Stability and Effects of Protected Palmitic Acid on In Vitro Rumen Degradability and Fermentation in Lactating Goats

Abstract

1. Introduction

2. Materials and Methods

2.1. Animal Ethics Standards and Localization

2.2. Preparation of Treatments

2.3. Culture Medium, Inoculation, and In Vitro Gas Production and Degradability

2.4. Laboratory Analysis

2.5. Calculations and Statistical Analysis

3. Results

4. Discussion

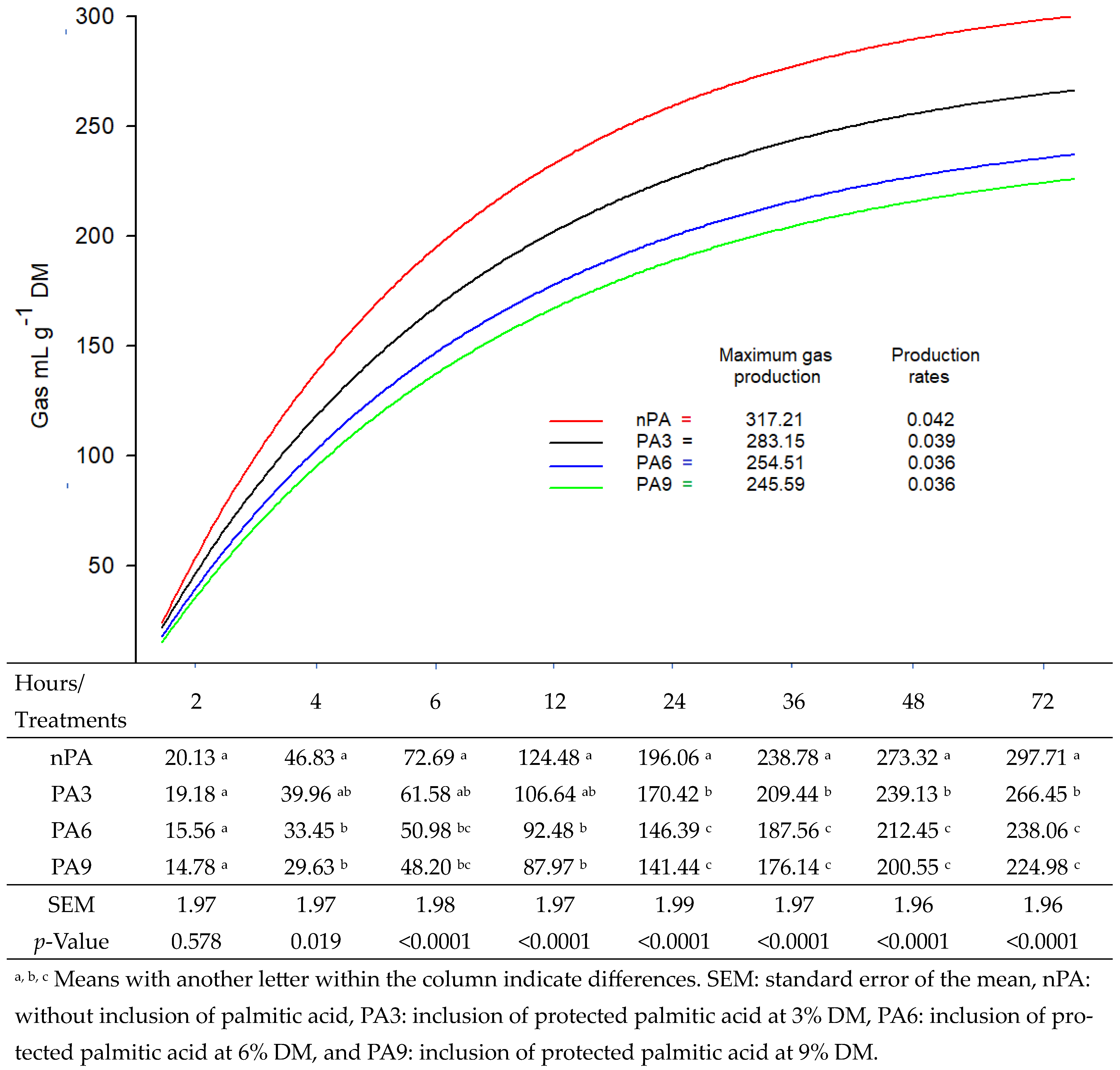

4.1. Gas Production

4.2. In Vitro Degradability

4.3. Saturated and Unsaturated Fatty Acids

4.4. Volatile Fatty Acids and Methane

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Setiawan, W.A.; Yusiati, L.M.; Hanim, C.; Muhlisin, M. Ruminal hydrolytic enzymes activity and in vitro gas production kinetics of pelleted leaves mixture as tannin source: Acacia mangium willd, Swietenia mahagoni, and Artocarpus heterophyllus. In Proceedings of the 4th International Conference of Animal Science and Technology (ICAST 2021), Makassar, Indonesia, 9–10 November 2021; Volume 2628. [Google Scholar] [CrossRef]

- Enjalbert, F.; Nicot, M.C.; Bayourthe, C.; Moncoulon, R. Effects of duodenal infusions of palmitic, stearic, or oleic acids on milk composition and physical properties of butter. J. Dairy Sci. 2000, 83, 1428–1433. [Google Scholar] [CrossRef] [PubMed]

- Jenkins, T.C.; Bridges, W.C. Protection of fatty acids against ruminal biohydrogenation in cattle. Eur. J. Lipid Sci. Technol. 2007, 109, 778–789. [Google Scholar] [CrossRef]

- Chinnadurai, K.; Kanwal, H.K.; Tyagi, A.K.; Stanton, C.; Ross, P. High conjugated linoleic acid enriched ghee (clarified butter) increases the antioxidant and antiatherogenic potency in female Wistar rats. Lipids Health Dis. 2013, 12, 121. [Google Scholar] [CrossRef] [PubMed]

- Tódero, C.; Ticiani, E.; Júnior, W.B.; Silva, E.D.; Miqueluti, D.J.; Oliveira, D.E. Palmitic acid increases milk fat content and yield in lactating cows. Trop. Subtrop. Agroecos. 2016, 19, 319–325. Available online: https://www.redalyc.org/pdf/939/93949148011.pdf (accessed on 5 April 2023). [CrossRef]

- Wang, J.P.; Bu, D.P.; Wang, J.Q.; Huo, X.K.; Guo, T.J.; Wei, H.Y.; Zhou, L.Y.; Rastani, R.R.; Baumgard, L.H.; Li, F.D. Effect of saturated fatty acid supplementation on production and metabolism indices in heat-stressed mid-lactation dairy cows. J. Dairy Sci. 2010, 93, 4121–4127. [Google Scholar] [CrossRef]

- Lock, A.L.; Preseault, C.L.; Rico, J.E.; DeLand, K.E.; Allen, M.S. Feeding a C16:0 enriched fat supplement increased the yield of milk fat and improved conversion of feed to milk. J. Dairy Sci. 2013, 96, 6650–6659. [Google Scholar] [CrossRef]

- Jensen, R.G. The composition of bovine milk lipids: January 1995 to December 2000. J. Dairy Sci. 2002, 85, 295–350. [Google Scholar] [CrossRef]

- Toyes-Vargas, E.; Cordoba-Matson, M.; Espinoza-Villavicencio, J.; Palacio-Espinosa, A.; Murillo-Amador, B. Goat milk fatty acid composition in the Peninsula of Baja California, México. Rev. MVZ Córdoba 2013, 18, 3843–3850. [Google Scholar] [CrossRef][Green Version]

- De Souza, J.; Lock, A.L. Effects of timing of palmitic acid supplementation on production responses of early-lactation dairy cows. J. Dairy Sci. 2019, 102, 260–273. [Google Scholar] [CrossRef]

- Western, M.M.; De Souza, J.; Lock, A.L. Effects of commercially available palmitic and stearic acid supplements on nutrient digestibility and production responses of lactating dairy cows. J. Dairy Sci. 2020, 103, 5131–5142. [Google Scholar] [CrossRef]

- De Souza, J.; Lock, A.L. Long-term palmitic acid supplementation interacts with parity in lactating dairy cows: Production responses, nutrient digestibility, and energy partitioning. J. Dairy Sci. 2018, 101, 3044–3056. [Google Scholar] [CrossRef]

- Weld, K.A.; Armentano, L.E. The effects of adding fat to diets of lactating dairy cows on total-tract neutral detergent fiber digestibility: A meta-analysis. J. Dairy Sci. 2017, 100, 1766–1779. [Google Scholar] [CrossRef]

- Stoop, W.M.; Van Arendonk, J.A.M.; Heck, J.M.L.; Van Valenberg, H.J.F.; Bovenhuis, H. Genetic parameters for major milk fatty acids and milk production traits of Dutch Holstein-Friesians. J. Dairy Sci. 2008, 91, 385–394. [Google Scholar] [CrossRef]

- Chilliard, Y.; Toral, P.G.; Shingfield, K.J.; Rouel, J.; Leroux, C.; Bernard, L. Effects of diet and physiological factors on milk fat synthesis, milk fat composition and lipolysis in the goat: A short review. Small Rumin. Res. 2014, 122, 31–37. [Google Scholar] [CrossRef]

- Lévesque, J.; Dion, S.; Rico, D.E.; Brassard, M.È.; Gervais, R.; Chouinard, P.Y. Milk yield and composition in dairy goats fed extruded flaxseed or a high-palmitic acid fat supplement. J. Dairy Res. 2022, 89, 355–366. [Google Scholar] [CrossRef]

- Nam, I.S.; Choi, J.H.; Seo, K.M.; Ahn, J.H. In vitro and lactation responses in mid-lactating dairy cows fed protected amino acids and fat. Asian-Australas. J. Anim. Sci. 2014, 27, 1705. [Google Scholar] [CrossRef] [PubMed]

- Behan, A.A.; Loh, T.C.; Fakurazi, S.; Kaka, U.; Kaka, A.; Samsudin, A.A. Effects of supplementation of rumen protected fats on rumen ecology and digestibility of nutrients in sheep. Animals 2019, 9, 400. [Google Scholar] [CrossRef] [PubMed]

- McGrath, J.; Duval, S.; Tamassia, L.F.M.; Kindermann, M.; Stemmler, R.T.; De Gouvea, V.N.; Acedo, T.S.; Immig, I.; Williams, S.N.; Celi, P. Nutritional strategies in ruminants: A lifetime approach. Res. Veter. Sci. 2017, 116, 28–39. [Google Scholar] [CrossRef]

- Gadeyne, F.; De Neve, N.; Vlaeminck, B.; Fievez, V. State of the art in rumen lipid protection technologies and emerging interfacial protein cross-linking methods. Europ. J. Lipid Sci. Technol. 2017, 119, 1600345. [Google Scholar] [CrossRef]

- Pena, O.M.; Murphy, K.; Long, N.; Lascano, G.J.; Jenkins, T.C.; Aguerre, M.J. Evaluating the Rumen Degradation of Novel Protected Gelatin Capsules Containing Fish Oil Fed to Lactating Dairy Cows. Animals 2023, 13, 16. [Google Scholar] [CrossRef] [PubMed]

- García, E. Modificación del Sistema de Clasificación Climática de Köppen; Instituto de Geografía, Universidad Nacional Autónoma de México: Mexico City, Mexico, 2004; Volume 5, pp. 11–90. Available online: http://www.publicaciones.igg.unam.mx/index.php/ig/catalog/book/83 (accessed on 5 May 2023).

- National Research Council. Nutrient Requirements of Small Ruminants: Sheep, Goats, Cervids and New World Camelids, 1st ed.; National Academic Press: Washington, DC, USA, 2007; pp. 271–292. [Google Scholar]

- Menke, K.H.; Steingass, H. Estimation if the energetic feed value obtained from the chemical analysis and the in vitro gas production using rumen fluid. Animal Res. Dev. 1988, 28, 9–52. [Google Scholar]

- Association of Official Agricultural Chemists. Official Methods of the Association of the Agricultural Chemists, 18th ed.; Association of Official Agricultural Chemists: Jasper, MI, USA, 2005; Available online: https://www.researchgate.net/publication/292783651–AOAC–2005 (accessed on 2 August 2023).

- Van Soest, P.J.; Roberson, J.B.; Lewis, B.A. Methods for dietary fiber, neutral detergent fiber, and nonstarch polysaccharides in relation to animal nutrition. J. Dairy Sci. 1991, 74, 3583–3597. [Google Scholar] [CrossRef] [PubMed]

- Palmquist, D.L.; Jenkins, T.C. Challenges with fats and fatty acid methods. J. Anim. Sci. 2003, 81, 3250–3254. [Google Scholar] [CrossRef] [PubMed]

- Darwin, C.W.; Cord-Ruwisch, R. Concurrent lactic and volatile fatty acid analysis of microbial fermentation samples by gas chromatography with heat pre-treatment. J. Chromatogr. Sci. 2018, 56, 1–5. [Google Scholar] [CrossRef] [PubMed]

- Ørskov, E.R.; McDonald, I. The estimation of protein degradability in the rumen from incubation measurements weighted according to rate of passage. J. Agric. Sci. 1979, 92, 499–503. [Google Scholar] [CrossRef]

- Oliveira, T.S.; Fernandes, A.M.; Processi, E.F.; Baffa, D.F.; Camilo, M.G. Stoichiometric models for prediction of enteric methane production. Bioscience 2022, 38, 1981–3163. [Google Scholar] [CrossRef]

- Ramirez, J.E.; Zinn, R.A. Interaction of dietary magnesium level on the feeding value of supplemental fat in finishing diets for feedlot steers. J. Anim. Sci. 2000, 78, 2072–2080. [Google Scholar] [CrossRef]

- Statistical Analysis System. SAS User’s Guide: Statics, Version 9.0.; SAS Institute, Inc.: Cary, NC, USA, 2011. [Google Scholar]

- Sujatha, S.; Prabhu, S.M. A Study on the importance of pre-hoc and post- hoc ANOVA tests in agriculture research. Int. J. Scient. Technol. Res. 2020, 9, 6142–6144. [Google Scholar]

- Amanullah, S.M.; Kim, D.H.; Paradhipta, D.H.V.; Lee, H.J.; Joo, Y.H.; Lee, S.S.; Kim, E.T.; Kim, S.C. Effects of Essential Fatty Acid Supplementation on in vitro Fermentation Indices, Greenhouse Gas, Microbes, and Fatty Acid Profiles in the Rumen. Front. Microbiol. 2021, 12, 637220. [Google Scholar] [CrossRef] [PubMed]

- Gomes de Souza, J.; dio Vaz, C. Ruminal biohidrogenation and main impact on met the fatty acid profile: A review. Res. Soc. Develop. 2021, 10, 13. [Google Scholar] [CrossRef]

- Nur Atikah, I.; Alimon, A.R.; Yaakub, H.; Abdullah, N.; Jahromi, M.F.; Ivan, M.; Samsudin, A.A. Profiling of rumen fermentation, microbial population and digestibility in goats fed with dietary oils containing different fatty acids. BMC Veter. Res. 2018, 14, 344. [Google Scholar] [CrossRef]

- Vargas, J.E.; Andrés, S.; López-Ferreras, L.; Snelling, T.J.; Yáñez-Ruíz, D.R.; García-Estrada, C.; López, S. Dietary supplemental plant oils reduce methanogenesis from anaerobic microbial fermentation in the rumen. Sci. Rep. 2020, 10, 1613. [Google Scholar] [CrossRef] [PubMed]

- Sun, X.; Wang, Y.; Ma, X.; Li, S.; Wang, W. Producing natural functional and low-carbon milk by regulating the diet of the cattle the fatty acid associated rumen fermentation, biohydrogenation, and microorganism response. Front. Nutr. 2022, 9, 955846. [Google Scholar] [CrossRef]

- Baldwin, R.L.; Connor, E.E. Rumen function and development. Vet. Clin. N. Am.-Food Anim. Pract. 2017, 33, 427–439. [Google Scholar] [CrossRef] [PubMed]

- Yanza, Y.R.; Szumacher-Strabel, M.; Jayanegara, A.; Kasenta, A.M.; Gao, M.; Huang, H.; Cieślak, A. The effects of dietary medium-chain fatty acids on ruminal methanogenesis and fermentation in vitro and in vivo: A meta-analysis. J. Anim. Physiol. Anim. Nutr. 2021, 105, 874–889. [Google Scholar] [CrossRef] [PubMed]

- Embaby, M.G.; Günal, M.; AbuGhazaleh, A. Effect of unconventional oils on in vitro rumen methane production and fermentation. Cienc. Investig. Agrar. 2019, 46, 276–285. [Google Scholar] [CrossRef]

- Li, H.; Wang, D.; Yuan, Y. Progress of Conjugated Linoleic Acid on Milk Fat Metabolism in Ruminants and Humans. Animals 2023, 13, 3429. [Google Scholar] [CrossRef]

- Jacob, A.B.; Balakrishnan, V.; Kathirvelan, C. Effect of amount and source of vegetable oils in a high fibrous cattle diet on in vitro rumen fermentation, nutrient degradability and rumen cis-9, trans-11 CLA concentration. J. Appl. Anim. Res. 2012, 40, 148–153. [Google Scholar] [CrossRef]

- Enjalbert, F.; Combes, S.; Zened, A.; Meynadier, A. Rumen microbiota and dietary fat: A mutual shaping. J. Appl. Microbiol. 2017, 123, 782–797. [Google Scholar] [CrossRef]

- Fessenden, S.W.; Hackmann, T.J.; Ross, D.A.; Foskolos, A.; Van Amburgh, M.E. Ruminal bacteria and protozoa composition, digestibility, and amino acid profile determined by multiple hydrolysis times. J. Dairy Sci. 2017, 100, 7211–7226. [Google Scholar] [CrossRef]

- Panahiha, P.; Mirzaei-Alamouti, H.; Kazemi-Bonchenari, M.; Aschenbach, J.R. Growth performance, nutrient digestibility, and ruminal fermentation of dairy calves fed starter diets with alfalfa hay versus corn silage as forage and soybean oil versus palm fatty acids as fat source. J. Dairy Sci. 2022, 105, 9597–9609. [Google Scholar] [CrossRef]

- Nur Atikah, I.; Alimon, A.R.; Yaakub, H.; Samsudin, A.A.; Candyrine, S.C.L.; Wan Nooraida, W.M.; Abidah, M.N.; Amirul, F.M.; Mookiah, S. Effects of vegetable oil supplementation on rumen fermentation and microbial population in ruminant: A review. Trop. Anim. Health Prod. 2021, 53, 422. [Google Scholar] [CrossRef]

- Mizrahi, I.; Wallace, R.J.; Moraïs, S. The rumen microbiome: Balancing food security and environmental impacts. Nat. Rev. Microbiol. 2021, 19, 553–566. [Google Scholar] [CrossRef]

- Zhao, W.; Chen, X.; Xiao, J.; Chen, X.H.; Zhang, X.F.; Wang, T.; Zhen, Y.G.; Qin, G.X. Pre partum body condition score affects milk yield, lipid metabolism and oxidation status of Holstein cows. Asian-Australas. J. Anim. Sci. 2019, 32, 1889–1896. [Google Scholar] [CrossRef]

- Prieto-Manrique, E.; Vargas-Sánchez, J.E.; Angulo-Arizala, J.; Mahecha-Ledesma, L. Aceites vegetales sobre ácidos grasos y producción de metano in vitro en vacas lecheras. Agron. Mesoam. 2017, 28, 1–18. [Google Scholar] [CrossRef][Green Version]

- Baee, H.; Ghoorchi, T.; Toghdory, A.; Mokhtarpour, A. Growth performance, ruminal fermentation characteristics and microbial protein synthesis of lambs fed palmitic and stearic acid. Anim. Feed Sci. Technol. 2023, 302, 115674. [Google Scholar] [CrossRef]

- Abubakr, A.R.; Alimon, A.R.; Yaakub, H.; Abdullah, N.; Ivan, M. Digestibility, rumen protozoa, and ruminal fermentation in goats receiving dietary palm oil by-products. J. Saudi Soc. Agric. Sci. 2013, 12, 147–154. [Google Scholar] [CrossRef]

- Castillo-Lopeza, E.; Domínguez, M.G. Factors affecting the ruminal microbial composition and methods to determine microbial protein yield. Review. Rev. Mex. Cienc. Pecu. 2019, 10, 120–148. [Google Scholar] [CrossRef]

- Cieslak, A.; El-Sherbiny, M.; Szczechowiak, J.; Kowalczyk, D.; Pers-Kamczyc, E.; Bryszak, M.; Szumacher-Strabel, M. Rapeseed and fish oil mixtures supplied at low dose can modulate milk fatty acid composition without affecting rumen fermentation and productive parameters in dairy cows. Anim. Sci. Pap. Rep. 2015, 33, 357–372. [Google Scholar]

- Kholif, A.E.; Morsy, T.A.; Abdo, M.M. Crushed flaxseed versus flaxseed oil in the diets of Nubian goats: Effect on feed intake, digestion, ruminal fermentation, blood chemistry, milk production, milk composition and milk fatty acid profile. Animal Feed Sci. Technol. 2018, 244, 66–75. [Google Scholar] [CrossRef]

- Arcos-Álvarez, D.N.; Aguilar-Urquizo, E.; Sanginés-García, J.R.; Chay-Canul, A.J.; Molina-Botero, I.; Tzec-Gamboa, M.; Piñeiro-Vázquez, Á.T. Effect of Adding Extra Virgin Olive Oil to Hair Sheep Lambs’ Diets on Productive Performance, Ruminal Fermentation Kinetics and Rumen Ciliate Protozoa. Animals 2022, 12, 2588. [Google Scholar] [CrossRef] [PubMed]

- Morgavi, D.P.; Forano, E.; Martin, C.; Newbold, C.J. Microbial ecosystem and methanogenesis in ruminants. Animals 2010, 4, 1024–1036. [Google Scholar] [CrossRef] [PubMed]

| Nutrient Composition | Treatments | ||||||

|---|---|---|---|---|---|---|---|

| nPA | PA3 | PA6 | PA9 | SEM | Linear | Quadratic | |

| Initial sample (mg−1) | |||||||

| DM | 456.72 | 456.97 | 464.35 | 463.87 | 0.38 | ||

| Nitrogen | 8.62 | 8.43 | 8.54 | 8.27 | 0.01 | ||

| OM | 384.33 | 383.17 | 390.75 | 390.71 | 0.32 | ||

| NDF | 179.13 | 186.26 | 203.24 | 197.14 | 0.16 | ||

| ADF | 70.75 | 78.96 | 93.10 | 96.35 | 0.07 | ||

| Fat | 9.32 | 26.60 | 35.38 | 48.24 | 0.02 | ||

| C16:0 | 2.52 | 18.95 | 27.33 | 39.98 | 0.03 | ||

| C18:0 | 0.21 | 0.67 | 0.97 | 1.35 | 0.02 | ||

| C18:1 | 2.22 | 2.92 | 3.05 | 3.28 | 0.02 | ||

| C18:2 | 3.93 | 3.04 | 2.65 | 2.17 | 0.02 | ||

| C18:3 | 0.22 | 0.22 | 0.23 | 0.27 | 0.02 | ||

| Residual sample in batch culture at 72 h (mg−1) | |||||||

| DM | 107.66 | 134.32 | 158.65 | 163.15 | 3.12 | <0.0001 | 0.002 |

| OM | 100.45 | 124.66 | 146.28 | 150.12 | 2.88 | <0.0001 | 0.002 |

| NDF | 68.82 | 74.64 | 80.85 | 77.74 | 1.90 | 0.035 | 0.130 |

| ADF | 38.24 | 45.39 | 47.90 | 47.84 | 1.50 | 0.018 | 0.119 |

| C16:0 | 2.19 | 20.40 | 28.98 | 41.68 | 0.60 | <0.0001 | 0.024 |

| C18:0 | 3.02 | 2.59 | 3.06 | 2.81 | 0.28 | 0.917 | 0.800 |

| C18:1 | 0.67 | 0.95 | 1.20 | 1.33 | 0.09 | 0.009 | 0.498 |

| C18:2 | 0.40 | 0.21 | 0.24 | 0.18 | 0.03 | 0.020 | 0.184 |

| C18:3 | 0.03 | 0.02 | 0.04 | 0.02 | 0.01 | 0.699 | 0.451 |

| Degradation in batch culture incubation at 72 h (%) | |||||||

| DM | 76.44 | 70.61 | 65.78 | 64.83 | 0.68 | <0.0001 | 0.001 |

| OM | 73.86 | 67.47 | 62.57 | 61.58 | 0.74 | <0.0001 | 0.001 |

| NDF | 65.64 | 64.47 | 65.47 | 64.64 | 8.74 | 0.962 | 0.986 |

| ADF | 37.90 | 35.21 | 42.42 | 43.95 | 2.12 | 0.096 | 0.465 |

| C16:0 | 12.91 | −7.48 | −6.02 | −4.24 | 3.39 | 0.077 | 0.079 |

| C18:0 | −1308.01 | −286.17 | −215.66 | −107.80 | 38.70 | <0.0001 | 0.001 |

| C18:1 | 69.93 | 67.47 | 60.74 | 59.59 | 2.95 | 0.066 | 0.854 |

| C18:2 | 89.81 | 92.96 | 90.91 | 91.85 | 1.14 | 0.614 | 0.540 |

| C18:3 | 88.70 | 92.16 | 87.97 | 94.37 | 2.69 | 0.375 | 0.637 |

| BH,% | 75.09 | 79.62 | 74.51 | 72.65 | 1.34 | 0.031 | 0.042 |

| Items | Treatments | ||||||

|---|---|---|---|---|---|---|---|

| nPA | PA3 | PA6 | PA9 | SEM | Linear | Quadratic | |

| VFA (mmol/100 mol) Acetate | 59.94 | 61.28 | 62.82 | 65.21 | 0.518 | <0.0001 | 0.33 |

| Propionate | 23.99 | 24.33 | 23.90 | 22.64 | 0.387 | 0.01 | 0.05 |

| Butirate | 16.07 | 14.39 | 13.28 | 12.13 | 0.392 | <0.0001 | 0.52 |

| Total VFA | 105.01 | 104.48 | 104.37 | 104.14 | 0.180 | 0.004 | 0.46 |

| A:P | 2.50 | 2.52 | 2.63 | 2.88 | 0.061 | <0.0001 | 0.06 |

| CH4 (mLg−1 DM) | 26.80 | 26.64 | 27.01 | 27.97 | 0.278 | 0.004 | 0.05 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Álvarez-Torres, J.N.; Ramírez-Bribiesca, J.E.; Bautista-Martínez, Y.; Crosby-Galván, M.M.; Granados-Rivera, L.D.; Ramírez-Mella, M.; Ruiz-González, A. Stability and Effects of Protected Palmitic Acid on In Vitro Rumen Degradability and Fermentation in Lactating Goats. Fermentation 2024, 10, 110. https://doi.org/10.3390/fermentation10020110

Álvarez-Torres JN, Ramírez-Bribiesca JE, Bautista-Martínez Y, Crosby-Galván MM, Granados-Rivera LD, Ramírez-Mella M, Ruiz-González A. Stability and Effects of Protected Palmitic Acid on In Vitro Rumen Degradability and Fermentation in Lactating Goats. Fermentation. 2024; 10(2):110. https://doi.org/10.3390/fermentation10020110

Chicago/Turabian StyleÁlvarez-Torres, Jenny Nathalia, Jacinto Efrén Ramírez-Bribiesca, Yuridia Bautista-Martínez, María Magdalena Crosby-Galván, Lorenzo Danilo Granados-Rivera, Mónica Ramírez-Mella, and Alexis Ruiz-González. 2024. "Stability and Effects of Protected Palmitic Acid on In Vitro Rumen Degradability and Fermentation in Lactating Goats" Fermentation 10, no. 2: 110. https://doi.org/10.3390/fermentation10020110

APA StyleÁlvarez-Torres, J. N., Ramírez-Bribiesca, J. E., Bautista-Martínez, Y., Crosby-Galván, M. M., Granados-Rivera, L. D., Ramírez-Mella, M., & Ruiz-González, A. (2024). Stability and Effects of Protected Palmitic Acid on In Vitro Rumen Degradability and Fermentation in Lactating Goats. Fermentation, 10(2), 110. https://doi.org/10.3390/fermentation10020110