Ultrasonic Treatment of Food Colloidal Systems Containing Oleogels: A Review

Abstract

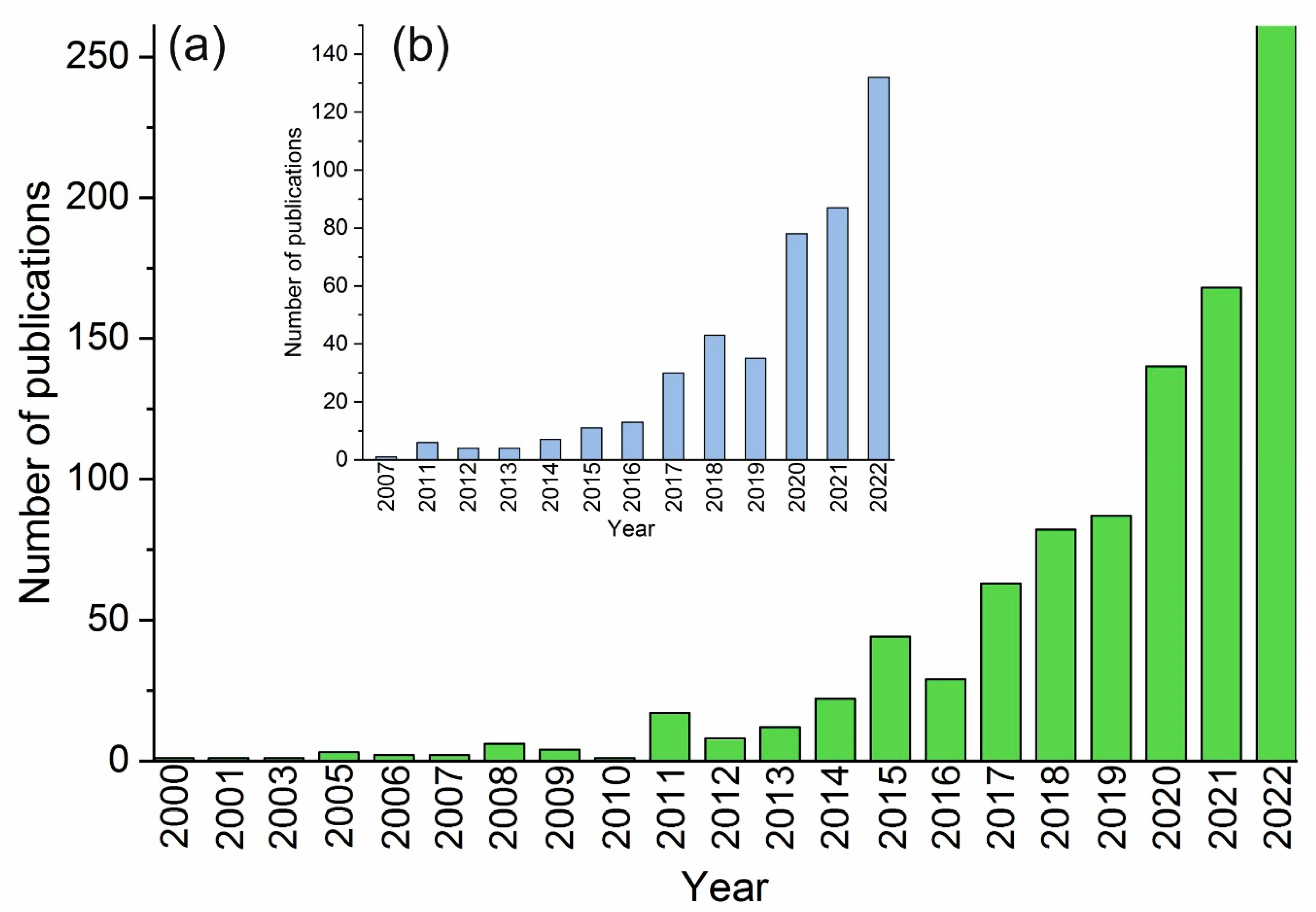

1. Introduction

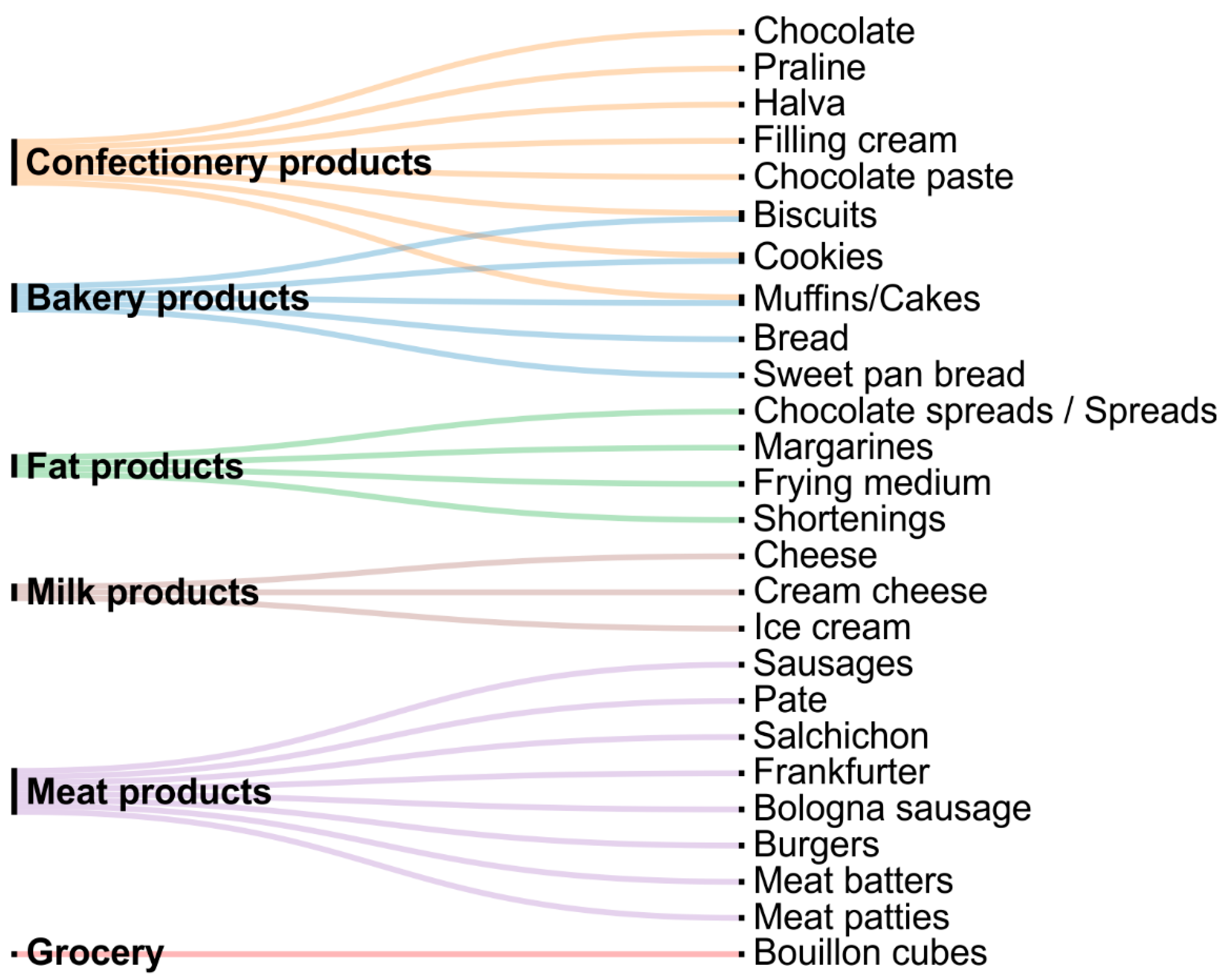

2. Oleogels in Food Products

3. Application of Ultrasonic Treatment in the Food Industry

4. Ultrasonic Treatment of Food Colloidal Systems Containing Oleogels

- Patents;

- Application of ultrasonic treatment to oleogels;

- Application of ultrasonic treatment to emulsion systems containing oleogels (emulsions, Pickering emulsions, nanoemulsions, bigels).

4.1. Patents

4.2. Application of Ultrasonic Treatment in Oleogels

4.2.1. Macro- and Microstructure

4.2.2. Rheological and Texture Properties

4.2.3. Thermal Properties

4.2.4. Oxidative Stability

4.2.5. Miscellaneous

4.3. Application of Ultrasonic Treatment to Emulsion Systems Containing Oleogels

4.3.1. Micro- and Macrostructure

4.3.2. Rheological and Texture Properties

4.3.3. Biologically Active Substances

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jadhav, H.B.; Annapure, U.S. Triglycerides of medium-chain fatty acids: A concise review. J. Food Sci. Technol. 2022, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Temkov, M.; Mureșan, V. Tailoring the structure of lipids, oleogels and fat replacers by different approaches for solving the trans-fat issue—A review. Foods 2021, 10, 1376. [Google Scholar] [CrossRef] [PubMed]

- Shahidi, F.; Hossain, A. Role of Lipids in Food Flavor Generation. Molecules 2022, 27, 5014. [Google Scholar] [CrossRef] [PubMed]

- Bhandari, S.D.; Delmonte, P.; Honigfort, M.; Yan, W.; Dionisi, F.; Fleith, M.; Iassonova, D.; Bergeson, L.L. Regulatory changes affecting the production and use of fats and oils: Focus on partially hydrogenated oils. J. Am. Oil Chem. Soc. 2020, 97, 797–815. [Google Scholar] [CrossRef]

- Frolova, Y.V.; Kochetkova, A.A.; Sobolev, R.V.; Vorobyeva, V.M.; Kodentsova, V.M. Oleogels as prospective nutritional ingredients of lipid nature. Nutr. Issue 2021, 90, 64–73. [Google Scholar] [CrossRef]

- Patel, A.R.; Nicholson, R.A.; Marangoni, A.G. Applications of fat mimetics for the replacement of saturated and hydrogenated fat in food products. Curr. Opin. Food Sci. 2020, 33, 61–68. [Google Scholar] [CrossRef]

- Li, L.; Liu, G.; Bogojevic, O.; Pedersen, J.N.; Guo, Z. Edible oleogels as solid fat alternatives: Composition and oleogelation mechanism implications. Compr. Rev. Food Sci. Food Saf. 2022, 21, 2077–2104. [Google Scholar] [CrossRef]

- Pinto, T.C.; Martins, A.J.; Pastrana, L.; Pereira, M.C.; Cerqueira, M.A. Oleogel-based systems for the delivery of bioactive compounds in foods. Gels 2021, 7, 86. [Google Scholar] [CrossRef]

- Feichtinger, A.; Scholten, E. Preparation of protein oleogels: Effect on structure and functionality. Foods 2020, 9, 1745. [Google Scholar] [CrossRef]

- Pușcaș, A.; Mureșan, V.; Muste, S. Application of analytical methods for the comprehensive analysis of oleogels—A review. Polymers 2021, 13, 1934. [Google Scholar] [CrossRef]

- Wang, Z.; Chandrapala, J.; Truong, T.; Farahnaky, A. Oleogels prepared with low molecular weight gelators: Texture, rheology and sensory properties, a review. Crit. Rev. Food Sci. Nutr. 2022, 1–45. [Google Scholar] [CrossRef] [PubMed]

- Hwang, H.-S. A critical review on structures, health effects, oxidative stability, and sensory properties of oleogels. Biocatal. Agric. Biotechnol. 2020, 26, 101657. [Google Scholar] [CrossRef]

- Martins, A.J.; Vicente, A.A.; Cunha, R.L.; Cerqueira, M.A. Edible oleogels: An opportunity for fat replacement in foods. Food Funct. 2018, 9, 758–773. [Google Scholar] [CrossRef] [PubMed]

- Co, E.D.; Marangoni, A.G. Organogels: An alternative edible oil-structuring method. J. Am. Oil Chem. Soc. 2012, 89, 749–780. [Google Scholar] [CrossRef]

- Bascuas, S.; Hernando, I.; Moraga, G.; Quiles, A. Structure and stability of edible oleogels prepared with different unsaturated oils and hydrocolloids. Int. J. Food Sci. Technol. 2020, 55, 1458–1467. [Google Scholar] [CrossRef]

- Pang, M.; Shi, Z.; Lei, Z.; Ge, Y.; Jiang, S.; Cao, L. Structure and thermal properties of beeswax-based oleogels with different types of vegetable oil. Grasas Y Aceites 2020, 71, 380. [Google Scholar] [CrossRef]

- Frolova, Y.; Sarkisyan, V.; Sobolev, R.; Makarenko, M.; Semin, M.; Kochetkova, A. The Influence of Edible Oils’ Composition on the Properties of Beeswax-Based Oleogels. Gels 2022, 8, 48. [Google Scholar] [CrossRef]

- Dassanayake, L.S.K.; Kodali, D.R.; Ueno, S. Formation of oleogels based on edible lipid materials. Curr. Opin. Colloid Interface Sci. 2011, 16, 432–439. [Google Scholar] [CrossRef]

- Lim, J.; Hwang, H.-S.; Lee, S. Oil-structuring characterization of natural waxes in canola oil oleogels: Rheological, thermal, and oxidative properties. Appl. Biol. Chem. 2017, 60, 17–22. [Google Scholar] [CrossRef]

- Frolova, Y.; Sobolev, R.; Kochetkova, A. Influence of oil combinations on the structural properties of oleogels. E3S Web Conf. 2021, 285, 05009. [Google Scholar] [CrossRef]

- Hwang, H.S.; Fhaner, M.; Winkler-Moser, J.K.; Liu, S.X. Oxidation of fish oil oleogels formed by natural waxes in comparison with bulk oil. Eur. J. Lipid Sci. Technol. 2018, 120, 1700378. [Google Scholar] [CrossRef]

- Palla, C.; de Vicente, J.; Carrín, M.E.; Ruiz, M.J.G. Effects of cooling temperature profiles on the monoglycerides oleogel properties: A rheo-microscopy study. Food Res. Int. 2019, 125, 108613. [Google Scholar] [CrossRef] [PubMed]

- Martins, A.J.; Cerqueira, M.A.; Pastrana, L.M.; Cunha, R.L.; Vicente, A.A. Sterol-based oleogels’ characterization envisioning food applications. J. Sci. Food Agric. 2019, 99, 3318–3325. [Google Scholar] [CrossRef]

- Sarkisyan, V.; Sobolev, R.; Frolova, Y.; Malinkin, A.; Makarenko, M.; Kochetkova, A. Beeswax fractions used as potential oil gelling agents. J. Am. Oil Chem. Soc. 2021, 98, 281–296. [Google Scholar] [CrossRef]

- Gravelle, A.J.; Barbut, S.; Marangoni, A.G. Ethylcellulose oleogels: Manufacturing considerations and effects of oil oxidation. Food Res. Int. 2012, 48, 578–583. [Google Scholar] [CrossRef]

- Espert, M.; Salvador, A.; Sanz, T. Cellulose ether oleogels obtained by emulsion-templated approach without additional thickeners. Food Hydrocoll. 2020, 109, 106085. [Google Scholar] [CrossRef]

- Oh, I.K.; Amoah, C.; Lim, J.; Jeong, S.; Lee, S. Assessing the effectiveness of wax-based sunflower oil oleogels in cakes as a shortening replacer. LWT 2017, 86, 430–437. [Google Scholar] [CrossRef]

- Giacomozzi, A.S.; Carrín, M.E.; Palla, C.A. Muffins elaborated with optimized monoglycerides oleogels: From solid fat replacer obtention to product quality evaluation. J. Food Sci. 2018, 83, 1505–1515. [Google Scholar] [CrossRef]

- Pehlivanoglu, H.; Özülkü, G.; Yildirim, R.M.; Demirci, M.; Toker, O.S.; Sağdiç, O. Investigating the usage of unsaturated fatty acid-rich and low-calorie oleogels as a shortening mimetics in cake. J. Food Process. Preserv. 2018, 42, e13621. [Google Scholar] [CrossRef]

- Oh, I.K.; Lee, S. Utilization of foam structured hydroxypropyl methylcellulose for oleogels and their application as a solid fat replacer in muffins. Food Hydrocoll. 2018, 77, 796–802. [Google Scholar] [CrossRef]

- Kim, M.; Hwang, H.-S.; Jeong, S.; Lee, S. Utilization of oleogels with binary oleogelator blends for filling creams low in saturated fat. LWT 2022, 155, 112972. [Google Scholar] [CrossRef]

- Doan, C.D.; Patel, A.R.; Tavernier, I.; De Clercq, N.; Van Raemdonck, K.; Van de Walle, D.; Delbaere, C.; Dewettinck, K. The feasibility of wax-based oleogel as a potential co-structurant with palm oil in low-saturated fat confectionery fillings. Eur. J. Lipid Sci. Technol. 2016, 118, 1903–1914. [Google Scholar] [CrossRef]

- Palla, C.A.; Wasinger, M.F.; Carrín, M.E. Monoglyceride oleogels as fat replacers in filling creams for sandwich cookies. J. Sci. Food Agric. 2021, 101, 2398–2405. [Google Scholar] [CrossRef] [PubMed]

- Palla, C.; Giacomozzi, A.; Genovese, D.B.; Carrín, M.E. Multi–objective optimization of high oleic sunflower oil and monoglycerides oleogels: Searching for rheological and textural properties similar to margarine. Food Struct. 2017, 12, 1–14. [Google Scholar] [CrossRef]

- Hwang, H.-S.; Singh, M.; Bakota, E.L.; Winkler-Moser, J.K.; Kim, S.; Liu, S.X. Margarine from organogels of plant wax and soybean oil. J. Am. Oil Chem. Soc. 2013, 90, 1705–1712. [Google Scholar] [CrossRef]

- Hwang, H.-S.; Singh, M.; Winkler-Moser, J.K.; Bakota, E.L.; Liu, S.X. Preparation of margarines from organogels of sunflower wax and vegetable oils. J. Food Sci. 2014, 79, C1926–C1932. [Google Scholar] [CrossRef]

- Rodríguez-Hernández, A.K.; Pérez-Martínez, J.D.; Gallegos-Infante, J.A.; Toro-Vazquez, J.F.; Ornelas-Paz, J.J. Rheological properties of ethyl cellulose-monoglyceride-candelilla wax oleogel vis-a-vis edible shortenings. Carbohydr. Polym. 2021, 252, 117171. [Google Scholar] [CrossRef]

- Ye, X.; Li, P.; Lo, Y.M.; Fu, H.; Cao, Y. Development of novel shortenings structured by ethylcellulose oleogels. J. Food Sci. 2019, 84, 1456–1464. [Google Scholar] [CrossRef]

- Pintado, T.; Cofrades, S. Quality characteristics of healthy dry fermented sausages formulated with a mixture of olive and chia oil structured in oleogel or emulsion gel as animal fat replacer. Foods 2020, 9, 830. [Google Scholar] [CrossRef]

- Zampouni, K.; Soniadis, A.; Dimakopoulou-Papazoglou, D.; Moschakis, T.; Biliaderis, C.G.; Katsanidis, E. Modified fermented sausages with olive oil oleogel and NaCl–KCl substitution for improved nutritional quality. LWT 2022, 158, 113172. [Google Scholar] [CrossRef]

- Utrilla, M.C.; Ruiz, A.G.; Soriano, A. Effect of partial replacement of pork meat with an olive oil organogel on the physicochemical and sensory quality of dry-ripened venison sausages. Meat Sci. 2014, 97, 575–582. [Google Scholar] [CrossRef] [PubMed]

- Kouzounis, D.; Lazaridou, A.; Katsanidis, E. Partial replacement of animal fat by oleogels structured with monoglycerides and phytosterols in frankfurter sausages. Meat Sci. 2017, 130, 38–46. [Google Scholar] [CrossRef] [PubMed]

- Panagiotopoulou, E.; Moschakis, T.; Katsanidis, E. Sunflower oil organogels and organogel-in-water emulsions (part II): Implementation in frankfurter sausages. LWT 2016, 73, 351–356. [Google Scholar] [CrossRef]

- Franco, D.; Martins, A.J.; López-Pedrouso, M.; Purriños, L.; Cerqueira, M.A.; Vicente, A.A.; Pastrana, L.M.; Zapata, C.; Lorenzo, J.M. Strategy towards replacing pork backfat with a linseed oleogel in frankfurter sausages and its evaluation on physicochemical, nutritional, and sensory characteristics. Foods 2019, 8, 366. [Google Scholar] [CrossRef]

- Wolfer, T.L.; Acevedo, N.C.; Prusa, K.J.; Sebranek, J.G.; Tarté, R. Replacement of pork fat in frankfurter-type sausages by soybean oil oleogels structured with rice bran wax. Meat Sci. 2018, 145, 352–362. [Google Scholar] [CrossRef] [PubMed]

- Barbut, S.; Wood, J.; Marangoni, A. Potential use of organogels to replace animal fat in comminuted meat products. Meat Sci. 2016, 122, 155–162. [Google Scholar] [CrossRef]

- Barbut, S.; Tiensa, B.E.; Marangoni, A.G. Partial fat replacement in liver pâté using canola oil organogel. LWT 2021, 139, 110428. [Google Scholar] [CrossRef]

- Alejandre, M.; Astiasarán, I.; Ansorena, D.; Barbut, S. Using canola oil hydrogels and organogels to reduce saturated animal fat in meat batters. Food Res. Int. 2019, 122, 129–136. [Google Scholar] [CrossRef]

- Martins, A.J.; Lorenzo, J.M.; Franco, D.; Pateiro, M.; Domínguez, R.; Munekata, P.E.S.; Pastrana, L.M.; Vicente, A.A.; Cunha, R.L.; Cerqueira, M.A. Characterization of enriched meat-based pâté manufactured with oleogels as fat substitutes. Gels 2020, 6, 17. [Google Scholar] [CrossRef]

- Gómez-Estaca, J.; Herrero, A.M.; Herranz, B.; Álvarez, M.D.; Jiménez-Colmenero, F.; Cofrades, S. Characterization of ethyl cellulose and beeswax oleogels and their suitability as fat replacers in healthier lipid pâtés development. Food Hydrocoll. 2019, 87, 960–969. [Google Scholar] [CrossRef]

- Moghtadaei, M.; Soltanizadeh, N.; Goli, S.A.H.; Sharifimehr, S. Physicochemical properties of beef burger after partial incorporation of ethylcellulose oleogel instead of animal fat. J. Food Sci. Technol. 2021, 58, 4775–4784. [Google Scholar] [CrossRef] [PubMed]

- Moghtadaei, M.; Soltanizadeh, N.; Goli, S.A.H. Production of sesame oil oleogels based on beeswax and application as partial substitutes of animal fat in beef burger. Food Res. Int. 2018, 108, 368–377. [Google Scholar] [CrossRef] [PubMed]

- Khiabani, A.A.; Tabibiazar, M.; Roufegarinejad, L.; Hamishehkar, H.; Alizadeh, A. Preparation and characterization of carnauba wax/adipic acid oleogel: A new reinforced oleogel for application in cake and beef burger. Food Chem. 2020, 333, 127446. [Google Scholar] [CrossRef] [PubMed]

- Adili, L.; Roufegarinejad, L.; Tabibiazar, M.; Hamishehkar, H.; Alizadeh, A. Development and characterization of reinforced ethyl cellulose based oleogel with adipic acid: Its application in cake and beef burger. LWT 2020, 126, 109277. [Google Scholar] [CrossRef]

- Özer, C.O.; Çelegen, Ş. Evaluation of quality and emulsion stability of a fat-reduced beef burger prepared with an olive oil oleogel-based emulsion. J. Food Process. Preserv. 2021, 45, e14547. [Google Scholar] [CrossRef]

- Silva, T.J.; Fernandes, G.D.; Bernardinelli, O.D.; Silva, E.C.d.R.; Barrera-Arellano, D.; Ribeiro, A.P.B. Organogels in low-fat and high-fat margarine: A study of physical properties and shelf life. Food Res. Int. 2021, 140, 110036. [Google Scholar] [CrossRef]

- Blake, A.I.; Marangoni, A.G. Factors affecting the rheological properties of a structured cellular solid used as a fat mimetic. Food Res. Int. 2015, 74, 284–293. [Google Scholar] [CrossRef]

- Tirgarian, B.; Yadegari, H.; Bagheri, A.; Neshagaran, E.; Mardani, M.; Farmani, J. Reduced-fat chocolate spreads developed by water-in-oleogel emulsions. J. Food Eng. 2023, 337, 111233. [Google Scholar] [CrossRef]

- Pandolsook, S.; Kupongsak, S. Influence of bleached rice bran wax on the physicochemical properties of organogels and water-in-oil emulsions. J. Food Eng. 2017, 214, 182–192. [Google Scholar] [CrossRef]

- Chemat, F.; Khan, M.K. Applications of ultrasound in food technology: Processing, preservation and extraction. Ultrason. Sonochem. 2011, 18, 813–835. [Google Scholar] [CrossRef]

- Gallo, M.; Ferrara, L.; Naviglio, D. Application of ultrasound in food science and technology: A perspective. Foods 2018, 7, 164. [Google Scholar] [CrossRef] [PubMed]

- Welti-Chanes, J.; la Peña, M.M.-d.; Jacobo-Velázquez, D.A.; Martín-Belloso, O. Opportunities and challenges of ultrasound for food processing: An industry point of view. Ultrasound Adv. Food Process. Preserv. 2017, 457–497. [Google Scholar] [CrossRef]

- Vilkhu, K.; Mawson, R.; Simons, L.; Bates, D. Applications and opportunities for ultrasound assisted extraction in the food industry—A review. Innov. Food Sci. Emerg. Technol. 2008, 9, 161–169. [Google Scholar] [CrossRef]

- Dai, J.; Bai, M.; Li, C.; Cui, H.; Lin, L. Advances in the mechanism of different antibacterial strategies based on ultrasound technique for controlling bacterial contamination in food industry. Trends Food Sci. Technol. 2020, 105, 211–222. [Google Scholar] [CrossRef]

- Bhargava, N.; Mor, R.S.; Kumar, K.; Sharanagat, V.S. Advances in application of ultrasound in food processing: A review. Ultrason. Sonochem. 2021, 70, 105293. [Google Scholar] [CrossRef]

- Arvanitoyannis, I.S.; Kotsanopoulos, K.V.; Savva, A.G. Use of ultrasounds in the food industry–Methods and effects on quality, safety, and organoleptic characteristics of foods: A review. Crit. Rev. Food Sci. Nutr. 2017, 57, 109–128. [Google Scholar] [CrossRef]

- Natarajan, S.; Ponnusamy, V. WITHDRAW: A review on the applications of ultrasound in food processing. Mater. Today Proc. 2020. [Google Scholar] [CrossRef]

- Chandrapala, J. Low intensity ultrasound applications on food systems. Int. Food Res. J. 2015, 22, 888–895. [Google Scholar]

- Zhou, L.; Zhang, J.; Xing, L.; Zhang, W. Applications and effects of ultrasound assisted emulsification in the production of food emulsions: A review. Trends Food Sci. Technol. 2021, 110, 493–512. [Google Scholar] [CrossRef]

- Dzah, C.S.; Duan, Y.; Zhang, H.; Wen, C.; Zhang, J.; Chen, G.; Ma, H. The effects of ultrasound assisted extraction on yield, antioxidant, anticancer and antimicrobial activity of polyphenol extracts: A review. Food Biosci. 2020, 35, 100547. [Google Scholar] [CrossRef]

- Munekata, P.E.; Alcántara, C.; Žugčić, T.; Abdelkebir, R.; Collado, M.C.; García-Pérez, J.V.; Jambrak, A.R.; Gavahian, M.; Barba, F.J.; Lorenzo, J.M. Impact of ultrasound-assisted extraction and solvent composition on bioactive compounds and in vitro biological activities of thyme and rosemary. Food Res. Int. 2020, 134, 109242. [Google Scholar] [CrossRef] [PubMed]

- Huang, G.; Chen, S.; Dai, C.; Sun, L.; Sun, W.; Tang, Y.; Xiong, F.; He, R.; Ma, H. Effects of ultrasound on microbial growth and enzyme activity. Ultrason. Sonochem. 2017, 37, 144–149. [Google Scholar] [CrossRef] [PubMed]

- Giacomozzi, A.; Palla, C.; Carrín, M.E.; Martini, S. Tailoring physical properties of monoglycerides oleogels using high-intensity ultrasound. Food Res. Int. 2020, 134, 109231. [Google Scholar] [CrossRef] [PubMed]

- Lane, K.E.; Li, W.; Smith, C.; Derbyshire, E. The bioavailability of an omega-3-rich algal oil is improved by nanoemulsion technology using yogurt as a food vehicle. Int. J. Food Sci. Technol. 2014, 49, 1264–1271. [Google Scholar] [CrossRef]

- Gharibzahedi, S.M.T.; Razavi, S.H.; Mousavi, M. Optimal development of a new stable nutraceutical nanoemulsion based on the inclusion complex of 2-hydroxypropyl-β-cyclodextrin with canthaxanthin accumulated by Dietzia natronolimnaea HS-1 using ultrasound-assisted emulsification. J. Dispers. Sci. Technol. 2015, 36, 614–625. [Google Scholar] [CrossRef]

- Bari, A.H.; Chawla, A.; Pandit, A.B. Sono-crystallization kinetics of K2SO4: Estimation of nucleation, growth, breakage and agglomeration kinetics. Ultrason. Sonochem. 2017, 35, 196–203. [Google Scholar] [CrossRef]

- da Silva, T.L.T.; Arellano, D.B.; Martini, S. Use of high-intensity ultrasound to change the physical properties of oleogels and emulsion gels. J. Am. Oil Chem. Soc. 2019, 96, 681–691. [Google Scholar] [CrossRef]

- Sharifi, M.; Goli, S.A.H.; Fayaz, G. Exploitation of high-intensity ultrasound to modify the structure of olive oil organogel containing propolis wax. Int. J. Food Sci. Technol. 2019, 54, 509–515. [Google Scholar] [CrossRef]

- Giacomozzi, A.S.; Palla, C.A.; Carrín, M.E.; Martini, S. Physical properties of monoglycerides oleogels modified by concentration, cooling rate, and high-intensity ultrasound. J. Food Sci. 2019, 84, 2549–2561. [Google Scholar] [CrossRef]

- Yao, Y.; Zhou, H.; Liu, W.; Li, C.; Wang, S. The effect of cooling rate on the microstructure and macroscopic properties of rice bran wax oleogels. J. Oleo Sci. 2021, 70, 135–143. [Google Scholar] [CrossRef]

- Blake, A.I.; Marangoni, A.G. The effect of shear on the microstructure and oil binding capacity of wax crystal networks. Food Biophys. 2015, 10, 403–415. [Google Scholar] [CrossRef]

- Trujillo-Ramírez, D.; Reyes, I.; Lobato-Calleros, C.; Vernon-Carter, E.J.; Alvarez-Ramirez, J. Chia seed oil-candelilla wax oleogels structural features and viscoelasticity are enhanced by annealing. LWT 2022, 153, 112433. [Google Scholar] [CrossRef]

- Jana, S.; Martini, S. Effect of high-intensity ultrasound and cooling rate on the crystallization behavior of beeswax in edible oils. J. Agric. Food Chem. 2014, 62, 10192–10202. [Google Scholar] [CrossRef] [PubMed]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. Syst. Rev. 2021, 10, 89. [Google Scholar] [CrossRef]

- Lassila, P.; Valoppi, F.; Tommiska, O.; Hyvönen, J.; Holmström, A.; Hietala, S.; Salmi, A.; Haeggström, E. Practical scale modification of oleogels by ultrasonic standing waves. Ultrason. Sonochem. 2022, 85, 105970. [Google Scholar] [CrossRef]

- da Silva, T.L.T.; Danthine, S. Influence of sonocrystallization on lipid crystals multicomponent oleogels structuration and physical properties. Food Res. Int. 2022, 154, 110997. [Google Scholar] [CrossRef]

- Gao, Z.; Zhang, C.; Wu, Y.; Chen, F.; Hu, B.; Wang, R.; Yang, J.; Nishinari, K. Composite oleogels formed by cellulose particles and sorbitan acid esters. Food Struct. 2022, 31, 100242. [Google Scholar] [CrossRef]

- Jadhav, H.B.; Pratap, A.P.; Gogate, P.R.; Annapure, U.S. Ultrasound-assisted synthesis of highly stable MCT based oleogel and evaluation of its baking performance. Appl. Food Res. 2022, 2, 100156. [Google Scholar] [CrossRef]

- Li, L.; Taha, A.; Geng, M.; Zhang, Z.; Su, H.; Xu, X.; Pan, S.; Hu, H. Ultrasound-assisted gelation of β-carotene enriched oleogels based on candelilla wax-nut oils: Physical properties and in-vitro digestion analysis. Ultrason. Sonochem. 2021, 79, 105762. [Google Scholar] [CrossRef]

- Szymańska, I.; Żbikowska, A.; Kowalska, M.; Golec, K. Application of Oleogel and Conventional Fats for Ultrasound-assisted Obtaining of Vegan Creams. J. Oleo Sci. 2021, 70, 1495–1507. [Google Scholar] [CrossRef]

- da Silva, T.L.T.; Danthine, S. Effect of high-intensity ultrasound on the oleogelation and physical properties of high melting point monoglycerides and triglycerides oleogels. J. Food Sci. 2021, 86, 343–356. [Google Scholar] [CrossRef] [PubMed]

- Qiu, H.; Qiu, Z.; Chen, Z.; Liu, L.; Wang, J.; Jiang, H.; Zhang, H.; Liu, G.-Q. Antioxidant properties of blueberry extract in different oleogel systems. LWT 2021, 137, 110364. [Google Scholar] [CrossRef]

- Valoppi, F.; Salmi, A.; Ratilainen, M.; Barba, L.; Puranen, T.; Tommiska, O.; Helander, P.; Heikkilä, J.; Haeggström, E. Controlling oleogel crystallization using ultrasonic standing waves. Sci. Rep. 2020, 10, 14448. [Google Scholar] [CrossRef] [PubMed]

- Liu, L.; Ramirez, I.S.A.; Yang, J.; Ciftci, O.N. Evaluation of oil-gelling properties and crystallization behavior of sorghum wax in fish oil. Food Chem. 2020, 309, 125567. [Google Scholar] [CrossRef] [PubMed]

- Shi, Z.; Cao, L.; Kang, S.; Jiang, S.; Pang, M. Influence of wax type on characteristics of oleogels from camellia oil and medium chain triglycerides. Int. J. Food Sci. Technol. 2022, 57, 2003–2014. [Google Scholar] [CrossRef]

- Blake, A.I.; Co, E.D.; Marangoni, A.G. Structure and physical properties of plant wax crystal networks and their relationship to oil binding capacity. J. Am. Oil Chem. Soc. 2014, 91, 885–903. [Google Scholar] [CrossRef]

- Yu, Y.; Wang, T.; Gong, Y.; Wang, W.; Wang, X.; Yu, D.; Wu, F.; Wang, L. Effect of ultrasound on the structural characteristics and oxidative stability of walnut oil oleogel coated with soy protein isolate-phosphatidylserine. Ultrason. Sonochem. 2022, 83, 105945. [Google Scholar] [CrossRef]

- Omonov, T.S.; Bouzidi, L.; Narine, S.S. Quantification of oil binding capacity of structuring fats: A novel method and its application. Chem. Phys. Lipids 2010, 163, 728–740. [Google Scholar] [CrossRef]

- Habibi, A.; Kasapis, S.; Truong, T. Effect of hydrogel particle size embedded into oleogels on the physico-functional properties of hydrogel-in-oleogel (bigels). LWT 2022, 163, 113501. [Google Scholar] [CrossRef]

- Sarkisyan, V.; Sobolev, R.; Frolova, Y.; Vorobiova, I.; Kochetkova, A. A Study of the Quantitative Relationship between Yield Strength and Crystal Size Distribution of Beeswax Oleogels. Gels 2022, 8, 39. [Google Scholar] [CrossRef]

- Sobolev, R.; Frolova, Y.; Sarkisyan, V.; Makarenko, M.; Kochetkova, A. Effect of beeswax and combinations of its fractions on the oxidative stability of oleogels. Food Biosci. 2022, 48, 101744. [Google Scholar] [CrossRef]

- Wagh, A.; Birkin, P.; Martini, S. High-intensity ultrasound to improve physical and functional properties of lipids. Annu. Rev. Food Sci. Technol. 2016, 7, 23–41. [Google Scholar] [CrossRef] [PubMed]

- da Silva, T.L.T.; Danthine, S. High-intensity Ultrasound as a Tool to Form Water in Oleogels Emulsions Structured by Lipids Oleogelators. Food Biophys. 2022, 17, 361–374. [Google Scholar] [CrossRef]

- Xia, T.; Wei, Z.; Xue, C. Impact of composite gelators on physicochemical properties of oleogels and astaxanthin delivery of oleogel-based nanoemulsions. LWT 2022, 153, 112454. [Google Scholar] [CrossRef]

- Xia, T.; Gao, Y.; Liu, Y.; Wei, Z.; Xue, C. Lactoferrin particles assembled via transglutaminase-induced crosslinking: Utilization in oleogel-based Pickering emulsions with improved curcumin bioaccessibility. Food Chem. 2022, 374, 131779. [Google Scholar] [CrossRef]

- Palla, C.A.; Aguilera-Garrido, A.; Carrín, M.E.; Galisteo-González, F.; Gálvez-Ruiz, M.J. Preparation of highly stable oleogel-based nanoemulsions for encapsulation and controlled release of curcumin. Food Chem. 2022, 378, 132132. [Google Scholar] [CrossRef]

- Yu, X.-H.; Zhou, F.-Z.; Xi, Y.-K.; Huang, X.-N.; Yin, S.-W.; Yang, X.-Q. Ethyl cellulose-chitosan complex particles stabilized W/O Pickering emulsion as a recyclable bio-catalytic microreactor. Coll. Surf. A Physicochem. Eng. Asp. 2022, 639, 128375. [Google Scholar] [CrossRef]

- Chen, X.-W.; Yin, W.-J.; Yang, D.-X.; Wan, Z.-L.; Ma, C.-G.; Yang, X.-Q. One-pot ultrasonic cavitational emulsification of phytosterols oleogel-based flavor emulsions and oil powder stabilized by natural saponin. Food Res. Int. 2021, 150, 110757. [Google Scholar] [CrossRef]

- Qi, W.; Li, T.; Zhang, Z.; Wu, T. Preparation and characterization of oleogel-in-water pickering emulsions stabilized by cellulose nanocrystals. Food Hydrocoll. 2021, 110, 106206. [Google Scholar] [CrossRef]

- Urbánková, L.; Sedláček, T.; Kašpárková, V.; Bordes, R. Formation of oleogels based on emulsions stabilized with cellulose nanocrystals and sodium caseinate. J. Colloid Interface Sci. 2021, 596, 245–256. [Google Scholar] [CrossRef]

- Pehlivanoglu, H.; Akcicek, A.; Can, A.M.; Karasu, S.; Demirci, M.; Yilmaz, M.T. Effect of oil type and concentration on solid fat contents and rheological properties of watery oleogels. Riv. Ital. Delle Sostanze Grasse 2021, 98, 177–186. [Google Scholar]

- Ren, Z.; Li, Z.; Chen, Z.; Zhang, Y.; Lin, X.; Weng, W.; Yang, H.; Li, B. Characteristics and application of fish oil-in-water pickering emulsions structured with tea water-insoluble proteins/κ-carrageenan complexes. Food Hydrocoll. 2021, 114, 106562. [Google Scholar] [CrossRef]

- Rocha-Guzmán, N.E.; Cháirez-Ramírez, M.H.; Pérez-Martínez, J.D.; Rosas-Flores, W.; Ornelas-Paz, J.D.J.; Moreno-Jiménez, M.R.; González-Laredo, R.F.; Gallegos-Infante, J.A. Use of organogel-based emulsions (o/w) as a tool to increase the bioaccessibility of lupeol, curcumin, and quercetin. J. Am. Oil Chem. Soc. 2021, 98, 1177–1188. [Google Scholar] [CrossRef]

- Qi, W.; Zhang, Z.; Wu, T. Encapsulation of β-carotene in oleogel-in-water Pickering emulsion with improved stability and bioaccessibility. Int. J. Biol. Macromol. 2020, 164, 1432–1442. [Google Scholar] [CrossRef] [PubMed]

- Shi, Z.; Shi, Z.; Wu, M.; Shen, Y.; Li, G.; Ma, T. Fabrication of emulsion gel based on polymer sanxan and its potential as a sustained-release delivery system for β-carotene. Int. J. Biol. Macromol. 2020, 164, 597–605. [Google Scholar] [CrossRef]

- Pehlivanoglu, H.; Demirci, M.; Toker, O.S. Rheological properties of wax oleogels rich in high oleic acid. Int. J. Food Prop. 2017, 20, S2856–S2867. [Google Scholar] [CrossRef]

| No | Gel Composition | Processing Options | Applications | References |

|---|---|---|---|---|

| 1 | Rapeseed oil, monoglyceride (MG) |

| To decrease effective stiffness; For use in the food, pharmaceutical, and cosmetic industries. | [85] |

| 2 | Fully hydrogenated rapeseed oil, rapeseed oil, MG, lecithin (LE) |

| To increase hardness; For use in food. | [86] |

| 3 | Glyceryl tridecanoate, α-cellulose particles, sorbitan monostearate (Span 60), sorbitan monopalmitate (Span 40) |

| Potential application in food industry. | [87] |

| 4 | Medium chain triglycerides, ethyl cellulose |

| To increase OBC, rheology, texture and oxidative stability; For use in bakery products (cookies). | [88] |

| 5 | Peanut oil, pine nut oil, walnut oil, candelilla wax, β-carotene |

| To increase rheology, texture and OBC of oleogels; To improve the protection of β-carotene; To reduce the β-carotene released during intestinal digestion; For use in food and pharmaceutical industries. | [89] |

| 6 | Rapeseed oil, linseed oil, candelilla wax |

| For use in vegan creams. | [90] |

| 7 | Fully hydrogenated rapeseed oil, rapeseed oil, MG |

| To increase hardness and OBC; For application in food industry. | [91] |

| 8 | Soybean oil, peanut oil, acidic blueberry powder, alkaline blueberry powder, resveratrol, sitosterol, LE |

| For application in food industry. | [92] |

| 9 | Rapeseed oil, sunflower wax, candelilla wax, MG |

| For use in cosmetics, pharmaceutical, chemical, and food industries. | [93] |

| 10 | High oleic sunflower oil, MG |

| To reduce crystal size; To increase rheology, texture and OBC of oleogels; For application in food industry. | [73] |

| 11 | Fish oil, sorghum wax |

| To reduce oil loss by reducing the crystal size. For application in food industry. | [94] |

| 12 | High-olein sunflower oil, MG |

| To increase OBC and hardness. For use as fat substitutes in bakery. | [79] |

| 13 | Olive oil, linseed oil, fish oil, ethyl cellulose, beeswax, sorbitan monostearate |

| For use as animal fat replacers for pork liver pâtés. | [50] |

| 14 | High-olein sunflower oil, fully hydrogenated crambe oil, monoacylglycerols (MAG), candelilla wax |

| To increase the hardness. For application in food industry. | [77] |

| No | Emulsion Composition | Processing Options | Applications | References |

|---|---|---|---|---|

| 1 | Walnut oil, rice bran wax, soy protein isolate, phosphatidylserine, water |

| To improve the oxidation stability and surface characteristics; For use in oils with a high unsaturated fatty acid. | [97] |

| 2 | Hardfat (HF), MG, LE, water |

| To improve hardness, elastic modulus and OBC; For use in food industry. | [103] |

| 3 | Corn oil, carnauba wax, behenyl alcohol, astaxanthin, fish collagen, water |

| For use as a nutraceutical delivery system. | [104] |

| 4 | Corn oil, carnauba wax, behenyl alcohol, lactoferrin, transglutaminase, curcumin, water |

| For use as a nutraceutical delivery system. | [105] |

| 5 | Canola oil, MAG, kappa-carrageenan, whey protein concentrate, potassium chloride, water |

| For use as a nutraceutical delivery system. | [99] |

| 6 | Extra virgin olive oil, MG, curcumin, Pluronic F-68, Tween-80, water |

| For use as a nutraceutical delivery system. | [106] |

| 7 | Corn oil, ethyl cellulose, chitosan, deionized water |

| For use as a nutraceutical delivery system. | [107] |

| 8 | Flavor oils, phytosterols, tea saponin, Quillaja saponin, octenylsuccinate starch, sodium caseinate, sorbitan monooleate, soybean lecithin, water |

| For use as a nutraceutical delivery system. | [108] |

| 9 | Milk fat, refined palmoil, rapeseed oil, linseed oil, candelilla wax, dairy cream, soy drink, water |

| For use in vegan creams. | [90] |

| 10 | Soybean oil, sodium chloride, beeswax, cellulose nanocrystals, deionized water |

| For use in emulsions for food applications | [109] |

| 11 | Extra virgin olive oil, hexadecane, casein sodium salt, cellulose nanocrystal, calcium chloride, sodium chloride, fluorescein sodium salt, Milli-Q water |

| For use as a nutraceutical delivery system. | [110] |

| 12 | High oleic sunflower oil, hazelnut oil, olive oil, blend fat, carnauba wax, β-carotene, water |

| For use in food production. | [111] |

| 13 | Fish oil, tea water-insoluble protein, κ-carrageenan, deionized water |

| For use in food production. | [112] |

| 14 | Canola oil, coconut oil, curcumin, quercetin, lupeol, Tween 20 (Polyoxyethylene-20-sorbitan monolaurate), Tween 80 (Polyoxyethylene-20-sorbitan monooleate), MG, water |

| For use in food production. | [113] |

| 15 | Soybean oil, beeswax, β-carotene, cellulose nanocrystals, sodium chloride, hydrogen chloride, sodium hydroxide, water |

| For use as a nutraceutical delivery system. | [114] |

| 16 | Sunflower oil, sanxan, β-carotene, sodium chloride, calcium chloride, water |

| For use as a nutraceutical delivery system. | [115] |

| 17 | High-oleic sunflower oil, candelilla wax, MAG, fully hydrogenated crambe oil, water |

| To increase the hardness. For application in the food industry. | [77] |

| 18 | Shortening, cotton oil, high-oleic sunflower oil, carnauba wax, citric acid, potassium sorbate, salt, emulsifiers, β-carotene, vitamin A, and D3, water |

| For use in batter. | [29] |

| 19 | Industrial blend oil, carnauba wax, high-oleic sunflower oil, sunflower lecithin, MG, β-carotene, vitamin A, vitamin D3, citric acid, potassium sorbate, sodium chloride, skim milk, water |

| For use in food production. | [116] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Frolova, Y.; Sarkisyan, V.; Sobolev, R.; Kochetkova, A. Ultrasonic Treatment of Food Colloidal Systems Containing Oleogels: A Review. Gels 2022, 8, 801. https://doi.org/10.3390/gels8120801

Frolova Y, Sarkisyan V, Sobolev R, Kochetkova A. Ultrasonic Treatment of Food Colloidal Systems Containing Oleogels: A Review. Gels. 2022; 8(12):801. https://doi.org/10.3390/gels8120801

Chicago/Turabian StyleFrolova, Yuliya, Varuzhan Sarkisyan, Roman Sobolev, and Alla Kochetkova. 2022. "Ultrasonic Treatment of Food Colloidal Systems Containing Oleogels: A Review" Gels 8, no. 12: 801. https://doi.org/10.3390/gels8120801

APA StyleFrolova, Y., Sarkisyan, V., Sobolev, R., & Kochetkova, A. (2022). Ultrasonic Treatment of Food Colloidal Systems Containing Oleogels: A Review. Gels, 8(12), 801. https://doi.org/10.3390/gels8120801