Does the Daily Light Integral Influence the Sowing Density of Tomato Plug Seedlings in a Controlled Environment?

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Sample Cultivation

2.2. Experimental Design

2.3. Analysis of the Growth

2.4. Analysis of the Gas Exchange Parameters

2.5. Root Activity

2.6. Analysis of Biomass Accumulation

2.7. Analysis of Seedling Quality

2.8. Analysis of Energy Consumption

2.9. Statistical Analysis

3. Results and Analysis

3.1. Effects of Light Intensity and Light Time on the Seedling Quality of Tomato

3.1.1. Biomass Accumulation

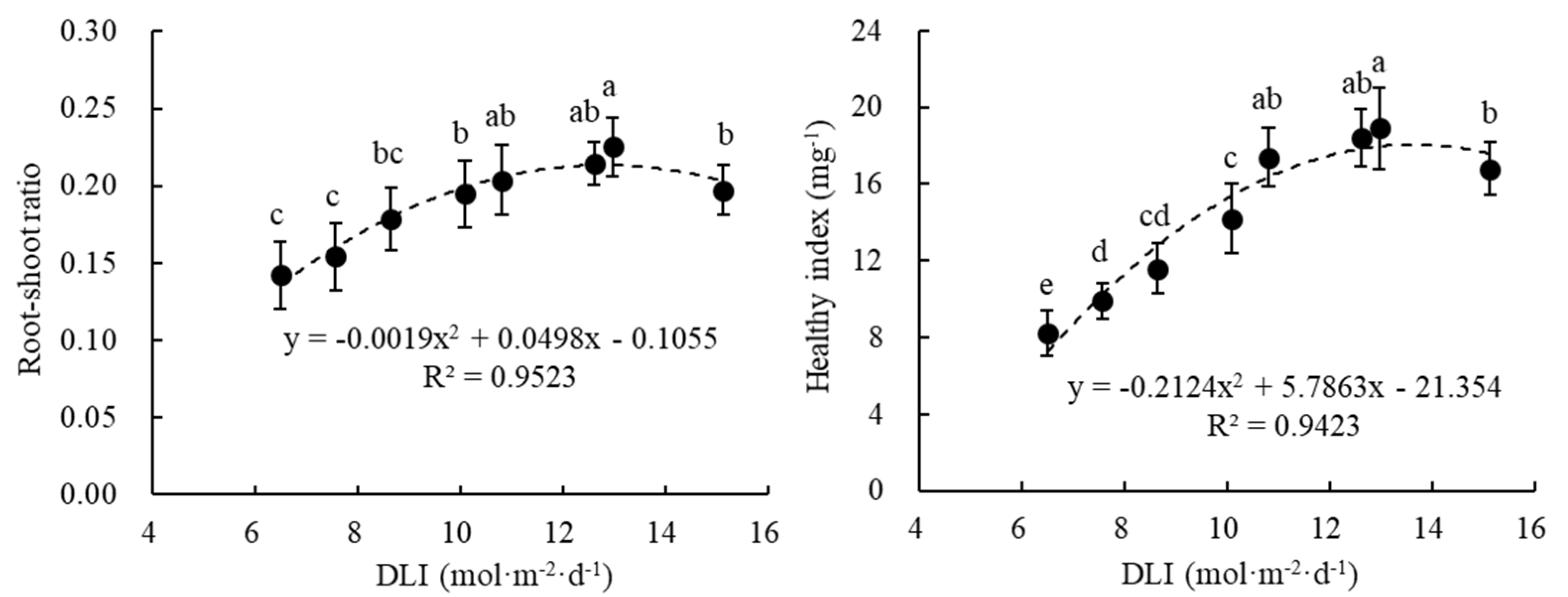

3.1.2. Seedling Quality

3.1.3. Energy Consumption

3.2. Effect of DLI and Sowing Density on the Seedling Quality of Tomato

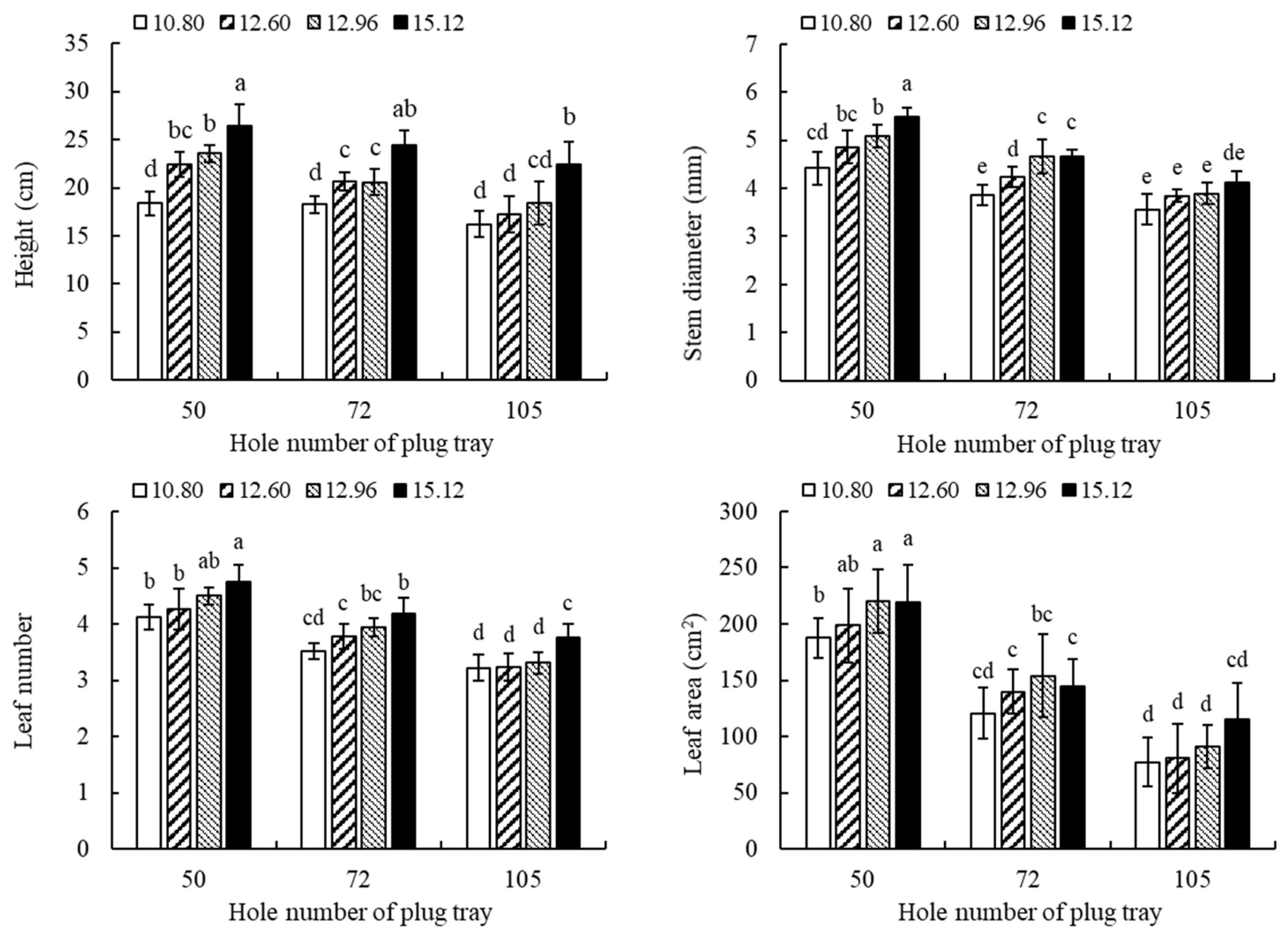

3.2.1. Growth

3.2.2. Photosynthetic Capacity

3.2.3. Root Activity

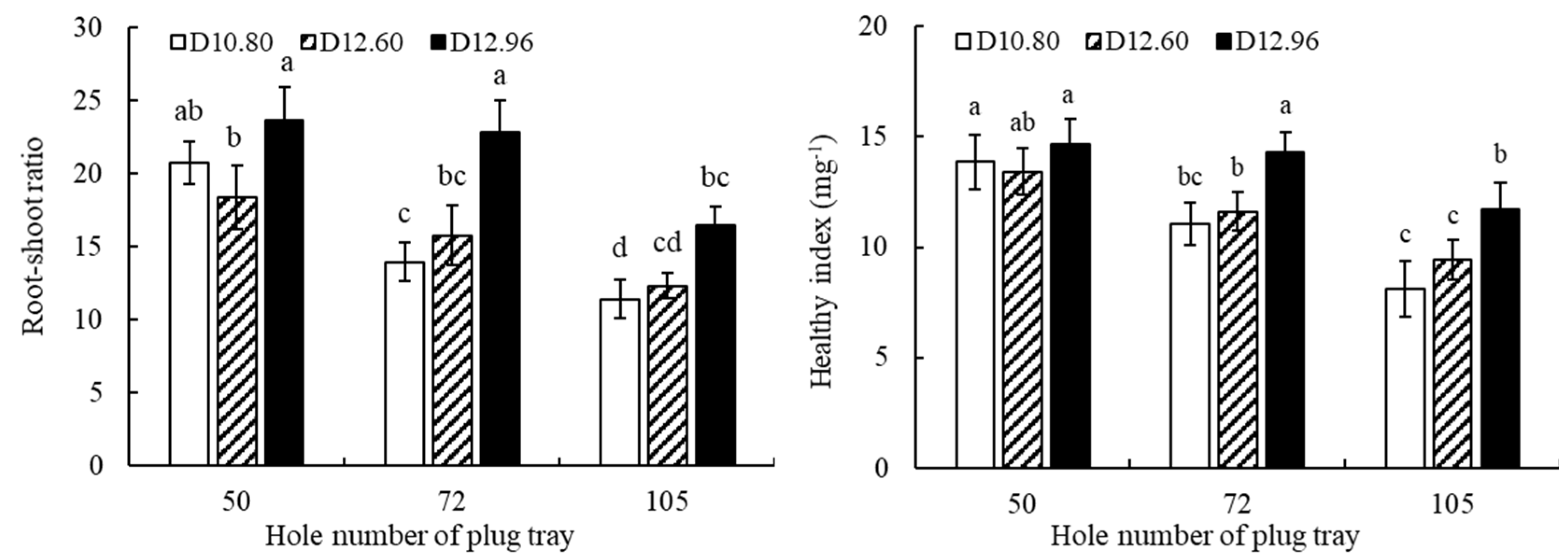

3.2.4. Biomass Accumulation

3.2.5. Energy Consumption

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sun, Y.; He, J.; Wei, F.; Yang, W. Evaluation on the development and international competitiveness of China’s tomato industry during the 13th Five-Year Plan period. China Cucurbits Veg. 2023, 36, 112–116. (In Chinese) [Google Scholar]

- Ali, A.; Cavallaro, V.; Santoro, P.; Mori, J.; Ferrante, A.; Cocetta, G. Quality and physiological evaluation of tomato subjected to different supplemental lighting systems. Sci. Hortic. 2024, 323, 112469. [Google Scholar] [CrossRef]

- Zhang, G.; Li, Z.; Cheng, J.; Cai, X.; Cheng, F.; Yang, Y.; Yan, Z. Morphological and physiological traits of greenhouse-grown tomato seedlings as influenced by supplemental white plus red versus red plus blue LEDs. Aronomy 2022, 12, 2450. [Google Scholar] [CrossRef]

- Mašková, T.; Herben, T. Root: Shoot ratio in developing seedlings: How seedlings change their allocation in response to seed mass and ambient nutrient supply. Ecol. Evol. 2018, 8, 7143–7150. [Google Scholar] [CrossRef]

- Song, J.; Fan, Y.; Li, X.; Li, Y.; Mao, H.; Zuo, Z.; Zou, Z. Effects of daily light integral on tomato (Solanum lycopersicon L.) grafting and quality in a controlled environment. Int. J. Agric. Biol. Eng. 2022, 15, 44–50. [Google Scholar] [CrossRef]

- Ji, F.; Gan, P.; Liu, N.; He, D.; Yang, P. Effects of LED spectrum and daily light integral on growth and energy use efficiency of tomato seedlings. Trans. Chin. Soc. Agric. Eng. 2020, 36, 231–238. (In Chinese) [Google Scholar]

- Kozai, T.; Niu, G. Plant Factory: Chapter 4: Plant Factory as a Resource-Efficient Closed Plant Production System; Academic Press: Cambridge, MA, USA, 2016; pp. 69–90. [Google Scholar]

- Costa, E.; Curi, T.; Figueiredo, T.; Binotti, F.; Cardoso, E. Kale seedlings production in different substrates, cell volumes and protected environments. Eng. Agrícola 2017, 37, 46–53. [Google Scholar] [CrossRef]

- Han, L.; Mo, M.; Gao, Y.; Ma, H.; Xiang, D.; Ma, G.; Mao, H. Effects of new compounds into substrates on seedling qualities for efficient transplanting. Agronomy 2022, 12, 983. [Google Scholar] [CrossRef]

- Singh, B.; Yadav, H.; Kumar, M.; Sirohi, N. Effect of plastic plug-tray cell size and shape on quality of soilless media grown tomato seedlings. Acta Hortic. 2007, 742, 57–60. [Google Scholar] [CrossRef]

- Zhou, M.; Sun, H.; Xu, X.; Yang, J.; Wang, G.; Wei, Z.; Xu, T.; Yin, J. Study on the method and mechanism of seedling picking for pepper (Capsicum annuum L.) plug seedlings. Agriculture 2024, 14, 11. [Google Scholar] [CrossRef]

- Goncalves, G.; Prins, C.; Diel, M.; Lucio, A. Plot and sample sizes for biometric variables in lettuce seedlings. Ciência Rural. Santa Maria 2024, 54, e20220471. [Google Scholar] [CrossRef]

- Wenneck, G.; Saath, R.; Rezende, R.; Vila, V.; Andrean, A.; Terassi, D. Cucumber seedlings production: Tray size impact on development. Braz. J. Biosyst. Eng. 2022, 16, 1079. [Google Scholar] [CrossRef]

- Kumi, F.; Korkpoe, F.; Osei, G. Influence of plug cell volume and substrate type on the development of cucumber seedlings for transplanting. Int. J. Technol. Manag. Res. 2020, 4, 50–64. [Google Scholar] [CrossRef]

- Garcia, C.; Lopez, R. Supplemental radiation quality influences cucumber, tomato, and pepper transplant growth and development. HortScience 2020, 55, 804–811. [Google Scholar] [CrossRef]

- Song, J.; Cao, K.; Hao, Y.; Song, S.; Su, W.; Liu, H. Hypocotyl elongation is regulated by supplemental blue and red light in cucumber seedling. Gene 2019, 707, 117–125. [Google Scholar] [CrossRef] [PubMed]

- Song, J.; He, D.; Wang, J.; Mao, H. How to diagnose potassium abundance and deficiency in tomato leaves at the early cultivation stage. Horticulturae 2023, 9, 1225. [Google Scholar] [CrossRef]

- Ma, G.; Mao, H.; Bu, Q.; Han, L.; Shabbir, A.; Gao, F. Effect of compound biochar substrate on the root growth of cucumber plug seedlings. Agronomy 2020, 10, 1080. [Google Scholar] [CrossRef]

- Garland, K.; Burnett, S.; Day, M.; Iersel, M. Influence of substrate water content and daily light integral on photosynthesis, water use efficiency, and morphology of heuchera americana. J. Am. Soc. Hortic. Sci. 2012, 137, 57–67. [Google Scholar] [CrossRef]

- Zha, L.; Liu, W. Effects of light quality, light intensity, and photoperiod on growth and yield of cherry radish grown under red plus blue LEDs. Hortic. Environ. Biotechnol. 2018, 59, 511–518. [Google Scholar] [CrossRef]

- Wu, Y.; Gong, W.; Yang, W. Shade inhibits leaf size by controlling cell proliferation and enlargement in soybean. Sci. Rep. 2017, 7, 9259. [Google Scholar] [CrossRef]

- Feng, L.; Raza, M.; Li, Z.; Chen, Y.; Khalid, M.; Du, J.; Liu, W.; Wu, X.; Song, C.; Yu, L.; et al. The influence of light intensity and leaf movement on photosynthesis characteristics and carbon balance of soybean. Front. Plant Sci. 2019, 9, 1952. [Google Scholar] [CrossRef]

- Yang, Y.; Dong, L.; Shi, L.; Guo, J.; Jiao, Y.; Xiong, H.; Dickson, R.; Shi, A. Effects of low temperature and low light on physiology of tomato seedlings. Am. J. Plant Sci. 2020, 11, 162–179. [Google Scholar] [CrossRef][Green Version]

- Wang, D.; Wang, S.; Wang, Y. Responses of seedlings to light temporal heterogeneity in different habitats. Chin. J. Ecol. 2024, 43, 86–95. [Google Scholar]

- Oh, W.; Runkle, E.; Warner, R. Daily light integral during the seedling stage influences transplant quality and subsequent performance in selected annual plants. Hortscience 2008, 43, 1123. [Google Scholar]

- Yu, P.; Song, J.; Cai, W.; Li, Y.; Fan, Y.; Shen, C.; Qu, K.; Mao, H. Effects of LED supplementary light intensity and supplementary light time at night on seedling quality of tomato in the controlled environment. Jiangsu J. Agric. Sci. 2023, 39, 1917–1926. (In Chinese) [Google Scholar]

- Yang, Z.; He, W.; Mou, S.; Wang, X.; Chen, D.; Hu, X.; Chen, L.; Bai, J. Plant growth and development of pepper seedlings under different photoperiods and photon flux ratios of red and blue LEDs. Trans. Chin. Soc. Agric. Eng. 2017, 33, 173–180. [Google Scholar]

- Gao, W.; He, D.; Ji, F.; Zhang, S.; Zheng, J. Effects of daily light integral and LED spectrum on growth and nutritional quality of hydroponic spinach. Agronomy 2020, 10, 1082. [Google Scholar] [CrossRef]

- Zhang, X.; He, D.; Niu, G.; Yan, Z.; Song, J. Effects of environment lighting on the growth, photosynthesis, and quality of hydroponic lettuce in a plant factory. Int. J. Agric. Biol. Eng. 2018, 11, 33–40. [Google Scholar] [CrossRef]

- Yan, Z.; He, D.; Niu, G.; Zhou, Q.; Qu, Y. Growth, nutritional quality, and energy use efficiency of hydroponic lettuce as influenced by daily light integrals exposed to white versus white plus red light-emitting diodes. Hortscience 2019, 54, 1737–1744. [Google Scholar] [CrossRef]

- Fan, X.; Xu, Z.; Liu, X.; Tang, C.; Wang, L.; Han, X. Effects of light intensity on the growth and leaf development of young tomato plants grown under a combination of red and blue light. Sci. Hortic. 2013, 153, 50–55. [Google Scholar] [CrossRef]

- Cavalcanti, S.; Gomes, N.; Pandorfi, H.; Almeida, G.; Montenegro, A. Variação espaço-temporal da temperatura do substrato em bandejas de produção de mudas. Rev. Agric. Neotrop. 2019, 6, 66–73. [Google Scholar] [CrossRef]

- Al-Menaie, H.; Al-Ragam, O.; Al-Dosery, N.; Zalzaleh, M.; Mathew, M.; Suresh, N. Effect of pot size on plant growth and multiplication of water lilies (Nymphaea sp). Am.-Eurasian J. Agric. Environ. Sci. 2012, 12, 148–153. [Google Scholar]

- Takashi, F.; Kunio, S.; Takashi, O.; Mansu, C. Growth characteristics of cabbage plug seedlings due to mutual shading among neighboring seedlings. Biosyst. Eng. 2014, 121, 77–84. [Google Scholar]

- Poel, B.; Runkle, E. Evaluating light-emitting diodes for use in supplemental greenhouse lighting for seedling plug production. Hortscience 2015, 50, 252. [Google Scholar]

- Kim, S.; Jung, T.; Lee, Y.; Song, D.; Yu, H.; Lee, C.; Kim, Y. Effect of nursery stage and plug cell size on seedling growth of waxy corn. Korean J. Crop Sci. 2009, 54, 407–415. [Google Scholar]

- Zhang, C.; Akhlaq, M.; Yan, H.; Ni, Y.; Liang, S.; Zhou, J.; Xue, R.; Li, M.; Adnan, R.; Li, J. Chlorophyll fluorescence parameter as a predictor of tomato growth and yield under CO2 enrichment in protective cultivation. Agric. Water Manag. 2023, 284, 108333. [Google Scholar] [CrossRef]

- Hou, M.; Ni, J.; Mao, H. Effects of airflow disturbance on the content of biochemical components and mechanical properties of cucumber seedling stems. Agronomy 2023, 13, 1125. [Google Scholar] [CrossRef]

- Hermans, C.; Hammond, J.; White, P.; Verbruggen, N. How do plants respond to nutrient shortage by biomass allocation. Trends Plant Sci. 2006, 11, 610–617. [Google Scholar] [CrossRef] [PubMed]

- Jang, D.; Kwon, Y.; Choi, K.; Kim, S. Comparison of growth characteristics fruit vegetable seedlings grown on cylindrical paper pot trays of plug trays. Prot. Hortic. Plant Fact. 2018, 27, 381–390. [Google Scholar] [CrossRef]

- Costa, E.; Durante, L.; Santos, A.; Ferreira, C. Production of eggplant from seedlings produced in different environments, containers and substrates. Hortic. Bras. 2013, 31, 139–146. [Google Scholar] [CrossRef]

| Treatment | Energy Consumption (KWh g−1 DW) | LUE | EUE |

|---|---|---|---|

| P150-H12 | 0.230 ± 0.024 a | 0.076 ± 0.013 b | 0.022 ± 0.004 b |

| P200-H12 | 0.227 ± 0.018 a | 0.074 ± 0.011 b | 0.023 ± 0.006 b |

| P250-H12 | 0.180 ± 0.024 b | 0.091 ± 0.010 ab | 0.029 ± 0.004 ab |

| P300-H12 | 0.161 ± 0.028 b | 0.101 ± 0.016 a | 0.032 ± 0.004 a |

| P150-H14 | 0.228 ± 0.032 a | 0.076 ± 0.007 b | 0.023 ± 0.002 b |

| P200-H14 | 0.223 ± 0.018 a | 0.075 ± 0.012 b | 0.023 ± 0.004 b |

| P250-H14 | 0.182 ± 0.021 b | 0.090 ± 0.009 ab | 0.028 ± 0.003 ab |

| P300-H14 | 0.203 ± 0.026 ab | 0.080 ± 0.008 b | 0.025 ± 0.003 b |

| Treatment | Net Photosynthetic Rate (μmol·m−2·s−1) | Stomatal Conductivity (mol·m−2·s−1) | Intercellular CO2 Concentration (μmol·mol−1) | Transpiration Rate (mmol·m−2·s−1) |

|---|---|---|---|---|

| D10.80-K50 | 17.6 ± 1.4 b | 0.377 ± 0.056 ab | 696 ± 32 b | 3.42 ± 0.54 ab |

| D12.60-K50 | 18.7 ± 1.2 ab | 0.421 ± 0.043 ab. | 684 ± 25 bc | 3.75 ± 0.47 ab |

| D12.96-K50 | 20.3 ± 0.9 a | 0.446 ± 0.039 a | 645 ± 27 c | 3.96 ± 0.23 a |

| D10.80-K75 | 15.3 ± 0.8 c | 0.364 ± 0.046 ab | 719 ± 31 ab | 3.19 ± 0.34 b |

| D12.60-K75 | 16.2 ± 0.9 bc | 0.385 ± 0.049 ab | 710 ± 29 ab | 3.22 ± 0.21 b |

| D12.96-K75 | 18.6 ± 1.1 ab | 0.398 ± 0.031 ab | 672 ± 19 bc | 3.87 ± 0.19 a |

| D10.80-K105 | 12.2 ± 1.6 d | 0.335 ± 0.032 b | 739 ± 24 a | 2.63 ± 0.26 c |

| D12.60-K105 | 14.3 ± 1.5 cd | 0.341 ± 0.037 b | 724 ± 19 ab | 2.64 ± 0.23 c |

| D12.96-K105 | 14.7 ± 1.4 cd | 0.342 ± 0.042 b | 715 ± 27 ab | 2.86 ± 0.33 bc |

| Treatment | Energy Consumption (KWh g−1 DW) | LUE | EUE |

|---|---|---|---|

| D10.80-K50 | 0.34 ± 0.023 a | 0.048 ± 0.007 c | 0.015 ± 0.003 c |

| D12.60-K50 | 0.37 ± 0.019 a | 0.044 ± 0.009 c | 0.014 ± 0.002 c |

| D12.96-K50 | 0.34 ± 0.017 a | 0.047 ± 0.009 c | 0.015 ± 0.002 c |

| D10.80-K75 | 0.26 ± 0.022 bc | 0.063 ± 0.007 b | 0.020 ± 0.003 b |

| D12.60-K75 | 0.28 ± 0.016 b | 0.058 ± 0.006 bc | 0.018 ± 0.003 bc |

| D12.96-K75 | 0.26 ± 0.024 bc | 0.063 ± 0.005 b | 0.020 ± 0.002 b |

| D10.80-K105 | 0.25 ± 0.021 c | 0.065 ± 0.004 b | 0.020 ± 0.003 b |

| D12.60-K105 | 0.26 ± 0.017 bc | 0.063 ± 0.006 b | 0.020 ± 0.002 b |

| D12.96-K105 | 0.20 ± 0.018 d | 0.081 ± 0.004 a | 0.026 ± 0.003 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, X.; Yang, F.; Song, J.; Zhang, R.; Cai, W. Does the Daily Light Integral Influence the Sowing Density of Tomato Plug Seedlings in a Controlled Environment? Horticulturae 2024, 10, 730. https://doi.org/10.3390/horticulturae10070730

Xu X, Yang F, Song J, Zhang R, Cai W. Does the Daily Light Integral Influence the Sowing Density of Tomato Plug Seedlings in a Controlled Environment? Horticulturae. 2024; 10(7):730. https://doi.org/10.3390/horticulturae10070730

Chicago/Turabian StyleXu, Xiangru, Fulin Yang, Jinxiu Song, Rong Zhang, and Wei Cai. 2024. "Does the Daily Light Integral Influence the Sowing Density of Tomato Plug Seedlings in a Controlled Environment?" Horticulturae 10, no. 7: 730. https://doi.org/10.3390/horticulturae10070730

APA StyleXu, X., Yang, F., Song, J., Zhang, R., & Cai, W. (2024). Does the Daily Light Integral Influence the Sowing Density of Tomato Plug Seedlings in a Controlled Environment? Horticulturae, 10(7), 730. https://doi.org/10.3390/horticulturae10070730