Effects of Different Cutting Stages and Additives on the Fermentation Quality and Microbial Community of Sudangrass (Sorghum sudanense Stapf.) Silages

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Materials and Additives

2.2. Experimental Methods and Silage Preparation

2.3. Chemical Analyses

2.4. Microbial Population Analysis

2.5. Bacterial Community Analysis

2.6. Calculations and Statistical Analysis

3. Results and Discussion

3.1. Characteristics of Fresh Sudangrass before Ensiling

3.2. Chemical Characteristics of Sudangrass after Ensiling

3.3. Fermentation Profile and Microbial Counts of Sudangrass Silage

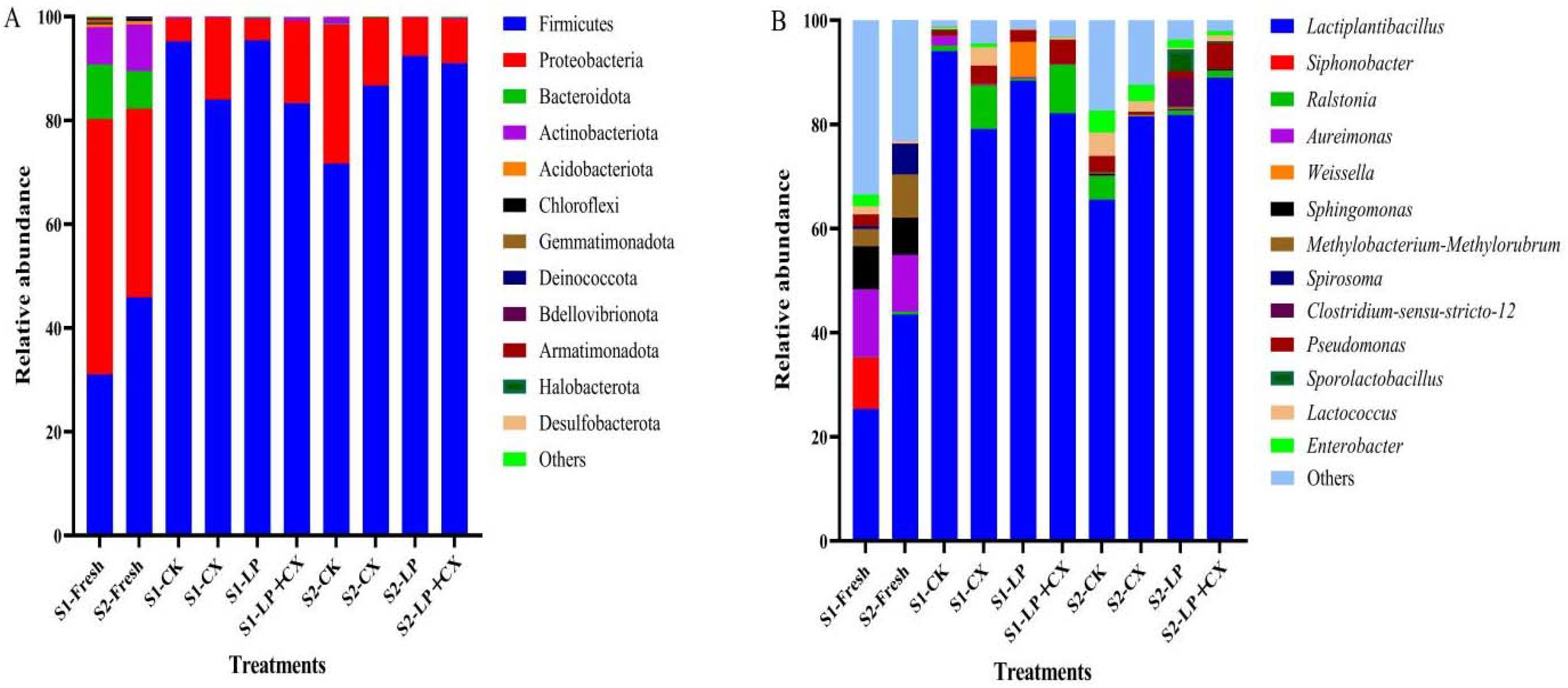

3.4. Bacterial Diversity and Community of Fresh Material and Sudangrass Silage on Day 60

3.5. Correlation Analysis of the Microbial Community and Some Silage Parameters

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhu, Y.Q.; Wang, X.; Huang, L.K.; Lin, C.W.; Zhang, X.Q.; Xu, W.Z.; Peng, J.H.; Li, Z.; Yan, H.D.; Luo, F.X.; et al. Transcriptomic Identification of Drought-related Genes and SSR Markers in Sudan Grass Based on RNA-Seq. Front. Plant Sci. 2017, 8, 687. [Google Scholar] [CrossRef]

- Arenhardt, E.G.; da Silva, J.A.G.; Gewehr, E.; Arenhardt, L.G.; Arenhardt, C.L.; Nonnenmacher, G. CG FARRAPO: A Sudangrass Cultivar with High Biomass and Grain Yields. Crop Breed. Appl. Biotechnol. 2016, 16, 158–162. [Google Scholar] [CrossRef][Green Version]

- Bibi, A.; Sadaqat, H.A.; Akram, H.M.; Khan, T.M.; Usman, B.F. Physiological and Agronomic Responses of Sudangrass to Water Stress. J. Agric. Res. 2010, 48, 369–379. [Google Scholar]

- Nasiyev, B.; Zhanatalapov, N.; Shibaikin, V.; Yancheva, H. Adaption of Elements of Sudan Grass Cultivation Technology to the Conditions of Dry-steppe Zone. Turk. J. Field Crop. 2020, 25, 57–65. [Google Scholar] [CrossRef]

- Wang, S.R.; Li, J.F.; Zhao, J.; Dong, Z.H.; Shao, T. An Investigation on Fermentative Profile, Microbial Numbers, Bacterial Community Diversity and Their Predicted Metabolic Characteristics of Sudangrass (Sorghum sudanense Stapf.) Silages. Anim. Biosci. 2022, 35, 1162–1173. [Google Scholar] [CrossRef]

- Chen, Q.; Wei, S.S.; Deng, Z.R.; Yin, L.P.; He, B.; Kong, X.L. Optimization of DNA Extraction from Seeds of Sorghum sudanense (Piper) Stapf. Not. Bot. Horti Agrobot. Cluj Napoca 2009, 37, 256–260. [Google Scholar] [CrossRef]

- Cai, Y.M.; Pang, H.L.; Kitahara, M.; Ohkuma, M. Lactobacillus nasuensis sp. nov., A Lactic Acid Bacterium Isolated from Silage, and Emended Description of the Genus Lactobacillus. Int. J. Syst. Evol. Microbiol. 2012, 62, 1140–1144. [Google Scholar] [CrossRef]

- Du, Z.M.; Sun, L.; Chen, C.; Lin, J.; Yang, F.Y.; Cai, Y.M. Exploring Microbial Community Structure and Metabolic Gene Clusters during Silage Fermentation of Paper Mulberry, A High-Protein Woody Plant. Anim. Feed Sci. Technol. 2021, 275, 114766. [Google Scholar] [CrossRef]

- Nazar, M.; Wang, S.R.; Zhao, J.; Dong, Z.H.; Li, J.F.; Kaka, N.A.; Shao, T. Abundance and Diversity of Epiphytic Microbiota on Forage Crops and Their Fermentation Characteristic during the Ensiling of Sterile Sudan Grass. World J. Microbiol. Biotechnol. 2021, 37, 27. [Google Scholar] [CrossRef]

- Jiang, H.; Wang, H.; Bao, B.; Qu, H.; Wang, J.; Sun, L.; Liu, B.; Gao, F. Effect of Compound Additives on Nutritional Composition, Fermentation Quality, and Bacterial Community of High-Moisture Alfalfa Silage. Fermentation 2023, 9, 453. [Google Scholar] [CrossRef]

- Oliveira, S.S.; Costa, K.A.D.; Souza, W.F.; Santos, C.B.; Teixeira, D.A.A.; Silva, V.C. Production and Quality of the Silage of Sorghum Intercropped with Paiaguas palisadegrass in Different Forage Systems and at Different Maturity Stages. Anim. Prod. Sci. 2020, 60, 694–704. [Google Scholar] [CrossRef]

- Li, X.M.; Chen, F.; Xu, J.J.; Guo, L.N.; Xiong, Y.; Lin, Y.L.; Ni, K.K.; Yang, F.Y. Exploring the Addition of Herbal Residues on Fermentation Quality, Bacterial Communities, and Ruminal Greenhouse Gas Emissions of Paper Mulberry Silage. Front. Microbiol. 2022, 12, 820011. [Google Scholar] [CrossRef] [PubMed]

- Jensen, C.; Weisbjerg, M.R.; Nørgaard, P.; Hvelplund, T. Effect of Maize Silage Maturity on Site of Starch and NDF Digestion in Lactating Dairy Cows. Anim. Feed Sci. Technol. 2005, 118, 279–294. [Google Scholar] [CrossRef]

- Fu, Z.H.; Sun, L.; Wang, Z.J.; Liu, J.Y.; Hou, M.L.; Lu, Q.; Hao, J.F.; Jia, Y.S.; Ge, G.T. Effects of Growth Stage on the Fermentation Quality, Microbial Community, and Metabolomic Properties of Italian ryegrass (Lolium multiflorum Lam.) Silage. Front. Microbiol. 2023, 13, 1054612. [Google Scholar] [CrossRef]

- Long, S.H.; Li, X.F.; Yuan, X.J.; Su, R.A.; Pan, J.X.; Chang, Y.; Shi, M.L.; Cui, Z.H.; Huang, N.X.; Wang, J. The Effect of Early and Delayed Harvest on Dynamics of Fermentation Profile, Chemical Composition, and Bacterial community of King Grass Silage. Front. Microbiol. 2022, 13, 864649. [Google Scholar] [CrossRef]

- Zheng, Y.L.; Li, M.X.; Xu, J.Y.; Sun, H.; Cheng, Q.M.; Xie, Y.X.; Wang, C.M.; Chen, C.; Li, P. Effects of Different Cutting Methods and Additives on the Fermentation Quality and Microbial Community of Saccharum Arundinaceum silage. Front. Microbiol. 2022, 13, 999881. [Google Scholar] [CrossRef]

- Muck, R.E.; Nadeau, E.M.G.; McAllister, T.A.; Contreras-Govea, F.E.; Santos, M.C.; Kung, L. Silage Review: Recent Advances and Future Uses of Silage Additives. J. Dairy Sci. 2018, 101, 3980–4000. [Google Scholar] [CrossRef]

- He, L.W.; Zhou, W.; Wang, C.; Yang, F.Y.; Chen, X.Y.; Zhang, Q. Effect of Cellulase and Lactobacillus casei on Ensiling Characteristics, Chemical Composition, Antioxidant Activity, and Digestibility of Mulberry Leaf Silage. J. Dairy Sci. 2019, 102, 9919–9931. [Google Scholar] [CrossRef]

- Xu, J.Y.; Zhang, K.Y.; Lin, Y.F.; Li, M.X.; Wang, X.K.; Yu, Q.; Sun, H.; Cheng, Q.M.; Xie, Y.X.; Wang, C.M.; et al. Effect of Cellulase and Lactic Acid Bacteria on the Fermentation Quality, Carbohydrate Conversion, and Microbial Community of Ensiling Oat with Different Moisture Contents. Front. Microbiol. 2022, 13, 1013258. [Google Scholar] [CrossRef]

- Yu, P.; McKinnon, J.J.; Christensen, D.A. Hydroxycinnamic Acids and Ferulic Acid Esterase in Relation to Biodegradation of Complex Plant Cell Walls. Can. J. Anim. Sci. 2005, 85, 255–267. [Google Scholar] [CrossRef]

- Chateigner-Boutin, A.L.; Ordaz-Ortiz, J.J.; Alvarado, C.; Bouchet, B.; Durand, S.; Verhertbruggen, Y.; Barriere, Y.; Saulnier, L. Developing Pericarp of Maize: A model to study arabinoxylan synthesis and feruloylation. Front. Microbiol. 2016, 7, 1476. [Google Scholar] [CrossRef] [PubMed]

- Krueger, N.A.; Adesogan, A.T.; Staples, C.R.; Krueger, W.K.; Dean, D.B.; Littell, R.C. The Potential to Increase Digestibility of Tropical Grasses with a Fungal, Ferulic Acid Esterase Enzyme Preparation. Anim. Feed Sci. Technol. 2008, 145, 95–108. [Google Scholar] [CrossRef]

- Addah, W.; Baah, J.; Okine, E.K.; McAllister, T.A. A Third-Generation Esterase Inoculant Alters Fermentation Pattern and Improves Aerobic Stability of Barley Silage and the Efficiency of Body Weight Gain of Growing Feedlot Cattle. J. Anim. Sci. 2012, 90, 1541–1552. [Google Scholar] [CrossRef] [PubMed]

- Li, F.H.; Ding, Z.T.; Ke, W.C.; Xu, D.M.; Zhang, P.; Bai, J.; Mudassar, S.; Muhammad, I.; Guo, X.S. Ferulic Acid Esterase-Producing Lactic Acid Bacteria and Cellulase Pretreatments of Corn Stalk Silage at Two Different Temperatures: Ensiling Characteristics, Carbohydrates Composition and Enzymatic Saccharification. Bioresour. Technol. 2019, 282, 211–221. [Google Scholar] [CrossRef] [PubMed]

- Dodd, D.; Cann, I.K.O. Enzymatic Deconstruction of Xylan for Biofuel Production. Glob. Change Biol. Bioenergy 2009, 1, 2–17. [Google Scholar] [CrossRef]

- Mkabayi, L.; Malgas, S.; Wilhelmi, B.S.; Pletschke, B.I. Evaluating Feruloyl Esterase-Xylanase Synergism for Hydroxycinnamic Acid and Xylo-oligosaccharide Production from Untreated, Hydrothermally Pre-treated and Dilute-acid Pre-treated Corn Cobs. Agronomy 2020, 10, 688. [Google Scholar] [CrossRef]

- Faulds, C.B.; Mandalari, G.; Lo Curto, R.B.; Bisignano, G.; Christakopoulos, P.; Waldron, K.W. Synergy Between Xylanases from Glycoside Hydrolase Family 10 and Family 11 and A Feruloyl Esterase in the Release of Phenolic Acids from Cereal Arabinoxylan. Appl. Microbiol. Biotechnol. 2006, 71, 622–629. [Google Scholar] [CrossRef]

- Uraji, M.; Arima, J.; Inoue, Y.; Harazono, K.; Hatanaka, T. Application of Two Newly Identified and Characterized Feruloyl Esterases from Streptomyces sp. in the Enzymatic Production of Ferulic Acid from Agricultural Biomass. PLoS ONE 2014, 9, e104584. [Google Scholar] [CrossRef]

- Li, P.; Zhang, Y.; Gou, W.L.; Cheng, Q.M.; Bai, S.Q.; Cai, Y.M. Silage Fermentation and Bacterial Community of Bur Clover, Annual Ryegrass and Their Mixtures Prepared with Microbial Inoculant and Chemical Additive. Anim. Feed Sci. Technol. 2019, 247, 285–293. [Google Scholar] [CrossRef]

- Broderick, G.A.; Kang, J.H. Automated simultaneous determination of ammonia and total amino acids in ruminal fluid and in vitro media. J. Dairy Sci. 1980, 63, 64–75. [Google Scholar] [CrossRef]

- Murphy, R.P. A Method for the Extraction of Plant Samples and the Determination of Total Soluble Carbohydrates. J. Sci. Food Agric. 1958, 9, 714–717. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis, 16th ed.; Association of Official Analytical Chemists: Washington, DC, USA, 1995; Volume 1. [Google Scholar]

- McDonald, P.; Henderson, A.; Heron, S.J.E. The Biochemistry of Silage; Chalcombe Publications: Marlow, UK, 1991. [Google Scholar]

- Van Soest, P.J.; Robertson, J.B.; Lewis, B.A. Methods for Dietary Fiber, Neutral Detergent Fiber, and Nonstarch Polysaccharides in Relation to Animal Nutrition. J. Dairy Sci. 1991, 74, 3583–3597. [Google Scholar] [CrossRef] [PubMed]

- Bergero, D.; Préfontaine, C.; Miraglia, N.; Peiretti, P.G. A Comparison Between the 2N and 4N HCl Acid-Insoluble ash methods for Digestibility Trials in Horses. Animal 2009, 3, 1728–1732. [Google Scholar] [CrossRef] [PubMed]

- Ma, J.; Sun, G.; Shah, A.M.; Fan, X.; Li, S.; Yu, X. Effects of Different Growth Stages of Amaranth Silage on the Rumen Degradation of Dairy Cows. Animals 2019, 9, 793. [Google Scholar] [CrossRef]

- Xu, D.M.; Ding, Z.T.; Bai, J.; Ke, W.C.; Zhang, Y.X.; Li, F.H.; Guo, X.S. Evaluation of the Effect of Feruloyl Esterase-Producing Lactobacillus plantarum and Cellulase Pretreatments on Lignocellulosic Degradation and Cellulose Conversion of Co-ensiled Corn Stalk and Potato Pulp. Bioresour. Technol. 2020, 310, 123476. [Google Scholar] [CrossRef]

- Thompson, I.P.; Bailey, M.J.; Fenlon, J.S.; Fermor, T.R.; Lilley, A.K.; Lynch, J.M.; Mccormack, P.J.; Mcquilken, M.P.; Purdy, K.J.; Rainey, P.B. Quantitative and Qualitative Seasonal Changes in the Microbial Community from the Phyllosphere of Sugar Beet (Beta vulgaris). Plant Soil 1993, 150, 177–191. [Google Scholar] [CrossRef]

- Li, F.H.; Ke, W.C.; Ding, Z.T.; Bai, J.; Zhang, Y.X.; Xu, D.M.; Li, Z.Q.; Guo, X.S. Pretreatment of Pennisetum sinese Silages with Ferulic Acid Esterase-Producing Lactic Acid Bacteria and Cellulase at two dry matter contents: Fermentation characteristics, carbohydrates composition and Enzymatic Saccharification. Bioresour. Technol. 2020, 295, 122261. [Google Scholar] [CrossRef]

- Li, J.F.; Yuan, X.J.; Dong, Z.H.; Mugabe, W.; Shao, T. The Effects of Fibrolytic Enzymes, Cellulolytic Fungi and Bacteria on the Fermentation Characteristics, Structural Carbohydrates Degradation, and Enzymatic Conversion Yields of Pennisetum sinese Silage. Bioresour. Technol. 2018, 264, 123–130. [Google Scholar] [CrossRef]

- Ni, K.K.; Wang, F.F.; Zhu, B.G.; Yang, J.X.; Zhou, G.A.; Pan, Y.; Tao, Y.; Zhong, J. Effects of Lactic Acid Bacteria and Molasses Additives on the Microbial Community and Fermentation Quality of Soybean Silage. Bioresour. Technol. 2017, 238, 706–715. [Google Scholar] [CrossRef]

- Bilal, M.Q. Effect of Molasses and Corn as Silage Additives on the Characteristic of Mott Dwarf Elephant Grass Silage at Different Fermentation Periods. Pak. Vet. J. 2009, 29, 19–23. [Google Scholar] [CrossRef]

- Maurya, D.P.; Singla, A.; Negi, S. An Overview of Key Pretreatment Processes for Biological Conversion of Lignocellulosic Biomass to Bioethanol. 3 Biotech 2015, 5, 597–609. [Google Scholar] [CrossRef] [PubMed]

- Larsen, S.U.; Arnbye-Jensen, M.; Jorgensen, H.; Jorgensen, U. Ensiling of the Pulp Fraction after Biorefining of Grass into Pulp and Protein Juice. Ind. Crop. Prod. 2019, 139, 111576. [Google Scholar] [CrossRef]

- Dong, L.F.; Zhang, H.S.; Gao, Y.H.; Diao, Q.Y. Dynamic Profiles of Fermentation Characteristics and Bacterial Community Composition of Broussonetia papyrifera Ensiled with Perennial Ryegrass. Bioresour. Technol. 2020, 310, 123396. [Google Scholar] [CrossRef] [PubMed]

- Ohmomo, S.; Tanaka, O.; Kitamoto, H.K.; Cai, Y.M. Silage and Microbial Performance, Old Story but New Problems. JARQ-Jpn. Agric. Res. Q. 2002, 36, 59–71. [Google Scholar] [CrossRef]

- Pereira, O.G.; Rocha, K.D.; Ferreira, C.L.L.F. Chemical Composition, Characterization, and Population of Microorganisms on Elephantgrass “Cameroon” (Pennisetum Purpureum Schum) and Iits Silages. Braz. J. Anim. Sci. 2007, 36, 1742–1750. [Google Scholar] [CrossRef]

- McGarvey, J.; Franco, R.; Palumbo, J.; Hnasko, R.; Stanker, L.; Mitloehner, F. Bacterial Population Dynamics during the Ensiling of Medicago Sativa (Alfalfa) and Subsequent Exposure to Air. J. Appl. Microbiol. 2013, 114, 1661–1670. [Google Scholar] [CrossRef] [PubMed]

- Méndez-García, C.; Peláez, A.I.; Mesa, V.; Sánchez, J.; Golyshina, O.V.; Ferrer, M. Microbial Diversity and Metabolic Networks in Acid Mine Drainage Habitats. Front. Microbiol. 2015, 6, 475. [Google Scholar] [CrossRef]

- Li, M.X.; Yu, Q.; Xu, J.Y.; Sun, H.; Cheng, Q.M.; Xie, Y.X.; Wang, C.M.; Li, P.; Chen, C.; Zheng, Y.L. Effect of Different Organic Acid Additives on the Fermentation Quality and Bacterial Community of Paper Mulberry (Broussonetia papyrifera) Silage. Front. Microbiol. 2022, 13, 1038549. [Google Scholar] [CrossRef]

- Yin, X.J.; Zhao, J.; Wang, S.R.; Dong, Z.H.; Li, J.F.; Shao, T. The Effects of Epiphytic Microbiota and Chemical Composition of Italian Ryegrass Harvested at Different Growth Sages on Silage Fermentation. J. Sci. Food Agric. 2023, 103, 1385–1393. [Google Scholar] [CrossRef]

- Zhang, Q.; Guo, X.; Zheng, M.Y.; Chen, D.K.; Chen, X.Y. Altering Microbial Communities: A Possible Way of Lactic Acid Bacteria Inoculants Changing Smell of Silage. Anim. Feed Sci. Technol. 2021, 279, 114998. [Google Scholar] [CrossRef]

- Zhao, M.R.; Zhang, H.Y.; Pan, G.; Yin, H.; Sun, J.J.; Yu, Z.; Bai, C.S.; Xue, Y.L. Effect of Exogenous Microorganisms on the Fermentation Quality, Nitrate Degradation and Bacterial Community of Sorghum-sudangrass silage. Front. Microbiol. 2022, 13, 1052837. [Google Scholar] [CrossRef] [PubMed]

- Zhao, J.; Yin, X.J.; Li, J.F.; Wang, S.R.; Dong, Z.H.; Shao, T. Effects of Developmental Stage and Store Time on the Microbial Community and Fermentation Quality of Sweet Sorghum Silage. Ital. J. Anim. Sci. 2022, 21, 1543–1557. [Google Scholar] [CrossRef]

- Graf, K.; Ulrich, A.; Idler, C.; Klocke, M. Bacterial Community Dynamics during Ensiling of Perennial Ryegrass at Two Compaction Levels Monitored by Terminal Restriction Fragment Length Polymorphism. J. Appl. Microbiol. 2016, 120, 1479–1491. [Google Scholar] [CrossRef] [PubMed]

| Item | Fresh Sudangrass | p Value | |

|---|---|---|---|

| S1 Stage | S2 Stage | ||

| DM (g·kg−1 FM) | 223.04 ± 2.41 | 241.62 ± 1.17 | 0.002 |

| pH | 6.37 ± 0.14 | 6.52 ± 0.18 | 0.544 |

| WSCs (g·kg−1 DM) | 36.65 ± 1.52 | 44.09 ± 1.13 | 0.018 |

| Crude protein (g·kg−1 DM) | 73.67 ± 0.30 | 85.87 ± 0.24 | <0.001 |

| NDF (g·kg−1 DM) | 650.31 ± 3.32 | 684.44 ± 4.16 | 0.003 |

| ADF (g·kg−1 DM) | 317.59 ± 2.10 | 336.47 ± 1.53 | 0.002 |

| ADL (g·kg−1 DM) | 34.28 ± 0.51 | 40.19 ± 1.68 | 0.028 |

| AIA (g·kg−1 DM) | 5.14 ± 0.18 | 5.39 ± 0.14 | 0.324 |

| LAB (log cfu·g−1 FM) | 4.27 ± 0.12 | 5.43 ± 0.08 | 0.001 |

| Yeasts (log cfu·g−1 FM) | 3.75 ± 0.14 | 3.81 ± 0.09 | 0.74 |

| Items | Ensiling Days | S1 | S2 | SEM | p-Value | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CK | CX | LP | LP+CX | CK | CX | LP | LP+CX | D | A | S | D × A | D × S | A × S | D × A × S | |||

| DM g.kg−1 FM | 30 d | 173.39 a | 160.58 bB | 174.27 aB | 178.99 a | 178.25 a | 169.13 ab | 179.37 a | 180.40 a | 0.82 | ** | *** | * | 0.47 | 0.66 | 0.63 | 0.92 |

| 60 d | 174.88 cd | 170.90 dA | 181.10 abcA | 184.10 ab | 180.33 abc | 177.07 bcd | 181.43 abc | 186.26 a | |||||||||

| WSCs g.kg−1 DM | 30 d | 8.37 c | 17.67 bA | 8.74 c | 18.71 ab | 9.37 c | 17.74 bA | 9.58 c | 19.35 a | 0.14 | 0.23 | *** | * | *** | 0.91 | * | 0.21 |

| 60 d | 8.29 d | 15.63 bB | 8.42 d | 19.67 a | 9.17 d | 14.16 bB | 11.14 c | 20.35 a | |||||||||

| CP g.kg−1 DM | 30 d | 71.24 bB | 70.54 bB | 74.30 bB | 77.26 ab | 79.64 ab | 79.97 ab | 79.78 abB | 85.12 a | 0.37 | *** | *** | *** | * | *** | 0.07 | ** |

| 60 d | 82.57 dA | 88.07 abA | 86.55 bcA | 84.36 cd | 79.35 e | 79.90 e | 90.32 aA | 88.59 ab | |||||||||

| NDF g.kg−1 DM | 30 d | 614.28 ab | 546.28 d | 618.17 ab | 520.44 d | 639.92 a | 600.47 bcA | 623.53 ab | 574.41 cA | 2.19 | *** | *** | *** | 1.00 | * | * | 0.40 |

| 60 d | 605.87 a | 544.73 b | 597.98 a | 514.55 c | 613.94 a | 563.15 bB | 609.21 a | 543.58 bB | |||||||||

| ADF g.kg−1 DM | 30 d | 322.02 bA | 272.11 cA | 318.94 bA | 268.62 cA | 335.84 aA | 313.41 bA | 332.80 aA | 279.38 cA | 0.86 | *** | *** | *** | 0.30 | * | *** | * |

| 60 d | 289.69 bcB | 240.32 eB | 280.27 cB | 226.77 fB | 307.43 aB | 280.18 cB | 298.24 abB | 266.59 dB | |||||||||

| ADL g.kg−1 DM | 30 d | 36.83 a | 29.99 ab | 31.51 ab | 30.49 ab | 32.55 ab | 33.58 ab | 29.51 ab | 27.99 b | 0.68 | 0.93 | * | 0.24 | 0.55 | 0.81 | 0.05 | 0.50 |

| 60 d | 35.76 a | 27.44 ab | 35.53 a | 31.88 ab | 35.26 a | 33.49 a | 31.46 ab | 22.49 b | |||||||||

| AIA g.kg−1 DM | 30 d | 4.93 | 4.79 | 5.26 | 5.26 | 5.06 | 5.46 | 4.86 | 5.19 | 0.06 | 0.92 | 0.16 | 0.48 | 0.76 | 0.98 | 0.31 | 0.40 |

| 60 d | 4.93 | 4.93 | 5.09 | 5.26 | 4.96 | 4.99 | 5.03 | 5.53 | |||||||||

| Items | Ensiling Days | S1 | S2 | SEM | p-Value | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CK | CX | LP | LP+CX | CK | CX | LP | LP+CX | D | A | S | D × A | D × S | A × S | D × A × S | |||

| pH | 30 d | 4.25 aA | 3.78 cd | 4.22 aA | 3.80 cA | 3.90 b | 3.74 d | 3.79 cdB | 3.76 cdA | 0.01 | * | *** | *** | ** | *** | *** | ** |

| 60 d | 4.13 aB | 3.78 d | 4.07 aB | 3.72 deB | 3.88 bc | 3.80 cd | 3.93 bA | 3.68 eB | |||||||||

| Lactic acid g.kg−1 DM | 30 d | 45.54 eB | 92.26 b | 52.45 d | 95.97 ab | 83.22 c | 101.24 aA | 94.29 bA | 93.10 b | 0.47 | * | *** | *** | *** | ** | *** | *** |

| 60 d | 54.45 eA | 87.89 bc | 54.99 e | 92.78 b | 85.81 c | 87.42 bcB | 79.57 dB | 98.31 a | |||||||||

| Acetic acid g.kg−1 DM | 30 d | 15.09 b | 18.02 aB | 16.25 ab | 17.71 a | 9.67 c | 8.84 c | 9.92 c | 10.07 c | 0.28 | *** | * | *** | 0.24 | 0.53 | 0.34 | 0.90 |

| 60 d | 18.12 b | 22.73 aA | 19.67 ab | 19.55 ab | 11.21 c | 13.86 c | 11.75 c | 11.88 c | |||||||||

| Lactic acid/ acetic acid | 30 d | 3.03 d | 5.14 c | 3.26 d | 5.43 c | 8.63 b | 11.49 aA | 9.56 bA | 9.45 b | 0.11 | *** | *** | *** | *** | *** | 0.10 | * |

| 60 d | 3.14 ef | 3.94 de | 2.82 f | 4.77 d | 7.69 ab | 6.38 cB | 6.77 bcB | 8.28 a | |||||||||

| Propionic acid g.kg−1 DM | 30 d | 71.69 aB | 43.16 cB | 52.68 bB | 48.98 bc | 6.49 d | 7.95 d | 7.96 d | 7.42 d | 0.93 | *** | ** | *** | 0.30 | ** | *** | 0.26 |

| 60 d | 79.51 aA | 68.45 abA | 71.71 abA | 57.09 c | 11.49 c | 12.11 c | 11.97 c | 11.25 c | |||||||||

| Butyric acid g.kg−1 DM | 30 d | 10.04 | 4.95 | 5.54 | 6.35 | ND | ND | 2.18 | 2.57 | - | - | - | - | - | - | - | - |

| 60 d | 9.32 | 11.76 | 9.60 | 9.62 | ND | ND | 2.88 | 1.69 | |||||||||

| NH3-N g.kg−1 TN | 30 d | 21.56 b | 12.32 e | 18.75 A | 9.86 fB | 25.61 aB | 19.84 bcB | 20.82 b | 15.51 dB | 0.12 | *** | *** | *** | *** | *** | *** | 0.74 |

| 60 d | 20.11 cd | 13.69 f | 15.16 eB | 11.28 gA | 27.78 aA | 24.94 bA | 20.69 c | 19.33 dA | |||||||||

| Items | Ensiling Days | S1 | S2 | SEM | p-Value | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CK | CX | LP | LP+CX | CK | CX | LP | LP+CX | D | A | S | D × A | D × S | A × S | D × A × S | |||

| LAB Log cfu·g−1 FM | 30 d | 6.70 b | 6.68 b | 6.91 aA | 6.41 dA | 6.57 cB | 6.85 aA | 6.76 b | 6.52 cA | 0.007 | 0.10 | *** | * | *** | * | *** | 0.06 |

| 60 d | 6.77 a | 6.64 b | 6.79 aB | 6.30 dB | 6.72 aA | 6.76 aB | 6.80 a | 6.44 cB | |||||||||

| Enterobacteriaceae log cfu·g−1 FM | 30 d | ND | ND | ND | ND | ND | ND | ND | ND | 0.011 | - | - | - | - | - | - | - |

| 60 d | ND | ND | ND | ND | ND | ND | 3.19 | 2.96 | |||||||||

| Yeasts log cfu·g−1 FM | 30 d | ND | ND | ND | ND | ND | ND | ND | ND | - | - | - | - | - | - | - | - |

| 60 d | ND | ND | ND | ND | ND | ND | ND | ND | |||||||||

| Treatment | Pielou’s e | Chao1 | Shannon | Simpson | Good’s Coverage |

|---|---|---|---|---|---|

| S1 | 0.12 E | 67.03 CD | 0.76 D | 0.19 E | 0.999 A |

| S2 | 0.09 E | 48.88 D | 0.48 D | 0.14 E | 0.999 A |

| S1-CK | 0.25 D | 70.97 C | 1.64 C | 0.47 CD | 0.999 A |

| S1-CX | 0.36 C | 102.69 B | 2.30 B | 0.58 B | 0.999 A |

| S1-LP | 0.24 D | 68.33 C | 1.61 C | 0.45 CD | 0.999 A |

| S1-LP+CX | 0.24 D | 65.00 CD | 1.39 C | 0.41 D | 0.999 A |

| S2-CK | 0.43 B | 122.47 A | 3.77 A | 0.71 A | 0.999 A |

| S2-CX | 0.51 A | 76.67 C | 3.52 A | 0.76 A | 0.999 A |

| S2-LP | 0.32 C | 62.46 CD | 1.89 BC | 0.52 BC | 0.999 A |

| S2-LP+CX | 0.25 D | 69.67 C | 1.57 C | 0.45 CD | 0.999 A |

| SEM | 0.005 | 1.83 | 0.06 | 0.01 | 0.00 |

| p-value | <0.001 | <0.001 | <0.001 | <0.001 | 0.791 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, Q.; Li, M.; Zhang, Y.; Xu, J.; Li, P.; Sun, H.; Xie, Y.; Dong, R.; Zheng, Y.; Chen, C. Effects of Different Cutting Stages and Additives on the Fermentation Quality and Microbial Community of Sudangrass (Sorghum sudanense Stapf.) Silages. Fermentation 2023, 9, 777. https://doi.org/10.3390/fermentation9080777

Yu Q, Li M, Zhang Y, Xu J, Li P, Sun H, Xie Y, Dong R, Zheng Y, Chen C. Effects of Different Cutting Stages and Additives on the Fermentation Quality and Microbial Community of Sudangrass (Sorghum sudanense Stapf.) Silages. Fermentation. 2023; 9(8):777. https://doi.org/10.3390/fermentation9080777

Chicago/Turabian StyleYu, Qiang, Mengxin Li, Yu Zhang, Jinyi Xu, Ping Li, Hong Sun, Yixiao Xie, Rui Dong, Yulong Zheng, and Chao Chen. 2023. "Effects of Different Cutting Stages and Additives on the Fermentation Quality and Microbial Community of Sudangrass (Sorghum sudanense Stapf.) Silages" Fermentation 9, no. 8: 777. https://doi.org/10.3390/fermentation9080777

APA StyleYu, Q., Li, M., Zhang, Y., Xu, J., Li, P., Sun, H., Xie, Y., Dong, R., Zheng, Y., & Chen, C. (2023). Effects of Different Cutting Stages and Additives on the Fermentation Quality and Microbial Community of Sudangrass (Sorghum sudanense Stapf.) Silages. Fermentation, 9(8), 777. https://doi.org/10.3390/fermentation9080777