Current Strategies to Modify the Functional Properties of Proteins Extracted from Pumpkin Seeds: A Comprehensive Review

Abstract

:1. Introduction

2. Protein Extraction Methods

2.1. Solvent Extraction

2.1.1. Organic Solvent, Aqueous, Acid Solvent-Based Protein Extraction

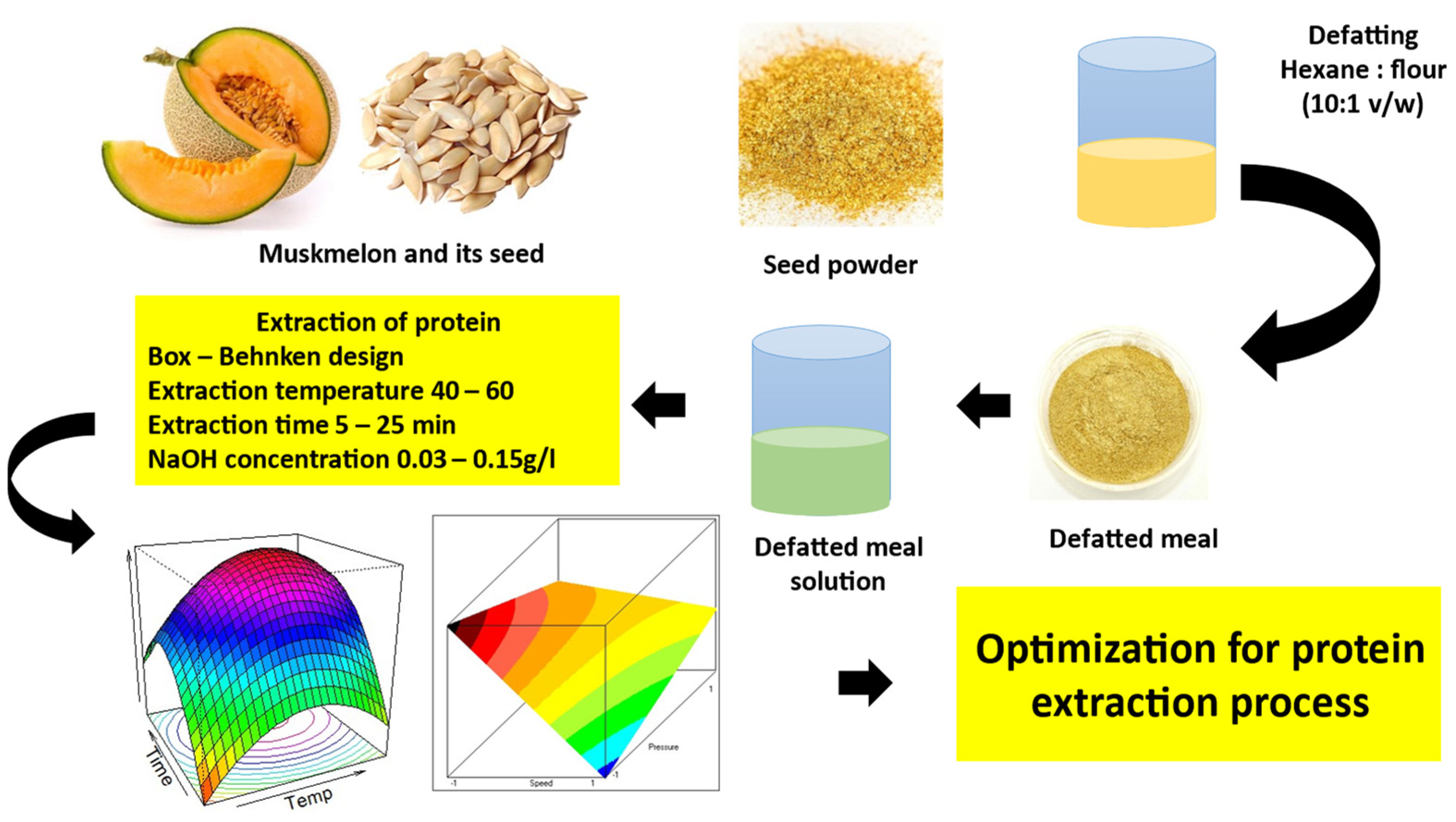

2.1.2. Alkali Based Protein Extraction

2.2. Enzymatic Assisted Extraction (EAE)

2.3. Ultrasound-Assisted Extraction

3. Characterization of Pumpkin Seed Protein

3.1. FTIR Spectroscopy

3.2. SDS-PAGE

3.3. Amino Acid Profiling

4. Modification of Functional Properties

4.1. Heat Treatment and Denaturation

4.2. Enzyme Modification

4.3. pH Adjustment

4.4. Chemical Modification

4.5. Ultrasonication

4.6. High Pressure Processing (HPP)

4.7. Significance of Substrates

5. Applications in Food Industry

5.1. Meat Industry

5.2. Bakery Industry

5.3. Dairy Industry

6. Future Perspective

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Vega-Gálvez, A.; Zura-Bravo, L.; Lemus-Mondaca, R.; Ah-Hen, K.; Di Scala, K. Nutritional composition and health benefits of seeds: Recent research insights. Nutr. Food Sci. 2020, 50, 925–940. [Google Scholar] [CrossRef]

- Barroso, M.E.; Roriz, C.L.; Barreira, J.C.; Dias, M.I.; Santos-Buelga, C.; Ferreira, I.C.; Heleno, S.A. Nutritional profile and the health-promoting properties of seeds: A comprehensive review of recent research. J. Food Sci. Nutr. Res. 2021, 9, 157–167. [Google Scholar] [CrossRef]

- Saini, R.K.; Keum, Y.S. Tocopherols and tocotrienols in plants and their relevance in human health: A critical review. Crit. Rev. Food Sci. Nutr. 2016, 56, 775–779. [Google Scholar] [CrossRef]

- Ayyildiz, H.F.; Topkafa, M.; Kara, H. Pumpkin (Cucurbita pepo L.) seed oil. In Fruit Oils: Chemistry and Functionality; Springer: Berlin/Heidelberg, Germany, 2019; pp. 765–788. [Google Scholar]

- Patel, S.; Rauf, A. Edible seeds from Cucurbitaceae family as potential functional foods: Immense promises, few concerns. Biomed. Pharmacother. 2017, 91, 330–337. [Google Scholar] [CrossRef]

- Lestari, B.; Meiyanto, E. A review: The emerging nutraceutical potential of pumpkin seeds. Indones. J. Cancer Chemoprev. 2018, 9, 92–101. [Google Scholar] [CrossRef]

- Dhakad, G.G.; Nannaware, M.S.; Wagh, G.V.; Shrirao, A.V.; Kochar, N.I.; Chandewar, A.V. Review on medicinal Use of Pumpkin Seed on Human Health. Res. J. Pharmacol. Pharmacodyn. 2023, 15, 59–65. [Google Scholar] [CrossRef]

- Tripathi, N.K.; Shrivastava, A. Recent developments in bioprocessing of recombinant proteins: Expression hosts and process development. Front. Bioeng. Biotechnol. 2019, 7, 420. [Google Scholar] [CrossRef]

- Saud, S.; Pan, B.; Chen, Y.; Fahad, S. Climate-resilient pumpkin cultivation under variable conditions. J. Agric. Sci. 2019, 11, 129–137. [Google Scholar] [CrossRef]

- Hosen, M.; Rafii, M.Y.; Mazlan, N.; Jusoh, M.; Oladosu, Y.; Chowdhury, M.F.N.; Khan, M.M.H. Pumpkin (Cucurbita spp.): A crop to mitigate food and nutritional challenges. Horticulturae 2021, 7, 352. [Google Scholar] [CrossRef]

- Nerson, H. Seed production and germinability of cucurbit crops. Hortic. Rev. 2005, 31, 293–361. [Google Scholar] [CrossRef]

- Paris, H.S. Overview of cucurbit breeding. Plant Breed. Rev. 2016, 20, 115–173. [Google Scholar] [CrossRef]

- Fernández-López, J.; Botella-Martínez, C.; Navarro-Rodríguez de Vera, C.; Sayas-Barberá, M.E.; Viuda-Martos, M.; Sánchez-Zapata, E.; Pérez-Álvarez, J.A. Vegetable soups and creams: Raw materials, processing, health benefits, and innovation trends. Plants 2020, 9, 1769. [Google Scholar] [CrossRef] [PubMed]

- Kosseva, M.R. Sources, characteristics and treatment of plant-based food waste. In Food Industry Wastes; Academic Press: Cambridge, MA, USA, 2020; pp. 37–66. [Google Scholar]

- Gómez-García, R.; Campos, D.A.; Aguilar, C.N.; Madureira, A.R.; Pintado, M. Valorization of melon fruit (Cucumis melo L.) by-products: Phytochemical and biofunctional properties with Emphasis on Recent Trends and Advances. Trends Food Sci. Technol. 2020, 99, 507–519. [Google Scholar] [CrossRef]

- Hussain, A.; Kausar, T.; Murtaza, M.A.; Jamil, M.A.; Iqbal, M.A.; Majeed, M.A.; Rafique, A.; Iftikhar, K.; Noreen, S.; Quddoos, M.Y.; et al. Production, characterization, food application and biological study of powder of pumpkin (Cucurbita maxima) parts (peel, flesh and seeds). Pure Appl. Biol. 2023, 12, 48–60. [Google Scholar] [CrossRef]

- Šmídová, Z.; Rysová, J. Gluten-free bread and bakery products technology. Foods 2022, 11, 480. [Google Scholar] [CrossRef]

- Skendi, A.; Papageorgiou, M.; Varzakas, T. High protein substitutes for gluten in gluten-free bread. Foods 2021, 10, 1997. [Google Scholar] [CrossRef] [PubMed]

- Adams, G.G.; Imran, S.; Wang, S.; Mohammad, A.; Kok, S.; Gray, D.A.; Channell, G.A.; Morris, G.A.; Harding, S.E. The hypoglycemic effect of pumpkins as anti-diabetic and functional medicines. Food Res. Int. 2011, 44, 862–867. [Google Scholar] [CrossRef]

- Wu, C.; Wang, M.; Zhao, H.; Liu, Z.; Wang, L. Characterization and antioxidant properties of peptides from pumpkin seed protein prepared by enzymatic hydrolysis. Food Chem. 2021, 344, 128678. [Google Scholar]

- Villamil, R.A.; Escobar, N.; Romero, L.N.; Huesa, R.; Plazas, A.V.; Gutiérrez, C.; Robelto, G.E. Perspectives of pumpkin pulp and pumpkin shell and seeds uses as ingredients in food formulation. Nutr. Food Sci. 2023, 53, 459–473. [Google Scholar] [CrossRef]

- Zia, S.; Khan, M.R.; Shabbir, M.A.; Aadil, R.M. An update on functional, nutraceutical and industrial applications of watermelon by-products: A comprehensive review. Trends Food Sci. Technol. 2021, 114, 275–291. [Google Scholar] [CrossRef]

- Balbino, S.; Dorić, M.; Vidaković, S.; Kraljić, K.; Škevin, D.; Drakula, S.; Voučko, B.; Čukelj, N.; Obranović, M.; Ćurić, D. Application of cryogenic grinding pretreatment to enhance extractability of bioactive molecules from pumpkin seed cake. J. Food Process Eng. 2019, 42, e13300. [Google Scholar] [CrossRef]

- Zeng, L.; Wang, Z.; He, Z.; Zeng, M.; Qin, F.; Chen, J. Physicochemical and gel properties of pumpkin seed protein: A comparative study. Int. J. Food Sci. Technol. 2023, 58, 1639–1651. [Google Scholar] [CrossRef]

- Wang, S.; Karthickeyan, V.; Sivakumar, E.; Lakshmikandan, M. Experimental investigation on pumpkin seed oil methyl ester blend in diesel engine with various injection pressure, injection timing and compression ratio. Fuel 2020, 264, 116868. [Google Scholar] [CrossRef]

- Krimer-Malešević, V. Pumpkin seeds: Phenolic acids in pumpkin seed (Cucurbita pepo L.). In Nuts and Seeds in Health and Disease Prevention; Academic Press: Cambridge, MA, USA, 2020; pp. 533–542. [Google Scholar]

- Petropoulos, S.A.; Fernandes, Â.; Calhelha, R.C.; Rouphael, Y.; Petrović, J.; Soković, M.; Ferreira, I.C.F.R.; Barros, L. Antimicrobial properties, cytotoxic effects, and fatty acids composition of vegetable oils from purslane, linseed, luffa, and pumpkin seeds. Appl. Sci. 2021, 11, 5738. [Google Scholar] [CrossRef]

- Prasad, K.V.; Hanumesh, V.; Kumar Swamy, K.; Renuka, S. Pumpkin seeds classification: Artificial neural network and machine learning methods. J. Int. Acad. Phys. Sci. 2023, 27, 23–33. [Google Scholar]

- Joshi, D.C.; Das, S.K.; Mukherjee, R.K. Physical properties of pumpkin seeds. J. Agric. Eng. Res. 1993, 54, 219–229. [Google Scholar] [CrossRef]

- Gao, D.; Helikh, A.O.; Filon, A.M.; Duan, Z.; Vasylenko, O.O. Effect of Ph-shifting treatment on the gel properties of pumpkin seed protein isolate. J. Chem. Technol. 2022, 30, 198–204. [Google Scholar]

- Peng, M.; Lu, D.; Liu, J.; Jiang, B.; Chen, J. Effect of roasting on the antioxidant activity, phenolic composition, and nutritional quality of pumpkin (Cucurbita pepo L.) seeds. Front. Nutr. 2021, 8, 647354. [Google Scholar] [CrossRef]

- Abdelkader, C.; Cherif, F.Z.H.; Elius, E.A.E.; Lucchesi, D.; Pucci, L.; Yahia, D.A. Pumpkin seed proteins (Cucurbita pepo L.) protect against diet-induced metabolic syndrome by improving insulin resistance and markers of oxidative stress and inflammation in rats. Biologia 2022, 77, 2677–2687. [Google Scholar] [CrossRef]

- Karabulut, G.; Goksen, G.; Mousavi Khaneghah, A.M. Plant-based protein modification strategies towards challenges. J. Agric. Food Res. 2024, 15, 101017. [Google Scholar] [CrossRef]

- Kyriakopoulou, K.; Keppler, J.K.; van Der Goot, A.J. Functionality of ingredients and additives in plant-based meat analogues. Foods 2021, 10, 600. [Google Scholar] [CrossRef] [PubMed]

- Senna, C.; Soares, L.; Egea, M.B.; Fernandes, S.S. The techno-functionality of chia seed and its fractions as ingredients for meat analogs. Molecules 2024, 29, 440. [Google Scholar] [CrossRef] [PubMed]

- Axentii, M.; Codină, G.G. Exploring the nutritional potential and functionality of hemp and rapeseed proteins: A review on unveiling anti-nutritional factors, bioactive compounds, and functional attributes. Plants 2024, 13, 1195. [Google Scholar] [CrossRef]

- Zoumpoulakis, P.; Sinanoglou, V.J.; Batrinou, A.; Strati, I.F.; Miniadis-Meimaroglou, S.; Sflomos, K. A combined methodology to detect γ-irradiated white sesame seeds and evaluate the effects on fat content, physicochemical properties and protein allergenicity. Food Chem. 2012, 131, 713–721. [Google Scholar] [CrossRef]

- Pramanik, J.; Kumar, A.; Prajapati, B. A review on flaxseeds: Nutritional profile, health benefits, value added products, and toxicity. eFood 2023, 4, e114. [Google Scholar] [CrossRef]

- Kumar, M.; Tomar, M.; Potkule, J.; Verma, R.; Punia, S.; Mahapatra, A.; Belwal, T.; Dahuja, A.; Joshi, S.; Berwal, M.K.; et al. Advances in the plant protein extraction: Mechanism and recommendations. Food Hydrocoll. 2021, 115, 106595. [Google Scholar] [CrossRef]

- Santhi, J.V.; Tavanandi, H.A.; Sharma, R.; Prabhakar, G.; Raghavarao, K.S.M.S. Differential partitioning of coconut whey proteins and fat using aqueous two phase extraction. Fluid Phase Equilibria 2020, 503, 112314. [Google Scholar] [CrossRef]

- Yahiaoui, M.; Laribi-Habchi, H.; Bouacem, K.; Asmani, K.L.; Mechri, S.; Harir, M.; Bendif, H.; Aïssani-El Fertas, R.; Jaouadi, B. Purification and biochemical characterization of a new organic solvent-tolerant chitinase from Paenibacillus timonensis strain LK-DZ15 isolated from the Djurdjura Mountains in Kabylia, Algeria. Carbohydr. Res. 2019, 483, 107747. [Google Scholar] [CrossRef]

- Mao, C.; Wu, J.; Zhang, X.; Ma, F.; Cheng, Y. Improving the solubility and digestibility of potato protein with an online ultrasound-assisted pH shifting treatment at medium temperature. Foods 2020, 9, 1908. [Google Scholar] [CrossRef]

- Michael, A.; Kyewalyanga, M.S.; Lugomela, C.V. Biomass and nutritive value of Spirulina (Arthrospira fusiformis) cultivated in a cost-effective medium. Ann. Microbiol. 2019, 69, 1387–1395. [Google Scholar] [CrossRef]

- Shanthakumar, P.; Klepacka, J.; Bains, A.; Chawla, P.; Dhull, S.B.; Najda, A. The current situation of pea protein and its application in the food industry. Molecules 2022, 27, 5354. [Google Scholar] [CrossRef] [PubMed]

- Lang, B.J.; Guerrero, M.E.; Prince, T.L.; Okusha, Y.; Bonorino, C.; Calderwood, S.K. The functions and regulation of heat shock proteins; key orchestrators of proteostasis and the heat shock response. Arch. Toxicol. 2021, 95, 1943–1970. [Google Scholar] [CrossRef] [PubMed]

- Rüger, N.; Fassauer, G.M.; Bock, C.; Emmrich, T.; Bodtke, A.; Link, A. Substituted tetrazoles as multipurpose screening compounds. Mol. Divers. 2017, 21, 9–27. [Google Scholar] [CrossRef] [PubMed]

- Geada, P.; Moreira, C.; Silva, M.; Nunes, R.; Madureira, L.; Rocha, C.M.R.; Pereira, R.N.; Vicente, A.A.; Teixeira, J.A. Algal proteins: Production strategies and nutritional and functional properties. Bioresour. Technol. 2021, 332, 125125. [Google Scholar] [CrossRef] [PubMed]

- Norris, S.C.P.; Delgado, S.M.; Kasko, A.M. Mechanically robust photodegradable gelatin hydrogels for 3D cell culture and in situ mechanical modification. Polym. Chem. 2019, 10, 3180–3193. [Google Scholar] [CrossRef]

- Dahmen-Ben Moussa, I.; Masmoudi, M.A.; Choura, S.; Chamkha, M.; Sayadi, S. Extraction optimization using response surface methodology and evaluation of the antioxidant and antimicrobial potential of polyphenols in Scenedesmus sp. and Chlorella sp. Biomass Convers. Biorefin. 2021, 13, 7185–7198. [Google Scholar] [CrossRef]

- Mazloomi-Kiyapey, S.N.; Sadeghi-Mahoonak, A.; Ranjbar-Nedamani, E.; Nourmohammadi, E. Production of antioxidant peptides through hydrolysis of medicinal pumpkin seed protein using pepsin enzyme and the evaluation of their functional and nutritional properties. ARYA Atheroscler. 2019, 15, 218–227. [Google Scholar] [CrossRef]

- Kaewka, D.; Jitjumnong, S.; Phongthai, S. Physicochemical and functional properties of protein hydrolysates from pumpkin seed (Cucurbita pepo L.) produced by enzymatic hydrolysis. Food Sci. Biotechnol. 2021, 30, 893–903. [Google Scholar] [CrossRef]

- Al-U’datt, M.H.; Wan Ahmad, W.A.N.; Ahmad, F.; Mhd Sarbon, N. Recent Advances in In Vitro and In Vivo Studies of Antioxidant, ACE-Inhibitory and Anti-Inflammatory Peptides from Legume Protein Hydrolysates. Molecules 2023, 28, 2423. [Google Scholar] [CrossRef]

- Dyankova, S.; Doneva, M.; Terziyska, M.; Metodieva, P.; Nacheva, I. Optimization of the Process for Obtaining Antioxidant Protein Hydrolysates from Pumpkin Seed Oil Cake Using Response Surface Methodology. Appl. Sci. 2024, 14, 1967. [Google Scholar] [CrossRef]

- Nadar, S.S.; Rao, P.; Rathod, V.K. Enzyme assisted extraction of biomolecules as an approach to novel extraction technology: A review. Food Res. Int. 2018, 108, 309–330. [Google Scholar] [CrossRef] [PubMed]

- Filho, D.G.; Silva, A.G.; Guidini, C.Z. Lipases: Sources, immobilization methods, and industrial applications. Appl. Microbiol. Biotechnol. 2019, 103, 7399–7423. [Google Scholar] [CrossRef]

- Du, H.; Zhang, J.; Wang, S.; Manyande, A.; Wang, J. Effect of high-intensity ultrasonic treatment on the physicochemical, structural, rheological, behavioral, and foaming properties of pumpkin (Cucurbita moschata Duch.)-seed protein isolates. LWT 2022, 155, 112952. [Google Scholar] [CrossRef]

- Carreira-Casais, A.; Otero, P.; Garcia-Perez, P.; Garcia-Oliveira, P.; Pereira, A.G.; Carpena, M.; Soria-Lopez, A.; Simal-Gandara, J.; Prieto, M.A. Benefits and drawbacks of ultrasound-assisted extraction for the recovery of bioactive compounds from marine algae. Int. J. Environ. Res. Public Health 2021, 18, 9153. [Google Scholar] [CrossRef]

- Das, M.; Devi, L.M.; Badwaik, L.S. Ultrasound-assisted extraction of pumpkin seeds protein and its physicochemical and functional characterization. Appl. Food Res. 2022, 2, 100121. [Google Scholar] [CrossRef]

- Panda, S.K. Technology for Wine and Beer Production from Ipomoea Batatas; CRC Press: Boca Raton, FL, USA, 2019. [Google Scholar]

- Pérez-Beltrán, C.H.; García-Guzmán, J.J.; Ferreira, B.; Estévez-Hernández, O.; López-Iglesias, D.; Cubillana-Aguilera, L.; Link, W.; Stănică, N.; Rosa da Costa, A.M.; Palacios-Santander, J.M. One-minute and green synthesis of magnetic iron oxide nanoparticles assisted by design of experiments and high energy ultrasound: Application to biosensing and immunoprecipitation. Mater. Sci. Eng. C Mater. Biol. Appl. 2021, 123, 112023. [Google Scholar] [CrossRef]

- Cortez-Trejo, M.C.; Mendoza, S.; Loarca-Piña, G.; Figueroa-Cárdenas, J.D. Physicochemical characterization of protein isolates of amaranth and common bean and a study of their compatibility with xanthan gum. Int. J. Biol. Macromol. 2021, 166, 861–868. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Wu, Q.; Lv, J.; Jia, X.; Gao, J.; Zhang, Y.; Wang, L. Associations of protein molecular structures with their nutrient supply and biodegradation characteristics in different byproducts of seed-used pumpkin. Animals 2022, 12, 956. [Google Scholar] [CrossRef]

- Nasrollahzadeh, F.; Roman, L.; Skov, K.; Jakobsen, L.M.A.; Trinh, B.M.; Tsochatzis, E.D.; Mekonnen, T.; Corredig, M.; Dutcher, J.R.; Martinez, M.M. A comparative investigation of seed storage protein fractions: The synergistic impact of molecular properties and composition on anisotropic structuring. Food Hydrocoll. 2023, 137, 108400. [Google Scholar] [CrossRef]

- Andronie, L.; Pop, I.; Matei, F.; Coroian, A.; Rotaru, A.; Sobolu, R.; Bebu, A. Results obtained by investigating pumpkin (Cucurbita maxima L.) using FT-IR spectroscopy [Scientific papers]. Horticulture 2022, 66, 357. [Google Scholar]

- Saridewi, N.; Syaputro, H.T.; Aziz, I.; Dasumiati, D.; Kumila, B.N. Synthesis and characterization of ZnO nanoparticles using pumpkin seed extract (Cucurbita moschata) by the sol–gel method. AIP Conf. Proc. 2021, 2349, 020010. [Google Scholar] [CrossRef]

- Miller, L.M.; Bourassa, M.W.; Smith, R.J. FTIR spectroscopic imaging of protein aggregation in living cells. Biochim. Biophys. Acta 2013, 1828, 2339–2346. [Google Scholar] [CrossRef]

- Undavalli, V.K.; Ling, C.; Khandelwal, B. Impact of alternative fuels and properties on elastomer compatibility. In Aviation Fuels; Academic Press: Cambridge, MA, USA, 2021; pp. 113–132. [Google Scholar]

- Win, T.; Khan, S.; Bo, B.; Zada, S.; Fu, P. Green synthesis and characterization of Fe3O4 nanoparticles using Chlorella-K01 extract for potential enhancement of plant growth stimulating and antifungal activity. Sci. Rep. 2021, 11, 21996. [Google Scholar] [CrossRef]

- Kumar, A.; Sasmal, S. Rheological and physico-chemical properties of milk gel using isolate of pumpkin (Cucurbita moschata) seeds: A new source of milk clotting peptidase. Food Hydrocoll. 2020, 106, 105866. [Google Scholar] [CrossRef]

- Fatma, N.; Metusalach, M.; Taslim, N.A.; Nurilmala, M. SDS-PAGE protein profile of albumin extracted by steaming from four marine and three brackish-water fishes. Biodivers. J. Biol. Divers. 2023, 24, 4027–4033. [Google Scholar] [CrossRef]

- Vinayashree, S.; Vasu, P. Biochemical, nutritional and functional properties of protein isolate and fractions from pumpkin (Cucurbita moschata var. Kashi Harit) seeds. Food Chem. 2021, 340, 128177. [Google Scholar] [CrossRef] [PubMed]

- Kim, E.Y.; Kwon, C.W.; Chang, P.S. Purification and characterization of a novel acid-tolerant and heterodimeric β-glucosidase from pumpkin (Cucurbita moschata) seed. J. Biosci. Bioeng. 2021, 132, 125–131. [Google Scholar] [CrossRef]

- Yang, C.; Liu, J.; Han, Y.; Wang, B.; Liu, Z.; Hu, H.; Guan, Z.; Yang, Y.; Wang, J. Fabrication of polyphenol-pumpkin seed protein isolate (PSPI) covalent conjugate microparticles to protect free radical scavenging activity of polyphenol. Food Biosci. 2023, 55, 102982. [Google Scholar] [CrossRef]

- Yang, C.; Wang, B.; Wang, J.; Xia, S.; Wu, Y. Effect of pyrogallic acid (1, 2, 3-benzenetriol) polyphenol-protein covalent conjugation reaction degree on structure and antioxidant properties of pumpkin (Cucurbita sp.) seed protein isolate. LWT 2019, 109, 443–449. [Google Scholar] [CrossRef]

- Gani, A.; ul Ashraf, Z.; Noor, N.; Ahmed Wani, I.A. Ultrasonication as an innovative approach to tailor the apple seed proteins into nanosize: Effect on protein structural and functional properties. Ultrason. Sonochem. 2022, 86, 106010. [Google Scholar] [CrossRef]

- Kashyap, P.; Singh Riar, C.S.; Jindal, N. Detoxification of Meghalayan cherry (Prunus nepalensis) kernel and its effect on structural and thermal properties of proteins. Food Res. Int. 2023, 164, 112437. [Google Scholar] [CrossRef] [PubMed]

- Muhammad, S.; Kausar, M.; Shahzadi, I. Characterization of Pumpkin Seed Protein Isolates. Pak. J. Bot. 2021, 53, 185–194. [Google Scholar] [CrossRef]

- Goetz, H.; Kuschel, M.; Wulff, T.; Sauber, C.; Miller, C.; Fisher, S.; Woodward, C. Comparison of selected analytical techniques for protein sizing, quantitation and molecular weight determination. J. Biochem. Biophys. Methods 2004, 60, 281–293. [Google Scholar] [CrossRef]

- Glew, R.H.; Glew, R.S.; Chuang, L.T.; Huang, Y.S.; Millson, M.; Constans, D.; Vanderjagt, D.J. Amino acid, mineral and fatty acid content of pumpkin seeds (Cucurbita spp.) and Cyperus esculentus nuts in the Republic of Niger. Plant Foods Hum. Nutr. 2006, 61, 51–56. [Google Scholar] [CrossRef]

- Sá, A.G.A.; da Silva, D.C.; Pacheco, M.T.B.; Moreno, Y.M.F.; Carciofi, B.A.M. Oilseed by-products as plant-based protein sources: Amino acid profile and digestibility. Future Foods 2021, 3, 100023. [Google Scholar] [CrossRef]

- Vidhya, C.S.; Loganathan, M.; Bhuvana, S.; Wadje, P.; Meenatchi, R. A study on the evaluation of proximate, fatty acid and amino acid profile of two species of pumpkin using advanced techniques. Uttar Pradesh J. Zool. 2022, 43, 74–83. [Google Scholar] [CrossRef]

- Sá, A.G.A.; Pacheco, M.T.B.; Moreno, Y.M.F.; Carciofi, B.A.M. Processing effects on the protein quality and functional properties of cold-pressed pumpkin seed meal. Food Res. Int. 2023, 169, 112876. [Google Scholar] [CrossRef]

- Dotto, J.M.; Chacha, J.S. The potential of pumpkin seeds as a functional food ingredient: A review. Sci. Afr. 2020, 10, e00575. [Google Scholar] [CrossRef]

- Sitohy, M.Z.; Desoky, E.S.M.; Osman, A.; Rady, M.M. Pumpkin seed protein hydrolysate treatment alleviates salt stress effects on Phaseolus vulgaris by elevating antioxidant capacity and recovering ion homeostasis. Sci. Hortic. 2020, 271, 109495. [Google Scholar] [CrossRef]

- Akintade, A.O.; Awolu, O.O.; Ifesan, B.O. Nutritional evaluation of fermented, germinated and roasted pumpkin (Cucurbita maxima) seed flour. Acta Univ. Cibiniensis. Ser. E 2019, 23, 179–186. [Google Scholar] [CrossRef]

- Prandi, B.; Faccini, A.; Lambertini, F.; Bencivenni, M.; Jorba, M.; Van Droogenbroek, B.; Bruggeman, G.; Schöber, J.; Petrusan, J.; Elst, K.; et al. Food wastes from agrifood industry as possible sources of proteins: A detailed molecular view on the composition of the nitrogen fraction, amino acid profile and racemisation degree of 39 food waste streams. Food Chem. 2019, 286, 567–575. [Google Scholar] [CrossRef] [PubMed]

- Latif, S.N.; Abdullah, N. The development of pumpkin seeds flour as supplemented products. J. Hosp. Netw. 2020, 1, 71–77. [Google Scholar]

- Hussain, A.; Kausar, T.; Sehar, S.; Sarwar, A.; Ashraf, A.H.; Jamil, M.A.; Noreen, S.; Rafique, A.; Iftikhar, K.; Aslam, J.; et al. Utilization of pumpkin, pumpkin powders, extracts, isolates, purified bioactives and pumpkin based functional food products: A key strategy to improve health in current post COVID 19 period: An updated review. Appl. Food Res. 2022, 2, 100241. [Google Scholar] [CrossRef] [PubMed]

- Kotova, E.E.; Kotov, S.A.; Gontova, T.M.; Kotov, A.G. Study of qualitative and quantitative content of amino acids in pumpkin seeds for further standardization of the herbal drug. Eur. Pharm. J. 2020, 67, 27–32. [Google Scholar] [CrossRef]

- Nikbakht Nasrabadi, M.; Sedaghat Doost, A.; Mezzenga, R. Modification approaches of plant-based proteins to improve their techno-functionality and use in food products. Food Hydrocoll. 2021, 118, 106789. [Google Scholar] [CrossRef]

- Vanga, S.K.K. Thermal and Electric Field Effects on Peanut Protein Using Molecular Modeling and “In-Vitro” Digestibility; McGill University: Montreal, QC, Canada, 2015. [Google Scholar]

- Setiowati, A.D.; Wijaya, W.; Van der Meeren, P. Whey protein-polysaccharide conjugates obtained via dry heat treatment to improve the heat stability of whey protein stabilized emulsions. Trends Food Sci. Technol. 2020, 98, 150–161. [Google Scholar] [CrossRef]

- Zhao, J.; Chen, H.; Zhang, Y. Impact of Heat Treatment on Seed Proteins. Food Chem. 2022, 365, 130508. [Google Scholar] [CrossRef]

- Liu, Q.; Zhang, X.; Zhang, J. Foaming and Emulsifying Properties of Proteins. J. Agric. Food Chem. 2021, 69, 7496–7504. [Google Scholar] [CrossRef]

- Bilal, M.; Iqbal, H.M.N. Sustainable bioconversion of food waste into high-value products by immobilized enzymes to meet bio-economy challenges and opportunities—A review. Food Res. Int. 2019, 123, 226–240. [Google Scholar] [CrossRef]

- Saheed, I.O.; Da Oh, W.D.; Suah, F.B.M. Chitosan modifications for adsorption of pollutants–A review. J. Hazard. Mater. 2021, 408, 124889. [Google Scholar] [CrossRef]

- Arnold, N.D.; Brück, W.M.; Garbe, D.; Brück, T.B. Enzymatic modification of native chitin and conversion to specialty chemical products. Mar. Drugs 2020, 18, 93. [Google Scholar] [CrossRef]

- Cruz-Casas, D.E.; Aguilar, C.N.; Ascacio-Valdés, J.A.; Rodríguez-Herrera, R.; Chávez-González, M.L.; Flores-Gallegos, A.C. Enzymatic hydrolysis and microbial fermentation: The most favorable biotechnological methods for the release of bioactive peptides. Food Chem. Mol. Sci. 2021, 3, 100047. [Google Scholar] [CrossRef]

- Akbari, M.; Razavi, S.H.; Kieliszek, M. Recent advances in microbial transglutaminase biosynthesis and its application in the food industry. Trends Food Sci. Technol. 2021, 110, 458–469. [Google Scholar] [CrossRef]

- Li, Y.; Gao, J.; Lv, J.; Lambo, M.T.; Wang, Y.; Wang, L.; Zhang, Y. Replacing soybean meal with high-oil pumpkin seed cake in the diet of lactating Holstein dairy cows modulated rumen bacteria and milk fatty acid profile. J. Dairy Sci. 2023, 106, 1803–1814. [Google Scholar] [CrossRef]

- Momen, S.; Alavi, F.; Aider, M. Alkali-mediated treatments for extraction and functional modification of proteins: Critical and application review. Trends Food Sci. Technol. 2021, 110, 778–797. [Google Scholar] [CrossRef]

- Momen, S.; Rodrigue, D.; Aider, M. Fabrication and characterization of heat-set composite gels obtained from complexation of electro-activated whey/canola proteins mixture. Food Hydrocoll. 2023, 141, 108751. [Google Scholar] [CrossRef]

- Navas, D.; Ibañez, A.; González, I.; Palma, J.L.; Dreyse, P. Controlled dispersion of ZnO nanoparticles produced by basic precipitation in solvothermal processes. Heliyon 2020, 6, e05821. [Google Scholar] [CrossRef] [PubMed]

- Muneer, F.; Johansson, E.; Hedenqvist, M.S.; Plivelic, T.S.; Kuktaite, R. Impact of pH modification on protein polymerization and structure–function relationships in potato protein and wheat gluten composites. Int. J. Mol. Sci. 2018, 20, 58. [Google Scholar] [CrossRef]

- Mao, H.; Yang, Y.; Zhang, H.; Zhang, J.; Huang, Y. A critical review of the possible effects of physical and chemical properties of subcritical water on the performance of water-based drilling fluids designed for ultra-high temperature and ultra-high pressure drilling applications. J. Pet. Sci. Eng. 2020, 187, 106795. [Google Scholar] [CrossRef]

- Andronie, A.; Danciu, C.; Calin, S. Analysis of Protein Functional Properties. Food Chem. 2022, 367, 130658. [Google Scholar] [CrossRef]

- Kim, J.H.; Park, J.S. Enzymatic Hydrolysis of Pumpkin Seed Proteins. Food Hydrocoll. 2021, 114, 106551. [Google Scholar] [CrossRef]

- Miller, D.J.; Althoff, J. pH Effects on Protein Solubility. Int. J. Food Sci. Technol. 2013, 48, 1683–1690. [Google Scholar] [CrossRef]

- Oracz, J.; Zyzelewicz, D. In vitro antioxidant activity and ftir characterization of high-molecular weight melanoidin fractions from different types of cocoa beans. Antioxidants 2019, 8, 560. [Google Scholar] [CrossRef] [PubMed]

- Win, N.N.; Phan, T.T.H.; Lee, J.H. Synergy of Proteins and Polyphenols. J. Food Sci. 2021, 86, 1534–1544. [Google Scholar] [CrossRef]

- Rezig, L.; Gharsallah, K.; Chouaibi, M. Bioactive Phytochemicals from Pumpkin Seed Oil-Processing By-Products. In Bioactive Phytochemicals from Vegetable Oil and Oilseed Processing By-Products; Springer International Publishing: Cham, Switzerland, 2022; pp. 1–55. [Google Scholar]

- Shen, Y.; Li, Y. Acylation modification and/or guar gum conjugation enhanced functional properties of pea protein isolate. Food Hydrocoll. 2021, 117, 106686. [Google Scholar] [CrossRef]

- Bilbrough, T.; Piemontese, E.; Seitz, O. Dissecting the role of protein phosphorylation: A chemical biology toolbox. Chem. Soc. Rev. 2022, 51, 5691–5730. [Google Scholar] [CrossRef]

- Wang, J.; Wang, J.; Wang, Q.; Ma, H. Ultrasonic-assisted extraction of proteins from plant-based foods: Mechanism and application. J. Food Eng. 2021, 292, 110251. [Google Scholar] [CrossRef]

- Zisu, B.; Brncic, M.; Gharibzahedi, S.M.T. The role of ultrasonics in dairy and non-dairy protein gelation: A review. Food Hydrocoll. 2017, 70, 369–382. [Google Scholar] [CrossRef]

- Agarwal, R.; Gupta, M.; Singh, A.K. Ultrasonic modification of plant proteins: A review on structure-functional properties relationship. Ultrason. Sonochem. 2022, 80, 105832. [Google Scholar] [CrossRef]

- Aadil, R.M.; Zeng, X.-A.; Han, Z.; Sun, D.-W. Sonication and its application for the treatment of food and food processing. Food Res. Int. 2019, 123, 473–480. [Google Scholar] [CrossRef]

- Jambrak, A.R.; Šimunović, K.; Djekic, I. Ultrasound effect on physical properties, texture and microstructure in food processing. Food Bioprocess Technol. 2018, 11, 1761–1776. [Google Scholar] [CrossRef]

- Alavi, F.; Chen, L.; Fryer, P.J. Plant protein-based emulsion gels as plant protein carriers: Effects of ultrasonic treatment on the physicochemical and functional properties. J. Food Sci. 2020, 85, 730–741. [Google Scholar] [CrossRef]

- Patel, A.; Ojha, S.; Kumar, L.; Kumar, V. Applications of ultrasound in food technology: Processing, preservation, and extraction. Food Eng. Rev. 2021, 13, 789–806. [Google Scholar] [CrossRef]

- Ma, H.; Zeng, X. High pressure processing of proteins and its effects on functional properties: A review. Food Eng. Rev. 2019, 11, 249–263. [Google Scholar] [CrossRef]

- McClements, D.J.; Weiss, J.; Decker, E.A. Advances in food emulsions and applications in plant-based foods. Annu. Rev. Food Sci. Technol. 2017, 8, 219–237. [Google Scholar] [CrossRef]

- Hu, H.; Wu, J.; Wang, Q. Advances in high-pressure processing of plant proteins. Trends Food Sci. Technol. 2020, 98, 19–31. [Google Scholar] [CrossRef]

- Pereira, R.N.; Vicente, A.A. Environmental impact of high-pressure processing. Food Bioprocess Technol. 2010, 3, 807–813. [Google Scholar] [CrossRef]

- Lalnunthari, C.; Devi, L.M.; Badwaik, L.S. Extraction of protein and pectin from pumpkin industry by-products and their utilization for developing edible film. J. Food Sci. Technol. 2020, 57, 1807–1816. [Google Scholar] [CrossRef]

- de Souza, D.; Sbardelotto, A.F.; Ziegler, D.R.; Marczak, L.D.F.; Tessaro, I.C. Characterization of rice starch and protein obtained by a fast alkaline extraction method. Food Chem. 2016, 191, 36–44. [Google Scholar] [CrossRef]

- Zhou, Y.; Wu, W.; Zhang, N.; Soladoye, O.P.; Zhang, Y.; Fu, Y. Deep eutectic solvents as new media for green extraction of food proteins: Opportunity and challenges. Food Res. Int. 2022, 161, 111842. [Google Scholar] [CrossRef]

- Öztürk, T.; Turhan, S. Physicochemical properties of pumpkin (Cucurbita pepo L.) seed kernel flour and its utilization in beef meatballs as a fat replacer and functional ingredient. J. Food Process. Preserv. 2020, 44, e14695. [Google Scholar] [CrossRef]

- Rani, R.; Kumar, S.; Yadav, S. Pumpkin and chia seed as dietary fibre source in meat products: A review. J. Pharm. Innov. J 2021, 10, 477–485. [Google Scholar]

- Uzlaşır, T.; Aktaş, N.; Gerçekaslan, K.E. Pumpkin seed oil as a partial animal fat replacer in bologna-type sausages. Food Sci. Anim. Resour. 2020, 40, 551–562. [Google Scholar] [CrossRef] [PubMed]

- Valdez-Arjona, L.P.; Ramírez-Mella, M. Pumpkin waste as livestock feed: Impact on nutrition and animal health and on quality of meat, milk, and egg. Animals 2019, 9, 769. [Google Scholar] [CrossRef] [PubMed]

- Galenko, O.; Hasyuk, O.; Kravchuk, V.; Medianuk, M. Study of combination of pumpkin seed flour and turkey meat in hams. Ukr. J. Food Sci. 2021, 9, 48–60. [Google Scholar] [CrossRef]

- Litvynchuk, S.; Galenko, O.; Cavicchi, A.; Ceccanti, C.; Mignani, C.; Guidi, L.; Shevchenko, A. Conformational changes in the structure of dough and bread enriched with pumpkin seed flour. Plants 2022, 11, 2762. [Google Scholar] [CrossRef]

- Goranova, Z.; Petrova, T.; Bakalov, I.; Baeva, M. Application of Pumpkin Seed Powder in Sponge Cakes. In Proceedings of the 8th International Specialized Scientific and Practical Conference, Kyiv, Ukraine, 12 September 2019. [Google Scholar] [CrossRef]

- Tomić, J.; Škrobot, D.; Maravić, N.; Hadnađev, M.; Dapčević-Hadnađev, T.; Popović, L.; Čakarević, J. Potential Use of Pumpkin Seed Oil Processing By-Product to Improve Quality of Gluten-Free Crackers. In Proceedings of the 8th International Conference—Sustainable Postharvest and Food Technologies—INOPTEP 2023, Subotica, Serbia, 23–28 April 2023. [Google Scholar]

- Shahein, M.R.; Atwaa, E.S.H.; Alrashdi, B.M.; Ramadan, M.F.; Abd El-Sattar, E.S.; Siam, A.A.H.; Alblihed, M.A.; Elmahallawy, E.K. Effect of Fermented Camel Milk Containing Pumpkin Seed Milk on the Oxidative Stress Induced by Carbon Tetrachloride in Experimental Rats. Fermentation 2022, 8, 223. [Google Scholar] [CrossRef]

- Habib, A.; Biswas, S.; Siddique, A.H.; Manirujjaman, M.; Uddin, B.; Hasan, S.; Rahman, M. Nutritional and lipid composition analysis of pumpkin seed (Cucurbita maxima Linn.). J. Nutr. Food Sci. 2015, 5, 374. [Google Scholar]

- Gao, D.; Helikh, A.; Duan, Z.; Xie, Q. Thermal, structural, and emulsifying properties of pumpkin seed protein isolate subjected to pH-shifting treatment. J. Food Meas. Charact. 2023, 17, 2301–2312. [Google Scholar] [CrossRef]

| Source/Seed Type | Protein Type | Protein Properties | Applications in Food Sector | References |

|---|---|---|---|---|

| Pumpkin Seeds | Albumin | High solubility | Emulsifiers, foaming agents, binders | [33] |

| Sunflower Seeds | Globulin | Good emulsifying capacity | Salad dressings, baked goods, protein bars | [34] |

| Chia Seeds | Albumin, Globulin | High in essential amino acids | Nutritional supplements, baking ingredients | [35] |

| Hemp Seeds | Globulin, Albumin | Balanced amino acid profile | Protein powders, vegan products, Snacks | [36] |

| Sesame Seeds | Globulin, Albumin | Rich in antioxidants | Tahini, halva, baked goods, salad toppings | [37] |

| Flax Seeds | Globulin, Albumin | Source of omega-3 fatty acids | Omega-3 supplements, baking ingredients | [38] |

| Functional Properties | Food System | References |

|---|---|---|

| Solubility | Beverages | [137] |

| Protein concentrates/isolates | ||

| Water—binding and holding capacity | Muscle foods | [24] |

| Cheese | ||

| Yogurt | ||

| Gelation | Muscle foods | [23] |

| Eggs | ||

| Yogurt | ||

| Gelation | ||

| Tofu | ||

| Baked goods | ||

| Emulsification | Salad dressing | [107] |

| Mayonnaise | ||

| Ice cream | ||

| Gravy | ||

| Foaming | Meringues | [138] |

| Whipped toppings | ||

| Angel cake | ||

| Marshmallows |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pandey, V.K.; Singh, K.; Suthar, T.; Srivastava, S.; Rustagi, S.; Ungai, D.; Kovács, B.; Shaikh, A.M. Current Strategies to Modify the Functional Properties of Proteins Extracted from Pumpkin Seeds: A Comprehensive Review. Horticulturae 2024, 10, 1194. https://doi.org/10.3390/horticulturae10111194

Pandey VK, Singh K, Suthar T, Srivastava S, Rustagi S, Ungai D, Kovács B, Shaikh AM. Current Strategies to Modify the Functional Properties of Proteins Extracted from Pumpkin Seeds: A Comprehensive Review. Horticulturae. 2024; 10(11):1194. https://doi.org/10.3390/horticulturae10111194

Chicago/Turabian StylePandey, Vinay Kumar, Kriti Singh, Tejas Suthar, Shivangi Srivastava, Sarvesh Rustagi, Diána Ungai, Béla Kovács, and Ayaz Mukarram Shaikh. 2024. "Current Strategies to Modify the Functional Properties of Proteins Extracted from Pumpkin Seeds: A Comprehensive Review" Horticulturae 10, no. 11: 1194. https://doi.org/10.3390/horticulturae10111194

APA StylePandey, V. K., Singh, K., Suthar, T., Srivastava, S., Rustagi, S., Ungai, D., Kovács, B., & Shaikh, A. M. (2024). Current Strategies to Modify the Functional Properties of Proteins Extracted from Pumpkin Seeds: A Comprehensive Review. Horticulturae, 10(11), 1194. https://doi.org/10.3390/horticulturae10111194