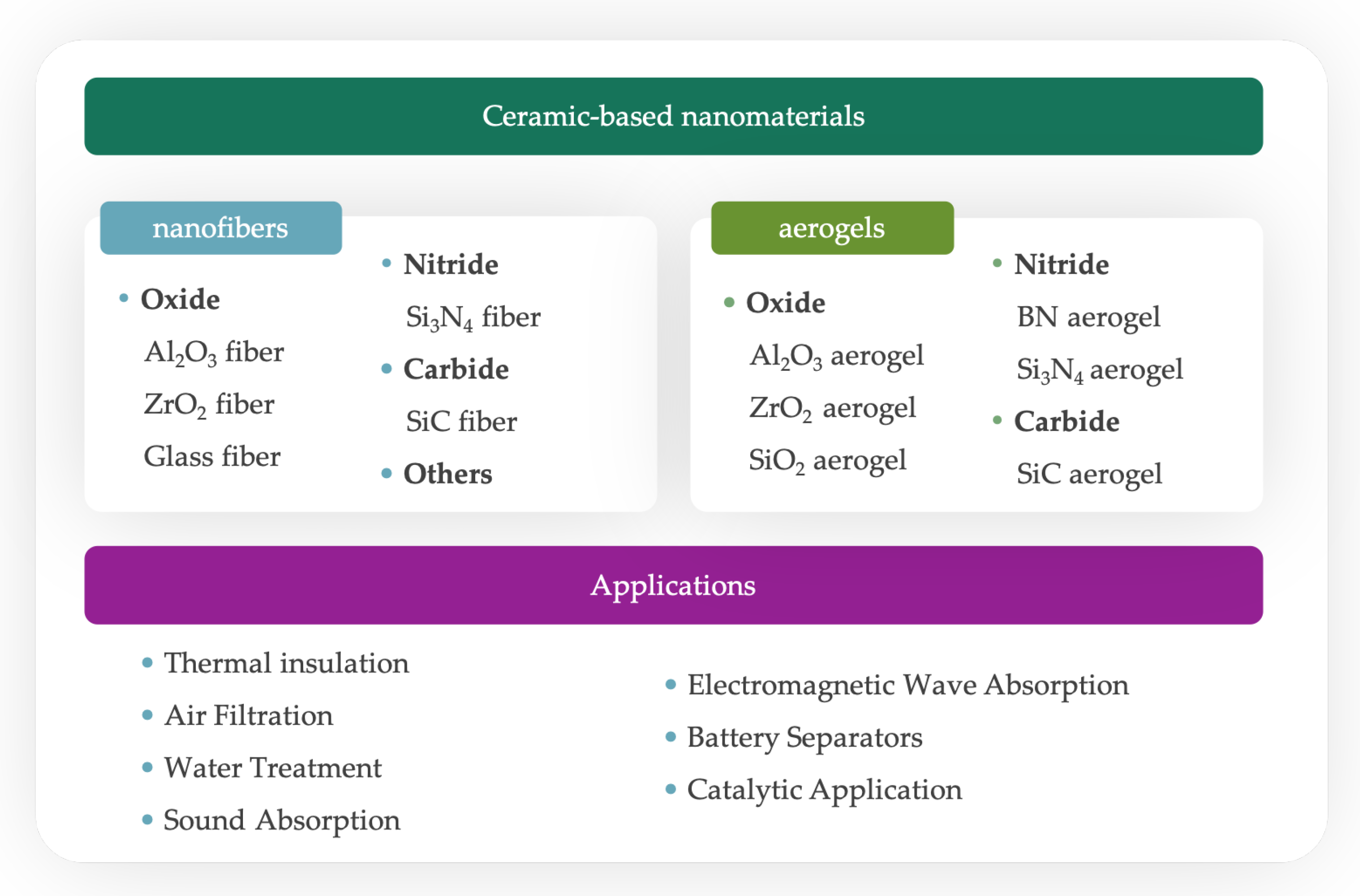

Fabrication and Applications of Ceramic-Based Nanofiber Materials Service in High-Temperature Harsh Conditions—A Review

Abstract

1. Introduction

2. Ceramic Nanofibers

2.1. Oxide Fibers

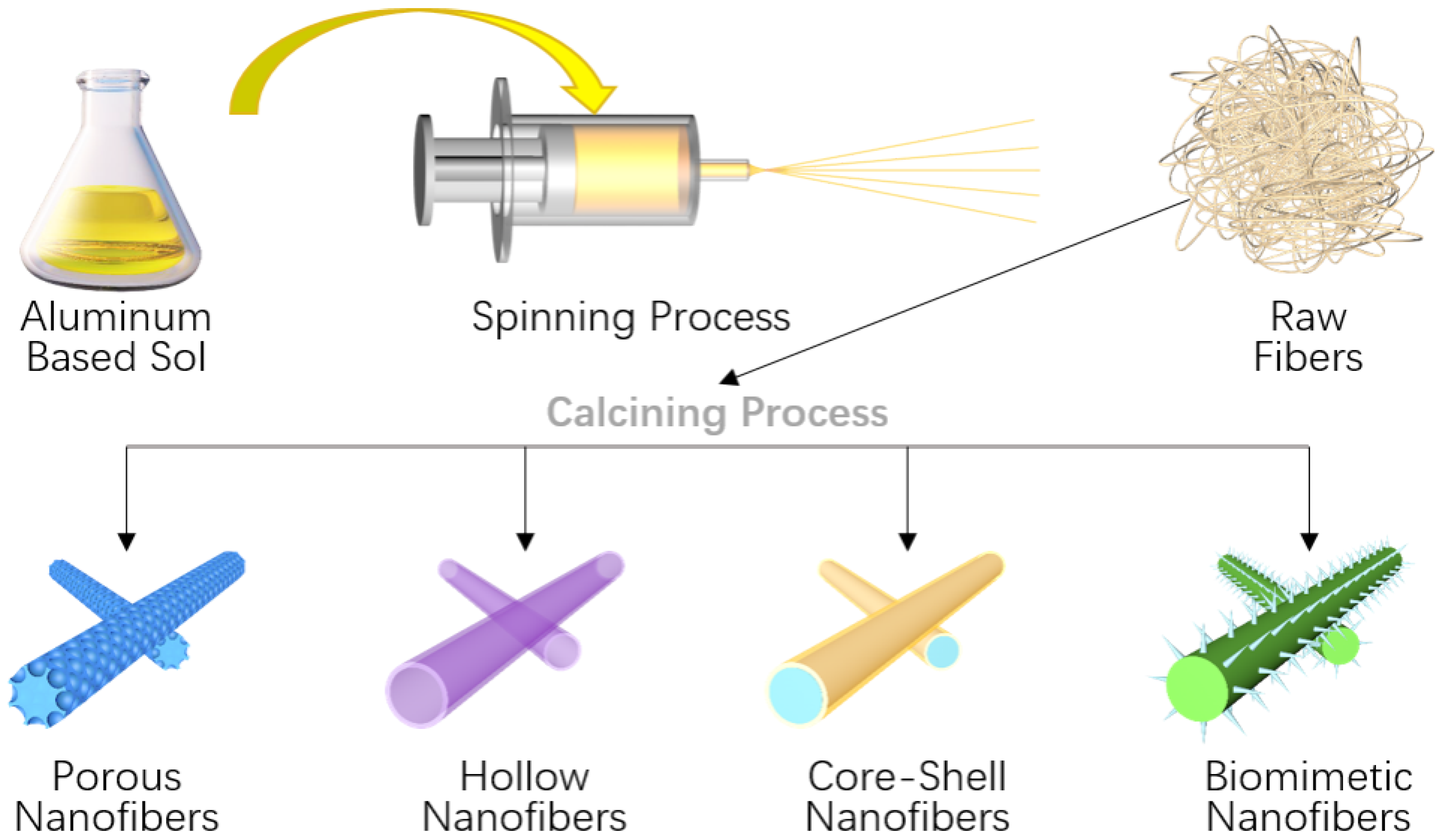

2.1.1. Al2O3 Fiber

2.1.2. ZrO2 Fiber

2.1.3. Glass Fiber

2.2. Nitride Fibers

Si3N4 Fiber

2.3. Carbide Fibers

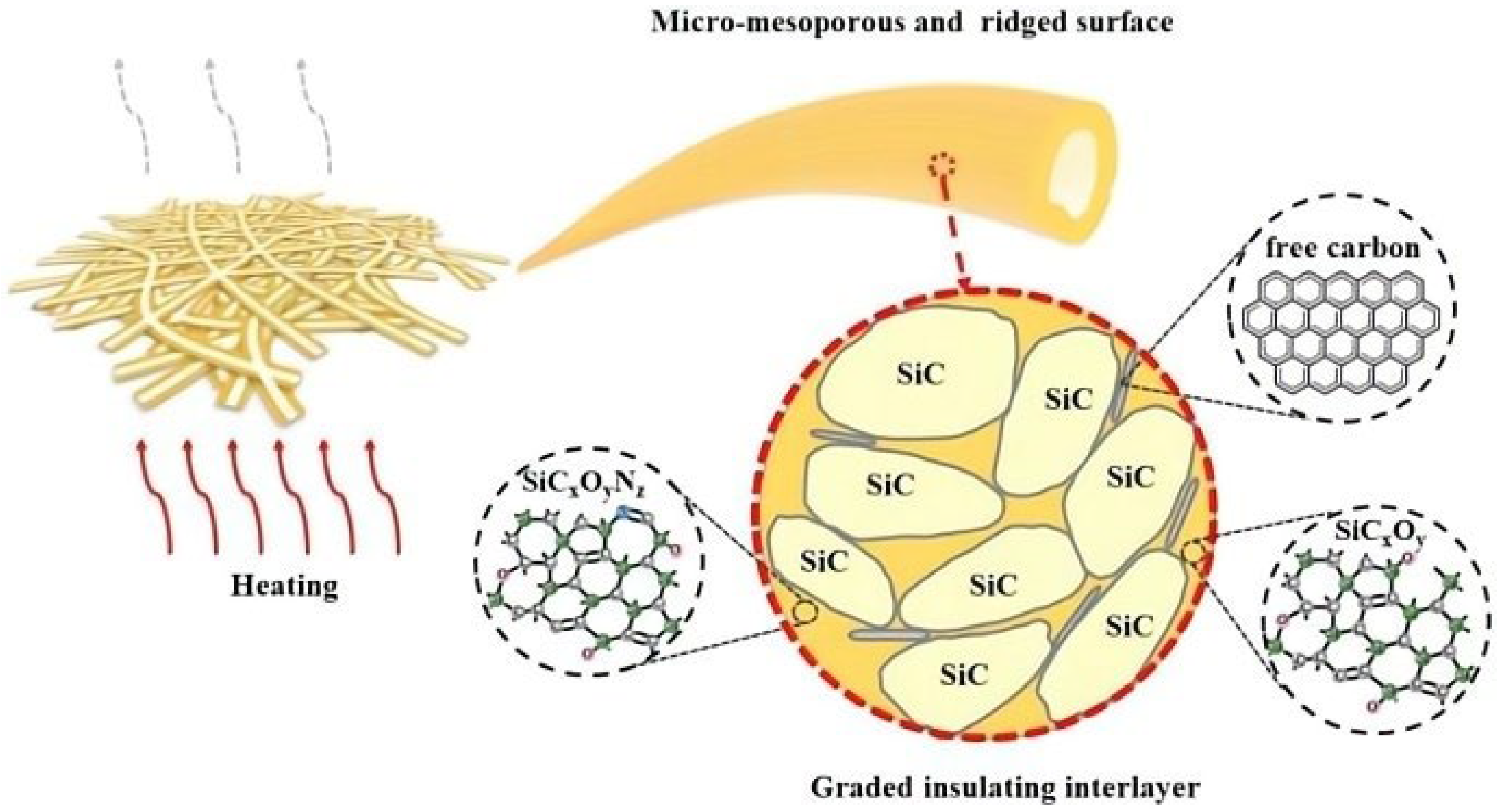

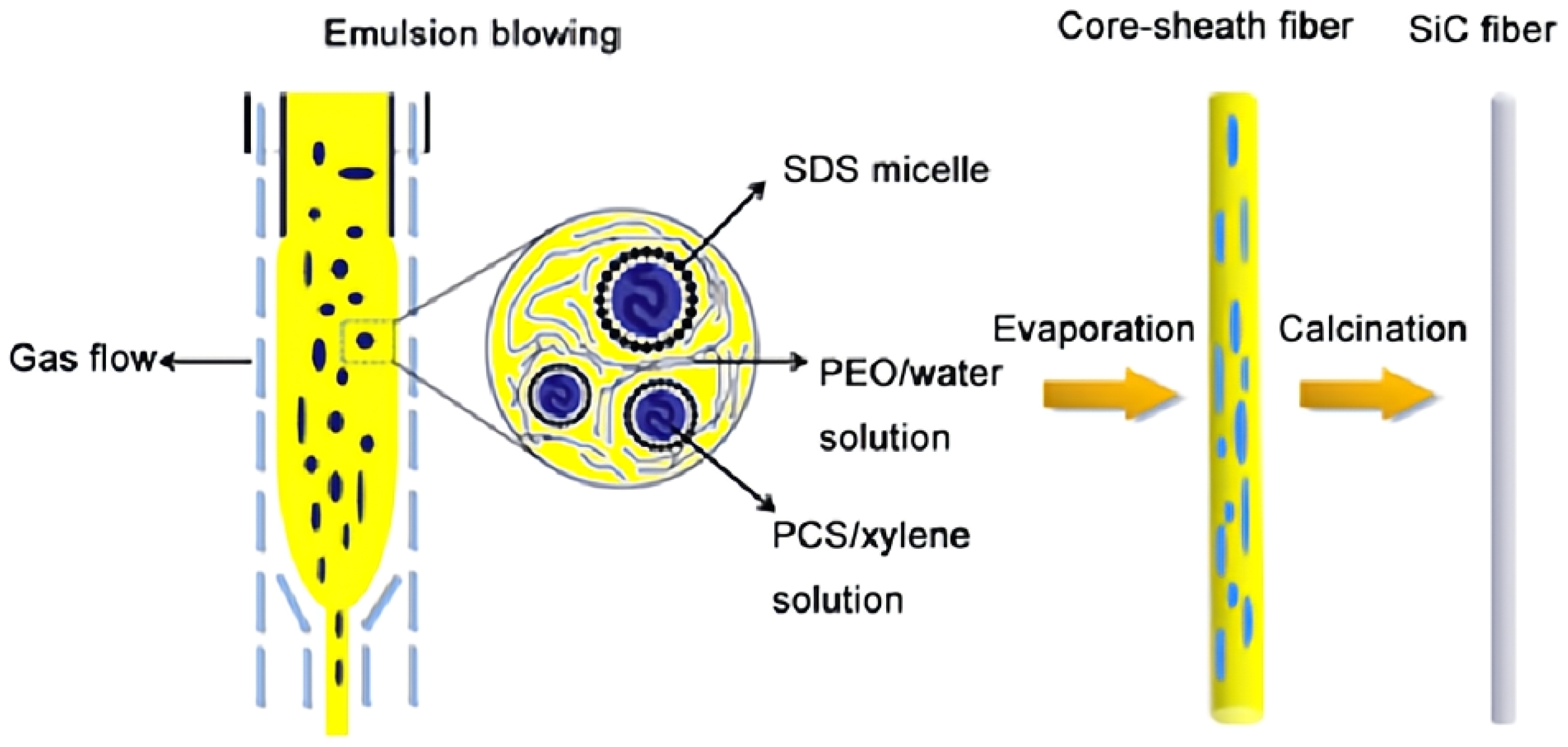

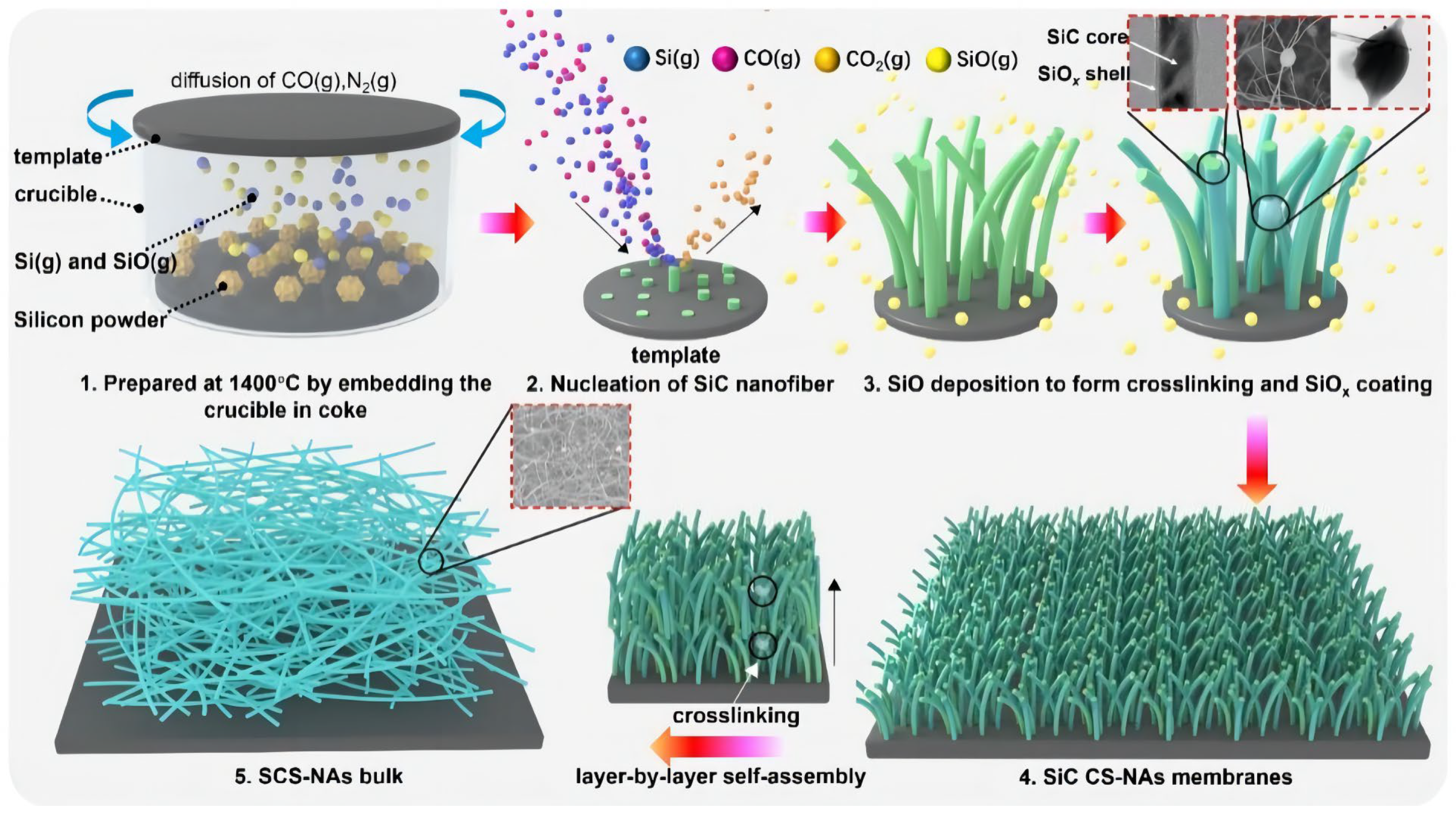

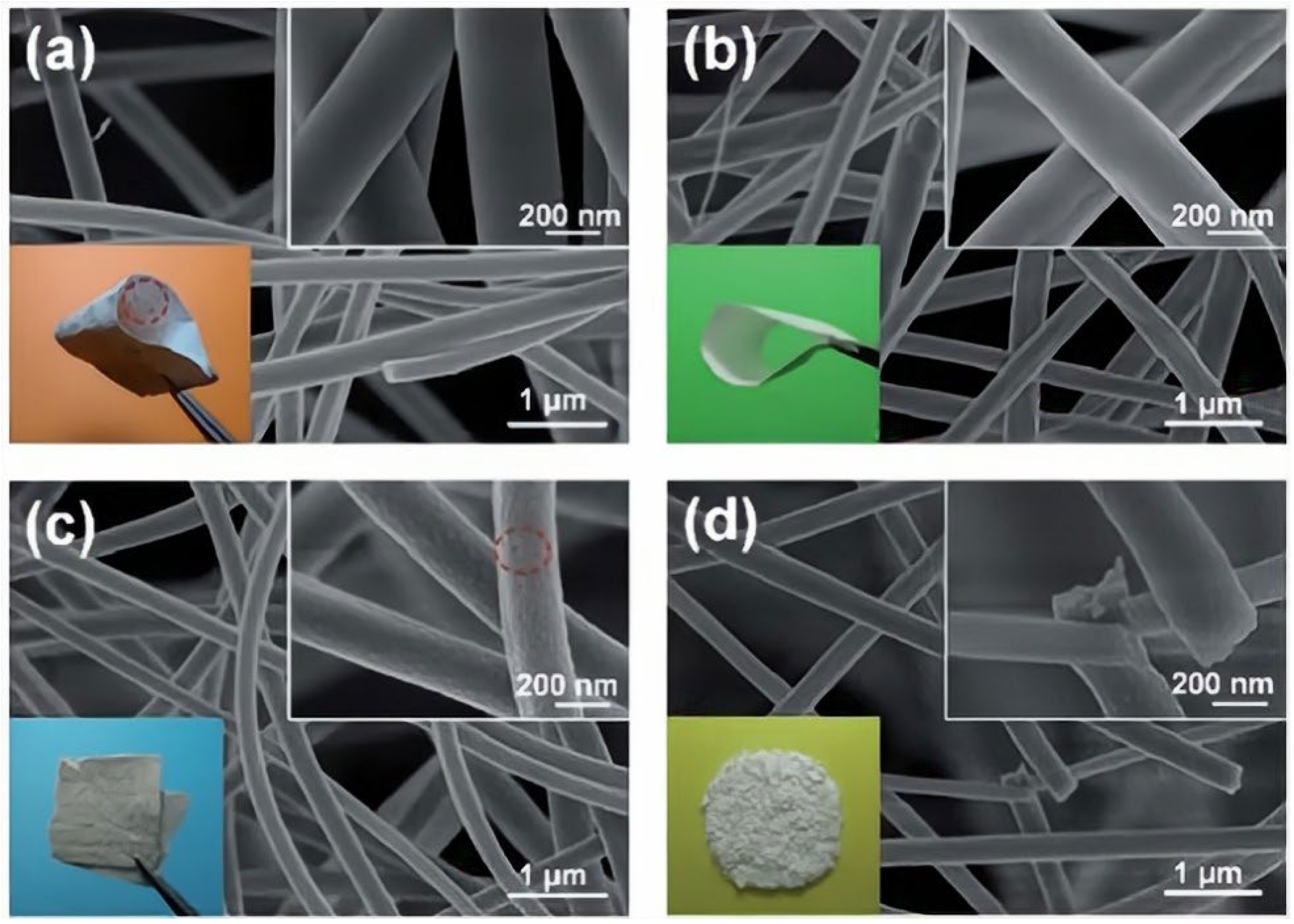

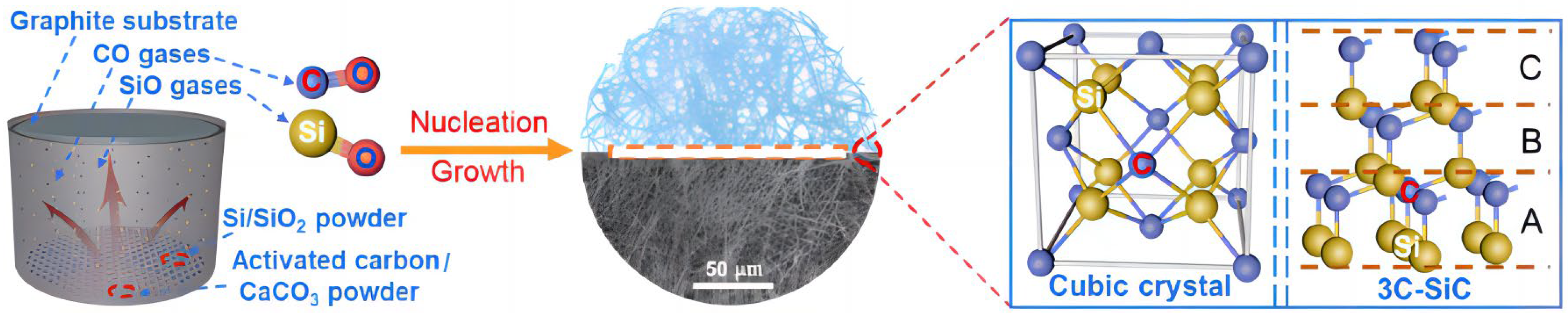

SiC Fiber

2.4. Other Fibers

3. Ceramic Aerogels

3.1. Oxide Aerogels

3.1.1. Al2O3 Aerogel

3.1.2. ZrO2 Aerogel

3.1.3. SiO2 Aerogel

3.2. Nitride Aerogels

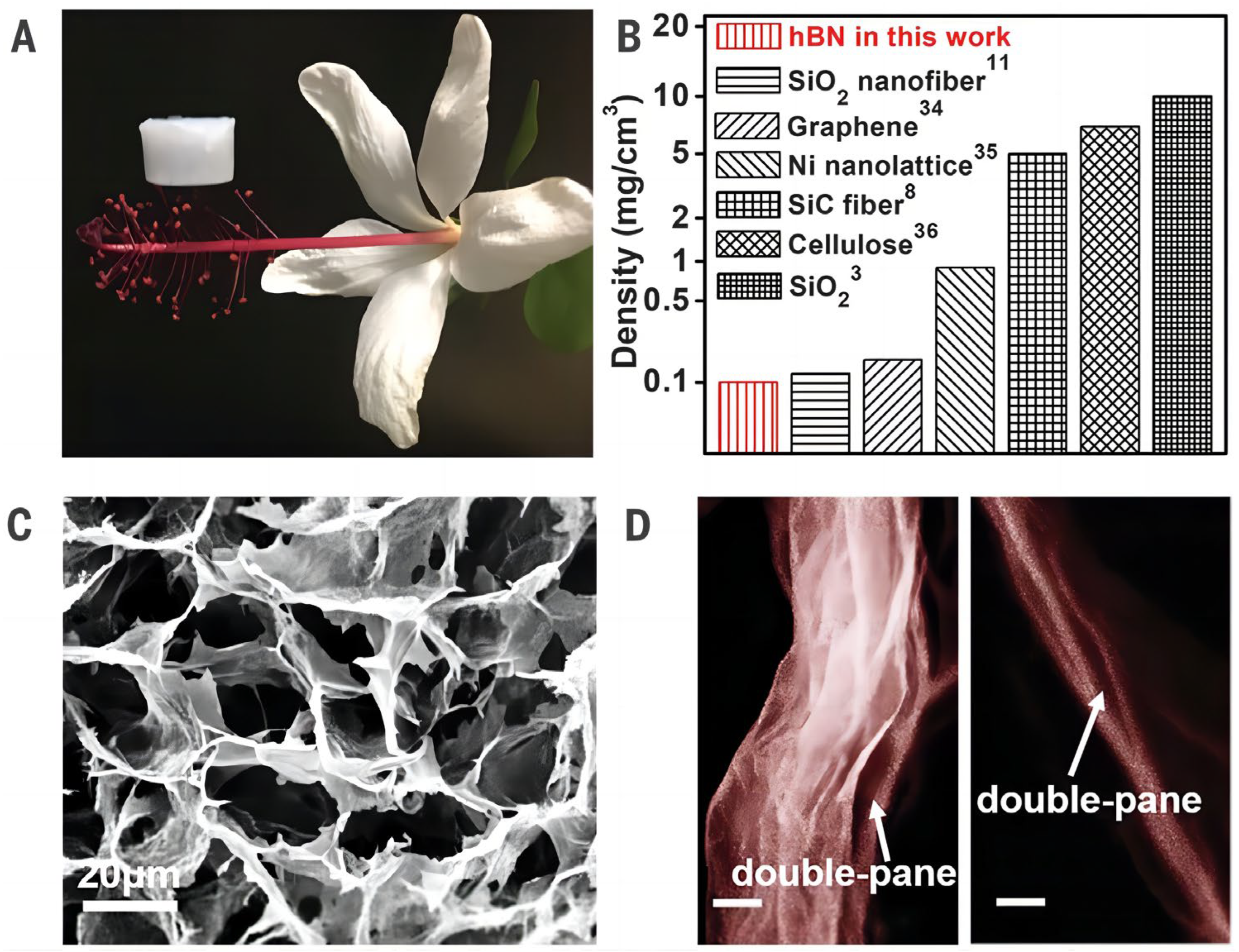

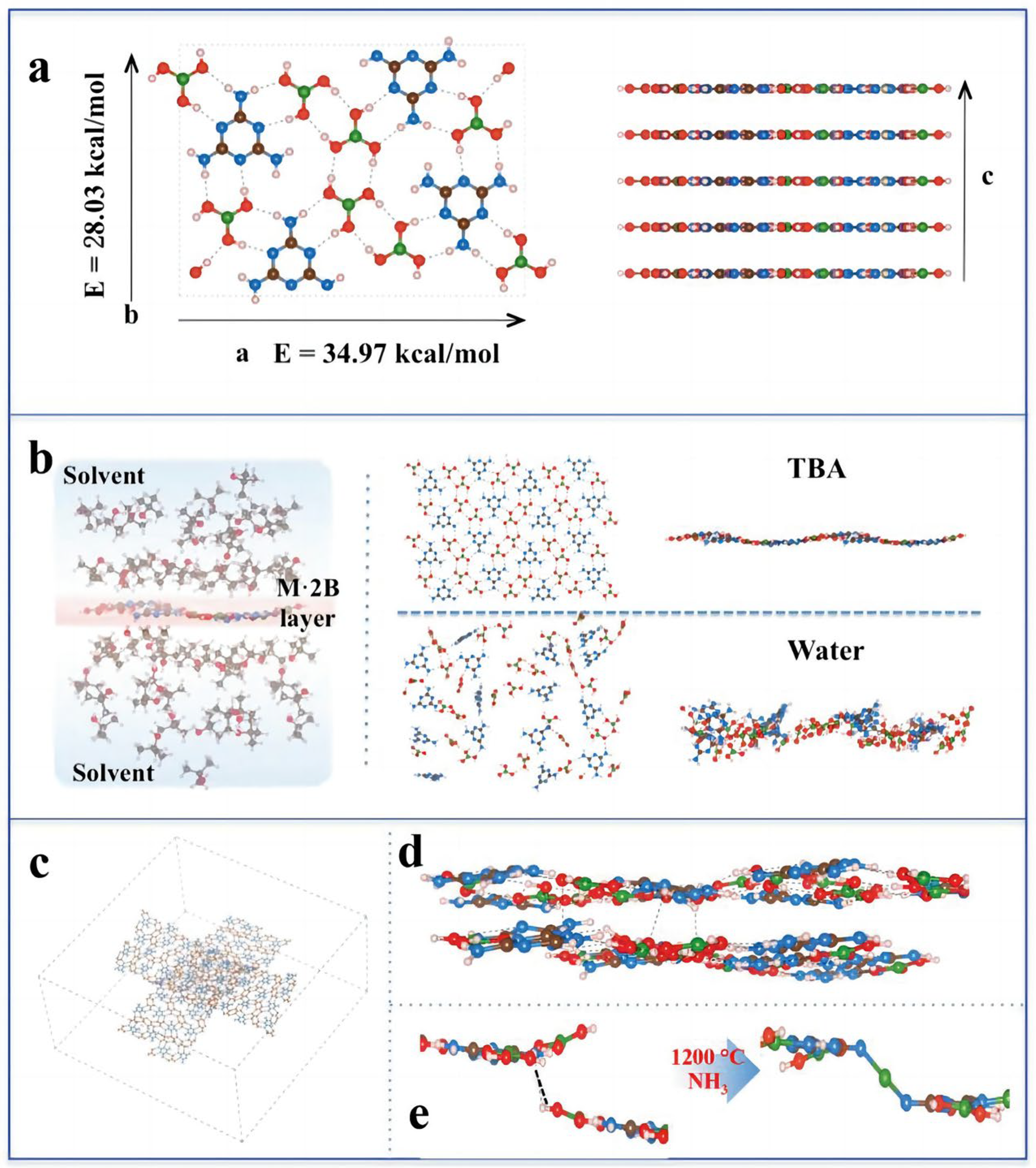

3.2.1. BN Aerogels

3.2.2. Si3N4 Aerogels

3.3. Carbide Aerogels

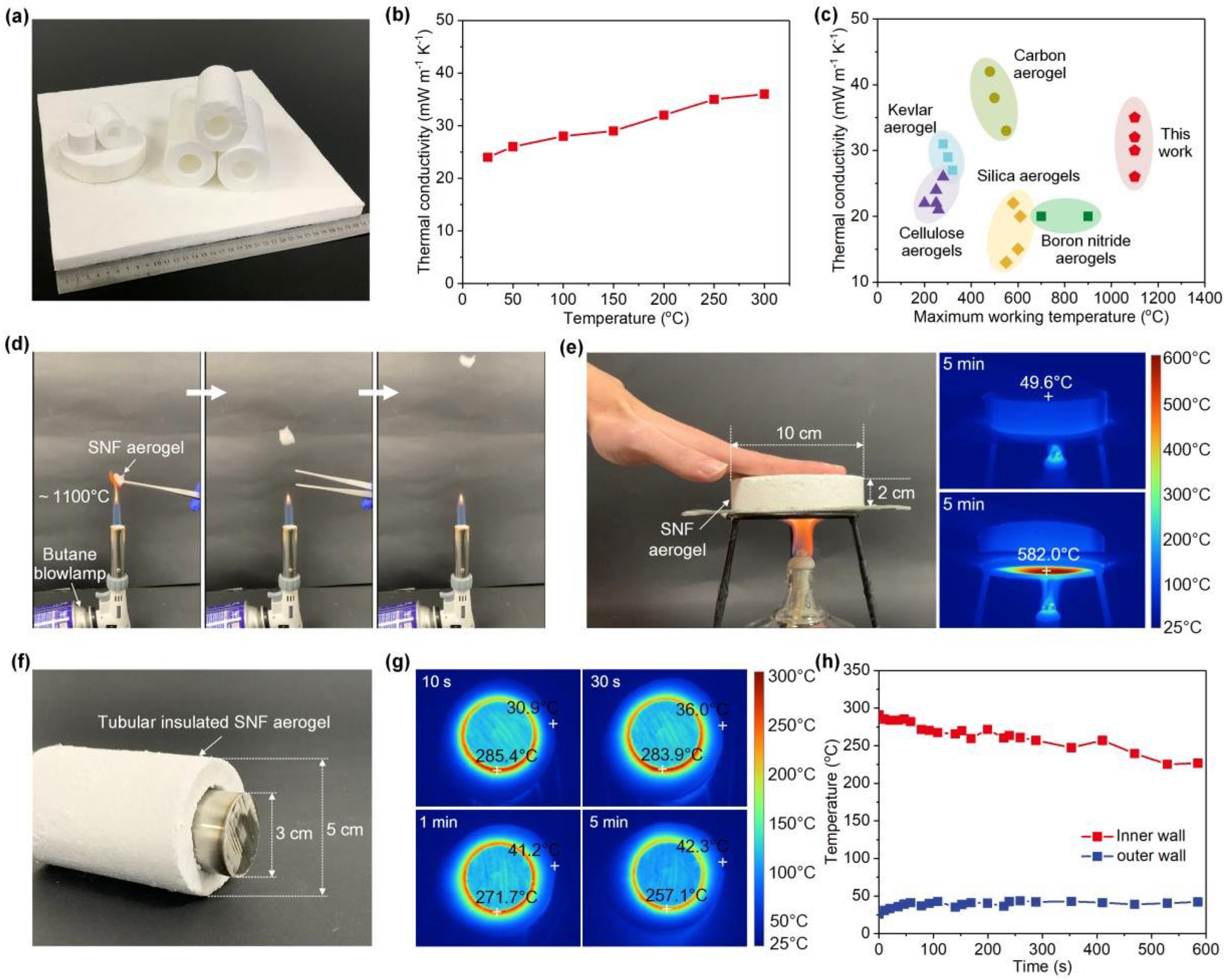

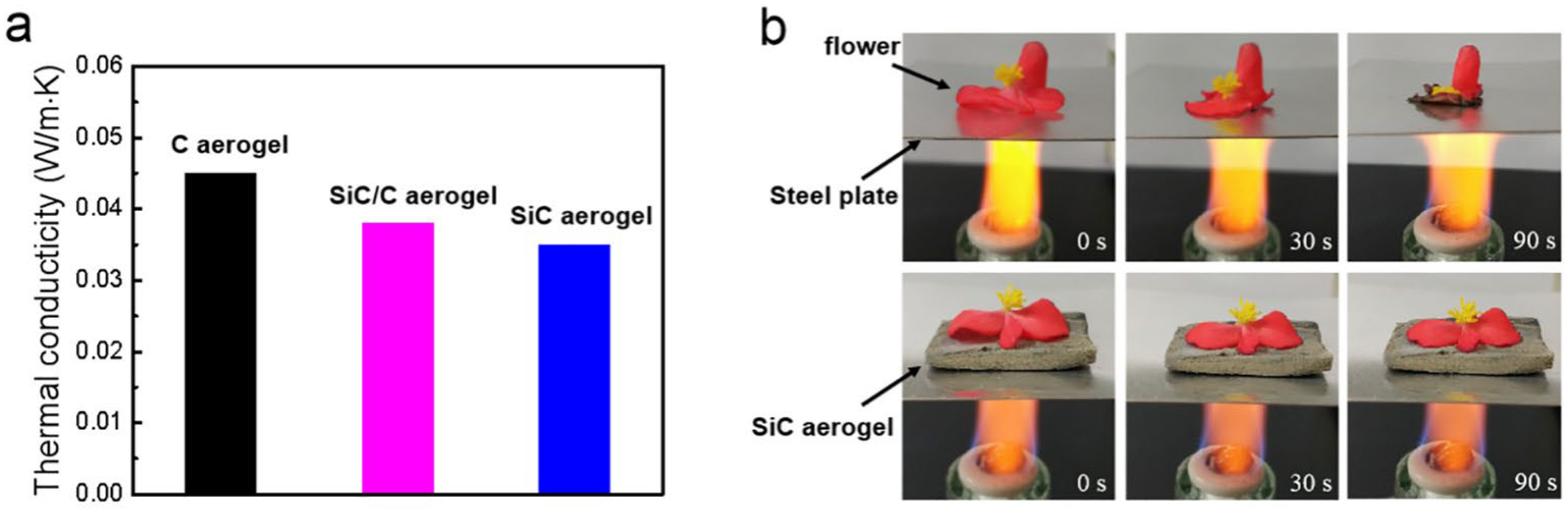

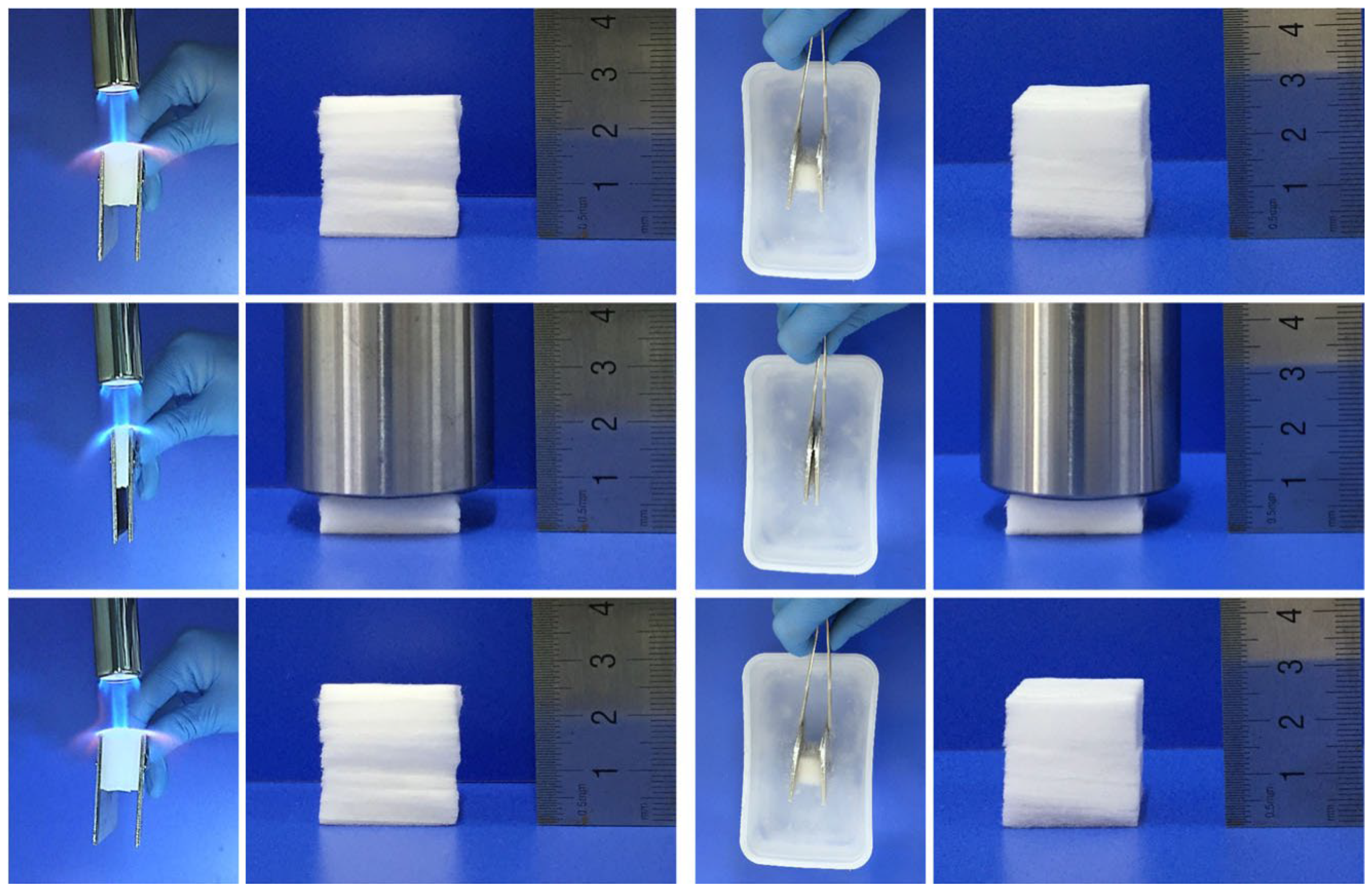

SiC Aerogel

4. Applications

4.1. Thermal Insulation

4.2. Air Filtration

4.3. Water Treatment

4.4. Sound Absorption

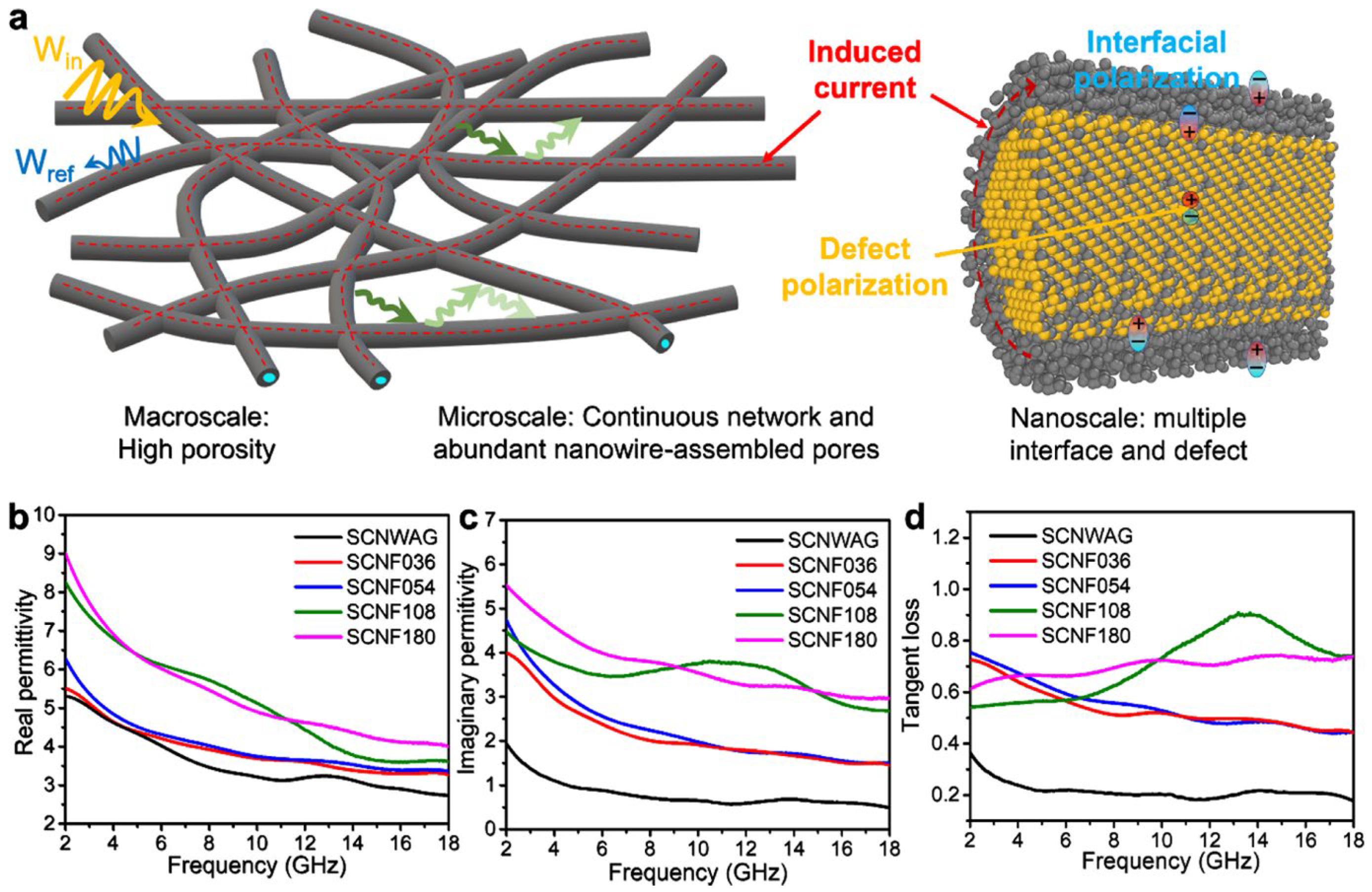

4.5. Electromagnetic Wave Absorption

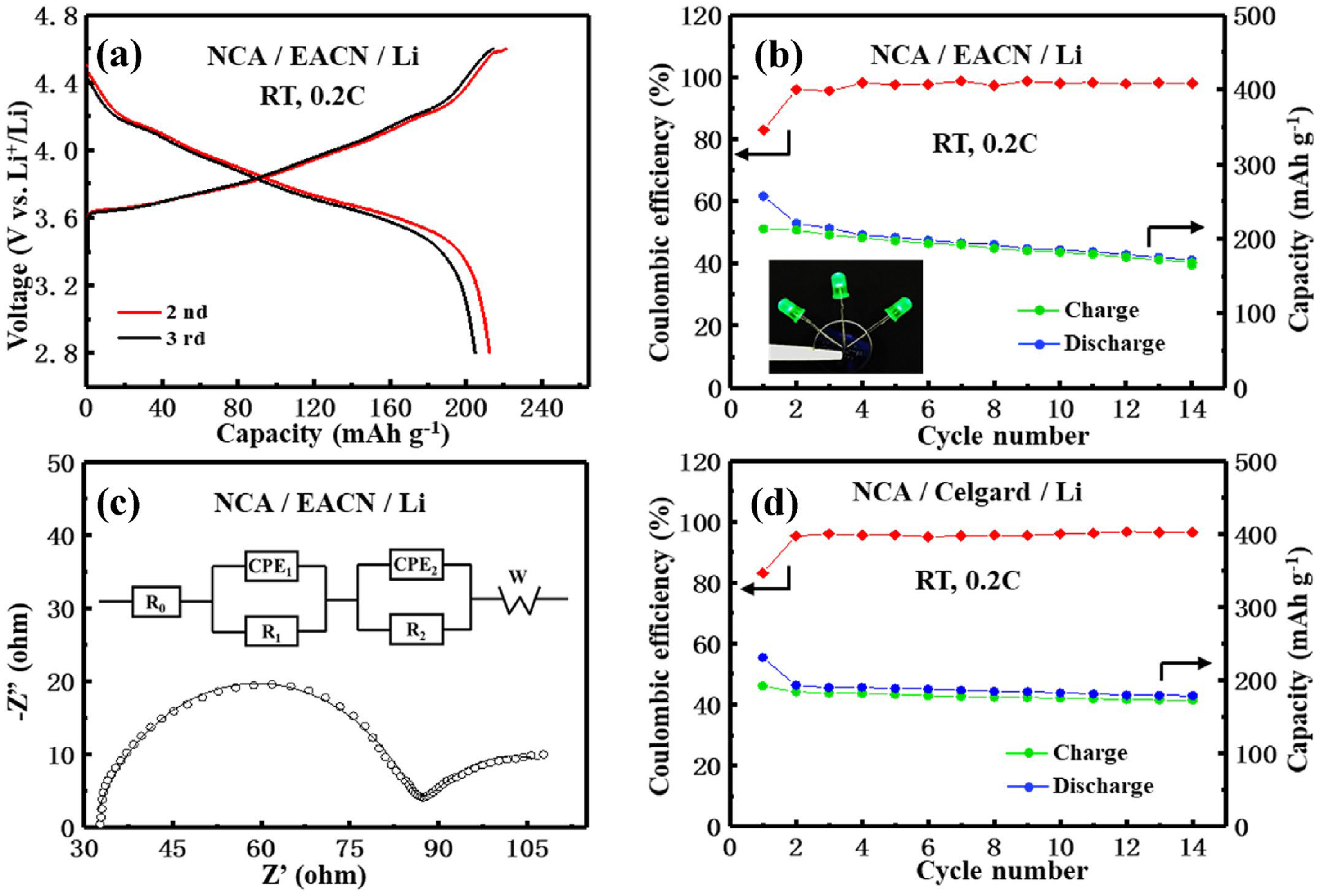

4.6. Battery Separators

4.7. Catalytic Application

5. Summary and Prospects

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Huang, Z. (Translator); Ceramic. In Ceramics (Part II); China Light Industry Press Ltd.: Beijing, China, 1989; pp. 207–214. [Google Scholar]

- Xi, G. Thermophysical Properties of Inorganic Materials; Shanghai Science and Technology Press: Shanghai, China, 1981. [Google Scholar]

- Okada, K.; Kato, H.; Nakajim, K. Preparation of silicon carbide fiber from activated carbon fiber and gaseous silicon monoxide. J. Am. Ceram. Soc. 1994, 77, 1691–1693. [Google Scholar] [CrossRef]

- Zhou, X.; Li, Z. Reflections on the current situation and development strategy of China’s specialty paper industry. China Paper. 2003, 1, 14–16. [Google Scholar]

- Su, W. The present and future of ceramic fibers. Inorg. Salt Ind. 1982, 6, 47. [Google Scholar]

- Jia, C.; Xu, Z.; Luo, D.; Xiang, H.; Zhu, M. Flexible ceramic fibers: Recent development in preparation and application. Adv. Fiber Mater. 2022, 4, 573–603. [Google Scholar] [CrossRef]

- Johnson, D. Nextel-312 ceramic fiber from 3M. J. Coat. Fabr. 1981, 10, 282–296. [Google Scholar] [CrossRef]

- Hildmarm, B.O.; Schneider, H.; Schmücker, M. High temperature behavior of polycrystalline alumino-silicate fibres with mullite bulk composition: II, kinetics of mullite formation. J. Eur. Ceram. Soc. 1996, 16, 287–292. [Google Scholar] [CrossRef]

- Kaya, C.; Butler, E.G.; Lewis, M.H. Microstructurally controlled mullite ceramics produced from monophasic and diphasic sol-derived pastes using extrusion. J. Mater. Sci. 2003, 38, 767–777. [Google Scholar] [CrossRef]

- Clauß, B. Fibers for Ceramic Matrix Composites; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2008. [Google Scholar] [CrossRef]

- Ohira, H.; Shiga, H.; Isamil, M.G.; Nakai, Z.; Akiba, T.; Yasuda, E. Compressive creep of mullite ceramics. J. Mater. Sci. Lett. 1991, 10, 847–849. [Google Scholar] [CrossRef]

- Wilson, D.M.; Visser, L.R. Nextel TM 650 ceramic oxide fiber: New alumilla-based fiber for high temperature composite reinforcement. Ceram. Eng. Sci Proc. 2000, 21, 363–373. [Google Scholar] [CrossRef]

- Poulon-Quintin, A.; Berger, M.H.; Bunsell, A.R. Mechanical and micro-structural characterization of Nextel-650 alumina-zirconia fibres. J. Eur. Ceram. Soc. 2004, 24, 2769–2783. [Google Scholar] [CrossRef]

- Chen, D.; Han, W.; Li, S.; Lu, Z.; Qiu, H.; Shao, C.; Wang, C.; Wang, H.; Zhang, M.; Zhou, X.; et al. Preparation, Structure, Properties and Applications of Continuous Ceramic Fibers: Current Research Status and Development Direction. Mod. Technol. Ceram. 2018, 39, 151–222. [Google Scholar]

- Song, S.; Liu, K. Specialty Ceramics and Refractories; Metallurgical Industry Press: Beijing, China, 2004. [Google Scholar]

- Jia, Y. Preparation and Properties of Alumina Nanostructured Fibers. Ph.D. Thesis, Shandong University, Jinan, China, 2011. [Google Scholar]

- Zhang, P. Electrostatic Spinning Preparation and Performance study of Nanostructured Alumina Fibers. Ph.D. Thesis, Shandong University, Jinan, China, 2012. [Google Scholar]

- Li, W.; Ma, X.; Zhang, X.; Luo, Y.; Luo, Q.; Yang, Y. Preparation of flexible alumina nanofibers and testing of their filtration properties. Yunnan Chem. 2021, 48, 37–39. [Google Scholar]

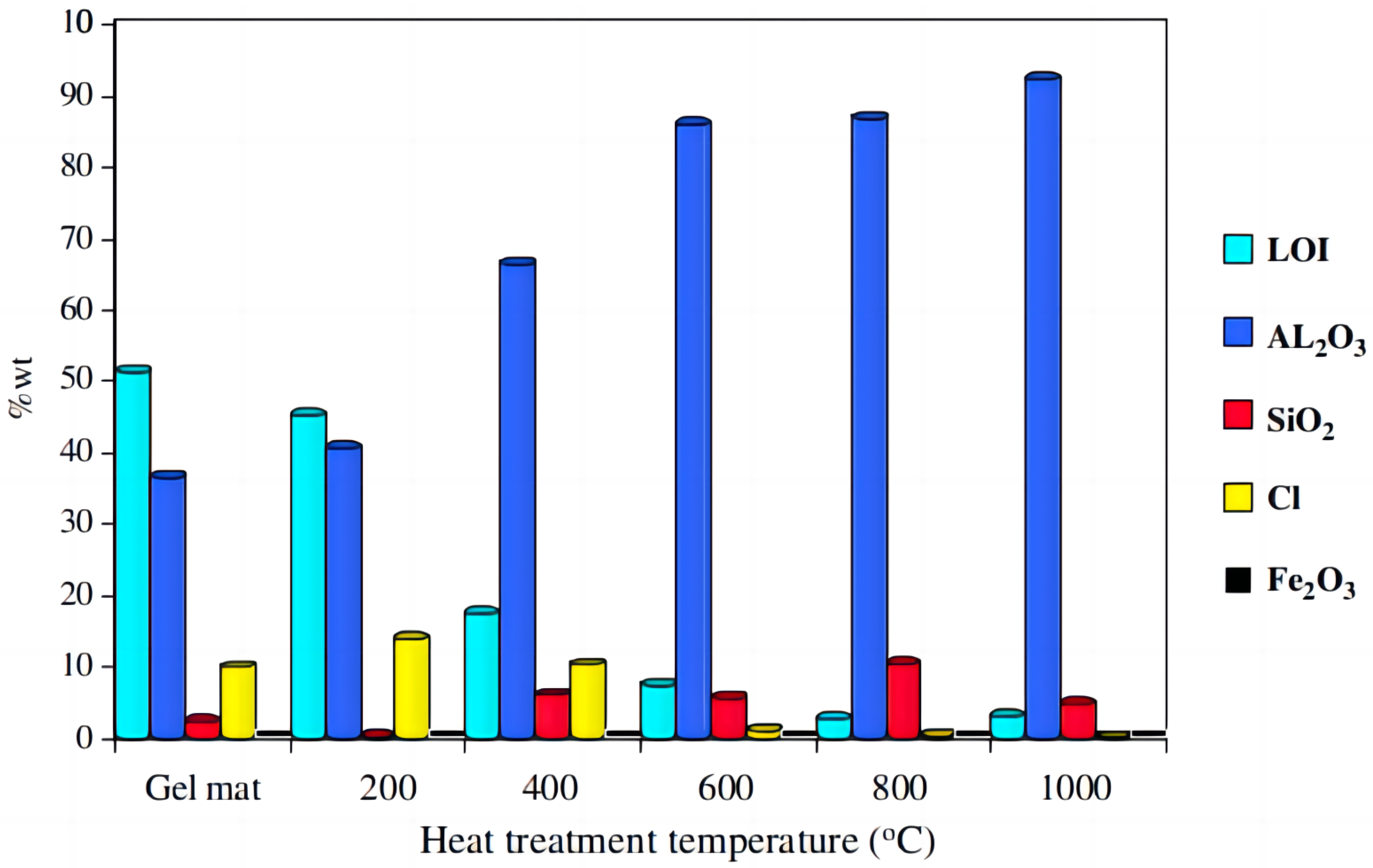

- Wei, S.; Jin, L. Study of heat treatment process in alumina fiber preparation. Ind. Technol. Innov. 2022, 9, 32–37. [Google Scholar]

- Milanović, P.; Vuksanović, M.M.; Mitrić, M.; Stojanović, D.B.; Kojović, A.; Rogan, J.R.; Jančić-Heinemann, R. Electrospun alumina fibers doped with ferric and magnesium oxides. Sci. Sinter. 2018, 50, 77–83. [Google Scholar] [CrossRef]

- Zhou, X.; Ju, J.; Li, Z.; Zhang, M.; Deng, N.; Cheng, B.; Kang, W. Design and fabrication of flexible mesoporous Si-doped Al2O3 ultrafine fibers by electro-blow spinning (EBS) technique. Ceram. Int. 2017, 43, 9729–9737. [Google Scholar] [CrossRef]

- Almeida, R.S.M.; Bergmüller, E.L.; Lührs, H.; Wendschuh, M.; Clauß, B.; Tushtev, K.; Rezwan, K. Thermal exposure effects on the long-term behavior of a mullite fiber at high temperature. J. Am. Ceram. Soc. 2017, 100, 4101–4109. [Google Scholar] [CrossRef]

- Song, K.C.; Woo, K.J.; Kang, Y. Preparation of alumina fibers from aluminum salts by the sol-gel method. Korean J. Chem. Eng. 1999, 16, 75–81. [Google Scholar] [CrossRef]

- Sun, P.; Chen, X.; Gu, L.; Gu, L. Study on the microstructure of continuous Al2O3-SiO2 fiber precursor sol. Synth. Technol. Appl. 2006, 3, 18–21. [Google Scholar]

- Chen, X.; Gu, L. Structural evolution of sol-gel derived mullite fibers with different solid contents during sintering. J. Mater. Process Technol. 2009, 209, 3991–3998. [Google Scholar] [CrossRef]

- Tan, H.; Guo, C. Preparation of long alumina fibers by sol-gel method using malic acid. T Nonferrous Metals Soc 2011, 21, 1563–1567. [Google Scholar] [CrossRef]

- Mahapatra, A.; Mishra, B.G.; Hota, G. Synthesis of ultra-fine α-Al2O3 fibers via electrospinning method. Ceram. Int. 2011, 37, 2329–2333. [Google Scholar] [CrossRef]

- Wang, Y.; Li, W.; Xia, Y.; Jiao, X.; Chen, D. Electrospun flexible self-standing γ-alumina fibrous membranes and their potential as high-efficiency fine particulate filtration media. J. Mater. Chem. A 2014, 2, 15124–15131. [Google Scholar] [CrossRef]

- Li, L.; Liu, X.; Wang, G.; Liu, Y.; Kang, W.; Deng, N.; Zhuang, X.; Zhou, X. Research progress of ultrafine alumina fiber prepared by sol-gel method: A review. Chem. Eng. J. 2021, 421, 127744. [Google Scholar] [CrossRef]

- Wang, Y.; Li, W.; Jiao, X.; Chen, D. Electrospinning preparation and adsorption properties of mesoporous alumina fibers. J. Mater. Chem. A 2013, 1, 10720–10726. [Google Scholar] [CrossRef]

- Li, L.; Kang, W.; Zhao, Y.; Li, Y.; Shi, J.; Cheng, B. Preparation of flexible ultra-fine Al2O3 fiber mats via the solution blowing method. Ceram. Int. 2015, 41, 409–415. [Google Scholar] [CrossRef]

- Sedaghat, A.; Taheri-Nassaj, E.; Naghizadeh, R. An alumina mat with a nano microstructure prepared by centrifugal spinning method. J. Non-Cryst. Solids 2006, 352, 2818–2828. [Google Scholar] [CrossRef]

- Akia, M.; Capitanachi, D.; Martinez, M.; Hernandez, C.; de Santiago, H.; Mao, Y.; Lozano, K. Development and optimization of alumina fine fibers utilizing a centrifugal spinning process. Microporous Mesoporous Mater. 2018, 262, 175–181. [Google Scholar] [CrossRef]

- Chen, X.; Gu, L. Spinnablity and structure characterization of mullite fibers via sol-gel-ceramic route. J. Non-Cryst. Solids 2009, 355, 2415–2421. [Google Scholar] [CrossRef]

- Zadeh, M.M.A.; Keyanpour-Rad, M.; Ebadzadeh, T. Synthesis of mullite nanofibres by electrospinning of solutions containing different proportions of polyvinyl butyral. Ceram. Int. 2013, 39, 9079–9084. [Google Scholar] [CrossRef]

- Song, X.; Ma, Y.; Wang, J.; Liu, B.; Yao, S.; Cai, Q.; Liu, W. Homogeneous and flexible mullite nanofibers fabricated by electrospinning through diphasic mullite sol-gel route. J. Mater. Sci. 2018, 53, 14871–14883. [Google Scholar] [CrossRef]

- Da Costa Farias, R.M.; Menezes, R.R.; Oliveira, J.E.; de Medeiros, E.S. Production of submicrometric fibers of mullite by solution blow spinning (SBS). Mater. Lett. 2015, 149, 47–49. [Google Scholar] [CrossRef]

- Fu, C.; Li, S.; Bai, J.; Liu, J. Research on preparation technology of alumina/zirconia precursor fiber spinning liquid. Mater. Rep. 2015, 29, 68–72. [Google Scholar]

- Zhong, L.; Cao, L.; Huang, J.; Liu, Y.; OuYang, H.; Wang, Q. Research progress of oxide fiber reinforced oxide ceramic matrix composites. J. Shaanxi Univ. Sci. Technol. 2022, 40, 121–133. [Google Scholar]

- Han, D.; Zhen, S.; Sun, X.; Zhang, S.; Fang, K.; Ai, B.; Tao, L.; Wang, C.; Sun, H. Study on heat transfer performance of zirconia fiber high-temperature thermal insulation materials. Ceramic 2022, 7, 9–12. [Google Scholar]

- Li, X. Preparation and Performance Study of Continuous Alumina Fiber Reinforced Zirconia Ceramic Matrix Composites. Master’s Thesis, Shanghai Jiao Tong University, Shanghai, China, 2020. [Google Scholar]

- Wang, J. Research on Preparation Process of Alumina Fiber Reinforced Zirconia/Alumina Composites. Master’s Thesis, Shandong University, Jinan, China, 2007. [Google Scholar]

- Lang, Y. Preparation and Performance Study of Fiber-Reinforced Porous YSZ Ceramic Materials. Ph.D. Thesis, Tsinghua University, Beijing, China, 2014. [Google Scholar]

- Wang, H.; Zhang, X.; Wang, N.; Li, Y.; Feng, X.; Huang, Y.; Zhao, C.; Liu, Z.; Fang, M.; Ou, G.; et al. Ultralight, scalable, and high-temperature-resilient ceramic nanofiber sponges. Sci. Adv. 2017, 3, e1603170. [Google Scholar] [CrossRef]

- Sun, G.; Du, X.; Zhang, M.; Zhou, C.; Chen, J.; Liu, F. Fabrication of zirconia fibers by a sol-gel combined rotational centrifugal spinning technique. Trans. Indian Ceram. Soc. 2014, 73, 228–232. [Google Scholar] [CrossRef]

- Liu, H.Y.; Chen, Y.; Liu, G.S.; Pei, S.G.; Liu, J.Q.; Ji, H.; Wang, R.D. Preparation of high-quality zirconia fibers by super-high rotational centrifugal spinning of inorganic sol. Mater. Manuf. Process. 2013, 28, 133–138. [Google Scholar] [CrossRef]

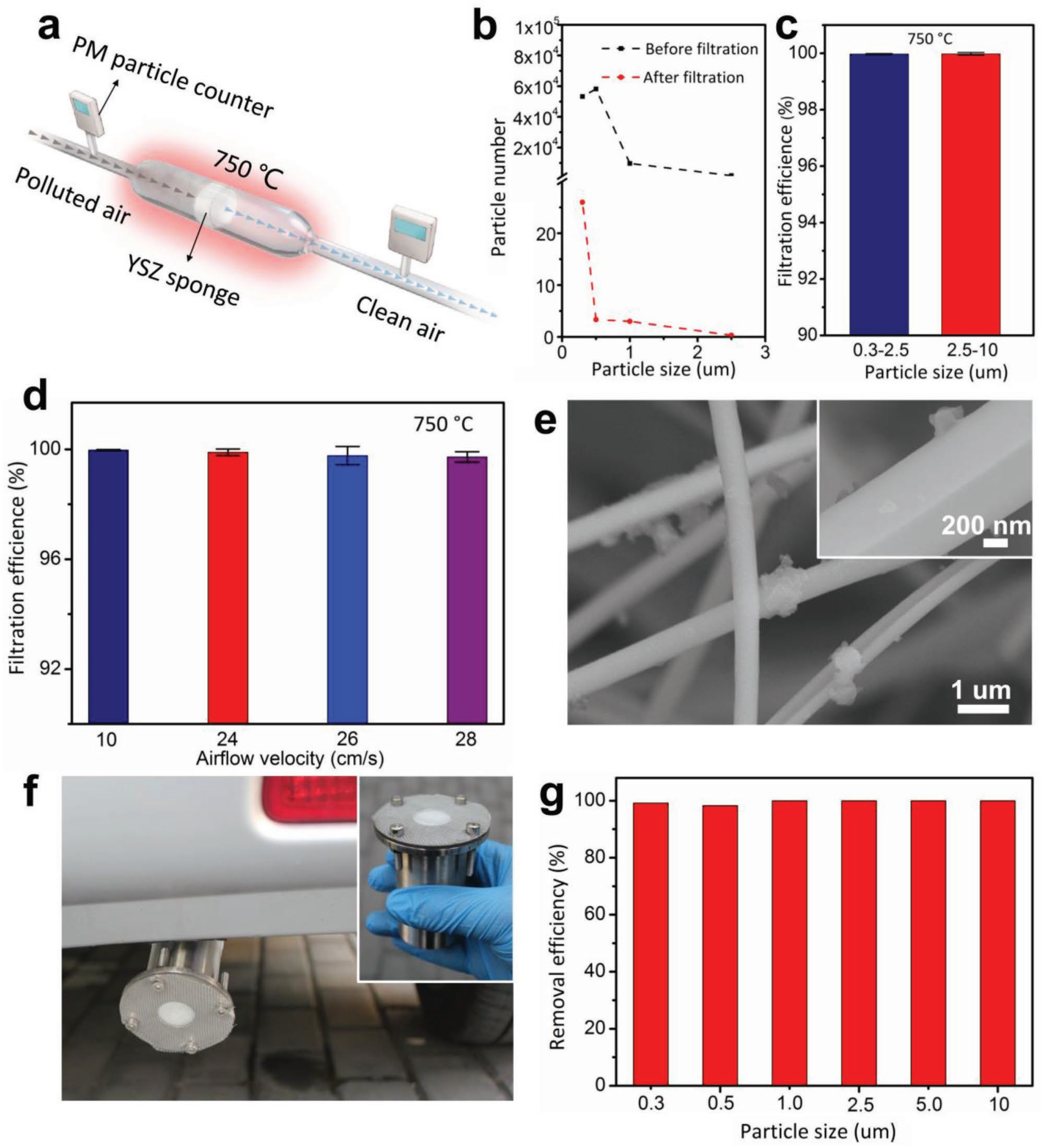

- Wang, H.; Lin, S.; Yang, S.; Yang, X.; Song, J.; Wang, D.; Wang, H.; Liu, Z.; Li, B.; Fang, M.; et al. High-temperature particulate matter filtration with resilient yttria-stabilized ZrO2 nanofiber sponge. Small 2018, 14, 1800258. [Google Scholar] [CrossRef]

- Ma, J.; Jia, X.; Tang, J.; Zhang, X.; Dai, S.; Yang, X. Comparison of pyrolysis and combustion characteristics of carbon fiber, glass fiber/epoxy resin. J. Compos. Mater. 2022, 1–10. [Google Scholar] [CrossRef]

- Sujatha, E.R.; Atchaya, P.; Darshan, S.; Subhashini, S. Mechanical properties of glass fibre reinforced soil and its application as subgrade reinforcement. Road Mater. Pavement Des. 2021, 22, 2384–2395. [Google Scholar] [CrossRef]

- Wang, B.; Hou, Y.; Chen, W.; Wu, Q.; Hu, J.; Shan, Z.; Zhao, H.; Cheng, S.; Wang, Z.; Cao, G. Preparation of glass fiber from blast furnace slag and its properties. Sci. Technol. Innov. 2022, 4, 35–38. [Google Scholar]

- Ma, Q. Research on chemical attack resistance of glass fiber recycled concrete. Guangdong Build. Mater. 2022, 38, 11–14. [Google Scholar]

- Zhang, X.; Huo, W.; Chen, Y.; Hu, Z.; Wang, Y.; Gan, K.; Yang, J. Novel micro-spherical Si3N4 nanowire sponges from carbon-doped silica sol foams via reverse templating method. J. Am. Ceram. Soc. 2019, 102, 962–969. [Google Scholar] [CrossRef]

- Huo, W.; Zhang, X.; Xu, J.; Hu, Z.; Yan, S.; Gan, K.; Yang, J. In situ synthesis of three-dimensional nanofiber-knitted ceramic foams via reactive sintering silicon foams. J. Am. Ceram. Soc. 2019, 102, 2245–2250. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, Y.; Choi, W.C.; Chae, S.; Lee, J.; Kim, B.S.; Park, M.; Kim, H.Y. Highly flexible, erosion resistant and nitrogen doped hollow SiC fibrous mats for high temperature thermal insulators. J. Mater. Chem. A 2017, 5, 2664–2672. [Google Scholar] [CrossRef]

- Li, Y.; Yan, G.; Zhao, Y.; Kang, W.; Li, L.; Zhuang, X.; Chen, B.; Li, X. Emulsion-Blow Spun Self-Sustained Crystalline β-Silicon Carbide (SiC) Fiber Mat and Its Conductivity Property. Trans. Indian Ceram. Soc. 2017, 76, 159–164. [Google Scholar] [CrossRef]

- Zhang, M.; Wang, Y.; Zhang, Y.; Song, J.; Si, Y.; Yan, J.; Ma, C.; Liu, Y.; Yu, J.; Ding, B. Conductive and elastic TiO2 nanofibrous aerogels: A new concept toward self-supported electrocatalysts with superior activity and durability. Angew. Chem. Int. Ed. 2020, 59, 23252–23260. [Google Scholar] [CrossRef]

- Santos, A.M.C.; Mota, M.F.; Leite, R.S.; Neves, G.A.; Medeiros, E.S.; Menezes, R.R. Solution blow spun titania nanofibers from solutions of high inorganic/organic precursor ratio. Ceram. Int. 2018, 44, 1681–1689. [Google Scholar] [CrossRef]

- Costa, D.L.; Leite, R.S.; Neves, G.A.; Lima Santana, L.N.; Medeiros, E.S.; Menezes, R.R. Synthesis of TiO2 and ZnO nano and submicrometric fibers by solution blow spinning. Mater. Lett. 2016, 183, 109–113. [Google Scholar] [CrossRef]

- Li, F.; Kang, Z.; Huang, X.; Zhang, G. Fabrication of zirconium carbide nanofibers by electrospinning. Ceram. Int. 2014, 40, 10137–10141. [Google Scholar] [CrossRef]

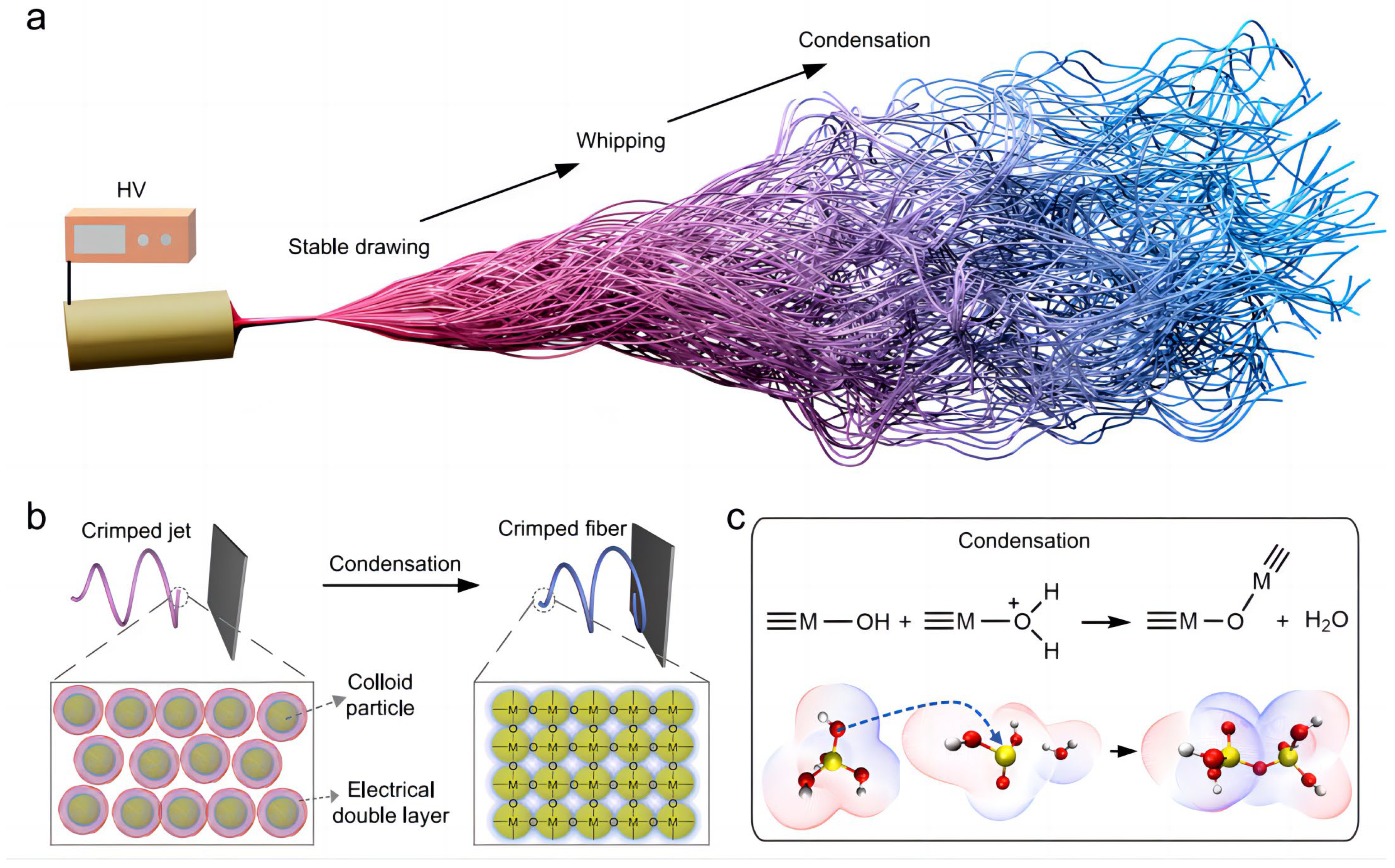

- Cheng, X.; Liu, Y.T.; Si, Y.; Yu, J.; Ding, B. Direct synthesis of highly stretchable ceramic nanofibrous aerogels via 3D reaction electrospinning. Nat. Commun. 2022, 13, 2637. [Google Scholar] [CrossRef]

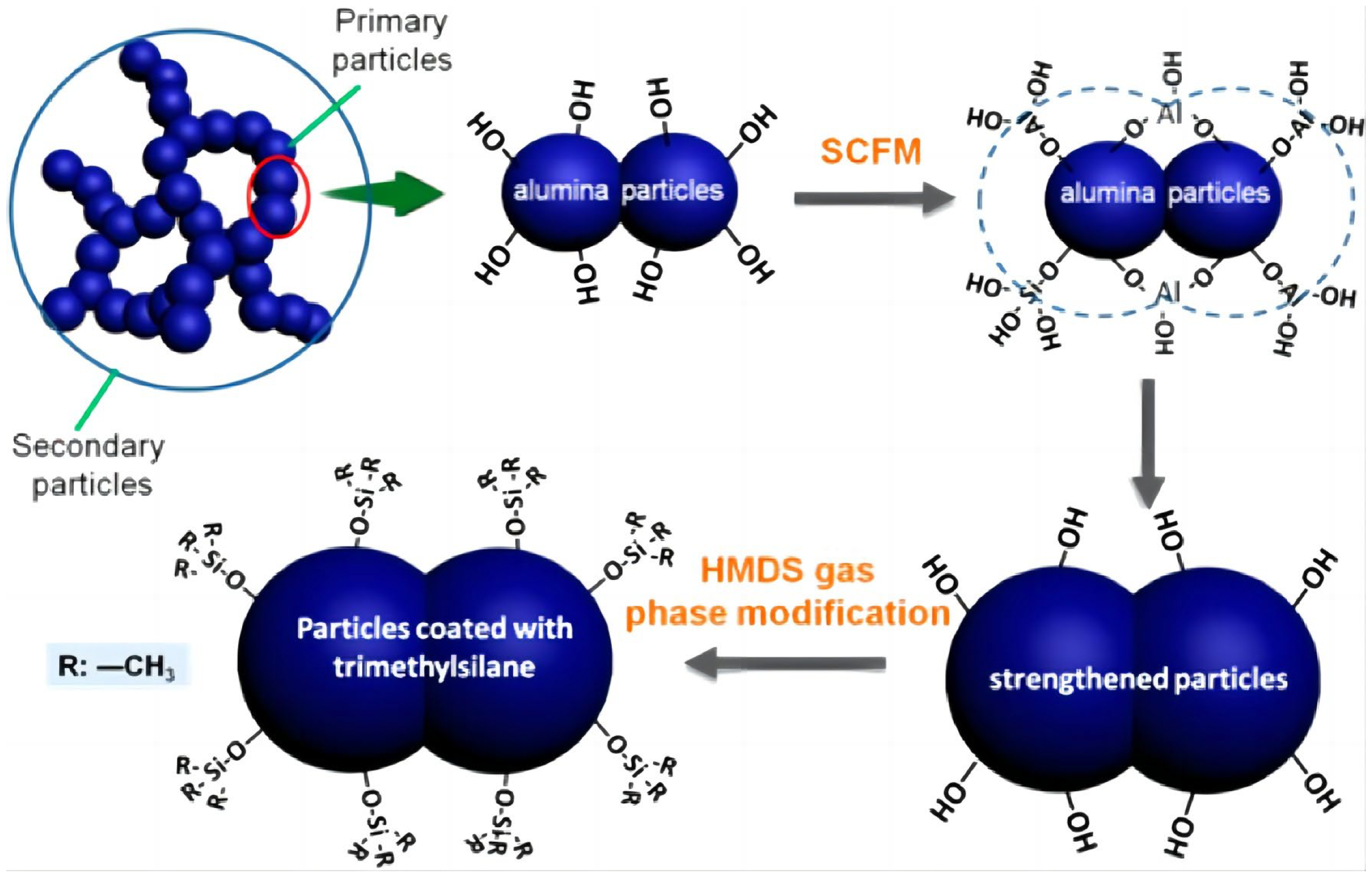

- Zu, G.; Shen, J.; Zou, L.; Wang, W.; Lian, Y.; Zhang, Z.; Du, A. Nanoengineering Super Heat-Resistant, Strong Alumina Aerogels. Chem. Mater. 2013, 25, 4757–4764. [Google Scholar] [CrossRef]

- Sun, J.; Hu, Z.; Wu, W.; Zhou, J.; Li, J. Preparation and performance of alumina aerogel composite high temperature heat insulation tile. Aerosp. Mater. Technol. 2017, 47, 33–36+41. [Google Scholar]

- Liu, X.; Su, L.; Miao, L.; Zhou, J.; Yang, B.; Wu, B.; Xia, R.; Cao, M.; Qian, J. Preparation and performance study of high temperature resistant Al2O3-SiO2 nano aerogel. Acta Ceram. Sin. 2021, 42, 620–625. [Google Scholar]

- Zhou, J.; Chen, X.; Song, H.; Hu, Z.; Sun, C.; Yao, X. Effect of yttrium oxide doping on the structure and properties of Al2O3 bulk aerogels. Ceram. Bull. 2010, 29, 1002–1006. [Google Scholar]

- Corrias, A.; Casula, M.F.; Falqui, A.; Paschina, G. Preparation and Characterization of FeCo-Al2O3 and Al2O3 Aerogels. J. Sol-Gel Sci. Technol. 2004, 31, 83–86. [Google Scholar] [CrossRef]

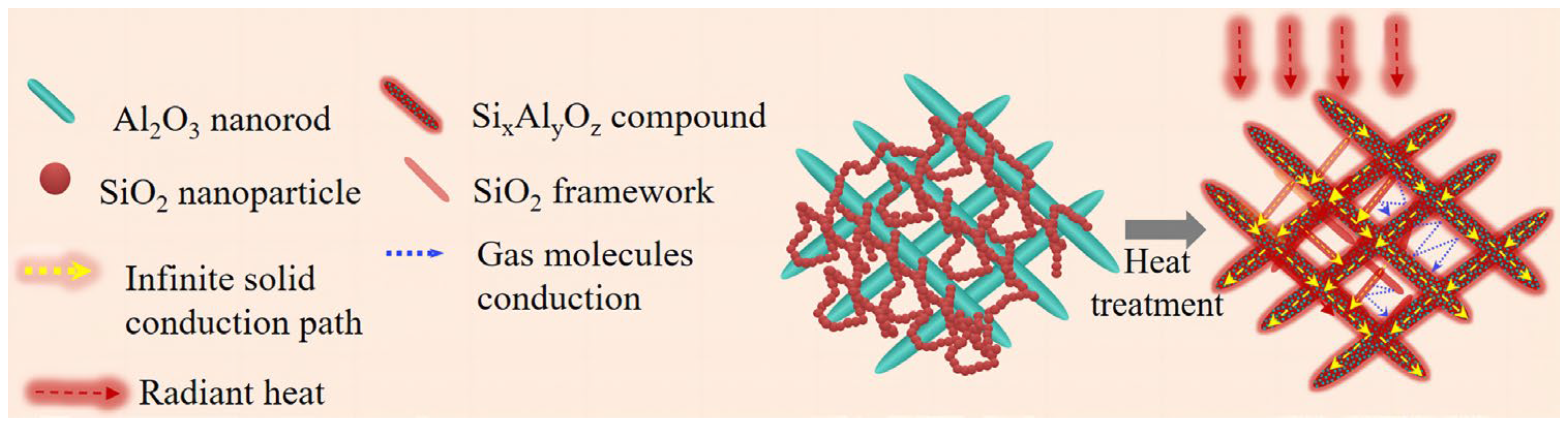

- Zhang, E.; Zhang, W.; Lv, T.; Li, J.; Dai, J.; Zhang, F.; Zhao, Y.; Yang, J.; Li, W.; Zhang, H. Insulating and robust ceramic nanorod aerogels with high-temperature resistance over 1400 C. ACS Appl. Mater. Interfaces 2021, 13, 20548–20558. [Google Scholar] [CrossRef]

- Mei, J. Functionalization of Alumina Aerogels and Their Applications. Master’s Thesis, Southeast University, Nanjing, China, 2019. [Google Scholar]

- Ren, B.; Liu, J.; Rong, Y.; Wang, L.; Lu, Y.; Xi, X.; Yang, J. Nanofibrous Aerogel Bulk Assembled by Cross-Linked SiC/SiOx Core-Shell Nanofibers with Multifunctionality and TemperatureInvariant Hyperelasticity. ACS Nano 2019, 13, 11603–11612. [Google Scholar] [CrossRef]

- Zou, W.; Wang, X.; Wu, Y.; Zu, G.; Zou, L.; Zhang, R.; Yao, X.; Shen, J. Highly thermally stable alumina-based aerogels modified by partially hydrolyzed aluminum tri-sec-butoxide. J. Sol-Gel Sci. Technol. 2017, 84, 507–514. [Google Scholar] [CrossRef]

- Liu, B. High-Strength Design and Mechanism Study of Zirconia-Based Nanofiber Composite Nanoporous Aerogel Materials. Ph.D. Thesis, Institute of Advanced Materials, Shandong Academy of Sciences, Jinan, China, 2020. [Google Scholar]

- Ruiz-Rosas, R.; Bedia, J.; Rosas, J.M.; Lallave, M.; Loscertales, I.G.; Rodríguez-Mirasol, J.; Cordero, T. Methanol decomposition on electrospun zirconia nanofibers. Catal. Today 2012, 187, 77–87. [Google Scholar] [CrossRef]

- Chen, Y.; Mao, X.; Shan, H.; Yang, J.; Wang, H.; Chen, S.; Tian, F.; Yu, J.; Ding, B. Free-standing zirconia nanofibrous membranes with robust flexibility for corrosive liquid filtration. RSC Adv. 2014, 4, 2756–2763. [Google Scholar] [CrossRef]

- Koo, J.Y.; Hwang, S.; Ahn, M.; Choi, M.; Byun, D.; Lee, W. Controlling the diameter of electrospun yttria-stabilized zirconia nanofibers. J. Am. Ceram. Soc. 2016, 99, 3146–3150. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, Z.; Zhang, J.; Yu, Q.; Cui, S. Rapid synthesis of silica aerogels by microwave irradiation. J. Porous Mater. 2021, 28, 1469–1479. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, Z.; Zhang, J.; Ye, X.; Cui, S. Hydrophobic silica aerogels prepared by microwave irradiation. Chem. Phys. Lett. 2021, 762, 138127. [Google Scholar] [CrossRef]

- Ye, X.; Chen, Z.; Li, M.; Wang, T.; Wu, C.; Zhang, J.; Zhou, Q.; Liu, H.; Cui, S. Effect of heat treatment temperature on melamine sponge reinforced silica aerogel. Mater. Res. Express 2019, 6, 125517. [Google Scholar] [CrossRef]

- Ye, X.; Chen, Z.; Zhang, J.; Wu, C.; Xiang, J. SiC network reinforced SiO2 aerogel with improved compressive strength and preeminent microwave absorption at elevated temperatures. Ceram. Int. 2021, 47, 31497–31505. [Google Scholar] [CrossRef]

- Lee, S.W.; Kim, Y.U.; Choi, S.S.; Park, T.Y.; Joo, Y.L.; Lee, S.G. Preparation of SiO2/TiO2 composite fibers by sol-gel reaction and electrospinning. Mater. Lett. 2007, 61, 889–893. [Google Scholar] [CrossRef]

- Tang, X.; Sun, A.; Chu, C.; Yu, M.; Ma, S.; Cheng, Y.; Guo, J.; Xu, G. A novel silica nanowire-silica composite aerogels dried at ambient pressure. Mater. Des. 2017, 115, 415–421. [Google Scholar] [CrossRef]

- Calisir, M.D.; Kilic, A. A comparative study on SiO2 nanofiber production via two novel non-electrospinning methods: Centrifugal spinning vs solution blowing. Mater. Lett. 2020, 258, 126751. [Google Scholar] [CrossRef]

- Wang, F.; Dou, L.; Dai, J.; Li, Y.; Huang, L.; Si, Y.; Yu, J.; Ding, B. In situ synthesis of biomimetic silica nanofibrous aerogels with temperature-invariant superelasticity over one million compressions. Angew. Chem. Int. Ed. Engl. 2020, 59, 8285–8292. [Google Scholar] [CrossRef]

- Mi, H.Y.; Jing, X.; Huang, H.X.; Turng, L.S. Instantaneous self-assembly of three-dimensional silica fibers in electrospinning: Insights into fiber deposition behavior. Mater. Lett. 2017, 204, 45–48. [Google Scholar] [CrossRef]

- Huang, T.; Zhu, Y.; Zhu, J.; Yu, H.; Zhang, Q.; Zhu, M. Self-reinforcement of light, temperature-resistant silica nanofibrous aerogels with tunable mechanical properties. Adv. Fiber Mat. 2020, 2, 338–347. [Google Scholar] [CrossRef]

- Tepekiran, B.N.; Calisir, M.D.; Polat, Y.; Akgul, Y.; Kilic, A. Centrifugally spun silica (SiO2) nanofibers for high-temperature air filtration. Aerosol. Sci. Technol. 2019, 53, 921–932. [Google Scholar] [CrossRef]

- Wang, X.; Sun, M.; Wang, X.; Wang, S.; Bian, H.; Wu, W.; Dai, H. Study on pore structure regulation of hexagonal boron nitride/nanocellulose aerogel and thermal conductivity of composite film. Made China Pap. 2021, 40, 36–43. [Google Scholar]

- Xu, X.; Zhang, Q.; Hao, M.; Hu, Y.; Lin, Z.; Peng, L.; Wang, T.; Ren, X.; Wang, C.; Zhao, Z.; et al. Double-negative-index ceramic aerogels for thermal superinsulation. Science 2019, 363, 723–727. [Google Scholar] [CrossRef] [PubMed]

- Lu, D.; Su, L.; Wang, H.; Niu, M.; Xu, L.; Ma, M.; Gao, H.; Cai, Z.; Fan, X. Scalable fabrication of resilient SiC nanowires aerogels with exceptional high-temperature stability. ACS Appl. Mater. Interfaces 2019, 11, 45338–45344. [Google Scholar] [CrossRef]

- Yang, H.; Li, C.; Yue, X.; Huo, J.; Ye, F.; Liu, J.; Shi, F.; Ma, J. New bn/sioc aerogel composites fabricated by the sol-gel method with excellent thermal insulation performance at high temperature. Mater. Des. 2020, 185, 108217. [Google Scholar] [CrossRef]

- Aravind, P.R.; Soraru, G.D. Porous silicon oxycarbide glasses from hybrid ambigels. Microporous Mesoporous Mater. 2011, 142, 511–517. [Google Scholar] [CrossRef]

- Zeng, X.; Ye, L.; Yu, S.; Sun, R.; Xu, J.; Wong, C.P. Facile preparation of superelastic and ultralow dielectric boron nitride nanosheet aerogels via freeze-casting process. Chem. Mater. 2015, 27, 5849–5855. [Google Scholar] [CrossRef]

- Li, G.; Zhu, M.; Gong, W.; Du, R.; Eychmüller, A.; Li, T.; Lv, W.; Zhang, X. Boron nitride aerogels with super-flexibility ranging from liquid nitrogen temperature to 1000 °C. Adv. Funct. Mater. 2019, 29, 1900188. [Google Scholar] [CrossRef]

- Kong, Y.; Zhang, J.; Zhao, Z.; Jiang, X.; Shen, X. Monolithic silicon nitride-based aerogels with large specific surface area and low thermal conductivity. Ceram. Int. 2019, 45, 16331–16337. [Google Scholar] [CrossRef]

- Su, L.; Li, M.; Wang, H.; Niu, M.; Lu, D.; Cai, Z. Resilient Si3N4 nanobelt aerogel as fire-resistant and electromagnetic wave-transparent thermal insulator. ACS Appl. Mater. Interfaces 2019, 11, 15795–15803. [Google Scholar] [CrossRef]

- Mahalingam, S.; Pierin, G.; Colombo, P.; Edirisinghe, M. Facile onepot formation of ceramic fibres from preceramic polymers by pressurised gyration. Ceram. Int. 2015, 41, 6067–6073. [Google Scholar] [CrossRef]

- Liang, C.; Wang, Z. Eggplant-derived SiC aerogels with high-performance electromagnetic wave absorption and thermal insulation properties. Chem. Eng. J. 2019, 373, 598–605. [Google Scholar] [CrossRef]

- Su, L.; Wang, H.; Niu, M.; Fan, X.; Ma, M.; Shi, Z.; Guo, S.W. Ultralight, recoverable, and high-temperature-resistant SiC nanowire aerogel. ACS Nano 2018, 12, 3103–3111. [Google Scholar] [CrossRef]

- Leventis, N.; Sadekar, A.; Chandrasekaran, N.; Sotiriou-Leventis, C. Click synthesis of monolithic silicon carbide aerogels from polyacrylonitrile-coated 3D silica networks. Chem. Mater. 2010, 22, 2790–2803. [Google Scholar] [CrossRef]

- Chen, Y.; Ola, O.; Liu, G.; Han, L.; Hussain, M.Z.; Thummavichai, K.; Wen, J.; Zhang, L.; Wang, N.; Xia, Y.; et al. Multifunctional porous SiC nanowire scaffolds. J. Eur. Ceram. Soc. 2021, 41, 3970–3979. [Google Scholar] [CrossRef]

- Song, L.; Fan, B.; Chen, Y.; Gao, Q.; Li, Z.; Wang, H.; Zhang, X.; Guan, L.; Zhang, R. Ultralight and hyperelastic SiC nanofiber aerogel spring for personal thermal energy regulation. J. Am. Ceram. Soc. 2022, 11, 1235–1248. [Google Scholar] [CrossRef]

- Song, X.; Zhang, K.; Song, Y.; Duan, Z.; Liu, Q.; Liu, Y. Morphology, microstructure and mechanical properties of electrospun alumina nanofibers prepared using different polymer templates: A comparative study. J. Alloy. Compd. 2020, 829, 154502. [Google Scholar] [CrossRef]

- Liu, R.; Dong, X.; Xie, S.; Jia, T.; Xue, Y.; Liu, J.; Jing, W.; Guo, A. Ultralight, thermal insulating, and high-temperature resistant mullite-based nanofibrous aerogels. Chem. Eng. J. 2019, 360, 464–472. [Google Scholar] [CrossRef]

- Song, X.; Liu, W.; Wang, J.; Xu, S.; Liu, B.; Cai, Q.; Ma, Y. Highly aligned continuous mullite nanofibers: Conjugate electrospinning fabrication, microstructure and mechanical properties. Mater. Lett. 2018, 212, 20–24. [Google Scholar] [CrossRef]

- Si, Y.; Wang, X.; Dou, L.; Yu, J.; Ding, B. Ultralight and fire-resistant ceramic nanofibrous aerogels with temperature-invariant superelasticity. Sci. Adv. 2018, 4, eaas8925. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Dou, L.; Li, Z.; Yang, L.; Yu, J.; Ding, B. Flexible hierarchical ZrO2 nanoparticle-embedded SiO2 nanofibrous membrane as a versatile tool for efficient removal of phosphate. ACS Appl. Mater. Interfaces 2016, 8, 34668–34676. [Google Scholar] [CrossRef] [PubMed]

- Mao, X.; Si, Y.; Chen, Y.; Yang, L.; Zhao, F.; Ding, B.; Yu, J. Silica nanofibrous membranes with robust flexibility and thermal stability for high-efficiency fine particulate filtration. RSC Adv. 2012, 2, 12216–12223. [Google Scholar] [CrossRef]

- Yan, J.; Zhao, Y.; Wang, X.; Xia, S.; Zhang, Y.; Han, Y.; Yu, J.; Ding, B. Polymer template synthesis of soft, light, and robust oxide ceramic films. Iscience 2019, 15, 185–195. [Google Scholar] [CrossRef]

- Lu, B.; He, Y.; Duan, H.; Zhang, Y.; Li, X.; Zhu, C.; Xie, E. A new ultrahigh-speed method for the preparation of nanofibers containing living cells: A bridge towards industrial bioengineering applications. Nanoscale 2012, 4, 1003–1009. [Google Scholar] [CrossRef]

- Ren, L.; Simmons, T.J.; Lu, F.; Rahmi, O.; Kotha, S.P. Template free and large-scale fabrication of silica nanotubes with centrifugal jet spinning. Chem. Eng. J. 2014, 254, 39–45. [Google Scholar] [CrossRef]

- Ren, L.; Ozisik, R.; Kotha, S.P. Rapid and efficient fabrication of multilevel structured silica micro-/nanofibers by centrifugal jet spinning. J. Colloid Interface Sci. 2014, 425, 136–142. [Google Scholar] [CrossRef]

- Loccufier, E.; Geltmeyer, J.; Daelemans, L.; D’hooge, D.R.; De Buysser, K.; De Clerck, K. Silica nanofibrous membranes for the separation of heterogeneous azeotropes. Adv. Funct. Mater. 2018, 28, 1804138. [Google Scholar] [CrossRef]

- An, Z.; Ye, C.; Zhang, R.; Zhou, P. Flexible and recoverable SiC nanofiber aerogels for electromagnetic wave absorption. Ceram. Int. 2019, 45, 22793–22801. [Google Scholar] [CrossRef]

- Zheng, C.; Li, X.; Yu, Y.; Wang, H.; Cao, F.; Zhao, D. Study of high temperature resistant SiC(Al) fibers precursor—Polyaluminocarbosilane fibers. Acta Polym. Sin. 2006, 6, 768–773. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, J.; Sun, Q.; Ye, X.; Ma, X.; Wang, J. Sol-Gel Routes toward Ceramic Nanofibers for High-Performance Thermal Management. Chemistry 2022, 4, 1475–1497. [Google Scholar] [CrossRef]

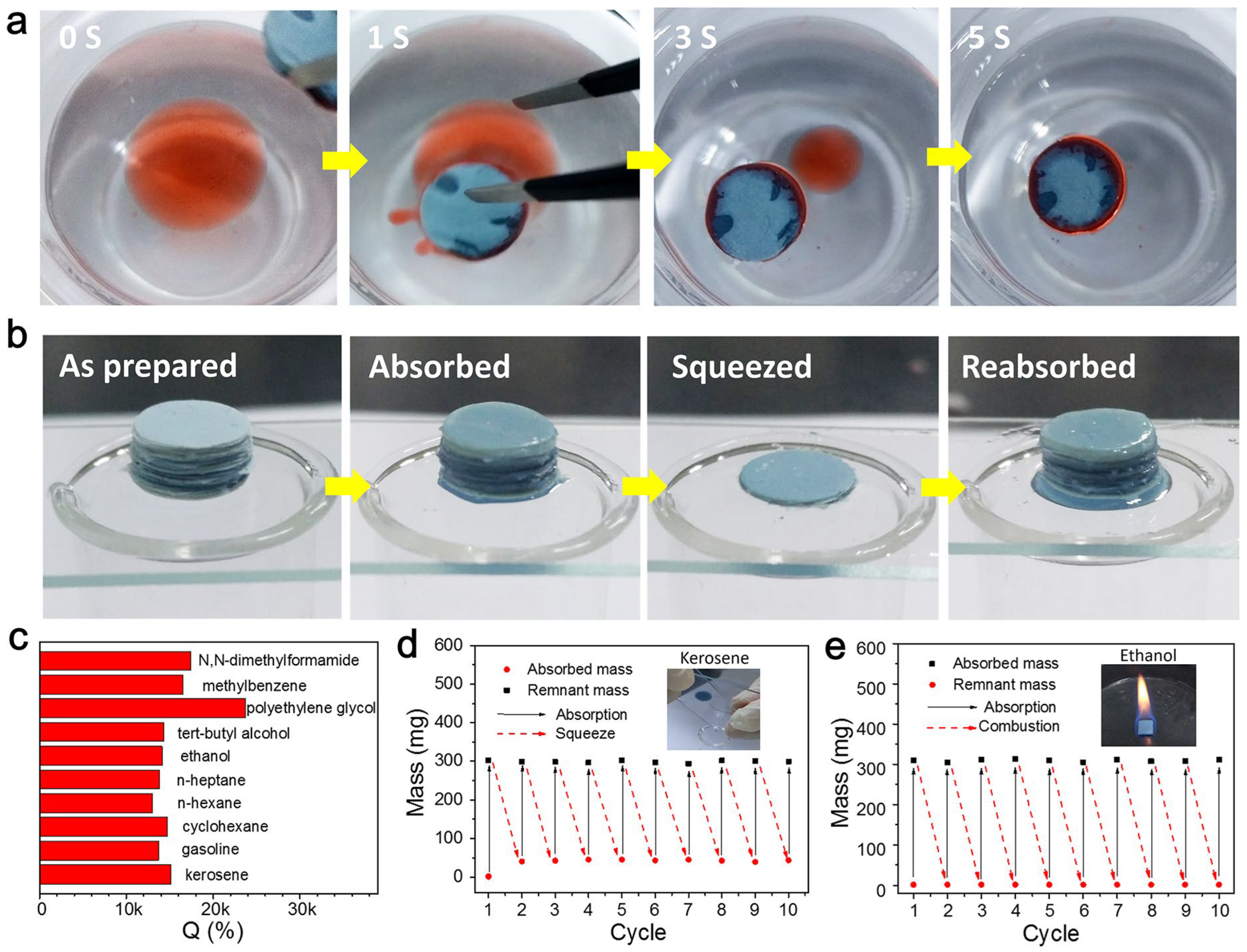

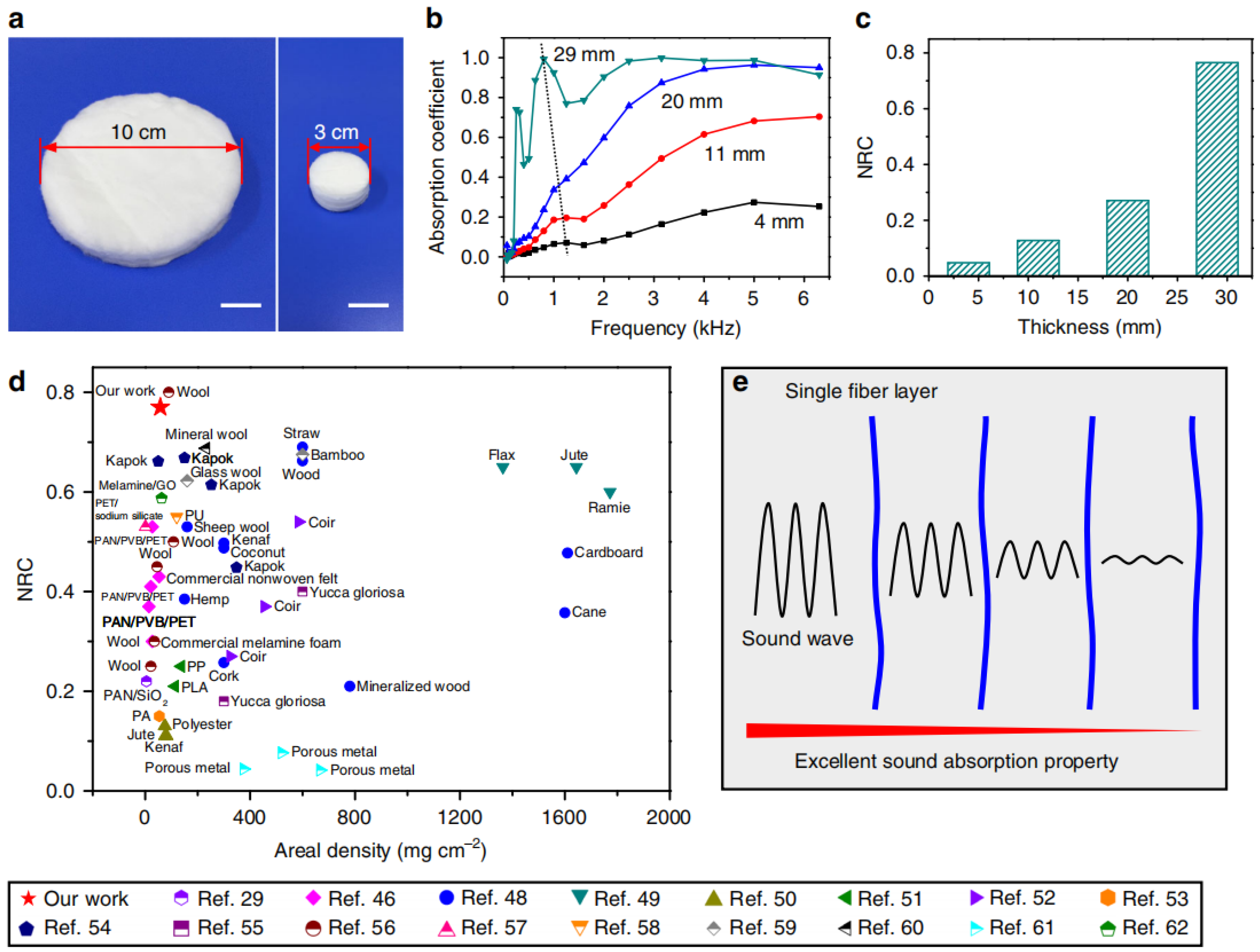

- Jia, C.; Li, L.; Liu, Y.; Fang, B.; Ding, H.; Song, J.; Liu, Y.; Xiang, K.; Lin, S.; Li, Z.; et al. Highly compressible and anisotropic lamellar ceramic sponges with superior thermal insulation and acoustic absorption performances. Nat. Commun. 2020, 11, 3732. [Google Scholar] [CrossRef] [PubMed]

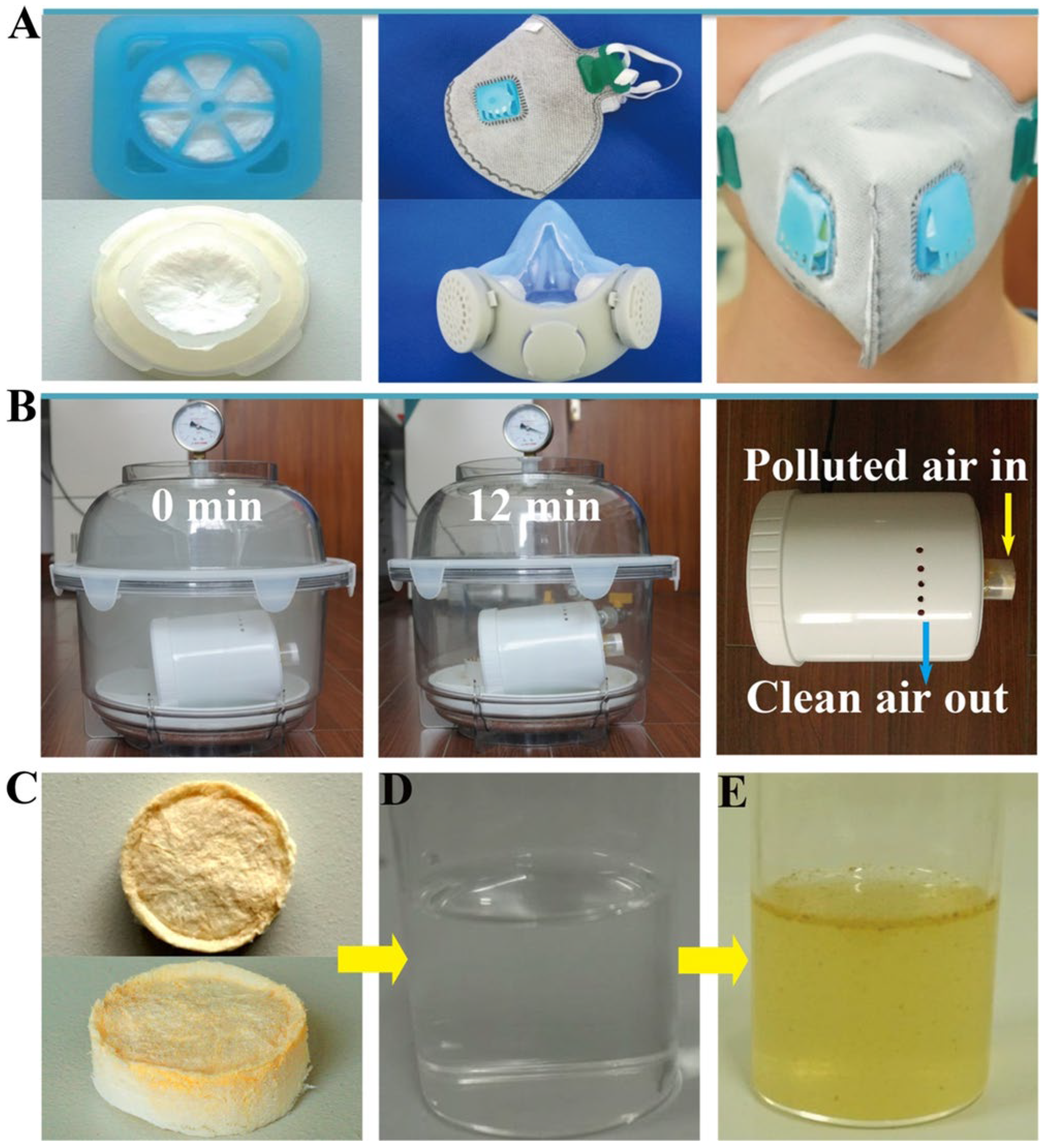

- Jia, C.; Liu, Y.; Li, L.; Song, J.; Wang, H.; Liu, Z.; Li, Z.; Li, B.; Fang, M.; Wu, H. A foldable all-ceramic air filter paper with high efficiency and high-temperature resistance. Nano Lett. 2020, 20, 4993–5000. [Google Scholar] [CrossRef]

- Li, P.; Wang, C.; Zhang, Y.; Wei, F. Air filtration in the free molecular flow regime: A review of high-efficiency particulate air filters based on carbon nanotubes. Small 2014, 10, 4543–4561. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhu, Y.; Xiong, C.; Wu, J.; Chen, F. Bioinspired ultralight inorganic aerogel for highly efficient air filtration and oil–water separation. ACS Appl. Mater. Interfaces 2018, 10, 13019–13027. [Google Scholar] [CrossRef]

- Song, Y.; Li, B.; Yang, S.; Ding, G.; Zhang, C.; Xie, X. Ultralight boron nitride aerogels via template-assisted chemical vapor deposition. Sci. Rep. 2015, 5, 10337. [Google Scholar] [CrossRef] [PubMed]

- Xue, Y.; Dai, P.; Zhou, M.; Wang, X.; Pakdel, A.; Zhang, C.; Weng, Q.; Takei, T.; Fu, X.; Popov, Z.I.; et al. Multifunctional superelastic foam-like boron nitride nanotubular cellular-network architectures. ACS Nano 2017, 11, 558–568. [Google Scholar] [CrossRef]

- Ye, X.; Zhang, J.; Chen, Z.; Xiang, J.; Jiang, Y.; Xie, F.; Ma, X. Microwave absorption properties of Ni/C@ SiC composites prepared by precursor impregnation and pyrolysis processes. Def. Technol. 2021; in press. [Google Scholar] [CrossRef]

- Ye, X.; Chen, Z.; Li, M.; Wang, T.; Wu, C.; Zhang, J.; Zhou, Q.; Liu, H.; Cui, S. Hollow SiC foam with a double interconnected network for superior microwave absorption ability. J. Alloys Compd. 2020, 817, 153276. [Google Scholar] [CrossRef]

- Cai, Z.; Su, L.; Wang, H.; Niu, M.; Gao, H.; Lu, D.; Li, M. Hydrophobic SiC@ C nanowire foam with broad-band and mechanically controlled electromagnetic wave absorption. ACS Appl. Mater. Interfaces 2020, 12, 8555–8562. [Google Scholar] [CrossRef] [PubMed]

- Hou, Y.; Cheng, L.; Zhang, Y.; Yang, Y.; Deng, C.; Yang, Z.; Chen, Q.; Du, X.; Zheng, L. SiC nanofiber mat: A broad-band microwave absorber, and the alignment effect. ACS Appl. Mater. Interfaces 2017, 9, 43072–43080. [Google Scholar] [CrossRef] [PubMed]

- Hou, Y.; Cheng, L.; Zhang, Y.; Yang, Y.; Deng, C.; Yang, Z.; Chen, Q.; Du, X.; Zhao, C.; Zheng, L. Enhanced flexibility and microwave absorption properties of HfC/SiC nanofiber mats. ACS Appl. Mater. Interfaces 2018, 10, 29876–29883. [Google Scholar] [CrossRef]

- Zhao, Y.; Yan, J.; Cai, W.; Lai, Y.; Song, J.; Yu, J.; Ding, B. Elastic and well-aligned ceramic LLZO nanofiber based electrolytes for solid-state lithium batteries. Energy Storage Mater. 2019, 23, 306–313. [Google Scholar] [CrossRef]

- Zhang, W.; Wang, H.; Guan, K.; Wei, Z.; Zhang, X.; Meng, J.; Liu, X.; Meng, J. La0. 6Sr0. 4Co0. 2Fe0. 8O3− δ/CeO2 heterostructured composite nanofibers as a highly active and robust cathode catalyst for solid oxide fuel cells. ACS Appl. Mater. Interfaces 2019, 11, 26830–26841. [Google Scholar] [CrossRef]

- Wang, Y.; Li, J.; Sun, J.; Wang, Y.; Zhao, X. Electrospun flexible self-standing Cu–Al2O3 fibrous membranes as Fenton catalysts for bisphenol A degradation. J. Mater. Chem. A 2017, 5, 19151–19158. [Google Scholar] [CrossRef]

- Cheng, Z.; Zhao, S.; Han, L. A novel preparation method for ZnO/γ-Al2O3 nanofibers with enhanced absorbability and improved photocatalytic water-treatment performance by Ag nanoparticles. Nanoscale 2018, 10, 6892–6899. [Google Scholar] [CrossRef]

| Class Number | 1 | 2 | 3 | 4 | 5 | 6 | |

|---|---|---|---|---|---|---|---|

| Components | Grading temperature/°C | <1200 | 1260 | 1400 | 1400 | 1550 | 1600 |

| SiO2 | 53.9 | 53 | 45 | 55 | 15 | 5 | |

| Al2O3 | 43.4 | 47 | 55 | 41 | 85 | 95 | |

| Cr2O3 | - | - | - | 4 | - | - | |

| TiO2 | 1.7 | - | - | - | - | - | |

| Fe2O3 | 0.8 | - | - | - | - | - | |

| K2O + Na2O | 0.2 | - | - | - | - | - | |

| Phase | Content | ||||||

| Mullite | ~65 | 65 | 75 | 57 | 54 | 18 | |

| Cristobalite | 35 | 35 | 25 | 43 | - | - | |

| Al2O3 | - | - | - | - | - | - | |

| Structure | Amorphous | Amorphous | Amorphous | Amorphous | Polycrystalline | Polycrystalline | |

| Ceramics | Precursors | Solvents | Calcination Conditions | Methods | Products | References |

|---|---|---|---|---|---|---|

| Al2O3 | Aluminum acetate | Ethanol | 20 °C·min−1, 1000 °C for 2 h, in air | Electrospinning | Nanofiber | [27] |

| Aluminum powder | H2O | 1 °C·min−1, 600 °C for 2 h, 5 °C·min−1, 700–1000 °C for 2 h, in air | Electrospinning | Nanofiber | [28] | |

| AlCl3·6H2O, aluminum powder | H2O | 4 °C·min−1, 600–1100 °C for 2 h, in air | Solution blow spinning | Nanofiber | [31] | |

| AlCl3·6H2O, aluminum powder | H2O | 4 °C·min−1, 400–1200 °C for 4 h, in air | Centrifugal spinning | Nanofiber | [23] | |

| Al(NO3)3·9H2O, aluminum isopropoxide | H2O | 5 °C·min−1, 900 °C for 1 h, in air | Electrospinning | Nanofiber | [100] | |

| Aluminum isopropoxide | H2O | 3 °C·min−1, 650 °C/1200 °C for 3 h, in air | Centrifugal spinning | Nanofiber | [33] | |

| Mullite | Aluminum trisec-butoxide, polyhydromethylsiloxane | Isopropanol, DMF, ethylacetoacetate | 2 °C·min−1, 800–1500 °C, in air | Electrospinning | Aerogel | [101] |

| Aluminium isopropoxide, Al(NO3) 3·9H2O, TEOS | H2O, ethanol | 800–1400 °C for 2 h, in air | Electrospinning | Nanofiber | [35] | |

| Aluminum acetate, Colloidal silica | H2O, ethanol | 5 °C·min−1, 800 °C for 1 h, 800–1200 °C for 1 h in air | Electrospinning | Nanofiber | [36] | |

| Aluminum acetate, TEOS | H2O, ethanol | 5 °C·min−1, 800 °C for 1 h, 1000 °C for 1 h, in air | Electrospinning | Nanofiber | [102] | |

| TEOS, Al(NO3)3·9H2O | THF | 600–1000 °C, in air | Solution blow spinning | Nanofiber | [37] | |

| ZrO2 | ZrOCl2·8H2O | H2O | 1 °C·min−1, 800 °C for 1 h, 5 °C·min−1, 1200 °C for 1 h, in air | Centrifugal spinning | Nanofiber | [45] |

| Zirconium acetate | Acetic acid | 200–1000 °C for 2 h, in air | Electrospinning | Nanofiber | [71] | |

| ZrOCl2·8H2O | H2O | 600–1300 °C, in air | Electrospinning | Nanofiber | [72] | |

| Zirconium acetate hydroxide | DMF | 5 °C·min−1, 280 °C for 1 h, 1 °C·min−1, 800 °C for 3 h, in air | Electrospinning | Nanofiber | [73] | |

| ZrOCl2·8H2O | Ethanol, H2O | 2 °C·min−1, 800 °C for 200 min, in air | Solution blow spinning | Nanofiber | [44] | |

| ZrOCl2·8H2O | H2O2, H2O | 1.2–3 °C·min−1, 1300 °C form 3 h, in steam atmosphere | Centrifugal spinning | Nanofiber | [46] | |

| Zirconium n-propoxide | Ethanol | 2 °C·min−1, 800 °C for 200 min, in air | Solution blow spinning | Nanofiber | [47] | |

| SiO2 | TEOS | H2O | 5 °C·min−1, 600–1200 °C, in air | Electrospinning | Nanofiber (82,109–111), Aerogel (108) | [81,103,104,105,106] |

| TEOS | H2O | 5 °C·min−1, 800 °C for 2 h, in air | Electrospinning | Aerogel | [83] | |

| TEOS | Ethanol | 6 °C·min−1, 550 °C for 1 h, in air | Air-jet spinning | Nanofiber | [107] | |

| TEOS | Ethanol | 850 °C,6 h, in air | Centrifugal jet spinning | Nanofiber | [108,109] | |

| TEOS | Ethanol | 2 °C·min−1, 300, 600 and 900 °C, in air | Centrifugal spinning | Nanofiber | [84] | |

| TEOS | Ethanol | 10 °C·min−1, 250–1000 °C for 3 h, in air | Electrospinning | Nanofiber | [110] | |

| BN | Boric acid, melamine | H2O, tertiary butyl alcohol | 1200 °C for 3 h in NH3 | Self-assembly | Aerogel | [91] |

| Si3N4 | Methyltrimethoxysilane, dimethyldimethoxysilane | Ethanol | 5 °C·min−1, 1500 °C for 2 h in N2 | Chemical vapor deposition | Aerogel | [93] |

| Silica sol, carbon black | / | 3 °C·min−1, 1600 °C for 3 h in N2 | Chemical vapor deposition | Aerogel | [96] | |

| PCS | DMF, THF | 2 °C·min−1, 210 °C for 2 h in air, calcinated at 800 °C for 2 h, 1300 °C for 2 h in Ar | Polymer conversion | Aerogel | [111] | |

| PCS | Toluene, DMF | Stabilized at 170 °C for 3 h in air, calcinated at 1100–1500 °C in N2/calcinated at 1500 °C in Ar | Polymer conversion | Nanofiber | [54] | |

| Methyltrimethoxysilane, dimethyldimethoxysilane | Ethanol, H2O | 5 °C·min−1, 1550 °C for 2 h, in Ar | Chemical vapor deposition | Aerogel | [87] | |

| PCS | Xylene, H2O | Stabilized at 200 °C for 10 h in air, calcinated at 1400 °C for 2 h in Ar | Polymer conversion | Nanofiber | [55] | |

| Polysilocarbonsilane | / | Stabilized at 160–220 °C for 6–8 h in air, calcinated at 1800 °C in Ar | Melt spinning | Nanofiber | [112] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; Zhang, X.; Wang, L.; Zhang, J.; Liu, R.; Sun, Q.; Ye, X.; Ma, X. Fabrication and Applications of Ceramic-Based Nanofiber Materials Service in High-Temperature Harsh Conditions—A Review. Gels 2023, 9, 208. https://doi.org/10.3390/gels9030208

Zhang J, Zhang X, Wang L, Zhang J, Liu R, Sun Q, Ye X, Ma X. Fabrication and Applications of Ceramic-Based Nanofiber Materials Service in High-Temperature Harsh Conditions—A Review. Gels. 2023; 9(3):208. https://doi.org/10.3390/gels9030208

Chicago/Turabian StyleZhang, Jing, Xi Zhang, Lifeng Wang, Junxiong Zhang, Rong Liu, Qilong Sun, Xinli Ye, and Xiaomin Ma. 2023. "Fabrication and Applications of Ceramic-Based Nanofiber Materials Service in High-Temperature Harsh Conditions—A Review" Gels 9, no. 3: 208. https://doi.org/10.3390/gels9030208

APA StyleZhang, J., Zhang, X., Wang, L., Zhang, J., Liu, R., Sun, Q., Ye, X., & Ma, X. (2023). Fabrication and Applications of Ceramic-Based Nanofiber Materials Service in High-Temperature Harsh Conditions—A Review. Gels, 9(3), 208. https://doi.org/10.3390/gels9030208