Functional Acrylic Surfaces Obtained by Scratching

Abstract

:1. Introduction

2. Equilibrium Profile and Dynamic Capillary Rise

2.1. Equilibrium Profile

2.2. Capillary Rise

3. Experiments

3.1. Equilibrium Height and Characterization of the Micro V-Grooves

3.2. Functional Surfaces: Capillary Rise

4. Functionality of Scratched Surfaces in Other Cases

4.1. Droplets on Human Skin

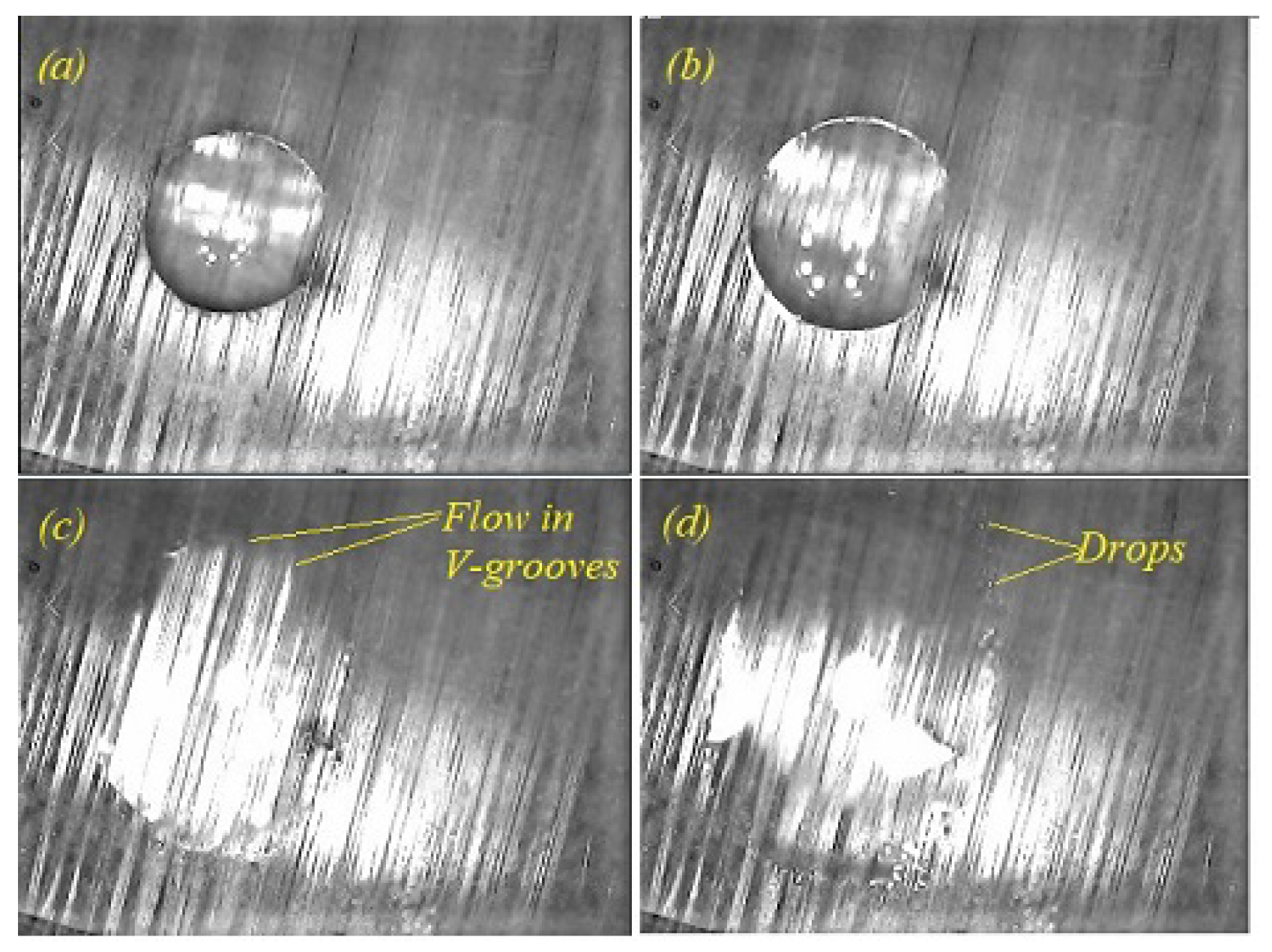

4.2. Droplets on Scratched Acrylic Sheets

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Godi, A.; De Chiffre, L. Functional Surfaces in Mechanical Systems: Classification, Fabrication, and Characterization. In Surface Engineering Techniques and Applications: Research Advancements; Santo, L., Davim, J.P., Eds.; IGI Global: Hershey, PA, USA, 2014; pp. 1–44. [Google Scholar]

- Deng, D.; Tang, Y.; Zeng, J.; Yang, S.; Shao, H. Characterization of capillary rise dynamics in parallel micro V-grooves. Int. J. Heat Mass Transf. 2014, 77, 311–320. [Google Scholar] [CrossRef]

- Chen, H.; Zhang, P.; Zhang, L.; Liu, H.; Jiang, Y.; Zhang, D.; Han, Z.; Jiang, L. Continuous directional water transport on the peristome surface of Nepenthes alata. Nature 2016, 532, 85–89. [Google Scholar] [CrossRef]

- Li, C.; Li, N.; Zhang, X.; Dong, Z.; Chen, H.; Jiang, L. Uni-Directional Transportation on Peristome-Mimetic Surfaces for Completely Wetting Liquids. Angew. Chem. Int. Ed. 2016, 55, 14988. [Google Scholar] [CrossRef]

- Chen, H.; Zhang, L.; Zhang, Y.; Zhang, P.; Zhang, D.; Jiang, L. Uni-directional liquid spreading control on a bio-inspired surface from the peristome of Nepenthes alata. J. Mater. Chem. A 2017, 5, 6914–6920. [Google Scholar] [CrossRef]

- Zhang, P.; Zhang, L.; Chen, H.; Dong, Z.; Zhang, D. Surfaces inspired by the Nepenthes Peristome for unidirectional liquid transport. Adv. Mater. 2017, 29, 1702995. [Google Scholar] [CrossRef] [PubMed]

- Zhou, S.; Yu, C.; Li, C.; Dong, Z.; Jiang, L. Programmable unidirectional liquid transport on peristome-mimetic surfaces under liquid environments. J. Mater. Chem. A 2019, 7, 18244–18248. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, G.; Chen, H.; Liu, X.; Ran, T.; Zhang, Y.; Gan, Y.; Zhang, D. Bioinspired unidirectional liquid transport micro-nano structures: A review. J. Bionic Eng. 2021, 18, 1–29. [Google Scholar] [CrossRef]

- Tian, Y.; Jiang, Y.; Zhou, J.; Doi, M. Dynamics of Taylor rising. Langmuir 2019, 35, 5183–5190. [Google Scholar] [CrossRef] [Green Version]

- Bamorovat Abadi, G.; Bahrami, M. A general form of capillary rise equation in micro-grooves. Sci. Rep. 2020, 10, 19709. [Google Scholar] [CrossRef]

- Vorobyev, A.Y.; Guo, C. Metal pumps liquid uphill. Appl. Phys. Lett. 2009, 94, 224102. [Google Scholar] [CrossRef]

- Dussaud, A.D.; Adler, P.M.; Lips, A. Liquid transport in the networked microchannels of the skin surface. Langmuir 2003, 19, 7341–7345. [Google Scholar] [CrossRef]

- Paul, S.; Mukhopadhyay, S.; Mandal, S.; Agarwal, P.; Chanda, N. Fabrication of durable haemophobic surfaces on cast acrylic sheets using UV laser micromachining. Micro Nano Lett. 2019, 14, 1175–1177. [Google Scholar] [CrossRef]

- Higuera, F.J.; Medina, A.; Liñán, A. Capillary rise of a liquid between two vertical plates making a small angle. Phys. Fluids 2008, 20, 102102. [Google Scholar] [CrossRef] [Green Version]

- Günay, A.A.; Kim, M.-K.; Yan, X.; Miljkovic, N.; Sett, S. Droplet evaporation dynamics on microstructured biphilic, hydrophobic, and smooth surfaces. Exp. Fluids 2021, 62, 153. [Google Scholar] [CrossRef]

- Landau, L.D.; Lifshits, I.M. Fluid Mechanics (Volume 6 of Course of Theoretical Physics); Pergamon Press: Oxford, UK, 1987. [Google Scholar]

- Taylor, B., IX. Part of a letter from Mr. Brook Taylor, F. R. S. to Dr. Hans Sloane R. S. Secr. concerning the ascent of water between two glass planes. Philos. Trans. R. Soc. 1712, 27, 538. [Google Scholar]

- Hauksbee, F.X. An Account of an experiment touching the ascent of water between two glass planes, in an Hyperbolick figure. Philos. Trans. R. Soc. Lond. 1712, 27, 539. [Google Scholar]

- Sanchez, F.A.; Gutierrez, G.J.; Medina, A. Capillary penetration in cells with periodical corrugations. Rev. Mex. Fis. 2009, 55, 467–471. [Google Scholar]

- Ponomarenko, A.; Quéré, D.; Clanet, C. A universal law for capillary rise in corners. J. Fluid Mech. 2011, 666, 146–154. [Google Scholar] [CrossRef] [Green Version]

- Bell, J.M.; Cameron, F.K. The flow of liquids through capillary spaces. J. Phys. Chem. 1906, 10, 658–674. [Google Scholar] [CrossRef] [Green Version]

- Lucas, R. Ueber das Zeitgesetz des kapillaren Aufstiegs von Flüssigkeiten. Kolloid-Zeitschrift 1918, 23, 15–22. [Google Scholar] [CrossRef]

- Washburn, E.W. The dynamics of capillary flow. Phys. Rev. 1921, 17, 273–283. [Google Scholar] [CrossRef]

- Fandeli Is a Manufacturer of Abrasives. Available online: https://fandeli.com/wp-content/uploads/2020/10/presentacion.pdf (accessed on 16 December 2021). (In Spanish).

- Chatterjee, S.; Murallidharan, J.S.; Agrawal, A.; Bhardwaj, R. Why coronavirus survives longer on impermeable than porous surfaces. Phys. Fluids 2021, 33, 021701. [Google Scholar] [CrossRef] [PubMed]

- Bhardwaja, R.; Agrawal, A. Tailoring surface wettability to reduce chances of infection of COVID-19 by a respiratory droplet and to improve the effectiveness of personal protection equipment. Phys. Fluids 2020, 32, 081702. [Google Scholar] [CrossRef]

- Bhardwaja, R.; Agrawal, A. Likelihood of survival of coronavirus in a respiratory droplet deposited on a solid surface. Phys. Fluids 2020, 32, 061704. [Google Scholar] [CrossRef]

- Tian, J.; Kannangara, D.; Li, X.; Shen, W. Capillary driven low-cost V-groove microfluidic device with high sample transport efficiency. Lab Chip 2010, 10, 2258–2264. [Google Scholar] [CrossRef] [PubMed]

- Kolliopoulos, P.; Kumar, S. Capillary flow of liquids in open microchannels: Overview and recent advances. npj Microgravity 2021, 7, 51. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Medina, A.; López-Villa, A.; Vargas, C.A. Functional Acrylic Surfaces Obtained by Scratching. Fluids 2021, 6, 463. https://doi.org/10.3390/fluids6120463

Medina A, López-Villa A, Vargas CA. Functional Acrylic Surfaces Obtained by Scratching. Fluids. 2021; 6(12):463. https://doi.org/10.3390/fluids6120463

Chicago/Turabian StyleMedina, Abraham, Abel López-Villa, and Carlos A. Vargas. 2021. "Functional Acrylic Surfaces Obtained by Scratching" Fluids 6, no. 12: 463. https://doi.org/10.3390/fluids6120463

APA StyleMedina, A., López-Villa, A., & Vargas, C. A. (2021). Functional Acrylic Surfaces Obtained by Scratching. Fluids, 6(12), 463. https://doi.org/10.3390/fluids6120463