Impact of Navier’s Slip and MHD on a Hybrid Nanofluid Flow over a Porous Stretching/Shrinking Sheet with Heat Transfer

Abstract

:1. Introduction

- (i)

- Small magnetic particles colloidally suspended in a liquid medium are called ferrofluid. Ferrofluid have some significant applications in heat exchangers and can be used for mechanical dampening in loudspeakers.

- (ii)

- Nanoparticles of metallic oxides, such as Al2O3, SiO2, ZnO, and TiO2, can easily be dissolved in base liquids, and Al2O3 is one of these metal oxides with high thermal properties.

- (iii)

- The Darcy phenomenon is taken into account by the fluid flow.

- (iv)

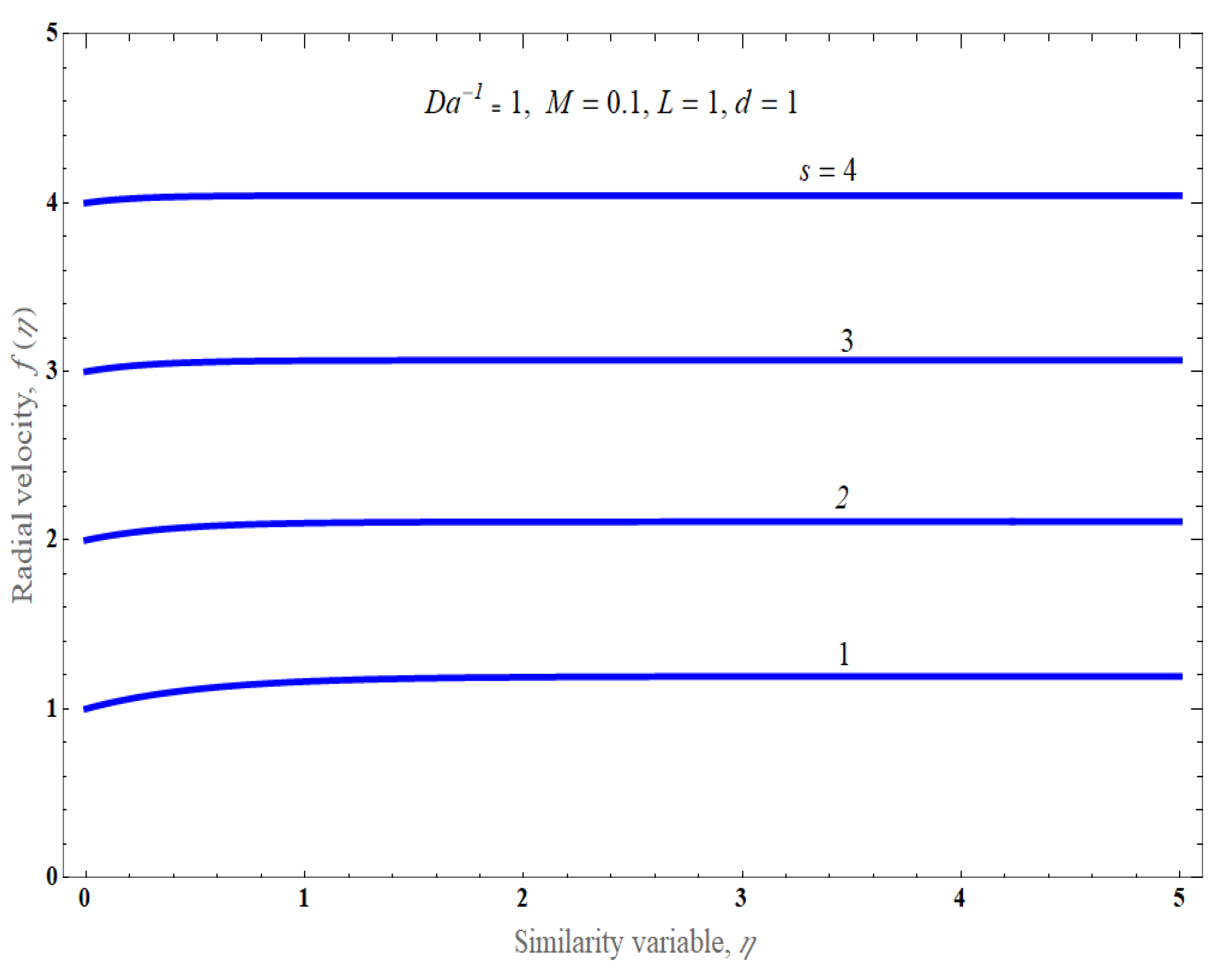

- The Lorentz force tends to accelerate body forces, which increase flow velocity and develop a thicker momentum boundary layer.

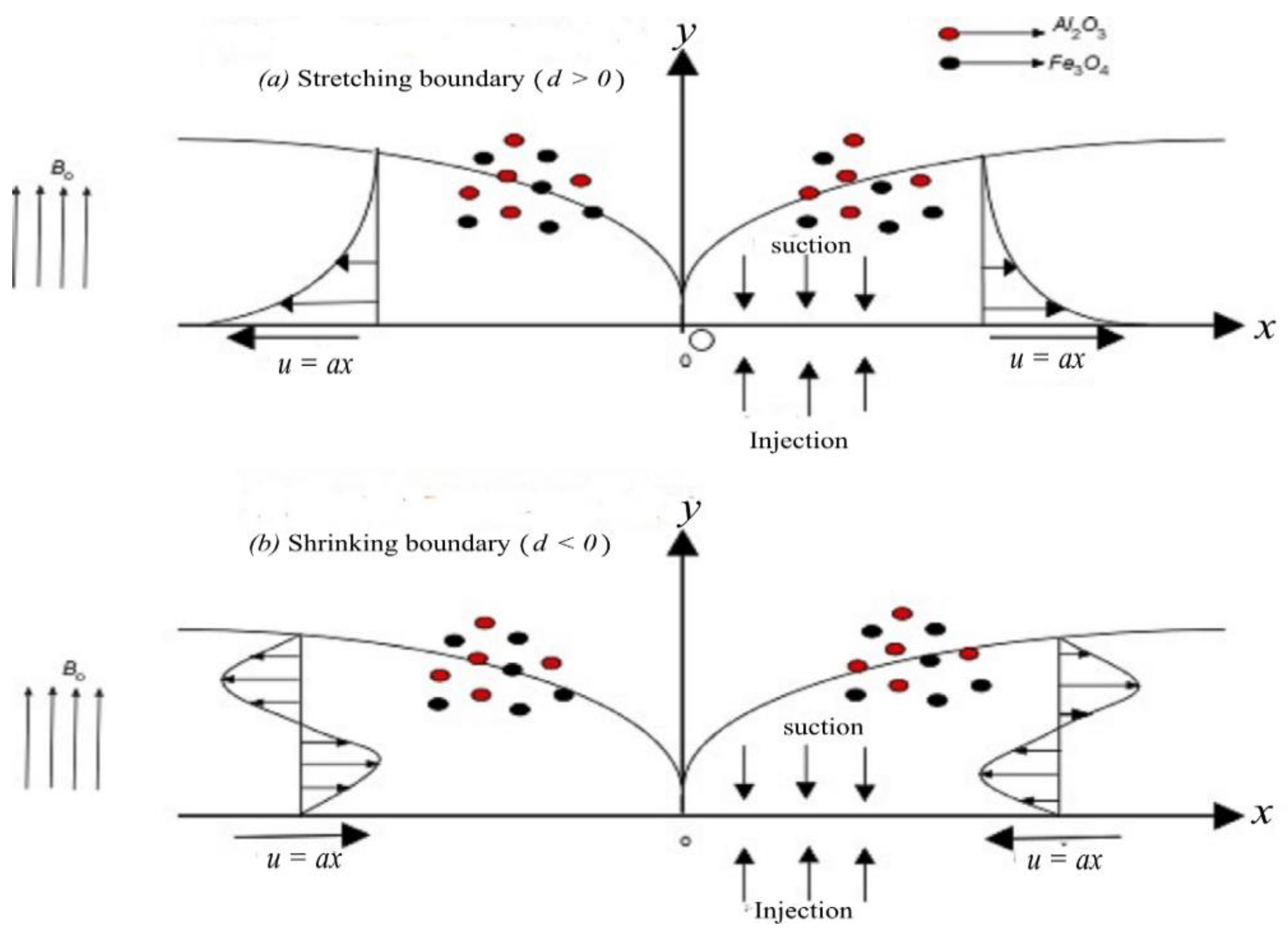

2. Materials and Methods

Similarity Transformations

- is the inverse Darcy number,

- is the Prandtl number,

- is the radiation parameter,

3. Analytical Solution for Momentum

4. Heat Transfer Solution

5. Results

6. Conclusions

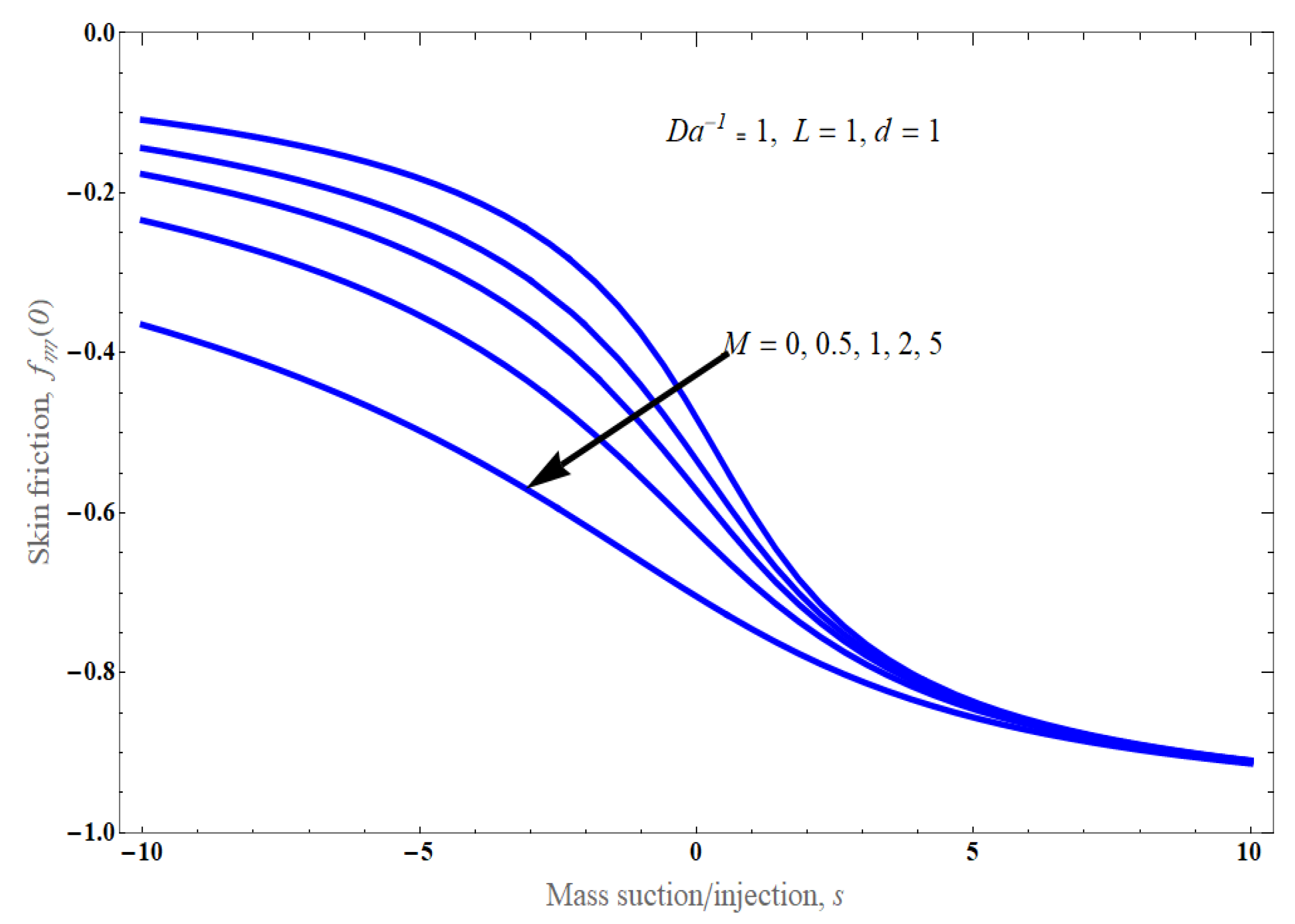

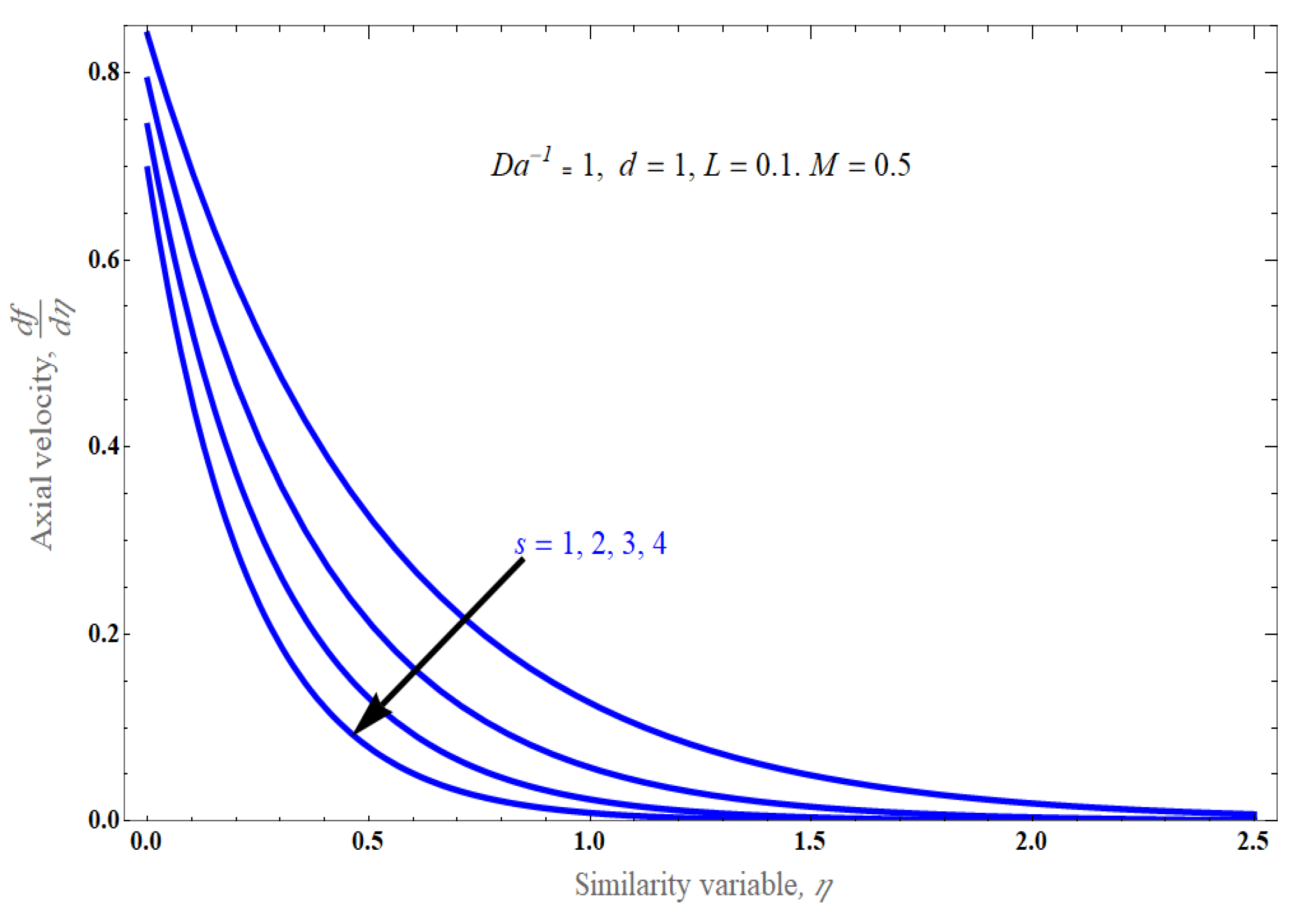

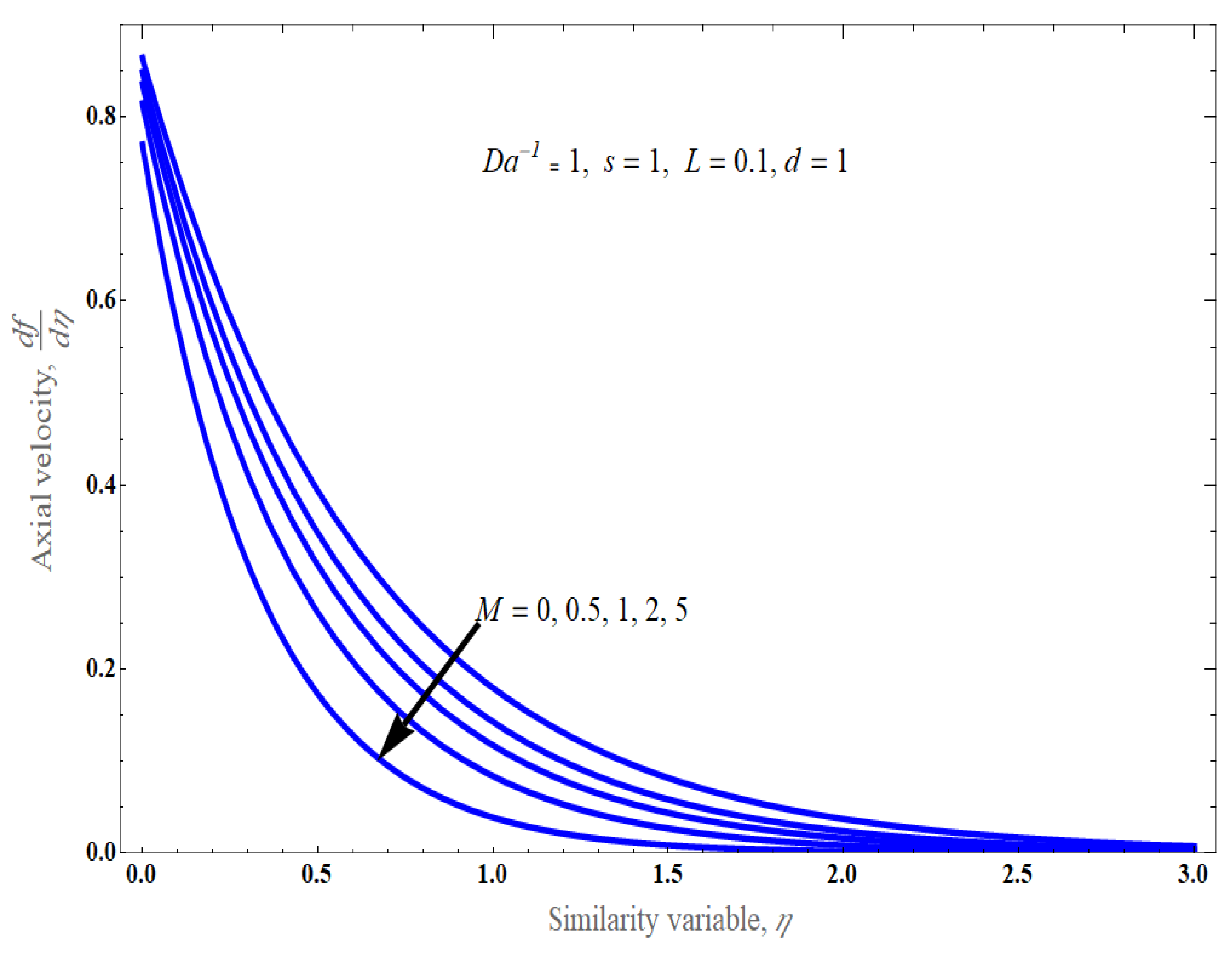

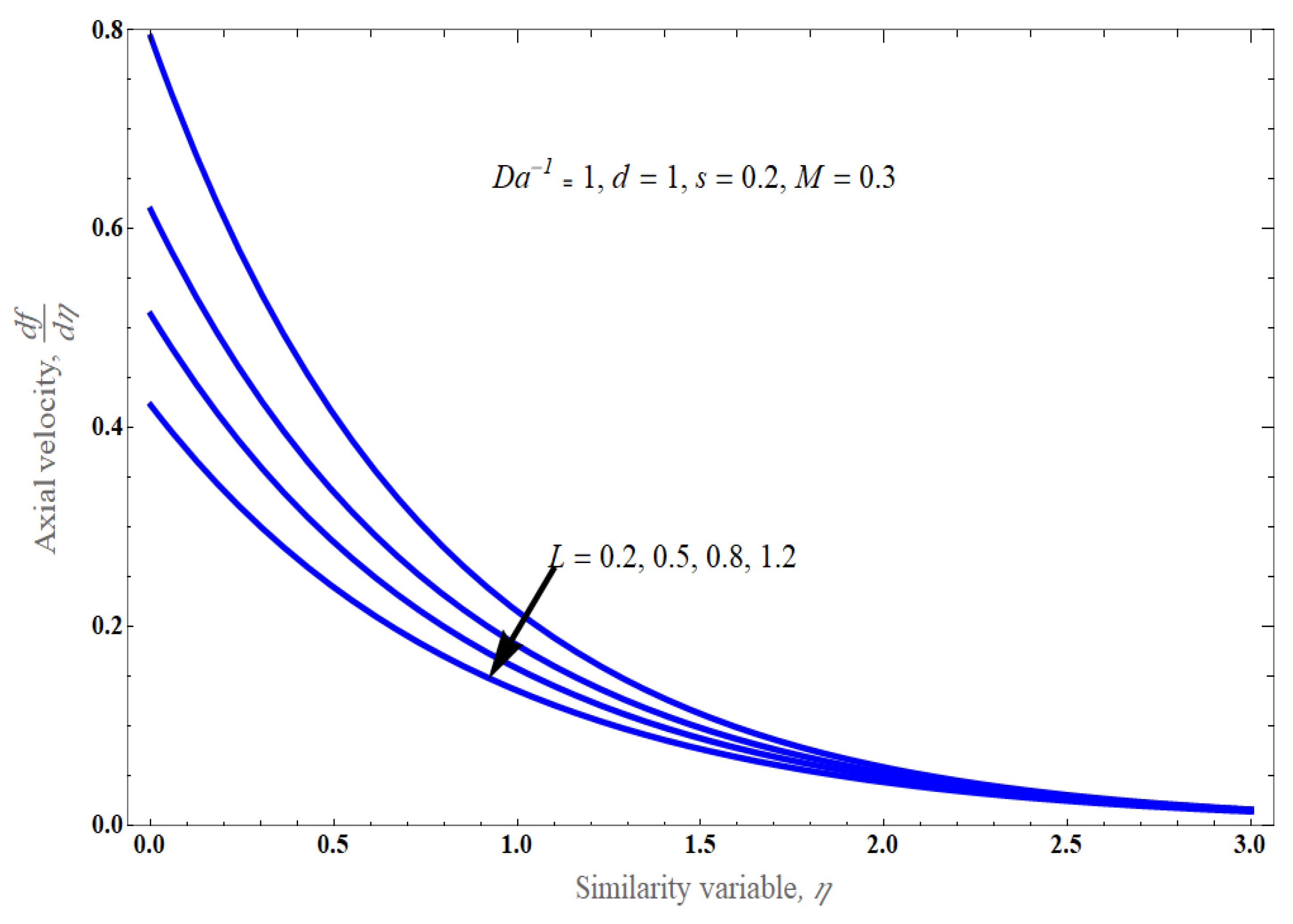

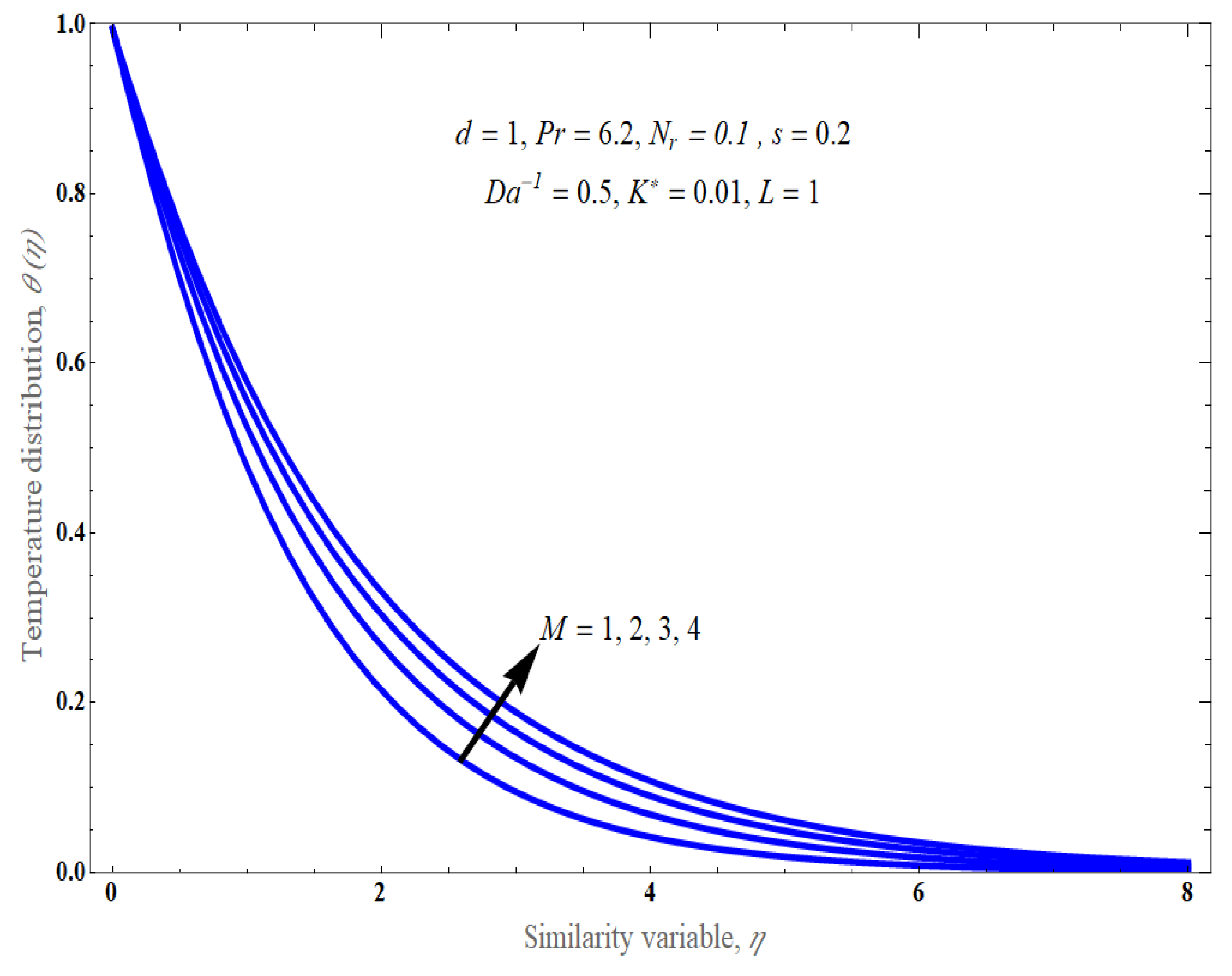

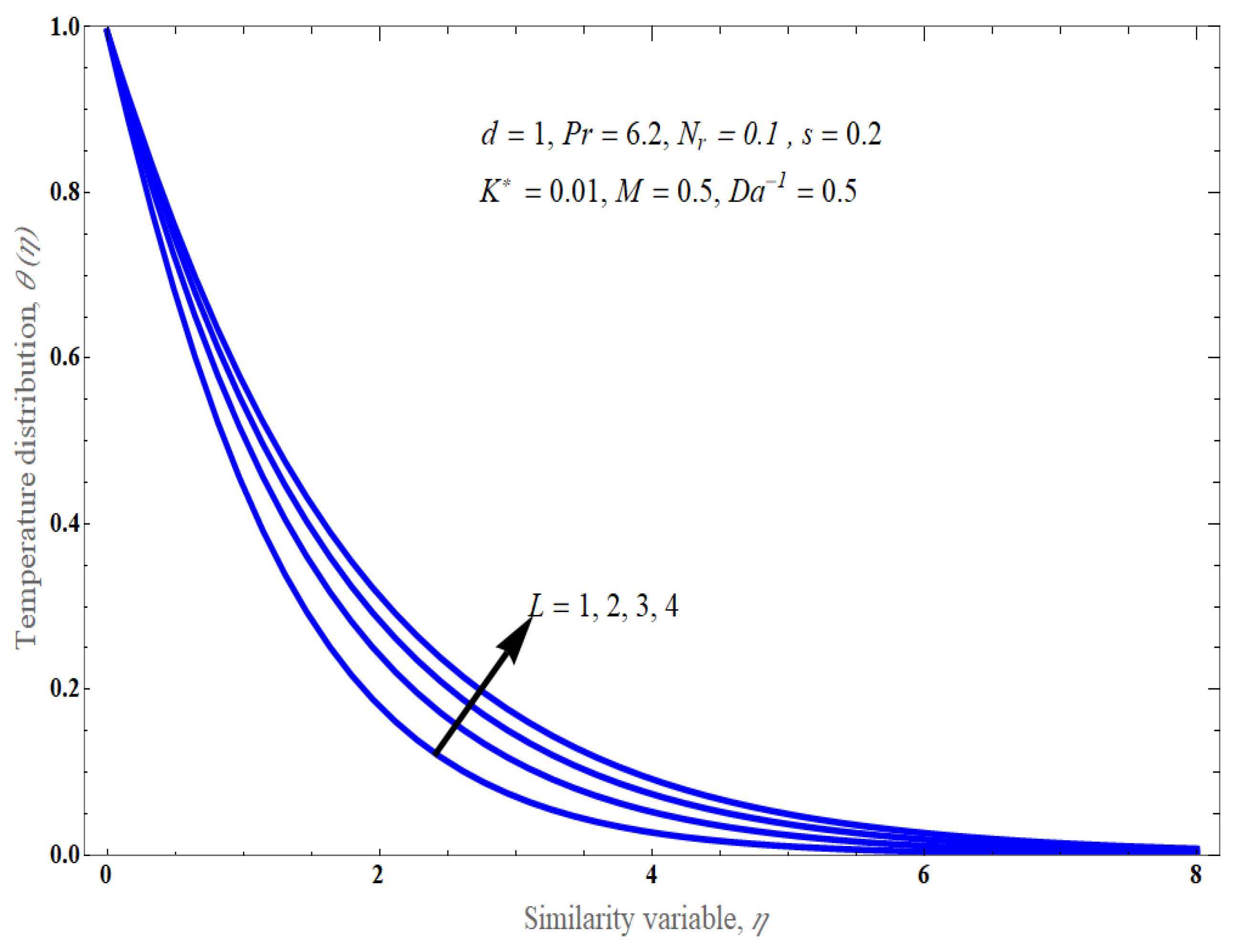

- Because of the strong magnetic field, inverse Darcy number, and velocity slip parameter, the non-dimensional velocity profile reduces along the flow region, while temperature increases.

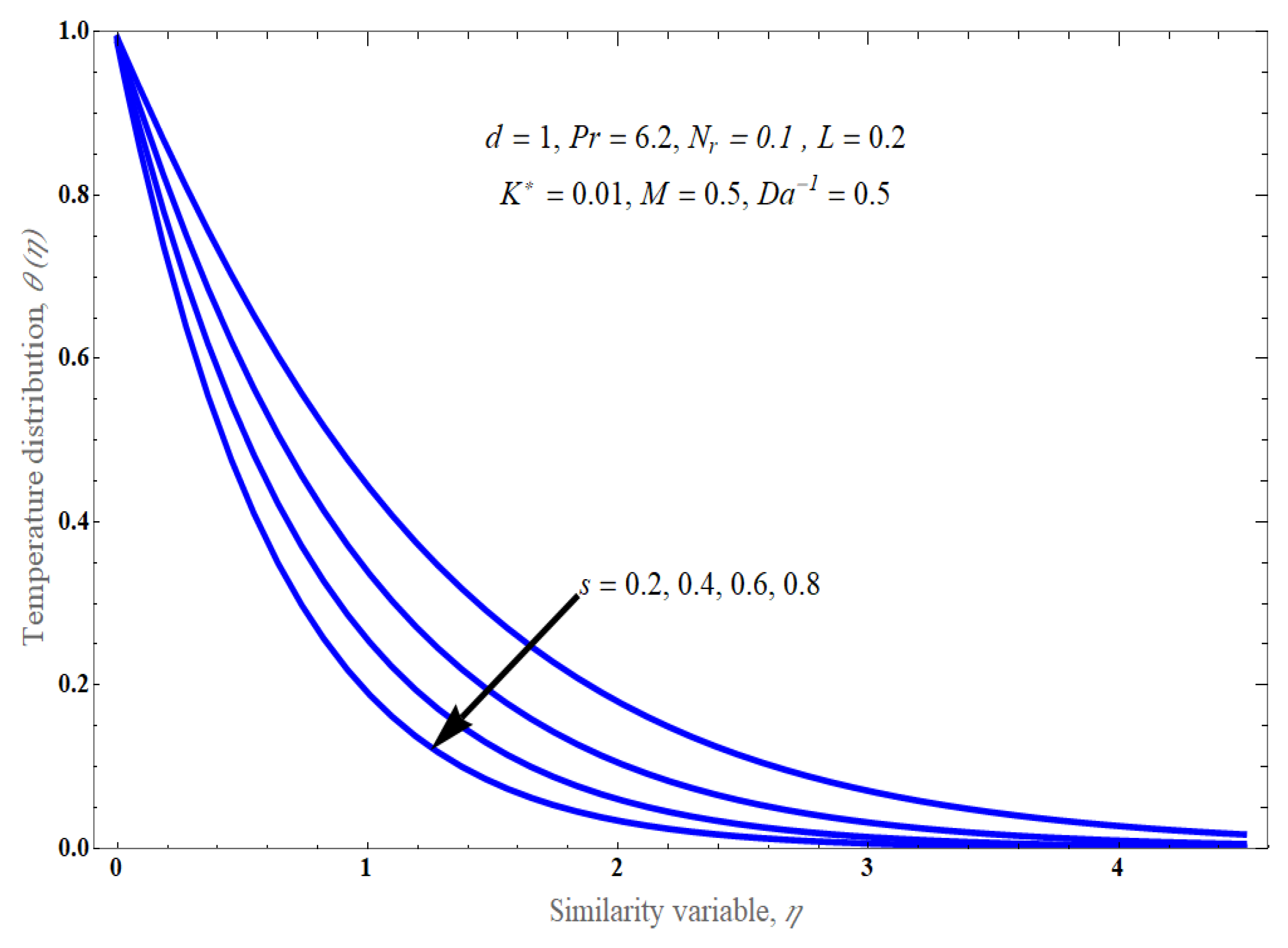

- As the coefficient of temperature increases, the temperature profile decreases.

- The increased radiation improves heat transfer when the thermal BL increases.

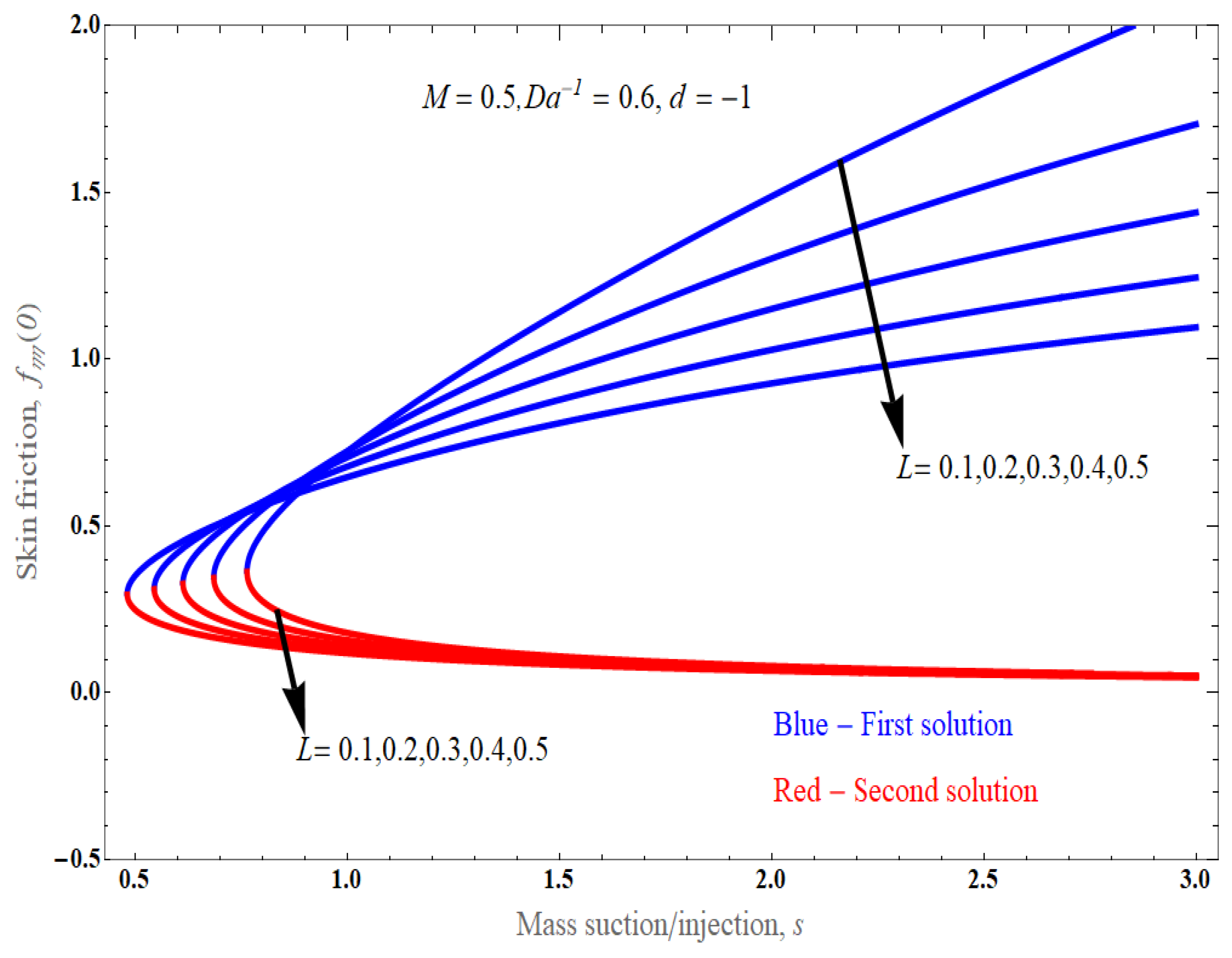

- A dual solution exists for shrinking cases only.

- As velocity slip increases in magnitude, the skin friction profile diminishes, while the opposite effect occurs in the Nusselt number profile.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Symbols | |

| Constants (-) | |

| Magnetic flux (Tesla) | |

| Stretching/shrinking parameter (-) | |

| Inverse Darcy number (-) | |

| Permeability () | |

| Temperature increase (K) | |

| Mean absorption | |

| First-order slip (-) | |

| Velocity slip (-) | |

| Magnetic field (-) | |

| Radiation (-) | |

| Prandtl number (-) | |

| Radiative heat flux | |

| Mass suction/injection (-) | |

| Fluid temperature | |

| Wall temperature | |

| Far temperature | |

| Velocity components | |

| Horizontal axis (-) | |

| Vertical axis (-) | |

| Greek symbols | |

| Density () | |

| Heat capacitance () | |

| Electrical conductivity (S/m) | |

| Thermal conductivity () | |

| Kinematic viscosity () | |

| Similarity variable (-) | |

| Similarity variable (-) | |

| Constants (-) | |

| Stefan–Boltzmann constant (-) | |

| Subscripts | |

| Nanofluid (-) | |

| Hybrid nanofluid (-) | |

| Abbreviations | |

| MHD | Magnetohydrodynamic |

| ODEs | Ordinary differential equations |

| PDEs | Partial differential equations |

| BL | Boundary layer |

References

- Choi, S.U.S. Enhancing thermal conductivity of fluids with nanoparticles, Development and Applications of Non-Newtonian flows. J. Heat Transf. 1995, 66, 99–105. [Google Scholar]

- Crane, L.J. Flow past a stretching plate. Z. Angew. Math. Phys. 1970, 21, 645–647. [Google Scholar] [CrossRef]

- Hayat, T.; Nadeem, S. Heat transfer enhancement with Ag–CuO/water hybrid nanofluid. Results Phys. 2017, 7, 2317–2324. [Google Scholar] [CrossRef]

- Sun, B.; Guo, Y.; Yang, D.; Li, H. The effect of constant magnetic field on convective heat transfer of Fe3O4/water magnetic nanofluid in horizontal circular tubes. Appl. Term. Eng. 2020, 171, 114920. [Google Scholar] [CrossRef]

- Yarmand, H.; Gharehkhani, S.; Ahmadi, G.; Shirazi, S.F.S.; Baradaran, S.; Zubir, M.N.M.; Alehashem, M.S.; Dahari, M. Graphene nanoplatelets-silver hybrid nanofluids for enhanced heat transfer. Energy Conv. Manag. 2015, 100, 419–428. [Google Scholar] [CrossRef]

- Waini, I.; Ishak, A.; Pop, I. Hybrid nanofluid flow and heat transfer past a permeable stretching/shrinking surface with a convective boundary condition. J. Phys Conf. Ser. 2019, 1366, 012022. [Google Scholar] [CrossRef]

- Mahabaleshwar, U.S.; Anusha, T.; Hatami, M. The MHD Newtonian hybrid nanofluid flow and mass transfer analysis due to super-linear stretching sheet embedded in porous medium. Sci. Rep. 2021, 11, 22518. [Google Scholar] [CrossRef] [PubMed]

- Sneha, K.N.; Mahabaleshwar, U.S.; Bhattacharyya, S. An effect of thermal radiation on inclined MHD flow in hybrid nanofluid over a stretching/shrinking sheet. J. Therm. Anal. Calorim. 2023, 148, 2961–2975. [Google Scholar] [CrossRef]

- Zainal, N.A.; Nazar, R.; Naganthran, K.; Pop, I. Stability analysis of MHD hybrid nanofluid flow over a stretching/shrinking sheet with quadratic velocity. Alex. Eng. J. 2021, 60, 915–926. [Google Scholar] [CrossRef]

- Devi, S.P.A.; Devi, S.S.U. Numerical investigation of hydromagnetic hybrid Cu—Al2O3/water nanofluid flow over a permeable stretching sheet with suction. Int. J. Nonlinear Sci. Numer. Simul. 2016, 17, 249–257. [Google Scholar] [CrossRef]

- Tripathi, J.; Vasu, B.; Beg, O.A.; Gorla, R.S.R. Unsteady hybrid nanoparticle—Mediated magneto—Hemodynamics and heat transfer through an overlapped stenotic artery: Biomedical drug delivery simulation. Proc. Inst. Mech. Eng. Part H 2021, 235, 1175–1196. [Google Scholar] [CrossRef] [PubMed]

- Asghar, A.; Ying, T.Y. Three dimensional MHD hybrid nanofluid flow with rotating stretching/shrinking sheet and joule heating. CFD Lett. 2021, 13, 1–19. [Google Scholar]

- Mahabaleshwar, U.S.; Vishalakshi, A.B.; Anderson, H.I. Hybrid nanofluid flow past a stretching/shrinking sheet with thermal radiation and mass transpiration. Chin. J. Phys. 2022, 75, 152–168. [Google Scholar] [CrossRef]

- Reddy, P.S.; Sreedevi, P.; Chamkha, A.J. Hybrid nanofluid heat and mass transfer characteristics over a stretching/shrinking sheet with slip effects. J. Nanofluids 2023, 12, 251–260. [Google Scholar] [CrossRef]

- Tulu, A.; Ibrahim, W. Mixed convection hybrid nanofluids flow of MWCNTs-Al2O3/engine oil over a spinning cone with variable viscosity and thermal conductivity. Heat Transf. 2021, 50, 3776–3799. [Google Scholar] [CrossRef]

- Rosca, N.C.; Rosca, A.V.; Aly, E.H.; Pop, I. Flow and heat transfer past a stretching/shrinking sheet using modified Buongiorno nanoliquid model. Mathematics 2021, 9, 3047. [Google Scholar] [CrossRef]

- Bakar, S.A.; Arifin, N.M.; Bachok, N.; Ali, F.M. Effect of thermal radiation and MHD on hybrid Ag—TiO2/H2O nanofluid past a permeable porous medium with heat generation. Case Stud. Therm. Eng. 2021, 28, 101681. [Google Scholar] [CrossRef]

- Gul, H.; Ramzan, M.; Chung, J.D.; Chu, Y.M.; Kadry, S. Multiple slips impact in the MHD hybrid nanofluid flow with Cattaneo-Christov heat flux and autocatalytic chemical reaction. Sci. Rep. 2021, 11, 14625. [Google Scholar] [CrossRef]

- Jiang, X.; Hatami, M.; Abderrahmane, A.; Younis, O.; Makhdoum, M.B.; Guedri, K. Mixed convection heat transfer and entropy generation of MHD hybrid nanofluid in a cubic porous cavity with wavy wall and rotating cylinders. Appl. Therm. Eng. 2023, 226, 120302. [Google Scholar] [CrossRef]

- Tulu, A. Numerical analysis of magnetohydrodynamic and dissipated hybrid casson nanofluid flow over an unsteady stretchable rotating disk with Cattaneo-Christov heat flux model. J. Nanofluids 2023, 12, 1748–1760. [Google Scholar] [CrossRef]

- Tulu, A.; Ibrahim, W. Effects of second-order slip flow and variable viscosity on natural convection flow of (CNTs-Fe3O4)/water hybrid nanofluids due to stretching surface. Math. Probl. Eng. 2021, 6, 8407194. [Google Scholar]

- Kumar, T.S. Hybrid nanofluid slip flow and heat transfer over a stretching surface. Partial. Differ. Equ. Appl. Math. 2021, 4, 100070. [Google Scholar] [CrossRef]

- Das, K.; Acharya, N.; Tausif, S.K.M.; Duari, P.R.; Chakraborty, T. Slip flow of hybrid nanofluid in presence of solar radiation. Int. J. Mod. Phys. C 2022, 33, 2250017. [Google Scholar] [CrossRef]

- Mohamed, M.K.A.; Ong, H.R.; Alkasasbeh, H.T.; Salleh, M.Z. Heat transfer of Ag-Al2O3/ water hybrid nanofluid on a stagnation point flow over a stretching sheet with Newtonian heating. J. Phys. Conf. Ser. 2020, 1529, 042085. [Google Scholar] [CrossRef]

- Dinarvand, S.; Yousefi, M.; Chamkha, A.J. Numerical simulation of unsteady flow towards a stretching/shrinking sheet in a porous medium filled with hybrid nanofluid. J. Appl. Comput. Mech. 2022, 8, 11–20. [Google Scholar]

- Prakash, O.; Rao, P.S.; Sharma, R.P.; Mishra, S.R. Hybrid nanofluid MHD motion towards an exponentially stretching/shrinking sheet with the effect of thermal radiation, heat source and viscous dissipation. Pramana 2023, 64, 97. [Google Scholar] [CrossRef]

- Turkyilmazoglu, M. Exact analytical solutions for heat and mass transfer of MHD slip flow in nanofluids. Chem. Eng. Sci. 2021, 84, 182–187. [Google Scholar] [CrossRef]

- Abel, M.S.; Shambajee, N.R.S. Effects of velocity and solutal slip boundary conditions on the flow and heat transfer of nanofluids past a linear stretching sheet with prescribed constant wall temperature. Int. J. Emerg. Technol. 2016, 7, 393–403. [Google Scholar]

- Shobha, K.C.; Mallikarjun, B.P. Effect of non-linear thermal radiation on flow of Williamson nanofluid in a vertical porous channel with heat source or sink by using Adomian decomposition method. J. Nanofluids 2022, 11, 39–47. [Google Scholar] [CrossRef]

- Mahabaleshwar, U.S.; Maranna, T.; Perez, L.M.; Bognar, G.V.; Oztop, H.F. An impact of radiation on laminar flow of dusty ternary nanofluid over porous stretching/shrinking sheet with mass transpiration. Results Eng. 2023, 18, 101227. [Google Scholar] [CrossRef]

- Maranna, T.; Mahabaleshwar, U.S.; Ravichandra Nayakar, S.N.; Sarris, I.E.; Souayeh, B. An influence of radiation and magnetohydrodynamic flow of hybrid nanofluid past a stretching/shrinking sheet with mass transpiration. ZAMM Z. Fur Angew. Math. Mech. 2023, 103, e202300140. [Google Scholar] [CrossRef]

- Suneetha, K.; Ibrahim, S.M.; Kumar, P.V.; Jyothsna, K. Linear thermal radiation effects on MHD viscoelastic fluid flow through porous moving plate with first order chemical reaction, variable temperature and concentration. J. Comput. Appl. Res. Mech. Eng. 2021, 10, 496–509. [Google Scholar]

- Tulu, A.; Asefa, L.; Sohail, M. Unsteady magnetohydrodynamic hybrid nanofluid flow over a rotating disk with viscous dissipation and Cattaneo-Christov heat flux model. Int. J. Thermofluids 2024, 21, 100586. [Google Scholar] [CrossRef]

- Khashi’ie, N.S.; Arifin, N.M.; Pop, I. Unsteady axisymmetric radiative Cu-Al2O3 flow over a radially stretching/shrinking surface. Chin. J. Phys. 2022, 78, 169–179. [Google Scholar] [CrossRef]

- Zainodin, S.; Jamaludin, A.; Nazar, R.; Pop, I. MHD mixed convection of hybrid ferrofluid flow over an exponentially stretching/shrinking surface with heat source/sink and velocity slip. Mathematics 2022, 10, 4400. [Google Scholar] [CrossRef]

| Characteristics | Hnfs |

|---|---|

| Density | |

| Heat capacity | |

| Dynamic viscosity | |

| Thermalconductivity | |

| Electricalconductivity | where |

| Nanoparticle/Base Fluid | ||||

|---|---|---|---|---|

| Water | 997.1 | 0.613 | 4179 | 0.05 |

| Aluminium oxide | 3970 | 765 | 40 | 1 × 10−10 |

| Ferrofluid | 5180 | 9.7 | 650 | 0.74 × 10−10 |

| Related Studies by Other Authors | Fluids | Value of |

|---|---|---|

| Turkyilmazoglu et al. [28] | Non-Newtonian | |

| Present problem | Non-Newtonian |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maranna, T.; Sachin, G.M.; Mahabaleshwar, U.S.; Pérez, L.M.; Shevchuk, I.V. Impact of Navier’s Slip and MHD on a Hybrid Nanofluid Flow over a Porous Stretching/Shrinking Sheet with Heat Transfer. Fluids 2024, 9, 180. https://doi.org/10.3390/fluids9080180

Maranna T, Sachin GM, Mahabaleshwar US, Pérez LM, Shevchuk IV. Impact of Navier’s Slip and MHD on a Hybrid Nanofluid Flow over a Porous Stretching/Shrinking Sheet with Heat Transfer. Fluids. 2024; 9(8):180. https://doi.org/10.3390/fluids9080180

Chicago/Turabian StyleMaranna, Thippaiah, Gadhigeppa Myacher Sachin, Ulavathi Shettar Mahabaleshwar, Laura M. Pérez, and Igor V. Shevchuk. 2024. "Impact of Navier’s Slip and MHD on a Hybrid Nanofluid Flow over a Porous Stretching/Shrinking Sheet with Heat Transfer" Fluids 9, no. 8: 180. https://doi.org/10.3390/fluids9080180

APA StyleMaranna, T., Sachin, G. M., Mahabaleshwar, U. S., Pérez, L. M., & Shevchuk, I. V. (2024). Impact of Navier’s Slip and MHD on a Hybrid Nanofluid Flow over a Porous Stretching/Shrinking Sheet with Heat Transfer. Fluids, 9(8), 180. https://doi.org/10.3390/fluids9080180