The Effects of Pigeage, Délestage, Remontage and Oxygenation Treatments Applied during Maceration on Phenolic Content, Aroma Composition and Sensory Properties of Red Teran (Vitis vinifera L.) Wine

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Chemicals

2.1.2. Grapes

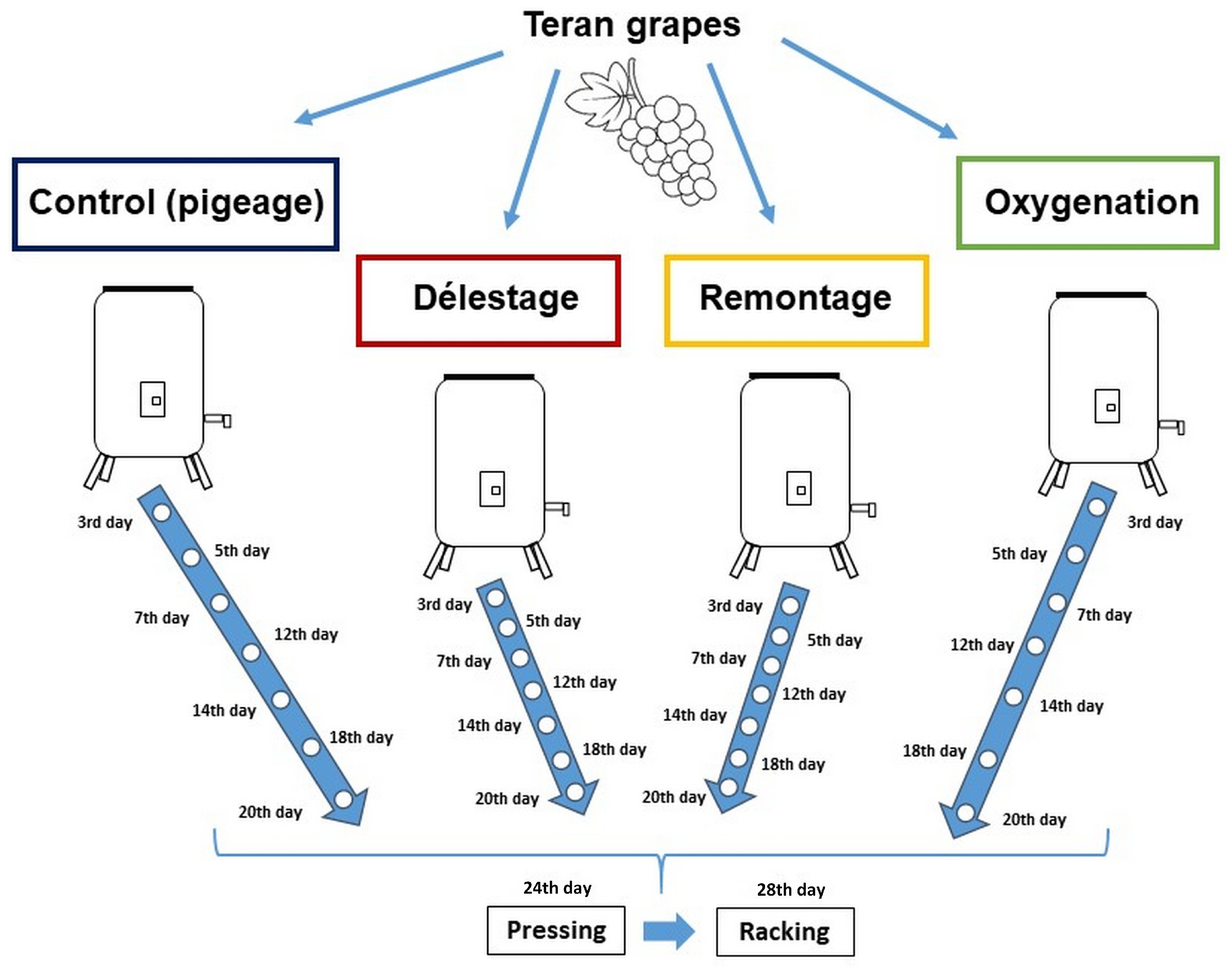

2.1.3. Winemaking and Maceration Treatments

- (i)

- Pigeage (control treatment), in which the caps were punched down with a stainless steel stick with a flat plate end (‘pigeou’) two times per day, with an interval of 10–12 h between immersions;

- (ii)

- The délestage treatment involved a rack and return procedure of 30–40 L of fermenting must/wine on the 3rd, 5th, 7th, 12th and 14th days, together with punching down the cap twice a day (the racked fermenting must/wine was kept in a separate stainless steel tank for one hour before being returned to the original tank);

- (iii)

- The remontage treatment consisted of 12 min of pumping over operations on the 3rd, 5th, 7th, 12th and 14th day, along with punching down the cap twice a day;

- (iv)

- The oxygenation treatment consisted of a total of 40 mg/L of oxygen added in four portions (3rd day: 5 mg/L, 5th: day 10 mg/L, 7th: day 15 mg/L, and 18th day: 10 mg/L), with the punch down treatments performed daily as in the previous variants. Oxygen was supplied using a silicone diffuser located at the bottom of the tank, and the oxygen flow controller was used to measure the oxygen supply, as described by Lukić et al. [21].

2.2. Methods

2.2.1. Spectrophotometric Analysis of Phenolic Compounds

2.2.2. CIELab Analysis of Chromatic Characteristics

2.2.3. GC/MS Analysis of Aroma Compounds

2.2.4. Sensory Analysis

2.2.5. Statistical Analysis

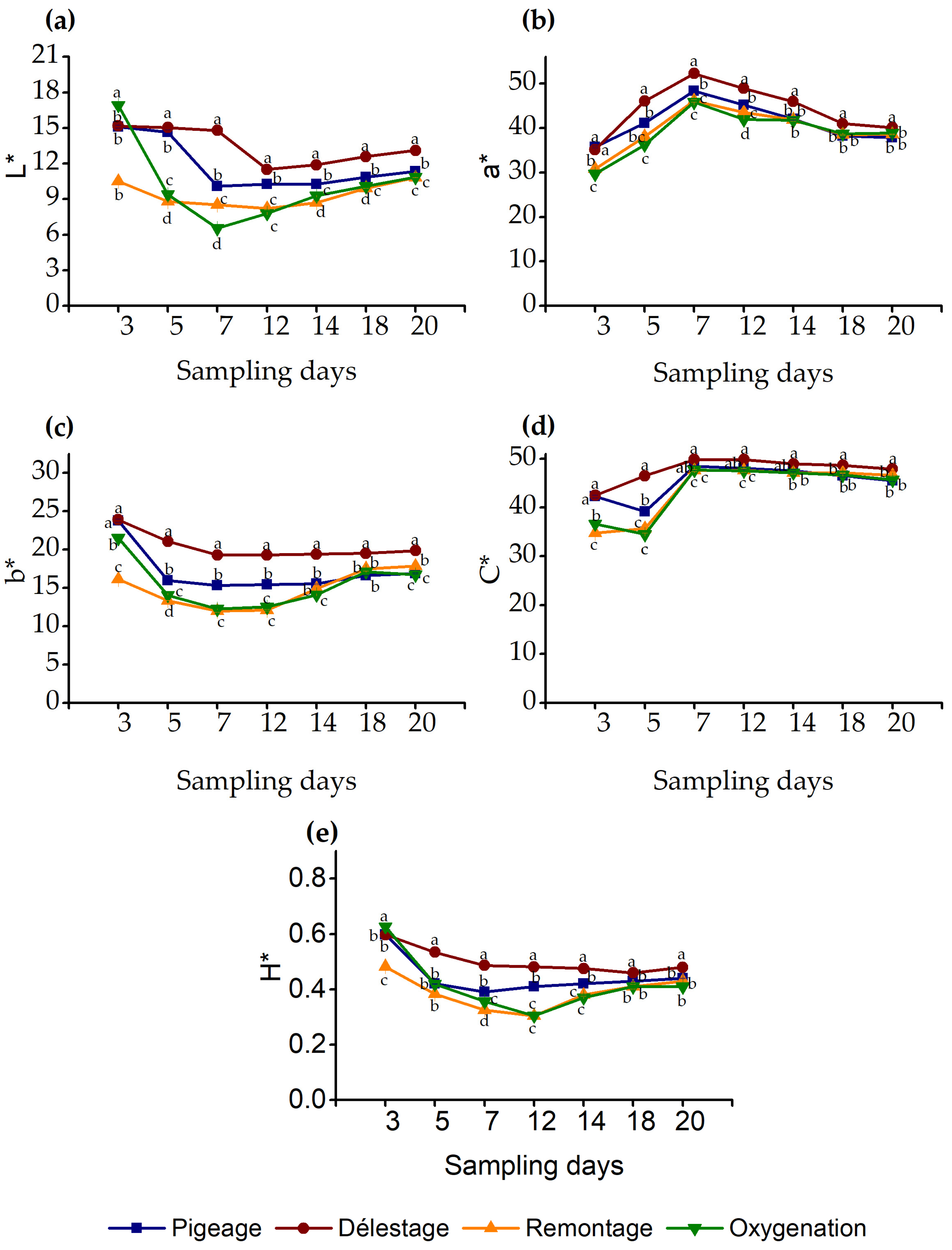

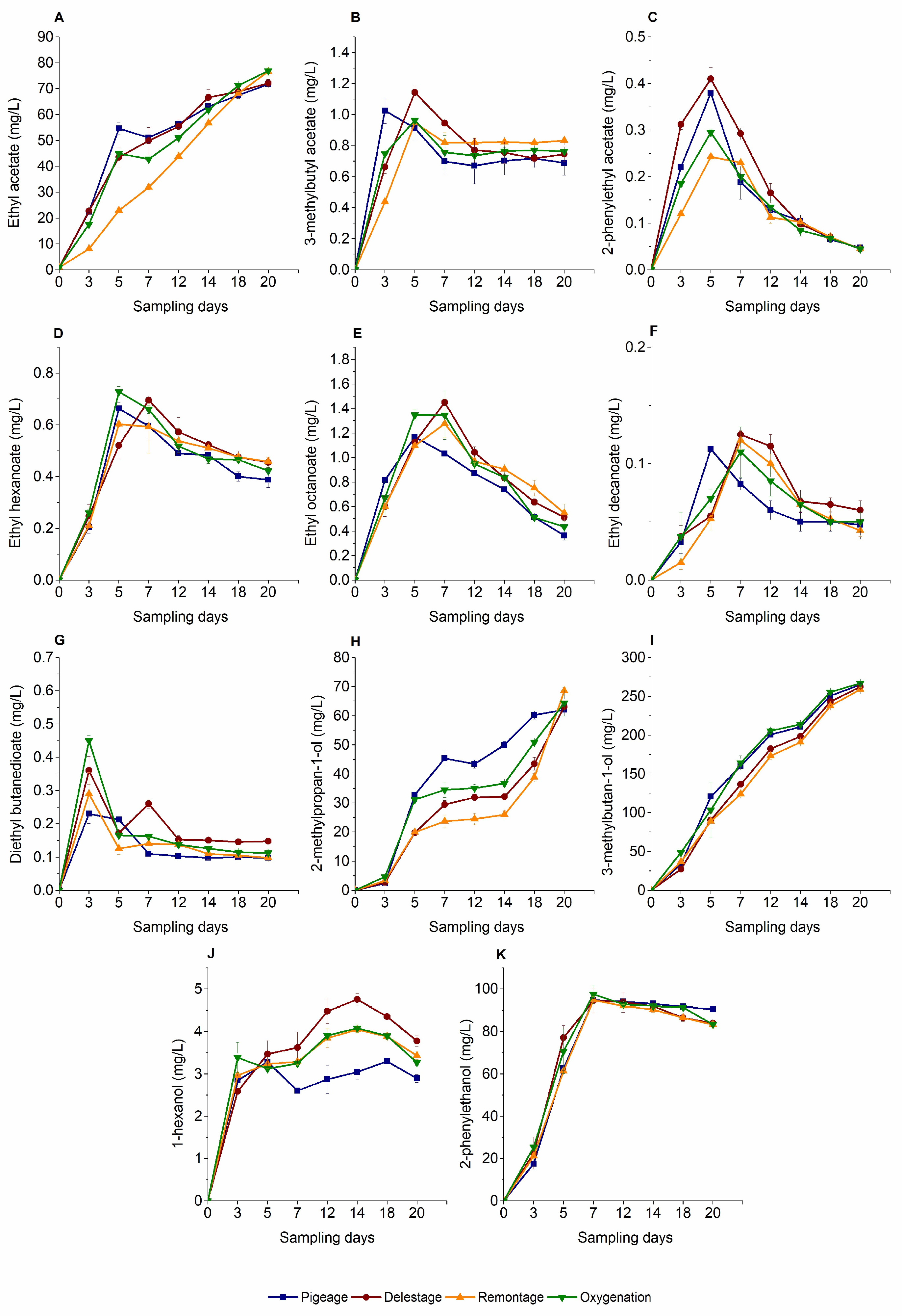

3. Results and Discussion

3.1. Changes in Phenolics and Chromatic Characteristics during Maceration

3.2. Changes in Aroma Composition during Maceration

3.3. Phenolic, Color and Aroma Composition of Wines after Pressing and Racking

3.4. Sensory Characterization of Produced Wines by Pigeage, Délestage, Remontage and Oxygenation Treatments

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ribéreau-Gayon, P.; Glories, Y.; Maujean, A.; Dubourdieu, D. Handbook of Enology, Volume 2: The Chemistry of Wine Stabilization and Treatments; John Wiley & Sons: Hoboken, NJ, USA, 2006. [Google Scholar]

- Guaita, M.; Bosso, A. Polyphenolic characterization of grape skins and seeds of four Italian red cultivars at harvest and after fermentative maceration. Foods 2019, 8, 395. [Google Scholar] [CrossRef]

- Sacchi, K.L.; Bisson, L.F.; Adams, D.O. A review of the effect of winemaking techniques on phenolic extraction in red wines. Am. J. Enol. Vitic. 2005, 56, 197–206. [Google Scholar] [CrossRef]

- Casassa, L.F.; Beaver, C.W.; Mireles, M.; Larsen, R.C.; Hopfer, H.; Heymann, H.; Harbertson, J.F. Influence of fruit maturity, maceration length, and ethanol amount on chemical and sensory properties of Merlot wines. Am. J. Enol. Vitic. 2013, 64, 437–449. [Google Scholar] [CrossRef]

- Bambina, P.; Pollon, M.; Squadrito, M.; Barone, S.; Cinquanta, L.; Corona, O. The effect of prolonged (150 days) post-fermentative maceration in steel tanks and oak barrels on Cabernet Sauvignon wine quality: Mathematical modelization of the phenolic compounds’ behaviour. J. Wine Res. 2023, 34, 247–271. [Google Scholar] [CrossRef]

- Jagatić Korenika, A.-M.; Kozina, B.; Preiner, D.; Tomaz, I.; Volarević, J.; Jeromel, A. The effect of seed removal and extraction time on the phenolic profile of Plavac Mali wine. Appl. Sci. 2023, 13, 5411. [Google Scholar] [CrossRef]

- Lisov, N.; Čakar, U.; Milenković, D.; Čebela, M.; Vuković, G.; Despotović, S.; Petrović, A. The influence of Cabernet Sauvignon ripeness, healthy state and maceration time on wine and fermented pomace phenolic profile. Fermentation 2023, 9, 695. [Google Scholar] [CrossRef]

- Casassa, F.L.; Beaver, C.W.; Mireles, M.S.; Harbertson, J.F. Effect of extended maceration and ethanol concentration on the extraction and evolution of phenolics, colour components and sensory attributes of M erlot wines. Aust. J. Grape Wine Res. 2013, 19, 25–39. [Google Scholar] [CrossRef]

- Puertas, B.; Guerrero, R.; Jurado, M.; Jimenez, M.; Cantos-Villar, E. Evaluation of alternative winemaking processes for red wine color enhancement. Food Sci. Technol. Int. 2008, 14, 21–27. [Google Scholar] [CrossRef]

- Francesca, N.; Romano, R.; Sannino, C.; Le Grottaglie, L.; Settanni, L.; Moschetti, G. Evolution of microbiological and chemical parameters during red wine making with extended post-fermentation maceration. Int. J. Food Microbiol. 2014, 171, 84–93. [Google Scholar] [CrossRef]

- Frost, S.C.; Blackman, J.W.; Hjelmeland, A.K.; Ebeler, S.E.; Heymann, H. Extended maceration and cap management impacts on the phenolic, volatile, and sensory profiles of Merlot wine. Am. J. Enol. Vitic. 2018, 69, 360–370. [Google Scholar] [CrossRef]

- Harbertson, J.F.; Mireles, M.S.; Harwood, E.D.; Weller, K.M.; Ross, C.F. Chemical and sensory effects of saignée, water addition, and extended maceration on high brix must. Am. J. Enol. Vitic. 2009, 60, 450–460. [Google Scholar] [CrossRef]

- Fischer, U.; Strasser, M.; Gutzler, K. Impact of fermentation technology on the phenolic and volatile composition of German red wines. Int. J. Food Sci. Technol. 2000, 35, 81–94. [Google Scholar] [CrossRef]

- Marais, J. Effect of different wine-making techniques on the composition and quality of Pinotage wine. II. Juice/skin mixing practices. S. Afr. J. Enol. Vitic. 2003, 24, 76–79. [Google Scholar] [CrossRef]

- Zoecklein, B.W.; Pélanne, L.M.; Birkenmaier, S.S. Effect of Délestage with Partial Seed Deportation on Merlot and Cabernet Sauvignon Wines. 2008. Available online: https://www.semanticscholar.org/paper/Effect-of-D%C3%A9lestage-with-Partial-Seed-Deportation-Zoecklein-Pelanne/ace5ffb192aa2179cea2595181898a3063547e79 (accessed on 15 January 2024).

- Morata, A.; González, C.; Tesfaye, W.; Loira, I.; Suárez-Lepe, J.A. Maceration and fermentation: New technologies to increase extraction. In Red Wine Technology; Elsevier: Amsterdam, The Netherlands, 2019; pp. 35–49. [Google Scholar]

- Picariello, L.; Slaghenaufi, D.; Ugliano, M. Fermentative and post-fermentative oxygenation of Corvina red wine: Influence on phenolic and volatile composition, colour and wine oxidative response. J. Sci. Food Agric. 2020, 100, 2522–2533. [Google Scholar] [CrossRef] [PubMed]

- Day, M.; Schmidt, S.; Smith, P.; Wilkes, E. Use and impact of oxygen during winemaking. Aust. J. Grape Wine Res. 2015, 21, 693–704. [Google Scholar] [CrossRef]

- Tarko, T.; Duda-Chodak, A.; Sroka, P.; Siuta, M. The impact of oxygen at various stages of vinification on the chemical composition and the antioxidant and sensory properties of white and red wines. Int. J. Food Sci. 2020, 2020, 7902974. [Google Scholar] [CrossRef] [PubMed]

- Plavsa, T.; Jurinjak, N.; Antunovic, D.; Persuric, Ð.; Ganic, K.K. The influence of skin maceration time on the phenolic composition and antioxidant activity of red wine Teran (Vitis vinifera L.). Food Technol. Biotechnol. 2012, 50, 152. [Google Scholar]

- Lukić, I.; Horvat, I.; Radeka, S.; Damijanić, K.; Staver, M. Effect of different levels of skin disruption and contact with oxygen during grape processing on phenols, volatile aromas, and sensory characteristics of white wine. J. Food Process. Preserv. 2019, 43, e13969. [Google Scholar] [CrossRef]

- Singleton, V.L.; Rossi, J.A. Colorimetry of total phenolics with phosphomolybdic-phosphotungstic acid reagents. Am. J. Enol. Vitic. 1965, 16, 144–158. [Google Scholar] [CrossRef]

- Ribéreau-Gayon, P.; Stonestreet, E. Determination of anthocyanins in red wine. Bull. Soc. Chim. Fr. 1965, 9, 2649–2652. [Google Scholar]

- OIV. Compendium of international analysis of methods. In Determination of Chromatic Characteristics According to CIELab; OIV-MA-AS2-11; OIV: Paris, France, 2009. [Google Scholar]

- Tomašević, M.; Gracin, L.; Ćurko, N.; Ganić, K.K. Impact of pre-fermentative maceration and yeast strain along with glutathione and SO2 additions on the aroma of Vitis vinifera L. Pošip wine and its evaluation during bottle aging. LWT-Food Sci. Technol. 2017, 81, 67–76. [Google Scholar] [CrossRef]

- OIV. OIV Standard for International Wine and Spirituous Beverages of Vitivinicultural Origin Competitions; OIV: Paris, France, 2021. [Google Scholar]

- Stone, H.; Sidel, J.L. Introduction to sensory evaluation. In Sensory Evaluation Practices (Third Edition); Academic Press: San Diego, CA, USA, 2004; pp. 1–19. [Google Scholar]

- Meilgaard, M.C.; Carr, B.T.; Civille, G.V. Sensory Evaluation Techniques; CRC Press: Boca Raton, FL, USA, 1999. [Google Scholar]

- ISO 11035:1994; Sensory Analysis—Identification and Selection of Descriptors for Establishing a Sensory Profile by a Multidimensional Approach. ISO: Geneva, Switzerland, 1994.

- ISO 3591:1977; Sensory Analysis—Apparatus—Wine-Tasting Glass. ISO: Geneva, Switzerland, 1997.

- Casassa, L.F.; Harbertson, J.F. Extraction, evolution, and sensory impact of phenolic compounds during red wine maceration. Annu. Rev. Food Sci. 2014, 5, 83–109. [Google Scholar] [CrossRef] [PubMed]

- Baiano, A.; Terracone, C.; Gambacorta, G.; La Notte, E. Phenolic content and antioxidant activity of Primitivo wine: Comparison among winemaking technologies. J. Food Sci. 2009, 74, C258–C267. [Google Scholar] [CrossRef] [PubMed]

- De Beer, D.; Joubert, E.; Marais, J.; Manley, M. Maceration before and during fermentation: Effect on Pinotage wine phenolic composition, total antioxidant capacity and objective colour parameters. S. Afr. J. Enol. Vitic. 2006, 27, 137–150. [Google Scholar] [CrossRef]

- Soto Vázquez, E.; Río Segade, S.; Orriols Fernández, I. Effect of the winemaking technique on phenolic composition and chromatic characteristics in young red wines. Eur. Food Res. Technol. 2010, 231, 789–802. [Google Scholar] [CrossRef]

- Smith, P.; McRae, J.; Bindon, K. Impact of winemaking practices on the concentration and composition of tannins in red wine. Aust. J. Grape Wine Res. 2015, 21, 601–614. [Google Scholar] [CrossRef]

- Gómez-Plaza, E.; Gil-Muñoz, R.; López-Roca, J.; Martínez-Cutillas, A.; Fernández-Fernández, J. Phenolic compounds and color stability of red wines: Effect of skin maceration time. Am. J. Enol. Vitic. 2001, 52, 266–270. [Google Scholar] [CrossRef]

- Bautista-Ortín, A.B.; Busse-Valverde, N.; Fernández-Fernández, J.I.; Gómez-Plaza, E.; Gil-Muñoz, R. The extraction kinetics of anthocyanins and proanthocyanidins from grape to wine in three different varieties. OENO One 2016, 50. [Google Scholar] [CrossRef]

- Romero-Cascales, I.; Fernández-Fernández, J.I.; López-Roca, J.M.; Gómez-Plaza, E. The maceration process during winemaking extraction of anthocyanins from grape skins into wine. Eur. Food Res. Technol. 2005, 221, 163–167. [Google Scholar] [CrossRef]

- Setford, P.C.; Jeffery, D.W.; Grbin, P.R.; Muhlack, R.A. Factors affecting extraction and evolution of phenolic compounds during red wine maceration and the role of process modelling. Trends Food Sci. Technol. 2017, 69, 106–117. [Google Scholar] [CrossRef]

- Fulcrand, H.; Dueñas, M.; Salas, E.; Cheynier, V. Phenolic reactions during winemaking and aging. Am. J. Enol. Vitic. 2006, 57, 289–297. [Google Scholar] [CrossRef]

- Casassa, L.F. Flavonoid phenolics in red winemaking. In Phenolic Compounds-Natural Sources, Importance and Applications; Intech Open: London, UK, 2017; pp. 153–196. [Google Scholar]

- Marquez, A.; Serratosa, M.P.; Merida, J. Pyranoanthocyanin derived pigments in wine: Structure and formation during winemaking. J. Chem. 2013, 2013, 713028. [Google Scholar] [CrossRef]

- Casassa, L.F.; Bolcato, E.A.; Sari, S.E.; Barda, N. Effects of maceration length after prefermentative cold soak: Detailed chromatic, phenolic and sensory composition of cabernet sauvignon, malbec and merlot wines. J. Food Compos. Anal. 2021, 104, 104168. [Google Scholar] [CrossRef]

- Gómez-Míguez, M.; Heredia, F.J. Effect of the maceration technique on the relationships between anthocyanin composition and objective color of Syrah wines. J. Agric. Food Chem. 2004, 52, 5117–5123. [Google Scholar] [CrossRef]

- Sommer, S.; Cohen, S.D. Comparison of different extraction methods to predict anthocyanin concentration and color characteristics of red wines. Fermentation 2018, 4, 39. [Google Scholar] [CrossRef]

- Petropulos, V.I.; Bogeva, E.; Stafilov, T.; Stefova, M.; Siegmund, B.; Pabi, N.; Lankmayr, E. Study of the influence of maceration time and oenological practices on the aroma profile of Vranec wines. Food Chem. 2014, 165, 506–514. [Google Scholar] [CrossRef]

- Aleixandre-Tudo, J.L.; Weightman, C.; Panzeri, V.; Nieuwoudt, H.; Du Toit, W. Effect of skin contact before and during alcoholic fermentation on the chemical and sensory profile of South African Chenin blanc white wines. S. Afr. J. Enol. Vitic. 2015, 36, 366–377. [Google Scholar] [CrossRef]

- Koundouras, S. Environmental and viticultural effects on grape composition and wine sensory properties. Elements 2018, 14, 173–178. [Google Scholar] [CrossRef]

- Lambrechts, M.; Pretorius, I. Yeast and its importance to wine aroma-a review. S. Afr. J. Enol. Vitic. 2000, 21, 97–129. [Google Scholar] [CrossRef]

- Robinson, A.L.; Boss, P.K.; Solomon, P.S.; Trengove, R.D.; Heymann, H.; Ebeler, S.E. Origins of grape and wine aroma. Part 1. Chemical components and viticultural impacts. Am. J. Enol. Vitic. 2014, 65, 1–24. [Google Scholar] [CrossRef]

- Cai, J.; Zhu, B.-Q.; Wang, Y.-H.; Lu, L.; Lan, Y.-B.; Reeves, M.J.; Duan, C.-Q. Influence of pre-fermentation cold maceration treatment on aroma compounds of Cabernet Sauvignon wines fermented in different industrial scale fermenters. Food Chem. 2014, 154, 217–229. [Google Scholar] [CrossRef]

- Bosso, A.; Panero, L.; Petrozziello, M.; Follis, R.; Motta, S.; Guaita, M. Influence of submerged-cap vinification on polyphenolic composition and volatile compounds of Barbera wines. Am. J. Enol. Vitic. 2011, 62, 503–511. [Google Scholar] [CrossRef]

- Valero, E.; Moyano, L.; Millan, M.; Medina, M.; Ortega, J.M. Higher alcohols and esters production by Saccharomyces cerevisiae. Influence of the initial oxygenation of the grape must. Food Chem. 2002, 78, 57–61. [Google Scholar] [CrossRef]

- McRae, J.M.; Day, M.P.; Bindon, K.A.; Kassara, S.; Schmidt, S.A.; Schulkin, A.; Kolouchova, R.; Smith, P.A. Effect of early oxygen exposure on red wine colour and tannins. Tetrahedron 2015, 71, 3131–3137. [Google Scholar] [CrossRef]

- Martínez, J.; Melgosa, M.; Pérez, M.; Hita, E.; Negueruela, A. Note. Visual and instrumental color evaluation in red wines. Food Sci. Technol. Int. 2001, 7, 439–444. [Google Scholar] [CrossRef]

- Hornedo-Ortega, R.; González-Centeno, M.R.; Chira, K.; Jourdes, M.; Teissedre, P.-L. Phenolic compounds of grapes and wines: Key compounds and implications in sensory perception. In Chemistry and Biochemistry of Winemaking, Wine Stabilization and Aging; Intech Open: London, UK, 2020; pp. 1–26. [Google Scholar]

- Patrianakou, M.; Roussis, I. Decrease of wine volatile aroma esters by oxidation. S. Afr. J. Enol. Vitic. 2013, 34, 241–245. [Google Scholar] [CrossRef]

- Bubola, M.; Sivilotti, P.; Rossi, S.; Bestulić, E.; Plavša, T.; Radeka, S. Impact of canopy management practices on phenolic composition and sensory profile of cv. Teran wine. In Proceedings of the BIO Web of Conferences; EDP Sciences: Paris, France, 2022; p. 02001. [Google Scholar]

- Sun, B.; Neves, A.C.; Fernandes, T.A.; Fernandes, A.L.; Mateus, N.; De Freitas, V.; Leandro, C.; Spranger, M.I. Evolution of phenolic composition of red wine during vinification and storage and its contribution to wine sensory properties and antioxidant activity. J. Agric. Food Chem. 2011, 59, 6550–6557. [Google Scholar] [CrossRef]

- Pittari, E.; Moio, L.; Piombino, P. Interactions between polyphenols and volatile compounds in wine: A literature review on physicochemical and sensory insights. Appl. Sci. 2021, 11, 1157. [Google Scholar] [CrossRef]

| Days | Pigeage (C) | Délestage | Remontage | Oxygenation |

|---|---|---|---|---|

| TP (mg GAE/L) | ||||

| 3 | 1418.6 ± 7.5 c | 1711.8 ± 18.0 b | 1772.8 ± 18.4 ab | 1802.3 ± 20.5 a |

| 5 | 2046.4 ± 19.0 a | 1964.5 ± 20.9 a | 1986.8 ± 22.1 a | 1863.2 ± 20.4 b |

| 7 | 2092.5 ± 17.7 ab | 2028.2 ± 21.1 bc | 2127.9 ± 13.0 a | 2000.5 ± 27.9 c |

| 12 | 2301.8 ± 24.9 a | 2231.0 ± 21.1 a | 2279.0 ± 20.1 a | 2200.5 ± 25.7 a |

| 14 | 2532.0 ± 27.2 a | 2442.6 ± 16.0 a | 2540.8 ± 10.9 a | 2520.6 ± 36.6 a |

| 18 | 2633.3 ± 26.5 ab | 2539.7 ± 27.2 b | 2690.9 ± 20.8 a | 2662.6 ± 28.6 a |

| 20 | 2609.6 ± 16.6 b | 2499.1 ± 17.6 c | 2682.0 ± 14.8 a | 2615.6 ± 12.8 b |

| TA (mg/L) | ||||

| 3 | 556.0 ± 2.9 b | 722.8 ± 2.9 a | 556.2 ± 4.1 b | 400.9 ± 2.0 c |

| 5 | 724.7 ± 1.7 b | 767.1 ± 0.8 a | 710.9 ± 1.9 c | 712.5 ± 2.0 c |

| 7 | 806.4 ± 3.8 b | 781.9 ± 4.4 c | 870.5 ± 4.0 a | 735.3 ± 4.6 d |

| 12 | 757.0 ± 2.4 b | 610.5 ± 3.2 d | 770.0 ± 3.3 a | 718.3 ± 3.2 c |

| 14 | 742.1 ± 3.7 a | 580.5 ± 3.8 c | 740.3 ± 5.1 a | 707.0 ± 1.4 b |

| 18 | 683.0 ± 2.3 a | 547.2 ± 3.4 c | 691.1 ± 4.6 a | 660.3 ± 2.2 b |

| 20 | 628.9 ± 4.1 a | 530.1 ± 2.8 b | 625.2 ± 3.3 a | 624.7 ± 2.9 a |

| Stage | Pigeage (C) | Délestage | Remontage | Oxygenation | |

|---|---|---|---|---|---|

| Pressing | |||||

| Phenolics (mg/L) | TP | 2635.9 ± 20.8 b | 2607.3 ± 23.5 b | 2809.1 ± 27.3 a | 2661.5 ± 15.6 b |

| TA | 617.8 ± 3.5 a | 512.7 ± 6.0 b | 610.2 ± 4.6 a | 615.2 ± 4.4 a | |

| Color | L* | 10.88 ± 0.08 b | 12.87 ± 0.02 a | 11.27 ± 0.02 b | 10.87 ± 0.18 b |

| a* | 39.00 ± 0.30 b | 41.35 ± 0.06 a | 39.78 ± 0.06 b | 40.12 ± 0.28 b | |

| b* | 16.84 ± 0.13 bc | 19.74 ± 0.03 a | 17.51 ± 0.02 b | 16.09 ± 0.29 c | |

| C* | 44.71 ± 0.33 b | 47.52 ± 0.06 a | 45.56 ± 0.06 b | 45.24 ± 0.12 b | |

| H* | 0.42 ± 0.00 b | 0.45 ± 0.00 a | 0.42 ± 0.00 b | 0.41 ± 0.01 b | |

| ΔE*ab | - | 4.2 | 1.1 | 1.3 | |

| Aroma (mg/L) | Ethyl acetate | 71.35 ± 2.87 b | 72.13 ± 2.40 ab | 70.08 ± 2.03 c | 74.31 ± 4.36 a |

| 3-methylbutyl acetate | 0.68 ± 0.01 b | 0.75 ± 0.07 ab | 0.85 ± 0.00 a | 0.77 ± 0.01 ab | |

| 2-phenylethyl acetate | 0.03 ± 0.01 a | 0.03 ± 0.01 a | 0.04 ± 0.00 a | 0.03 ± 0.01 a | |

| Ethyl hexanoate | 0.38 ± 0.01 a | 0.43 ± 0.02 a | 0.43 ± 0.04 a | 0.40 ± 0.00 a | |

| Ethyl octanoate | 0.32 ± 0.05 a | 0.40 ± 0.01 a | 0.34 ± 0.06 a | 0.37 ± 0.01 a | |

| Ethyl decanoate | 0.06 ± 0.01 a | 0.06 ± 0.00 a | 0.04 ± 0.00 b | 0.06 ± 0.01 a | |

| Diethyl butanedioate | 0.11 ± 0.02 ab | 0.16 ± 0.01 a | 0.10 ± 0.00 b | 0.11 ± 0.00 ab | |

| 2-methylpropan-1-ol | 66.32 ± 0.56 a | 67.23 ± 0.30 a | 62.05 ± 0.25 b | 61.50 ± 0.38 b | |

| 3-methylbutan-1-ol | 264.33 ± 0.57 b | 254.82 ± 1.07 c | 264.23 ± 0.07 b | 288.42 ± 1.26 a | |

| 1-hexanol | 2.80 ± 0.11 c | 3.65 ± 0.05 a | 3.19 ± 0.01 b | 3.19 ± 0.03 b | |

| 2-phenylethanol | 89.24 ± 0.81 b | 85.29 ± 1.16 b | 97.94 ± 2.70 a | 78.64 ± 0.84 c | |

| Racking | |||||

| Phenolics (mg/L) | TP | 2575.9 ± 24.8 b | 2550.3 ± 27.9 b | 2745.1 ± 19.5 a | 2586.5 ± 13.2 b |

| TA | 608.0 ± 2.2 a | 507.2 ± 5.0 c | 586.6 ± 2.9 b | 603.7 ± 2.8 a | |

| Color | L* | 11.86 ± 0.03 b | 12.99 ± 0.02 a | 11.98 ± 0.33 b | 11.49 ± 0.04 b |

| a* | 38.22 ± 0.11 b | 40.52 ± 0.06 a | 38.99 ± 0.59 ab | 39.32 ± 0.15 ab | |

| b* | 16.73 ± 0.05 bc | 19.91 ± 0.03 a | 17.37 ± 0.25 b | 16.32 ± 0.07 c | |

| C* | 44.81 ± 0.13 b | 47.48 ± 0.07 a | 45.84 ± 0.45 b | 45.36 ± 0.16 b | |

| H* | 0.43 ± 0.00 ab | 0.46 ± 0.00 a | 0.44 ± 0.01 ab | 0.41 ± 0.00 b | |

| ΔE*ab | - | 4.1 | 1.0 | 1.2 | |

| Aroma (mg/L) | Ethyl acetate | 70.26 ± 2.73 a | 71.65 ± 2.77 a | 68.14 ± 2.40 a | 71.10 ± 0.23 a |

| 3-methylbutyl acetate | 0.68 ± 0.05 bc | 0.70 ± 0.01 ab | 0.75 ± 0.07 a | 0.61 ± 0.07 c | |

| 2-phenylethyl acetate | 0.03 ± 0.01 a | 0.03 ± 0.01 a | 0.02 ± 0.01 a | 0.02 ± 0.01 a | |

| Ethyl hexanoate | 0.36 ± 0.04 b | 0.41 ± 0.01 a | 0.36 ± 0.03 b | 0.34 ± 0.00 c | |

| Ethyl octanoate | 0.34 ± 0.04 a | 0.35 ± 0.01 a | 0.30 ± 0.01 b | 0.32 ± 0.01 b | |

| Ethyl decanoate | 0.06 ± 0.01 a | 0.06 ± 0.01 a | 0.04 ± 0.01 b | 0.04 ± 0.01 b | |

| Diethyl butanedioate | 0.11 ± 0.01 b | 0.16 ± 0.01 a | 0.12 ± 0.01 ab | 0.11 ± 0.00 b | |

| 2-methylpropan-1-ol | 65.88 ± 1.98 b | 66.76 ± 1.34 a | 60.68 ± 1.08 c | 60.91 ± 2.22 c | |

| 3-methylbutan-1-ol | 268.11 ± 2.50 b | 259.88 ± 3.75 c | 265.49 ± 0.50 b | 279.27 ± 0.71 a | |

| 1-hexanol | 2.81 ± 0.01 c | 3.61 ± 0.06 a | 3.19 ± 0.06 b | 3.11 ± 0.09 b | |

| 2-phenylethanol | 87.78 ± 2.40 b | 82.61 ± 1.31 b | 92.40 ± 0.0 a | 74.61 ± 2.70 c |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tomašević, M.; Perić, K.; Damijanić, K.; Staver, M.; Ćurko, N.; Kovačević Ganić, K. The Effects of Pigeage, Délestage, Remontage and Oxygenation Treatments Applied during Maceration on Phenolic Content, Aroma Composition and Sensory Properties of Red Teran (Vitis vinifera L.) Wine. Fermentation 2024, 10, 252. https://doi.org/10.3390/fermentation10050252

Tomašević M, Perić K, Damijanić K, Staver M, Ćurko N, Kovačević Ganić K. The Effects of Pigeage, Délestage, Remontage and Oxygenation Treatments Applied during Maceration on Phenolic Content, Aroma Composition and Sensory Properties of Red Teran (Vitis vinifera L.) Wine. Fermentation. 2024; 10(5):252. https://doi.org/10.3390/fermentation10050252

Chicago/Turabian StyleTomašević, Marina, Katarina Perić, Kristijan Damijanić, Mario Staver, Natka Ćurko, and Karin Kovačević Ganić. 2024. "The Effects of Pigeage, Délestage, Remontage and Oxygenation Treatments Applied during Maceration on Phenolic Content, Aroma Composition and Sensory Properties of Red Teran (Vitis vinifera L.) Wine" Fermentation 10, no. 5: 252. https://doi.org/10.3390/fermentation10050252

APA StyleTomašević, M., Perić, K., Damijanić, K., Staver, M., Ćurko, N., & Kovačević Ganić, K. (2024). The Effects of Pigeage, Délestage, Remontage and Oxygenation Treatments Applied during Maceration on Phenolic Content, Aroma Composition and Sensory Properties of Red Teran (Vitis vinifera L.) Wine. Fermentation, 10(5), 252. https://doi.org/10.3390/fermentation10050252