Naturally Colored Ice Creams Enriched with C-Phycocyanin and Spirulina Residual Biomass: Development of a Fermented, Antioxidant, Tasty and Stable Food Product

Abstract

:1. Introduction

2. Materials and Methods

2.1. Spirulina Biomass

2.2. Green Extraction and Purification of C-PC and Gettering of RB

2.3. Analytical Methods

2.4. Formulation of the Fermented Ice Creams

2.4.1. Fermented Milk Base

2.4.2. Ice Cream Manufacture

2.5. Microbiological Quality

2.6. Color Stability of C-PC- and RB-Supplemented Ice Creams

2.7. Antioxidant Activity, Total Phenolic Content, and Bioaccessibility of the Manufactured Samples

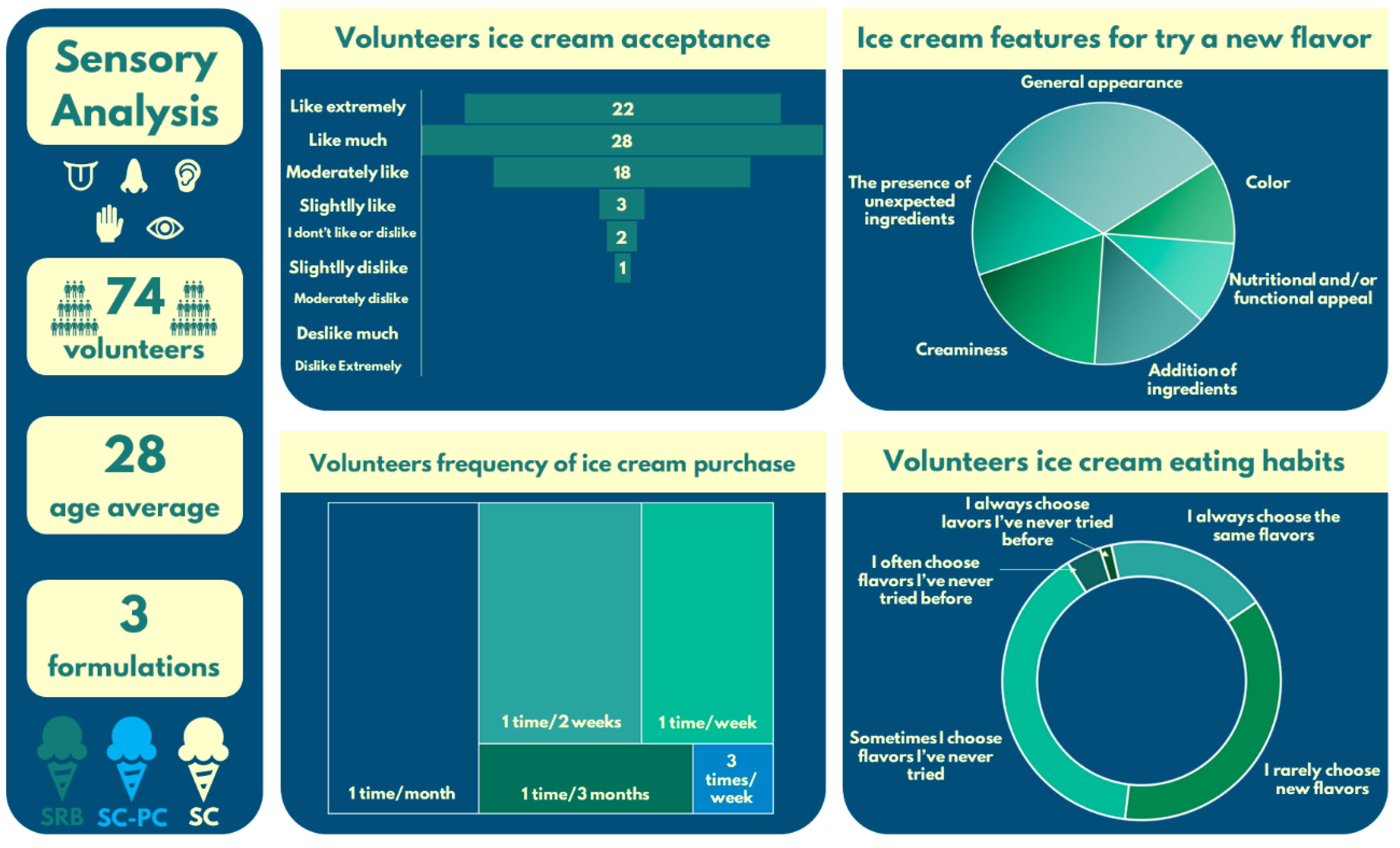

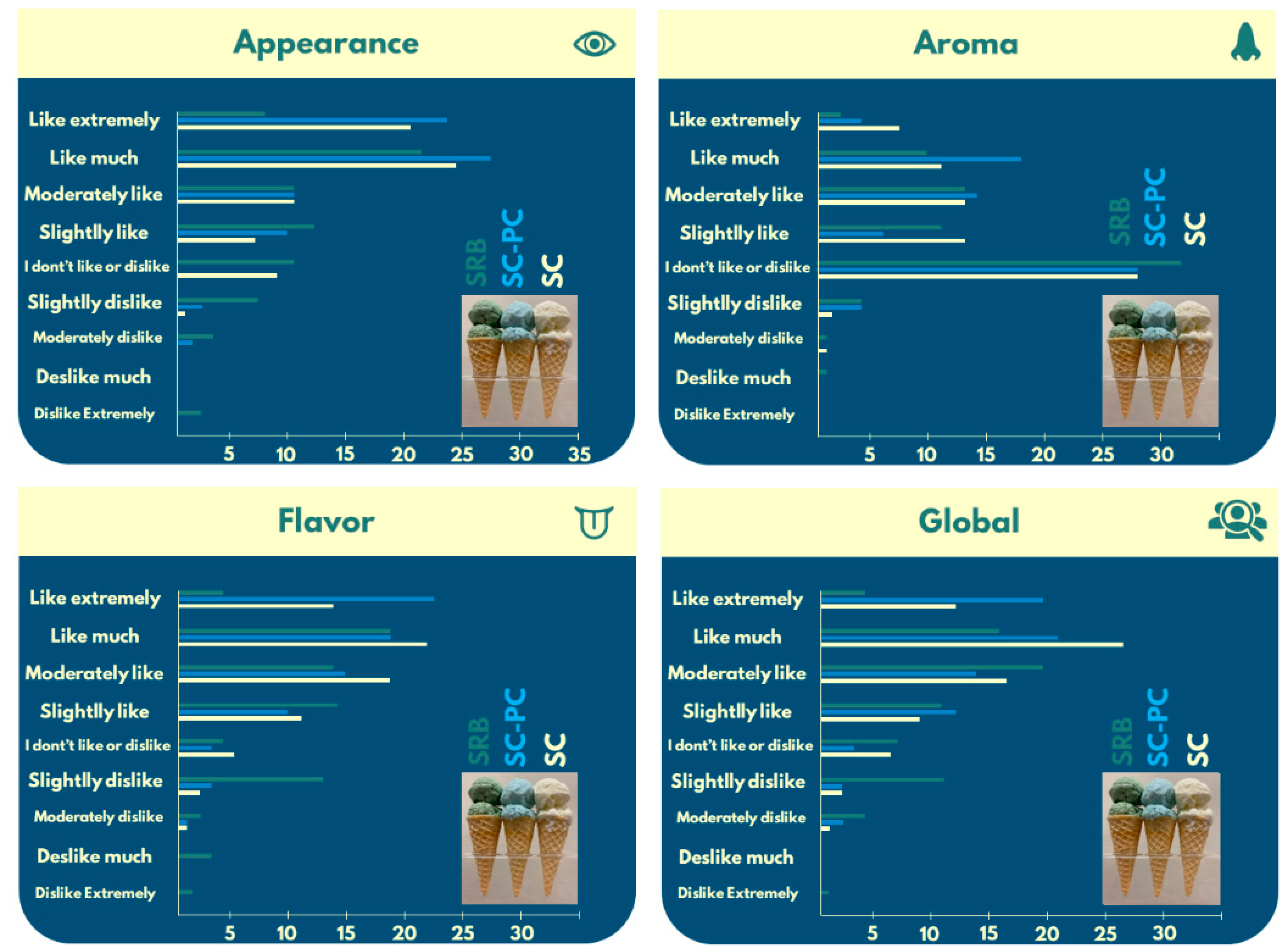

2.8. Sensory Analysis

2.9. Statistical Analysis

3. Results

3.1. Microbiological Quality and Shelf Life

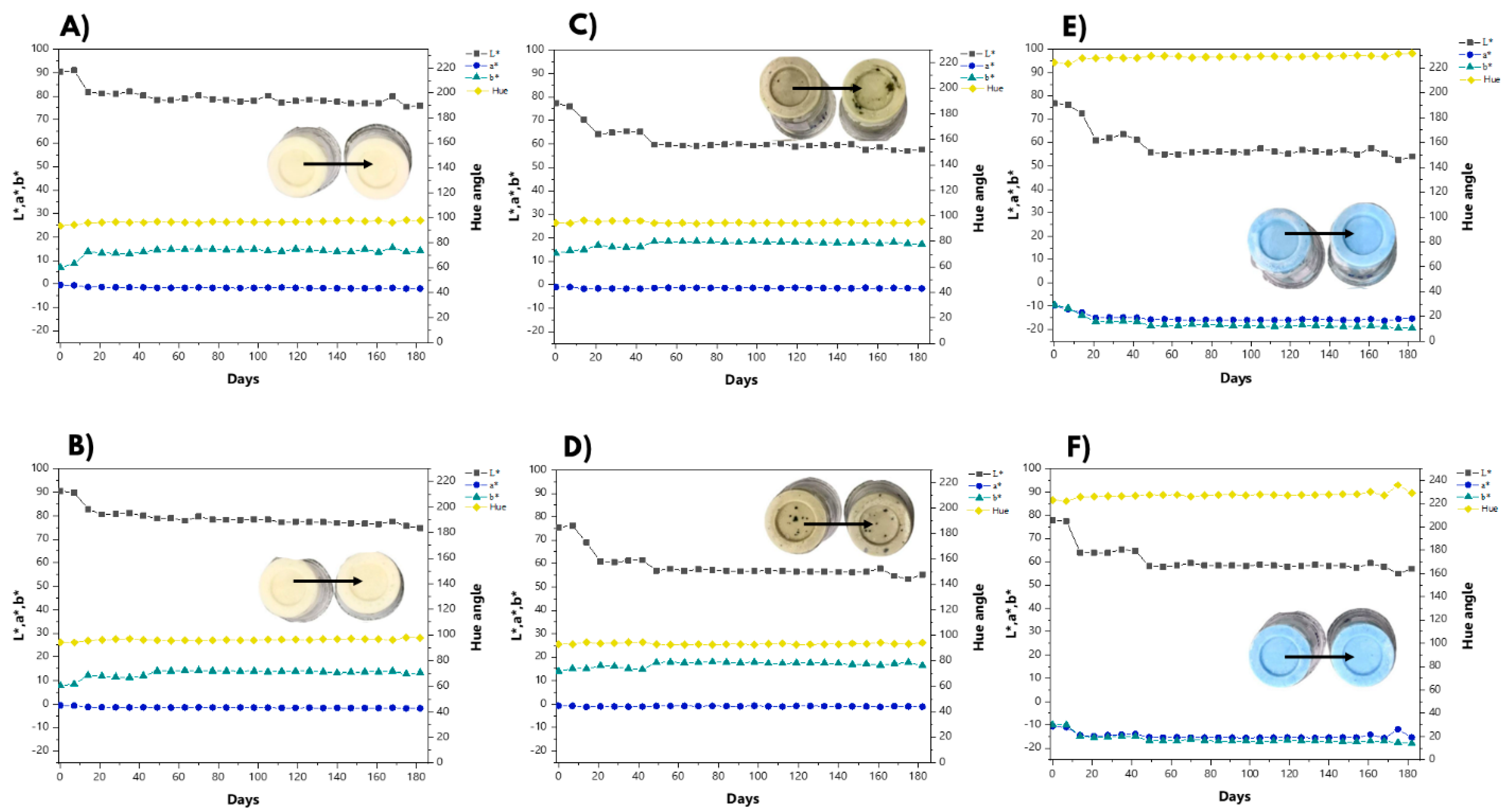

3.2. Color Stability of C-PC- and RB-Supplemented Ice Creams

3.3. Antioxidant Activity, Total Phenolic Content, and Bioaccessibility of the Manufactured Samples

3.4. Sensory Analysis

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, Q.J.; Mielby, L.A.; Junge, J.Y.; Bertelsen, A.S.; Kidmose, U.; Spence, C.; Byrne, D.V. The Role of Intrinsic and Extrinsic Sensory Factors in Sweetness Perception of Food and Beverages: A Review. Foods 2019, 8, 211. [Google Scholar] [CrossRef] [PubMed]

- Landim Neves, M.I.; Silva, E.K.; Meireles, M.A.A. Natural Blue Food Colorants: Consumer Acceptance, Current Alternatives, Trends, Challenges, and Future Strategies. Trends Food Sci. Technol. 2021, 112, 163–173. [Google Scholar] [CrossRef]

- Echegaray, N.; Guzel, N.; Kumar, M.; Guzel, M.; Hassoun, A.; Lorenzo, J.M. Recent Advancements in Natural Colorants and Their Application as Coloring in Food and in Intelligent Food Packaging. Food Chem. 2023, 404, 134453. [Google Scholar] [CrossRef] [PubMed]

- Gordillo, B.; Sigurdson, G.T.; Lao, F.; González-Miret, M.L.; Heredia, F.J.; Giusti, M.M. Assessment of the Color Modulation and Stability of Naturally Copigmented Anthocyanin-Grape Colorants with Different Levels of Purification. Food Res. Int. 2018, 106, 791–799. [Google Scholar] [CrossRef]

- Buchweitz, M. Natural Solutions for Blue Colors in Food. In Handbook on Natural Pigments in Food and Beverages; Elsevier: Amsterdam, The Netherlands, 2016; pp. 355–384. [Google Scholar]

- Spence, C. Background Colour & Its Impact on Food Perception & Behaviour. Food Qual. Prefer. 2018, 68, 156–166. [Google Scholar] [CrossRef]

- Lucas, B.F.; de Morais, M.G.; Santos, T.D.; Costa, J.A.V. Spirulina for Snack Enrichment: Nutritional, Physical and Sensory Evaluations. LWT Food Sci. Technol. 2018, 90, 270–276. [Google Scholar] [CrossRef]

- Özbal, B.; Çelekli, A.; Gün, D.; Bozkurt, H. Effect of Arthrospira Platensis Incorporation on Nutritional and Sensory Attributes of White Chocolate. Int. J. Gastron. Food Sci. 2022, 28, 100544. [Google Scholar] [CrossRef]

- Üstün-Aytekin, Ö.; Çoban, I.; Aktaş, B. Nutritional Value, Sensory Properties, and Antioxidant Activity of a Traditional Kefir Produced with Arthrospira platensis. J. Food Process Preserv. 2022, 46, e16380. [Google Scholar] [CrossRef]

- Gremski, L.A.; Coelho, A.L.K.; Santos, J.S.; Daguer, H.; Molognoni, L.; do Prado-Silva, L.; Sant’Ana, A.S.; Rocha, R.d.S.; da Silva, M.C.; Cruz, A.G.; et al. Antioxidants-Rich Ice Cream Containing Herbal Extracts and Fructooligossaccharides: Manufacture, Functional and Sensory Properties. Food Chem. 2019, 298, 125098. [Google Scholar] [CrossRef]

- Monteiro, M.J.P.; Costa, A.I.A.; Fliedel, G.; Cissé, M.; Bechoff, A.; Pallet, D.; Tomlins, K.; Pintado, M.M.E. Chemical-Sensory Properties and Consumer Preference of Hibiscus Beverages Produced by Improved Industrial Processes. Food Chem. 2017, 225, 202–212. [Google Scholar] [CrossRef]

- Martins, N.; Roriz, C.L.; Morales, P.; Barros, L.; Ferreira, I.C.F.R. Food Colorants: Challenges, Opportunities and Current Desires of Agro-Industries to Ensure Consumer Expectations and Regulatory Practices. Trends Food Sci. Technol. 2016, 52, 1–15. [Google Scholar] [CrossRef]

- Kapadia, G.J.; Tokuda, H.; Sridhar, R.; Balasubramanian, V.; Takayasu, J.; Bu, P.; Enjo, F.; Takasaki, M.; Konoshima, T.; Nishino, H. Cancer Chemopreventive Activity of Synthetic Colorants Used in Foods, Pharmaceuticals and Cosmetic Preparations. Cancer Lett. 1998, 129, 87–95. [Google Scholar] [CrossRef] [PubMed]

- El-Wahab, H.M.F.A.; Moram, G.S.E.-D. Toxic Effects of Some Synthetic Food Colorants and/or Flavor Additives on Male Rats. Toxicol. Ind. Health 2013, 29, 224–232. [Google Scholar] [CrossRef] [PubMed]

- Okafor, S.N.; Obonga, W.; Ezeokonkwo, M.A.; Nurudeen, J.; Orovwigho, U.; Ahiabuike, J. Assessment of the Health Implications of Synthetic and Natural Food Colourants—A Critical Review. Pharm. Biosci. J. 2016, 4, 1–11. [Google Scholar] [CrossRef]

- Oplatowska-Stachowiak, M.; Elliott, C.T. Food Colors: Existing and Emerging Food Safety Concerns. Crit. Rev. Food. Sci. Nutr. 2017, 57, 524–548. [Google Scholar] [CrossRef] [PubMed]

- Nigg, J.T.; Lewis, K.; Edinger, T.; Falk, M. Meta-Analysis of Attention-Deficit/Hyperactivity Disorder or Attention-Deficit/Hyperactivity Disorder Symptoms, Restriction Diet, and Synthetic Food Color Additives. J. Am. Acad. Child Adolesc. Psychiatry 2012, 51, 86–97.e8. [Google Scholar] [CrossRef] [PubMed]

- Harley, J.P.; Matthews, C.G.; Eichman, P. Synthetic Food Colors and Hyperactivity in Children: A Double-Blind Challenge Experiment. Pediatrics 1978, 62, 975–983. [Google Scholar] [CrossRef] [PubMed]

- Feketea, G.; Tsabouri, S. Common Food Colorants and Allergic Reactions in Children: Myth or Reality? Food Chem. 2017, 230, 578–588. [Google Scholar] [CrossRef] [PubMed]

- Hannuksela, M.; Haahtela, T. Hypersensitivity Reactions to Food Additives. Allergy 1987, 42, 561–575. [Google Scholar] [CrossRef]

- Olas, B.; Białecki, J.; Urbańska, K.; Bryś, M. The Effects of Natural and Synthetic Blue Dyes on Human Health: A Review of Current Knowledge and Therapeutic Perspectives. Adv. Nutr. 2021, 12, 2301–2311. [Google Scholar] [CrossRef]

- Nakamoto, M.M.; Assis, M.; de Oliveira Filho, J.G.; Braga, A.R.C. Spirulina Application in Food Packaging: Gaps of Knowledge and Future Trends. Trends Food Sci. Technol. 2023, 133, 138–147. [Google Scholar] [CrossRef]

- Cabrita, M.; Simões, S.; Álvarez-Castillo, E.; Castelo-Branco, D.; Tasso, A.; Figueira, D.; Guerrero, A.; Raymundo, A. Development of Innovative Clean Label Emulsions Stabilized by Vegetable Proteins. Int. J. Food Sci. Technol. 2023, 58, 406–422. [Google Scholar] [CrossRef]

- Arnold, L.E.; Lofthouse, N.; Hurt, E. Artificial Food Colors and Attention-Deficit/Hyperactivity Symptoms: Conclusions to Dye For. Neurotherapeutics 2012, 9, 599–609. [Google Scholar] [CrossRef] [PubMed]

- Rambler, R.M.; Rinehart, E.; Boehmler, W.; Gait, P.; Moore, J.; Schlenker, M.; Kashyap, R. A Review of the Association of Blue Food Coloring with Attention Deficit Hyperactivity Disorder Symptoms in Children. Cureus 2022, 14, e29241. [Google Scholar] [CrossRef]

- Lim, H.R.; Khoo, K.S.; Chew, K.W.; Chang, C.K.; Munawaroh, H.S.H.; Kumar, P.S.; Huy, N.D.; Show, P.L. Perspective of Spirulina Culture with Wastewater into a Sustainable Circular Bioeconomy. Environ. Pollut. 2021, 284, 117492. [Google Scholar] [CrossRef] [PubMed]

- Capelli, B.; Cysewski, G.R. Potential Health Benefits of Spirulina MicroalgaePotential health benefits of Spirulina microalgae* A review of the existing literature. Nutrafoods 2010, 9, 19–26. [Google Scholar] [CrossRef]

- Gurreri, L.; Calanni Rindina, M.; Luciano, A.; Lima, S.; Scargiali, F.; Fino, D.; Mancini, G. Environmental Sustainability of Microalgae-Based Production Systems: Roadmap and Challenges towards the Industrial Implementation. Sustain. Chem. Pharm. 2023, 35, 101191. [Google Scholar] [CrossRef]

- Christaki, E.; Florou-Paneri, P.; Bonos, E. Microalgae: A Novel Ingredient in Nutrition. Int. J. Food Sci. Nutr. 2011, 62, 794–799. [Google Scholar] [CrossRef] [PubMed]

- Dolganyuk, V.; Belova, D.; Babich, O.; Prosekov, A.; Ivanova, S.; Katserov, D.; Patyukov, N.; Sukhikh, S. Microalgae: A Promising Source of Valuable Bioproducts. Biomolecules 2020, 10, 1153. [Google Scholar] [CrossRef]

- Singh, S.; Kate, B.N.; Banecjee, U.C. Bioactive Compounds from Cyanobacteria and Microalgae: An Overview. Crit. Rev. Biotechnol. 2005, 25, 73–95. [Google Scholar] [CrossRef]

- Fratelli, C.; Burck, M.; Amarante, M.C.A.; Braga, A.R.C. Antioxidant Potential of Nature’s “Something Blue”: Something New in the Marriage of Biological Activity and Extraction Methods Applied to C-Phycocyanin. Trends Food Sci. Technol. 2021, 107, 309–323. [Google Scholar] [CrossRef]

- Silva-Neto, A.F.; Fratelli, C.; Pucci, V.G.; Boldarine, V.T.; Ferreira, Y.A.M.; Telles, M.M.; Braga, A.R.C.; Oyama, L.M. C-Phycocyanin Extracted from Spirulina Using a Green Solvent Approach Presents an Anti-Obesity Characteristic in Mice Fed a Hyperlipidic Diet. J. Funct. Foods 2023, 108, 105747. [Google Scholar] [CrossRef]

- Fratelli, C.; Bürck, M.; Silva-Neto, A.F.; Oyama, L.M.; De Rosso, V.V.; Braga, A.R.C. Green Extraction Process of Food Grade C-Phycocyanin: Biological Effects and Metabolic Study in Mice. Processes 2022, 10, 1793. [Google Scholar] [CrossRef]

- Salgado, M.T.S.F.; Fernandes e Silva, E.; Matsumoto, A.M.; Mattozo, F.H.; de Amarante, M.C.A.; Kalil, S.J.; de Souza Votto, A.P. C-Phycocyanin Decreases Proliferation and Migration of Melanoma Cells: In Silico and in Vitro Evidences. Bioorg. Chem. 2022, 122, 105757. [Google Scholar] [CrossRef]

- Braga, A.R.C.; Nunes, M.C.; Raymundo, A. The Experimental Development of Emulsions Enriched and Stabilized by Recovering Matter from Spirulina Biomass: Valorization of Residue into a Sustainable Protein Source. Molecules 2023, 28, 6179. [Google Scholar] [CrossRef] [PubMed]

- Fratelli, C.; Nunes, M.C.; De Rosso, V.V.; Raymundo, A.; Braga, A.R.C. Spirulina and Its Residual Biomass as Alternative Sustainable Ingredients: Impact on the Rheological and Nutritional Features of Wheat Bread Manufacture. Front. Food Sci. Technol. 2023, 3, 1258219. [Google Scholar] [CrossRef]

- Martelli, F.; Alinovi, M.; Bernini, V.; Gatti, M.; Bancalari, E. Arthrospira Platensis as Natural Fermentation Booster for Milk and Soy Fermented Beverages. Foods 2020, 9, 350. [Google Scholar] [CrossRef] [PubMed]

- ANVISA. RDC N° 266; ANVISA: Brasilia, Brazil, 2005. [Google Scholar]

- Cedillos, R.; Aleman, R.S.; Page, R.; Olson, D.W.; Boeneke, C.; Prinyawiwatkul, W.; Aryana, K. Influence of Hesperidin on the Physico-Chemical, Microbiological and Sensory Characteristics of Frozen Yogurt. Foods 2024, 13, 808. [Google Scholar] [CrossRef]

- Akarca, G.; Kilinç, M.; Denizkara, A.J. Quality Specification of Ice Creams Produced with Different Homofermentative Lactic Acid Bacteria. Food Sci. Nutr. 2024, 12, 192–203. [Google Scholar] [CrossRef]

- de Amarante, M.C.A.; Braga, A.R.C.; Sala, L.; Kalil, S.J. Colour Stability and Antioxidant Activity of C-Phycocyanin-Added Ice Creams after in Vitro Digestion. Food Res. Int. 2020, 137, 109602. [Google Scholar] [CrossRef]

- El Baky, H.H.A.; El Baroty, G.S.; Ibrahem, E.A. Functional Characters Evaluation of Biscuits Sublimated with Pure Phycocyanin Isolated from Spirulina and Spirulina Biomass. Nutr. Hosp. 2015, 32, 231–241. [Google Scholar] [CrossRef] [PubMed]

- Sözeri Atik, D.; Gürbüz, B.; Bölük, E.; Palabıyık, İ. Development of Vegan Kefir Fortified with Spirulina Platensis. Food Biosci. 2021, 42, 101050. [Google Scholar] [CrossRef]

- Arslan, A.A.; Gocer, E.M.C.; Demir, M.; Atamer, Z.; Hinrichs, J.; Kücükcetin, A. Viability of Lactobacillus Acidophilus ATCC 4356 Incorporated into Ice Cream Using Three Different Methods. Dairy Sci. Technol. 2016, 96, 477–487. [Google Scholar] [CrossRef]

- Polo, A.; Tlais, A.Z.A.; Filannino, P.; Da Ros, A.; Arora, K.; Cantatore, V.; Vincentini, O.; Nicolodi, A.; Nicolodi, R.; Gobbetti, M.; et al. Novel Fermented Ice Cream Formulations with Improved Antiradical and Anti-Inflammatory Features. Fermentation 2023, 9, 117. [Google Scholar] [CrossRef]

- Ağagündüz, D.; Yılmaz, B.; Şahin, T.Ö.; Güneşliol, B.E.; Ayten, Ş.; Russo, P.; Spano, G.; Rocha, J.M.; Bartkiene, E.; Özogul, F. Dairy Lactic Acid Bacteria and Their Potential Function in Dietetics: The Food–Gut-Health Axis. Foods 2021, 10, 3099. [Google Scholar] [CrossRef]

- de Amarante, M.C.A.; Braga, A.R.C.; Sala, L.; Moraes, C.C.; Kalil, S.J. Design Strategies for C-Phycocyanin Purification: Process Influence on Purity Grade. Sep. Purif. Technol. 2020, 252, 117453. [Google Scholar] [CrossRef]

- Moraes, C.C.; Kalil, S.J. Strategy for a Protein Purification Design Using C-Phycocyanin Extract. Bioresour. Technol. 2009, 100, 5312–5317. [Google Scholar] [CrossRef]

- Patil, G.; Chethana, S.; Madhusudhan, M.C.; Raghavarao, K.S.M.S. Fractionation and purification of the phycobiliproteins from Spirulina platensis. Bioresour. Technol. 2008, 99, 7393–7396. [Google Scholar] [CrossRef]

- ANVISA. RDC N° 331; ANVISA: Brasilia, Brazil, 2019. [Google Scholar]

- AOAC. Association of Official Analytical Chemists, 18th ed.; AOAC: Washington, DC, USA, 2005. [Google Scholar]

- Braga, A.R.C.; de Souza Mesquita, L.M.; Martins, P.L.G.; Habu, S.; de Rosso, V.V.; Mesquita, L.M.d.S.; Martins, P.L.G.; Habu, S.; de Rosso, V.V. Lactobacillus Fermentation of Jussara Pulp Leads to the Enzymatic Conversion of Anthocyanins Increasing Antioxidant Activity. J. Food Compos. Anal. 2018, 69, 162–170. [Google Scholar] [CrossRef]

- De Rosso, V.V.; Mercadante, A.Z. HPLC–PDA–MS/MS of Anthocyanins and Carotenoids from Dovyalis and Tamarillo Fruits. J. Agric. Food Chem. 2007, 55, 9135–9141. [Google Scholar] [CrossRef]

- Rodrigues, E.; Mariutti, L.R.B.; Faria, A.F.; Mercadante, A.Z. Microcapsules Containing Antioxidant Molecules as Scavengers of Reactive Oxygen and Nitrogen Species. Food Chem. 2012, 134, 704–711. [Google Scholar] [CrossRef] [PubMed]

- Re, R.; Pellegrini, N.; Proteggente, A.; Pannala, A.; Yang, M.; Rice-Evans, C. Antioxidant Activity Applying an Improved ABTS Radical Cation Decolorization Assay. Free Radic. Biol. Med. 1999, 26, 1231–1237. [Google Scholar] [CrossRef] [PubMed]

- Slinkard, K.; Singleton, V.L. Total Phenol Analysis: Automation and Comparison with Manual Methods. Am. J. Enol. Vitic. 1997, 28, 49–55. [Google Scholar] [CrossRef]

- Minekus, M.; Alminger, M.; Alvito, P.; Ballance, S.; Bohn, T.; Bourlieu, C.; Carriere, F.; Boutrou, R.; Corredig, M.; Dupont, D.; et al. A Standardised Static in Vitro Digestion Method Suitable for Food—An International Consensus. Food Funct. 2014, 5, 1113–1124. [Google Scholar] [CrossRef]

- Brodkorb, A.; Egger, L.; Alminger, M.; Alvito, P.; Assunção, R.; Ballance, S.; Bohn, T.; Bourlieu-Lacanal, C.; Boutrou, R.; Carrière, F.; et al. INFOGEST Static in Vitro Simulation of Gastrointestinal Food Digestion. Nat. Protoc. 2019, 14, 991–1014. [Google Scholar] [CrossRef]

- Misturini Rodrigues, L.; Gonzales Domiciano, M.; Araujo de Almeida, E.; Sereia, M.J.; Peron, A.P.; da Silva, R. Production of Bioactive and Functional Frozen Yogurt through Easy-to-Make Microspheres Incorporation. J. Food Sci. Technol. 2024, 61, 192–200. [Google Scholar] [CrossRef]

- Ly, B.C.K.; Dyer, E.B.; Feig, J.L.; Chien, A.L.; Del Bino, S. Research Techniques Made Simple: Cutaneous Colorimetry: A Reliable Technique for Objective Skin Color Measurement. J. Investig. Dermatol. 2020, 140, 3–12.e1. [Google Scholar] [CrossRef]

- Mohammadi-Gouraji, E.; Soleimanian-Zad, S.; Ghiaci, M. Phycocyanin-Enriched Yogurt and Its Antibacterial and Physicochemical Properties during 21 Days of Storage. LWT 2019, 102, 230–236. [Google Scholar] [CrossRef]

- Şanlıdere Aloğlu, H.; Öner, Z. Determination of Antioxidant Activity of Bioactive Peptide Fractions Obtained from Yogurt. J. Dairy Sci. 2011, 94, 5305–5314. [Google Scholar] [CrossRef]

- Sabokbar, N.; Khodaiyan, F.; Moosavi-Nasab, M. Optimization of Processing Conditions to Improve Antioxidant Activities of Apple Juice and Whey Based Novel Beverage Fermented by Kefir Grains. J. Food Sci. Technol. 2014, 52, 3422–3432. [Google Scholar] [CrossRef]

- Stobiecka, M.; Król, J.; Brodziak, A. Antioxidant Potential of Yogurts Produced from Milk of Cows Fed Fodder Supplemented with Herbal Mixture with Regard to Refrigerated Storage. Appl. Sci. 2023, 13, 10469. [Google Scholar] [CrossRef]

- Lamothe, S.; Guérette, C.; Dion, F.; Sabik, H.; Britten, M. Antioxidant Activity of Milk and Polyphenol-Rich Beverages during Simulated Gastrointestinal Digestion of Linseed Oil Emulsions. Food Res. Int. 2019, 122, 149–156. [Google Scholar] [CrossRef] [PubMed]

- de Abreu, E.; Preci, D.; Zeni, J.; Steffens, C.; Steffens, J. Desenvolvimento de Frozen Yogurt de Iogurte Em Pó de Leite de Ovelha. Rev. Ceres 2018, 65, 7–15. [Google Scholar] [CrossRef]

- Hoffmann, A.; Kleniewska, P.; Pawliczak, R. Antioxidative Activity of Probiotics. Arch. Med. Sci. 2021, 17, 792–804. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.; Li, S.; Tao, Y.; Li, D.; Han, Y.; Show, P.L.; Wen, G.; Zhou, J. Fermentation of Blueberry and Blackberry Juices Using Lactobacillus Plantarum, Streptococcus Thermophilus and Bifidobacterium Bifidum: Growth of Probiotics, Metabolism of Phenolics, Antioxidant Capacity in Vitro and Sensory Evaluation. Food Chem. 2021, 348, 129083. [Google Scholar] [CrossRef]

- Amaretti, A.; di Nunzio, M.; Pompei, A.; Raimondi, S.; Rossi, M.; Bordoni, A. Antioxidant Properties of Potentially Probiotic Bacteria: In Vitro and in Vivo Activities. Appl. Microbiol. Biotechnol. 2013, 97, 809–817. [Google Scholar] [CrossRef] [PubMed]

- Giaconia, M.A.; Ramos, S.d.P.; Fratelli, C.; Assis, M.; Mazzo, T.M.; Longo, E.; de Rosso, V.V.; Braga, A.R.C.; Ramos, P.; Fratelli, C.; et al. Fermented Jussara: Evaluation of Nanostructure Formation, Bioaccessibility, and Antioxidant Activity. Front. Bioeng. Biotechnol. 2022, 10, 814466. [Google Scholar] [CrossRef] [PubMed]

- Braga, A.R.C.; Murador, D.C.; de Souza Mesquita, L.M.; de Rosso, V.V. Bioavailability of Anthocyanins: Gaps in Knowledge, Challenges and Future Research. J. Food Compos. Anal. 2018, 68, 31–40. [Google Scholar] [CrossRef]

- Alshuniaber, M.A.; Krishnamoorthy, R.; AlQhtani, W.H. Antimicrobial Activity of Polyphenolic Compounds from Spirulina against Food-Borne Bacterial Pathogens. Saudi J. Biol. Sci. 2021, 28, 459. [Google Scholar] [CrossRef]

- Niccolai, A.; Venturi, M.; Galli, V.; Pini, N.; Rodolfi, L.; Biondi, N.; Granchi, L.; Tredici, M.R. Vegetable Oils Protect Phycocyanin from Thermal Degradation during Cooking of Spirulina-Based “Crostini”. LWT 2021, 138, 110776. [Google Scholar] [CrossRef]

- Vázquez, C.V.; Rojas, M.G.V.; Ramírez, C.A.; Chávez-Servín, J.L.; García-Gasca, T.; Ferriz Martínez, R.A.; García, O.P.; Rosado, J.L.; López-Sabater, C.M.; Castellote, A.I.; et al. Total Phenolic Compounds in Milk from Different Species. Design of an Extraction Technique for Quantification Using the Folin–Ciocalteu Method. Food Chem. 2015, 176, 480–486. [Google Scholar] [CrossRef] [PubMed]

- Wei, S.T.; Ou, L.C.; Luo, M.R.; Hutchings, J.B. Optimisation of Food Expectations Using Product Colour and Appearance. Food Qual. Prefer. 2012, 23, 49–62. [Google Scholar] [CrossRef]

- Ferreira, L.G.B.; Faria, R.X.; Ferreira, N.C.D.S.; Soares-Bezerra, R.J. Brilliant Blue Dyes in Daily Food: How Could Purinergic System Be Affected? Int. J. Food Sci. 2016, 2016. [Google Scholar] [CrossRef] [PubMed]

- Lucas, B.F.; Brunner, T.A. Attitudes and Perceptions towards Microalgae as an Alternative Food: A Consumer Segmentation in Switzerland. Algal. Res. 2024, 103386. [Google Scholar] [CrossRef]

- Colonia, B.S.O.; de Melo Pereira, G.V.; de Carvalho, J.C.; Karp, S.G.; Rodrigues, C.; Soccol, V.T.; Fanka, L.S.; Soccol, C.R. Deodorization of Algae Biomass to Overcome Off-Flavors and Odor Issues for Developing New Food Products: Innovations, Trends, and Applications. Food Chem. Adv. 2023, 2, 100270. [Google Scholar] [CrossRef]

- Marques, C.; Lise, C.C.; Bonadimann, F.S.; Mitterer-Daltoé, M.L. Flash Profile as an Effective Method for Assessment of Odor Profile in Three Different Fishes. J. Food Sci. Technol. 2019, 56, 4036. [Google Scholar] [CrossRef]

- Prasetiyo, H.; Purwaningsih, S.; Setyaningsih, I.; Nurilmala, M.; Uju, U.; Tarman, K. Off-Odour Identification from Volatile Organic Compounds (VOCs) of Spirulina. BIO Web. Conf. 2024, 92, 02006. [Google Scholar] [CrossRef]

| Formulation | ORAC (µM TE/g) | ABTS (µM TE/g) | Total Phenolics | ||

|---|---|---|---|---|---|

| Ice Cream | Ice Cream after In Vitro Digestion | Ice Cream | Ice Cream after In Vitro Digestion | (mg GAE/100 g of Sample) | |

| SC | 5.0 cA ± 2.4 | 5.3 bA ± 0.7 | 0.5 aA ± 0.1 | 0.2 bB ± 0.1 | 2.46 b ± 0.1 |

| SC-PC | 15.4 bcB ± 2.0 | 41.3 aA ± 2.6 | 1.6 aA ± 0.8 | 2.1 aA ± 0.6 | 2.89 ab ± 0.3 |

| SRB | 15.3 bcB ± 3.7 | 38.0 aA ± 4.3 | 1.4 bA ± 0.5 | 1.9 aA ± 0.5 | 2.20 b ± 0.1 |

| MC | 9.5 bcA ± 1.1 | 8.9 bA ± 2.9 | 0.7 bA ± 0.1 | 0.6 bA ± 0.2 | 2.44 b ± 0.1 |

| MC-PC | 22.6 abA ± 3.4 | 37.1 aA ± 8.3 | 2.5 aA ± 1.1 | 2.2 aA ± 0.8 | 3.19 a ± 0.4 |

| MRB | 37.5 aA ± 3.9 | 49.9 aA ± 2.9 | 2.7 aA ± 0.6 | 2.0 aA ± 0.8 | 2.40 b ± 0.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bürck, M.; Fratelli, C.; Assis, M.; Braga, A.R.C. Naturally Colored Ice Creams Enriched with C-Phycocyanin and Spirulina Residual Biomass: Development of a Fermented, Antioxidant, Tasty and Stable Food Product. Fermentation 2024, 10, 304. https://doi.org/10.3390/fermentation10060304

Bürck M, Fratelli C, Assis M, Braga ARC. Naturally Colored Ice Creams Enriched with C-Phycocyanin and Spirulina Residual Biomass: Development of a Fermented, Antioxidant, Tasty and Stable Food Product. Fermentation. 2024; 10(6):304. https://doi.org/10.3390/fermentation10060304

Chicago/Turabian StyleBürck, Monize, Camilly Fratelli, Marcelo Assis, and Anna Rafaela Cavalcante Braga. 2024. "Naturally Colored Ice Creams Enriched with C-Phycocyanin and Spirulina Residual Biomass: Development of a Fermented, Antioxidant, Tasty and Stable Food Product" Fermentation 10, no. 6: 304. https://doi.org/10.3390/fermentation10060304