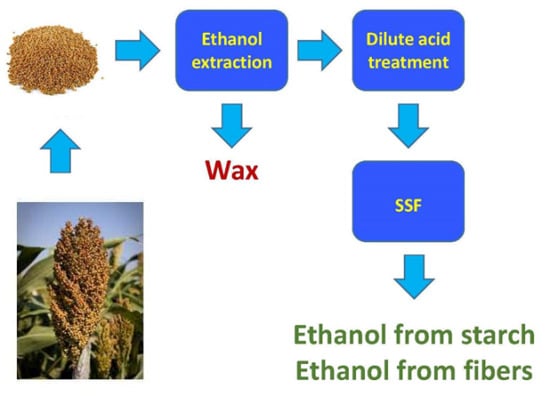

Integrated Process for Extraction of Wax as a Value-Added Co-Product and Improved Ethanol Production by Converting Both Starch and Cellulosic Components in Sorghum Grains

Abstract

Share and Cite

Nghiem, N.P.; O’Connor, J.P.; Hums, M.E. Integrated Process for Extraction of Wax as a Value-Added Co-Product and Improved Ethanol Production by Converting Both Starch and Cellulosic Components in Sorghum Grains. Fermentation 2018, 4, 12. https://doi.org/10.3390/fermentation4010012

Nghiem NP, O’Connor JP, Hums ME. Integrated Process for Extraction of Wax as a Value-Added Co-Product and Improved Ethanol Production by Converting Both Starch and Cellulosic Components in Sorghum Grains. Fermentation. 2018; 4(1):12. https://doi.org/10.3390/fermentation4010012

Chicago/Turabian StyleNghiem, Nhuan P., James P. O’Connor, and Megan E. Hums. 2018. "Integrated Process for Extraction of Wax as a Value-Added Co-Product and Improved Ethanol Production by Converting Both Starch and Cellulosic Components in Sorghum Grains" Fermentation 4, no. 1: 12. https://doi.org/10.3390/fermentation4010012

APA StyleNghiem, N. P., O’Connor, J. P., & Hums, M. E. (2018). Integrated Process for Extraction of Wax as a Value-Added Co-Product and Improved Ethanol Production by Converting Both Starch and Cellulosic Components in Sorghum Grains. Fermentation, 4(1), 12. https://doi.org/10.3390/fermentation4010012