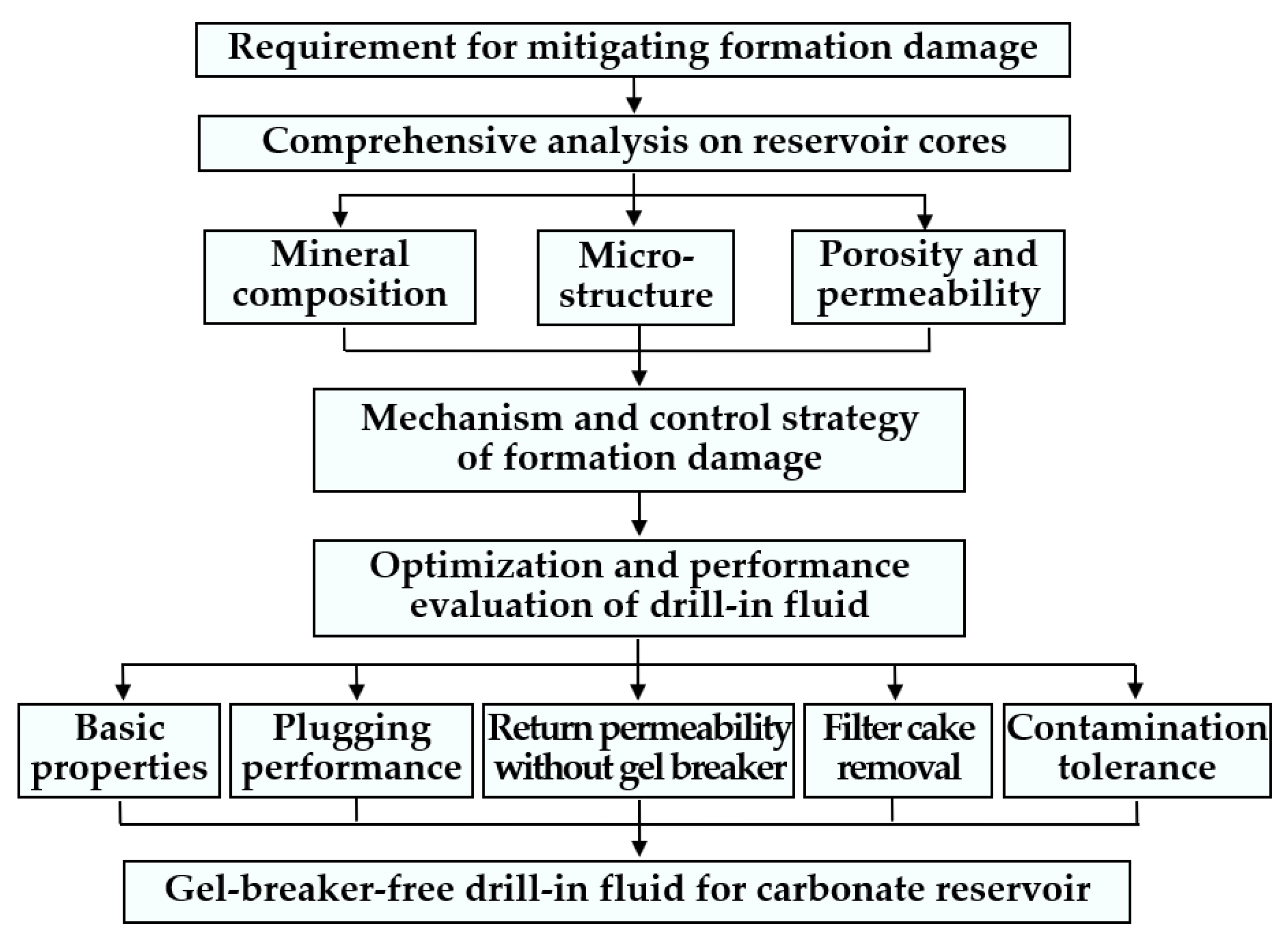

Formation-Damage Mechanism and Gel-Breaker-Free Drill-In Fluid for Carbonate Reservoir

Abstract

:1. Introduction

2. Geological Setting and Reservoir Characteristics

3. Results and Discussion

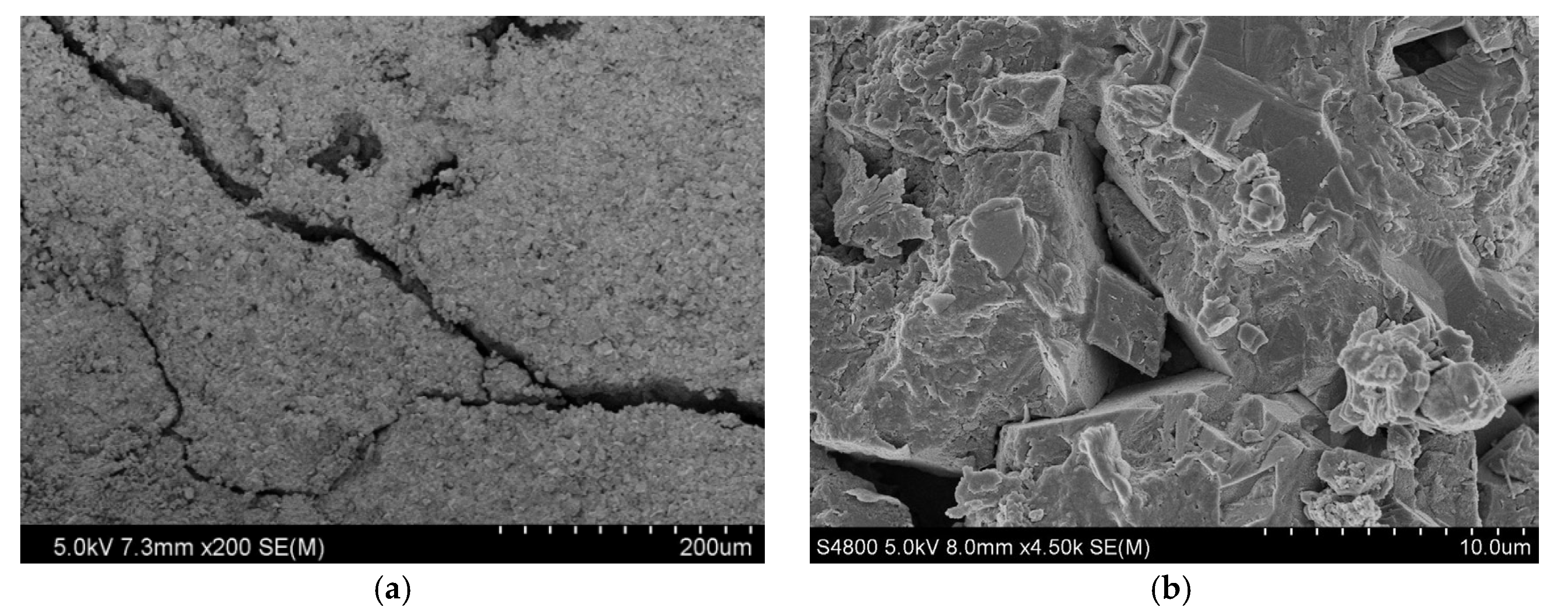

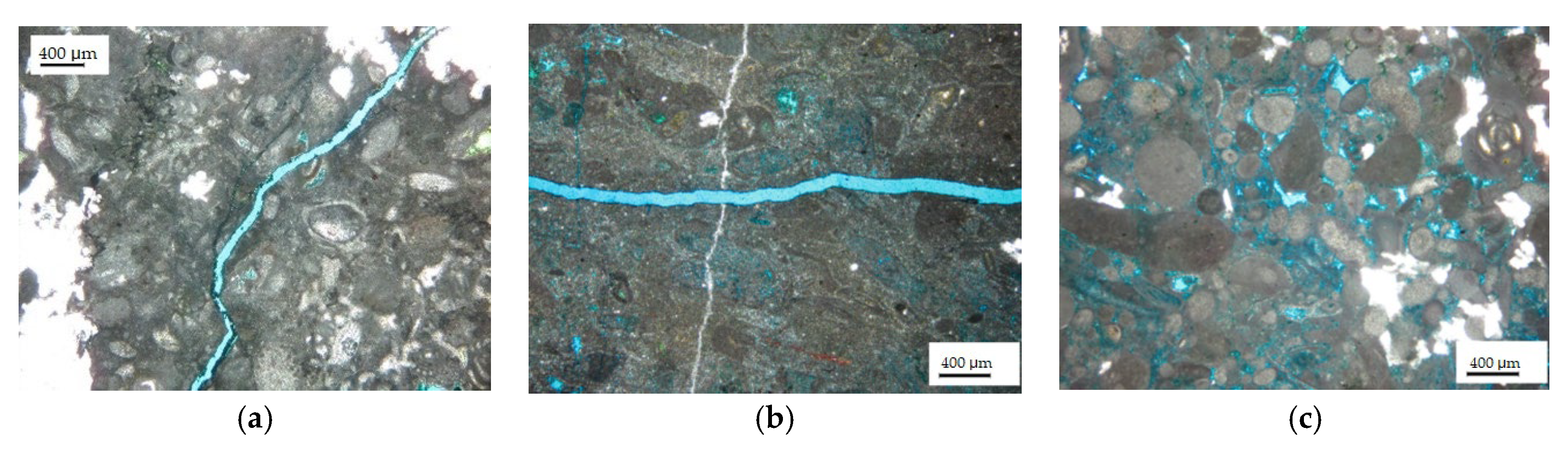

3.1. Formation Damage Mechanism Analysis

- (1)

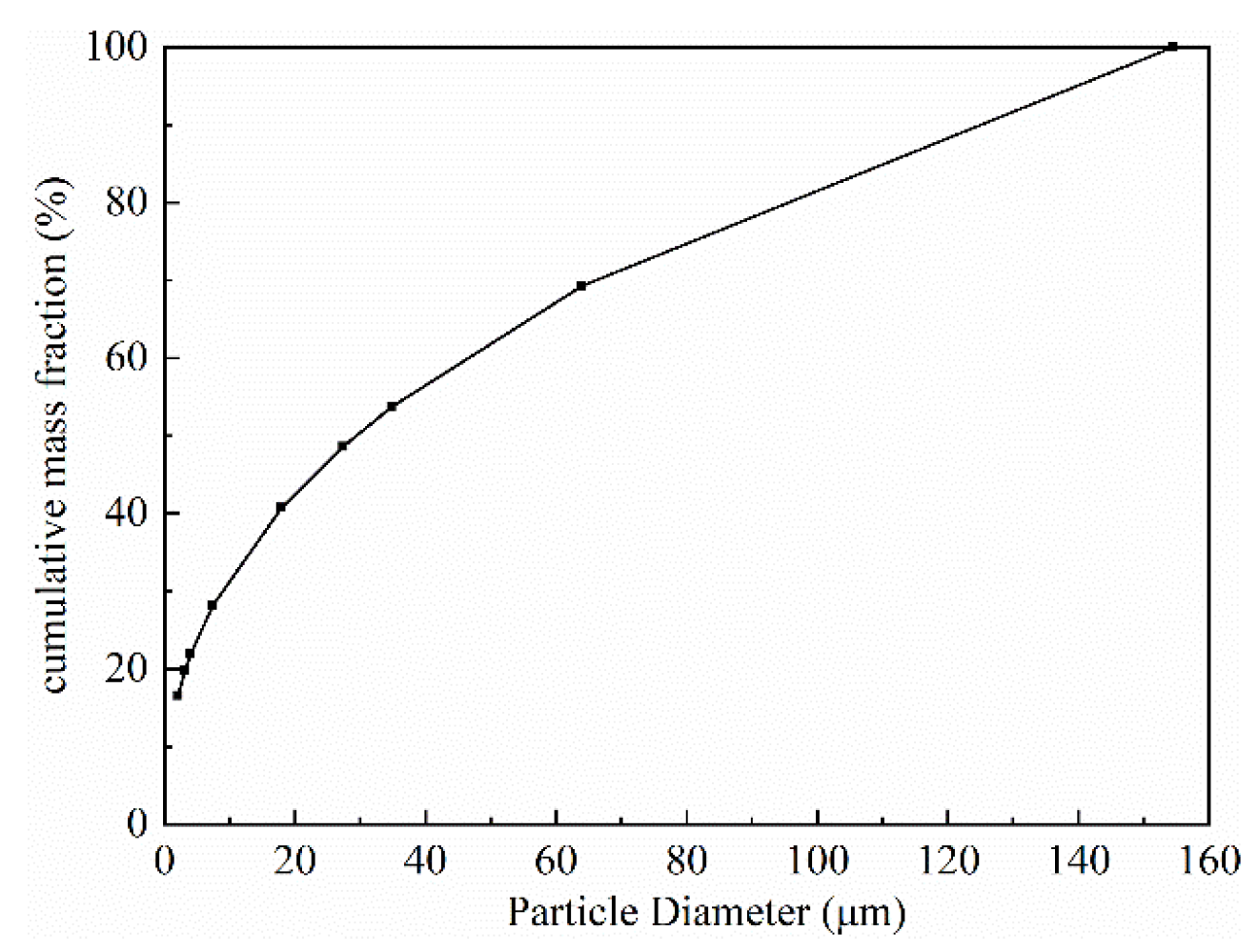

- The micro-fractures in the formation provided a natural channel for solids and filtrates of drilling fluids to invade the formation, and even lost circulation of drilling fluids could occur, causing serious formation damage. In accordance with the size of the micro-fractures in the reservoir formation, it was necessary to select a temporary plugging agent that could be subsequently removed, and to reasonably design the particle size gradation, in order to achieve effective temporary plugging of the micro-fractures in the process of drilling in the reservoir formation, thus preventing formation damage caused by drilling-fluid invasion;

- (2)

- Because of the low porosity and permeability of the reservoir formation, the main seepage channels were micro-fractures and micro-throats, which caused high irreducible water saturation of the reservoir rock [13,14]. As a result, it was difficult for oil and gas to flow in the micro-channels, therefore water-blocking damage occurred;

- (3)

- From the point of view of mineral composition, the reservoir rock was mainly composed of dolomite, which could react with alkali liquor to produce a new mineral phase Mg(OH)2, as shown in Equation (1) [33]. The mineral particles tended to disperse and migrate to the pore throats, causing a blockage. Accordingly, it was desirable to avoid excessively high pH of the drill-in fluid. Because the content of clay minerals in the reservoir was extremely low (about 1%), there was no problem of potential sensitivity damage caused by clay minerals.

3.2. Drill-In Fluid for Mitigating Carbonate Formation Damage

4. Conclusions

5. Experimental Section

5.1. Materials

5.2. Methods

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mu, L.; Chen, Y.; Xu, A.; Wang, R. Technological progress and development directions of PetroChina overseas oil and gas field production. Pet. Explor. Dev. 2020, 47, 124–133. [Google Scholar] [CrossRef]

- Jafarpour, H.; Moghadasi, J.; Khormali, A.; Petrakov, D.G.; Ashena, R. Increasing the stimulation efficiency of heterogeneous carbonate reservoirs by developing a multi-bached acid system. J. Pet. Sci. Eng. 2019, 172, 50–59. [Google Scholar] [CrossRef]

- Aghli, G.; Moussavi-Harami, R.; Mohammadian, R. Reservoir heterogeneity and fracture parameter determination using electrical image logs and petrophysical data (a case study, carbonate Asmari Formation, Zagros Basin, SW Iran). Pet. Sci. 2020, 17, 51–69. [Google Scholar] [CrossRef]

- Mohsenipour, A.; Soleimani, B.; Zahmatkesh, I.; Veisi, I. Determination of reservoir rock typing using integrating geological and petrophysical methods in one of the oil field in south-west of Iran. Carbonates Evaporites 2022, 37, 31. [Google Scholar] [CrossRef]

- Ahmadi, M.; Sharma, M.M.; Pope, G.A.; Torres, D.E.; McCulley, C.A.; Linnemeyer, H. Chemical treatment to mitigate condensate and water blocking in gas wells in carbonate reservoirs. SPE Prod. Oper. 2011, 26, 67–74. [Google Scholar] [CrossRef]

- Ghosh, B.; Ali, S.A.; Belhaj, H. Controlling excess water production in fractured carbonate reservoirs: Chemical zonal protection design. J. Pet. Explor. Prod. Technol. 2020, 10, 1921–1931. [Google Scholar] [CrossRef]

- Radwan, A.E. Integrated reservoir, geology, and production data for reservoir damage analysis: A case study of the Miocene sandstone reservoir, Gulf of Suez, Egypt. Interpretation 2021, 9, 27–37. [Google Scholar] [CrossRef]

- Abdelghany, W.K.; Radwan, A.E.; Elkhawaga, M.A.; Wood, D.A.; Sen, S.; Kassem, A.A. Geomechanical modeling using the depth-of-damage approach to achieve successful underbalanced drilling in the Gulf of Suez Rift Basin. J. Pet. Sci. Eng. 2021, 202, 108311. [Google Scholar] [CrossRef]

- Huang, T.; Crews, J.B.; Clark, D.E. Protecting the reservoir with surfactant micellar drill-in fluids in carbonate-containing formations. SPE Drill. Complet. 2011, 26, 492–498. [Google Scholar] [CrossRef]

- Zhao, X.; Qiu, Z.; Sun, B.; Liu, S.; Xing, X.; Wang, M. Formation damage mechanisms associated with drilling and completion fluids for deepwater reservoirs. J. Pet. Sci. Eng. 2019, 173, 112–121. [Google Scholar] [CrossRef]

- Lin, C.; Kang, Y.; Xu, C.; You, L.; Zhang, Z.; Tan, Q. An engineered formation-damage-control drill-in fluid technology for deep-fractured tight-sandstone oil reservoir in northern Tarim Basin. SPE Drill. Complet. 2020, 35, 026–037. [Google Scholar] [CrossRef]

- Zhao, X.; Qiu, Z.; Gao, J.; Ren, X.; Li, J.; Huang, W. Mechanism and effect of nanoparticles on controlling fines migration in unconsolidated sandstone formations. SPE J. 2021, 26, 3819–3831. [Google Scholar] [CrossRef]

- Mohammadi, M.K.; Riahi, S.; Boek, E.S. An insight review on formation damage induced by drilling fluids. Rev. Chem. Eng. 2022, in press. [Google Scholar] [CrossRef]

- Civan, F. Reservoir Formation Damage; Gulf Professional Publishing: Houston, TX, USA, 2015. [Google Scholar]

- Civan, F. Effective Correlation of Stress and Thermal Effects on Porosity and Permeability of Naturally Fractured Formations by a Modified Power Law. SPE J. 2019, 24, 2378–2397. [Google Scholar] [CrossRef]

- Radwan, A.E.; Wood, D.A.; Abudeif, A.M.; Attia, M.M.; Mahmoud, M.; Kassem, A.A.; Kania, M. Reservoir formation damage; reasons and mitigation: A case study of the Cambrian–Ordovician Nubian ‘C’Sandstone Gas and Oil Reservoir from the Gulf of Suez Rift Basin. Arab. J. Sci. Eng. 2021, in press. [Google Scholar] [CrossRef]

- Ezati, M.; Azizzadeh, M.; Riahi, M.A.; Fattahpour, V.; Honarmand, J. Characterization of micro-fractures in carbonate Sarvak reservoir, using petrophysical and geological data, SW Iran. J. Pet. Sci. Eng. 2018, 170, 675–695. [Google Scholar] [CrossRef]

- Kiani, M.; Ramazani SaadatAbadi, A.; Jafari Behbahani, T. Wettability alteration of carbonate rock by nonionic surfactants in water-based drilling fluid. Int. J. Environ. Sci. Technol. 2019, 16, 6547–6556. [Google Scholar] [CrossRef]

- Hassani, A.; Mostofi, M.; Kamali, M.R. Determination of critical alkalinity (pH) in Fahliyan carbonate reservoir using a new methodology. J. Pet. Explor. Prod. Technol. 2019, 9, 2343–2351. [Google Scholar] [CrossRef]

- Radwan, A.E.; Abudeif, A.M.; Attia, M.M.; Mahmoud, M.A. Development of formation damage diagnosis workflow, application on Hammam Faraun reservoir: A case study, Gulf of Suez, Egypt. J. Afr. Earth Sci. 2019, 153, 42–53. [Google Scholar] [CrossRef]

- Petri, D.F.S.; de Queiroz Neto, J.C. Identification of lift-off mechanism failure for salt drill-in drilling fluid containing polymer filter cake through adsorption/desorption studies. J. Pet. Sci. Eng. 2010, 70, 89–98. [Google Scholar] [CrossRef]

- Ali, I.; Ahmad, M.; Ganat, T. Biopolymeric formulations for filtrate control applications in water-based drilling muds: A review. J. Pet. Sci. Eng. 2021, 210, 110021. [Google Scholar] [CrossRef]

- He, Z.; Wang, J.; Liao, B.; Bai, Y.; Shao, Z.; Huang, X.; Wang, Q.; Li, Y. Molecular Simulation of Interactions between High-Molecular-Polymer Flocculation Gel for Oil-Based Drilling Fluid and Clay Minerals. Gels 2022, 8, 442. [Google Scholar] [CrossRef] [PubMed]

- Wei, Z.; Zhou, F.; Chen, S.; Long, W. Synthesis and Weak Hydrogelling Properties of a Salt Resistance Copolymer Based on Fumaric Acid Sludge and Its Application in Oil Well Drilling Fluids. Gels 2022, 8, 251. [Google Scholar] [CrossRef]

- Xu, B.; Hill, A.D.; Zhu, D.; Wang, L. Experimental evaluation of guar-fracture-fluid filter-cake behavior. SPE Prod. Oper. 2011, 26, 381–387. [Google Scholar]

- Imqam, A.; Bai, B.; Wei, M.; Elue, H.; Muhammed, F.A. Use of hydrochloric acid to remove filter-cake damage from preformed particle gel during conformance-control treatments. SPE Prod. Oper. 2016, 31, 247–257. [Google Scholar] [CrossRef]

- Li, Z.; Su, G.; Zheng, L. Enhancing filter cake removal by engineering parameter optimization for clean development of fossil hydrogen energy: A numerical simulation. Int. J. Hydrogen Energy 2021, 46, 12784–12800. [Google Scholar] [CrossRef]

- Reddy, B.R. Laboratory characterization of gel filter cake and development of nonoxidizing gel breakers for zirconium-crosslinked fracturing fluids. SPE J. 2014, 19, 662–673. [Google Scholar] [CrossRef]

- Almubarak, T.; Ng, J.H.C.; AlKhaldi, M.; Panda, S.; Nasr-EL-Din, H.A. Insights on potential formation damage mechanisms associated with the use of gel breakers in hydraulic fracturing. Polymers 2020, 12, 2722. [Google Scholar] [CrossRef]

- Siddig, O.; Mahmoud, A.A.; Elkatatny, S. A review of the various treatments of oil-based drilling fluids filter cakes. J. Pet. Explor. Prod. Technol. 2022, 12, 365–381. [Google Scholar] [CrossRef]

- Wang, H.; Qi, M.; Sun, F. The Study of Complex Carbonate Reservoir Feature and Its Impact on Oilfield Development in Asmari Formation in A Oilfield, Iraq. J. Earth Sci. 2019, 9, 383–389. [Google Scholar]

- Wang, J.; Zhou, F.J. Cause analysis and solutions of water blocking damage in cracked/non-cracked tight sandstone gas reservoirs. Pet. Sci. 2021, 18, 219–233. [Google Scholar] [CrossRef]

- Gillott, J.E. Petrology of Dolomitic Limestones, Kingston, Ontario, Canada. Geol. Soc. Am. Bull. 1963, 74, 759–778. [Google Scholar] [CrossRef] [Green Version]

- Hands, N.; Kowbel, K.; Maikranz, S.; Nouris, R. Drill-in fluid reduces formation damage, increases production rates. Oil Gas J. 1998, 96, 65–68. [Google Scholar]

- Whitfill, D. Lost circulation material selection, particle size distribution and fracture modeling with fracture simulation software. In Proceedings of the IADC/SPE Asia Pacific Drilling Technology Conference and Exhibition, SPE, Jakarta, Indonesia, 25 August 2008. [Google Scholar]

- Akpan, E.U.; Enyi, G.C.; Nasr, G.G. Enhancing the performance of xanthan gum in water-based mud systems using an environmentally friendly biopolymer. J. Pet. Explor. Prod. Technol. 2020, 10, 1933–1948. [Google Scholar] [CrossRef]

- Czuprat, O.; Dahle, B.O.; Dehmel, U.; Ritschel, R.; Storhaug, J.; Adrian, T.; Patey, I. Systematic Selection of Drill-In and Completion Fluids for Development of the Dvalin HT Gas Field. In Proceedings of the SPE Norway One Day Seminar, Bergen, Norway, 14 May 2019. [Google Scholar]

- Ward, C.R.; Taylor, J.C.; Matulis, C.E.; Dale, L.S. Quantification of mineral matter in the Argonne Premium Coals using interactive Rietveld-based X-ray diffraction. Int. J. Coal Geol. 2001, 46, 67–82. [Google Scholar] [CrossRef]

- Cai, Y.; Liu, D.; Yao, Y.; Li, Z.; Pan, Z. Partial coal pyrolysis and its implication to enhance coalbed methane recovery, Part I: An experimental investigation. Fuel 2014, 132, 12–19. [Google Scholar] [CrossRef]

- Tang, Z.; Qiu, Z.; Zhong, H.; Kang, Y.; Guo, B. Wellbore Stability through Novel Catechol-Chitosan Biopolymer Encapsulator-Based Drilling Mud. Gels 2022, 8, 307. [Google Scholar] [CrossRef]

- Ezeakacha, C.P.; Salehi, S.; Hayatdavoudi, A. Experimental study of drilling fluid’s filtration and mud cake evolution in sandstone formations. J. Energy Resour. Technol. 2017, 139, 022912. [Google Scholar] [CrossRef]

- SY-T/6540-2002; Lab Testing Method of Drilling and Completion Fluids Damaging Oil Formation. Petroleum and Natural Gas Industry Standard of the People’s Republic of China: Beijing, China, 2002.

| Depth (m) | Mineral Composition (%) | ||||||

|---|---|---|---|---|---|---|---|

| Quartz | Plagioclase | Calcite | Dolomite | Halite | Anhydrite | Clay | |

| 2991.5 | 1 | 1 | - | 92 | - | 5 | 1 |

| 3008.9 | 1 | 1 | - | 93 | - | 3 | 1 |

| 3026.8 | 1 | 1 | - | 89 | 1 | 6 | 2 |

| 3029.5 | 1 | 1 | 2 | 87 | - | 8 | 1 |

| Depth (m) | Porosity (%) | Permeability (mD) | Max Throat Radius (μm) | Average Throat Radius (μm) | Effect Pore Throat Radius (μm) |

|---|---|---|---|---|---|

| 2976.6 | 5.8 | 0.80 | 0.974 | 0.220 | 0.8–0.16 |

| 3008.2 | 7.6 | 0.24 | 1.432 | 0.325 | 1.9–0.16 |

| 3017.2 | 19.1 | 56.6 | 6.085 | 2.895 | 6.3–2.5 |

| Condition | Apparent Viscosity (mPa·s) | Plastic Viscosity (mPa·s) | Yield Point (Pa) | Gel Strengh (Pa) | FLAPI mL | pH | Lubricating Coefficient |

|---|---|---|---|---|---|---|---|

| BHR | 40.0 | 26.0 | 14.0 | 3.5/8.0 | 3.6 | 10 | |

| AHR | 27.5 | 18.0 | 9.5 | 2.5/4.5 | 4.9 | 9.5 | 0.093 |

| Addition | Condition | Apparent Viscosity (mPa·s) | Plastic Viscosity (mPa·s) | Yield Point (Pa) | Gel Strengh (Pa) | FLAPI mL |

|---|---|---|---|---|---|---|

| None | BHR | 40.0 | 26.0 | 14.0 | 3.5/8.0 | 3.6 |

| AHR | 27.5 | 18.0 | 9.5 | 2.5/4.5 | 4.9 | |

| 1 wt.% CaCl2 | BHR | 41.5 | 27.0 | 14.5 | 3.5/14.0 | 4.5 |

| AHR | 34.5 | 24.0 | 10.5 | 3.0/5.0 | 5.6 | |

| 8 wt.% bentonite | BHR | 49.5 | 32.0 | 17.5 | 5.0/9.0 | 4.0 |

| AHR | 37.0 | 24.0 | 13.0 | 3.5/5.0 | 5.1 |

| Condition | Initial Permeability (10−3 µm2) | Final Permeability (10−3 µm2) | Return Permeability (%) | Plugging Removal Method |

|---|---|---|---|---|

| Static | 3.245 | 2.802 | 86.35 | Cut off the plugging layer |

| 4.672 | 3.957 | 84.7 | Completion fluid | |

| Dynamic | 3.751 | 3.401 | 90.67 | Cut off the plugging layer |

| 5.122 | 4.505 | 87.95 | Completion fluid |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fang, Q.; Zhao, X.; Sun, H.; Wang, Z.; Qiu, Z.; Shan, K.; Ren, X. Formation-Damage Mechanism and Gel-Breaker-Free Drill-In Fluid for Carbonate Reservoir. Gels 2022, 8, 565. https://doi.org/10.3390/gels8090565

Fang Q, Zhao X, Sun H, Wang Z, Qiu Z, Shan K, Ren X. Formation-Damage Mechanism and Gel-Breaker-Free Drill-In Fluid for Carbonate Reservoir. Gels. 2022; 8(9):565. https://doi.org/10.3390/gels8090565

Chicago/Turabian StyleFang, Qingchao, Xin Zhao, Hao Sun, Zhiwei Wang, Zhengsong Qiu, Kai Shan, and Xiaoxia Ren. 2022. "Formation-Damage Mechanism and Gel-Breaker-Free Drill-In Fluid for Carbonate Reservoir" Gels 8, no. 9: 565. https://doi.org/10.3390/gels8090565

APA StyleFang, Q., Zhao, X., Sun, H., Wang, Z., Qiu, Z., Shan, K., & Ren, X. (2022). Formation-Damage Mechanism and Gel-Breaker-Free Drill-In Fluid for Carbonate Reservoir. Gels, 8(9), 565. https://doi.org/10.3390/gels8090565