Formulation of a Gluten-Free Carob-Based Bakery Product: Evaluation of Glycemic Index, Antioxidant Activity, Rheological Properties, and Sensory Features

Abstract

:1. Introduction

2. Materials and Methods

2.1. Chemicals and Reagents

2.2. Characterization of Carob Pulp Flour

2.2.1. Total Content of Polyphenol Compounds

2.2.2. Phenolic Acid Content

2.2.3. Flavonoid Content

2.2.4. Antioxidant Performances

2.3. Preparation of Milk Kefir

2.4. Carob Flour-Based Bakery Product: Preparation and Sampling

Water Activity and pH Determination

2.5. Antioxidant Characteristics of Carob Flour-Based Bakery Product Samples

2.6. Rheological Characterization of Dough and Bakery Product Samples

2.6.1. Dynamic Rheological Tests

2.6.2. Dynamic-Mechanical Analyses

2.7. Sensory Analysis

2.8. Determination of Glycemic Index

2.9. Statistical Analysis

3. Results and Discussion

3.1. Antioxidant Properties of Carob Pulp Flour

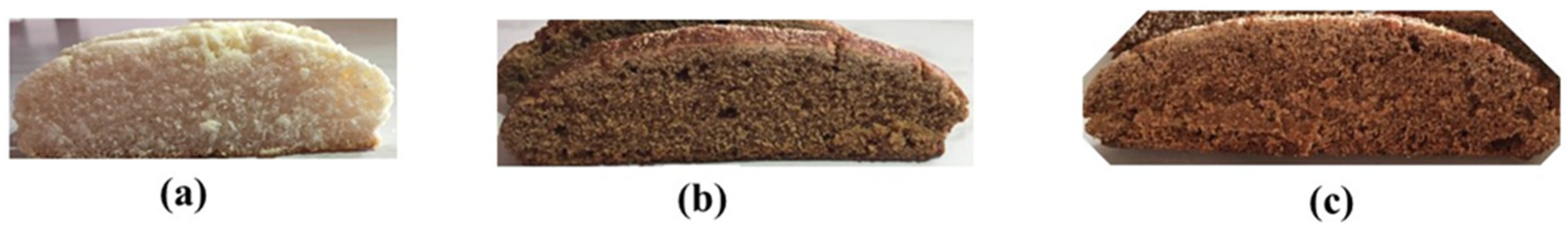

3.2. Carob Flour-Based Bakery Product Preparation

3.3. Rheological Characterization of Dough and Baked Samples

3.4. Antioxidant Characterization of Baked Samples

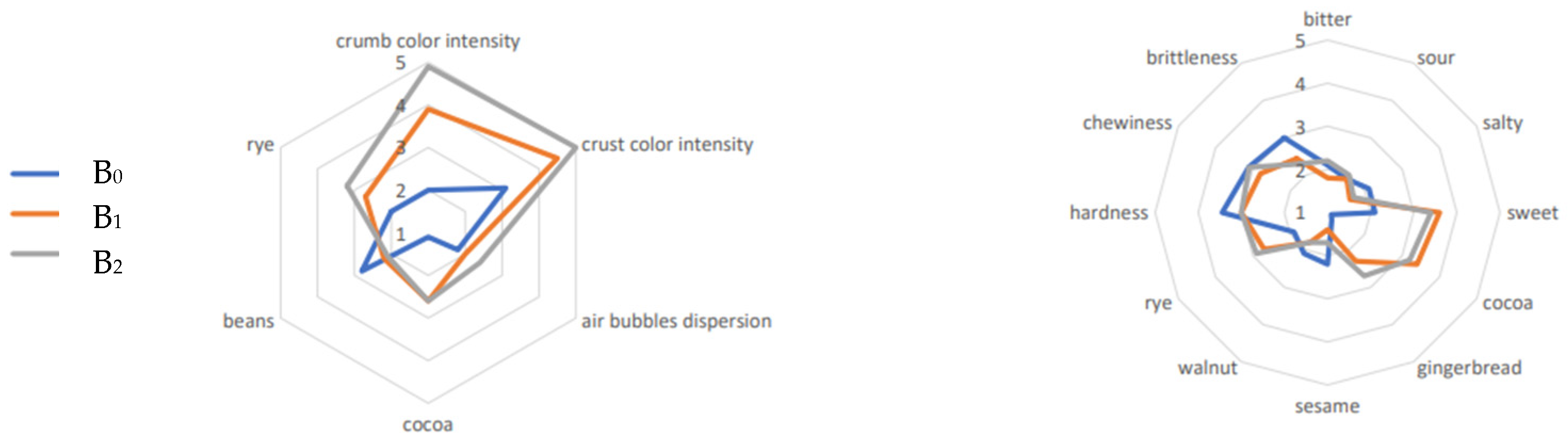

3.5. Sensory Analysis

3.6. Determination of Glycemic Index

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Taraghikhah, N.; Ashtari, S.; Asri, N.; Shahbazkhani, B.; Al-Dulaimi, D.; Rostami-Nejad, M.; Rezaei-Tavirani, M.; Razzaghi, M.R.; Zali, M.R. An updated overview of spectrum of gluten-related disorders: Clinical and diagnostic aspects. BMC Gastroenterol. 2020, 20, 258–269. [Google Scholar] [CrossRef]

- Al-Toma, A.; Volta, U.; Auricchio, R.; Castillejo, G.; Sanders, D.S.; Cellier, C.; Mulder, C.J.; Lundin, K. European Society for the Study of Coeliac Disease (ESsCD) guideline for coeliac disease and other gluten-related disorders. United Eur. Gastroenterol. J. 2019, 7, 583–613. [Google Scholar] [CrossRef]

- Leonard, M.M.; Sapone, A.; Catassi, C.; Fasano, A. Celiac disease and nonceliac gluten sensitivity: A review. JAMA 2017, 318, 647–656. [Google Scholar] [CrossRef]

- Lerner, A.; O’Bryan, T.; Matthias, T. Navigating the Gluten-Free Boom: The Dark Side of Gluten Free Diet. Front. Pediatr. 2019, 7, 414–421. [Google Scholar] [CrossRef] [Green Version]

- Aguiar, E.V.; Santos, F.G.; Krupa-Kozak, U.; Capriles, V.D. Nutritional facts regarding commercially available gluten-free bread worldwide: Recent advances and future challenges. Crit. Rev. Food Sci. 2023, 63, 693–705. [Google Scholar] [CrossRef]

- Grandviewresearch. Gluten-Free Products Market Size, Share & Trends Analysis Report by Product (Bakery Products, Dairy/Dairy Alternatives), by Distribution Channel (Supermarkets & Hypermarkets, Convenience Stores), by Region, and Segment Forecasts, 2022–2030 Report ID: GVR-1-68038-834-3 available at: Gluten-Free Products Market Size Report, 2022–2030. 2021. Available online: grandviewresearch.com (accessed on 20 May 2023).

- Prada, M.; Godinho, C.; Rodrigues, D.L.; Lopes, C.; Garrido, M.V. The impact of a gluten-free claim on the perceived healthfulness, calories, level of processing and expected taste of food products. Food Qual. Prefer. 2019, 73, 284–287. [Google Scholar] [CrossRef] [Green Version]

- European Union. Regulation (EU) No 609/2013 of the European Parliament and of the Council of 12 June 2013 on food intended for infants and young children, food for special medical purposes, and total diet replacement for weight control and repealing Council Directive 92/52/EEC, Commission Directives 96/8/EC, 1999/21/EC, 2006/125/EC and 2006/141/EC, Directive 2009/39/EC of the European Parliament and of the Council and Commission Regulations (EC) No 41/2009 and (EC) No 953/2009. 2013. [Google Scholar]

- McCabe, M.S. Balancing consumer protection and scientific integrity in the face of uncertainty: The example of gluten-free foods. Food Drug Law J. 2010, 65, 367–390. [Google Scholar]

- Lee, A.R. Review article: Dietary management of coeliac disease. Aliment. Pharmacol. Ther. 2022, 56, 38–48. [Google Scholar] [CrossRef]

- El Khoury, D.; Balfour-Ducharme, S.; Joye, I.J. A review on the gluten-free diet: Technological and nutritional challenges. Nutrients 2018, 10, 1410. [Google Scholar] [CrossRef] [Green Version]

- Krupa-Kozak, U.; Lange, E. The gluten-free diet and glycaemic index in the management of coeliac disease associated with Type 1 Diabetes. Food Rev. Int. 2019, 35, 587–608. [Google Scholar] [CrossRef]

- Scazzina, F.; Dall’Asta, M.; Pellegrini, N.; Brighenti, F. Glycaemic index of some commercial gluten-free foods. Eur. J. Nutr. 2015, 54, 1021–1026. [Google Scholar] [CrossRef]

- Šmídová, Z.; Rysová, J. Gluten-Free Bread and Bakery Products Technology. Foods 2022, 11, 480. [Google Scholar] [CrossRef]

- Gao, Y.; Janes, M.E.; Chaiya, B.; Brennan, M.A.; Brennan, C.S.; Prinyawiwatkul, W. Gluten-free bakery and pasta products: Prevalence and quality improvement. Int. J. Food Sci. Technol. 2018, 53, 19–32. [Google Scholar] [CrossRef] [Green Version]

- Woomer, J.S.; Adedeji, A.A. Current applications of gluten-free grains—A review. Crit. Rev. Food Sci. Nutr. 2021, 61, 14–24. [Google Scholar] [CrossRef]

- Naqash, F.; Gani, A.; Gani, A.; Masoodi, F.A. Gluten-free baking: Combating the challenges—A review. Trends Food Sci. Technol. 2017, 66, 98–107. [Google Scholar] [CrossRef]

- Spizzirri, U.G.; Abduvakhidov, A.; Caputo, P.; Crupi, P.; Muraglia, M.; Oliviero Rossi, C.; Clodoveo, M.L.; Aiello, F.; Restuccia, D. Kefir Enriched with Carob (Ceratonia siliqua L.) Leaves Extract as a New Ingredient during a Gluten-Free Bread-Making Process. Fermentation 2022, 8, 305. [Google Scholar] [CrossRef]

- Rizzo, V.; Tomaselli, F.; Gentile, A.; La Malfa, S.; Maccarone, E. Rheological properties and sugar composition of Locust Bean gum from different carob varieties (Ceratonia siliqua L.). J. Agric. Food Chem. 2004, 52, 7925–7930. [Google Scholar] [CrossRef]

- Brassesco, M.E.; Brandao, T.R.S.; Silva, C.L.M.; Pintado, M. Carob bean (Ceratonia siliqua L.): A new perspective for functional food. Trends Food Sci. Technol. 2021, 114, 310–322. [Google Scholar] [CrossRef]

- Xu, J.; Zhang, Y.; Wang, W.; Li, Y. Advanced properties of gluten-free cookies, cakes, and crackers: A review. Trends Food Sci. Technol. 2020, 103, 200–213. [Google Scholar] [CrossRef]

- Bourrie, B.C.; Willing, B.P.; Cotter, P.D. The Microbiota and Health Promoting Characteristics of the Fermented Beverage Kefir. Front. Microbiol. 2016, 7, 647. [Google Scholar] [CrossRef] [Green Version]

- Guzel-Seydim, Z.B.; Kok-Tas, T.; Greene, A.K.; Seydim, A.C. Review: Functional properties of kefir. Crit. Rev. Food Sci. Nutr. 2011, 51, 261–268. [Google Scholar] [CrossRef]

- De Luca, M.; Restuccia, D.; Spizzirri, U.G.; Crupi, P.; Ioele, G.; Gorelli, B.; Clodoveo, M.L.; Saponara, S.; Aiello, F. Wine Lees as Source of Antioxidant Molecules: Green Extraction Procedure and Biological Activity. Antioxidant 2023, 12, 622. [Google Scholar] [CrossRef]

- Carullo, G.; Spizzirri, U.G.; Montopoli, M.; Cocetta, V.; Armentano, B.; Tinazzi, M.; Sciubba, F.; Giorgi, G.; Di Cocco, M.E.; Bohn, T.; et al. Milk Kefir Enriched with Inulin Grafted Seed Extract from White Wine Pomace: Chemical Characterization, Antioxidant Profile and in vitro Gastrointestinal Digestion. Int. J. Food Sci. Technol. 2022, 57, 4086–4095. [Google Scholar] [CrossRef]

- Spizzirri, U.G.; Carullo, G.; Aiello, F.; Paolino, D.; Restuccia, D. Valorisation of olive oil pomace extracts for a functional pear beverage formulation. Int. J. Food Sci. Technol. 2021, 56, 5497–5505. [Google Scholar] [CrossRef]

- La Torre, C.; Fazio, A.; Caputo, P.; Plastina, P.; Caroleo, M.C.; Cannataro, R.; Cione, E. Effects of Long-Term Storage on Radical Scavenging Properties and Phenolic Content of Kombucha from Black Tea. Molecules 2021, 26, 5474. [Google Scholar] [CrossRef]

- Gómez, A.V.; Ferrero, C.; Puppo, C.; Tadini, C.C.; Abraham, A.G. Fermented milk obtained with kefir grains as an ingredient in breadmaking. Int. J. Food Sci. 2014, 49, 2315–2322. [Google Scholar] [CrossRef]

- Pawłowska, K.; Kuligowski, M.; Jasińska-Kuligowska, I.; Kidoń, M.; Siger, A.; Rudzińska, M.; Nowak, J. Effect of Replacing Cocoa Powder by Carob Powder in the Muffins on Sensory and Physicochemical Properties. Plant Foods Hum. Nutr. 2018, 73, 196–202. [Google Scholar] [CrossRef] [Green Version]

- Papageorgiou, M.; Paraskevopoulou, A.; Pantazi, F.; Skendi, A. Cake Perception, Texture and Aroma Profile as Affected by Wheat Flour and Cocoa Replacement with Carob Flour. Foods 2020, 9, 1586. [Google Scholar] [CrossRef]

- ISO 8586:2012; Sensory Analysis—General Guidelines for the Selection, Training and Monitoring of Selected Assessors and Expert Sensory Assessors. ISO: Geneva, Switzerland, 2015.

- ISO 4121:2003; Sensory Analysis—Guidelines for the Use of Quantitative Response Scales. ISO: Geneva, Switzerland, 2003.

- Laureati, M.; Giussani, B.; Pagliarini, E. Sensory and hedonic perception of gluten-free bread: Comparison between celiac and non-celiac subjects. Food Res. Int. 2012, 46, 326–333. [Google Scholar] [CrossRef]

- de Kock, H.L.; Magano, N.N. Sensory tools for the development of gluten-free bakery foods. J. Cereal Sci. 2020, 94, 102990. [Google Scholar] [CrossRef]

- ISO 8589:2007; Sensory Analysis—General Guidance for the Design of Test Rooms. ISO: Geneva, Switzerland, 2017.

- Wolever, T.; Katzman-Relle, L.; Jenkins, A.; Vuksan, V.; Josse, R.G.; Jenkins, D. Glycaemic index of 102 complex carbohydrate foods in patients with diabetes. Nutr. Res. 2001, 14, 651–669. [Google Scholar] [CrossRef]

- Omage, K.; Omage, S.O. Evaluation of the glycemic indices of three commonly eaten mixed meals in Okada, Edo State. Food Sci. Nutr. 2017, 6, 220–228. [Google Scholar] [CrossRef] [Green Version]

- Petkova, N.; Petrova, I.; Ivanov, I.; Mihov, R.; Hadjikinova, R.; Ognyanov, M.; Nikolova, V. Nutritional and antioxidant potential of carob (Ceratonia siliqua) flour and evaluation of functional properties of its polysaccharide fraction. J. Pharm. Sci. Res. 2017, 9, 2189–2195. [Google Scholar]

- Stavrou, I.J.; Christou, A.; Kapnissi-Christodoulou, C.P. Polyphenols in carobs: A review on their composition, antioxidant capacity and cytotoxic effects, and health impact. Food Chem. 2018, 269, 355–374. [Google Scholar] [CrossRef]

- Durazzo, A.; Turfani, V.; Narducci, V.; Azzini, E.; Maiani, G.; Carcea, M. Nutritional characterization and bioactive components of commercial carobs flours. Food Chem. 2014, 153, 109–113. [Google Scholar] [CrossRef]

- Custódio, L.; Escapa, A.L.; Fernandes, E.; Fajardo, A.; Aligué, R.; Alberício, F.; Neng, N.; Nogueira, J.M.F.; Romano, A. Phytochemical profile, antioxidant and cytotoxic activities of the carob tree (Ceratonia siliqua L.) germ flour extracts. Plant Foods Hum Nutr. 2011, 66, 78–84. [Google Scholar] [CrossRef]

- Uysal, S.; Zengin, G.; Aktumsek, A.; Karatas, S. Chemical and biological approaches on nine fruit tree leaves collected from the Mediterranean region of Turkey. J. Funct. Foods 2016, 22, 518–532. [Google Scholar] [CrossRef]

- Aissani, N.; Coroneo, V.; Fattouch, S.; Caboni, P. Inhibitory effect of Carob (Ceratonia siliqua) leaves methanolic extract on listeria monocytogenes. J. Agric. Food Chem. 2012, 60, 9954–9958. [Google Scholar] [CrossRef]

- Rodríguez-Solana, R.; Romano, A.; Moreno-Rojas, J.M. Carob Pulp: A Nutritional and Functional By-Product Worldwide Spread in the Formulation of Different Food Products and Beverages. A Review. Process. 2021, 9, 1146. [Google Scholar] [CrossRef]

- Graça, C.; Raymundo, A.; Sousa, I. Wheat Bread with Dairy Products-Technology, Nutritional, and Sensory Properties. Appl. Sci. 2019, 9, 4101. [Google Scholar] [CrossRef] [Green Version]

- Ziobro, R.; Witczak, T.; Juszczak, L.; Korus, J. Supplementation of gluten-free bread with non-gluten proteins. Effect on dough rheological properties and bread characteristic. Food Hydrocoll. 2013, 32, 213–220. [Google Scholar] [CrossRef]

- Kazakos, S.; Mantzourani, I.; Plessas, S. Quality Characteristics of Novel Sourdough Breads Made with Functional Lacticaseibacillus paracasei SP5 and Prebiotic Food Matrices. Foods 2022, 11, 3226. [Google Scholar] [CrossRef]

- Coppola, L.; Gianferri, R.; Oliviero, C.; Nicotera, I.; Ranieri, G.A. Structural Changes in CTAB/H2O Mixtures Using a Rheological Approach. Phys. Chem. Chem. Phys. 2004, 6, 2364–2372. [Google Scholar] [CrossRef]

- Carullo, G.; Scarpelli, F.; Belsito, E.L.; Caputo, P.; Oliviero Rossi, C.; Mincione, A.; Leggio, A.; Crispini, A.; Restuccia, D.; Spizzirri, U.G.; et al. Formulation of New Baking (+)-Catechin Based Leavening Agents: Effects on Rheology, Sensory and Antioxidant Features during Muffin Preparation. Foods 2020, 9, 1569. [Google Scholar] [CrossRef]

- Marchetti, L.; Cardós, M.; Campaña, L.; Ferrero, C. Effect of glutens of different quality on dough characteristics and breadmaking performance. LWT—Food Sci. Technol. 2012, 46, 224–231. [Google Scholar] [CrossRef]

- Salehi, F. Improvement of gluten-free bread and cake properties using natural hydrocolloids: A review. Food Sci Nutr. 2019, 7, 3391–3402. [Google Scholar] [CrossRef] [Green Version]

- Novotni, D.; Mutak, N.; Nanjara, L.; Drakula, S.; Čukelj Mustač, N.; Voučko, B.; Ćurić, D. Sourdough fermentation of carob flour and its application in wheat bread. Food Technol Biotechnol. 2020, 58, 465–474. [Google Scholar]

- Martuscelli, M.; Di Teodoro, G.; Sacchetti, G.; Pittia, P. Amaretti senza amido e farina quali ingredienti in sistemi alimentari ad alta umidità: Reidratazione e caratteristiche fisiche. Ind. Aliment. 2008, 482, 717–724. [Google Scholar]

- Pittia, P.; Sacchetti, G. Antiplasticization effect of water in amorphous foods. A review. Food Chem. 2008, 106, 1417–1427. [Google Scholar] [CrossRef]

- Satir, G.; Guzel-Seydim, Z.B. Influence of Kefir fermentation on the bioactive substances of different breed goat milks. LWT—Food Sci. Technol. 2015, 63, 852–858. [Google Scholar] [CrossRef]

- Debelo, H.; Li, M.; Ferruzzi, M.G. Processing influences on food polyphenol profiles and biological activity. Curr. Opin. Food Sci. 2020, 32, 90–102. [Google Scholar] [CrossRef]

- Turfani, V.; Narducci, V.; Durazzo, A.; Galli, V.; Carcea, M. Technological, nutritional and functional properties of wheat bread enriched with lentil or carob flours. LWT—Food Sci. Technol. 2017, 78, 361–366. [Google Scholar] [CrossRef]

- Christodoulou, M.C.; Orellana Palacios, J.C.; Hesami, G.; Jafarzadeh, S.; Lorenzo, J.M.; Domínguez, R.; Moreno, A.; Hadidi, M. Spectrophotometric Methods for Measurement of Antioxidant Activity in Food and Pharmaceuticals. Antioxidants 2022, 11, 2213. [Google Scholar] [CrossRef]

- Rosa, C.S.; Tessele, K.; Prestes, R.C.; Silveira, M.; Franco, F. Effect of substituting of cocoa powder for carob flour in cakes made with soy and banana flours. Int. Food Res. J. 2015, 22, 2111–2118. [Google Scholar]

- Issaoui, M.; Flamini, G.; Delgado, A. Sustainability Opportunities for Mediterranean Food Products through New Formulations Based on Carob Flour (Ceratonia siliqua L.). Sustainability 2021, 13, 8026. [Google Scholar] [CrossRef]

- Kirchhof, E.; Schieberle, P. Quantitation of Odor-Active Compounds in Rye Flour and Rye Sourdough Using Stable Isotope Dilution Assays. J. Agric. Food Chem. 2002, 50, 5378–5385. [Google Scholar] [CrossRef]

- Antoniou, C.; Kyratzis, A.C.; Soteriou, G.A.; Rouphael, Y.; Kyriacou, M.C. Configuration of the Volatile Aromatic Profile of Carob Powder Milled from Pods of Genetic Variants Harvested at Progressive Stages of Ripening from High and Low Altitudes. Front. Nutr. 2021, 8, 789169. [Google Scholar] [CrossRef]

- Livesey, G.; Taylor, R.; Livesey, H.; Liu, S. Is there a dose-response relation of dietary glycemic load to risk of type 2 diabetes? Meta-analysis of prospective cohort studies. Am. J. Clin. Nutr. 2013, 97, 584–596. [Google Scholar] [CrossRef] [Green Version]

- Liu, S.; Willett, W.C.; Stampfer, M.J.; Hu, F.B.; Franz, M.; Sampson, L.; Hennekens, C.H.; Manson, J.E.A. prospective study of dietary glycemic load, carbohydrate intake, and risk of coronary heart disease in US women. Am. J. Clin. Nutr. 2000, 71, 1455–1461. [Google Scholar] [CrossRef] [Green Version]

- Brand-Miller, J.C.; Holt, S.H.; Pawlak, D.B.; McMillan, J. Glycemic index and obesity. Am. J. Clin. Nutr. 2013, 76, 281–285. [Google Scholar] [CrossRef] [Green Version]

- Penagini, F.; Dilillo, D.; Meneghin, F.; Mameli, C.; Fabiano, V.; Zuccotti, G.V. Gluten free diet in children: An approach to a nutritionally adequate and balanced diet. Nutrients 2013, 5, 4553–4565. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Segura, M.E.; Rosell, C.M. Chemical composition and starch digestibility of different gluten-free breads. Plant Foods Hum. Nutr. 2011, 66, 224–230. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zuccotti, G.; Fabiano, V.; Dilillo, D.; Picca, M.; Cravidi, C.; Brambilla, P. Intakes of nutrients in Italian children with celiac disease and the role of commercially available gluten-free products. J. Hum. Nutr. Diet. 2013, 26, 436–444. [Google Scholar] [CrossRef] [PubMed]

- Kylökäs, A.; Kaukinen, K.; Huhtala, H.; Collin, P.; Mäki, M.; Kurppa, K. Type 1 and type 2 diabetes in celiac disease: Prevalence and effect on clinical and histological presentation. BMC Gastroenterol. 2016, 16, 76–82. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Average Values for 100 g of Product | % RDA | |

|---|---|---|

| Energy value (Kcal) | 371 | |

| Fat (g) | 0.3 | 0.4 |

| Of which is saturated (g) | <0.1 | <0.1 |

| Carbohydrate (g) | 41.30 | 15.48 |

| Of which is sugar (g) | 36.50 | |

| Fiber (g) | 6.50 | 26 |

| Protein (g) | 4.70 | 9.4 |

| Salt (mg) | 0 | 0 |

| Potassium (mg) | 800 | 39 |

| Vitamin B2 (mg) | 0.45 | 32 |

| Sample | Storage Time (d) | TPC (mg GAE g DW−1) | PAC (mg GAE g DW−1) | FC (mg CT g DW−1) | IC50 (mg mL−1) | |

|---|---|---|---|---|---|---|

| DPPH Radical | ABTS Radical | |||||

| CPF | 50.94 ± 0.25 | 10.89 ± 0.14 | 1.54 ± 0.06 | 0.082 ± 0.003 | 0.078 ± 0.003 | |

| B0 | 1 | 0.208 ± 0.009 f | - | - | - | - |

| 4 | 0.147 ± 0.008 g | - | - | - | - | |

| 6 | 0.118 ± 0.005 h | - | - | - | - | |

| B1 | 1 | 1.542 ± 0.046 d | 0.103 ± 0.004 c | 0.059 ± 0.002 c | 0.788 ± 0.029 d | 0.160 ± 0.008 c |

| 4 | 1.464 ± 0.034 d | 0.099 ± 0.002 c | 0.049 ± 0.001 d | 0.867 ± 0.033 e | 0.165 ± 0.008 c | |

| 6 | 1.354 ± 0.035 e | 0.087 ± 0.002 d | 0.042 ± 0.001 e | 0.954 ± 0.041 f | 0.172 ± 0.009 c | |

| B2 | 1 | 2.532 ± 0.085 a | 0.155 ± 0.007 a | 0.091 ± 0.003 a | 0.478 ± 0.020 a | 0.112 ± 0.005 a |

| 4 | 2.242 ± 0.078 b | 0.141 ± 0.005 b | 0.088 ± 0.004 a | 0.621 ± 0.029 b | 0.120 ± 0.005 a | |

| 6 | 2.082 ± 0.074 c | 0.135 ± 0.005 b | 0.078 ± 0.002 b | 0.772 ± 0.033 c | 0.132 ± 0.007 b | |

| Positive control | ||||||

| Ascorbic acid | 0.002 ± 0.001 | 0.005 ± 0.001 | ||||

| Sample | Days | Slope ± 400 |

|---|---|---|

| B0 | 1 | 63,100 |

| 6 | 61,700 | |

| B1 | 1 | 24,000 |

| 6 | 37,000 | |

| B2 | 1 | 1100 |

| 6 | 3700 |

| Samples | Available CHO (g) | GI Value | Classification |

|---|---|---|---|

| B0 | 50 | 100 | High |

| B1 | 50 | 115 | High |

| B2 | 50 | 62 | Medium |

| Samples | IAUC ± SD | p Value |

|---|---|---|

| B0 | 3430 ± 1233 | |

| B1 | 3114 ± 1183 | NS |

| B2 | 1147 ± 1174 | <0.05 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Restuccia, D.; Esposito, L.; Spizzirri, U.G.; Martuscelli, M.; Caputo, P.; Rossi, C.O.; Clodoveo, M.L.; Pujia, R.; Mazza, E.; Pujia, A.; et al. Formulation of a Gluten-Free Carob-Based Bakery Product: Evaluation of Glycemic Index, Antioxidant Activity, Rheological Properties, and Sensory Features. Fermentation 2023, 9, 748. https://doi.org/10.3390/fermentation9080748

Restuccia D, Esposito L, Spizzirri UG, Martuscelli M, Caputo P, Rossi CO, Clodoveo ML, Pujia R, Mazza E, Pujia A, et al. Formulation of a Gluten-Free Carob-Based Bakery Product: Evaluation of Glycemic Index, Antioxidant Activity, Rheological Properties, and Sensory Features. Fermentation. 2023; 9(8):748. https://doi.org/10.3390/fermentation9080748

Chicago/Turabian StyleRestuccia, Donatella, Luigi Esposito, Umile Gianfranco Spizzirri, Maria Martuscelli, Paolino Caputo, Cesare Oliviero Rossi, Maria Lisa Clodoveo, Roberta Pujia, Elisa Mazza, Arturo Pujia, and et al. 2023. "Formulation of a Gluten-Free Carob-Based Bakery Product: Evaluation of Glycemic Index, Antioxidant Activity, Rheological Properties, and Sensory Features" Fermentation 9, no. 8: 748. https://doi.org/10.3390/fermentation9080748

APA StyleRestuccia, D., Esposito, L., Spizzirri, U. G., Martuscelli, M., Caputo, P., Rossi, C. O., Clodoveo, M. L., Pujia, R., Mazza, E., Pujia, A., Montalcini, T., & Aiello, F. (2023). Formulation of a Gluten-Free Carob-Based Bakery Product: Evaluation of Glycemic Index, Antioxidant Activity, Rheological Properties, and Sensory Features. Fermentation, 9(8), 748. https://doi.org/10.3390/fermentation9080748