Alternative Uses of Fermented Wheat Bran: A Mini Review

Abstract

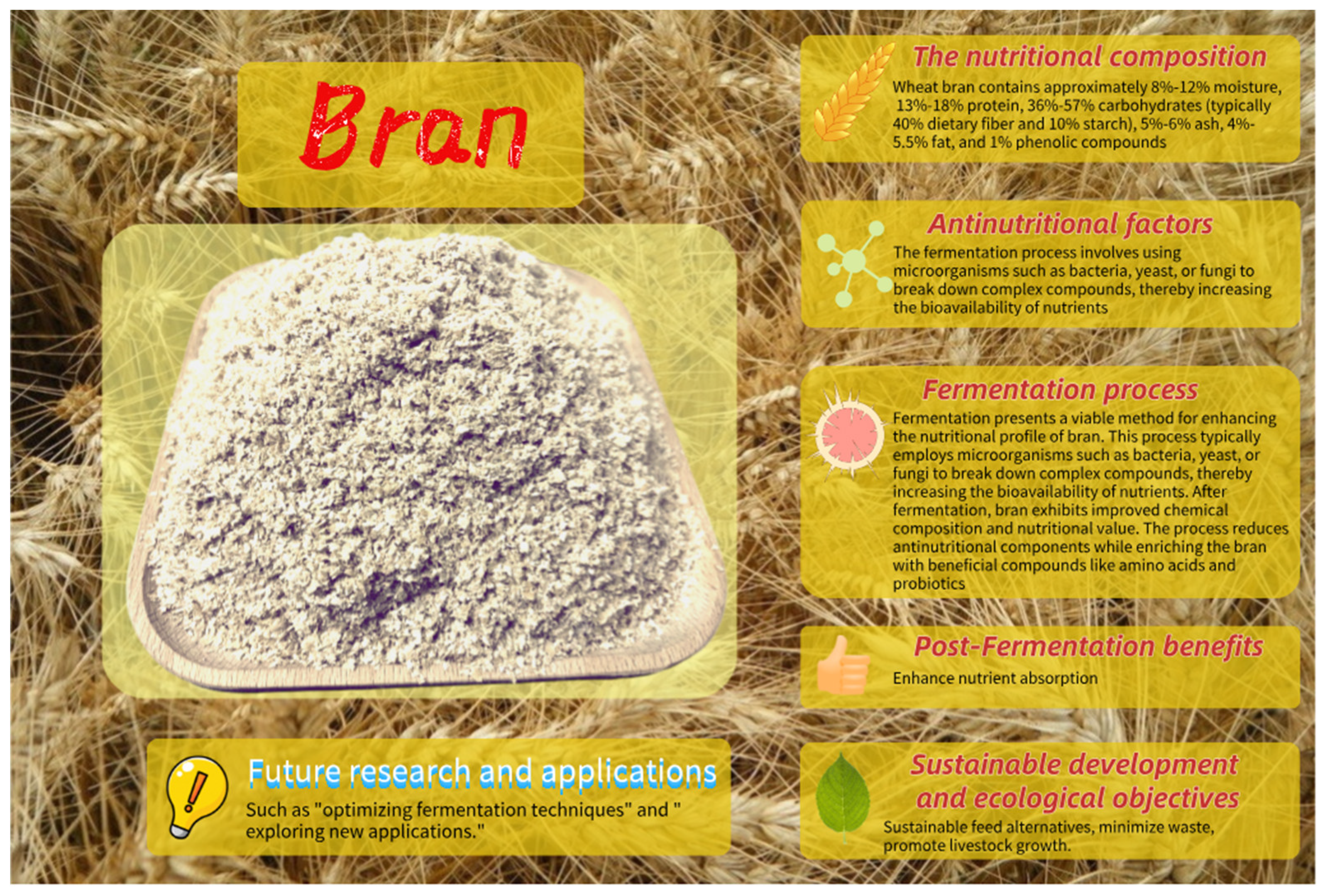

1. Introduction

2. Issues in the Application of Wheat Bran

3. Fermentation Technology and Strain Selection

3.1. Solid-State Fermentation

3.2. Liquid State Fermentation

3.3. Influence of Pivotal Strains

- It can reduce antinutritional factors in feed ingredients, thereby enhancing their nutritional quality.

- It promotes the absorption and utilization of nutrients such as proteins, vitamins, and minerals.

- It elevates the levels of bioactive substances in fermentation substrates and generates beneficial metabolic products.

- It regulates gut health in livestock and poultry, boosts immune function, and enhances animal productivity.

4. Transformation Analysis of Chemical Constituents in Fermented Bran

4.1. Enhancing Nutritional Value Through Fermentation

4.2. Reduction of Antinutritional Factors

5. Functional Study of Fermented Bran

5.1. Exhibiting Probiotic Properties

5.2. Antioxidants and Immune Modulation

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kim, J.C.; Simmins, P.H.; Mullan, B.P.; Pluske, J.R. The digestible energy value of wheat for pigs, with special reference to the post-weaned animal. Anim. Feed Sci. Technol. 2005, 122, 257–287. [Google Scholar] [CrossRef]

- McCann, M.E.E.; McEvoy, J.D.G.; McCracken, K.J.; Simmins, P.H. Effect of variety, endosperm hardness, the 1B/1R translocation and enzyme addition on the nutritive value of wheat for growing pigs. Irish J. Agric. Food Res. 2006, 45, 173–185. [Google Scholar]

- Acquaah, G. Principles of Plant Genetics and Breeding, 2nd ed.; Wiley-Blackwell: Oxford, UK, 2012. [Google Scholar]

- Brown, A. Understanding Food: Principles and Preparation, 4th ed.; Wadsworth Inc. Fulfillment: Pacific Grave, CA, USA, 2010; p. 372, Chapter 17. [Google Scholar]

- Jakobsen, G.V.; Jensen, B.B.; Knudsen, K.E.; Canibe, N. Improving the nutritional value of rapeseed cake and wheat dried distillers grains with solubles by addition of enzymes during liquid fermentation. Anim. Feed. Sci. Technol. 2015, 208, 198–213. [Google Scholar] [CrossRef]

- Missotten, J.A.; Michiels, J.; Degroote, J.; De Smet, S. Fermented liquid feed for pigs: An ancient technique for the future. J. Anim. Sci. Biotechnol. 2016, 7, 4. [Google Scholar] [CrossRef]

- Wiseman, J. Variations in starch digestibility in non-ruminants. Anim. Feed Sci. Technol. 2006, 130, 66–77. [Google Scholar] [CrossRef]

- Oleson, B.T. World wheat production, utilization and trade. In Wheat—Production, Properties and Quality; Bushuk, W., Rasper, V.F., Eds.; Blackie Academic & Professional, An Imprint of Chapman & Hall: London, UK, 1994; pp. 1–11, Chapter 1. [Google Scholar]

- McFall, K.L.; Fowler, M.E. Overview of wheat classification and trade. In Wheat: Science and Trade; Carver, B.F., Ed.; Wiley-Blackwell: London, UK, 2009; pp. 439–454, Chapter 19. [Google Scholar]

- Myrie, S.B.; Bertolo, R.F.; Sauer, W.C.; Ball, R.O. Effect of common antinutritive factors and fibrous feedstuffs in pig diets on amino acid digestibilites with special emphasis on threonine. J. Anim. Sci. 2008, 86, 609–619. [Google Scholar] [CrossRef]

- Sauer, W.C.; Kennelly, J.J.; Aherne, F.X.; Cichon, R.M. Availabilities of amino acids in barley and wheat for growing pigs. Can. J. Anim. Sci. 1981, 61, 793–802. [Google Scholar] [CrossRef]

- Laurinen, P.; Valaja, J.; Näsi, M.; Smeds, K. Effects of different expander processing conditions on the nutritive value of barley and wheat by-products in pig diets. Anim. Feed Sci. Technol. 1998, 74, 213–227. [Google Scholar] [CrossRef]

- Huang, S.X.; Sauer, W.C.; Marty, B.; Hardin, R.T. Amino acid digestibilities in different samples of wheat shorts for growing pigs. J. Anim. Sci. 1999, 77, 2469–2477. [Google Scholar] [CrossRef]

- Jondreville, C.; van den Broecke, J.; Grosjean, F.; van Cauwenberghe, S.; Gâtel, F. Ileal true digestibility of amino acids in wheat milling by-products for pigs. Ann. Zootech. 2000, 49, 55–65. [Google Scholar] [CrossRef]

- Rosenfelder, P.; Eklund, M.; Mosenthin, R. Nutritive value of wheat and wheat by-products in pig nutrition: A review. Anim. Feed Sci. Technol. 2013, 185, 107–125. [Google Scholar] [CrossRef]

- Zhao, J.B.; Liu, P.; Huang, C.F.; Liu, L.; Li, E.K.; Zhang, G.; Zhang, S. Effect of wheat bran on apparent total tract digestibility, growth performance, fecal microbiota and their metabolites in growing pigs. Anim. Feed. Sci. Technol. 2018, 239, 14–26. [Google Scholar] [CrossRef]

- Slominski, B.A.; Boros, D.; Campbell, L.D.; Guenter, W.; Jones, O. Wheat by-products in poultry nutrition. Part I. Chemical and nutritive composition of wheat screenings, bakery by-products and wheat mill run. Can. J. Anim. Sci. 2004, 84, 421–428. [Google Scholar] [CrossRef]

- Onipe, O.O.; Jideani AI, O.; Beswa, D. Composition and functionality of wheat bran and its application in some cereal food products. Int. J. Food Sci. Technol. 2015, 50, 2509–2518. [Google Scholar] [CrossRef]

- Zhang, R.; Li, Y.; Ren, C.; Yang, H.; Zhang, L. Current research status of wheat bran application in feed and food processing fields. Food Food Ind. 2023, 30, 1–5. [Google Scholar]

- Adebo, J.A.; Njobeh, P.B.; Gbashi, S.; Oyedeji, A.B.; Ogundele, O.M.; Oyeyinka, S.A.; Adebo, O.A. Fermentation of Cereals and Legumes: Impact on Nutritional Constituents and Nutrient Bioavailability. Fermentation 2022, 8, 63. [Google Scholar] [CrossRef]

- Olaniran, A.F.; Okonkwo, C.E.; Iranloye, Y.M.; Morakinyo, O.O.; Taiwo, A.E.; Erinle, O.C.; Bamidele, O.P.; Ojo, O.A.; Malomo, A.A.; Osemwegie, O.O. Fermented Gluten-Free Multi-Grain Cereal Paste Development: The Role of the Orange-Fleshed Sweet Potato (OFSP) as a Dietary Supplement. Nutr. Metab. Insights 2023, 16, 1–11. [Google Scholar] [CrossRef]

- Paz, A.; Outeiriño, D.; Pinheiro de Souza Oliveira, R.; Domínguez, J.M. Fed-batch production of vanillin by Bacillus aryabhattai BA03. New Biotechnol. 2018, 40, 186–191. [Google Scholar] [CrossRef]

- Prasath, C.S.; Sivadas, C.A.; Chandran, C.H.; Suchithra, T. Precision fermentation of sustainable products in the food industry. In Entrepreneurship with Microorganisms; Elsevier: Amsterdam, The Netherlands, 2024; pp. 163–177. [Google Scholar]

- Nayak, J.; Basu, A.; Dey, P.; Kumar, R.; Upadhaya, A.; Ghosh, S.; Bishayee, B.; Mishra, S.R.; Tripathy, S.K.; Banerjee, S.; et al. Transformation of agro-biomass into vanillin through novel membrane integrated value-addition process: A state-of-art review. Biomass Convers. Biorefinery 2023, 13, 14317–14340. [Google Scholar] [CrossRef]

- Taiwo, A.E.; Madzimbamuto, T.N.; Ojumu, T.V. Process Optimization and Biotransformation of Ferulic Acid to Vanillin in a Low-Cost Nitrogen Source. ChemEngineering 2024, 8, 68. [Google Scholar] [CrossRef]

- Wei, S.; Jiaying, X.; Xuechun, L.; Jinghong, X.; Yue, L. Research Progress on Distribution, Forms and Preparation Methods of Ferulic Acid in Wheat. Sci. Technol. Food Ind. 2022, 43, 445–452. [Google Scholar]

- Xin, Z.; Zengping, G.A. Research Progress in Ferulic Acid. Chin. J. Mod. Chin. Med. 2020, 22, 138–147. [Google Scholar]

- Winkler-Moser, J.K.; Hwang, H.S.; Bakota, E.L.; Palmquist, D.A. Synthesis of steryl ferulates with various sterol structures and comparison of their antioxidant activity. Food Chem. 2015, 169, 92–101. [Google Scholar] [CrossRef]

- Pontonio, E.; Dingeo, C.; Gobbetti, M.; Rizzello, C.G. Maize milling by-Products: From food wastes to functional ingredients through lactic acid bacteria fermentation. Front. Microbiol. 2019, 10, 561. [Google Scholar] [CrossRef]

- Hu, B.H. Using Fermentation Release Type Bound Phenolic Acids in the Wheat Bran and Its Antioxidant Activity; South China University of Technology: Guangzhou, China, 2015. [Google Scholar]

- Andreasen, M.F.; Kroon, P.A.; Williamson, G.; Garcia-Conesa, M.T. Esterase Activity Able to Hydrolyze Dietary Antioxidant Hydroxycinnamates Is Distributed along the Intestine of Mammals. J. Agric. Food Chem. 2001, 49, 5679–5684. [Google Scholar] [CrossRef]

- Mathew, S.; Abraham, T.E. Ferulic acid:an antioxidant found naturally in plant cell walls and feruloyl esterases involved in its release and their applications. Crit. Rev. Biotechnol. 2004, 24, 59–83. [Google Scholar] [CrossRef]

- Adom, K.K.; Sorrells, M.E.; Liu, R.H. Phytochemicals and antioxidant activity of milled fractions of different wheat varieties. J. Agric. Food Chem. 2002, 50, 3010–3014. [Google Scholar] [CrossRef] [PubMed]

- Fenglian, C. Preparation of Xylooligosacchatide from Wheat Bran by Biological Technique; Northeast Forestry University Paper: Harbin, China, 2006. [Google Scholar]

- Lyu, Z.; Li, Y.; Liu, H.; Li, E.; Li, P.; Zhang, S.; Wang, F.; Lai, C. Net energy content of rice bran, defatted rice bran, corn gluten feed, and corn germ meal fed to growing pigs using indirect calorimetry. J. Anim. Sci. 2018, 96, 1877–1888. [Google Scholar] [CrossRef]

- Crepin, V.; Faulds, C.; Connerton, I. Functional classification of the microbial feruloyl esterases. Appl. Microbiol. Bi0technology 2004, 63, 647–652. [Google Scholar] [CrossRef] [PubMed]

- Zhao, L.; Xue, L.; Li, B.; Jiang, A.; Lu, S. Effect of Ferulic Acid on Accumulation of Histamine and Histamine-Producing Bacteria in Smoked Horsemeat Sausages. Chin. J. Food Biotechnol. 2020, 39, 39–46. [Google Scholar]

- Zeng, X.-R.; Chen, W.-L.; Liu, C.-X.; Xun, F. Protective Effect of Sodium Ferulate on Contrast-Induced Nephropathy in Diabetic Rats. J. Wuhan Univ. (Med.) 2014, 35, 89–92. [Google Scholar]

- Cheng, Q.; Li, Y.W.; Yang, C.F.; Zhong, Y.J.; He, H.; Zhu, F.C.; Li, L. Methyl ferulic acid attenuates ethanol-induced hepatic steatosis by regulating AMPK and FoxO1 pathways in rats and L-02 cells. Chem. Biol. Interact. 2018, 291, 180–189. [Google Scholar] [CrossRef] [PubMed]

- Chen, A.C.; Shu, H.Q.; Zhou, Z.H.; Xiao, R. Experimental study of the sodium ferulate in chronic cerebral ischemic rats. Chin. J. Neuroimmunol. Psychiatry 2017, 24, 411–415. [Google Scholar]

- Xia, L.; Huang, M.; Mei, J.; Yan, L.Z. Ferulic acid inhibits the invasion and migration of cervical cancer HeLa cells by regulating mitochondrial apoptosis in vitro. J. Wenzhou Med. Univ. 2021, 51, 974–979. [Google Scholar]

- Ou, S. The Function and Application of Ferulic Acid; Guangzhou Food Industry Science and Technology: Guangzhou, China, 2002; pp. 50–53. [Google Scholar]

- Liu, Y.; Dai, Q.Z.; Huang, X.G.; Chen, L.X. Biological Functions of Ferulic Acid and Its Application in Livestock Production. Chin. J. Anim. Nutr. 2020, 32, 5524–5531. (In Chinese) [Google Scholar]

- Pyrzynska, K. Ferulic acid-A brief review of its extraction, bioavailability and biological activity. Separations 2024, 11, 204. [Google Scholar] [CrossRef]

- Valadez-García, K.M.; Avendaño-Reyes, L.; Díaz-Molina, R.; Mellado, M.; Meza-Herrera, C.A.; Correa-Calderón, A.; Macías-Cruz, U. Free ferulic acid supplementation of heat-stressed hair ewe lambs: Oxidative status, feedlot performance, carcass traits and meat quality. Meat Sci. 2021, 173, 108395. [Google Scholar] [CrossRef]

- Kavitha, M.; Manivasagam, T.; Essa, M.M.; Tamilselvam, K.; Selvakumar, G.P.; Karthikeyan, S.; Thenmozhi, J.A.; Subash, S. Mangiferin antagonizes rotenone: Induced apoptosis through attenuating mitochondrial dysfunction and oxidativestress in SK-N-SH neuroblastoma cells. Neurochem. Res. 2014, 4, 668–676. [Google Scholar] [CrossRef]

- Brindzová, L.; Mikulášová, M.; Takácsová, M.; Mošovská, S.; Opattová, A. Evaluation of the mutagenicity and antimutagenicity of extracts from oat, buckwheat and wheat bran in the Salmonella/microsome assay. J. Food Compos. Anal. 2009, 22, 87–90. [Google Scholar] [CrossRef]

- Krygier, K.; Sosulski, F.; Lawrence, H. Free, esterified and insoluble-bound phenolic acids. 2. composition of phenolic acids in rapeseed flour and hulls. J. Agric. Food Chem. 1982, 30, 334–336. [Google Scholar] [CrossRef]

- Wang, B.N.; Liu, H.F.; Zheng, J.B.; Fan, M.T.; Cao, W. Distribution of phenolic acids in different tissues of jujube and their antioxidant acitivity. J. Agric. Food Chem. 2006, 54, 1288–1292. [Google Scholar]

- Sunan, B.; Matthida, W.; Sirithon, S. Changes in phenolic acids and antioxidant activity in tissues of jujube and their antioxidant activity. J. Agric. Food Chem. 2009, 57, 45–71. [Google Scholar]

- Landete, J.M. Plant and mammalian lignans: A review of source, intake, metabolism, intestinal bacteria and health. Food Res. Int. 2012, 46, 410–424. [Google Scholar] [CrossRef]

- Yuan, X.P.; Wang, J.; Yao, H.Y. Antioxidant Activity of feruloylated oligosaccharides from wheat bran. Food Chem. 2005, 90, 759–764. [Google Scholar] [CrossRef]

- Lin, C.M.; Chiu, J.H.; Wu, I.H.; Wang, B.W.; Pan, C.M.; Chen, Y.H. Ferulic acid augments angiogenesis viaVEGF, PDGF and HIF-1α. J. Nutr. Biochem. 2010, 21, 627–633. [Google Scholar] [CrossRef]

- Lin, Q. Ferulic Acid Reduces Oxidative Damage of PC12 Cells Induced by H2O, by Regulating IGF-1/PI3K/AKT Pathway; Guangzhou University of Traditional Chinese Medicine: Guangzhou, China, 2019. [Google Scholar]

- Celiktas, M.S.; Kirsch, C.; Smirnova, I. Cascade processing of wheat bran through a biorefinery approach. Energy Convers. Manag. 2014, 84, 633–639. [Google Scholar] [CrossRef]

- Nakaji, S.; Sugawara, K.; Ohta, M.; Iwane, S.; Aisawa, T.; Munakata, A. Endoscopic evaluation of the preventive effect of wheat bran against 1,2-dimethylhydrazine induced large bowel carcinogenesis in rats. Nutr. Res. 1996, 16, 1521–1527. [Google Scholar] [CrossRef]

- Katina, K.; Laitila, A.; Juvonen, R.; Liukkonen, K.H.; Kariluoto, S.; Piironen, V.; Landberg, R.; Åman, P.; Poutanen, K. Bran fermentation as a means to enhance technological properties and bioactivity of rye. Food Microbiol. 2007, 24, 175. [Google Scholar] [CrossRef]

- Wrigley, C.W.; Corke, H.; Seetharaman, K.; Faubion, J. Encyclopedia of Food Grains, 2nd ed.; Academic Press: Oxford, UK, 2016. [Google Scholar]

- Yan, H. Mechanistic Study of the Weight Loss and Lipid-Lowering Effects of Wheat Bran Polyphenols and Wheat Bran Oil on Diet-Induced Obese Rats; Xinjiang Medical University: Urumqi, China, 2023; pp. 6+48. [Google Scholar]

- Ferri, M.; Happel, A.; Zanaroli, G.; Bertolini, M.; Chiesa, S.; Commisso, M.; Guzzo, F.; Tassoni, A. Advances in combined enzymatic extraction of ferulic acid from wheat bran. New Biotechnol. 2020, 56, 38–45. [Google Scholar] [CrossRef]

- National Research Council (NRC). Basic Research Opportunities in Earth Science; National Academy Press: Washington, DC, USA, 2012.

- University of California Agriculture and Natural Resources (ANR). Table of By-Products and Unconventional Feed Ingredients in the United States Feedstuffs; University of California: St. Davis, CA, USA, 2017. [Google Scholar]

- INRAE. INRA Scientific Database; INRAE: Paris, France, 2024. [Google Scholar]

- Chinese Feed Ingredients and Nutritional Values, 31st ed.; Tongfang Knowledge Network: Beijing, China, 2020; pp. 73–78. [CrossRef]

- Park, S.; Cho, E.; Chung, H.; Cho, K.; Sa, S.; Balasubramanian, B.; Choi, T.; Jeong, Y. Digestibility of phosphorous in cereals and co-products for animal feed. Saudi J. Biol. Sci. 2019, 26, 373–377. [Google Scholar] [CrossRef]

- Zhu, Y.; González-Ortiz, G.; Solà-Oriol, D.; López-Colom, P.; Martín-Orúe, S.M. Screening of the ability of natural feed ingredients commonly used in pig diets to interfere with the attachment of ETEC K88 (F4) to intestinal epithelial cells. Anim. Feed. Sci. Technol. 2018, 242, 111–119. [Google Scholar] [CrossRef]

- Shi, S.; Wen, J.; Liu, Y.-X. Recent Advances in Wheat Bran Polysaccharides:Extraction, Structure and Bioactivities. Food Ind. Sci. Technol. 2023, 44, 466–473. [Google Scholar]

- Zhou, Y.; Sun, H.; Lv, F. Study on modification of wheat dietary fiber. Chin. Feed. 2022, 57–61. [Google Scholar] [CrossRef]

- Zhao, X.Q. Preparation of wheat bran Xylan by double enzymes. Food Eng. 2023, 1, 48–51. [Google Scholar]

- Ana, F.; Nuno, M.; Victor, F. Polyphenol-Dietary Fiber Conjugates from Fruits and Vegetables: Nature and Biological Fate in a Food and Nutrition Perspective. Foods 2023, 12, 1052. [Google Scholar] [CrossRef]

- Papadaki, E.S.; Palaiogiannis, D.; Lalas, S.I.; Mitlianga, P.; Makris, D.P. Polyphenol Release from Wheat Bran Using Ethanol-Based Organosolv Treatment and Acid/Alkaline Catalysis: Process Modeling Based on Severity and Response Surface Optimization. Antioxidants 2022, 11, 2457. [Google Scholar] [CrossRef]

- Martín-Diana, A.B.; García-Casas, M.J.; Martínez-Villaluenga, C.; Frías, J.; Peñas, E.; Rico, D. Wheat and Oat Brans as Sources of Polyphenol Compounds for Development of Antioxidant Nutraceutical Ingredients. Foods 2021, 10, 115. [Google Scholar] [CrossRef]

- Girard Audrey, L.; Awika Joseph, M. Effects of edible plant polyphenols on gluten protein functionality and potential applications of polyphenol-gluten interactions. Compr. Rev. Food Sci. Food Saf. 2020, 19, 2164–2199. [Google Scholar] [CrossRef]

- Xu, X.; Lu, J.; Wang, F. Study on the Scavenging Effect of Wheat Bran Total Flavones on 2, 2-Diphenyl-1-Picrylhydrazyl Radical. Processing 2014, 39, 42–44. [Google Scholar]

- Shi, Q.; Guan, F.Q.; Sun, H.; Zhao, Y.-Y.; Wang, M.; Zhang, J.-H.; Feng, X.; Shan, Y. Antitumor effects and preliminary mechanism of total flavone from wheat bran. Food Sci. Technol. 2013, 38, 220–222+226. [Google Scholar] [CrossRef]

- Yu, C.Q.; Zhang, D.; Mou, G.Q.; Fu, S.X.; Liu, J.; Zhang, L. Effect of Flavonoids Extract of Wheat Germ on Serum Lipids and Antioxidation. Chin. J. Nutr. 2001, 23, 390–392. [Google Scholar]

- Yu, C.; Yuan, X.; Fu, S.; Zhang, A.; Zhang, L. A Study for the Effect of Fiavonoids of Wheat Germ on Serum Lipids Level and Antioxidation in Experimental Rats. Chin. J. Food Sci. 2001, 1, 30–33. [Google Scholar]

- Bai, F.; Cai, T. Research progress of flavonoid bioactivity and its mechanism. Food Sci. 1999, 20, 11–13. [Google Scholar]

- Wang, C.; Shi, C.; Su, W.; Jin, M.; Xu, B.; Hao, L.; Zhang, Y.; Lu, Z.; Wang, F.; Wang, Y.; et al. Dynamics of the Physicochemical Characteristics, Microbiota, and Metabolic Functions of Soybean Meal and Corn Mixed Substrates during Two-Stage Solid-State Fermentation. mSystems 2020, 5, 19. [Google Scholar] [CrossRef]

- Călinoiu, L.F.; Cătoi, A.-F.; Vodnar, D.C. Solid-state yeast fermented wheat and oat bran as a route for delivery of antioxidants. Antioxidants 2019, 8, 372. [Google Scholar] [CrossRef]

- Chu, Y.T.; Lo, C.T.; Chang, S.C.; Lee, T.T. Effects of trichoderma fermented wheat bran on growth performance, intestinal morphology and histological findings in broiler chickens. Ital. J. Anim. Sci. 2017, 16, 82–92. [Google Scholar] [CrossRef]

- Lin, W.; Lee, M.; Lin, L.; Chang, S.; Lee, T. Immunomodulation properties of solid-state fermented laetiporussulphureus ethanol extracts in chicken peripheral blood monocytes in vitro. Braz. J. Poult. Sci. 2019, 21, 1–10. [Google Scholar] [CrossRef]

- Zhao, H.M.; Guo, X.N.; Zhu, K.X. Impact of solid state fermentation on nutritional, physical and flavor properties of wheat bran. Food Chem. 2017, 217, 28–36. [Google Scholar] [CrossRef]

- Lin, W.C.; Lee, T.T. Effects of laetiporus sulphureus-fermented wheat bran on growth performance, intestinal microbiota and digesta characteristics in broiler chickens. Animals 2020, 10, 1457. [Google Scholar] [CrossRef]

- Zhang, A.; Wei, M.; Yan, L.; Zhou, G.; Li, Y.; Wang, H.; Yang, Y.; Yin, W.; Guo, J.; Cai, X. Effects of feeding solid-state fermented wheat bran on growth performance and nutrient digestibility in broiler chickens. Poult. Sci. 2022, 101, 101402. [Google Scholar] [CrossRef]

- Lee, M.; Lin, W.; Lin, L.; Wang, S.; Chang, S.; Lee, T. Effects of dietary antrodia cinnamomea fermented product supplementation on antioxidation, anti-inflammation, and lipid metabolism in broiler chickens. Asian-Australas. J. Anim. Sci. 2020, 33, 1113. [Google Scholar] [CrossRef] [PubMed]

- Teng, P.Y.; Chang, C.L.; Huang, C.M.; Chang, S.C.; Lee, T.T. Effects of solid-state fermented wheat bran by bacillus amyloliquefaciens and saccharomyces cerevisiae on growth performance and intestinal microbiota in broiler chickens. Ital. J. Anim. Sci. 2017, 16, 552–562. [Google Scholar] [CrossRef]

- Song, G.J.; Li, R.Z.; Pan, Y.Q.; Cui, Y.H.; Liu, C.Z.; Wei, X.B.; Liu, X.Y. Advantages of probiotic fermented feed and its application in livestock and poultry production. China Poult. 2016, 38, 64–67. [Google Scholar]

- Yang, C.H. Effects of Compound Chinese Herbal Additives on Growth Performance and Serum Biochemical Indices of Meat Duck. Feed. Res. 2021, 44, 35–38. [Google Scholar]

- Missotten, J.; Michiels, J.; Ovyn, A.; Smet, S.D.; Dierick, N. Fermented liquid feed for pigs. Arch. Anim. Nutr. 2010, 64, 437–466. [Google Scholar] [CrossRef]

- Shen, Y.H.; Huang, X.L.; Lv, H.; Chen, P.; Wang, Z.; Zheng, N.; Zheng, Y.L. Fermentation feed production process and its application in pig production. Guangdong Agric. Sci. 2018, 45, 118–125. [Google Scholar]

- Guan, X.F.; Liu, Z.Y.; Huang, J.X.; Liu, Z.H. Application of liquid fermented feed in pig production. J. Anim. Nutr. 2018, 30, 4312–4319. [Google Scholar]

- He, Y.B. Analysis of highly standardized meat duck breeding and disease prevention and control. China Anim. Health 2022, 24, 103+105. [Google Scholar]

- Zhang, Y.; Xiao, Y.L.; Dai, X. Meat duck breeding technology and key points of disease prevention and control. Anim. Husb. Environ. 2021, 020, 90. [Google Scholar]

- Cui, Y.Y.; Tian, Z.M.; Lu, H.J.; Deng, D.; Ma, X.; Chen, W. Bran Nutritional Value and Its Fermented Feed Application in Animal Production. Chin. Livest. J. Anim. Husb. Vet. Med. 2019, 46, 2902–2915. [Google Scholar]

- Chen, X.X. Effects of Storage Condition on the Storage Quality of Fish Meal, Wheat Bran and Extruded Full-Fat Soybean; Henan University of Technology: Zhengzhou, China, 2011. [Google Scholar]

- Hou, Z.; Liu, J. Study on storage conditions of wheat bran. Mod. Anim. Sci. Technol. 2016, 7, 68. [Google Scholar] [CrossRef]

- Gong, Z.; Lv, X.; Yang, J.; Luo, X.; Shuai, L. Chemocatalytic Conversion of Lignocellulosic Biomass to Ethanol: A Mini-Review. Catalysts 2022, 12, 922. [Google Scholar] [CrossRef]

- Wang, L.; Ding, C.; Yang, S. The Research of Ethanol Production from Cellulosic Materials. Agric. Prod. Process. 2010, 4, 21-24+41. [Google Scholar]

- Coda, R.; Kärki, I.; Nordlund, E.; Heiniö, R.L.; Poutanen, K.; Katina, K. Influence of particle size on bioprocess induced changes on technological functionality of wheat bran. Food Microbiol. 2014, 37, 69–77. [Google Scholar] [CrossRef] [PubMed]

- Yan, Y.; Su, G.; He, Y. Improvement the Content of Phenolic Compounds and Antioxidant Activityin Sugarcane Leaves by Mixed Fungi Solid-State Fermentation. Food Ind. 2021, 42, 271–275. [Google Scholar]

- Niu, M.; Hou, G.G.; Wang, L.; Chen, Z. Effects of superfine grinding on the quality characteristics of whole-wheat flour and its raw noodle product. J. Cereal Sci. 2014, 60, 382–388. [Google Scholar] [CrossRef]

- Ding, C.; Zhou, Y.; Zhang, H.; Zhang, N.; Zhang, Z. Study of pretreatment conditions in preparing wheat bran oligosaccharides. Food Oil 2014, 27, 23–26. [Google Scholar]

- Zhang, Y.; Fengmin, G.; Zhonghu, H. Effects of bran hydration and autoclaving on processing quality of Chinese steamed bread and noodles produced from whole grain wheat flour. Cereal Chem. 2019, 96, 104–114. [Google Scholar] [CrossRef]

- Li, H.; Song, Z.; Fan, Z. The main nutritional characteristic of wheat bran and its application in animal feed. China Feed 2018, 66–69. [Google Scholar]

- Cowieson, A.J.; Acamovic, T.; Bedford, M.R. Phytic acid and phytase: Implications for protein utilization by poultry. Poult. Sci. 2006, 85, 878–885. [Google Scholar] [CrossRef]

- Satinder, K.; Savita, S.; Baljit, S.; Dar, B.N. Effect of extrusion variables (temperature, moisture) on the antinutrient components of cereal brans. J. Food Sci. Technol. 2015, 52, 1670–1676. [Google Scholar]

- Li, C.; Ma, L.; Wang, L.; Zhang, Z.; Chen, Y.; Chen, J.; Jiang, Q.; Song, Z.; He, X.; Tan, B.; et al. Optimization of Solid-State Fermentation Conditions of Quercus liaotungensis by Bacillus subtilis. Fermentation 2023, 9, 75. [Google Scholar] [CrossRef]

- Liu, H.Y.; Yu, D.J.; Qiu, C.W.; Wu, C. Research progress on the development and application technology of fermented feed resources. Contemp. Livest. Poult. Breed. Ind. 2020, 48–49. [Google Scholar]

- Albers, E.; Larsson, C.; Lidén, G.; Niklasson, C.; Gustafsson, L. Influence of the nitrogen source on Saccharomyces cerevisiae anaerobic growth and product formation. Appl. Environ. Microbiol. 1996, 62, 3187–3195. [Google Scholar] [CrossRef] [PubMed]

- Davis, L.; Rogers, P.; Pearce, J.; Peiris, P. Evaluation of zymomonas-based ethanol production from a hydrolysed waste starch stream. Biomass Bioenergy 2006, 30, 809–814. [Google Scholar] [CrossRef]

- Li, Z.; Wang, D.; Shi, Y.-C. Effects of nitrogen source on ethanol production in very high gravity fermentation of corn starch. J. Taiwan Inst. Chem. Eng. 2017, 70, 229–235. [Google Scholar] [CrossRef]

- Edwinoliver, N.; Thirunavukarasu, K.; Purushothaman, S.; Rose, C.; Gowthaman, M.; Kamini, N. Corn steep liquor as a nutrition adjunct for the production of Aspergillus niger lipase and hydrolysis of oils thereof. J. Agric. Food Chem. 2009, 57, 10658–10663. [Google Scholar] [CrossRef]

- Sreenath, H.K.; Jeffries, T.W. Effect of corn steep liquor on fermentation of mixed sugars by candida shehatae fpl-702. Appl. Biochem. Biotechnol. 1996, 57, 551–561. [Google Scholar] [CrossRef]

- Taiwo, A.E.; Madzimbamuto, T.N.; Ojumu, T.V. Optimization of Corn Steep Liquor Dosage and Other Fermentation Parameters for Ethanol Production by Saccharomyces cerevisiae Type 1 and Anchor Instant Yeast. Energies 2018, 11, 1740. [Google Scholar] [CrossRef]

- Gao, J.; Atiyeh, H.K.; Phillips, J.R.; Wilkins, M.R.; Huhnke, R.L. Development of low cost medium for ethanol production from syngas by clostridium ragsdalei. Bioresour. Technol. 2013, 147, 508–515. [Google Scholar] [CrossRef]

- Açıkel, Ü.; Er¸san, M.; Açıkel, Y.S. Optimization of critical medium components using response surface methodology for lipase production by rhizopus delemar. Food Bioprod. Process 2010, 88, 31–39. [Google Scholar] [CrossRef]

- Ba¸s, D.; Boyacı, I.H. Modeling and optimization ii: Comparison of estimation capabilities of response surface methodology with artificial neural networks in a biochemical reaction. J. Food Eng. 2007, 78, 846–854. [Google Scholar] [CrossRef]

- Hahn, R.; Cecot, C. The benefits and costs of ethanol: An evaluation of the government’s analysis. J. Regul. Econ. 2009, 35, 275–295. [Google Scholar] [CrossRef]

- Malherbe, S.; Bauer, F.; Du Toit, M. Understanding problem fermentations: A review. S. Afr. J. Enol. Vitic. 2007, 28, 169–186. [Google Scholar] [CrossRef]

- Pfeiffer, T.; Morley, A. An evolutionary perspective on the crabtree effect. Front. Mol. Biosci. 2014, 1, 17. [Google Scholar] [CrossRef]

- Tesfaw, A.; Assefa, F. Current trends in bioethanol production by Saccharomyces cerevisiae: Substrate, inhibitor reduction, growth variables, coculture, and immobilization. Int. Sch. Res. Not. 2014, 2014, 532852. [Google Scholar] [CrossRef] [PubMed]

- Li, X.H. Types and main roles of feed microorganisms. Feed. Ind. 2002, 02, 30–32. [Google Scholar]

- Zhu, L.G. Process Research and Application of Microbial Fermented Feed for Meat Duck; Northwestern University: Evanston, IL, USA, 2007. [Google Scholar]

- Wang, Y.; Song, D.; Li, A.; Wang, W.; Zhou, H.; Wang, L.; Liu, K. Research progress on development and application technology of fermented feed resources. China Feed 2019, 11, 75–80. [Google Scholar] [CrossRef]

- Feng, Y.; Wang, L.; Khan, A.; Zhao, R.; Wei, S.; Jing, X. Fermented wheat bran by xylanase-producing Bacillus cereus boosts the intestinal microflora of broiler chickens. Poult. Sci. 2019, 99, 263–271. [Google Scholar] [CrossRef]

- Shen, T.; Wang, G.; You, L.; Zhang, L.; Ren, H.; Hu, W.; Qiang, Q.; Wang, X.; Ji, L.; Gu, Z.; et al. Polysaccharide from wheat bran induces cytokine expression via the toll-like receptor 4-mediated p38 MAPK signaling pathway and prevents cyclophosphamide-induced immunosuppression in mice. Food Nutr. Res. 2017, 61, 1344523. [Google Scholar] [CrossRef]

- Li, J.Y.; Shen, J.; Lu, Z.F.; Yu, J.X. Process control and application of bran fermentation feed. Chin. J. Anim. Sci. 2013, 49, 46–50. [Google Scholar]

- Li, A.K.; Wang, W.W.; Wang, Y.W.; He, B.B. Research Progress of Biological Feed and Its Use Technology in Substitution and Reduction of Antibiotics. Chin. J. Anim. Nutr. 2020, 32, 4773–4806. [Google Scholar]

- State Council of the People’s Republic of China. Regulations on the Administration of Feed and Feed Additives; State Council of the People’s Republic of China: Beijing, China, 2017.

- Tao, L.J.; Li, J.T.; Yang, G.Q. Microbial fermented feed and its application in animal production. China Feed 2020, 13, 15–20. [Google Scholar] [CrossRef]

- Salim, H.M.; Kang, H.K.; Akter, N.; Kim, D.W.; Kim, J.H.; Kim, M.J.; Na, J.C.; Jong, H.B.; Choi, H.C.; Suh, O.S.; et al. Supplementation of direct-fed microbials as an alternative to antibiotic on growth performance, immune response, cecal microbial population, and ileal morphology of broiler chickens. Poult. Sci. 2013, 92, 2084–2090. [Google Scholar] [CrossRef] [PubMed]

- Kobashi, Y.; Ohmori, H.; Tajima, K.; Kawashima, T.; Uchiyama, H. Reduction of chlortetracycline-resistant Escherichia coli in weaned piglets fed fermented liquid feed. Anaerobe 2008, 14, 201–204. [Google Scholar] [CrossRef]

- Mehdi, R.A. (Ed.) Aflatoxins—Recent Advances and Future Prospects; IntechOpen: London, UK, 2013. [Google Scholar]

- Pan, H.; Zhang, Y.; Xiao, J. Study on the application of Bacillus probiotics used in antibiotic-free breeding. China Feed 2019, 50–56. [Google Scholar]

- Yuan, Y.; Ge, Y.; Zhong, Z.Y.; Wang, M.; Xie, P. Research Progress of Sacharomyces in Animal Feed Nutrition. Feed. Rev. 2018, 4, 19–22. [Google Scholar]

- Zhong, W.; Qi, H.; Zhao, Y. Application of Yeast Preparation to Regulate Ruminant Production and Rumen Ecology. Chin. J. Anim. Husb. 2018, 54, 26–30. [Google Scholar]

- Xia, C.; Ai, Q.; Xiang, N.; Zhan, S.; Liu, X.; Fang, B. The Function of Fermented Wheat Bran and Its Application in Animal Feed. Chin. J. Anim. Husb. 2017, 53, 17–21. [Google Scholar] [CrossRef]

- Shantha, T.; Rati, E.R.; Bhavani Shankar, T.N. Behaviour of Aspergillus flavus in presence of Aspergillus niger during biosynthesis of aflatoxin B1. Antonie Van Leeuwenhoek 1990, 58, 121–127. [Google Scholar] [CrossRef]

- Liu, J. Applications of Aspergillus Niger Media in Biological Fermentation Feed and Effects of Its Production on Animal Disease-Resistant Ability. Ph.D. Thesis, Jilin University, Changchun, China, 2012. [Google Scholar]

- Kumar, V.; Singh, A. Phytate: Its chemistry and potential impacts on nutrition and health. Curr. Res. Nutr. Food Sci. 2021, 9, 75–84. [Google Scholar]

- Schlemmer, U.; Frøkiær, H. Phytate: Nutritional impacts. In Phytate in Food and Feed; Wageningen Academic Publishers: Wageningen, The Netherlands, 2008; pp. 57–78. [Google Scholar]

- Vaintraub, I.A.; Lapteva, N.A. The role of phytases in the ecosystems. J. Gen. Microbiol. 1988, 134, 90–95. [Google Scholar]

- O’Dell, B.L.; Savage, J.E. Factors affecting the nutritional availability of zinc in the presence of phytate. J. Nutr. 1970, 100, 388–394. [Google Scholar]

- Reddy, N.R.; Sathe, S.K. Phytates in legumes and cereals. Adv. Food Nutr. Res. 2002, 44, 1–15. [Google Scholar]

- Rahman, K. Phytate and protein interactions in cereal grains: Consequences for nutrition and human health. Food Chem. 2007, 105, 1177–1189. [Google Scholar]

- Pallavi, R.; Kumar, A. Phytase enzyme production from selected fungal strains: A review. Food Technol. Biotechnol. 2019, 57, 12–21. [Google Scholar]

- Zhang, H.; Wang, Y. The interaction of phytate with dietary minerals and its implications for human health. Food Rev. Int. 2018, 34, 470–486. [Google Scholar]

- Wang, Z. Effects of Different Strains Fermented Bran on the Production Performance, Antioxidant and Fecal Microorganism of Pigs; Shandong Agricultural University: Taian, China, 2018. [Google Scholar]

- Wang, L.; Dai, S.; Sun, F. Effect of Biofermenting on the Nutrient Composition of Wheat Bran. J. Anhui Univ. Sci. Technol. 2002, 16, 31–33. [Google Scholar]

- Wang, J.; Sun, B.; Cao, Y.; Wang, C. Wheat bran feruloyl oligosaccharides enhance the antioxidant activityof rat plasma. Food Chem. 2010, 123, 472–476. [Google Scholar] [CrossRef]

- Wang, C.C.; Lin, L.J.; Chao, Y.P.; Chiang, C.J.; Lee, M.T.; Chang, S.C.; Yu, B.; Lee, T.T. Antioxidantmolecular targets of wheat bran fermented by white rotfungi and its potential modulation of antioxidative status in broiler chickens. Br. Poult. Sci. 2017, 58, 262–271. [Google Scholar] [CrossRef]

- Zhao, S.; Zhang, S.; Yao, G. Preparation and Preparation of Bacillus licheniformis, Bacillus subtilis and Lactobacillus plantarum. CN 103911323A, 9 July 2014. [Google Scholar]

- Yang, F.; Lv, J.L. Study on the degradation of milk protein by Aspergillus oryzae. Food Sci. Technol. 2009. [Google Scholar]

- Newton, G.L.; Hale, O.M.; Plank, C.O. Effect of wheat bran in practical diets on mineral absorption by pigs at two ages. Canadian Vet. J. La Rev. Vet. Can. 1983, 63, 399–408. [Google Scholar] [CrossRef]

- Ekholm, P.; Virkki, L.; Ylinen, M.; Johansson, L. The effect of phytic acid and some natural chelating agents on the solubility of mineral elements in oat bran. Food Chem. 2003, 80, 165–170. [Google Scholar] [CrossRef]

- Zhai, F.; Wen, S.; Yan, Q. Anti-nutrition factors in livestock and poultry diets. Feed Expo 2003, 11, 22–23. [Google Scholar]

- Butel, M.J. Probiotics, gut microbiota and health. Médecine Mal. Infect. 2014, 44, 1. [Google Scholar] [CrossRef] [PubMed]

- Abudabos, A.M.; Alyemni, A.H.; Almarshad, M.B.A. Bacillus subtilis PB6 based-probiotic (CloSTATTM) improves intestinal morphological and microbiological status of broiler chickens under Clostridium perfringens challenge. Int. J. Agric. Biol. 2013, 15, 978–982. [Google Scholar]

- Courtin, C.M.; Broekaert, W.F.; Swennen, K.; Lescroart, O.; Onagbesan, O.; Buyse, J.; Decuypere, E.; Van de Wiele, T.; Marzorati, M.; Verstraete, W.; et al. Dietary Inclusion of Wheat Bran Arabinoxylooligosaccharides Induces Beneficial Nutritional Effects in Chickens. Cereal Chem. 2008, 85, 607–613. [Google Scholar] [CrossRef]

- Kanski, J.; Aksenova, M.; Stoyanova, A.; Butterfield, D.A. Ferulic acid antioxidant protection against hydroxyland peroxyl radical oxidation in synaptosomal andneuronal cell culture systems in vitro: Structure-activitystudies. J. Nutr. Biochem. 2002, 13, 273–281. [Google Scholar] [CrossRef]

- Hromádková, Z.; Paulsen, B.S.; Polovka, M.; Košťálová, Z.; Ebringerová, A. Structural features of two heteroxylan polysaccharide fractions from wheat bran with anti-complementary and antioxidant activities. Carbohydr. Polym. 2013, 93, 22–30. [Google Scholar] [CrossRef]

- Duan, Y.X. Effects of Feruloylated Saccharides on Antioxidative Capacity in Wistar Rats and the Its Regulation Mechanism. Master’s Thesis, Inner Mongolia Agricultural University, Hohhot, China, 2018. [Google Scholar]

- Yu, X.H. Preparation of Feruloyl Oligosaccharides by Fermentation of Wheat Bran by Spore Stalk Fungus and Its Biological Activity. Ph.D. Thesis, Nanjing Agricultural University, Nanjing, China, 2012. [Google Scholar]

- Ling, A.-J.; Li, X.-P.; Liu, L.; Ma, Z.; Hu, X.-Z. Effect of Fungal Fermentation on Wheat Bran Phenolic Acids Contents and Antioxidant Activity. Chin. J. Food Biotechnol. 2019, 38, 136–142. [Google Scholar]

- Stevenson, L.E.; Phillips, F.; O’Sullivan, K.; Walton, J. Wheat bran: Its composition and benefits to health, a European perspective. Int. J. Food Sci. Nutr. 2012, 63, 1001–1013. [Google Scholar] [CrossRef] [PubMed]

- Hu, Y.C.; Wang, Y.; Meng, Z.Q.; Liu, Y.H.; Wang, R.F.; Wang, W.W.; Hao, X.R.; An, X.P.; Qi, J.W. Effects of Fermented Wheat Bran Polysaccharides on Meat Quality, Muscle Amino Acid Composition and Expression of Antioxidant Enzymes and Muscle Fiber Type-Related Genes in Muscle of Mutton Sheep. Chin. J. Anim. Nutr. 2019, 322, 932–940. [Google Scholar]

- Shi, J.X. Study on Microbial Fermentation of Bran Polysaccharide and Antioxidant Activity of Its Crude Products. Master’s Thesis, Inner Mongolia Agricultural University, Hohhot, Chian, 2017. [Google Scholar]

- An, X.; Wang, Y.; Shi, J.; Duan, Y.-X.; Zhang, Q.-R.; Meng, Z.-Q.; Li, X.; Qi, J.-W. Extraction of Fermented Wheat Bran Polysaccharides and lts Antioxidative Effects on Rats. Food Ind. Sci. Technol. 2018, 39, 281–285. [Google Scholar]

| Item | Dry Matter | Crude Protein | Crude Ash | Crude Fat | Crude Fibre | Neutral Detergent Fiber | Acid Detergent Fiber | Ca | P | N-Free Extract | Reference Material |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Wheat bran | 87.38 | 15.08 | 4.16 | 4.72 | 7.77 | 32.28 | 11.00 | 0.10 | 0.99 | - | NRC 2012 [61] |

| Wheat bran | 89.00 | 17.10 | 6.90 | 4.40 | 11.30 | - | 15.00 | 0.13 | 1.38 | - | USA FEEDSTUFF [62] |

| Wheat bran | 87.10 | 14.80 | 5.00 | 3.40 | 9.20 | 39.60 | 11.90 | - | - | - | INRA [63] |

| Primary bran | 87.00 | 15.70 | 4.90 | 3.90 | 6.50 | 37.00 | 13.00 | 0.11 | 0.92 | 56.00 | Chinese feed ingredients and nutritional value Value (Edition 31, 2020) [64] |

| Secondary bran | 87.00 | 14.30 | 4.80 | 4.00 | 6.80 | 41.30 | 11.90 | 0.10 | 0.93 | 57.00 | |

| Wheat bran (Korea) | 87.14 | 17.02 | 5.09 | 2.88 | 8.45 | 34.21 | 11.24 | 0.70 | 3.02 | 53.70 | Park et al. (2019) [65] |

| Kamut bran | 89.89 | 11.77 | 3.56 | 2.38 | - | 29.07 | 9.42 | - | - | - | Zhu et al. (2018) [66] |

| Wheat bran | 88.29~91.38 | 13.47~15.97 | 3.96~5.54 | 2.33~2.97 | - | 29.16~46.13 | 8.27~14.81 | - | - | - | |

| Spelt bran | 89.57~89.76 | 14.11~15.4 | 3.28~7.07 | 2.83~3.55 | - | 21.03~36.76 | 5.46~13.55 | - | - | - |

| Nutritional Components | Pre-Fermentation (Bran) | Post-Fermentation (Treated with Different Strains) | References |

|---|---|---|---|

| Crude fibre | 6.5%–11.3%, Higher content, affects nutrient absorption, possesses antinutritional factors. | Upon fermentation, 20–30% of the crude fiber is degraded, thereby diminishing the obstruction to mineral absorption. | [1,3,4,5,8,9,10,11,12,13,15,16,17,18,19,31,33,56,57,66,80,85,87,105,128,138] |

| Crude protein | Approximately 11.77% to 18%. | Following fermentation, it is transformed into easily absorbable small peptides and amino acids, with their content increasing, reaching up to 21% at its peak. | [1,3,4,5,8,9,10,11,12,13,15,16,17,18,19,31,33,56,57,66,80,85,87,105,128,138] |

| Phytic acid | High in content, it reduces the bioavailability of minerals. | Fermentation reduces phytic acid by approximately 50%, thereby enhancing the bioavailability of minerals. | [83,94,141,142,143,144,145,146,147,148] |

| Phenolic | When bound to cellulose, their bioactivity becomes restricted. | Post-fermentation, 20–30% of these compounds are liberated, thereby enhancing their antioxidant capacity. | [15,16,33,34,49,50,58,149] |

| Bioactive | Present in low concentrations. | Enhancement of amino acids, small peptides, and related probiotics. | [74,80,82,116,150,151,152] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, L.; Wang, H.; Qiu, Y.; Bai, Z.; Yang, Z.; Li, E.; Ma, X.; Xiao, D. Alternative Uses of Fermented Wheat Bran: A Mini Review. Fermentation 2024, 10, 611. https://doi.org/10.3390/fermentation10120611

Ma L, Wang H, Qiu Y, Bai Z, Yang Z, Li E, Ma X, Xiao D. Alternative Uses of Fermented Wheat Bran: A Mini Review. Fermentation. 2024; 10(12):611. https://doi.org/10.3390/fermentation10120611

Chicago/Turabian StyleMa, Longteng, Hao Wang, Yutao Qiu, Ziyue Bai, Zizhong Yang, Enkai Li, Xiaokang Ma, and Dingfu Xiao. 2024. "Alternative Uses of Fermented Wheat Bran: A Mini Review" Fermentation 10, no. 12: 611. https://doi.org/10.3390/fermentation10120611

APA StyleMa, L., Wang, H., Qiu, Y., Bai, Z., Yang, Z., Li, E., Ma, X., & Xiao, D. (2024). Alternative Uses of Fermented Wheat Bran: A Mini Review. Fermentation, 10(12), 611. https://doi.org/10.3390/fermentation10120611