Abstract

The aroma-active compounds produced by Saccharomyces cerevisiae during the fermentation of wort are key to the unique aroma and flavour profiles of beer. In commercial fermentations, there is batch-to-batch variation depending on yeast “brewing fitness” or the health of the yeast, but how does yeast health impact fermentation performance and metabolite production during fermentation? To address this, daily samples were collected from three full-scale commercial fermentations. The specific gravity was measured immediately, and samples were collected for carbohydrate analysis by High-Performance Liquid Chromatography and volatile compound analysis by Head-Space Gas Chromatography Mass Spectrometry (HS-GC-MS). Acetate esters (3), medium-chain fatty acid ethyl esters (7), hop-derived compounds (3), and an off-flavour (1) were detected and identified, and their relative signal was recorded for each sample. While there did not appear to be an effect of generational age on the duration of fermentation, age, in terms of the number of generations from serial re-pitching, impacted the ratios of volatile compounds. This difference in ratios was observed as early as Day 2, resulting in a difference in the volatile compound profiles of finished beers, therefore resulting in inconsistency in the product. This is important knowledge for brewers as generational age must be considered when fermenting high-quality, consistent products and monitoring fermentation progress/duration may not be enough to determine the ability of yeast to produce balanced flavour profiles.

1. Introduction

Beer is produced by Saccharomyces cerevisiae (S. cerevisiae, brewer’s yeast) through the metabolism of the protein and carbohydrates in wort-producing ethanol, CO2, and a number of flavours and aromas [1,2,3]. These flavour- and aroma-active compounds are what make the sensory qualities of beer unique, both in their concentrations, but also in the proportions of the compounds due to the effects of the synergy of flavour and aroma compounds when in complex matrices [4]. These metabolites include organic acids, higher alcohols, carbonyl compounds, sulphur-containing compounds, phenolic compounds, and volatile esters [5,6,7,8,9,10,11,12]. In addition to strain selection, the physiological state of the yeast as a result of serial re-pitching [13,14,15,16,17] (inoculating successive fermentations with harvested yeast) and its generational age (how many fermentations it has been through) have a large impact on which flavours and aromas are produced, at what concentrations, and importantly, the overall balance and proportion of flavour compounds [18,19,20,21]. The physiological state, including intracellular carbohydrates, membrane integrity, surface characteristics, and generational age can be described as “brewing fitness”, or the yeast’s ability to ferment consistent, high-quality products.

Although volatile esters are at relatively low concentrations versus other metabolites, they are some of the most important of the yeast-derived aroma-active compounds and are responsible for the fruity character of beer. These volatile esters have very low thresholds of detection to humans. and yeast produces them at levels near these thresholds. Therefore, small changes in ester levels and proportions have large impacts on the quality and sensory experience of the final beer [7,22].

There are two major categories of aroma-active esters in beer: acetate esters and medium-chain fatty acid ethyl esters (MCFAEEs). The net concentration of these ester levels produced during fermentation is controlled by two factors: the availability of substrates and the activity of enzymes needed for biosynthesis and hydrolysis [6,9,23]; they are lipid-soluble, and as such, diffuse through the yeast plasma membrane and into the surrounding media, with varying degrees. For example, acetate esters can diffuse readily, while larger MCFAEEs decrease in diffusion with size (100% of ethyl hexanoate will diffuse versus 8–17% of ethyl decanoate) [7,9].

Acetate esters are a major flavour component in beer as they are found in higher concentrations than other volatile esters, in part due to their small size and lipophilic nature allowing them to readily diffuse into the extracellular medium (beer). Acetate esters are described as having flavour and aroma character including banana, tropical fruit, and fruity. Acetate esters are formed by the enzymatic condensation reaction between an acetate group attached to acetyl-CoA and a fusel alcohol. Although this may sound simple, the formation of fusel alcohols and associated acetate esters are the result of complex and intricate metabolic pathways that produce the desired balanced flavour and aroma profile [5,7,9,22].

Medium-chain fatty acids (MCFAs) and their associated esters are some of the main aroma-active compounds produced by yeast in beer although generally, S. cerevisiae produce low levels of MCFA esters [22,24]. An important type of MCFA esters in beer is MCFA ethyl esters (MCFAEEs), most notably the esters of C6–C10 fatty acids (ethyl hexanoate, ethyl octanoate, ethyl decanoate), which are described as having flavour and aroma characteristics including apple, anise, and apricot. These esters are produced by the condensation of C6-, C8-, and C10-acyl-CoA and ethanol, mediated by two acyl-CoA–ethanol O-acyl-transferases [24].

In addition to these desired flavours and aromas produced by yeast, beer may also contain undesirable compounds or off-flavours. One of these compounds is styrene, a compound that is the result of the enzymatic or non-enzymatic decarboxylation of cinnamic acid during wheat or barley fermentation and is described to have an aroma character of harsh plastic or chemical resin. Typically, this compound is derived from the wort and non-enzymatic reactions occurring during fermentation but can also be produced by enzymatic reactions as a result of yeast metabolism [25].

Although yeast is responsible for many important flavour and aroma compounds, hops are also a key ingredient in beer that provides important compounds. Hops contribute flavour and aroma to wort in the boil kettle and to the beer in dry hopping (the addition of hops during or after fermentation). These flavour and aroma compounds consist of terpenoids (α-humulene and β-myrcene) and various esters with branched-chain structures, including 3-methylbutyl isobutyrate. 3-methylbutyl isobutyrate can be unstable during the boil and therefore its contribution to beer is often a result of dry hopping [26].

The purpose of this paper is to evaluate fermentation progress and volatile compound profiles in commercial beer fermentation in order to better understand batch-to-batch variation and their potential causes in order to better control variation and enable brewers to produce consistent, high-quality products. Samples for carbohydrate analysis by High-Performance Liquid Chromatography and volatile metabolite analysis by Head-Space Gas Chromatography Mass Spectrometry (HS-GC-MS) were collected daily from three commercial fermentations. From our analyses, we concluded that generational age and serial-re-pitching were key contributing factors to the variations observed. This is a significant observation for brewers when considering how many re-pitches can be attempted from a single batch of yeast and the potential impacts on flavour profiles.

2. Materials and Methods

Daily samples were collected from three full-scale commercial fermentations using an English Ale strain of yeast at a commercial brewery (21st Street Brewery, Saskatoon, SK, Canada). Yeast was harvested from previous fermentations, with cell concentration counted, and re-pitched into successive fermentations. Generation refers to the number of fermentations the yeast had been through (G5 had been in 5 previous fermentations, Table 1). Lineage refers to generations originating from the same initial yeast slurry purchased and pitched as G0. Centrifuge tubes with 50 mL capacity were filled with 40 mL of sample and frozen at −80 °C until samples were thawed. Beer was analyzed for carbohydrates and metabolites. Yeast counts were measured by spectrophotometer at 600 nm and specific gravity (SG) was measured using a hydrometer.

Table 1.

Yeast generation, age, concentration, starting temperature, and original SG (OG) for batches SD1-3.

Carbohydrates were measured by HPLC using an Agilent 1100 Series HPLC (Santa Clara, CA, USA) with a CAPCELL PAK NH2 UG80 S5 4.6 mm ID × 250 mm column and a 1200 Series Quaternary Pump. No degasser was used for the eluent; instead, eluent was degassed by sonication for 5 min. Eluent was 70% acetonitrile (Fisher Sci, HPLC grade) in DI water with a flow rate of 1 mL/min. Software used was ChemStation Rev. B.04.01 (build number 481). Calibration was performed using five standards, limit of detection (LoD) was calculated by multiplying the baseline noise signal by 3×, and the limit of quantification was calculated by multiplying the baseline noise signal by 6×. Samples were thawed on ice and centrifuged at 4000 rpm for 15 min to remove yeast and other solids. Supernatant was then filtered through 0.2 µm nylon filters (Chromspec) into 1.5 mL glass autosampler vials. Samples were run as technical replicates with three 2 mL samples taken from the carbohydrate analysis subsample.

Volatile compounds were measured by Head-Space Gas Chromatography Mass Spectrometry (HS-GC-MS) at the Saskatchewan Structural Sciences Centre (SSSC) in 2022 and 2023. One of the frozen 50 mL centrifuge tubes was thawed on ice overnight and 5 mL was pipetted into a 15 mL glass vial; a rubber septum was clamped on. Samples were placed on a PerkinElmer TurboMatrix 40 trap autosampler where they were placed one at a time into an oven set to 80 °C and pressurized with helium gas to 40 psi. An amount of 100 mL of sample was injected into an HP-5Msi nonpolar column (30 m, 0.25 mm film, 0.25 ID) on an Agilent 7890A GC system and into a Jeol AccuTOF 4G GCV mass spectrometer. The first 1.5 min of sample from the column was discarded to protect the detector from ethanol damage. Data were processed using DataReduction software version 1.0.5.8. (Shrader Software Solutions, Grosse Pointe, MI, USA). Acetate esters (3), medium-chain fatty acid ethyl esters (5), other fatty acid esters (2), and hop-derived compounds (2) were detected and identified, and their relative signal was recorded for 51 beer samples. Sample volume limited analyses to one analysis per sample. Error bars represent the calculated instrument error for each analyte presented.

Data were plotted as signal intensity (a.u., arbitrary units) as no standards were used for this analysis. The intent was to identify compounds and capture trends and proportions of metabolites between batches rather than total concentrations. Signal was plotted versus day of fermentation to determine on which day compounds appeared in the beer and what trends were observed. In addition, to compare the relative abundance of yeast-derived metabolites in three batches, the signal of each compound was calculated as a percent of total yeast-derived compounds for each day.

3. Results

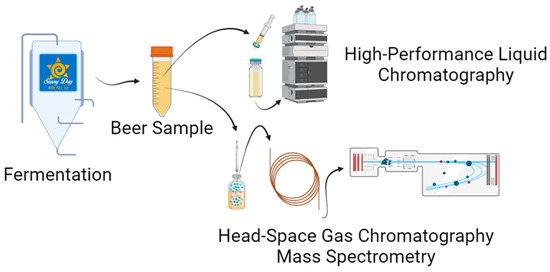

To gain insight into the effect of yeast generation age on beer fermentation, three commercial fermentations were sampled daily during primary fermentation (SD1, SD2, SD3). Fermentation parameters were monitored to evaluate fermentation progress, carbohydrate concentrations were measured to evaluate yeast metabolism of carbohydrates, and volatile compounds were measured to evaluate the development of volatile compound profiles throughout fermentation (Figure 1).

Figure 1.

Sample collection and analysis of commercial beer to determine carbohydrate concentrations and detect important volatile compounds. Daily samples were collected from three batches of Sunny Day fermentation (SD1-3). Samples were frozen until analysis by High-Performance Liquid Chromatography (HPLC) for carbohydrate concentrations and Head-Space Gas Chromatography Mass spectrometry for appearance of volatile compounds. Samples analyzed by HPLC were centrifuged and filtered prior to analysis and samples for HS-GC-MS were left uncentrifuged and unfiltered in order to minimize sample handling and potential off-gassing.

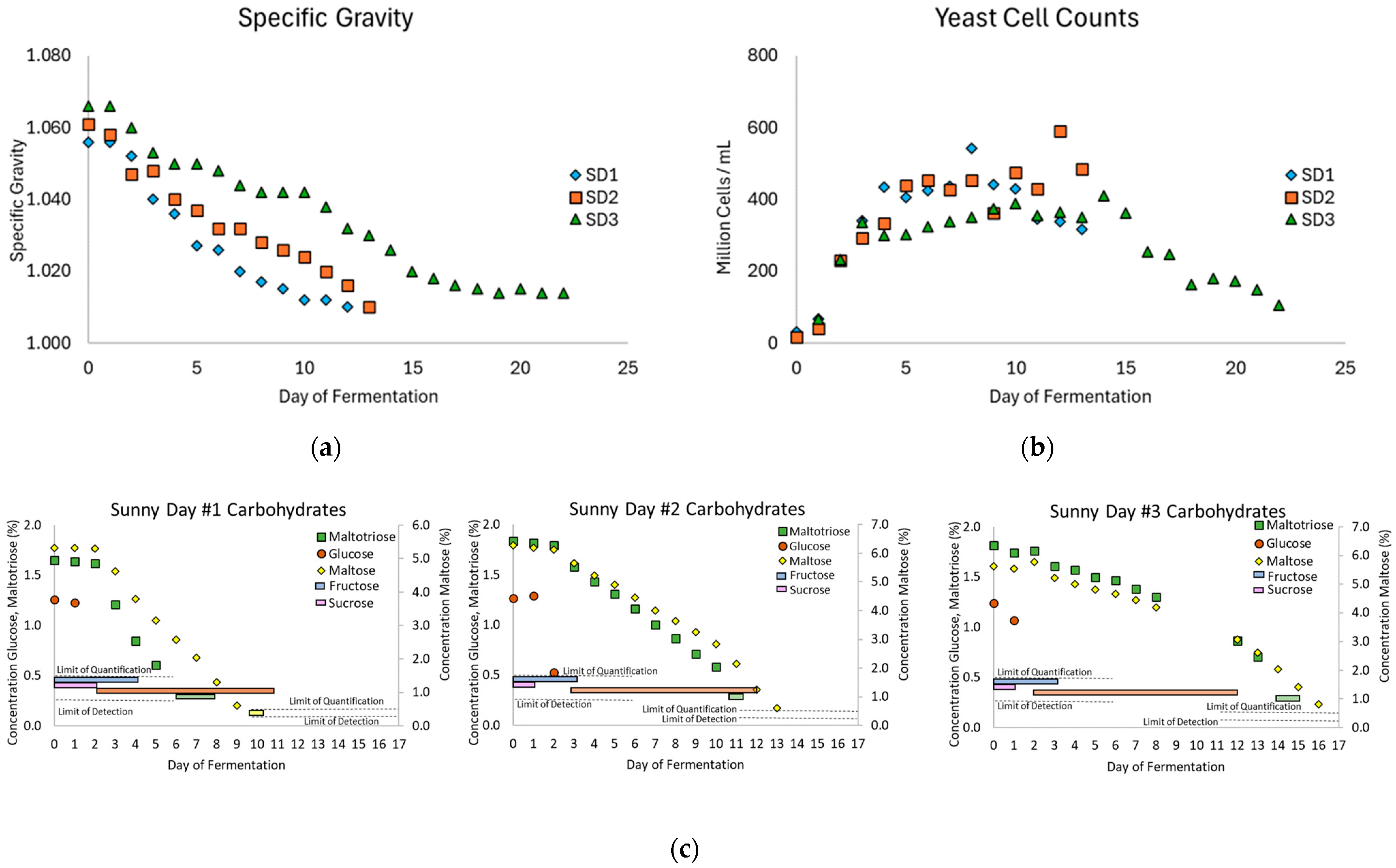

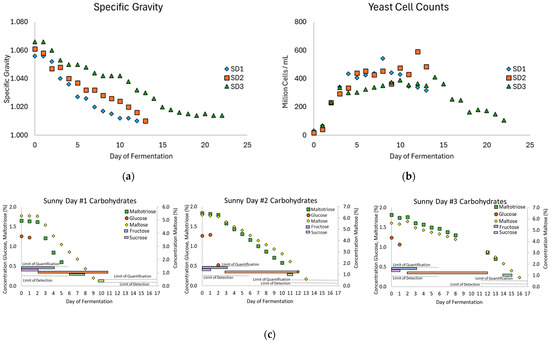

The progress of fermentation and total carbohydrate metabolism by yeast is usually monitored by measuring the SG to determine the stage of fermentation and when primary fermentation is complete; it also allows for early detection of fermentation issues such as “sluggish” or stalled fermentations. To gain insight into the effect of yeast generation (Table 1) on overall fermentation progress, fermentation parameters including SG, yeast cell counts, and fermentable carbohydrate concentration (Figure 2) were monitored during the three commercial fermentations.

Figure 2.

Fermentation parameters for 3 batches of Sunny Day (SD1-3). (a) Specific gravity versus day of fermentation for primary fermentation of three batches of SD indicating a lag in decreasing specific gravity from Day 0–1, rapid decrease in specific gravity from Day 2–5, and slow decrease for the remainder of fermentation. (b) Yeast cell counts during primary fermentation of SD1-3 indicating lag phase (Day 0–1), log phase (Day 1–5), and stationary phase (Day 5 to end of primary fermentation). (c) Carbohydrate concentration versus day of fermentation for SD1-3 measured by HPLC. Limit of quantification is 0.50% and limit of detection is 0.25%. Solid bars (pink, blue, orange, yellow) indicate detection but not quantification. Carbohydrate analysis indicated a lag in glucose metabolism (Day 0–1) for SD1-2 but not SD3. Maltose and maltotriose concentration did not decrease from Day 0–3 until after glucose concentration decreased to <0.55%. Low levels of glucose (0.25–0.5%) were detected throughout most of fermentation. Standard error of the mean (SEM) for triplicate carbohydrate measurements was <0.05% (error bars not visible).

The specific gravity (Figure 2a) and the density of the beer relative to water was measured daily as a proxy for the total carbohydrate content. The specific gravity at the beginning of fermentation (original gravity, OG) differed for the three batches at 1.056, 1.061, and 1.066, respectively. The trend in the decreasing SG for the three batches differed at the start of fermentation, with no change in the SG over the first 24 h for SD1 and SD3 and a decrease from 1.061 to 1.058 (5%) in SD2 during this time period. After the initial lag phase, the SG decreased for SD1 (26% between Day 2 and Day 3), SD2 (20% between Day 1 and Day 2), and SD3 (25% between Day 1 and Day 3). The SG of SD1 continued to decrease until approximately Day 7 (1.040–1.020), when it began to decrease more slowly (1.020–1.010) before finishing at Day 13. The SG in SD2 began decreasing before SD1 and SD3 and decreased from 1.047 to 1.032 by Day 6, and then 1.032 to 1.010 until Day 13, which is when it finished. SD3 had a divergent trend in the decreasing SG, with halts in the decreasing SG after Day 3, Day 7, and Day 15 and no further decreases were observed after Day 19 but fermentation was allowed to carry on until Day 22. SD1-2 finished primary fermentation when the SG was no longer decreasing on Day 13, and SD3 finished primary fermentation on Day 19. The final specific gravity (FG) was 1.010 for SD1 and SD2 and 1.014 for SD3. The apparent attenuation, the percent of total carbohydrate metabolism (the difference in OG and FG divided OG), was 82%, 84%, and 79% for SD1-3, respectively.

During the first days of fermentation, yeast consumes carbohydrates in order to build new biomass. Population doubling soon leads to exponential growth, and the timing or lagging of an exponential growth phase is an indication of yeast fitness. For these three fermentations, yeast was pitched at a rate of 1 million cells per mL per °Plato (density measurement relative to water, an alternative measure for specific gravity). That is, the number of yeast cells added to the fermentations was relative to the volume of wort and concentration of carbohydrates in each fermentation. The yeast cell counts in the harvested yeast slurry that was used differed (Table 1), so the appropriate volume of the slurry required for the total number of cells was pitched. Yeast cell counts (Figure 2b) were a measurement of the number of yeast cells in suspension and not the total number of yeast cells in the fermentation due to the location of the sampling port. SD1 and SD2 had similar trends with SD3, diverging after Day 4. Cell counts doubled over the first 24 h of fermentation (lag phase) for all three fermentations before reaching exponential growth from Day 1–5 (log phase) for SD1-2 and Day 1–4 for SD3. After Day 5 (stationary phase), the yeast counts in suspension either remained constant or decreased (except SD2 where yeast counts in suspension appeared to increase on Day 12). For SD3, the yeast counts in suspension (maximum 410 million cells/mL) did not reach the high counts for SD1-2 (542 and 590 million cells/mL, respectively).

Although the SG is a good proxy for the total carbohydrates in beer, during fermentation, S. cerevisiae will metabolize a range of carbohydrates in the following order of priority: sucrose, glucose, fructose, maltose, and maltotriose [1,27]. Therefore, it was important to measure the concentrations of specific carbohydrates in order to determine the effect, if any, of yeast generational age on carbohydrate metabolism. For carbohydrates (Figure 2c), an analysis of SD1 daily samples revealed a decrease in glucose between Days 1 and 2 from maximum concentrations of 1.24–1.27% to values below the LoQ, (0.5%) but still above the LoD (0.25%). This low-level presence of glucose continued to be detected throughout the duration of fermentation but could not be quantified. Similarly, fructose and sucrose signals were detected at the beginning of fermentation but were below the LoQ, with sucrose detected until Day 2 and fructose detected until Day 4, after which they were below the LoD and no longer detected. Maltose and maltotriose were detected from the beginning of fermentation and concentrations remained constant (5.19–5.35% and 1.60–1.65%, respectively) until Day 2 and decreased from Day 3 onwards. An analysis of SD2 daily samples revealed a similar pattern to SD1, with a decrease in glucose between Days 1 and 2, from maximum concentrations of 1.24–1.30% to values below the LoQ but still above the LoD until Day 12, after which glucose was no longer detected. Similarly, fructose and sucrose signals were detected at the beginning of fermentation but were below the LoQ, with sucrose detected until Day 1 and fructose detected until Day 3. Maltose and maltotriose concentrations remained constant (5.99–6.18% and 1.79–1.84%, respectively) until Day 2 and then decreased from Day 3 onwards. An analysis of SD3 daily samples revealed a divergence from SD1-2 in the total fermentation time, but the initial trends were similar, with a decrease in glucose between Days 0 and 2 from maximum concentrations of 1.24–1.25% to values below the LoQ but still above the LoD. This low-level detection of glucose continued throughout fermentation. Similarly, fructose and sucrose signals were detected but were below the LoQ and could not be quantified, with sucrose detected until Day 1 and fructose detected until Day 3. Maltose and maltotriose concentrations remained constant (5.00–5.79% and 1.58–1.90%, respectively) until Day 2 and then began to decrease from Day 3 onwards. The timing of when maltose and maltotriose concentrations are no longer detectable varies between the three fermentations, with SD1 having no detectable maltose or maltotriose after Day 10, but were detectable in SD2 until Day 13 and in SD3 until Day 19.

In addition to the comparisons of fermentation progress between the three fermentations, volatile compound profiles were investigated to gain insight into the impact of yeast generational age on the development of the volatile compound profile. Because volatile compounds are the most important for the sensory qualities of the beer, an analysis of the volatile compounds in sample Head-Space GC-MS was selected rather than liquid analysis, where the low levels of some of these compounds may not be detected. Twelve volatile compounds were detected by HS-GC-MS in all three batches of SD (Table 2), including three hop-derived compounds (3-methylbutyl isobutyrate, α-humulene, β-myrcene), one off-flavour (styrene), three acetate esters (isobutyl acetate, isoamyl acetate, and 2-methylbutyl acetate), and five MCFAEEs (ethyl butyrate, ethyl hexanoate, ethyl octanoate, ethyl decanoate, and ethyl dodecanoate). No data are available Days 11–13 for SD2 due to instrument failure and the lack of remaining samples.

Table 2.

Compounds detected by HS-GC-MS including hop-derived compounds and yeast-derived compounds (off-flavour, acetate esters, and MCFAEEs). Chemical formula, parent compounds, and aroma and flavour are listed for all compounds. Threshold of human detection is listed for compounds where information was available.

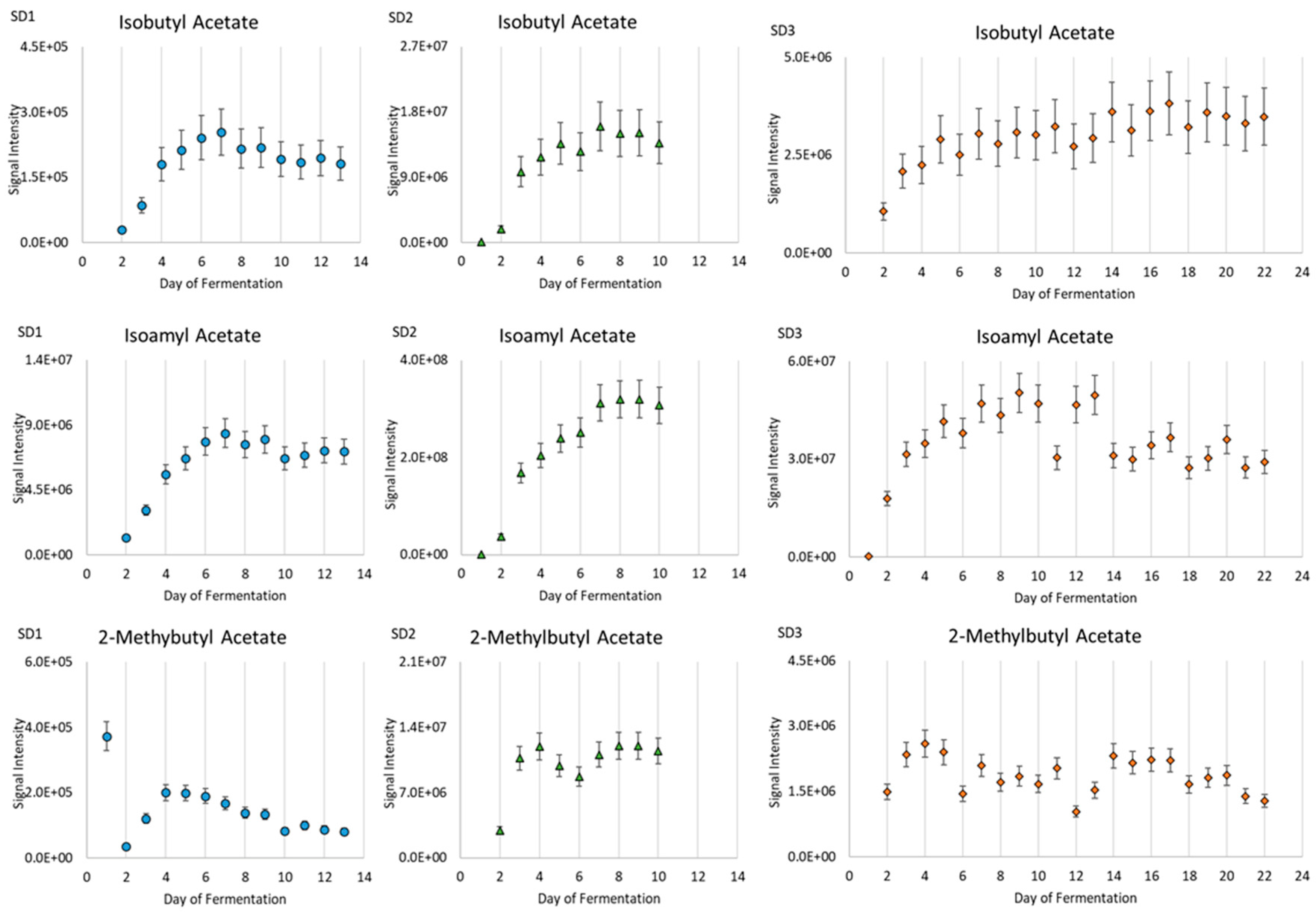

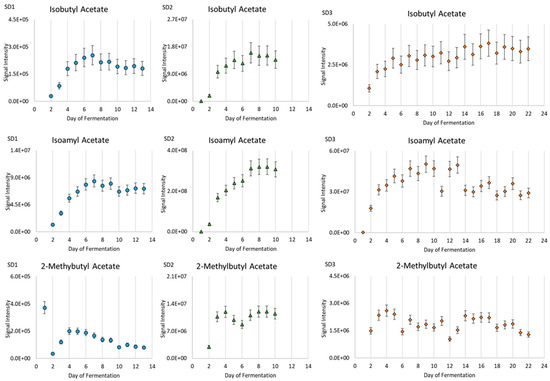

To gain insight into the development of the volatile compound profile throughout fermentation and the impact of generation age on the development, the general trends of each volatile compound were investigated. Some of the most important and desirable volatile compounds found in beer are acetate esters, the products of amino acid catabolism. An isobutyl acetate signal (Figure 3—Row 1) was first detected and was at the minimum on Day 1 for SD2 and Day 2 for SD1 and SD3. There was a sharp increase in the signal until a maximum on Day 7 for SD1 and SD2 followed by a generally decreasing trend until the end of fermentation. The SD3 isobutyl acetate signal continued to slowly increase after Day 5 until the end of fermentation.

Figure 3.

Trends in acetate ester production versus day of fermentation for SD1-3 measured by HS-GC-MS. Blue dots (1st column) represent SD1, green triangles (2nd column) represent SD2, and red diamonds (3rd column) represent SD3. The top row is isobutyl acetate signal, the second row is isoamyl acetate signal, and the third row is 2-methylbutyl acetate signal. First appearance of acetate esters was detected on Day 1 or 2 and was at a relative minimum (except for 2-methylbutyl acetate in SD1 and SD3). With the exception of SD1 2-methylbutyl acetate, SD1 and SD2 metabolite signals increased to a maximum before decreasing towards the end of fermentation. SD3 signals showed an increase at the beginning of fermentation followed by a decrease towards the end of fermentation for isoamyl acetate and 2-methylbutyl acetate and continued to increase until the end of fermentation for isobutyl acetate.

The isoamyl acetate signal showed a very similar pattern to isobutyl acetate with a first appearance and minimum value on Day 1 for SD2 and SD3 and Day 2 for SD1, followed by a sharp increase in signal to the maximum value on Day 7 for SD1, Day 8 for SD2, and Day 9 for SD3 (Figure 3—Row 2). The isoamyl acetate signal decreased from the maximum value for SD1 and SD3 throughout the rest of the fermentation while the SD2 signal stayed stable.

The 2-methylbutyl acetate signal differed from the other acetate esters (Figure 3—Row 3) and between batches. The first appearance and the maximum signal detected in SD1 occurred on Day 1 before a drop to a minimum on Day 2, an increase to a maximum on Day 4, and then a decrease for the rest of fermentation. The first appearance and minimum signal of 2-methylbutyl acetate in SD2 occurred on Day 2, followed by an increase until Day 4. The signal then decreased until Day 6 before it increased again and stayed at a maximum throughout fermentation. Scatter in the SD3 2-methylbutyl acetate data made it difficult to ascertain a trend other than the first appearance on Day 2 and the maximum on Day 4.

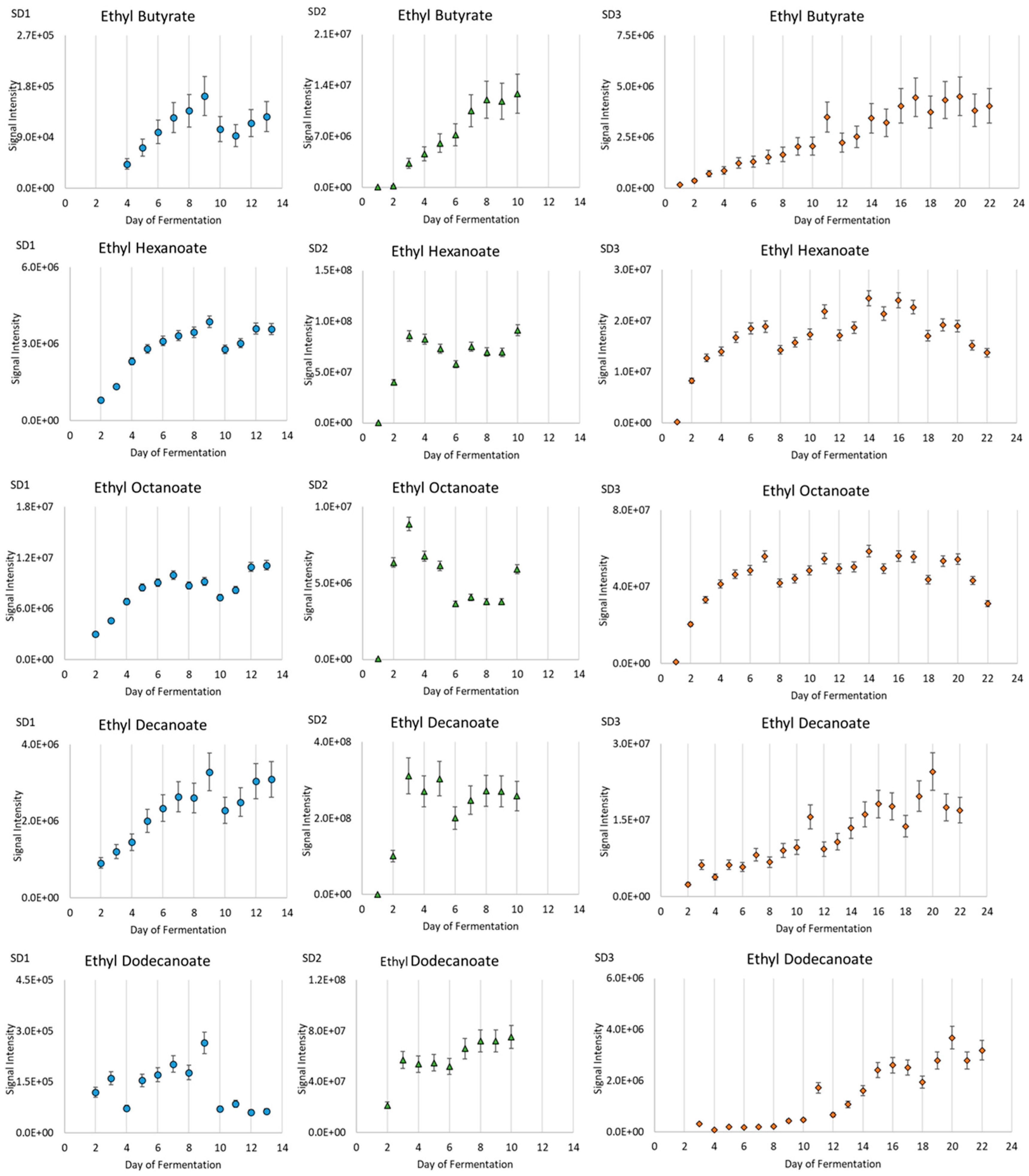

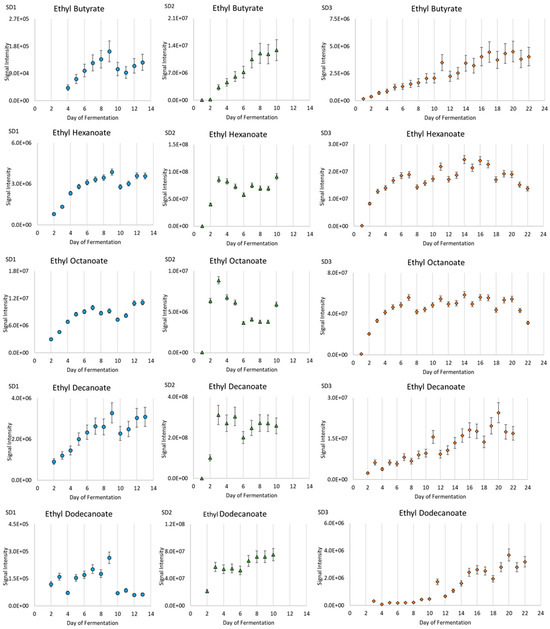

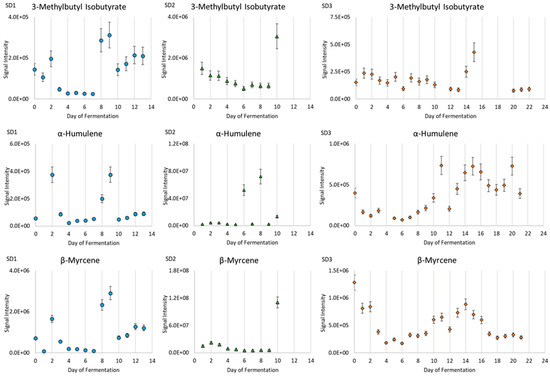

The trends for MCFAEEs (Figure 4; Ethyl Butyrate—Row 1; Ethyl Hexonate—Row 2; Ethyl Octanoate—Row 3; Ethyl Decanoate—Row 4; Ethyl Dodecanoate—Row 5) in the three batches were similar to the acetate esters with minimums at the beginning of fermentation followed by an increase in the signal, which either continued to increase, stabilized, or decreased towards the end of fermentation. The first appearance and minimum value for ethyl butyrate occurred on Day 1 for SD2 and SD3 but did not occur until Day 4 in SD1. The trend in SD1 differed somewhat with a steady increase in the signal until a maximum on Day 9, followed by a sharp decrease until Day 11, after which the signal appeared to increase again. SD2 and SD3 showed an increase in the signal throughout the fermentation without the decrease seen in SD1.

Figure 4.

Trends in MCFAEE production versus day of fermentation for SD1-3 measured by HS-GC-MS. Blue dots in the first column represent SD1, green triangles in the second column represent SD2, and red diamonds in the third column represent SD3. The top row is ethyl butyrate signal, the second row is ethyl hexanoate signal, the third row is ethyl octanoate signal, the fourth row is ethyl decanoate signal, and the bottom row is ethyl dodecanoate signal. Minimum signal was generally detected at the beginning of fermentation followed by an increase in signal, except for ethyl dodecanoate in SD1. SD1 showed a decrease on Day 10 before continuing to increase again. All MCFAEEs except ethyl butyrate in SD2 increased the fastest between Day 1 and Day 3 and decreased until Day 6, after which signal began to increase again.

The first appearance and minimum value for ethyl hexanoate occurred on Day 1 for SD2 and SD3 and Day 2 for SD1 (Figure 4—Row 1). Although there was an increase in the signal after the first appearance in the three batches, there were some differences in the timing of the trends. The SD1 ethyl hexanoate trend was similar to the trend in ethyl butyrate, with an increase until a maximum on Day 9, followed by a decrease on Day 10 and an increase through the rest of fermentation. The ethyl hexanoate signal in SD2 showed an increase until Day 3, a decrease until Day 6, and an increase until the maximum on Day 10. SD3 also showed an increase until Day 3, but then continued to increase until a maximum on Day 14, followed by a decrease through the rest of fermentation.

The trends in ethyl octanoate for the three batches differed from each other but were similar to the trends in ethyl hexanoate for each batch. The first appearance and minimum value occurred on Day 1 for SD2 and SD3 and Day 2 for SD1 (Figure 4—Row 2). The SD1 ethyl octanoate trend was similar to the trend in ethyl butyrate and ethyl hexanoate with an increase until Day 7, followed by a decrease on Day 1 and an increase through the rest of the fermentation to a maximum on Day 13. Ethyl octanoate in SD2 followed a similar trend to ethyl hexanoate, with an increase until a maximum on Day 3, followed by a decrease until Day 6. The signal then increased until Day 10 although not to the maximum seen in ethyl hexanoate. Ethyl octanoate in SD3 also followed a similar trend to ethyl hexanoate. SD3 showed a rapid increase until Day 4 but then continued to increase steadily until Day 20, followed by a decrease through the rest of fermentation.

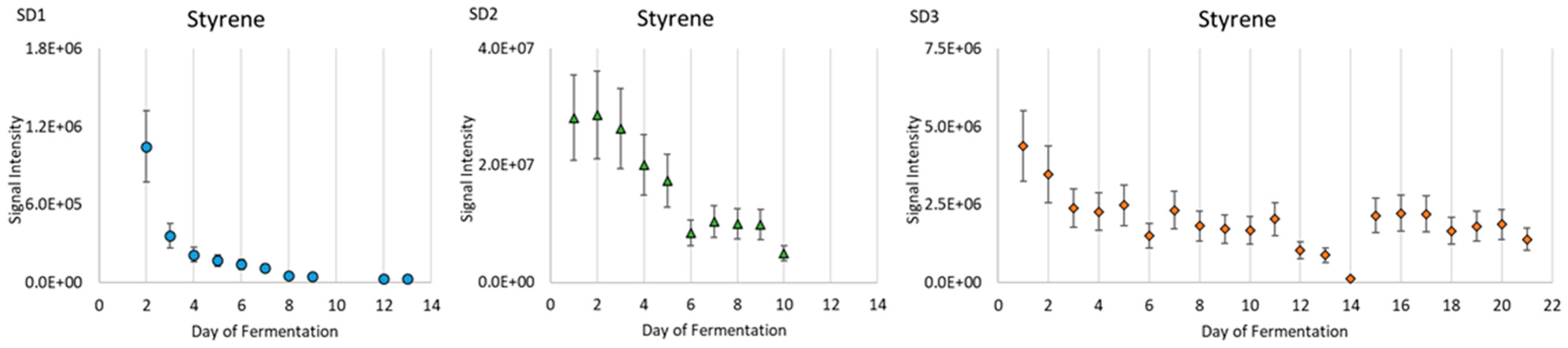

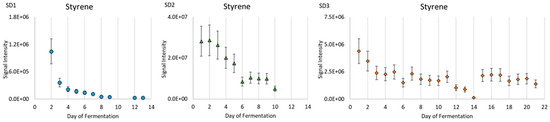

While there are many desirable flavours produced by yeast, they can also catalyze the production of styrene from precursors in the wort. Therefore, the presence of styrene was also investigated. Styrene is first detected on Day 1 in SD2 and SD3, and Day 2 in SD1 (Figure 5). The first appearance of styrene corresponds to the maximum signal, and the signal decreases throughout fermentation.

Figure 5.

Trends in styrene production versus day of fermentation for SD1-3 measured by HS-GC-MS. Blue dots in the first column represent SD1, green triangles in the second column represent SD2, and red diamonds in the third column represent SD3. Maximum signal was detected at the beginning of fermentation followed by a decrease in signal.

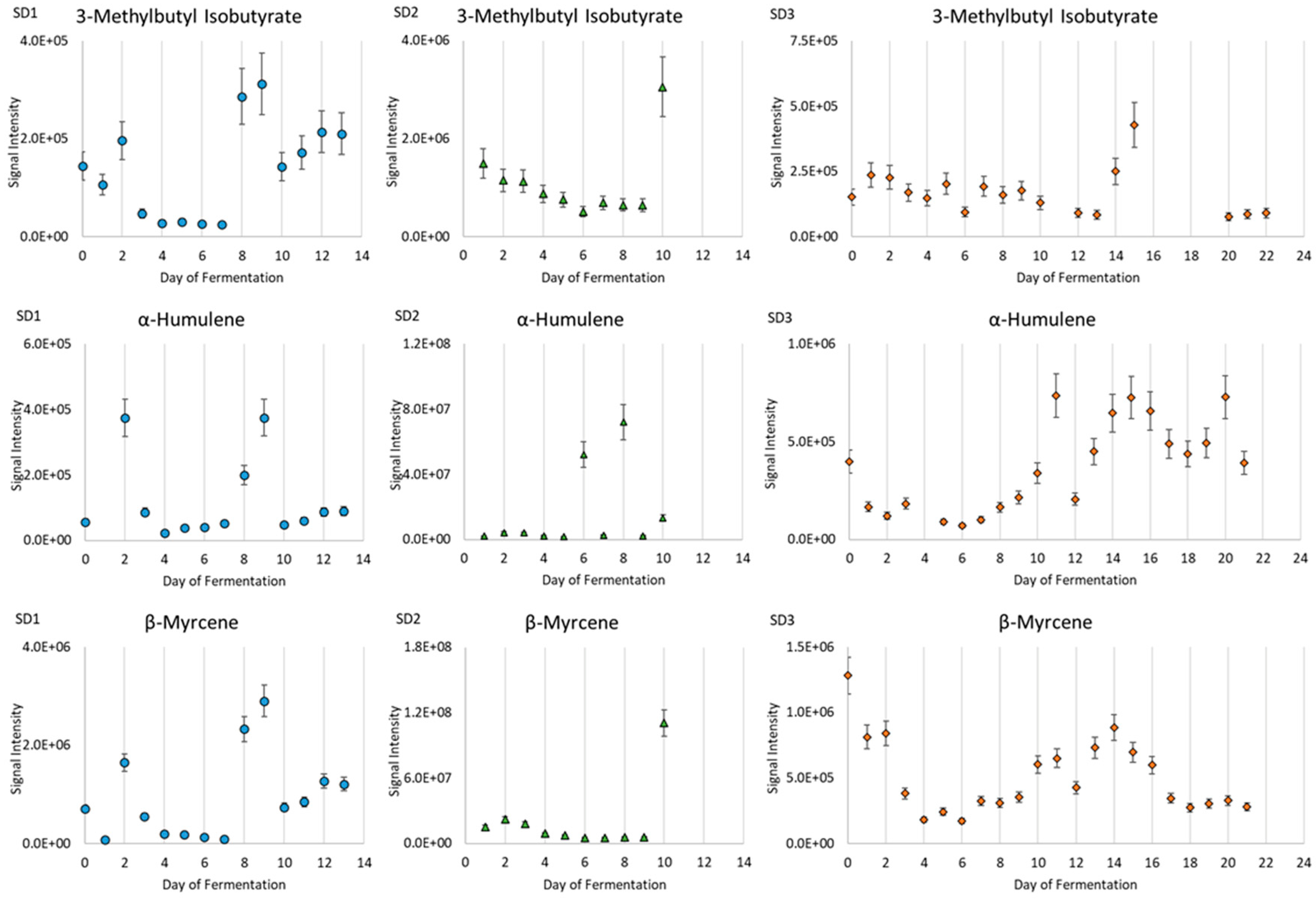

Hops also contribute to desirable flavour profiles in beer as a result of their initial hop oil composition, chemical transformations resulting from fermentation processes, biotransformation or absorption resulting from interactions with yeast, and synergistic effects with other volatile aroma-active compounds [30]. Therefore, trends in three hop-derived compounds were investigated to determine if there were any detectable relationships between yeast generational age and fitness with yeast in these compounds. The hop-derived compounds detected included 3-methylbutyl isobutyrate (Figure 6—Row 1), α-humulene (Figure 6—Row 2), and β-myrcene (Figure 6—Row 3). These compounds first appeared on Day 0 for SD1 and SD3 and on Day 1 for SD2. 3-methylbutyl isobutyrate decreased in the signal during the beginning of fermentation and had a sharp increase in signal after dry hopping (hops added to the fermentation vessel during or after primary fermentation) on Days 7, 10, and 15 for SD1, SD2, and SD3, respectively. α-humulene had a less well-defined trend, with sharp increases in SD1 and SD2 after dry hopping on Days 7 and 10, but also increases on Days 2 and 5 in SD1 and SD2, respectively, on days with no dry hopping. SD3 did not show any sharp increases in α-humulene. Again, there was a sharp increase in β-myrcene in SD1 and SD2 after dry hopping on Days 7 and 10 and a sharp increase on Day 2 in SD1. SD3 did not show any sharp increases in β-myrcene but showed a maximum on Day 0, which decreased until Day 5 and increased again until Day 14.

Figure 6.

Trends in hop-derived compounds versus day of fermentation for SD1-3 measured by HS-GC-MS. Blue dots in the first column represent SD1, green triangles in the second column represent SD2, and red diamonds in the third column represent SD3. 3-methylbutyl isobutyrate is in the first row, a-humulene in the second row, and b-myrcene in the bottom row. Dry hopping (hops added during fermentation) occurred when SG was <1.024 on Days 7, 10, and 15 for SD1, SD2, and SD3, respectively. Increases in 3-methylbutyl isobutyrate, a-humulene, and b-myrcene were all detected after dry hopping for SD1 and 3-methylbutyl isobutyrate and b-myrcene for SD2, but there was no clear increase in hop-derived compounds with dry hopping in SD3.

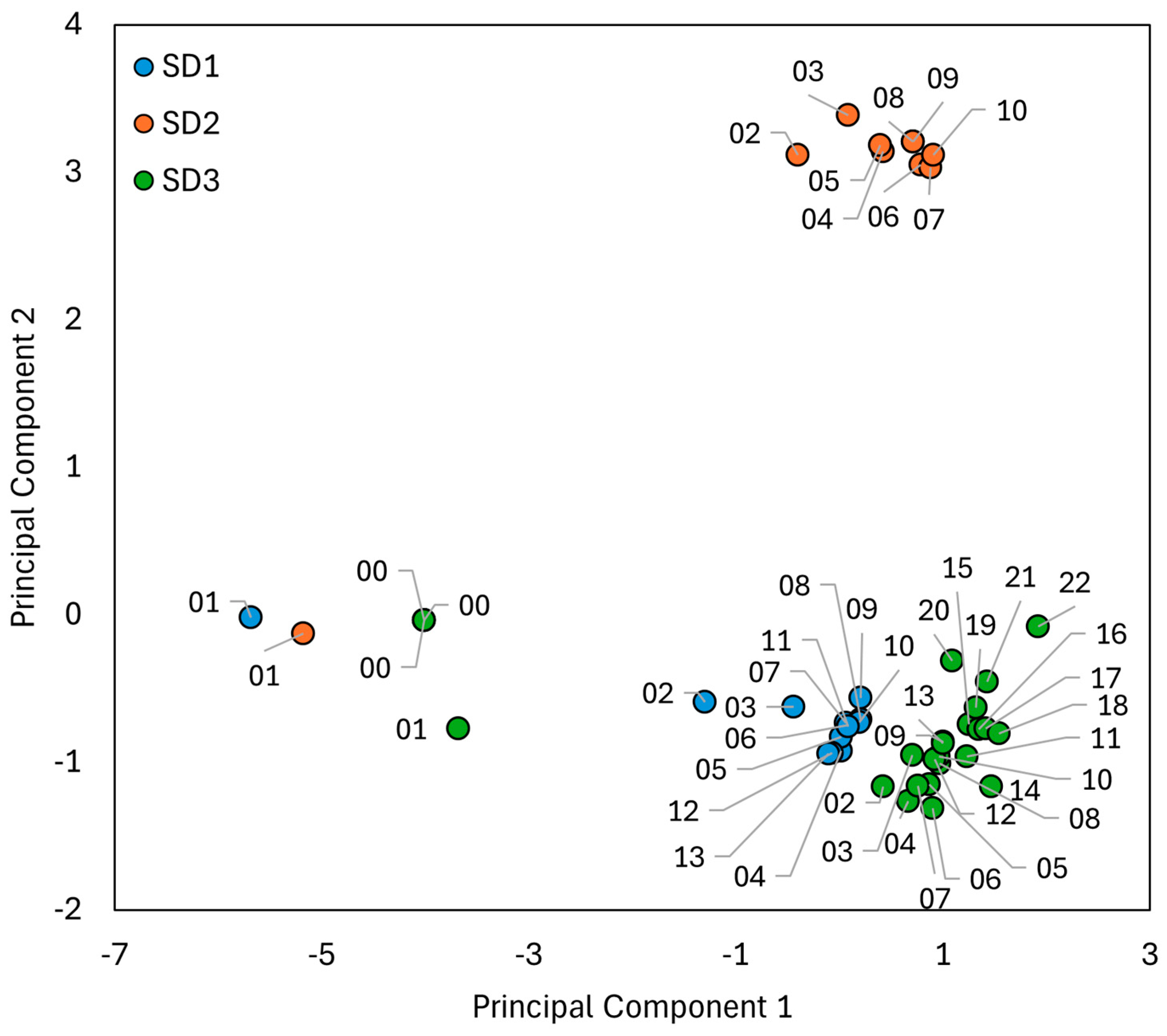

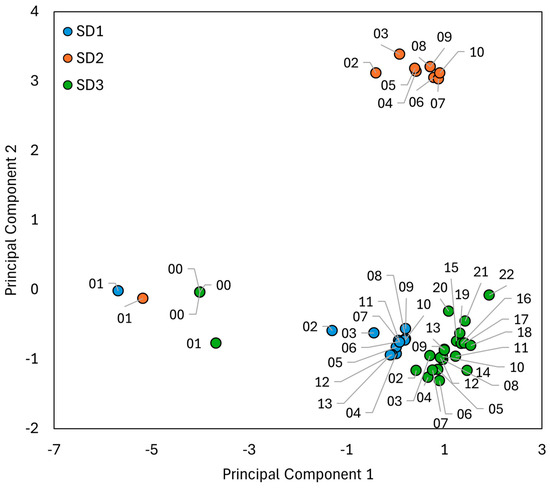

While the trends in volatile compound production reveal important information on the development of volatile compound profiles, the balance of these compounds is vital to the overall sensory experience of beer. In order to compare the balance of yeast-derived metabolites between three batches, the signal of each compound was calculated as a percent of the total yeast-derived compounds for each day. A principal component analysis was then performed on the yeast-derived metabolites detected to determine if there were differences in the development and final composition of the three batches (Figure 7). All three batches started with a similar profile, with SD1 and SD2 being more closely related on Day 1 with each other than with SD3. After Day 1, SD2 diverged from SD1 and SD3, with SD2 having a distinct cluster that was separate from the two closer clusters of SD1 and SD3.

Figure 7.

Principal component analysis of yeast-derived volatile compounds for the three batches of Sunny Day (SD1-3). SD1 values are the blue dots, SD2 are the orange dots, and SD3 are the green dots. The number on the label indicates the day of fermentation. On Day 1, all three batches cluster together before diverging, with SD1 and SD2 having a closer relationship with each other than with SD3. After Day 1, SD1 and SD3 formed two clusters close together, while SD2 appeared to form a distinct cluster separate from SD1 and SD3 as early as Day 2.

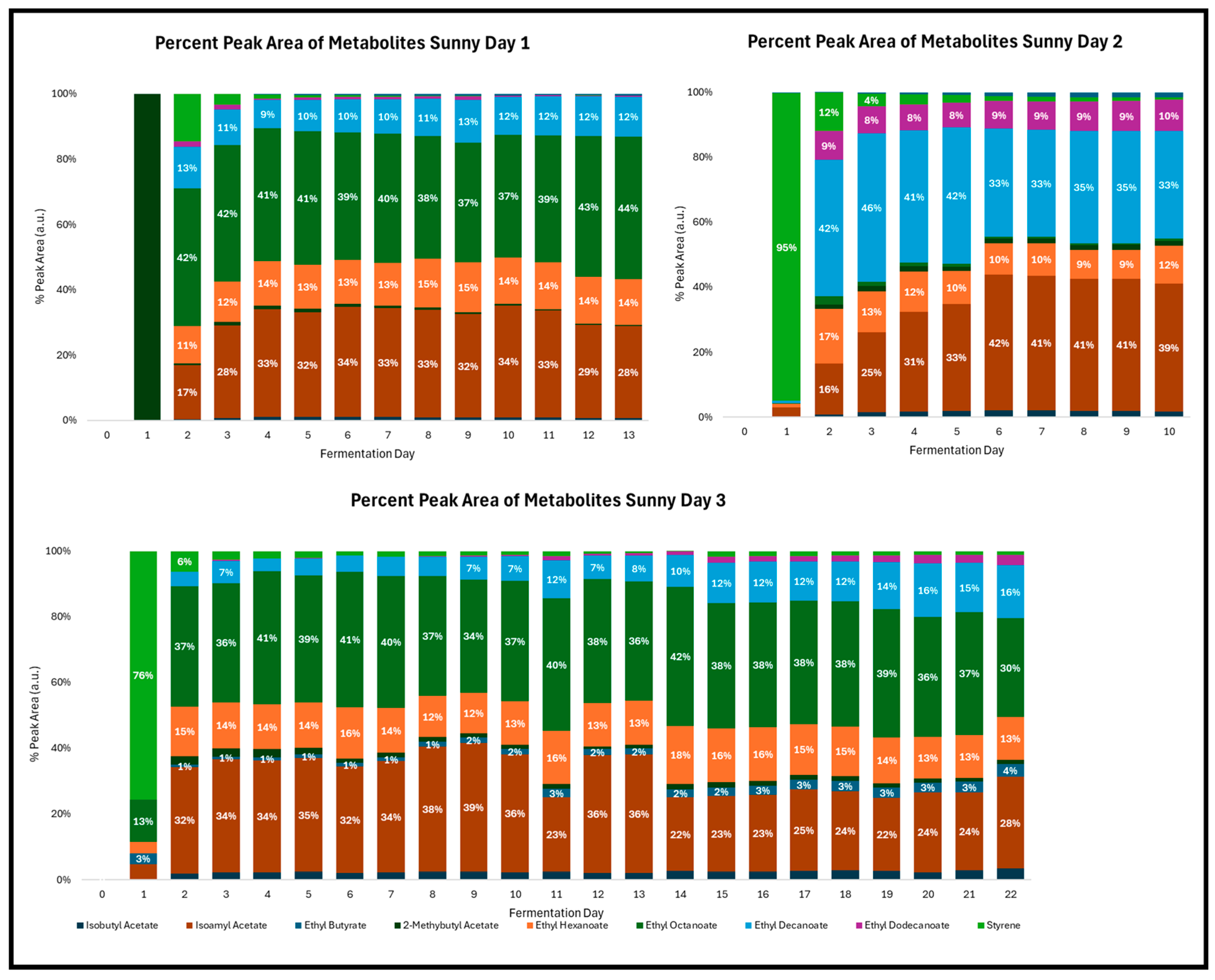

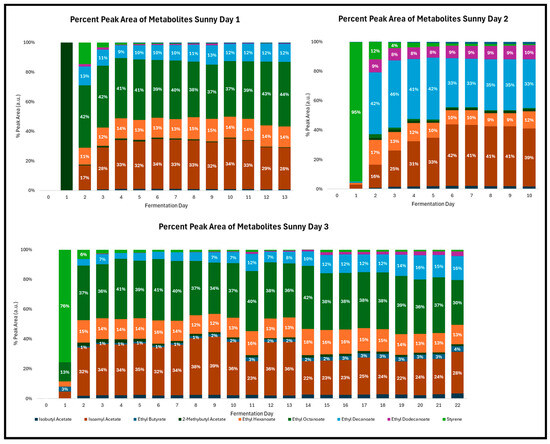

Since PCA can reveal a difference between the batches but not what is different about them, the same data were then plotted as bar graphs to determine which compounds varied the most between the three batches. One of the major contributors to the yeast-derived metabolite composition was isoamyl acetate (Figure 8). The proportion of isoamyl acetate was similar between the batches, with values between 28 and 34%, 25 and 42%, and 22 and 39% of the total composition for SD1-3, respectively. Ethyl hexanoate proportion was also similar between the three batches, with values of 12–15%, 9–13%, and 12–18% for SD1-3, respectively, even though the trends in ethyl hexanoate production appeared to vary. Although styrene was a major contributor to the daily yeast-derived metabolite composition (15%, 95%, and 76% for SD1-3, respectively) at the beginning of fermentation, it had little contribution to the composition later in fermentation (<1%) both because the signal decreased but also because other metabolites began to be produced at high levels (ex. MCFAEEs).

Figure 8.

Percent composition of yeast-derived metabolites for each day of SD1-3 fermentations. Relative quantification of flavour compounds expressed as percentages was performed. Each compound is colour-coded: isobutyl acetate (dark blue), isoamyl acetate (dark red), ethyl butyrate (medium blue), 2-methylbutyl acetate (dark green), ethyl hexanoate (orange), ethyl octanoate (green), ethyl decanoate (light blue), ethyl dodecanoate (purple), and styrene (light green). SD2 demonstrates a difference in metabolite content with the largest portion of MCFAEEs comprising ethyl decanoate (33–46%) instead of ethyl octanoate (30–44%) observed in SD1 and SD3.

While most compounds were of similar proportion in the three batches, there were some large differences in several compounds. The proportion of ethyl decanoate in SD2 after Day 2 was much higher (33–42%) compared to SD1 and SD3 (9–13% and 5–16%, respectively). The proportion of ethyl dodecanoate was also much higher in SD2 (8–10%) compared to SD1 and SD3 (<2% and <3%, respectively). In addition, SD2 had a very low abundance of ethyl octanoate (0–1%), while it was a major contributor to SD1 and SD3 (37–44% and 30–42%, respectively) after Day 2.

4. Discussion

In order to evaluate the impact of yeast generational age on fermentation progress and volatile compound production, three batches of commercial beer were fermented and sampled daily. The wort was brewed from the same batch of barley malt and used the same bags of hops in order to make the wort as consistent as possible. Fermentation parameters including SG, yeast cell count, and carbohydrate concentrations were measured. The changes in SG for the three batches revealed a similarity in the progress of SD1 and SD2 with a “sluggish” or slower later fermentation in SD3. SD1 and SD2 required 13 days to reach final gravity, while SD3 required 19 days. This is of significance to highlight, considering SD3 had the youngest generational age of yeast (G5), whereas SD1 and SD2 had older generations (G6 and G9, respectively). The OG for SD3 was the highest (1.066) compared to SD1 and SD2 (1.064 and 1.056, respectively), but likely did not have high enough osmolarity to result in a negative impact on the yeast’s ability to metabolize carbohydrates.

Yeast cell counts had similar initial trends, with exponential growth at the beginning of fermentation and had similar trends for SD1 and SD2 throughout fermentation. SD3 cell counts initially increased exponentially until Day 4 but did not reach the same maximum values as SD1 and SD3. This again indicated a “sluggish” fermentation in SD3, despite its younger age. Although sampling for yeast numbers was challenging due to yeast settling out of the solution, we still obtained similar values for the yeast still in suspension. We interpret this as each fermentation having similar yeast numbers, and, as such, divergence in the results is not due to different numbers of yeast.

Because yeast metabolizes carbohydrates in a specific order, the metabolism of specific carbohydrates was investigated in addition to the general decrease in total carbohydrates measured by the SG. The three batches showed similar trends, with a delay in the decreasing concentration of maltose and maltotriose, and a persistent low level of glucose was detected but not quantified. SD3 differed from SD1 and SD2 in the overall time of fermentation, but not in this trend. These results reveal a consistency at the beginning of fermentation, but a “sluggishness” after glucose has been consumed in SD3. It is of note that the starting temperature for the SD3 (17 °C) differed from SD1-2 starting temperatures (19 °C). The lower temperature in SD3 did not appear to impact the start of fermentation, and therefore is unlikely to be the cause of the later slowdown of fermentation progress. SD3 came from a different lineage, or original pitch of yeast, but the fermentation progress of previous batches was not monitored.

In addition to monitoring fermentation progression, trends in volatile compound production were investigated to determine the impact of yeast generation age on volatile compound profile formation. First, the trends in yeast-derived metabolites, including acetate esters and MCFAEEs, were investigated. With the exceptions of 2-methylbutyl acetate in SD1 and SD3 and ethyl dodecanoate in SD1, these compounds started at a minimum during the beginning of fermentation and either continued to increase throughout fermentation or began to decrease later in fermentation. This is likely the result of an initial lag in the process of yeast exporting these compounds to the media (i.e., beer) for the first 24–48 h, followed by an increase due to accumulation as the yeast continued to produce these compounds. A later decrease in these compounds could be the result of slowed production combined with off-gassing or degradation. Styrene has a different trend with maximum concentrations being present at the beginning of fermentation and decreasing throughout fermentation, indicating either low or no production of styrene after the initial precursors in the wort were converted and then either the off-gassing or degradation of styrene throughout the rest of fermentation. This lack of impact on styrene is expected as the yeast used does not have the genes required for styrene production [25], and no clear effect of yeast generation age was observed.

Although not yeast-derived, hop compounds are important to the overall flavour profile of beer. Three major hop compounds were investigated to determine the trends throughout fermentation and elucidate any impact of yeast generational age on the conversion of these compounds. There was an increase in hop-derived compounds that coincided with dry hopping in SD1 and with two of the hop-derived compounds in SD2 but no clear pattern was apparent in SD3. No impact of yeast generational age was apparent, indicating that yeast has little impact on the bioconversion of hop-derived compounds, as previously described [30].

It is not just the presence of these volatile compounds that is important to the quality of beer and its sensory experience but the combination and proportions of the compounds. Therefore, the proportion of each compound relative to the total yeast-derived compounds was calculated, and a PCA was performed. SD2 compound proportions differed from SD1 and SD3 as early as Day 2, with the final composition of SD1 and SD3 being similar to each other. This is surprising because the fermentation progress of SD1 and SD2 were similar, and SD3 was the outlier with its more sluggish fermentation; it was expected that the volatile compound profile of SD3 would be different than SD1 and SD2. Regardless, the generational age of the yeast in SD2 was G9, the oldest compared to G6 and G5 in SD1 and SD3. These observations indicate that although there appeared to be no detectable impact of yeast generational age on fermentation progress, there may be an impact on the metabolite production and therefore the balance of the flavour compounds produced by the yeast. We further concluded that the storage time of the yeast was not an issue as the yeast for SD1 and SD2 were stored for 30 days and 28 days, respectively.

To investigate what specific compounds differed in SD2 compared to SD1 and SD3, bar graphs of yeast-derived compounds were constructed for each day of fermentation. While most compounds were of similar proportion, the proportion of ethyl octanoate, ethyl decanoate, and ethyl dodecanoate were different in SD2 compared to SD1 and SD3, three important MCFAEEs in beer. SD2 had much lower concentrations of ethyl octanoate (0–1%), while it was a major contributor to SD1 and SD3 (37–44% and 30–42%, respectively) after Day 2. Also, the proportion of ethyl decanoate in SD2 after Day 2 was much higher (33–42%) compared to SD1 and SD3 (9–13% and 5–16%, respectively). The proportion of ethyl dodecanoate was also much higher in SD2 (8–10%) compared to SD1 and SD3 (<2% and <3%, respectively). The decrease in lower-carbon MCFAEEs (ethyl octanoate, C = 10) and increases in higher-carbon MCFAEEs (ethyl decanoate, C = 12 and ethyl dodecanoate, C = 14) indicate a more active FAS by the addition of two or four carbons before these compounds were exported from the FAS. Higher temperatures and a higher OG can result in increased FAS activity, but SD1 and SD2 had the same starting temperature (19 °C). Although the OG differed between the three batches, SD2 did not have the highest OG of the three batches (1.064); SD1 and SD3 had the largest difference in the OG (1.056 and 1.066, respectively) while having the most similar volatile compound profiles. The major difference in the three batches was the generation age of the yeast in SD2. The lack of difference in styrene and isoamyl acetate proportion indicates the production of these compounds may not be related to yeast generational age.

5. Conclusions

This study evaluated fermentation progress and volatile compound profiles in commercial beer fermentation in order to better understand batch-to-batch variation and their potential causes. Samples for carbohydrate analysis by High-Performance Liquid Chromatography and volatile metabolite analysis by Head-Space Gas Chromatography Mass Spectrometry (HS-GC-MS) were collected daily from three commercial fermentations. Although yeast generational age did not impact the time required for primary fermentation, there was an impact on the development of volatile compounds. As a result of this research, it is important that brewers consider the generational age due to the serial re-pitching of the yeast they are using and not solely rely on indicators of fermentation progress such as the SG to evaluate the “fitness” of the yeast for fermentation. Although fermentation may progress as expected, there is no guarantee that the metabolites produced, and therefore the balance of the flavour profile, will not be impacted by the generational age of the yeast. The yeast may behave differently during fermentation and produce a beer that tastes different. Yeast is a living organism and the “fitness” of the yeast, its physiological condition, generational age, and its behaviour must be considered for consistent, high-quality beer production. Future studies may aim at examining the impact of yeast storage conditions and storage time on fermentation progress and flavour profiles as it relates to “brewing fitness” in addition to serial re-pitching. This could be further expanded to include analyses of yeast genomic and proteomic profile changes during fermentation and sensory analysis of the final products to further quantify the impact of serial re-pitching on fundamental aspects of yeast biology.

Author Contributions

F.B.N. and C.E. developed the majority of the experimental protocols. J.P. collected initial samples and was involved with the conceptualization of the HPLC assays. C.M. was involved with the supervision of brewery sample collection. C.M. designed beer recipes and provided additional expertise on fermentation. F.B.N. executed the assays and collected data, performing the majority of the analytical assessment and manuscript construction. C.E. assisted with data interpretation and assisted with the final preparation of the manuscript. All authors have read and agreed to the published version of the manuscript.

Funding

We would like to thank the Agricultural Development Fund (Government of Saskatchewan) for supporting this research (Project #: 20210615). F.B.N.’s stipend was supported through MITACs (Funding Request ref: FR54887) and 21st Street Brewery.

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Acknowledgments

We would like to thank Zachery Belak at Proxima Research and Development (Saskatoon, SK, Canada) for his insight and expertise. Special thanks to Matt Enns and Maker’s Crafted Malt (Rosthern, Saskatchewan, Canada) for their kind donation of the malt used throughout the duration of the experimentation. Finally, we would like to thank the contributions of expertise from Ramaswami Sammynaiken (Saskatchewan Structural Sciences Center) and Nicholas Low (Emeritus—Department of Food and Bioproduct Sciences). These are the types of giving scientists that make research collaborations exciting and a pleasure to be involved with.

Conflicts of Interest

The authors declare no conflicts of interest. Dr. Christopher Eskiw is the co-founder of IntelliYeast Laboratories Inc.; however, there was no contribution from the company in this research.

References

- Stewart, G.G. Saccharomyces species in the production of beer. Beverages 2016, 2, 34. [Google Scholar] [CrossRef]

- Gallone, B.; Steensels, J.; Prahl, T.; Soriaga, L.; Saels, V.; Herrera-Malaver, B.; Merlevede, A.; Roncoroni, M.; Voordeckers, K.; Miraglia, L.; et al. Domestication and Divergence of Saccharomyces cerevisiae Beer Yeasts. Cell 2016, 166, 1397–1410. [Google Scholar] [CrossRef]

- Lodolo, E.J.; Kock, J.L.F.; Axcell, B.C.; Brooks, M. The yeast Saccharomyces cerevisiae—The main character in beer brewing. FEMS Yeast Res. 2008, 8, 1018–1036. [Google Scholar] [CrossRef]

- Meilgaard, M.C. Prediction of Flavor Differences between Beers from Their Chemical Composition. J. Agric. Food Chem. 1982, 30, 1009–1017. [Google Scholar] [CrossRef]

- Dzialo, M.C.; Park, R.; Steensels, J.; Lievens, B.; Verstrepen, K.J. Physiology, ecology and industrial applications of aroma formation in yeast. FEMS Microbiol. Rev. 2017, 69, 5228–5237. [Google Scholar] [CrossRef] [PubMed]

- Verstrepen, K.J.; Van Laere, S.D.M.; Vanderhaegen, B.M.P.; Derdelinckx, G.; Dufour, J.P.; Pretorius, I.S.; Winderickx, J.; Thevelein, J.M.; Delvaux, F.R. Expression levels of the yeast alcohol acetyltransferase genes ATF1, Lg-ATF1, and ATF2 control the formation of a broad range of volatile esters. Appl. Environ. Microbiol. 2003, 69, 5228–5237. [Google Scholar] [CrossRef]

- Saerens, S.M.G.; Delvaux, F.R.; Verstrepen, K.J.; Thevelein, J.M. Production and biological function of volatile esters in Saccharomyces cerevisiae. Microb. Biotechnol. 2010, 3, 165–177. [Google Scholar] [CrossRef] [PubMed]

- Saerens, S.M.G.; Verstrepen, K.J.; Van Laere, S.D.M.; Voet, A.R.D.; Van Dijck, P.; Delvaux, F.R.; Thevelein, J.M. The Saccharomyces cerevisiae EHT1 and EEB1 genes encode novel enzymes with medium-chain fatty acid ethyl ester synthesis and hydrolysis capacity. J. Biol. Chem. 2006, 281, 4446–4456. [Google Scholar] [CrossRef]

- Saerens, S.M.G.; Verbelen, P.J.; Vanbeneden, N.; Thevelein, J.M.; Delvaux, F.R. Monitoring the influence of high-gravity brewing and fermentation temperature on flavour formation by analysis of gene expression levels in brewing yeast. Appl. Microbiol. Biotechnol. 2008, 80, 1039–1051. [Google Scholar] [CrossRef]

- Hazelwood, L.A.; Daran, J.M.; Van Maris, A.J.A.; Pronk, J.T.; Dickinson, J.R. The Ehrlich pathway for fusel alcohol production: A century of research on Saccharomyces cerevisiae metabolism. Appl. Environ. Microbiol. 2008, 74, 2259–2266. [Google Scholar] [CrossRef]

- Thompson-Witrick, K.A.; Pitts, E. Nitrogen Content in Craft Malts: Effects on Total Ester Concentration in Beer. J. Am. Soc. Brew. Chem. 2020, 78, 308–313. [Google Scholar] [CrossRef]

- Fairbairn, S.; McKinnon, A.; Musarurwa, H.T.; Ferreira, A.C.; Bauer, F.F. The impact of single amino acids on growth and volatile aroma production by Saccharomyces cerevisiae strains. Front. Microbiol. 2017, 8, 2554. [Google Scholar] [CrossRef] [PubMed]

- Garge, R.K.; Geck, R.C.; Armstrong, J.O.; Dunn, B.; Boutz, D.R.; Battenhouse, A.; Leutert, M.; Dang, V.; Jiang, P.; Kwiatkowski, D.; et al. Systematic profiling of ale yeast protein dynamics across fermentation and repitching. G3 Genes Genomes Genet. 2024, 14, jkad293. [Google Scholar] [CrossRef] [PubMed]

- Bühligen, F.; Rüdinger, P.; Fetzer, I.; Stahl, F.; Scheper, T.; Harms, H.; Müuller, S. Sustainability of industrial yeast serial repitching practice studied by gene expression and correlation analysis. J. Biotechnol. 2013, 168, 718–728. [Google Scholar] [CrossRef]

- Wang, J.; Ding, H.; Zheng, F.; Li, Y.; Liu, C.; Niu, C.; Li, Q. Physiological Changes of Beer Brewer’s Yeast During Serial Beer Fermentation. J. Am. Soc. Brew. Chem. 2019, 77, 10–20. [Google Scholar] [CrossRef]

- Kosiv, R. Comparing The Efficiency Of Applying Yeast Of Different Generations In High Gravity Brewing. East.-Eur. J. Enterp. Technol. 2021, 6, 50–52. [Google Scholar] [CrossRef]

- Kalayu, G. Serial re-pitching: Its effect on yeast physiology, fermentation performance, and product quality. Ann. Microbiol. 2019, 69, 787–796. [Google Scholar] [CrossRef]

- Kordialik-Bogacka, E.; Diowksz, A. Physiological State of Reused Brewing Yeast. Czech J. Food Sci. 2013, 31, 264–269. [Google Scholar] [CrossRef]

- Verbelen, P.J.; Depraetere, S.A.; Winderickx, J.; Delvaux, F.R.; Delvaux, F. The influence of yeast oxygenation prior to brewery fermentation on yeast metabolism and the oxidative stress response. FEMS Yeast Res. 2009, 9, 226–239. [Google Scholar] [CrossRef]

- Kobayashi, M.; Shimizu, H.; Shioya, S. Physiological analysis of yeast cells by flow cytometry during serial-repitching of low-malt beer fermentation. J. Biosci. Bioeng. 2007, 103, 451–456. [Google Scholar] [CrossRef]

- Kucharczyk, K.; Tuszyński, T.; Żyła, K.; Puchalski, C. The effect of yeast generations on fermentation, maturation and volatile compounds of beer. Czech J. Food Sci. 2020, 38, 144–150. [Google Scholar] [CrossRef]

- Pires, E.J.; Teixeira, J.A.; Brányik, T.; Vicente, A.A. Yeast: The soul of beer’s aroma—A review of flavour-active esters and higher alcohols produced by the brewing yeast. Appl. Microbiol. Biotechnol. 2014, 98, 1937–1949. [Google Scholar] [CrossRef]

- Fukuda, K.; Yamamoto, N.; Kiyokawa, Y.; Yanagiuchi, T.; Wakai, Y.; Kitamoto, K.; Inoue, Y.; Kimura, A. Balance of Activities of Alcohol Acetyltransferase and Esterase in Saccharomyces cerevisiae Is Important for Production of Isoamyl Acetate. Appl. Environ. Microbiol. 1998, 64, 4076–4078. [Google Scholar] [CrossRef] [PubMed]

- Shi, W.; Li, J.; Chen, Y.; Chen, Y.; Guo, X.; Xiao, D. Enhancement of c6–c10 fatty acid ethyl esters production in Saccharomyces cerevisiae CA by metabolic engineering. LWT 2021, 145, 111496. [Google Scholar] [CrossRef]

- Haefliger, O.P.; Jeckelmann, N. Stripping of aroma compounds during beer fermentation monitored in real-time using an automatic cryotrapping sampling system and fast gas chromatography/mass spectrometry. Anal. Methods 2013, 5, 4409–4418. [Google Scholar] [CrossRef]

- Takoi, K.; Itoga, Y.; Koie, K.; Takayanagi, J.; Kaneko, T.; Watanabe, T.; Matsumoto, I.; Nomura, M. Behaviour of hop-derived branched-chain esters during fermentation and unique characteristics of huell melon and ekuanot (hbc366) hops. Brew. Sci. 2018, 71, 100–109. [Google Scholar] [CrossRef]

- Zastrow, C.R.; Mattos, M.A.; Hollatz, C.; Stambuk, B.U. Maltotriose metabolism by Saccharomyces cerevisiae. Biotechnol. Lett. 2000, 22, 455–459. [Google Scholar] [CrossRef]

- Laegreid, I.R. Genotypic and Phenotypic Characterization of Norwegian Farmhouse Ale Yeast Cultures: A Domestication-Driven Evolution. Master’s Thesis, Norwegian University of Science and Technology, Trondheim, Norway, 2017. [Google Scholar]

- Cameleyre, M.; Lytra, G.; Tempere, S.; Barbe, J.C. 2-Methylbutyl acetate in wines: Enantiomeric distribution and sensory impact on red wine fruity aroma. Food Chem. 2017, 237, 364–371. [Google Scholar] [CrossRef]

- Buiatti, S.; Tat, L.; Natolino, A.; Passaghe, P. Biotransformations Performed by Yeasts on Aromatic Compounds Provided by Hop—A Review. Fermentation 2023, 9, 327. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).