Characterization of Bee Bread Produced with Defined Starter Cultures Mimicking the Natural Fermentation Process

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Fermentation of Bee Pollen

2.2.2. Physicochemical Properties of Bee Bread

pH and Moisture Analysis

Carbohydrate and Organic Acid Levels

2.2.3. Amount of Free Phenolic Components in Bee Bread

2.2.4. In Vitro Protein Digestibility

2.2.5. Amino Acid Profile

2.2.6. Detection of Microbial Consortium during Bee Bread Fermentation

2.2.7. Statistical Analysis

3. Results and Discussion

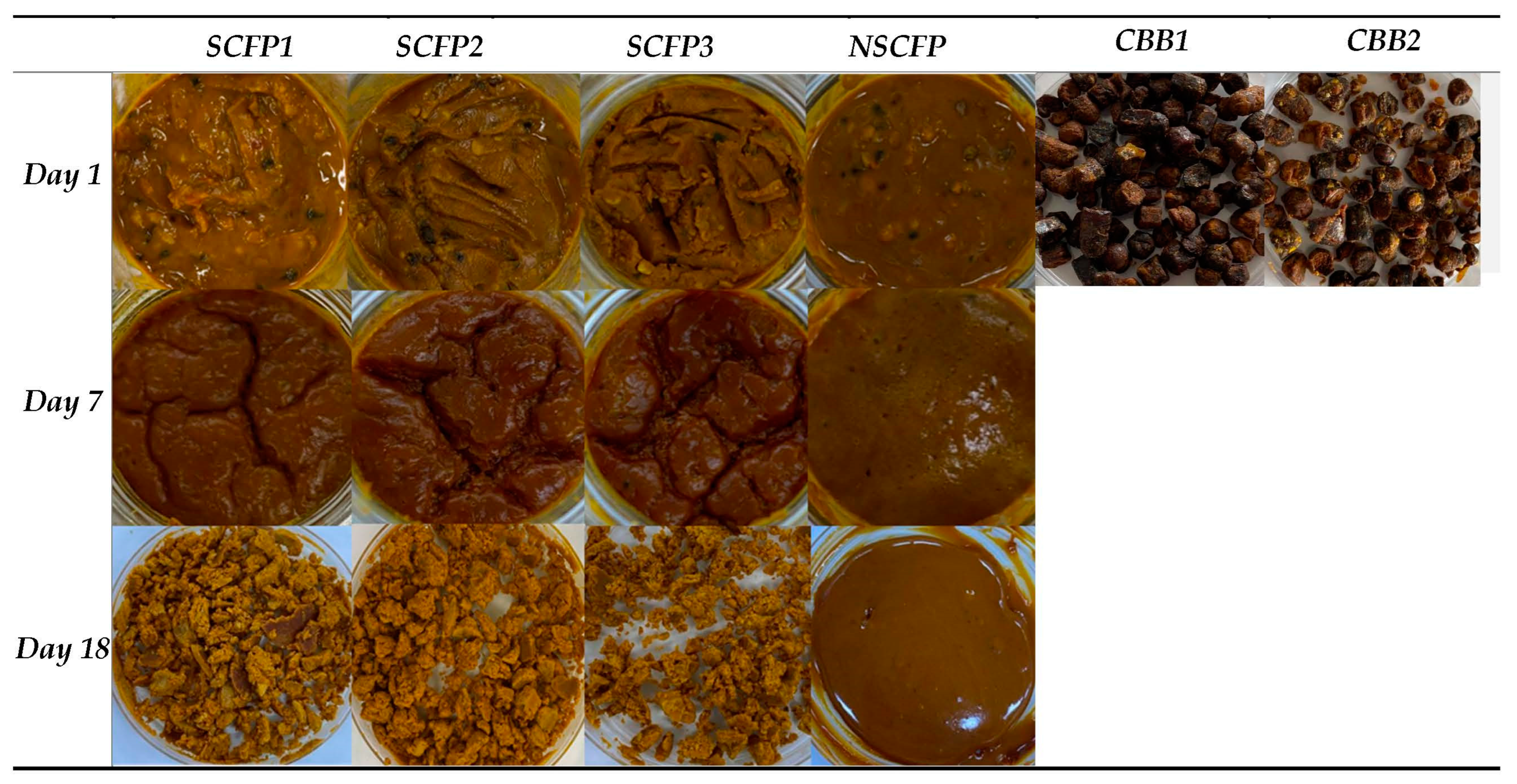

3.1. Fermentation of Bee Pollen

3.2. Physicochemical Properties of Bee Bread

3.3. Amount of Free Phenolic Components in Bee Bread

3.4. In vitro Digestibility of Bee Bread

3.5. Amino Acid Profile of Bee Bread

3.6. Microbial Profile of Bee Bread

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Brown, R. Hive products: Pollen, propolis and royal jelly. Bee World 1989, 3, 109–117. [Google Scholar] [CrossRef]

- Komosinska-Vassev, K.; Olczyk, P.; Kaźmierczak, J.; Mencner, L.; Olczyk, K. Bee pollen: Chemical composition and therapeutic application. Evid.-Based Complement. Altern. Med. 2015, 2015, 297425. [Google Scholar] [CrossRef] [Green Version]

- Urcan, A.; Mărghitaș, L.A.; Dezmirean, D.S.; Bobiș, O.; Bonta, V.; Mureșan, C.I.; Mărgăoan, R. Chemical Composition and Biological Activities of Beebread-Review. Bull. Univ. Agric. Sci. Vet. Med. Cluj-Napoca. Anim. Sci. Biotechnol. 2017, 74, 6. [Google Scholar] [CrossRef] [Green Version]

- Kieliszek, M.; Piwowarek, K.; Kot, A.M.; Błażejak, S.; Chlebowska-Śmigiel, A.; Wolska, I. Pollen and bee bread as new health-oriented products: A review. Trends Food Sci. Technol. 2018, 3, 170–180. [Google Scholar] [CrossRef]

- Zhang, Z.; Cao, H.; Chen, C.; Chen, X.; Wei, Q.; Zhao, F. Effects of fermentation by Ganoderma lucidum and Saccharomyces cerevisiae on rape pollen morphology and its wall. J. Food Sci. Technol. 2017, 3, 4026–4034. [Google Scholar] [CrossRef]

- Salazar-González, C.; Díaz-Moreno, C. The nutritional and bioactive aptitude of bee pollen for a solid-state fermentation process. J. Apic. Res. 2016, 3, 161–175. [Google Scholar] [CrossRef]

- Di Cagno, R.; Filannino, P.; Cantatore, V.; Gobbetti, M. Novel solid-state fermentation of bee-collected pollen emulating the natural fermentation process of bee bread. Food Microbiol. 2019, 3, 218–230. [Google Scholar] [CrossRef]

- Ispirli, H.; Dertli, E. Detection of fructophilic lactic acid bacteria (FLAB) in bee bread and bee pollen samples and determination of their functional roles. J. Food Process. Preserv. 2021, 3, e15414. [Google Scholar] [CrossRef]

- Janashia, I.; Carminati, D.; Rossetti, L.; Zago, M.; Fornasari, M.E.; Haertlé, T.; Chanishvili, N.; Giraffa, G. Characterization of fructophilic lactic microbiota of Apis mellifera from the Caucasus Mountains. Ann. Microbiol. 2016, 3, 1387–1395. [Google Scholar] [CrossRef]

- Acín Albiac, M.; Di Cagno, R.; Filannino, P.; Cantatore, V.; Gobbetti, M. How fructophilic lactic acid bacteria may reduce the FODMAPs content in wheat-derived baked goods: A proof of concept. Microb. Cell Factories 2020, 3, 182. [Google Scholar] [CrossRef] [PubMed]

- Yan, S.; Li, Q.; Xue, X.; Wang, K.; Zhao, L.; Wu, L. Analysis of improved nutritional composition of bee pollen (Brassica campestris L.) after different fermentation treatments. Int. J. Food Sci. Technol. 2019, 3, 2169–2181. [Google Scholar] [CrossRef]

- Detry, R.; Simon-Delso, N.; Bruneau, E.; Daniel, H.-M. Specialisation of yeast genera in different phases of bee bread maturation. Microorganisms 2020, 3, 1789. [Google Scholar] [CrossRef] [PubMed]

- Tomás, A.; Falcão, S.I.; Russo-Almeida, P.; Vilas-Boas, M. Potentialities of beebread as a food supplement and source of nutraceuticals: Botanical origin, nutritional composition and antioxidant activity. J. Apic. Res. 2017, 3, 219–230. [Google Scholar] [CrossRef]

- Adaškevičiūtė, V.; Kaškonienė, V.; Barčauskaitė, K.; Kaškonas, P.; Maruška, A. The Impact of Fermentation on Bee Pollen Polyphenolic Compounds Composition. Antioxidants 2022, 3, 645. [Google Scholar] [CrossRef] [PubMed]

- Fuenmayor, C.A.; Quicazán, M.C.; Figueroa, J. Desarrollo de un suplemento nutricional mediante la fermentación en fase sólida de polen de abejas empleando bacterias ácido lácticas probióticas. Aliment. Hoy 2011, 3, 17–39. [Google Scholar]

- Krishna, C. Solid-state fermentation systems—An overview. Crit. Rev. Biotechnol. 2005, 3, 1–30. [Google Scholar] [CrossRef]

- Singhania, R.R.; Patel, A.K.; Soccol, C.R.; Pandey, A. Recent advances in solid-state fermentation. Biochem. Eng. J. 2009, 3, 13–18. [Google Scholar] [CrossRef]

- Kostić, A.Ž.; Milinčić, D.D.; Barać, M.B.; Ali Shariati, M.; Tešić, Ž.L.; Pešić, M.B. The application of pollen as a functional food and feed ingredient—The present and perspectives. Biomolecules 2020, 3, 84. [Google Scholar] [CrossRef] [Green Version]

- Urcan, A.C.; Criste, A.D.; Dezmirean, D.S.; Bobiș, O.; Bonta, V.; Dulf, F.V.; Mărgăoan, R.; Cornea-Cipcigan, M.; Campos, M.G. Botanical origin approach for a better understanding of chemical and nutritional composition of beebread as an important value-added food supplement. LWT 2021, 3, 111068. [Google Scholar] [CrossRef]

- Shehu, A.; Ismail, S.; Rohin MA, K.; Harun, A.; Abd Aziz, A.; Haque, M. Antifungal properties of Malaysian Tualang honey and stingless bee propolis against Candida albicans and Cryptococcus neoformans. J. Appl. Pharm. Sci. 2016, 3, 044–050. [Google Scholar] [CrossRef] [Green Version]

- Mayda, N.; Özkök, A.; Ecem Bayram, N.; Gerçek, Y.C.; Sorkun, K. Bee bread and bee pollen of different plant sources: Determination of phenolic content, antioxidant activity, fatty acid and element profiles. J. Food Meas. Charact. 2020, 3, 1795–1809. [Google Scholar] [CrossRef]

- Sommano, S.R.; Bhat, F.M.; Wongkeaw, M.; Sriwichai, T.; Sunanta, P.; Chuttong, B.; Burgett, M. Amino acid profiling and chemometric relations of black dwarf honey and bee pollen. Front. Nutr. 2020, 7, 558579. [Google Scholar] [CrossRef]

- Benavides-Guevara, R.M.; Quicazan, M.C.; Ramírez-Toro, C. Digestibility and availability of nutrients in bee pollen applying different pretreatments. Ing. Y Compet. 2017, 3, 119–128. [Google Scholar]

- Bakour, M.; Fernandes, A.; Barros, L.; Sokovic, M.; Ferreira, I.C.; Lyoussi, B. Bee bread as a functional product: Chemical composition and bioactive properties. LWT 2019, 109, 276–282. [Google Scholar] [CrossRef] [Green Version]

- Dranca, F.; Ursachi, F.; Oroian, M. Bee bread: Physicochemical characterization and phenolic content extraction optimization. Foods 2020, 3, 1358. [Google Scholar] [CrossRef]

- Szczesna, T. Study on the sugar composition of honeybee-collected pollen. J. Apic. Sci. 2007, 51, 15–22. [Google Scholar]

- Suleiman, J.B.; Mohamed, M.; Abu Bakar, A.B.; Nna, V.U.; Zakaria, Z.; Othman, Z.A.; Aroyehun, A.B. Chemical Profile, Antioxidant Properties and Antimicrobial Activities of Malaysian Heterotrigona itama Bee Bread. Molecules 2021, 3, 4943. [Google Scholar] [CrossRef]

- Sawicki, T.; Starowicz, M.; Kłębukowska, L.; Hanus, P. The profile of polyphenolic compounds, contents of total phenolics and flavonoids, and antioxidant and antimicrobial properties of bee products. Molecules 2022, 3, 1301. [Google Scholar] [CrossRef]

- Othman, Z.; Noordin, L.; Ghazali WS, W.; Omar, N.; Mohamed, M. Nutritional, phytochemical and antioxidant analysis of bee bread from different regions of Malaysia. Indian J. Pharm. Sci. 2019, 3, 955–960. [Google Scholar] [CrossRef] [Green Version]

- Eva, I.; Miroslava, K.; Helena, F.; Jana, P.; Jana, H.; Valerii, B.; Serhii, V.; Leonora, A.; Zuzana, S.; Janette, M. Bee bread-perspective source of bioactive compounds for future. Potravinarstvo 2015, 9, 592–598. [Google Scholar] [CrossRef] [Green Version]

- Carpes, S.T.; Begnini, R.; Alencar SM, d.e.; Masson, M.L. Study of preparations of bee pollen extracts, antioxidant and antibacterial activity. Ciência E Agrotecnologia 2007, 3, 1818–1825. [Google Scholar] [CrossRef] [Green Version]

- Urcan, A.C.; Criste, A.D.; Dezmirean, D.S.; Mărgăoan, R.; Caeiro, A.; Graça Campos, M. Similarity of data from bee bread with the same taxa collected in India and Romania. Molecules 2018, 3, 2491. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Baltrušaitytė, V.; Venskutonis, P.R.; Čeksterytė, V. Radical scavenging activity of different floral origin honey and beebread phenolic extracts. Food Chem. 2007, 3, 502–514. [Google Scholar] [CrossRef]

- Atkin, S.L.; Barrier, S.; Cui, Z.; Fletcher, P.D.; Mackenzie, G.; Panel, V.; Sol, V.; Zhang, X. UV and visible light screening by individual sporopollenin exines derived from Lycopodium clavatum (club moss) and Ambrosia trifida (giant ragweed). J. Photochem. Photobiol. B: Biol. 2011, 3, 209–217. [Google Scholar] [CrossRef] [PubMed]

- Campos, M.; Frigerio, C.; Lopes, J.; Bogdanov, S. What is the future of Bee-Pollen? J. ApiProduct ApiMedical Sci. 2010, 2, 131–144. [Google Scholar] [CrossRef]

- Mohammad, S.M.; Mahmud-Ab-Rashid, N.-K.; Zawawi, N. Probiotic properties of bacteria isolated from bee bread of stingless bee Heterotrigona itama. J. Apic. Res. 2020, 3, 172–187. [Google Scholar] [CrossRef]

- Donkersley, P.; Rhodes, G.; Pickup, R.W.; Jones, K.C.; Power, E.F.; Wright, G.A.; Wilson, K. Nutritional composition of honey bee food stores vary with floral composition. Oecologia 2017, 3, 749–761. [Google Scholar] [CrossRef] [Green Version]

- Othman, Z.A.; Wan Ghazali, W.S.; Noordin, L.; Mohd Yusof, N.A.; Mohamed, M. Phenolic compounds and the anti-atherogenic effect of bee bread in high-fat diet-induced obese rats. Antioxidants 2019, 3, 33. [Google Scholar] [CrossRef] [Green Version]

- Bayram, N.E.; Gercek, Y.C.; Çelik, S.; Mayda, N.; Kostić, A.Ž.; Dramićanin, A.M.; Özkök, A. Phenolic and free amino acid profiles of bee bread and bee pollen with the same botanical origin–similarities and differences. Arab. J. Chem. 2021, 3, 103004. [Google Scholar] [CrossRef]

- Barry, J.P.; Metz, M.S.; Hughey, J.; Quirk, A.; Bochman, M.L. Two novel strains of Torulaspora delbrueckii isolated from the honey bee microbiome and their use in honey fermentation. Fermentation 2018, 3, 22. [Google Scholar] [CrossRef]

| SCFP1 * | SCFP2 | SCFP3 | NSCF | CBB1 | CBB2 | ||

|---|---|---|---|---|---|---|---|

| pH | Day 1 | 5.13 ± 0.002 a | 5.13 ± 0.001 a | 5.13 ± 0.002 a | 5.13 ± 0.002 a | 4.91 ± 0.002 b | 4.97 ± 0.004 c |

| Day 21 | 4.51 ± 0.003 a | 4.69 ± 0.001 b | 4.76 ± 0.44 c | 5.02 ± 0.009 d | 4.90 ± 0.005 d | 4.97 ± 0.004 d | |

| Day 50 | 4.15 ± 0.001 a | 4.22 ± 0.006 b | 4.24 ± 0.012 c | 4.85 ± 0.004 d | 4.80 ± 0.003 de | 4.87 ± 0.014 df | |

| % Moisture | Day 1 | 27.49 ± 0.002 a | 26.3 ± 0.000 ab | 27.02 ± 0.000 a | 25.64 ± 0.003 b | 12.69 ± 0.000 c | 16.93 ± 0.000 d |

| Day 21 | 22.28 ± 0.00 a | 20.63 ± 0.004 bfg | 21.42 ± 0.001 af | 19.59 ± 0.001 cg | 12.57 ± 0.000 d | 16.36 ± 0.000 e | |

| Day 50 | 21.79 ± 0.000 a | 19.62 ± 0.000 b | 20.55 ± 0.000 c | 18.93 ± 0.000 d | 11.24 ± 0.001 e | 15.19 ± 0.000 f | |

| SCFP1 * | SCFP2 | SCFP3 | NSCFP | CBB1 | CBB2 | ||

|---|---|---|---|---|---|---|---|

| SUGAR COMPOSITION (g 100 g−1) | Maltose | ND | ND | ND | ND | ND | ND |

| Glucose | 9.64 | 8.91 | 10.08 | 11.74 | 3.41 | 4.26 | |

| Fructose | 12.93 | 11.55 | 12.37 | 14.36 | 10.68 | 7.54 | |

| %Glucose | 42.71 | 43.56 | 44.89 | 44.98 | 24.21 | 36.12 | |

| %Fructose | 57.29 | 56.44 | 55.11 | 55.02 | 75.79 | 63.88 | |

| ORGANIC ACID (mg g−1) | Oxalic acid | 0.75 | 0.72 | 0.79 | 0.08 | 0.65 | 0.61 |

| Tartaric acid | 0.92 | ND ª | 0.96 | 0.28 | ND | 0.89 | |

| Formic acid | 1.45 | 1.29 | 1.45 | 0.88 | 0.25 | 1.40 | |

| Lactic acid | 3.30 | 3.42 | 4.40 | 4.15 | 0.45 | 1.21 | |

| Acetic acid | 3.51 | 2.96 | 3.57 | ND | ND | 2.08 | |

| Citric acid | 0.14 | 0.14 | 0.19 | 0.14 | 0.19 | 0.20 | |

| Propionic acid | 0.33 | 0.34 | 0.38 | 0.38 | 1.73 | 1.08 |

| SCFP1 * | SCFP2 | SCFP3 | NSCFP | CBB1 | CBB2 | |

|---|---|---|---|---|---|---|

| F.P.C. (mg GAE/g) | 14.68 ± 0.09 a | 14.16 ± 0.04 b | 15.09 ± 0.07 a | 13.95 ± 0.05 b | 12.87 ± 0.02 c | 13.33 ± 0.07 c |

| % I.v.D. | 50.35 ± 0.03 a | 48.28 ± 0.01 b | 61.64 ± 0.01 c | 45.32 ± 0.01 d | 36.23 ± 0.01 e | 35.74 ± 0.007 f |

| E.a.a. (g/100 g) | SCFP1 * | SCFP2 | SCFP3 | NSCFP | CBB1 | CBB2 |

|---|---|---|---|---|---|---|

| L-Tryptophan | 0.20 | 0.27 | 0.29 | 0.36 | 0.03 | 0.03 |

| L-L-Phenylalanine | 1.36 | 1.34 | 1.44 | 1.49 | 0.15 | 0.44 |

| L-Leucine | 3.49 | 3.34 | 3.79 | 3.66 | 0.20 | 0.98 |

| L-isoleucine | 0.86 | 0.88 | 0.96 | 1.00 | 0.01 | 0.27 |

| L-Valine | 1.67 | 1.62 | 1.78 | 0.02 | 0.19 | 0.05 |

| L-Threonine | 1.34 | 1.11 | 1.42 | 0.13 | 0.08 | 0.37 |

| L-Histidine | 1.98 | 1.28 | 1.70 | 2.14 | 0.18 | 0.66 |

| 1-Methyl-L-Histidine | 0.03 | 0.06 | 0.03 | 0.06 | 0.06 | 0.03 |

| 3-Methyl-L-Histidine | 0.06 | 0.03 | 0.01 | 0.01 | 0.02 | 0.01 |

| L-Alanine | 2.57 | 2.46 | 2.60 | 2.54 | 0.74 | 1.34 |

| C.e.a.a. (g/100 g) | SCFP1 | SCFP2 | SCFP3 | NSCFP | CBB1 | CBB2 |

| L-Tyrosine | 1.54 | 1.49 | 1.60 | 1.67 | 0.14 | 0.54 |

| L-Glutamine | ND | ND | ND | 0.32 | ND | ND |

| L-Glycine | 0.68 | 0.61 | 0.67 | 0.57 | 0.16 | 0.31 |

| L-Proline | 3.07 × 10−4 | 3.58 × 10−4 | 3.53 × 10−4 | 3.4 × 10−4 | 1.86 × 10−4 | 2.27 × 10−4 |

| Trans-4-hydroxy L-proline | 0.36 | 1.17 | 1.16 | 1.27 | 0.28 | 0.40 |

| L-Serine | 1.91 | 2.07 | 2.19 | 1.97 | 0.26 | 0.68 |

| O-Phospho-L-Serine | 0.0254 | 0.023 | 0.025 | 0.006 | 0.027 | 0.005 |

| L-Arginine | 1.616 | 0.001 | 0.005 | 1.681 | ND | 0.008 |

| L-Cystine | ND | 0.01 | 0.36 | 0.02 | 0.11 | 0.16 |

| L-ornithine | 0.089 | 0.030 | 0.018 | 0.028 | 0.021 | 0.032 |

| N.a.a. (g/100 g) | SCFP1 | SCFP2 | SCFP3 | NSCFP | CBB1 | CBB2 |

| Taurine | 0.146 | 0.129 | 0.112 | 0.102 | 0.119 | 0.112 |

| 3-Amino isobutyric acid | 1.206 | 0.124 | 1.378 | 1.371 | 0.209 | 0.423 |

| Gamma-aminobutyric acid | 2.92 | 2.94 | 3.12 | 2.91 | 0.48 | 0.98 |

| L-Norvaline | 1.03 | 0.95 | 1.09 | 1.76 | 0.04 | 0.56 |

| Ethanolamine | 1.13 | 0.02 | 0.26 | 0.10 | 0.02 | 0.16 |

| L-2-Aminoadipic acid | 0.03 | 2.57 | 2.78 | 3.37 | 0.29 | 0.72 |

| L-Aspartic acid | 3.62 | 2.51 | 3.16 | 2.59 | 0.91 | 2.26 |

| Sarcosine | 5.76 | 5.85 | 6.10 | 5.99 | 1.60 | 2.90 |

| Trans-4-hydroxy L-proline | 0.36 | 1.17 | 1.16 | 1.27 | 0.28 | 0.40 |

| L-Homocitrulline | 0.505 | 0.518 | 0.514 | 0.510 | ND | ND |

| L-Citrulline | ND | ND | ND | ND | 0.4621 | 0.462 |

| O-Phosphoryl Ethanolamine | 0.020 | 0.021 | 0.003 | 0.013 | 0.011 | 0.018 |

| DL-Homocystine | 0.006 | 0.013 | 0.022 | 0.038 | 0.004 | 0.039 |

| Argininosuccinic acid | 0.009 | 4.175 | 4.152 | ND | 0.186 | 0.564 |

| L-Carnosine | 0.315 | 0.336 | 0.004 | 0.334 | ND | 0.011 |

| L-Cystine | ND | 0.013 | 0.368 | 0.028 | 0.112 | 0.167 |

| DL-5-Hydroxylysine | 0.018 | ND | 0.106 | 0.057 | 0.061 | 0.0535 |

| L-Lysine | 2.628 | 0.017 | 3.302 | 0.001 | 0.034 | ND |

| DAY | SCFP1 | SCFP2 | SCFP3 | NSCFP | |

|---|---|---|---|---|---|

| 1. | FLAB * | 7.04 ± 0.014 | 7.98 ± 0.035 | 7.38 ± 0.205 | 5.11 ± 0.035 |

| LAB | 6.17 ± 0.007 | 8.17 ± 0.056 | 6.62 ± 0.219 | 5.13 ± 0.056 | |

| TMAB | 5.88 ± 0.021 | 6.79 ± 0.028 | 6.33 ± 0.084 | 4.5 ± 0.042 | |

| TY | 5.07 ± 0.042 | 4.97 ± 0.028 | 4.98 ± 0.049 | 4.82 ± 0.077 | |

| FLAB | 9.40 ± 0.091 | 8.43 ± 0.120 | 8.30 ± 0.106 | 7.17 ± 0.077 | |

| 3. | LAB | 9.44 ± 0.148 | 8.23 ± 0.304 | 8.37 ± 0.077 | 7.22 ± 0.134 |

| TMAB | 8.20 ± 0.056 | 7.24 ± 0.141 | 7.17 ± 0.042 | 7.28 ± 0.205 | |

| TY | 5.67 ± 0.339 | 5.32 ± 0.176 | 5.38 ± 0.212 | 5.37 ± 0.077 | |

| FLAB | 10.50 ± 0.268 | 11.17 ± 0.205 | 11.19 ± 0.183 | 8.69 ± 0.374 | |

| LAB | 10.63 ± 0.438 | 10.2 ± 0.014 | 11.28 ± 0.212 | 8.45 ± 0.028 | |

| 5. | TMAB | 9.28 ± 0.212 | 9.22 ± 0.028 | 9.40 ± 0.028 | 8.62 ± 0.028 |

| TY | 5.17 ± 0.084 | 5.03 ± 0.007 | 5.27 ± 0.056 | 4.93 ± 0.049 | |

| FLAB | 10.47 ± 0.374 | 11.58 ± 0.183 | 10.83 ± 0.134 | 9.72 ± 0.360 | |

| LAB | 10.57 ± 0.480 | 11.41 ± 0.162 | 8.83 ± 0.205 | 10.81 ± 0.233 | |

| TMAB | 9.38 ± 0.084 | 9.65 ± 0.021 | 9.33 ± 0.134 | 10.42 ± 0.473 | |

| 7. | TY | 3.85 ± 0.134 | 3.72 ± 0.049 | 3.21 ± 0.304 | 3.67 ± 0.282 |

| FLAB | 11.26 ± 0.049 | 10.56 ± 0.346 | 10.51 ± 0.176 | 9.34 ± 0.282 | |

| LAB | 9.36 ± 0.077 | 8.52 ± 0.183 | 9.57 ± 0.261 | 8.52 ± 0.268 | |

| TMAB | 10.64 ± 0.466 | 10.78 ± 0.042 | 9.56 ± 0.049 | 10.36 ± 0.233 | |

| TY | 3.35 ± 0.169 | 3.67 ± 0.106 | 3.36 ± 0.091 | 3.32 ± 0.452 | |

| 14. | FLAB | 6.33 ± 0.134 | 8.77 ± 0.028 | 9.46 ± 0.106 | 7.21 ± 0.586 |

| LAB | 8.42 ± 0.155 | 9.48 ± 0.530 | 8.65 ± 0.169 | 7.26 ± 0.219 | |

| TMAB | 8.75 ± 0.311 | 8.63 ± 0.183 | 7.47 ± 0.183 | 8.65 ± 0.353 | |

| TY | 3.51 ± 0.063 | 3.62 ± 0.028 | 3.47 ± 0.247 | 3.32 ± 0.459 | |

| 21. | FLAB | 7.13 ± 0.311 | 7.66 ± 0.148 | 7.92 ± 0.080 | 7.32 ± 0.296 |

| LAB | 7.52 ± 0.325 | 8.50 ± 0.636 | 7.91 ± 0.240 | 7.03 ± 0.007 | |

| TMAB | 7.94 ± 0.021 | 8.58 ± 0.371 | 6.61 ± 0.106 | 8.78 ± 0.070 | |

| TY | 3.48 ± 0.162 | 3.42 ± 0.169 | 2.42 ± 0.169 | 2.17 ± 0.247 | |

| 30. | FLAB | 7.50 ± 0.671 | 6.56 ± 0.183 | 3.40 ± 0.021 | 5.79 ± 0.212 |

| LAB | 6.73 ± 0.268 | 6.71 ± 0.261 | 4.55 ± 0.190 | 5.72 ± 0.120 | |

| TMAB | 6.63 ± 0.141 | 6.23 ± 0.268 | 5.48 ± 0.091 | 5.67 ± 0.056 | |

| TY | 3.36 ± 0.014 | 2.21 ± 0.296 | 2.47 ± 0.240 | 2.26 ± 0.374 | |

| 40. | FLAB | 6.29 ± 0.339 | 5.54 ± 0.035 | 4.59 ± 0.247 | 5.73 ± 0.296 |

| LAB | 5.75 ± 0.325 | 5.64 ± 0.014 | 5.31 ± 0.438 | 5.77 ± 0.049 | |

| TMAB | 5.60 ± 0.120 | 4.65 ± 0.169 | 5.28 ± 0.339 | 5.40 ± 0.473 | |

| TY | 2.26 ± 0.374 | ND | ND | 2.25 ± 0.353 | |

| 50. | FLAB | 6.29 ± 0.339 | 5.54 ± 0.035 | 4.59 ± 0.247 | 5.73 ± 0.296 |

| LAB | 5.75 ± 0.325 | 5.64 ± 0.014 | 5.31 ± 0.438 | 5.77 ± 0.049 | |

| TMAB | 5.60 ± 0.120 | 4.65 ± 0.169 | 5.28 ± 0.339 | 5.40 ± 0.473 | |

| TY | 2.26 ± 0.374 | ND | ND | 2.25 ± 0.353 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Poyraz, F.; Yalmanci, D.; İspirli, H.; Dertli, E. Characterization of Bee Bread Produced with Defined Starter Cultures Mimicking the Natural Fermentation Process. Fermentation 2023, 9, 174. https://doi.org/10.3390/fermentation9020174

Poyraz F, Yalmanci D, İspirli H, Dertli E. Characterization of Bee Bread Produced with Defined Starter Cultures Mimicking the Natural Fermentation Process. Fermentation. 2023; 9(2):174. https://doi.org/10.3390/fermentation9020174

Chicago/Turabian StylePoyraz, Fatmanur, Dilara Yalmanci, Hümeyra İspirli, and Enes Dertli. 2023. "Characterization of Bee Bread Produced with Defined Starter Cultures Mimicking the Natural Fermentation Process" Fermentation 9, no. 2: 174. https://doi.org/10.3390/fermentation9020174

APA StylePoyraz, F., Yalmanci, D., İspirli, H., & Dertli, E. (2023). Characterization of Bee Bread Produced with Defined Starter Cultures Mimicking the Natural Fermentation Process. Fermentation, 9(2), 174. https://doi.org/10.3390/fermentation9020174