Effect of Multi-Walled Carbon Nanotubes on the Mechanical and Thermal Properties of Curauá Natural-Fiber-Reinforced Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Specimen Preparation

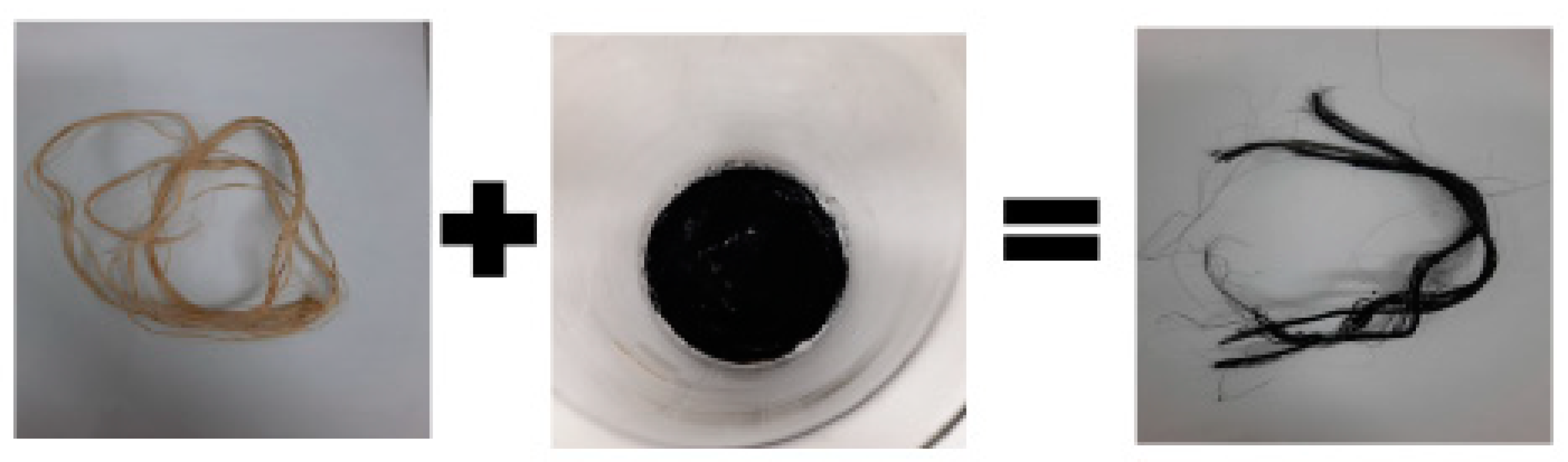

2.2.1. MWCNT-Coated Natural Fibers

2.2.2. MWCNT-Modified Composites

2.3. Test Methods

2.3.1. Fourier-Transform Infrared Spectroscopy (FTIR)

2.3.2. Single Fiber Test

2.3.3. Tensile and Flexural Tests

2.3.4. Thermogravimetric Analysis (TGA)

2.4. SEM Analysis

3. Results and Discussion

3.1. Mechanical and Thermal Properties of Fibers

3.1.1. FTIR

- At 3379 cm−1, there is a band corresponding to the elongation of OH groups found in cellulose and water;

- The band at 2916 cm−1 is attributed to the symmetrical and asymmetrical stretching of the aliphatic chain (C–H);

- At 1736 cm−1, there is a band corresponding to the elongation vibration of the carbonyl group (C=O);

- At 1430 cm−1, there is a band is associated with the aliphatic C–H vibration;

- At 1110 cm−1, there is an absorption band attributed to the elongation vibration of the ether groups [22];

- Other bands corresponding to the existence of a high content of oxygen functional groups on the MWCNT surface, such as (–C–O–C) groups like structural oxides and oxygen bridges, to name a few, are evident in the multiwall carbon nanotube FTIR transmission spectra [23].

3.1.2. Thermal Properties of Fibers

3.1.3. Single Fiber Test

3.2. Mechanical and Thermal Properties of Composites

3.2.1. Thermal Properties

3.2.2. Mechanical Properties

Tensile Test

Flexural Test

4. SEM Analysis

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Neto, J.; Queiroz, H.; Aguiar, R.; Lima, R.; Cavalcanti, D.; Banea, M.D. A Review of Recent Advances in Hybrid Natural Fiber Reinforced Polymer Composites. J. Renew. Mater. 2022, 10, 561–589. [Google Scholar] [CrossRef]

- Fitzgerald, A.; Proud, W.; Kandemir, A.; Murphy, R.J.; Jesson, D.A.; Trask, R.S.; Hamerton, I.; Longana, M.L. A life cycle engineering perspective on biocomposites as a solution for a sustainable recovery. Sustainability 2021, 13, 1160. [Google Scholar] [CrossRef]

- Jagadeesh, P.; Puttegowda, M.; Rangappa, S.M.; Siengchin, S. A review on extraction, chemical treatment, characterization of natural fibers and its composites for potential applications. Polym. Compos. 2021, 42, 6239–6264. [Google Scholar] [CrossRef]

- de Queiroz, H.F.M.; Banea, M.D.; Cavalcanti, D.K.K. Experimental analysis of adhesively bonded joints in synthetic- and natural fibre-reinforced polymer composites. J. Compos. Mater. 2019, 54, 1245–1255. [Google Scholar] [CrossRef]

- Banea, M.D.; Neto, J.S.S.; Cavalcanti, D.K.K. Recent Trends in Surface Modification of Natural Fibres for Their Use in Green Composites. In Green Composites; Thomas, S., Balakrishnan, P., Eds.; Springer: Singapore, 2021; pp. 329–350. [Google Scholar] [CrossRef]

- de Seixas, G.B.; de Queiroz, H.F.M.; Neto, J.S.S.; Banea, M.D. Effect of water on the mechanical and thermal properties of natural fibre reinforced hybrid composites. J. Compos. Mater. 2023, 57, 1941–1958. [Google Scholar] [CrossRef]

- Karger-Kocsis, J.; Mahmood, H.; Pegoretti, A. Recent advances in fiber/matrix interphase engineering for polymer composites. Prog. Mater. Sci. 2015, 73, 1–43. [Google Scholar] [CrossRef]

- Mohd Nurazzi, N.; Asyraf, M.M.; Khalina, A.; Abdullah, N.; Sabaruddin, F.A.; Kamarudin, S.H.; Ahmad, S.b.; Mahat, A.M.; Lee, C.L.; Aisyah, H. Fabrication, functionalization, and application of carbon nanotube-reinforced polymer composite: An overview. Polymers 2021, 13, 1047. [Google Scholar] [CrossRef]

- Prasad, V.; Sekar, K.; Joseph, M.A. Mechanical and water absorption properties of nano TiO2 coated flax fibre epoxy composites. Constr. Build. Mater. 2021, 284, 122803. [Google Scholar] [CrossRef]

- Fernandes Medeiros de Queiroz, H.; Banea, M.D.; Kioshi Kawasaki Cavalcanti, D.; de Souza e Silva Neto, J. The effect of multiscale hybridization on the mechanical properties of natural fiber-reinforced composites. J. Appl. Polym. Sci. 2021, 138, 51213. [Google Scholar] [CrossRef]

- Neto, J.S.S.; de Queiroz, H.F.M.; Cavalcanti, D.K.K.; Aguiar, R.A.A.; Pereira, A.B.; Banea, M.D. Effect of ultraviolet radiation and water spraying on the mechanical properties of multi-walled carbon nanotubes reinforced natural fiber and hybrid composites. J. Appl. Polym. Sci. 2022, 139, 51915. [Google Scholar] [CrossRef]

- Huang, S.; Fu, Q.; Yan, L.; Kasal, B. Characterization of interfacial properties between fibre and polymer matrix in composite materials–A critical review. J. Mater. Res. Technol. 2021, 13, 1441–1484. [Google Scholar] [CrossRef]

- Singh, N.P.; Gupta, V.; Singh, A.P. Graphene and carbon nanotube reinforced epoxy nanocomposites: A review. Polymer 2019, 180, 121724. [Google Scholar] [CrossRef]

- Lin, W.; Wang, Y.; Yousefpour, K.; Park, C.; Kumar, V. Evaluating the Lightning Strike Damage Tolerance for CFRP Composite Laminates Containing Conductive Nanofillers. Appl. Compos. Mater. 2022, 29, 1537–1554. [Google Scholar] [CrossRef]

- Godara, A.; Gorbatikh, L.; Kalinka, G.; Warrier, A.; Rochez, O.; Mezzo, L.; Luizi, F.; Van Vuure, A.W.; Lomov, S.V.; Verpoest, I. Interfacial shear strength of a glass fiber/epoxy bonding in composites modified with carbon nanotubes. Compos. Sci. Technol. 2010, 70, 1346–1352. [Google Scholar] [CrossRef]

- Zhao, Z.; Teng, K.; Li, N.; Li, X.; Xu, Z.; Chen, L.; Niu, J.; Fu, H.; Zhao, L.; Liu, Y. Mechanical, thermal and interfacial performances of carbon fiber reinforced composites flavored by carbon nanotube in matrix/interface. Compos. Struct. 2017, 159, 761–772. [Google Scholar] [CrossRef]

- Pulikkalparambil, H.; Saravana Kumar, M.; Babu, A.; Ayyappan, V.; Tengsuthiwat, J.; Rangappa, S.M.; Siengchin, S. Effect of graphite fillers on woven bamboo fiber-reinforced epoxy hybrid composites for semistructural applications: Fabrication and characterization. Biomass Convers. Biorefin. 2023, 1–17. [Google Scholar] [CrossRef]

- Anna Dilfi, K.F.; Che, Z.; Xian, G. Grafting ramie fiber with carbon nanotube and its effect on the mechanical and interfacial properties of ramie/epoxy composites. J. Nat. Fibers 2019, 16, 388–403. [Google Scholar] [CrossRef]

- Prabhudass, J.M.; Palanikumar, K.; Natarajan, E.; Markandan, K. Enhanced Thermal Stability, Mechanical Properties and Structural Integrity of MWCNT Filled Bamboo/Kenaf Hybrid Polymer Nanocomposites. Materials 2022, 15, 506. [Google Scholar] [CrossRef]

- Neto, J.S.S.; Banea, M.D.; Cavalcanti, D.K.K.; Queiroz, H.F.M.; Aguiar, R.A.A. Analysis of mechanical and thermal properties of epoxy multiwalled carbon nanocomposites. J. Compos. Mater. 2020, 54, 4831–4840. [Google Scholar] [CrossRef]

- de Freitas, A.E.; Padilha, F.d.J.; Barros, S.d.S.; Khan, T.M.; Pereira, B.; Barbosa, W.T.; Barbosa, J.D.; Calderaro, F.L.; da Silva, S.; Quirino, M.G. Curauá fiber from plants produced by tissue culture: Thermal, mechanical, and morphological characterizations. Cellulose 2023, 30, 2841–2858. [Google Scholar] [CrossRef]

- Costa, U.O.; Nascimento, L.F.C.; Garcia, J.M.; Monteiro, S.N.; Luz, F.S.d.; Pinheiro, W.A.; Garcia Filho, F.d.C. Effect of graphene oxide coating on natural fiber composite for multilayered ballistic armor. Polymers 2019, 11, 1356. [Google Scholar] [CrossRef]

- Stobinski, L.; Lesiak, B.; Kövér, L.; Tóth, J.; Biniak, S.; Trykowski, G.; Judek, J. Multiwall carbon nanotubes purification and oxidation by nitric acid studied by the FTIR and electron spectroscopy methods. J. Alloys Compd. 2010, 501, 77–84. [Google Scholar] [CrossRef]

- Neto, J.S.S.; de Queiroz, H.F.M.; Aguiar, R.A.A.; Banea, M.D. A Review on the Thermal Characterisation of Natural and Hybrid Fiber Composites. Polymers 2021, 13, 4425. [Google Scholar] [CrossRef]

- Martel, W.d.N.D.R.; Salgado, I.P.; Silva, F.A. The Influence of Fiber Treatment on the Morphology, Water Absorption Capacity and Mechanical Behavior of Curauá Fibers. J. Nat. Fibers 2022, 19, 642–657. [Google Scholar] [CrossRef]

- Neves, R.M.; Lopes, K.S.; Zimmermann, M.V.G.; Poletto, M.; Zattera, A.J. Characterization of polystyrene nanocomposites and expanded nanocomposites reinforced with cellulose nanofibers and nanocrystals. Cellulose 2019, 26, 4417–4429. [Google Scholar] [CrossRef]

- Latif, R.; Wakeel, S.; Zaman Khan, N.; Noor Siddiquee, A.; Lal Verma, S.; Akhtar Khan, Z. Surface treatments of plant fibers and their effects on mechanical properties of fiber-reinforced composites: A review. J. Reinf. Plast. Compos. 2018, 38, 15–30. [Google Scholar] [CrossRef]

- de Araujo Alves Lima, R.; Kawasaki Cavalcanti, D.; de Souza e Silva Neto, J.; Meneses da Costa, H.; Banea, M.D. Effect of surface treatments on interfacial properties of natural intralaminar hybrid composites. Polym. Compos. 2020, 41, 314–325. [Google Scholar] [CrossRef]

- Karimah, A.; Ridho, M.R.; Munawar, S.S.; Adi, D.S.; Ismadi; Damayanti, R.; Subiyanto, B.; Fatriasari, W.; Fudholi, A. A review on natural fibers for development of eco-friendly bio-composite: Characteristics, and utilizations. J. Mater. Res. Technol. 2021, 13, 2442–2458. [Google Scholar] [CrossRef]

- Jaiswal, D.; Devnani, G.L.; Rajeshkumar, G.; Sanjay, M.R.; Siengchin, S. Review on extraction, characterization, surface treatment and thermal degradation analysis of new cellulosic fibers as sustainable reinforcement in polymer composites. Curr. Res. Green Sustain. Chem. 2022, 5, 100271. [Google Scholar] [CrossRef]

- Wang, X.; Wang, Z.; Wang, L.; Hong, K.; Wei, L.; Wang, H.; Yuan, Z.; Zhao, D.; Li, Z. Mechanical and thermal properties of epoxy nanocomposites interfacial modified with styrene–butadiene–styrene grafted multi-walled carbon nanotubes. Polym. Compos. 2018, 39, E996–E1004. [Google Scholar] [CrossRef]

- Radue, M.S.; Odegard, G.M. Multiscale modeling of carbon fiber/carbon nanotube/epoxy hybrid composites: Comparison of epoxy matrices. Compos. Sci. Technol. 2018, 166, 20–26. [Google Scholar] [CrossRef]

- Hassanzadeh-Aghdam, M.-K.; Ansari, R.; Darvizeh, A. Multi-stage micromechanical modeling of effective elastic properties of carbon fiber/carbon nanotube-reinforced polymer hybrid composites. Mech. Adv. Mater. Struct. 2019, 26, 2047–2061. [Google Scholar] [CrossRef]

- Wu, Z.; Zhao, Y.; Yang, K.; Guan, J.; Wang, S.; Gu, Y.; Li, M.; Feng, Y.; Feng, W.; Ritchie, R.O. Enhancing the Mechanical Performance of Fiber-Reinforced Polymer Composites Using Carbon Nanotubes as an Effective Nano-Phase Reinforcement. Adv. Mater. Interfaces 2023, 10, 2201935. [Google Scholar] [CrossRef]

- Li, Y.; Chen, C.; Xu, J.; Zhang, Z.; Yuan, B.; Huang, X. Improved mechanical properties of carbon nanotubes-coated flax fiber reinforced composites. J. Mater. Sci. 2015, 50, 1117–1128. [Google Scholar] [CrossRef]

- Kavimani, V.; Gopal, P.M.; Sumesh, K.R.; Elanchezhian, R. Improvement on mechanical and flame retardancy behaviour of bio-exfoliated graphene-filled epoxy/glass fibre composites using compression moulding approach. Polym. Bull. 2022, 79, 6289–6307. [Google Scholar] [CrossRef]

- Pichandi, S.; Rana, S.; Parveen, S.; Fangueiro, R. A green approach of improving interface and performance of plant fibre composites using microcrystalline cellulose. Carbohydr. Polym. 2018, 197, 137–146. [Google Scholar] [CrossRef]

- Sumesh, K.R.; Kanthavel, K. Effect of TiO2 nano-filler in mechanical and free vibration damping behavior of hybrid natural fiber composites. J. Braz. Soc. Mech. Sci. Eng. 2020, 42, 211. [Google Scholar] [CrossRef]

| Fiber | T(100°C) (%) | TIDT (°C) | TFDT (°C) | Residual Mass (%) | TDTG (°C) |

|---|---|---|---|---|---|

| Curauá | 4.22 | 313.1 | 359.8 | 0.04 | 344.8 |

| MWCNT-modified curauá | 2.96 | 331.1 | 369.5 | 15.2 | 356.3 |

| Composite | T(100°C) (%) | TIDT (°C) | TFDT (°C) | Residual Mass (%) | TDTG (°C) |

|---|---|---|---|---|---|

| Curauá | 1.04 | 304.3 | 369 | 11.26 | 338.6 |

| (Curauá + MWCNT) + resin | 0.46 | 331.1 | 388.6 | 14.43 | 362.2 |

| Curauá + (resin + MWCNT) | 0.96 | 326.8 | 389 | 17.50 | 355.8 |

| Composite | Tensile Strength (MPa) | Young’s Modulus (GPa) |

|---|---|---|

| Curauá | 44.23 ± 7.20 | 4.95 ± 0.51 |

| (Curauá + MWCNT) + resin | 80.62 ± 8.45 | 7.60 ± 1.06 |

| Curauá + (resin + MWCNT) | 52.59 ± 5.29 | 6.80 ± 0.97 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Neto, J.S.S.; Cavalcanti, D.K.K.; da Cunha Ferro, L.E.; de Queiroz, H.F.M.; Aguiar, R.A.A.; Banea, M.D. Effect of Multi-Walled Carbon Nanotubes on the Mechanical and Thermal Properties of Curauá Natural-Fiber-Reinforced Composites. C 2023, 9, 102. https://doi.org/10.3390/c9040102

Neto JSS, Cavalcanti DKK, da Cunha Ferro LE, de Queiroz HFM, Aguiar RAA, Banea MD. Effect of Multi-Walled Carbon Nanotubes on the Mechanical and Thermal Properties of Curauá Natural-Fiber-Reinforced Composites. C. 2023; 9(4):102. https://doi.org/10.3390/c9040102

Chicago/Turabian StyleNeto, Jorge S. S., Daniel K. K. Cavalcanti, Luiz E. da Cunha Ferro, Henrique F. M. de Queiroz, Ricardo A. A. Aguiar, and Mariana D. Banea. 2023. "Effect of Multi-Walled Carbon Nanotubes on the Mechanical and Thermal Properties of Curauá Natural-Fiber-Reinforced Composites" C 9, no. 4: 102. https://doi.org/10.3390/c9040102

APA StyleNeto, J. S. S., Cavalcanti, D. K. K., da Cunha Ferro, L. E., de Queiroz, H. F. M., Aguiar, R. A. A., & Banea, M. D. (2023). Effect of Multi-Walled Carbon Nanotubes on the Mechanical and Thermal Properties of Curauá Natural-Fiber-Reinforced Composites. C, 9(4), 102. https://doi.org/10.3390/c9040102