Stress and Strain Characteristics under the Large Deformation of Surimi Gel during Penetration and Extension Tests Using Digital Image Correlation and the Numerical Simulation Method

Abstract

:1. Introduction

2. Result and Discussion

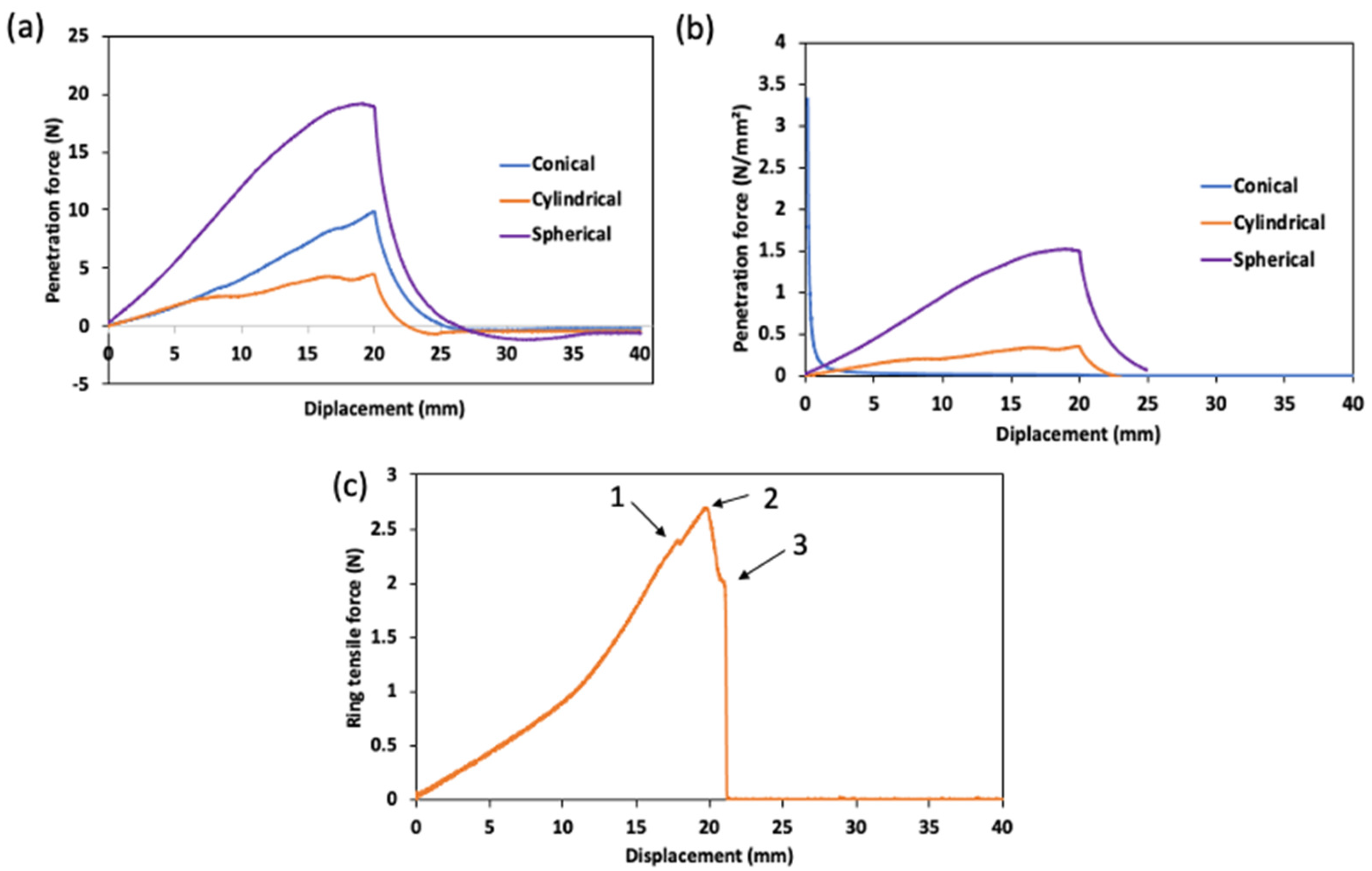

2.1. Mechanical Properties of Surimi Gel

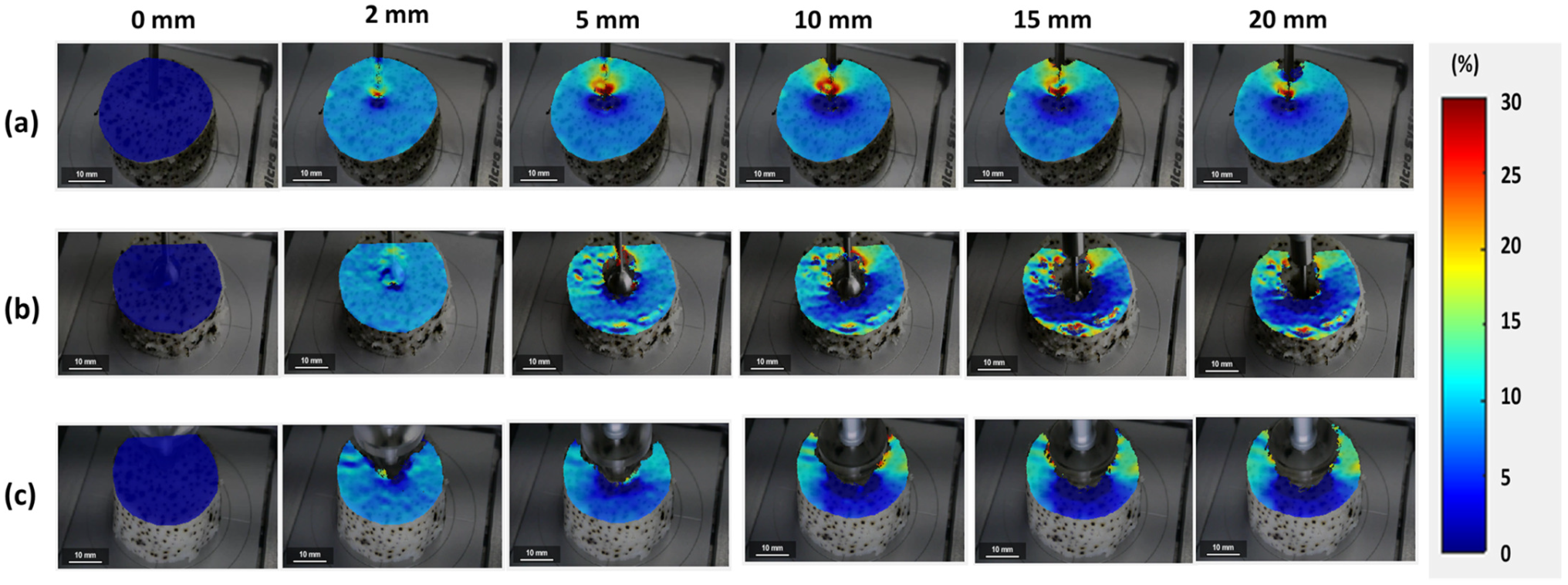

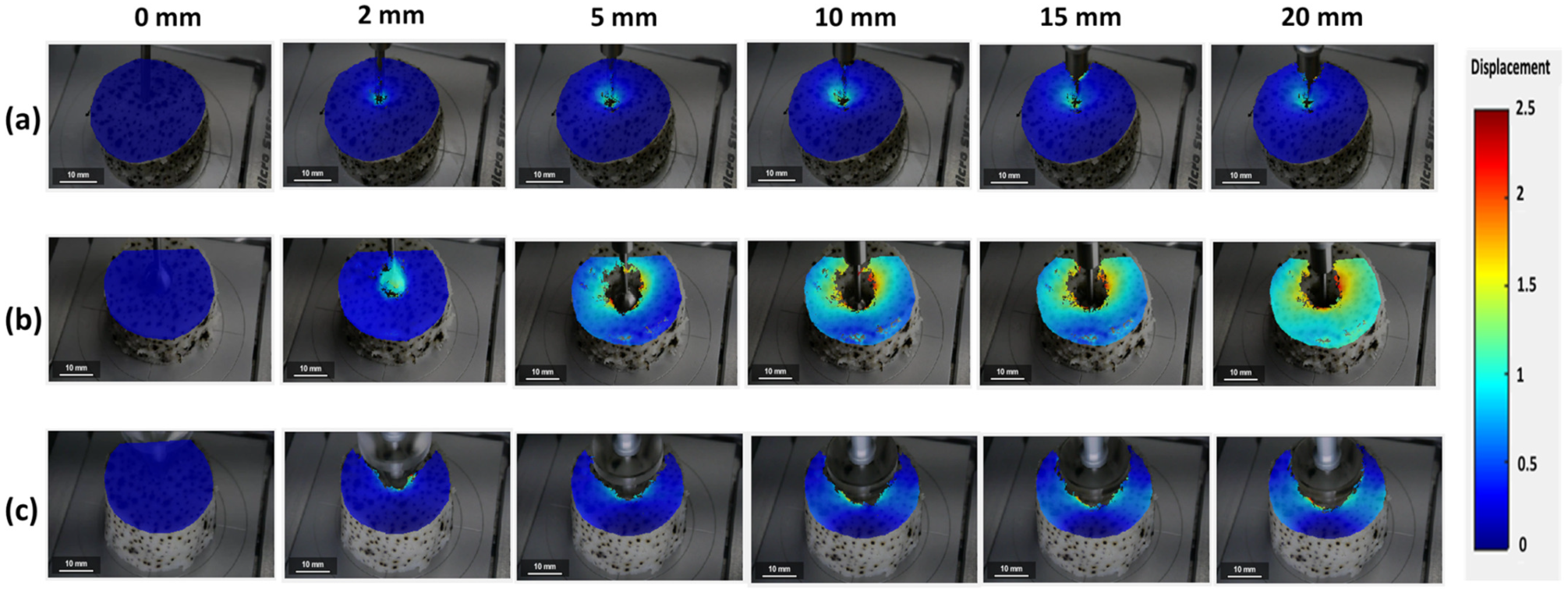

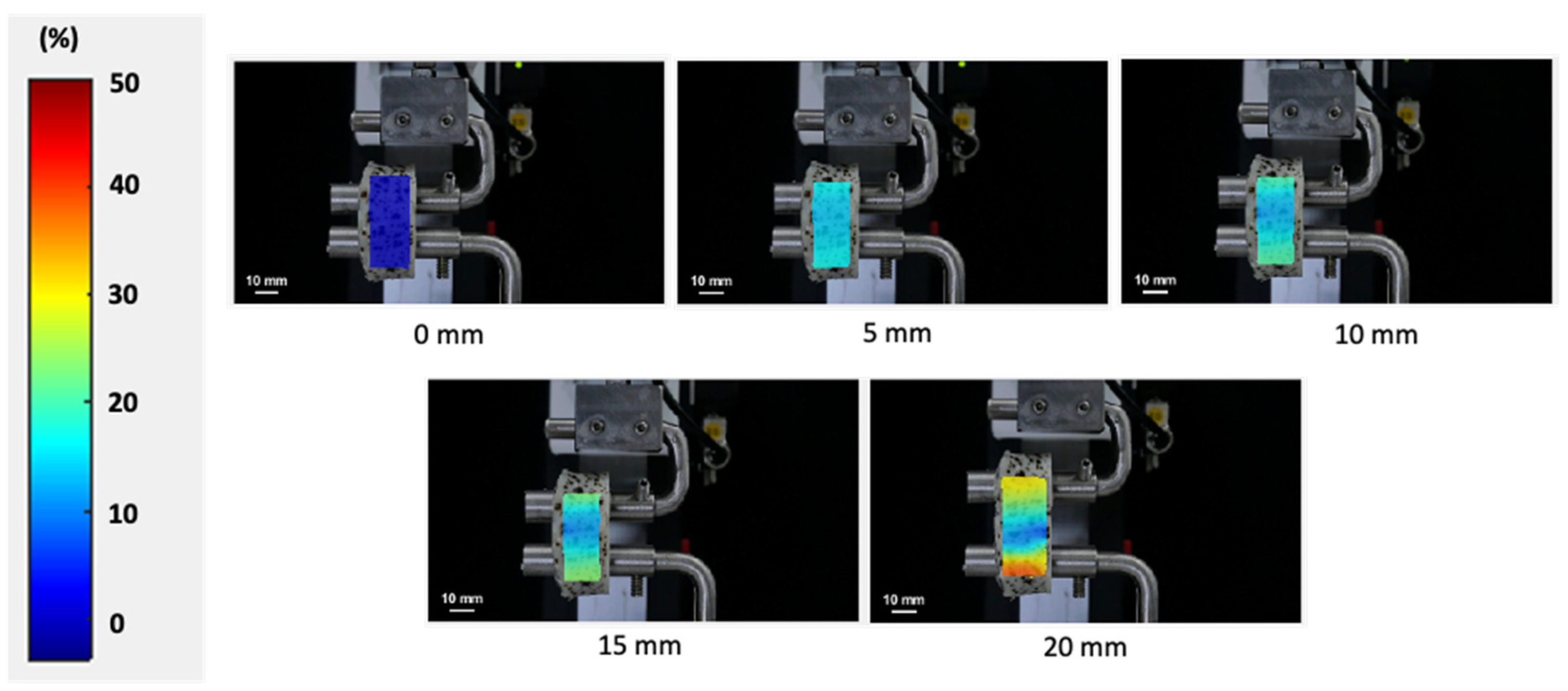

2.2. Evaluation of Strain and Displacement Properties of Surimi Gel by Digital Image Analysis (DIC)

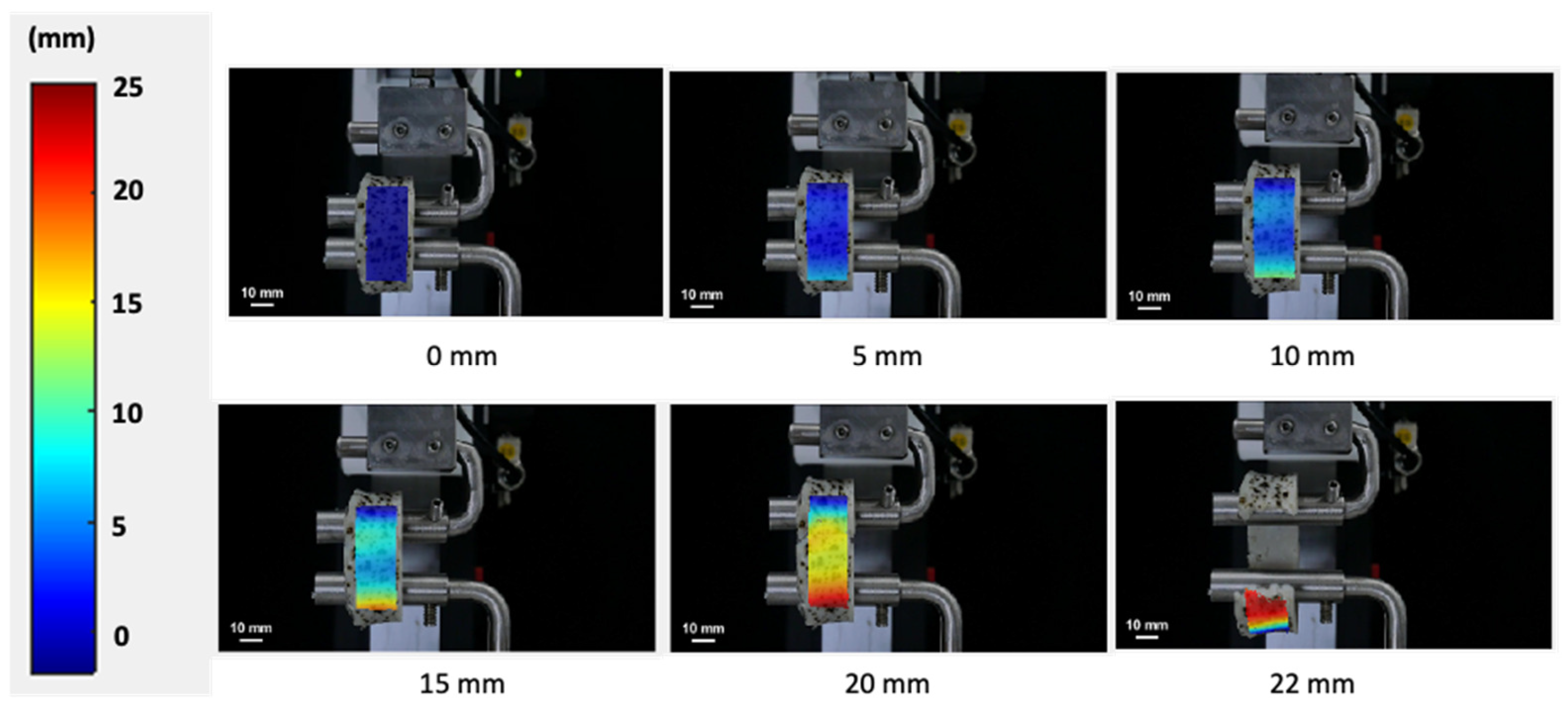

2.2.1. DIC of a Penetration Test

2.2.2. DIC Analysis of the Ring Tensile Test

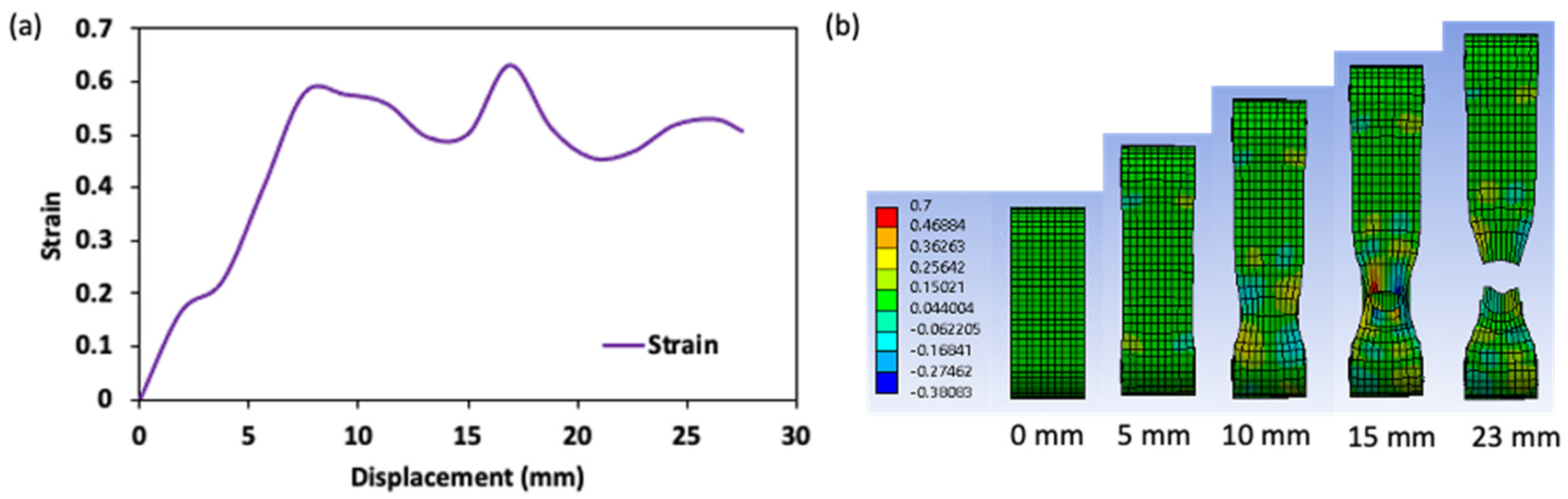

2.3. Evaluation of Stress and Strain Properties of Surimi Gel by Numerical Simulation

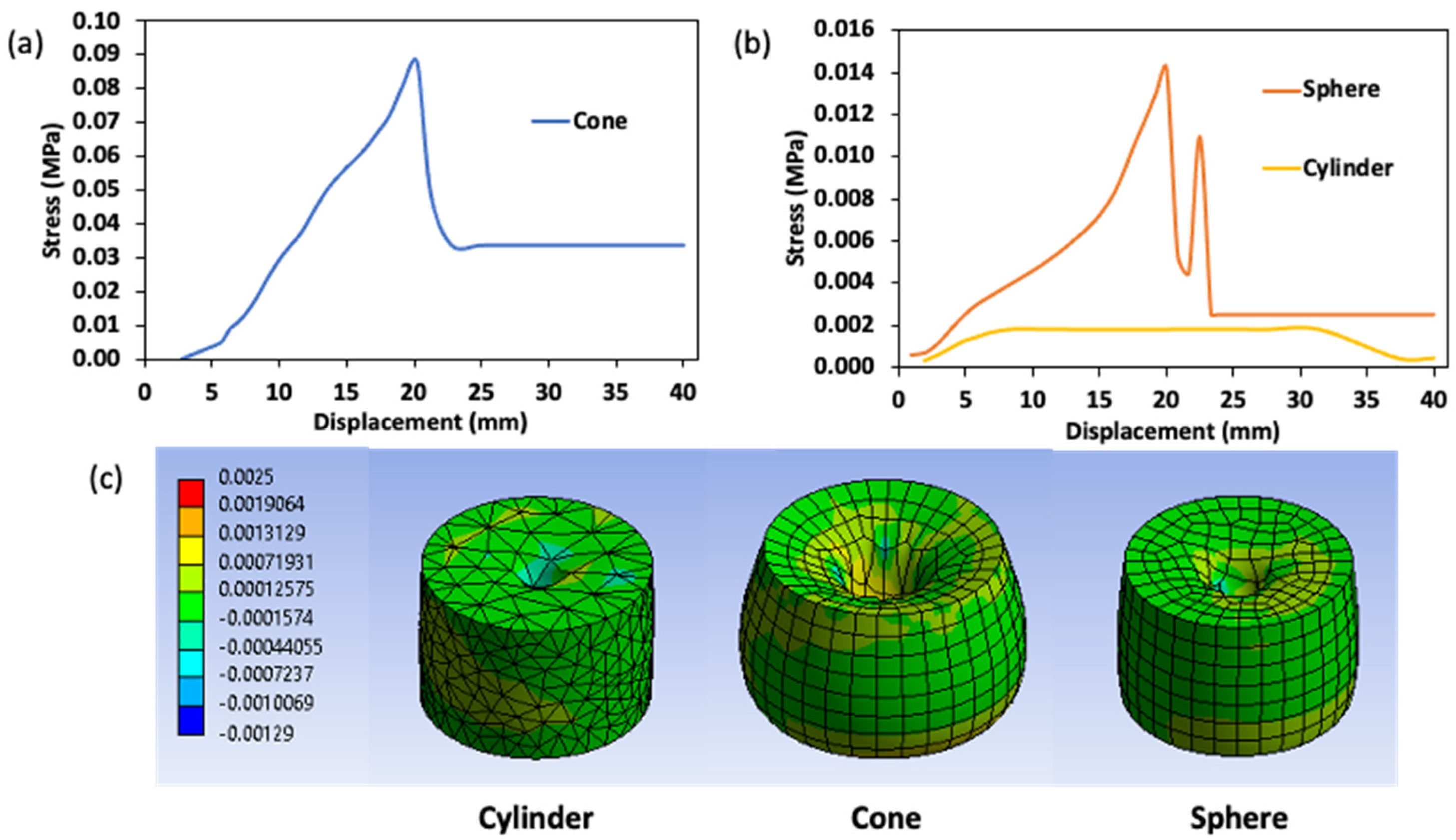

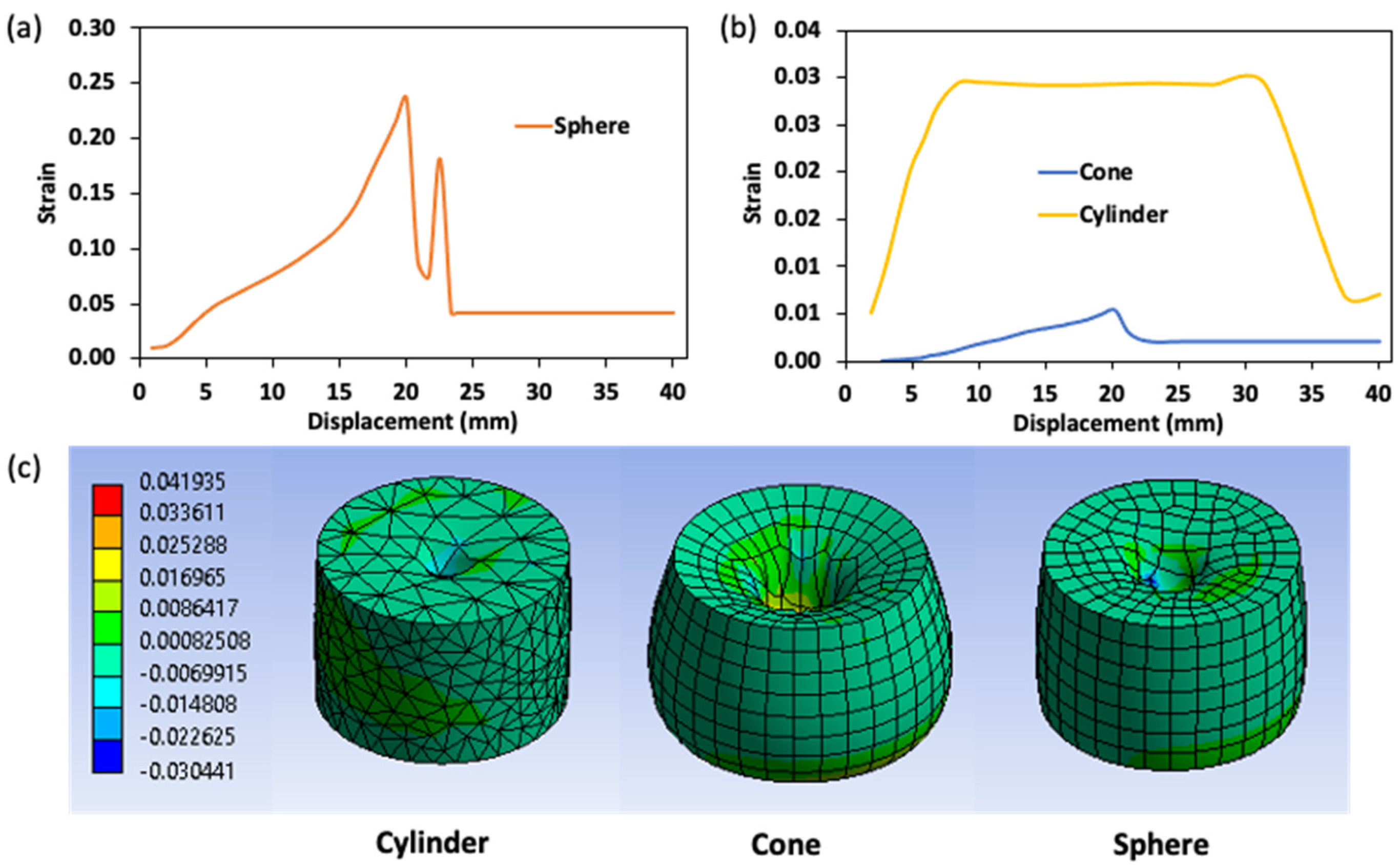

2.3.1. Numerical Analysis by a Penetration Test

2.3.2. Numerical Analysis of the Ring Tensile Test

3. Conclusions

4. Materials and Methods

4.1. Surimi gel Preparation

4.2. Mechanical Analysis of Surimi Gel

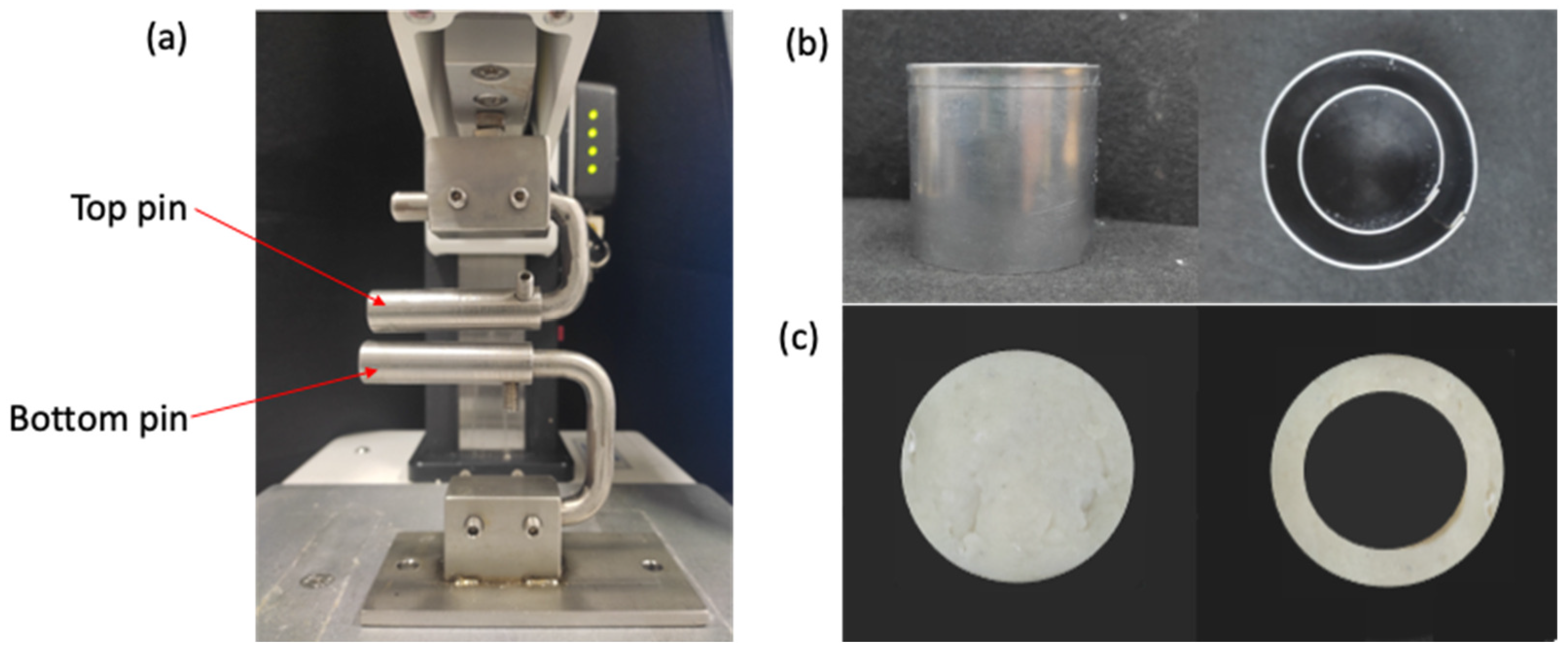

4.2.1. Penetration Test

4.2.2. Ring Tensile Test

4.3. Mechanical Properties of Surimi Gel

4.4. Image Analysis

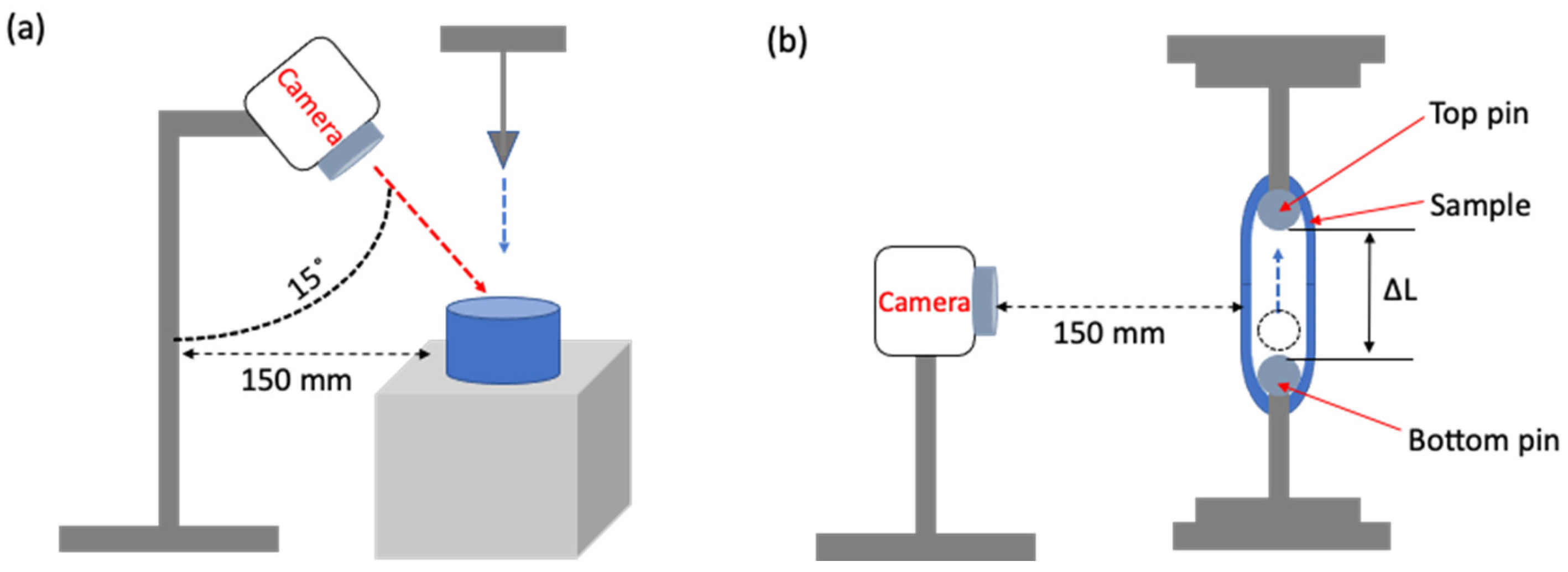

4.4.1. Digital Image Correlation (DIC)

4.4.2. Image Acquisition

4.5. Numerical Analysis

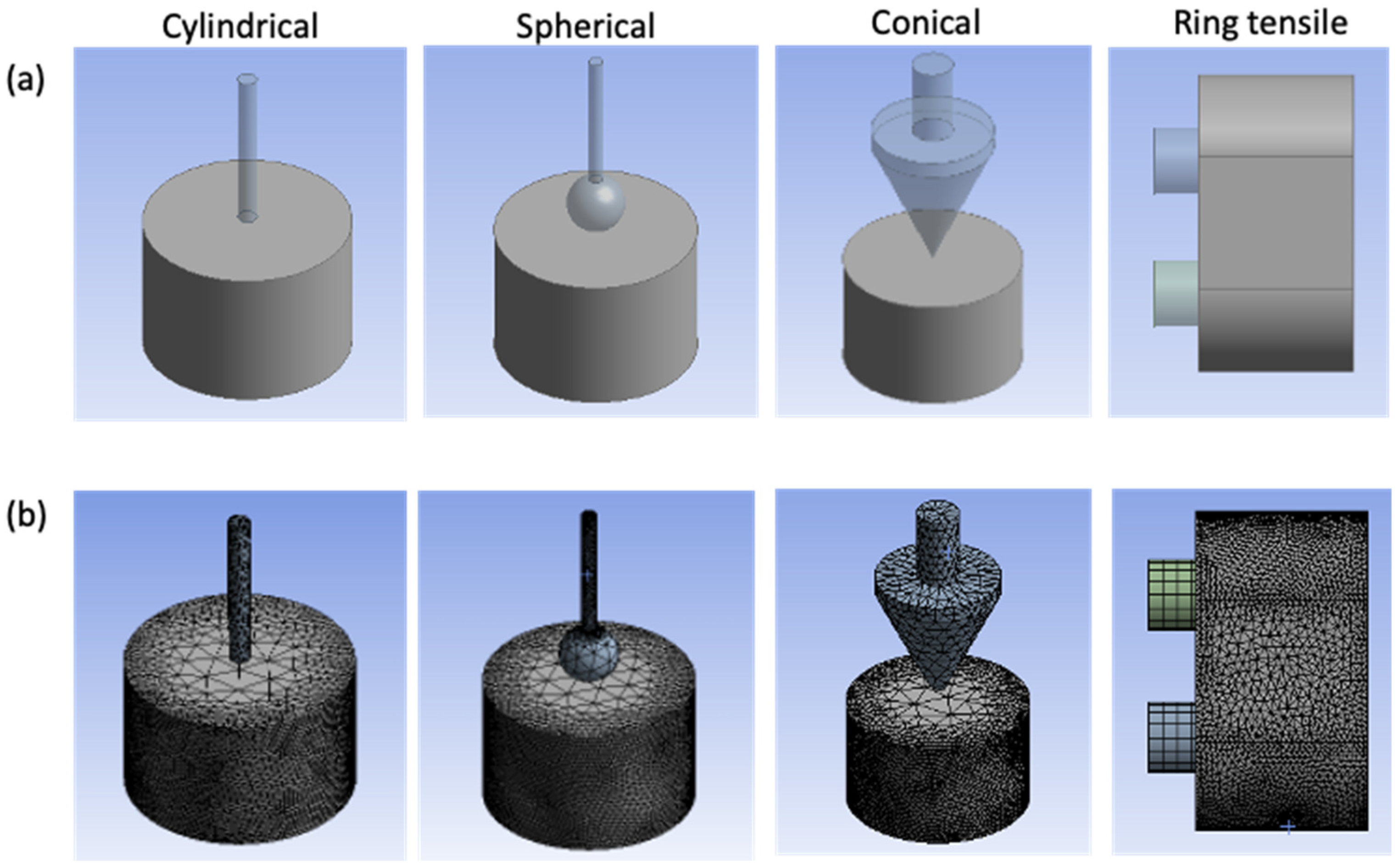

4.5.1. Geometry Description

4.5.2. Finite Element Method (FEM) Simulation

4.6. Statistical Analysis

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Oyinloye, T.M.; Yoon, W.B. Investigation of flow field, die swelling, and residual stress in 3D printing of surimi paste using the finite element method. Innov. Food Sci. Emerg. Technol. 2022, 78, 103008. [Google Scholar] [CrossRef]

- Park, H.W.; Yoon, W.B. Measuring ring tensile stress and strain of surimi gels using a novel ring tensile test with image analysis. J. Food Eng. 2015, 163, 9–16. [Google Scholar] [CrossRef]

- Medina, J.R.; Garrote, R.L. The effect of two cryoprotectant mixtures on frozen surubí surimi. Braz. J. Chem. Eng. 2002, 19, 419–424. [Google Scholar] [CrossRef] [Green Version]

- Tabilo-Munizaga, G.; Barbosa-Cánovas, G.V. Color and textural parameters of pressurized and heat-treated surimi gels as affected by potato starch and egg white. Food Res. Int. 2004, 37, 767–775. [Google Scholar] [CrossRef]

- Holmberg, S.; Enquist, B.; Thilderkvist, P. Evaluation of sheet metal formability by tensile tests. J. Mater. Process. Technol. 2004, 145, 72–83. [Google Scholar] [CrossRef]

- Laterreur, V.; Ruel, J.; Auger, F.A.; Vallières, K.; Tremblay, C.; Lacroix, D.; Tondreau, M.; Bourget, J.; Germain, L. Comparison of the direct burst pressure and the ring tensile test methods for mechanical characterization of tissue-engineered vascular substitutes. J. Mech. Behav. Biomed. Mater. 2014, 34, 253–263. [Google Scholar] [CrossRef]

- Hong, Y.; Uhm, J.; Yoon, W.B. Using numerical analysis to develop and evaluate the method of high temperature Sous-Vide to soften carrot texture in different-sized packages. J. Food Sci. 2014, 79, E546–E561. [Google Scholar] [CrossRef]

- Zhang, X.; Chu, X.; Ji, H.; Wang, Y. Effect of freezing rate on the onion cell deformation evaluated by digital image correlation. Food Anal. Methods 2016, 9, 3125–3132. [Google Scholar] [CrossRef]

- Bhashyam, G.R. ANSYS Mechanical—A Powerful Nonlinear Simulation Tool; Ansys Inc.: Canonsburg, PA, USA, 2002; Volume 1, 39p. [Google Scholar]

- Horabik, J. DEM modelling of tensile strength of starch tablets. In Proceedings of the 18th International Workshop for Young Scientists, Gödöllő, Hungary, 22–24 May 2019. [Google Scholar]

- Xu, Q.; Engquist, B.; Solaimanian, M.; Yan, K. A new nonlinear viscoelastic model and mathematical solution of solids for improving prediction accuracy. Sci. Rep. 2020, 10, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Hsu, C.; Chiang, B. Effects of water, oil, starch, calcium carbonate and titanium dioxide on the colour and texture of threadfin and hairtail surimi gels. Int. J. Food Sci. Technol. 2002, 37, 387–393. [Google Scholar] [CrossRef]

- Duangmal, K.; Taluengphol, A. Effect of protein additives, sodium ascorbate, and microbial transglutaminase on the texture and colour of red tilapia surimi gel. Int. J. Food Sci. Technol. 2010, 45, 48–55. [Google Scholar] [CrossRef]

- Benedito, J.; Simal, S.; Clemente, G.; Mulet, A. Manchego cheese texture evaluation by ultrasonics and surface probes. Int. Dairy J. 2006, 16, 431–438. [Google Scholar] [CrossRef]

- Teratsubo, M.; Tanaka, Y.; Saeki, S. Measurement of stress and strain during tensile testing of gellan gum gels: Effect of deformation speed. Carbohydr. Polym. 2002, 47, 1–5. [Google Scholar] [CrossRef]

- Blaber, J.; Adair, B.; Antoniou, A. Ncorr: Open-source 2D digital image correlation matlab software. Exp. Mech. 2015, 55, 1105–1122. [Google Scholar] [CrossRef]

- Nikhare, C.; Hodgson, P.D.; Weiss, M. Necking and fracture of advanced high strength steels. Mater. Sci. Eng. A 2011, 528, 3010–3013. [Google Scholar] [CrossRef]

- Pavazza, R. Torsion of thin-walled beams of open cross-section with influence of shear. Int. J. Mech. Sci. 2005, 47, 1099–1122. [Google Scholar] [CrossRef]

- Grytten, F.; Daiyan, H.; Polanco-Loria, M.; Dumoulin, S. Use of digital image correlation to measure large-strain tensile properties of ductile thermoplastics. Polym. Test. 2009, 28, 653–660. [Google Scholar] [CrossRef]

- Hamann, D.D.; Zhang, J.; Daubert, C.R.; Foegeding, E.A.; Diehl, K.C., Jr. Analysis of compression, tension and torsion for testing food gel fracture properties. J. Texture Stud. 2006, 37, 620–639. [Google Scholar] [CrossRef]

- Schreuders, F.K.; Schlangen, M.; Kyriakopoulou, K.; Boom, R.M.; van der Goot, A.J. Texture methods for evaluating meat and meat analogue structures: A review. Food Control 2021, 127, 108103. [Google Scholar] [CrossRef]

- Herrero, A.M.; De la Hoz, L.; Ordóñez, J.A.; Herranz, B.; de Ávila, M.R.; Cambero, M.I. Tensile properties of cooked meat sausages and their correlation with texture profile analysis (TPA) parameters and physico-chemical characteristics. Meat Sci. 2008, 80, 690–696. [Google Scholar] [CrossRef]

- de Ávila, M.D.R.; Cambero, M.I.; Ordóñez, J.A.; de la Hoz, L.; Herrero, A.M. Rheological behaviour of commercial cooked meat products evaluated by tensile test and texture profile analysis (TPA). Meat Sci. 2014, 98, 310–315. [Google Scholar] [CrossRef] [Green Version]

- Begonia, M.T.; Dallas, M.; Vizcarra, B.; Liu, Y.; Johnson, M.L.; Thiagarajan, G. Non-contact strain measurement in the mouse forearm loading model using digital image correlation (DIC). Bone 2015, 81, 593–601. [Google Scholar] [CrossRef] [Green Version]

- Yuan, Y.; Huang, J.; Fang, J.; Yuan, F.; Xiong, C. A self-adaptive sampling digital image correlation algorithm for accurate displacement measurement. Opt. Lasers Eng. 2015, 65, 57–63. [Google Scholar] [CrossRef]

- Zhu, F.; Bai, P.; Zhang, J.; Lei, D.; He, X. Measurement of true stress–strain curves and evolution of plastic zone of low carbon steel under uniaxial tension using digital image correlation. Opt. Lasers Eng. 2015, 65, 81–88. [Google Scholar] [CrossRef]

- Triki, E.; Gauvin, C. Analytical and experimental investigation of puncture-cut resistance of soft membranes. Mech. Soft Mater. 2019, 1, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Liu, P.F.; Zheng, J.Y. Finite element analysis of tensile behavior of ductile steel with defects. J. Fail. Anal. Prev. 2010, 10, 212–217. [Google Scholar] [CrossRef]

- Liu, P.F.; Zheng, J.Y. Progressive failure analysis of carbon fiber/epoxy composite laminates using continuum damage mechanics. Mater. Sci. Eng. A 2008, 485, 711–717. [Google Scholar] [CrossRef]

- Xu, P.; Zheng, J.Y.; Liu, P.F. Finite element analysis of burst pressure of composite hydrogen storage vessels. Mater. Des. 2009, 30, 2295–2301. [Google Scholar] [CrossRef]

- Song, B.; Sanborn, B. Relationship of compressive stress-strain response of engineering materials obtained at constant engineering and true strain rates. Int. J. Impact Eng. 2018, 119, 40–44. [Google Scholar] [CrossRef]

- Johnson, G.R.; Cook, W.H. A constitutive model and data for metals subjected to large strains, high strain rates and high temperatures. In Proceedings of the 7th International Symposium on Ballistics, The Hague, The Netherlands, 19–21 April 1983; pp. 541–547. [Google Scholar]

- Krasauskas, P.; Kilikevičius, S.; Česnavičius, R.; Pačenga, D. Experimental analysis and numerical simulation of the stainless AISI 304 steel friction drilling process. Mechanika 2014, 20, 590–595. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Young modulus, E (MPa) | 0.01719 |

| Poisson’s ratio | 0.5 |

| Density, ρ (g/cm−3) | 0.00097 |

| Initial yield strength, A (MPa) | 0.00833 |

| Hardening modulus, B (MPa) | 0.01212 |

| Strain hardening exponent, n | 0.6752 |

| Strain rate constant, C | 0.07 |

| Reference strain rate, ɛ0 (1/s) | 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jung, H.; Oyinloye, T.M.; Yoon, W.B. Stress and Strain Characteristics under the Large Deformation of Surimi Gel during Penetration and Extension Tests Using Digital Image Correlation and the Numerical Simulation Method. Gels 2022, 8, 740. https://doi.org/10.3390/gels8110740

Jung H, Oyinloye TM, Yoon WB. Stress and Strain Characteristics under the Large Deformation of Surimi Gel during Penetration and Extension Tests Using Digital Image Correlation and the Numerical Simulation Method. Gels. 2022; 8(11):740. https://doi.org/10.3390/gels8110740

Chicago/Turabian StyleJung, Hwabin, Timilehin Martins Oyinloye, and Won Byong Yoon. 2022. "Stress and Strain Characteristics under the Large Deformation of Surimi Gel during Penetration and Extension Tests Using Digital Image Correlation and the Numerical Simulation Method" Gels 8, no. 11: 740. https://doi.org/10.3390/gels8110740

APA StyleJung, H., Oyinloye, T. M., & Yoon, W. B. (2022). Stress and Strain Characteristics under the Large Deformation of Surimi Gel during Penetration and Extension Tests Using Digital Image Correlation and the Numerical Simulation Method. Gels, 8(11), 740. https://doi.org/10.3390/gels8110740