Effect of Inulin Addition on Physicochemical, Microbiological, Textural, and Sensorial Characteristics of Fermented Butifarra with Lactobacillus sakei

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Supplies

2.2. Preparation of Starter Cultures

2.3. Experimental Design

2.4. Preparation of Fermented Butifarra

2.5. Physicochemical Analysis

2.6. Microbiological Analysis

2.7. Texture Analysis

2.8. Sensory Analysis

2.9. Statistical Analysis

3. Results and Discussion

3.1. Physicochemical Properties

3.2. Microbiological Characteristic

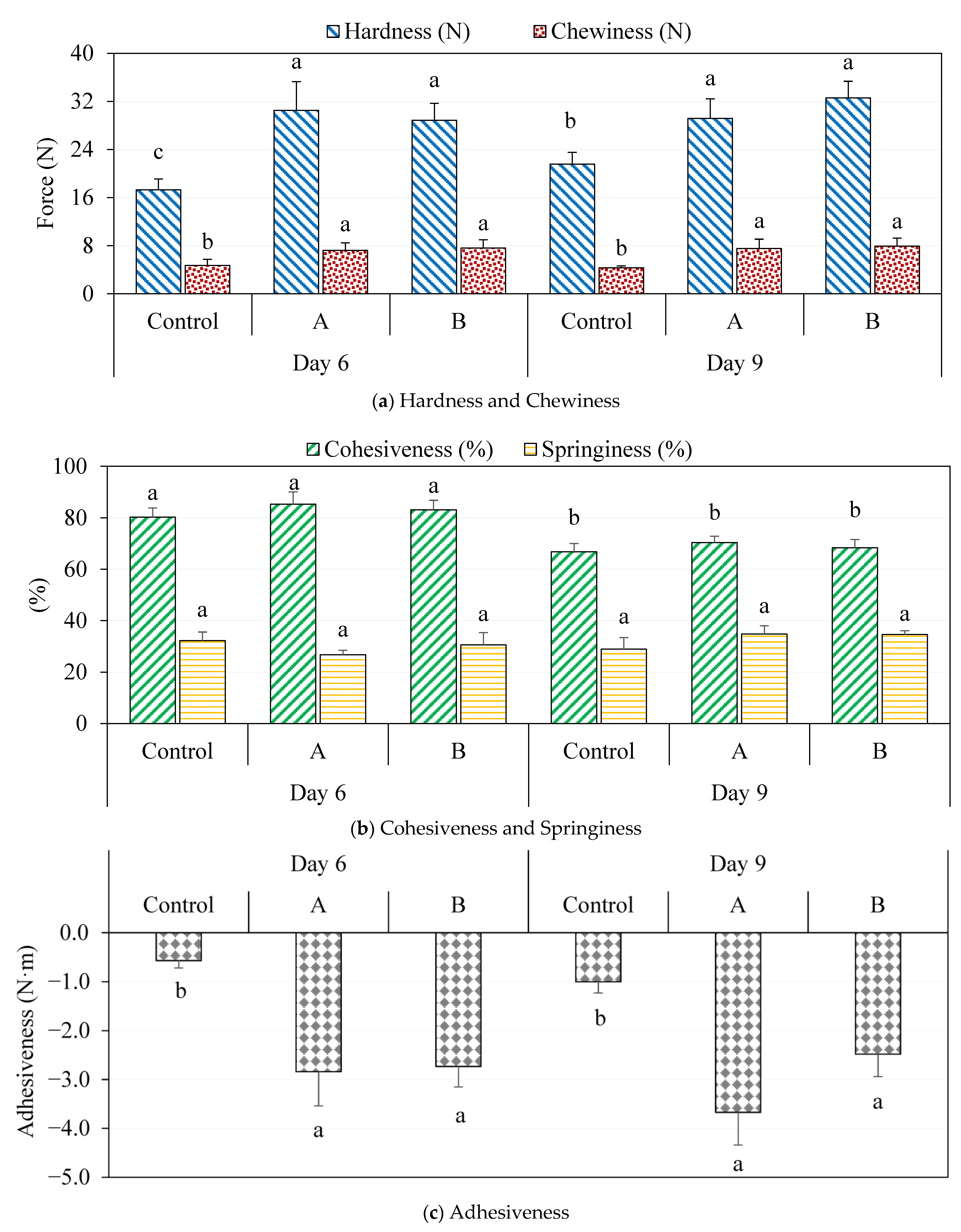

3.3. Textural Changes

3.4. Sensory Acceptability

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Williams, M.; Hekmat, S. Lactobacillus rhamnosus GR-1 in Fermented Rice Pudding Supplemented with Short Chain Inulin, Long Chain Inulin, and Oat as a Novel Functional Food. Fermentation 2017, 3, 55. [Google Scholar] [CrossRef]

- Shoaib, M.; Shehzad, A.; Omar, M.; Rakha, A.; Raza, H.; Sharif, H.R.; Shakeel, A.; Ansari, A.; Niazi, S. Inulin: Properties, Health Benefits and Food Applications. Carbohydr. Polym. 2016, 147, 444–454. [Google Scholar] [CrossRef] [PubMed]

- Montoya, L.; Quintero, N.; Ortiz, S.; Lopera, J.; Millán, P.; Rodríguez-Stouvenel, A. Inulin as a Fat-Reduction Ingredient in Pork and Chicken Meatballs: Its Effects on Physicochemical Characteristics and Consumer Perceptions. Foods 2022, 11, 1066. [Google Scholar] [CrossRef] [PubMed]

- White, J.; Hekmat, S. Development of Probiotic Fruit Juices Using Lactobacillus rhamnosus GR-1 Fortified with Short Chain and Long Chain Inulin Fiber. Fermentation 2018, 4, 27. [Google Scholar] [CrossRef]

- Muncey, L.; Hekmat, S. Development of Probiotic Almond Beverage Using Lacticaseibacillus rhamnosus GR-1 Fortified with Short-Chain and Long-Chain Inulin Fibre. Fermentation 2021, 7, 90. [Google Scholar] [CrossRef]

- Akköse, A.; Oğraş, Ş.Ş.; Kaya, M.; Kaban, G. Microbiological, Physicochemical and Sensorial Changes during the Ripening of Sucuk, a Traditional Turkish Dry-Fermented Sausage: Effects of Autochthonous Strains, Sheep Tail Fat and Ripening Rate. Fermentation 2023, 9, 558. [Google Scholar] [CrossRef]

- Mu, H.; Weng, P.; Wu, Z. Effect of Inoculation with Lacticaseibacillus casei and Staphylococcus carnosus on the Quality of Squid (Dosidicus gigas) Surimi Sausage. Fermentation 2023, 9, 794. [Google Scholar] [CrossRef]

- Cardona, M.; Izquierdo, D.; Barat, J.M.; Fernández-Segovia, I. Intrinsic and Extrinsic Attributes That Influence Choice of Meat and Meat Products: Techniques Used in Their Identification. Eur. Food Res. Technol. 2023, 249, 2485–2514. [Google Scholar] [CrossRef]

- Chaharaein, M.; Sadeghi, E.; Mohammadi, R.; Rouhi, M.; Soltani, M. The Effect of β-Glucan and Inulin on the Reduction of Aflatoxin B1 Level and Assessment of Textural and Sensory Properties in Chicken Sausages. Curr. Res. Food Sci. 2021, 4, 765–772. [Google Scholar] [CrossRef]

- de Souza Paglarini, C.; de Figueiredo Furtado, G.; Honório, A.R.; Mokarzel, L.; da Silva Vidal, V.A.; Ribeiro, A.P.B.; Cunha, R.L.; Pollonio, M.A.R. Functional emulsion gels as pork back fat replacers in Bologna sausage. Food Struct. 2019, 20, 100105. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhang, Y.; Peng, Z. Effect of Eggplant Powder on the Physicochemical and Sensory Characteristics of Reduced-Fat Pork Sausages. Foods 2021, 10, 743. [Google Scholar] [CrossRef] [PubMed]

- Dias, I.; Laranjo, M.; Potes, M.E.; Agulheiro-Santos, A.C.; Ricardo-Rodrigues, S.; Fraqueza, M.J.; Oliveira, M.; Elias, M. Staphylococcus spp. and Lactobacillus sakei Starters with High Level of Inoculation and an Extended Fermentation Step Improve Safety of Fermented Sausages. Fermentation 2022, 8, 49. [Google Scholar] [CrossRef]

- Li, J.; Cui, H.; Xu, X.; Li, J.; Lu, M.; Guan, X.; Zhu, D.; Liu, H. Effect of Fat Replacement by Inulin on the Physicochemical Properties and Sensory Attributes of Low-Fat Margarine. Food Hydrocoll. 2022, 133, 107868. [Google Scholar] [CrossRef]

- Zeng, X.; Lv, B.; Zhu, Y.; Li, Q.; Zhang, K.; Li, C.; Zhao, D.; Li, C. Influence of Hydrophilic Polysaccharide Fat Replacers on the In Vitro Digestibility of Protein in Emulsion-Type Sausage. Food Res. Int. 2023, 170, 113008. [Google Scholar] [CrossRef]

- Lee, J.; Wi, G.; Choi, M.-J. The Rheological Properties and Stability of Gelled Emulsions Applying to κ-Carrageenan and Methyl Cellulose as an Animal Fat Replacement. Food Hydrocoll. 2023, 136, 108243. [Google Scholar] [CrossRef]

- Rather, S.A.; Masoodi, F.A.; Akhter, R.; Rather, J.A.; Gani, A.; Wani, S.M.; Malik, A.H. Application of Guar–Xanthan Gum Mixture as a Partial Fat Replacer In Meat Emulsions. J. Food Sci. Technol. 2016, 53, 2876–2886. [Google Scholar] [CrossRef]

- Schmiele, M.; Nucci Mascarenhas, M.C.C.; Da Silva Barretto, A.C.; Rodrigues Pollonio, M.A. Dietary Fiber as Fat Substitute in Emulsified and Cooked Meat Model System. LWT—Food Sci. Technol. 2015, 61, 105–111. [Google Scholar] [CrossRef]

- Han, K.; Li, S.; Yang, Y.; Feng, X.; Tang, X.; Chen, Y. Mechanisms of Inulin Addition Affecting the Properties of Chicken Myofibrillar Protein Gel. Food Hydrocoll. 2022, 131, 107843. [Google Scholar] [CrossRef]

- Samakradhamrongthai, R.S.; Jannu, T.; Supawan, T.; Khawsud, A.; Aumpa, P.; Renaldi, G. Inulin Application on the Optimization of Reduced-Fat Ice Cream Using Response Surface Methodology. Food Hydrocoll. 2021, 119, 106873. [Google Scholar] [CrossRef]

- Frolova, Y.; Vorobyeva, V.; Vorobyeva, I.; Sarkisyan, V.; Malinkin, A.; Isakov, V.; Kochetkova, A. Development of Fermented Kombucha Tea Beverage Enriched with Inulin and B Vitamins. Fermentation 2023, 9, 552. [Google Scholar] [CrossRef]

- Zhuang, X.; Han, M.; Bai, Y.; Liu, Y.; Xing, L.; Xu, X.; Zhou, G. Insight into the Mechanism of Myofibrillar Protein Gel Improved by Insoluble Dietary Fiber. Food Hydrocoll. 2018, 74, 219–226. [Google Scholar] [CrossRef]

- Zhuang, X.; Wang, L.; Jiang, X.; Chen, Y.; Zhou, G. Insight into the Mechanism of Myofibrillar Protein Gel Influenced by Konjac Glucomannan: Moisture Stability and Phase Separation Behavior. Food Chem. 2021, 339, 127941. [Google Scholar] [CrossRef]

- NTC 1325. Industrias Alimentarias. Productos Carnicos Procesados no Enlatados. 5a Actualiz; Instituto Colombiano de Normas Técnicas y Certificación: Bogotá, Colombia, 2008; Available online: https://tienda.icontec.org/gp-industrias-alimentarias-productos-carnicos-procesados-no-enlatados-ntc1325-2008.html (accessed on 15 January 2021).

- Li, Y.; Xu, Z.; Sun, J.; Zhu, Y. Effects of an Inulin and Microcrystalline Cellulose Hybrid Hydrogel on the Short-Term Low Temperature Storage Characteristics of Pork Sausage Models. Food Hydrocoll. 2023, 139, 108572. [Google Scholar] [CrossRef]

- Acevedo, D.; Granados, C.; Montero, P.M. Caracterización de Propiedades Fisicoquímicas, Textura y Calidad Microbiológica de Butifarra Comercializada en Cartagena (Colombia). Inf. Tecnol. 2014, 25, 33–38. [Google Scholar] [CrossRef]

- Altamar Pérez, T.d.J.; Manotas Padilla, S.J.; Pugliesse Marrugo, M.V.; Castro Escorcia, Y.; Florez Cortes, E. Caracterización de Las Propiedades Fisicoquímicas y Microbiológicas de Butifarras Comercializadas En Puntos de Ventas En El Municipio de Soledad Atlántico. Rev. Gipama 2022, 3, 63–74. [Google Scholar]

- Julio, L.C.; Montero, P.M.; Acevedo, D. Calidad y Aceptabilidad de Chorizos Formulados con Plasma Sanguíneo Bovino y Pasta de Ajonjolí. Inf. Tecnol. 2015, 26, 25–32. [Google Scholar] [CrossRef]

- Ortiz, L.S.; Sinning, L.L.; Castillo, P.M.M. Evaluation of the Physicochemical Properties of Fermented Sausages with Staphylococcus xylosus and Lactobacillus sakei. Pak. J. Nutr. 2019, 18, 1068–1074. [Google Scholar] [CrossRef]

- Zuber, A.-Đ.; Horvat, M. Influence of Starter Cultures on the Free Fatty Acids during Ripening in Tea Sausages. Eur. Food Res. Technol. 2007, 224, 511–517. [Google Scholar] [CrossRef]

- Wang, X.; Ren, H.; Liu, D.; Zhu, W.; Wang, W. Effects of Inoculating Lactobacillus sakei Starter Cultures on the Microbiological Quality and Nitrite Depletion of Chinese Fermented Sausages. Food Control 2013, 32, 591–596. [Google Scholar] [CrossRef]

- Menegas, L.Z.; Pimentel, T.C.; Garcia, S.; Prudencio, S.H. Dry-Fermented Chicken Sausage Produced with Inulin and Corn Oil: Physicochemical, Microbiological, And Textural Characteristics and Acceptability during Storage. Meat Sci. 2013, 93, 501–506. [Google Scholar] [CrossRef]

- Sun, Q.; Chen, Q.; Li, F.; Zheng, D.; Kong, B. Biogenic Amine Inhibition and Quality Protection of Harbin Dry Sausages by Inoculation with Staphylococcus xylosus and Lactobacillus plantarum. Food Control 2016, 68, 358–366. [Google Scholar] [CrossRef]

- AOAC. Official Method of Analysis, 18th ed.; Association of Officiating Analytical Chemists International: Washington, DC, USA, 2005. [Google Scholar]

- Mikami, N.; Tsukada, Y.; Pelpolage, S.W.; Han, K.-H.; Fukushima, M.; Shimada, K. Effects of Sake Lees (Sake-Kasu) Supplementation on the Quality Characteristics of Fermented Dry Sausages. Heliyon 2020, 6, e03379. [Google Scholar] [CrossRef] [PubMed]

- Torres González, J.D.; González Morelo, K.J.; Acevedo Correa, D.; Jaimes Morales, J.d.C. Efecto de la Utilización de Harina de Lens culinaris Como Extensor en las Características Físicas y Aceptabilidad de una Salchicha. Rev. Tecnura 2016, 20, 15. [Google Scholar] [CrossRef]

- Choi, H.-S.; Choi, H.-G.; Choi, Y.-S.; Kim, J.-H.; Lee, J.-H.; Jung, E.-H.; Lee, S.-H.; Choi, Y.-I.; Choi, J.-S. Effect of Chicory Fiber and Smoking on Quality Characteristics of Restructured Sausages. Korean J. Food Sci. Anim. Resour. 2016, 36, 131–136. [Google Scholar] [CrossRef] [PubMed]

- Gadekar, Y.P.; Sharma, B.; Shinde, A.K.; Das, A.K.; Mendiratta, S. Effect of Incorporation of Functional Ingredients on Quality of Low Fat Restructured Goat Meat Product. Nutr. Food Sci. 2017, 47, 731–740. [Google Scholar] [CrossRef]

- Huang, S.C.; Tsai, Y.F.; Chen, C.M. Effects of Wheat Fiber, Oat Fiber, and Inulin on Sensory and Physico-chemical Properties of Chinese-style Sausages. Asian-Australas. J. Anim. Sci. 2011, 24, 875–880. [Google Scholar] [CrossRef]

- Choi, Y.-S.; Kim, H.-W.; Hwang, K.-E.; Song, D.-H.; Choi, J.-H.; Lee, M.-A.; Chung, H.-J.; Kim, C.-J. Physicochemical Properties and Sensory Characteristics of Reduced-Fat Frankfurters with Pork Back Fat Replaced by Dietary Fiber Extracted from Makgeolli Lees. Meat Sci. 2014, 96, 892–900. [Google Scholar] [CrossRef]

- Illippangama, A.U.; Jayasena, D.D.; Jo, C.; Mudannayake, D.C. Inulin as a Functional Ingredient and Their Applications in Meat Products. Carbohydr. Polym. 2022, 275, 118706. [Google Scholar] [CrossRef]

- De Souza Paglarini, C.; Vidal, V.A.; Ribeiro, W.; Badan Ribeiro, A.P.; Bernardinelli, O.D.; Herrero, A.M.; Ruiz-Capillas, C.; Sabadini, E.; Rodrigues Pollonio, M.A. Using Inulin-Based Emulsion Gels as Fat Substitute in Salt Reduced Bologna Sausage. J. Sci. Food Agric. 2021, 101, 505–517. [Google Scholar] [CrossRef]

- Choi, H.-Y.; Ryu, H.-K.; Park, K.-M.; Lee, E.G.; Lee, H.; Kim, S.-W.; Choi, E.-S. Direct lactic Acid Fermentation of Jerusalem Artichoke Tuber Extract Using Lactobacillus paracasei without Acidic or Enzymatic Inulin Hydrolysis. Bioresour. Technol. 2012, 114, 745–747. [Google Scholar] [CrossRef]

- Cardarelli, H.R.; Buriti, F.C.A.; Castro, I.A.; Saad, S.M.I. Inulin and Oligofructose Improve Sensory Quality and Increase the Probiotic Viable Count in Potentially Synbiotic Petit-Suisse Cheese. LWT—Food Sci. Technol. 2008, 41, 1037–1046. [Google Scholar] [CrossRef]

- Özer, C. Utilization of Jerusalem artichoke powder in production of low-fat and fat-free fermented sausage. Ital. J. Food Sci. 2018, 31, 1354. [Google Scholar] [CrossRef]

- Egea, M.; Álvarez, D.; Peñaranda, I.; Panella-Riera, N.; Linares, M.B.; Garrido, M.D. Fat Replacement by Vegetal Fibres to Improve the Quality of Sausages Elaborated with Non-Castrated Male Pork. Animals 2020, 10, 1872. [Google Scholar] [CrossRef] [PubMed]

- Fernández-Diez, A.; Caro, I.; Castro, A.; Salvá, B.K.; Ramos, D.D.; Mateo, J. Partial Fat Replacement by Boiled Quinoa on the Quality Characteristics of a Dry-Cured Sausage. J. Food Sci. 2016, 81, C1891–C1898. [Google Scholar] [CrossRef]

- Luisa García, M.; Cáceres, E.; Dolores Selgas, M. Effect of Inulin on the Textural and Sensory Properties of Mortadella, A Spanish Cooked Meat Product. Int. J. Food Sci. Technol. 2006, 41, 1207–1215. [Google Scholar] [CrossRef]

- Glisic, M.; Baltic, M.; Glisic, M.; Trbovic, D.; Jokanovic, M.; Parunovic, N.; Dimitrijevic, M.; Suvajdzic, B.; Boskovic, M.; Vasilev, D. Inulin-based emulsion-filled gel as a fat replacer in prebiotic- and PUFA-enriched dry fermented sausages. Int. J. Food Sci. Technol. 2019, 54, 787–797. [Google Scholar] [CrossRef]

- Han, M.; Bertram, H.C. Designing Healthier Comminuted Meat Products: Effect of Dietary Fibers on Water Distribution and Texture of a Fat-Reduced Meat Model System. Meat Sci. 2017, 133, 159–165. [Google Scholar] [CrossRef]

- Alaei, F.; Hojjatoleslamy, M.; Hashemi Dehkordi, S.M. The Effect of Inulin as a Fat Substitute on the Physicochemical and Sensory Properties of Chicken Sausages. Food Sci. Nutr. 2018, 6, 512–519. [Google Scholar] [CrossRef]

- Liaros, N.G.; Katsanidis, E.; Bloukas, J.G. Effect of the Ripening Time under Vacuum and Packaging Film Permeability on Processing and Quality Characteristics of Low-Fat Fermented Sausages. Meat Sci. 2009, 83, 589–598. [Google Scholar] [CrossRef]

- Salazar, P.; García, M.L.; Selgas, M.D. Short-Chain Fructooligosaccharides as Potential Functional Ingredient in Dry Fermented Sausages with Different Fat Levels. Int. J. Food Sci. Technol. 2009, 44, 1100–1107. [Google Scholar] [CrossRef]

- Beriain, M.J.; Gómez, I.; Petri, E.; Insausti, K.; Sarriés, M.V. The Effects of Olive Oil Emulsified Alginate on the Physico-Chemical, Sensory, Microbial, and Fatty Acid Profiles of Low-Salt, Inulin-Enriched Sausages. Meat Sci. 2011, 88, 189–197. [Google Scholar] [CrossRef] [PubMed]

- Noguerol, A.T.; Larrea, V.; Pagán, M.J. The Effect of Psyllium (Plantago ovata Forsk) Fibres on the Mechanical and Physicochemical Characteristics of Plant-Based Sausages. Eur. Food Res. Technol. 2022, 248, 2483–2496. [Google Scholar] [CrossRef] [PubMed]

- de Carvalho, F.A.L.; Munekata, P.E.S.; Lopes de Oliveira, A.; Pateiro, M.; Domínguez, R.; Trindade, M.A.; Lorenzo, J.M. Turmeric (Curcuma longa L.) Extract on Oxidative Stability, Physicochemical and Sensory Properties of Fresh Lamb Sausage with Fat Replacement by Tiger Nut (Cyperus esculentus L.) Oil. Food Res. Int. 2020, 136, 109487. [Google Scholar] [CrossRef]

- Ruiz, B.K.S.; La Molina, U.N.A.; Elías-Peñafiel, C.C.A.; Larico Condori, J.; Bleu, U.L.C. Optimizacion de Una Formulación de Butifarra Dulce Seca con Carne de Llama, pecanas y kañiwa. Rev. Investig. Altoandinas—J. High Andean Res. 2021, 23, 77–84. [Google Scholar] [CrossRef]

- dos Santos Alves, L.A.A.; Lorenzo, J.M.; Gonçalves, C.A.A.; Dos Santos, B.A.; Heck, R.T.; Cichoski, A.J.; Campagnol, P.C.B. Production of Healthier Bologna Type Sausages Using Pork Skin and Green Banana Flour as a Fat Replacers. Meat Sci. 2016, 121, 73–78. [Google Scholar] [CrossRef]

- Bis-Souza, C.V.; Barba, F.J.; Lorenzo, J.M.; Penna, A.L.B.; Barretto, A.C.S. New Strategies for the Development of Innovative Fermented Meat Products: A Review Regarding the Incorporation of Probiotics and Dietary Fibers. Food Rev. Int. 2019, 35, 467–484. [Google Scholar] [CrossRef]

- Souza, C.V.B.; Bellucci, E.R.B.; Lorenzo, J.M.; Barretto, A.C.d.S. Low-Fat Brazilian Cooked Sausage-Paio—With Added Oat Fiber and Inulin as a Fat Substitute: Effect on the Technological Properties and Sensory Acceptance. Food Sci. Technol. 2019, 39 (Suppl. S1), 295–303. [Google Scholar] [CrossRef]

- Guedes-Oliveira, J.M.; Costa-Lima, B.R.C.; Oliveira, D.; Neto, A.; Deliza, R.; Conte-Junior, C.A.; Guimarães, C.F.M. Mixture Design Approach for the Development of Reduced Fat Lamb Patties with Carboxymethyl Cellulose and Inulin. Food Sci. Nutr. 2019, 7, 1328–1336. [Google Scholar] [CrossRef]

| Ingredients | Control (%) | A: 5% Inulin | B: 7.5% Inulin |

|---|---|---|---|

| Beef meat | 60 | 60 | 60 |

| Pork meat | 22 | 17 | 14.5 |

| Ice | 14 | 14 | 14 |

| Inulin | 0 | 5 | 7.5 |

| Starter culture (mL) | 10 | 10 | 10 |

| Red onion | 0.2 | 0.2 | 0.2 |

| Long onion | 0.2 | 0.2 | 0.2 |

| Ground black pepper | 0.3 | 0.3 | 0.3 |

| Monosodium glutamate | 0.2 | 0.2 | 0.2 |

| Garlic powder | 0.2 | 0.2 | 0.2 |

| Paprika | 0.2 | 0.2 | 0.2 |

| Salt | 1.7 | 1.7 | 1.7 |

| Total | 100 | 100 | 100 |

| Samples | Components (% d.b) | ||||||

|---|---|---|---|---|---|---|---|

| Moisture | Fat | Protein | Ash | Fibre | Carbohydrates | ||

| Control | 54.02 ± 1.11 a | 15.98 ± 0.72 a | 28.15 ± 2.35 a | 1.26 ± 0.76 a | 0.12 ± 0.04 a | 0.47 ± 0.15 c | |

| A | 53.21 ± 1.24 a | 15.07 ± 0.48 a | 28.04 ± 4.17 a | 1.31 ± 0.57 a | 0.15 ± 0.03 a | 2.22 ± 0.91 b | |

| B | 49.63 ± 1.33 b | 14.88 ± 0.62 a | 27.57 ± 1.33 a | 1.19 ± 0.41 a | 0.18 ± 0.02 a | 6.54 ± 1.07 a | |

| ANOVA | F-value | 52.87 | 8.67 | 10.34 | 3.35 | 6.58 | 106.44 |

| p-value | 0.042 < 0.05 | 0.765 > 0.05 | 0.962 > 0.05 | 0.973 > 0.05 | 0.592 > 0.05 | 0.016 < 0.05 | |

| Microorganisms Analyzed | NTC 1325:2008 (CFU/g) | Day 9 (Maximum Fermentation) | ANOVA | |||

|---|---|---|---|---|---|---|

| Control | A | B | F-Value | p-Value | ||

| Total aerobic mesophiles (Log10 CFU/g) | 100,000 | <3.65 ± 0.09 a | <3.60 ± 0.05 a | <3.60 ± 0.08 a | 9.26 | 0.516 > 0.05 |

| Total Coliform MPN (Log10 CFU/mL) | <10 | <3.20 ± 0.07 a | <3.15 ± 0.08 a | <3.15 ± 0.05 a | 5.33 | 0.887 > 0.05 |

| Fecal Coliform MPN (Log10 CFU/mL) | <10 | 0.00 | 0.00 | 0.00 | NA | NA |

| Coagulase-positive staphylococcus (Log10 CFU/g) | <100 | <3.40 ± 0.02 b | <3.25 ± 0.05 a | <3.25 ± 0.01 a | 79.58 | 0.035 < 0.05 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Montero Castillo, P.M.; Morelos Martelo, V.; Gómez Acevedo, K.; Ligardo, Y.A.M.; Acevedo-Correa, D. Effect of Inulin Addition on Physicochemical, Microbiological, Textural, and Sensorial Characteristics of Fermented Butifarra with Lactobacillus sakei. Fermentation 2023, 9, 913. https://doi.org/10.3390/fermentation9100913

Montero Castillo PM, Morelos Martelo V, Gómez Acevedo K, Ligardo YAM, Acevedo-Correa D. Effect of Inulin Addition on Physicochemical, Microbiological, Textural, and Sensorial Characteristics of Fermented Butifarra with Lactobacillus sakei. Fermentation. 2023; 9(10):913. https://doi.org/10.3390/fermentation9100913

Chicago/Turabian StyleMontero Castillo, Piedad Margarita, Verónica Morelos Martelo, Katiuska Gómez Acevedo, Yesid Alejandro Marrugo Ligardo, and Diofanor Acevedo-Correa. 2023. "Effect of Inulin Addition on Physicochemical, Microbiological, Textural, and Sensorial Characteristics of Fermented Butifarra with Lactobacillus sakei" Fermentation 9, no. 10: 913. https://doi.org/10.3390/fermentation9100913

APA StyleMontero Castillo, P. M., Morelos Martelo, V., Gómez Acevedo, K., Ligardo, Y. A. M., & Acevedo-Correa, D. (2023). Effect of Inulin Addition on Physicochemical, Microbiological, Textural, and Sensorial Characteristics of Fermented Butifarra with Lactobacillus sakei. Fermentation, 9(10), 913. https://doi.org/10.3390/fermentation9100913