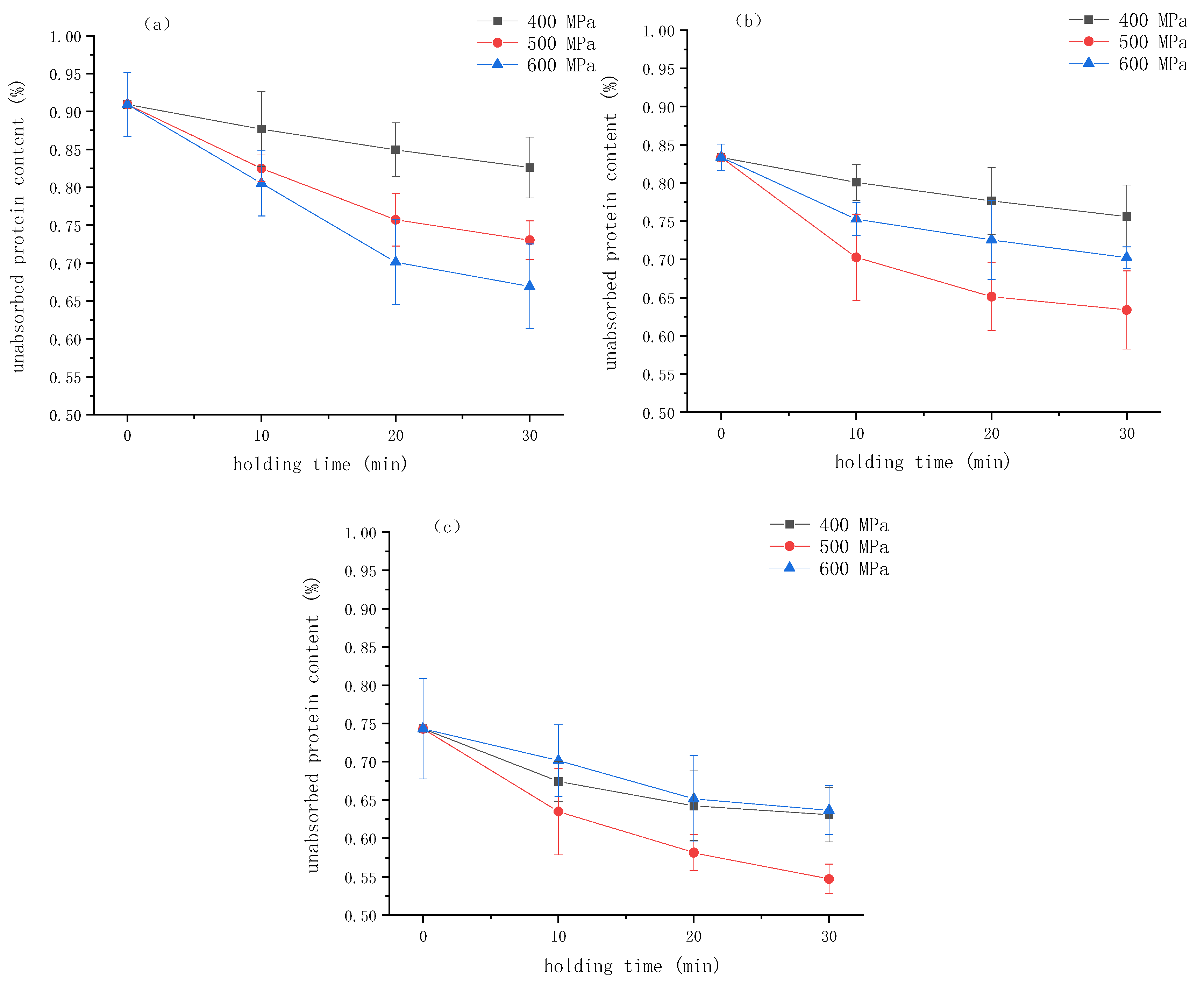

2.5. The Content of Interface Protein

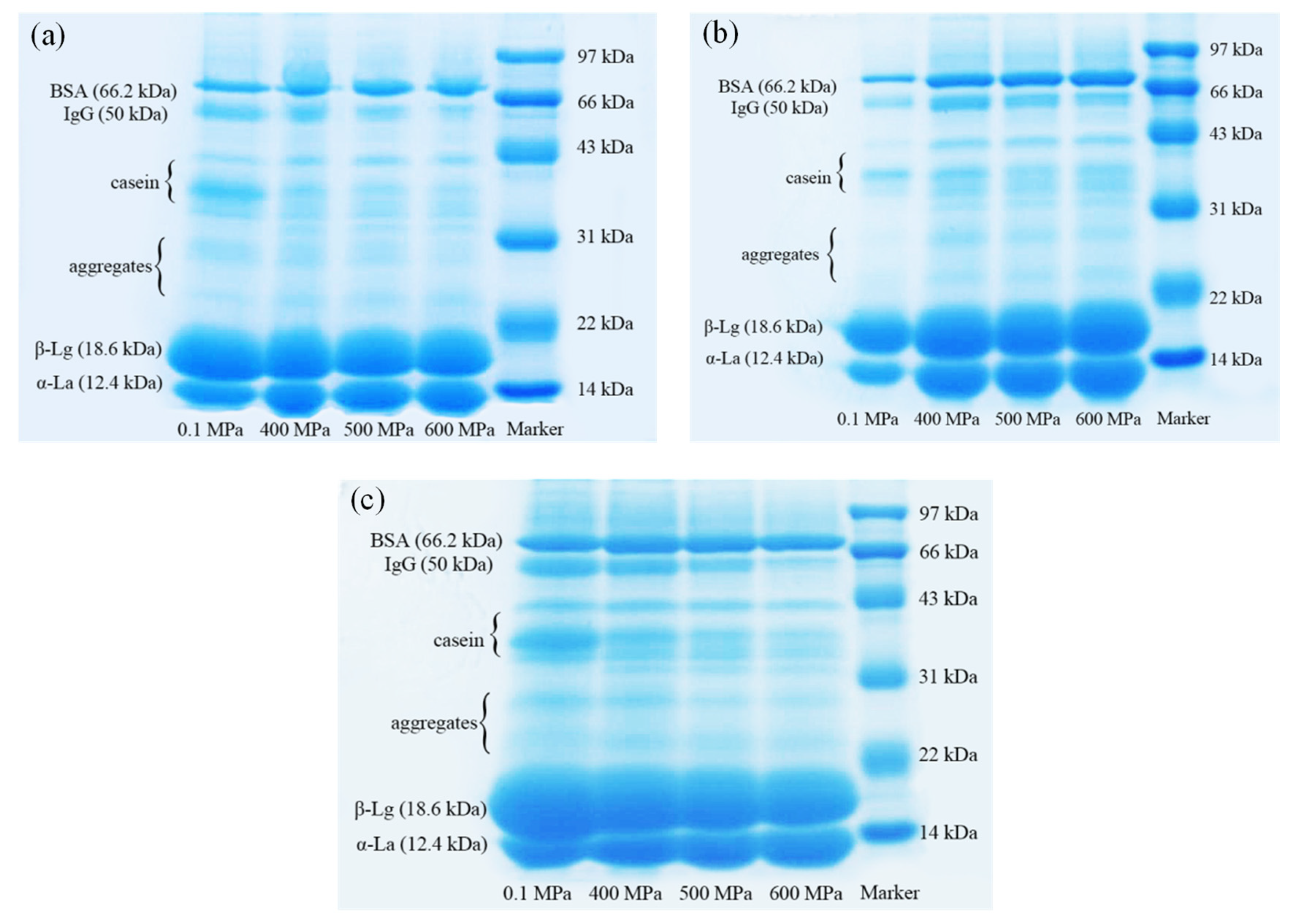

2.6. SDS-PAGE

3. Conclusions

4. Materials and Methods

4.1. Materials

4.2. Preparation of HPP-Induced WPI-CG Composite Emulsion Gel Loaded with Curcumin

4.2.1. Preparation of WPI-CG Compound Solution

4.2.2. Preparation of Curcumin-Loaded Oil-in-Water Emulsion

4.2.3. High Pressure Processing (HPP)

4.3. Swelling Rate Measurement

4.4. Texture Profile Analysis (TPA)

4.5. Stability of Curcumin in the Emulsion Gel

4.5.1. Photochemical Stability

4.5.2. Thermal Stability

4.6. Low-Field Nuclear Magnetic Resonance (LF-NMR)

4.7. The Contents of Interface Protein

4.8. Sodium Dodecyl Sulfate-Polyacrylamide Gel Electrophoresis (SDS-PAGE)

4.9. Statistical Analysis

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mun, S.; Kim, Y.R.; Shin, M.; McClements, D.J. Control of lipid digestion and nutraceutical bioaccessibility using starch-based filled hydrogels: Influence of starch and surfactant type. Food Hydrocoll. 2015, 44, 380–389. [Google Scholar] [CrossRef]

- Chaudhry, Q.; Castle, L. Food applications of nanotechnologies: An overview of opportunities and challenges for developing countries. Trends Food Sci. Technol. 2011, 22, 595–603. [Google Scholar] [CrossRef]

- Cushen, M.; Kerry, J.; Morris, M.; Cruz-Romero, M.; Cummins, E. Nanotechnologies in the food industry-Recent developments, risks and regulation. Trends Food Sci. Technol. 2012, 24, 30–46. [Google Scholar] [CrossRef]

- Feng, Y.N.; Su, C.; Ye, J.; Zhang, Y.; Yang, N.; Fang, Y. Research Progress in the Mechanical Properties and Application of Emulsion-gel. J. Chin. Inst. Food Sci. Technol. 2018, 18, 268–276. [Google Scholar] [CrossRef]

- McClements, D.J. Food Emulsions: Principles, Practice and Techniques; CRC Press: Boca Raton, FL, USA, 1998. [Google Scholar]

- Zhang, Z.; Yang, Y.; Zhou, P.; Zhang, X.; Wang, J. Effects of high pressure modification on conformation and gelation properties of myofibrillar protein. Food Chem. 2017, 217, 678–686. [Google Scholar] [CrossRef]

- Torres, O.; Murray, B.; Sarkar, A. Emulsion microgel particles: Novel encapsulation strategy for lipophilic molecules. Trends Food Sci. Technol. 2016, 55, 98–108. [Google Scholar] [CrossRef]

- Zhang, Q.Q.; Tang, J.; Wu, Y.F.; Qian, C.Y.; Qin, S.; Cai, Z.H.; Wang, H.; Xiao, H.M. Gelation of crocodile myofibrillar protein-κ-carrageenan mixtures in two low-NaCl solution. Food Chem. 2024, 445, 138753. [Google Scholar] [CrossRef]

- Dickinson, E.; James, J.D. Influence of high-pressure treatment on β-lactoglobulin-pectin associations in emulsions and gels. Food Hydrocoll. 2000, 4, 365–376. [Google Scholar] [CrossRef]

- Li, X.Y.; Mao, L.K.; He, X.Y.; Yuan, F. Characterization of β-lactoglobulin gels induced by high pressure processing. Innov. Food Sci. Emerg. Technol. 2018, 47, 335–345. [Google Scholar] [CrossRef]

- Kaveh, Z.; Azadmard-Damirchi, S.; Yousefi, G.; Hashem Hosseini, S.M. A new approach in improving granular cold water swelling starch properties using xanthan gum and β-lactoglobulin/xanthan gum electrostatic coupled gel. Food Hydrocoll. 2021, 113, 106438. [Google Scholar] [CrossRef]

- Lin, D.; Kelly, A.L.; Miao, S. Preparation, structure-property relationships and applications of different emulsion gels: Bulk emulsion gels, emulsion gel particles, and fluid emulsion gels. Trends Food Sci. Technol. 2020, 102, 123–137. [Google Scholar] [CrossRef]

- Wei, Y.H.; Liu, Y.J.; Yang, L.; Zhang, Z.J.; Liu, H.P. The effect of ultra-high pressure on the gel properties of whey protein isolated gel. Food Ferment. Ind. 2018, 44, 203–210. [Google Scholar] [CrossRef]

- Zhang, L.L.; Xue, Y.; Xu, J.; Li, Z.J.; Xue, C.H. Effects of high-temperature treatment (>100 °C) on Alaska pollock (Theragra chal-cogramma) surimi gels. J. Food Eng. 2013, 115, 115–120. [Google Scholar] [CrossRef]

- Bertram, H.C.; Kohler, A.; Böcker, U.; Ofstad, R.; Andersen, H.J. Heat-induced changes in myofibrillar protein structures and myowater of two pork qualities: A combined FT-IR spectroscopy and low-field NMR relaxometry study. J. Agric. Food Chem. 2006, 54, 1740–1746. [Google Scholar] [CrossRef]

- Chen, X.; Chen, C.G.; Zhou, Y.Z.; Li, P.Z.; Ma, F.; Nishiumi, T.; Suzuki, A. Effects of high pressure processing on the thermal gelling properties of chicken breast myosin containing κ-carrageenan. Food Hydrocoll. 2014, 40, 262–272. [Google Scholar] [CrossRef]

- Xue, S.; Yang, H.; Yu, X.; Qian, C.; Wang, M.; Zou, Y.; Xu, X.; Zhou, G. Applications of high pressure to pre-rigor rabbit muscles affect the water characteristics of myosin gels. Food Chem. 2018, 240, 59–66. [Google Scholar] [CrossRef]

- Cheng, H.; Khan, M.A.; Xie, Z.F.; Tao, S.N.; Li, Y.X.; Liang, L. A peppermint oil emulsion stabilized by resveratrol-zein-pectin complex particles: Enhancing the chemical stability and antimicrobial activity in combination with the synergistic effect. Food Hydrocoll. 2020, 103, 105675. [Google Scholar] [CrossRef]

- Yang, H.J.; Han, M.Y.; Wang, X.; Han, Y.Q.; Wu, J.Q.; Xu, X.L.; Zhou, G.H. Effect of high pressure on cooking losses and functional properties of reduced-fat and reduced-salt pork sausage emulsions. Innov. Food Sci. Emerg. Technol. 2015, 29, 125–133. [Google Scholar] [CrossRef]

- Lim, S.Y.; Swanson, B.G.; Clark, S. High Hydrostatic Pressure Modification of Whey Protein Concentrate for Improved Functional Properties. J. Dairy Sci. 2007, 91, 1299–1307. [Google Scholar] [CrossRef]

- Ma, P.H.; Zeng, Q.H.; Tai, K.D.; Yuan, F. Development of stable curcumin nanoemulsions: Effects of emulsifier type and surfactant-to-oil ratios. J. Food Sci. Technol. 2018, 55, 3485–3497. [Google Scholar] [CrossRef]

- Kotwaliwale, N.; Bakane, P.; Verma, A. Changes in textural and optical properties of oyster mushroom during hot air drying. J. Food Eng. 2007, 78, 1207–1211. [Google Scholar] [CrossRef]

- Dai, L.; Sun, C.; Li, R.; Mao, L.; Liu, F.; Gao, Y. Structural characterization, formation mechanism and stability of curcumin in zein-lecithin composite nanoparticles fabricated by antisolvent co-precipitation. Food Chem. 2017, 237, 1163. [Google Scholar] [CrossRef] [PubMed]

| Presssure | κ-CG Concentration | T2 (ms) | P (%) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| T21 | T22 | T23 | T24 | P21 | P22 | P23 | P24 | ||

| 0.1 MPa | 0.8% | 2.57 ± 0.53 a | 35.38 ± 2.83 a | 238.73 ± 34.61 a | / | 1.83 ± 0.06 b | 3.33 ± 0.25 b | 90.67 ± 0.31 a | / |

| 1.0% | 2.21 ± 0.17 a | 37.65 ± 2.97 a | 231.01 ± 10.00 a | / | 1.87 ± 0.06 ab | 3.57 ± 0.21 b | 90.53 ± 0.32 a | / | |

| 1.2% | 2.11 ± 0.25 a | 37.65 ± 3.56 a | 231.01 ± 2.34 a | / | 2.17 ± 0.25 a | 3.67 ± 0.21 a | 90.47 ± 0.25 b | / | |

| 400 MPa | 0.8% | 3.69 ± 0.30 a | 24.77 ± 0.90 a | 174.75 ± 1.56 a | / | 1.77 ± 0.15 a | 2.4 ± 0.01 a | 93.4 ± 0.75 a | 0.00 c |

| 500 MPa | 3.25 ± 0.71 a | 21.54 ± 0.20 b | 174.75 ± 11.00 a | 1355.93 ± 96.59 a | 1.60 ± 0.10 a | 1.97 ± 0.15 b | 94.07 ± 0.45 a | 0.27 ± 0.06 b | |

| 600 MPa | 3.05 ± 0.24 a | 19.67 ± 1.62 b | 151.99 ± 0.67 b | 1072.27 ± 58.45 b | 1.50 ± 0.20 a | 1.57 ± 0.32 b | 93.4 ± 0.10 a | 1.03 ± 0.15 a | |

| 400 MPa | 1.0% | 2.73 ± 0.75 a | 24.77 ± 0.90 a | 174.75 ± 5.64 a | / | 1.60 ± 0.17 a | 1.87 ± 0.12 a | 94.33 ± 0.91 a | 0.00 c |

| 500 MPa | 2.33 ± 0.32 a | 18.74 ± 0.35 b | 151.99 ± 2.46 b | 1072.27 ± 56.46 b | 1.60 ± 0.10 a | 1.73 ± 0.06 a | 93.33 ± 0.40 a | 0.80 ± 0.00 b | |

| 600 MPa | 2.53 ± 0.74 a | 17.52 ± 1.73 b | 151.99 ± 2.35 b | 1232.85 ± 89.45 a | 1.20 ± 0.57 a | 1.57 ± 0.07 b | 93.45 ± 0.35 a | 1.43 ± 0.06 a | |

| 400 MPa | 1.2% | 2.83 ± 0.62 a | 21.54 ± 0.65 a | 174.75 ± 1.65 a | 1629.75 ± 62.32 a | 1.87 ± 0.12 a | 1.87 ± 0.15 a | 93.70 ± 0.20 a | 0.27 ± 0.06 c |

| 500 MPa | 2.16 ± 0.58 a | 17.92 ± 1.41 b | 151.99 ± 5.13 b | 1072.27 ± 98.65 c | 1.57 ± 0.06 b | 1.67 ± 0.06 b | 93.97 ± 0.29 a | 1.03 ± 0.06 b | |

| 600 MPa | 2.14 ± 0.47 a | 17.11 ± 1.41 b | 151.99 ± 2.24 b | 1232.85 ± 20.20 b | 1.27 ± 0.06 c | 1.43 ± 0.06 c | 93.73 ± 0.64 a | 1.43 ± 0.06 a | |

| Pressure (MPa) | κ-CG Concentration | The Percentage of Components in WPI (%) | ||||

|---|---|---|---|---|---|---|

| BSA | IgG | Casein | β-Lg | α-La | ||

| 0.1 | 0.8% | 10.42 ± 0.25 c | 8.72 ± 0.07 a | 15.13 ± 0.14 a | 50.98 ± 0.24 a | 14.74 ± 0.30 d |

| 400 | 12.43 ± 0.33 ab | 7.20 ± 0.56 b | 13.36 ± 0.37 b | 43.84 ± 0.32 b | 23.39 ± 0.58 c | |

| 500 | 12.79 ± 0.39 a | 5.89 ± 0.33 c | 11.58 ± 0.35 c | 43.46 ± 0.43 b | 26.40 ± 0.42 b | |

| 600 | 11.94 ± 0.06 b | 4.00 ± 0.39 d | 10.02 ± 0.28 d | 43.64 ± 0.27 b | 30.41 ± 0.42 a | |

| 0.1 | 1.0% | 7.27 ± 0.11 c | 7.51 ± 0.06 a | 14.41 ± 0.13 a | 51.66 ± 0.32 a | 19.16 ± 0.12 d |

| 400 | 10.04 ± 0.04 b | 6.48 ± 0.21 b | 11.03 ± 0.25 b | 45.97 ± 0.22 bc | 26.48 ± 0.26 c | |

| 500 | 9.78 ± 0.26 b | 4.81 ± 0.18 c | 9.47 ± 0.23 c | 45.50 ± 0.35 c | 30.45 ± 0.32 b | |

| 600 | 10.41 ± 0.14 a | 3.38 ± 0.36 d | 8.87 ± 0.09 d | 46.15 ± 0.02 b | 31.19 ± 0.42 a | |

| 0.1 | 1.2% | 7.84 ± 0.35 c | 6.28 ± 0.29 b | 8.42 ± 0.38 c | 51.43 ± 0.58 a | 26.03 ± 0.45 c |

| 400 | 11.18 ± 0.24 b | 7.62 ± 0.15 a | 9.92 ± 0.57 a | 43.57 ± 0.31 b | 27.71 ± 0.54 b | |

| 500 | 11.73 ± 0.20 a | 6.35 ± 0.12 b | 8.97 ± 0.31 bc | 42.74 ± 0.52 b | 30.21 ± 0.52 a | |

| 600 | 11.46 ± 0.21 ab | 4.86 ± 0.29 c | 9.53 ± 0.51 ab | 43.41 ± 0.35 b | 30.75 ± 0.37 a | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, X.; Ren, S.; Li, H.; Han, D.; Liu, T.; Wu, M.; Wang, J. Preparation, Characterization and Formation Mechanism of High Pressure-Induced Whey Protein Isolate/κ-Carrageenan Composite Emulsion Gel Loaded with Curcumin. Gels 2024, 10, 542. https://doi.org/10.3390/gels10080542

He X, Ren S, Li H, Han D, Liu T, Wu M, Wang J. Preparation, Characterization and Formation Mechanism of High Pressure-Induced Whey Protein Isolate/κ-Carrageenan Composite Emulsion Gel Loaded with Curcumin. Gels. 2024; 10(8):542. https://doi.org/10.3390/gels10080542

Chicago/Turabian StyleHe, Xiaoye, Shuang Ren, Hu Li, Di Han, Tianxin Liu, Meishan Wu, and Jing Wang. 2024. "Preparation, Characterization and Formation Mechanism of High Pressure-Induced Whey Protein Isolate/κ-Carrageenan Composite Emulsion Gel Loaded with Curcumin" Gels 10, no. 8: 542. https://doi.org/10.3390/gels10080542

APA StyleHe, X., Ren, S., Li, H., Han, D., Liu, T., Wu, M., & Wang, J. (2024). Preparation, Characterization and Formation Mechanism of High Pressure-Induced Whey Protein Isolate/κ-Carrageenan Composite Emulsion Gel Loaded with Curcumin. Gels, 10(8), 542. https://doi.org/10.3390/gels10080542