From Waste Plastics to Carbon Nanotube Audio Cables

Abstract

:1. Introduction

2. Experimental Section

2.1. Carbon Nanotube Production

2.2. CNT Characterization

2.3. CNT/Cu Audio Cable

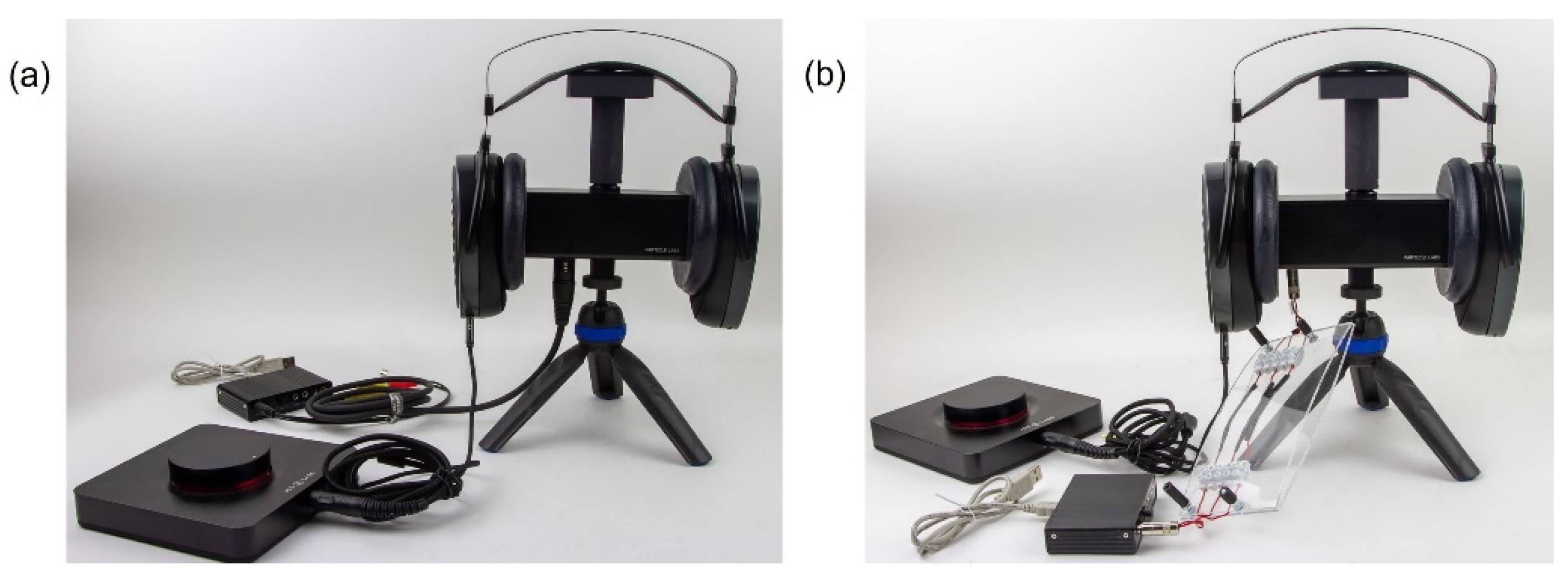

2.4. CNT/Cu Audio Cable Performance Testing

3. Results and Discussion

3.1. CNT Characterization

3.2. CNT/Cu Cable as Headphone Cable

3.3. CNT/Cu Cable as Microphone Cable

4. Conclusions

5. Patents

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Smalley, R.E. Future Global Energy Prosperity: The Terawatt Challenge. MRS Bull. 2005, 67, 412–417. [Google Scholar] [CrossRef] [Green Version]

- Peng, J.; He, Y.; Zhou, C.; Su, S.; Lai, B. The carbon nanotubes-based materials and their applications for organic pollutant removal: A critical review. Chin. Chem. Lett. 2021, 32, 1626–1636. [Google Scholar] [CrossRef]

- Prajapati, S.K.; Malaiya, A.; Kesharwani, P.; Soni, D.; Jain, A. Biomedical applications and toxicities of carbon nanotubes. Drug Chem. Toxicol. 2020, 2020. [Google Scholar] [CrossRef]

- Anzar, N.; Hasan, R.; Tyagi, M.; Yadav, N.; Narang, J. Carbon nanotube—A review on synthesis, properties and plethora of applications in the field of biomedical science. Sens. Int. 2020, 1, 100003. [Google Scholar] [CrossRef]

- Jain, N.; Gupta, E.; Kanu, N.J. Plethora of carbon nanotubes applications in various fields—A state-of-the-art-review. Smart Sci. 2021, 2021. [Google Scholar] [CrossRef]

- Jarosz, P.; Schauerman, C.; Alvarenga, J.; Moses, B.; Mastrangelo, T.; Raffaelle, R.; Ridgley, R.; Landi, B. Carbon nanotube wires and cables: Near-term applications and future. Nanoscale 2011, 3, 4542–4553. [Google Scholar] [CrossRef] [PubMed]

- Bulmer, J.S.; Kaniyoor, A.; Elliott, J.A. A meta-analysis of conductive and strong carbon nanotube materials. Adv. Mater. 2021, 33, 2008432. [Google Scholar] [CrossRef]

- Hjortstam, O.; Isberg, P.; Soderholm, S.; Dai, H. Can we achieve ultra-low resistivity in carbon nanotube-based metal composites? Appl. Phys. A Mater. Sci. Process. 2004, 78, 1175–1179. [Google Scholar] [CrossRef]

- Gangoli, V.S.; Barnett, C.J.; McGettrick, J.D.; Orbaek White, A.; Barron, A.R. Increased Electrical Conductivity of Carbon Nanotube Fibers by Thermal and Voltage Annealing. C 2022, 8, 1. [Google Scholar] [CrossRef]

- Janas, D.; Liszka, B. Copper matrix nanocomposites based on carbon nanotubes or graphene. Mater. Chem. Front. 2018, 2, 22–35. [Google Scholar] [CrossRef]

- Jordan, M.B.; Feng, Y.; Burkett, S.L. Development of seed layer for electrodeposition of copper on carbon nanotube bundles. J. Vac. Sci. Technol. B Nanotechnol. Microelectron. 2015, 33, 02120201–02120208. [Google Scholar] [CrossRef]

- Subramaniam, C.; Sekiguchi, A.; Yamada, T.; Futaba, D.N.; Hata, K. Nano-scale, planar and multi-tiered current pathways from a carbon nanotube–copper composite with high conductivity, ampacity and stability. Nanoscale 2016, 8, 3888–3894. [Google Scholar] [CrossRef] [PubMed]

- Kang, C.S.; Lee, I.J.; Seo, M.S.; Kim, S.H.; Baik, D.H. Effect of purification method on the electrical properties of the carbon nanotube fibers. Fibers Polym. 2017, 18, 1580–1585. [Google Scholar] [CrossRef]

- Gangoli, V.S.; Godwin, M.A.; Joshi, S.S.; Allanavar, A.B.; Reddy, G.; Bradley, R.K.; Barron, A.R. The state of HiPco single-walled carbon nanotubes in 2019. C 2019, 5, 65. [Google Scholar] [CrossRef] [Green Version]

- Barnett, C.J.; McGettrick, J.D.; Gangoli, V.S.; Kazimierska, E.; Orbaek White, A.; Barron, A.R. Effect of applied pressure on the electrical resistance of carbon nanotube fibres. Materials 2021, 14, 2106. [Google Scholar] [CrossRef]

- Orbaek White, A.; Hedayati, A.; Yick, T.; Gangoli, V.S.; Niu, Y.; Lethbridge, S.; Tsampanakis, I.; Swan, G.; Pointeaux, L.; Crane, A.; et al. On the Use of Carbon Cables from Plastic Solvent Combinations of Polystyrene and Toluene in Carbon Nanotube Synthesis. Nanomaterials 2022, 12, 9. [Google Scholar] [CrossRef]

- Hedayati, A.; Barnett, C.; Swan, G.; Orbaek White, A. Chemical Recycling of Consumer-Grade Black Plastic into Electrically Conductive Carbon Nanotubes. C 2019, 5, 32. [Google Scholar] [CrossRef] [Green Version]

- Hai-feng, L.I. Frequency Response Simulation of IEC711 Coupler. Audio Eng. 2009, 2009. [Google Scholar]

- Gangoli, V.S.; Raja, P.M.V.; Esquenazi, G.L.; Barron, A.R. The safe handling of bulk low-density nanomaterials. SN Appl. Sci. 2019, 1, 644. [Google Scholar] [CrossRef] [Green Version]

- Rueden, C.T.; Schindelin, J.; Hiner, M.C.; DeZonia, B.E.; Walter, A.E.; Arena, E.T.; Eliceiri, K.W. ImageJ2: ImageJ for the next Generation of Scientific Image Data. BMC Bioinform. 2017, 18, 1–26. [Google Scholar] [CrossRef]

- Bach through Nanotubes—Music Played using a Carbon Cables by Dr Alvin Orbaek White. Available online: https://youtu.be/3dXl2W4NjOk (accessed on 19 December 2021).

- Dresselhaus, M. Raman spectroscopy of carbon nanotubes. Phys. Rep. 2005, 409, 47–99. [Google Scholar] [CrossRef]

- Zhang, K.S.; Pham, D.; Lawal, O.; Ghosh, S.; Gangoli, V.S.; Smalley, P.; Kennedy, K.; Brinson, B.; Billups, W.E.; Hauge, R.; et al. Overcoming catalyst residue inhibition of the functionalization of single-walled carbon nanotubes via the Billups-Birch reduction. ACS Appl. Mater. Interfaces 2017, 9, 37972–37980. [Google Scholar] [CrossRef] [PubMed] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gangoli, V.S.; Yick, T.; Bian, F.; Orbaek White, A. From Waste Plastics to Carbon Nanotube Audio Cables. C 2022, 8, 9. https://doi.org/10.3390/c8010009

Gangoli VS, Yick T, Bian F, Orbaek White A. From Waste Plastics to Carbon Nanotube Audio Cables. C. 2022; 8(1):9. https://doi.org/10.3390/c8010009

Chicago/Turabian StyleGangoli, Varun Shenoy, Tim Yick, Fang Bian, and Alvin Orbaek White. 2022. "From Waste Plastics to Carbon Nanotube Audio Cables" C 8, no. 1: 9. https://doi.org/10.3390/c8010009

APA StyleGangoli, V. S., Yick, T., Bian, F., & Orbaek White, A. (2022). From Waste Plastics to Carbon Nanotube Audio Cables. C, 8(1), 9. https://doi.org/10.3390/c8010009