Aroma Compounds from Grape Pomace: Investigation of Key Winemaking Factors for Future Extraction Applications—A Review

Abstract

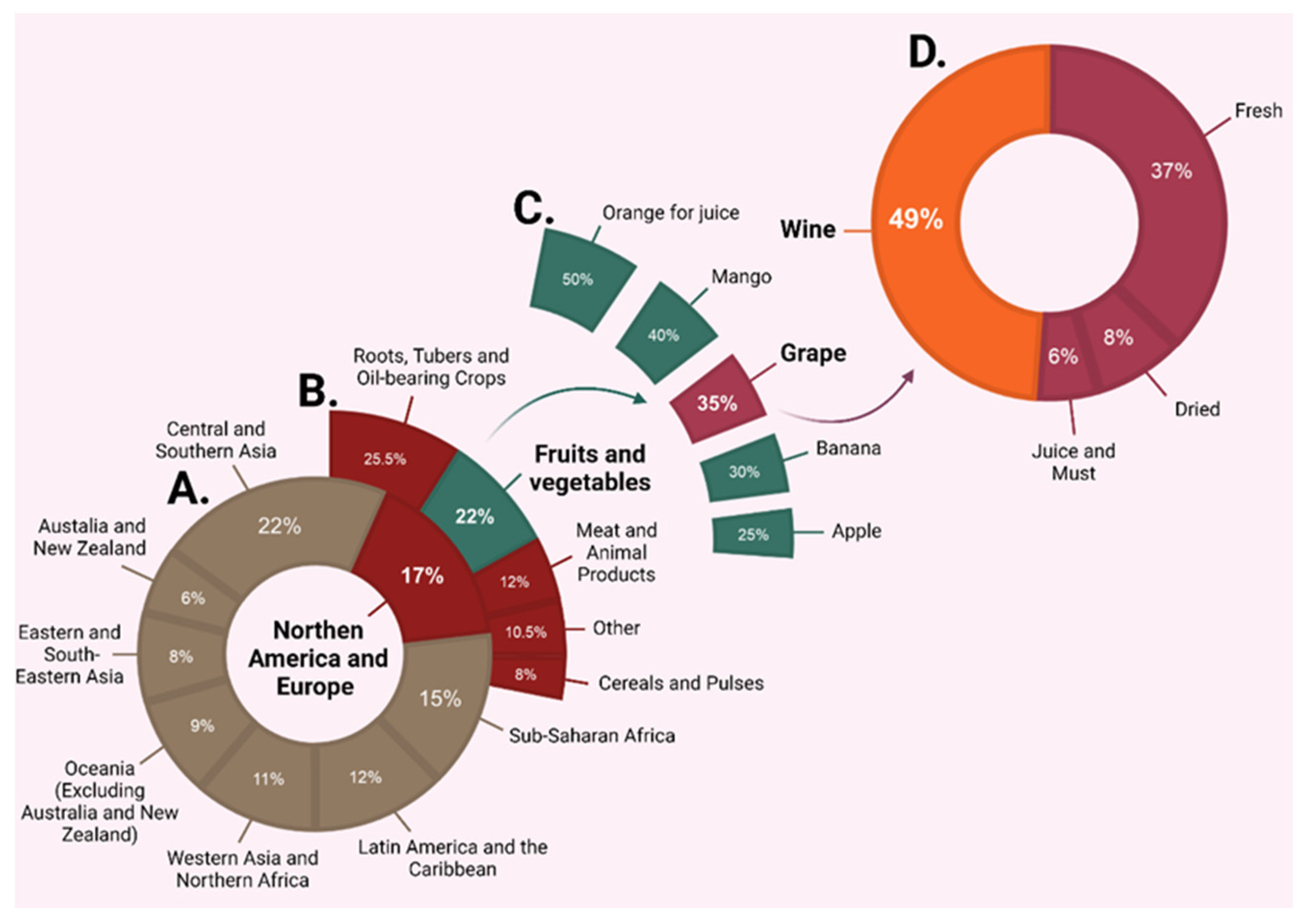

:1. Introduction

2. Characterization of Aroma Compounds from Grapes: Profiles and Their Impact on Flavor

2.1. C13-Norisoprenoids

2.2. Terpenes

2.3. Sulfur-Derived Organic Compounds (Thiols)

2.4. Methoxypyrazines

3. Factors Influencing Aromatic Compounds in Viticulture and Winemaking Processes

3.1. Irrigation

3.2. Leaf Removal

3.3. Bunch Thinning

| Viticultural/Oenological Practice | Grape Variety | Registered Aroma Compound Changes | Aroma Descriptors * |

|---|---|---|---|

| Irrigation | Merlot [60] | C13-norisoprenois ↑ | Fruity [37], herbaceous, floral [81] |

| Tocai Friulano [64] | Monoterpenes ↑ | Rose, fruity, herbal, citric, floral [82] | |

| Merlot [64] | Monoterpenes ↕ | ||

| Bobal [66] | C13-norisoprenois ↑ | Fruity [37], herbaceous, floral [81] | |

| Leaf removal | Sauvignon Blanc [67] | Thiols ↕ | Fruity, flinty, mineral [44,83] |

| Sauvignon Blanc [71] | Monoterpenes ↑ | Rose, fruity, herbal, citric, floral [82] | |

| Semillon [68] | Monoterpenes ↑ | Rose, fruity, herbal, citric, floral [82] | |

| C13-norisoprenois ↑ | Fruity [37], herbaceous, floral [81] | ||

| Cabernet Franc [72] | C13-norisoprenois ↓ | Fruity [37], herbaceous, floral [81] | |

| Petit Verdot [72] | C13-norisoprenois ↓ | Fruity [37], herbaceous, floral [81] | |

| Nero d’Avola [73] | Monoterpenes ↑ | Rose, fruity, herbal, citric, floral [82] | |

| Pinot Noir [74] | Monoterpenes ↑ | Rose, fruity, herbal, citric, floral [82] | |

| Bunch thinning | Syrah [75] | Varietal aromas ↑ | Black pepper, fruity, black olive [84] |

| Esters ↑ | Fruity [85,86] | ||

| Higher alcohols ↑ | Fruity, floral, honey [87] | ||

| Terpenes ↑ | Fruity, floral, muscatel [88] | ||

| Pinot Noir [76] | Monoterpenes ↑ | Rose, fruity, herbal, citric, floral [82] | |

| C13-norisoprenois ↑ | Fruity [37], herbaceous, floral [81] | ||

| Medium-chain fatty acids ↓ | Fruity [89] | ||

| Maraština [77] | Terpene ↑ | Fruity, floral, muscatel [88] | |

| Esters ↑ | Fruity [85,86] | ||

| Cabernet Sauvignon [78] | C13-norisoprenois ↑ | Fruity [37], herbaceous, floral [81] | |

| Terpene ↕ | Fruity, floral, muscatel [88] | ||

| Fertilization | Sauvignon Blanc [90] | Thiols ↑ | Fruity, flinty, mineral [44,83] |

| Merlot [81] | Thiols ↑ | Fruity, flinty, mineral [44,83] | |

| Sauvignon Blanc [91] | Thiols ↓ | Fruity, flinty, mineral [44,83] | |

| Merlot [91] | Thiols ↓ | Fruity, flinty, mineral [44,83] | |

| Cabernet Sauvignon [91] | Thiols ↓ | Fruity, flinty, mineral [44,83] | |

| Pre-fermentation practices | |||

| Maceratin | Sauvignon Blanc [92] | Thiols ↑ | Fruity, flinty, mineral [44,83] |

| Pyrazines ↕ | Green aromas [93] | ||

| Tannat [94] | Esters ↑ | Fruity [85,86] | |

| Higher alcohols ↑ | Fruity, floral, honey [87] | ||

| Monastrell [95] | Esters ↑ | Fruity [85,86] | |

| Acetates ↑ | Citrus, sweet/acid fruit, berry, floral [96] | ||

| Higher alcohols ↑ | Fruity, floral, honey [87] | ||

| Enzyme addition | Mencia [97] | Acetates ↑ | Citrus, sweet/acid fruit, berry, floral [96] |

| Albariño [98] | Terpenes ↑ | Fruity, floral, muscatel [88] | |

| C13-norisoprenois ↑ | Fruity [37], herbaceous, floral [81] | ||

| Pressing pressure | Sauvignon Blanc [99] | Thiols ↑ | Fruity, flinty, mineral [44,83] |

| Fermentation practices (Temperature/yeast strain) | Merlot [100] | Terpenes ↑ | Fruity, floral, muscatel [88] |

| Moscatell [101] | Esters ↑ | Fruity [85,86] | |

| Aurore [102] | Esters ↑ | Fruity [85,86] | |

| 3-methyl-1-butanol ↓ | Earthy, solvent [103] | ||

| 2-phenylethanol ↓ | Floral, rose [103] | ||

| Amyl alcohols ↑ | Fusel [104], herbaceous, whiskey, malt, burnt [105] | ||

| Aurore [102] | Esters ↑ | Fruity [85,86] | |

| 3-methyl-1-butanol ↓ | Earthy, solvent [103] | ||

| 2-phenylethanol ↓ | Floral, rose [103] | ||

| Amyl alcohols ↑ | Fusel [104], herbaceous, whiskey, malt, burnt [105] | ||

| Syrah [106,107] | Terpenes ↑ | Fruity, floral, muscatel [88] | |

| Sauvignon Blanc [106,107] | Terpenes ↑ | Fruity, floral, muscatel [88] | |

| Tempranillo [108] | Higher alcohols ↑ | Fruity, floral, honey [87] | |

| Verdejo [109] | Higher alcohols ↑ | Fruity, floral, honey [87] | |

| Syrah [110] | Higher alcohols ↑ | Fruity, floral, honey [87] | |

| Soave, Chardonnay [111] | Higher alcohols ↓ | Fruity, floral, honey [87] | |

| Barbera [112] | Higher alcohols ↓ | Fruity, floral, honey [87] | |

| Verdicchio [112] | Esters ↑ | Fruity [85,86] |

3.4. Fertilization

3.5. Pre-Fermentation Practices

3.6. Fermentation Practices

3.6.1. Temperature

3.6.2. Yeast Strain

3.6.3. Winemaking Aids (SO2 and Its Alternatives)

4. Volatile Compound Profile of the Grape Pomace

4.1. Red Grape Varieties

4.2. White Grape Varieties

| Grape Pomace (Variety) | Region | Particular Examined Parameters | Main Volatile Compounds | Concentration (µg/mL) | Aroma Descriptor ** | Analysis Method | References |

|---|---|---|---|---|---|---|---|

| Chardonnay | Australia | Alcohols | 1-butanol | 0.84–0.96 | Alcohol, medicine [154] | GC-MS | [153] |

| 1-hexanol | 1.58–9.25 | Floral, cut grass, herbaceous [154,155], woody, resin [156] | |||||

| Esters | 3-methylbutyl acetate | 0.01–0.02 | Banana [157] | ||||

| Ethyl benzoate | 0.01–0.02 | Floral, fruity, chamomile [158] | |||||

| Aldehydes | 2-undecanone | 0.01 | Pineapple, fruity notes [159] | ||||

| Phenols | Phenylacetaldehyde | 0.08–0.87 | Fruity [159] | ||||

| Benzyl alcohol | 0.17–0.92 | Chocolate, fig, tobacco [160] | |||||

| 2-Phenylethanol | 0.16–0.76 | Floral, rose [103] | |||||

| Terpenes | Nerol | 0.03 | Lime, roses [161] | ||||

| Geraniol | 0.21–0.22 | Citrus, floral, geranium [157] | |||||

| Nero d’Avola Frappato Nerello Mascalese Cabernet Sauvignon | Italy | Esters | Ethyl hexanoate | 0.38–1.08 | Anise, caramel, fruity, wine [156] | GC-FID/GC-MS | [137] |

| Ethyl octanoate | 0–0.02 | Fruit, musty, soapy, sweet, waxy [156] | |||||

| Ethyl decanoate | 0.01–0.03 | Brandy, fruity, grape [105] | |||||

| Ethyl dodecanoate | 0.01–0.02 | Fruity, soapy, sweet [156] | |||||

| Orujos *** | Spain Italy | Alcohols | 2-butanol | 0.01–0.06 | Alcohol, medicine, off-flavor [154] | GC-MS | [150] |

| 1-propanol | 0.17–0.2 | Fusel, alcohol, ripe fruit [162] | |||||

| 3-methyl-1-butanol | 0.52–0.89 | Earthy, solvent [103] | |||||

| 2-methyl-1-butanol | 0.16–0.3 | Fermented, malty, wine [163] | |||||

| 1-hexanol | 0.03 | Floral, cut grass, herbaceous [154,155], woody, resin [156] | |||||

| 2-phenylethanol | 0.04–0.07 | Floral, rose [103] | |||||

| Acetates | Ethyl acetate | 0.3–0.45 | Fruity [160], nail polish remover [103] | ||||

| Ethyl decanoate | 0.05–0.07 | Fruity, apple [158] | |||||

| Ethyl lactate | 0.06–0.23 | Solvent [103] | |||||

| Aldehydes and acetals | 1,1-diethoxyethane | 0.04–0.9 | Licorices, nutty, pungent, wood [156] | ||||

| Acetaldehyde | 0.23–0.25 | Unripe walnut, bruised fruit [164] | |||||

| Variety not mentioned (red grapes) | Romania | Aldehydes | Acetaldehyde | 0.03–0.04 | Unripe walnut, bruised fruit [164] | GC-FID | [145] |

| Acetates | Ethyl acetate | 0.1–0.16 | Fruity [160], nail polish remover [103] | ||||

| Alcohols | Methanol | 0.65–0.73 | Alcohol [165] | ||||

| 1-propanol | 0.03 | Alcohol [158] | |||||

| Isobutylic alcohol | 0.07–0.08 | Alcohol, nail polish, fusel [105] | |||||

| Isoamylic alcohol | 0.12–0.14 | Fusel [104], Herbaceous, whiskey, malty, burnt [105] | |||||

| Muscat de Frontignan | France | Alcohols | 1-hexanol | ns * (+++) | Floral, cut grass, herbaceous [154,155], woody, resin [156] | GC-FID/GC-MS | [151] |

| Cis 2-hexen-1-ol | ns * (++) | Grass aroma, apples [166] | |||||

| Cis 3-hexen-1-ol | ns * (++) | Green aroma [167] | |||||

| 2-octen-1-ol | ns * (++) | Fresh mushroom [168] | |||||

| 2-phenyl-1-ethanol | ns * (+) | Rose [87] | |||||

| Aldehydes | Hexanal | ns * (+++) | Floral [159] | ||||

| Benzaldehyde | ns * (+) | Almond, fragrant [105] | |||||

| Phenylacetaldehyde | ns * (+) | Fruity [159] | |||||

| Ketones | 3-hydroxy-2-butanone | ns * (+) | Unctuous, milky [169] | ||||

| Esters | 3-methylbutyl acetate | ns * (+) | Fruity, bananas, pears, acetone [170] | ||||

| Hexyl acetate | ns * (+) | Redberry [103] | |||||

| Lactones | y-butyrolactone | ns * (+) | Creamy, oily, fatty, caramel [171] | ||||

| Terpenes | β-citronellol | ns * (+++) | Citrus, clove, floral, fresh, green, rose, sour, sweet [105] | ||||

| Geraniol | ns * (+++) | Citrus, floral, geranium [157] | |||||

| Linalool | ns * (+++) | Floral, lavender [105] | |||||

| Nerol | ns * (+++) | Lime, roses [161] | |||||

| α-terpineol | ns * (++) | Flowers, lilies, sweet [105] | |||||

| Kalambaki, Roditis, Xinomavro, Zambella, Agiorgitico | Greece | Alcohols | Methanol | 0.41–0.98 | Alcohol [165] | GC-MS | [144] |

| 1-propanol | 0.06–0.28 | Alcohol [158] | |||||

| 2-methyl-butanol | 0.13–0.83 | Fermented, malty, wine [163] | |||||

| 2-methyl-propanol | 0.11–0.35 | Alcohol, nail polish, fusel [105] | |||||

| Hexanol-1 | 0–0.17 | Floral, cut grass, herbaceous [154,155], woody, resin [156] | |||||

| 3-Methyl-butanol | 0.14–0.70 | Fusel [104], herbaceous, whiskey, malty, burnt [105] | |||||

| Aldehydes | Acetaldehydes | 0.19–0.92 | Unripe walnut, bruised fruit [164] | ||||

| Esters | Ethyl acetate | 0.15–0.66 | Fruity [160], nail polish remover [103] |

5. Exploring Sensorial Characteristics in Pomace Valorization: The Impact of Long-Maceration on White Wines

6. Extraction Methods

6.1. Conventional Extraction Methods

6.2. Novel Extraction Methods

7. Applications of Aroma Compounds Extracted from Grape Pomace

7.1. Food and Beverage Industry

7.2. Other Industries

8. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| FAO | Food and Agriculture Organization |

| TDN | 1,6-trimethyl-1,2-dihydronaphthalene |

| TPB | (E)-1-(2,3,6-trimethylphenyl)buta-1,3-diene |

| GSH | Glutathione |

| Cys | Cysteinylated conjugates |

| 4MMP | 4-mercapto-4-methylpentan-2-one |

| 3MH | 3-mercaptohexan-1-ol |

| 3MHA | 3-mercaptohexyl acetate |

| Cys3MH | S-3-(hexane-1-ol)-cysteine |

| Cys4MMP | S-3-(4-mercapto-4-methyl pentane-2-one)-cysteine |

| G3MH | S-3-(hexane-1-ol)-glutathione |

| G4MMP | S-3-(4-mercapto-4-methyl pentane-2-one)-glutathione |

| MPs | Methoxypyrazines |

| MOMP | 2-methoxypyrazine |

| ETMP | 3-ethyl-2-methoxypyrazine |

| MEMP | 3-methyl-2-methoxypyrazine |

| MIBP | 2-methoxy-3-isobutylpyrazine |

| IBMP | 3-isobutyl-2-methoxypyrazine |

| IPMP | 3-isopropyl-2-methoxypyrazine |

| SBMP | 3-sec-butyl-2-methoxypyrazine |

| HLR | Hand leaf removal |

| MLR | Mechanical leaf removal |

| SO2 | Sulfur dioxide |

| VOCs | Volatile organic compounds |

| GC-MS | Gas chromatography–mass spectrometry |

| GC-FID | Gas Chromatography—Flame Ionization Detector |

References

- Caldeira, C.; De Laurentiis, V.; Corrado, S.; van Holsteijn, F.; Sala, S. Quantification of food waste per product group along the food supply chain in the European Union: A mass flow analysis. Resour. Conserv. Recycl. 2019, 149, 479–488. [Google Scholar] [CrossRef] [PubMed]

- Godfray, H.C.; Beddington, J.R.; Crute, I.R.; Haddad, L.; Lawrence, D.; Muir, J.F.; Pretty, J.; Robinson, S.; Thomas, S.M.; Toulmin, C. Food security: The challenge of feeding 9 billion people. Science 2010, 327, 812–818. [Google Scholar] [CrossRef] [PubMed]

- Food and Agriculture Organization of the United Nations. The Future of Food and Agriculture: Trends and Challenges; Food and Agriculture Organization of the United Nations: Rome, Italy, 2017; p. 163. [Google Scholar]

- Comunian, T.A.; Silva, M.P.; Souza, C.J.F. The use of food by-products as a novel for functional foods: Their use as ingredients and for the encapsulation process. Trends Food Sci. Technol. 2021, 108, 269–280. [Google Scholar] [CrossRef]

- Sheahan, M.; Barrett, C.B. Review: Food loss and waste in Sub-Saharan Africa. Food Policy 2017, 70, 1–12. [Google Scholar] [CrossRef]

- Buzby, J.C.; Hyman, J. Total and per capita value of food loss in the United States. Food Policy 2012, 37, 561–570. [Google Scholar] [CrossRef]

- Beretta, C.; Stoessel, F.; Baier, U.; Hellweg, S. Quantifying food losses and the potential for reduction in Switzerland. Waste Manag. 2013, 33, 764–773. [Google Scholar] [CrossRef]

- Xue, L.; Liu, G.; Parfitt, J.; Liu, X.; Van Herpen, E.; Stenmarck, A.; O’Connor, C.; Ostergren, K.; Cheng, S. Missing Food, Missing Data? A Critical Review of Global Food Losses and Food Waste Data. Environ. Sci. Technol. 2017, 51, 6618–6633. [Google Scholar] [CrossRef]

- Kok, M.G.; Castelein, R.B.; Broeze, J.; Snels, J.C.M.A. The Efficient Protocol: A Pragmatic and Integrated Methodology for Food Loss and Waste Quantification, Analysis of Causes and Intervention Design; Wageningen Food & Biobased Research: Wageningen, The Netherlands, 2021. [Google Scholar] [CrossRef]

- Ayala-Zavala, J.F.; Vega-Vega, V.; Rosas-Domínguez, C.; Palafox-Carlos, H.; Villa-Rodriguez, J.A.; Siddiqui, M.W.; Dávila-Aviña, J.E.; González-Aguilar, G.A. Agro-industrial potential of exotic fruit byproducts as a source of food additives. Food Res. Int. 2011, 44, 1866–1874. [Google Scholar] [CrossRef]

- Gomez, M.; Martinez, M.M. Fruit and vegetable by-products as novel ingredients to improve the nutritional quality of baked goods. Crit. Rev. Food Sci. Nutr. 2018, 58, 2119–2135. [Google Scholar] [CrossRef]

- Torres-León, C.; Ramírez-Guzman, N.; Londoño-Hernandez, L.; Martinez-Medina, G.A.; Díaz-Herrera, R.; Navarro-Macias, V.; Alvarez-Pérez, O.B.; Picazo, B.; Villarreal-Vázquez, M.; Ascacio-Valdes, J.; et al. Food Waste and Byproducts: An Opportunity to Minimize Malnutrition and Hunger in Developing Countries. Front. Sustain. Food Syst. 2018, 2, 52. [Google Scholar] [CrossRef]

- Fierascu, R.C.; Sieniawska, E.; Ortan, A.; Fierascu, I.; Xiao, J. Fruits By-Products—A Source of Valuable Active Principles. A Short Review. Front. Bioeng. Biotechnol. 2020, 8, 319. [Google Scholar] [CrossRef] [PubMed]

- FAO. The State of Food and Agriculture 2019. Moving Forward on Food Loss and Waste Reduction. 2019. Available online: https://openknowledge.fao.org/items/ba08937f-4a41-4ff5-a4e7-e495e5f5f599 (accessed on 19 September 2024).

- OIV (International Organisation of Vine and Wine). Statistical Report on World Vitiviniculture. 2019. Available online: https://www.oiv.int/public/medias/6782/oiv-2019-statistical-report-on-world-vitiviniculture.pdf (accessed on 8 August 2024).

- Kammerer, D.; Gajdos Kljusuric, J.; Carle, R.; Schieber, A. Recovery of anthocyanins from grape pomace extracts (Vitis vinifera L. cv. Cabernet Mitos) using a polymeric adsorber resin. Eur. Food Res. Technol. 2005, 220, 431–437. [Google Scholar] [CrossRef]

- Garrido, M.D.; Auqui, M.; Martí, N.; Linares, M.B. Effect of two different red grape pomace extracts obtained under different extraction systems on meat quality of pork burgers. LWT Food Sci. Technol. 2011, 44, 2238–2243. [Google Scholar] [CrossRef]

- Jin, Q.; O’Hair, J.; Stewart, A.C.; O’Keefe, S.F.; Neilson, A.P.; Kim, Y.T.; McGuire, M.; Lee, A.; Wilder, G.; Huang, H. Compositional Characterization of Different Industrial White and Red Grape Pomaces in Virginia and the Potential Valorization of the Major Components. Foods 2019, 8, 667. [Google Scholar] [CrossRef]

- Antonic, B.; Jancikova, S.; Dordevic, D.; Tremlova, B. Apple pomace as food fortification ingredient: A systematic review and meta-analysis. J. Food Sci. 2020, 85, 2977–2985. [Google Scholar] [CrossRef]

- Perdicaro, D.J.; Rodriguez Lanzi, C.; Fontana, A.R.; Antoniolli, A.; Piccoli, P.; Miatello, R.M.; Diez, E.R.; Vazquez Prieto, M.A. Grape pomace reduced reperfusion arrhythmias in rats with a high-fat-fructose diet. Food Funct. 2017, 8, 3501–3509. [Google Scholar] [CrossRef]

- Averilla, J.N.; Oh, J.; Kim, H.J.; Kim, J.S.; Kim, J.S. Potential health benefits of phenolic compounds in grape processing by-products. Food Sci. Biotechnol. 2019, 28, 1607–1615. [Google Scholar] [CrossRef]

- Rodriguez Lanzi, C.; Perdicaro, D.J.; Antoniolli, A.; Fontana, A.R.; Miatello, R.M.; Bottini, R.; Vazquez Prieto, M.A. Grape pomace and grape pomace extract improve insulin signaling in high-fat-fructose fed rat-induced metabolic syndrome. Food Funct. 2016, 7, 1544–1553. [Google Scholar] [CrossRef]

- Zhao, B.; Gong, H.; Li, H.; Zhang, Y.; Lan, T.; Chen, Z. Characterization of Chinese Grape Seed Oil by Physicochemical Properties, Fatty Acid Composition, Triacylglycrol Profiles, and Sterols and Squalene Composition. Int. J. Food Eng. 2019, 15, 9. [Google Scholar] [CrossRef]

- Antonic, B.; Jancikova, S.; Dordevic, D.; Tremlova, B. Grape Pomace Valorization: A Systematic Review and Meta-Analysis. Foods 2020, 9, 1627. [Google Scholar] [CrossRef]

- Hogervorst, J.C.; Miljić, U.; Puškaš, V. 5—Extraction of Bioactive Compounds from Grape Processing By-Products. In Handbook of Grape Processing By-Products; Academic Press: Cambridge, MA, USA, 2017; pp. 105–135. [Google Scholar] [CrossRef]

- Karovičová, J.; Kohajdová, Z.; Minarovičová, L.; Kuchtová, V. The Chemical Composition of Grape Fibre. Potravin. Slovak. J. Food Sci. 2015, 9, 53–57. [Google Scholar] [CrossRef]

- Afonso, S.; Horita, K.; Sousa e Silva, J.P.; Almeida, I.F.; Amaral, M.H.; Lobao, P.A.; Costa, P.C.; Miranda, M.S.; Esteves da Silva, J.C.; Sousa Lobo, J.M. Photodegradation of avobenzone: Stabilization effect of antioxidants. J. Photochem. Photobiol. B 2014, 140, 36–40. [Google Scholar] [CrossRef] [PubMed]

- Coelho, M.C.; Pereira, R.N.; Rodrigues, A.S.; Teixeira, J.A.; Pintado, M.E. The use of emergent technologies to extract added value compounds from grape by-products. Trends Food Sci. Technol. 2020, 106, 182–197. [Google Scholar] [CrossRef]

- Troilo, M.; Difonzo, G.; Paradiso, V.M.; Summo, C.; Caponio, F. Bioactive Compounds from Vine Shoots, Grape Stalks, and Wine Lees: Their Potential Use in Agro-Food Chains. Foods 2021, 10, 342. [Google Scholar] [CrossRef] [PubMed]

- Bueno, J.E.; Peinado, R.; Moreno, J.; Medina, M.; Moyano, L.; Zea, L. Selection of Volatile Aroma Compounds by Statistical and Enological Criteria for Analytical Differentiation of Musts and Wines of Two Grape Varieties. J. Food Sci. 2003, 68, 158–163. [Google Scholar] [CrossRef]

- Swiegers, J.H.; Bartowsky, E.J.; Henschke, P.A.; Pretorius, I.S. Yeast and bacterial modulation of wine aroma and flavour. Aust. J. Grape Wine Res. 2005, 11, 139–173. [Google Scholar] [CrossRef]

- Pedroza, M.A.; Zalacain, A.; Lara, J.F.; Salinas, M.R. Global grape aroma potential and its individual analysis by SBSE–GC–MS. Food Res. Int. 2010, 43, 1003–1008. [Google Scholar] [CrossRef]

- Dunlevy, J.D.; Kalua, C.M.; Keyzers, R.A.; Boss, P.K. The Production of Flavour & Aroma Compounds in Grape Berries, 2nd ed.; Roubelakis-Angelakis, K.A., Ed.; Springer: Dordrecht, The Netherlands, 2009. [Google Scholar]

- Parker, M.; Capone, D.L.; Francis, I.L.; Herderich, M.J. Aroma Precursors in Grapes and Wine: Flavor Release during Wine Production and Consumption. J. Agric. Food Chem. 2018, 66, 2281–2286. [Google Scholar] [CrossRef]

- Barreira, J.C.M.; Arraibi, A.A.; Ferreira, I.C.F.R. Bioactive and functional compounds in apple pomace from juice and cider manufacturing: Potential use in dermal formulations. Trends Food Sci. Technol. 2019, 90, 76–87. [Google Scholar] [CrossRef]

- Tomasino, E.; Bolman, S. The Potential Effect of beta-Ionone and beta-Damascenone on Sensory Perception of Pinot Noir Wine Aroma. Molecules 2021, 26, 1288. [Google Scholar] [CrossRef]

- Yuan, F.; Feng, H.; Qian, M.C. C13-Norisoprenoids in Grape and Wine Affected by Different Canopy Management. Adv. Wine Res. 2015, 1203, 147–160. [Google Scholar] [CrossRef]

- Mendes-Pinto, M.M. Carotenoid breakdown products the—Norisoprenoids—In wine aroma. Arch. Biochem. Biophys. 2009, 483, 236–245. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Zhu, X.-L.; Ullah, N.; Tao, Y.-S. Aroma Glycosides in Grapes and Wine. J. Food Sci. 2017, 82, 248–259. [Google Scholar] [CrossRef] [PubMed]

- Waterhouse, A.L.; Sacks, G.L.; Jeffery, D.W. Understanding Wine Chemistry; John Wiley & Sons: Hoboken, NJ, USA, 2016. [Google Scholar]

- Ferreira, V.; Lopez, R. The Actual and Potential Aroma of Winemaking Grapes. Biomolecules 2019, 9, 818. [Google Scholar] [CrossRef]

- Marais, J. Terpenes in the Aroma of Grapes and Wines: A Review. South. Afr. J. Enol. Vitic. 2017, 4, 49–58. [Google Scholar] [CrossRef]

- Swiegers, J.H.; Kievit, R.L.; Siebert, T.; Lattey, K.A.; Bramley, B.R.; Francis, I.L.; King, E.S.; Pretorius, I.S. The influence of yeast on the aroma of Sauvignon Blanc wine. Food Microbiol. 2009, 26, 204–211. [Google Scholar] [CrossRef]

- Roland, A.; Schneider, R.; Razungles, A.; Cavelier, F. Varietal thiols in wine: Discovery, analysis and applications. Chem. Rev. 2011, 111, 7355–7376. [Google Scholar] [CrossRef]

- Pineau, B.; Trought, M.C.T.; Stronge, K.; Beresford, M.K.; Wohlers, M.W.; Jaeger, S.R. Influence of fruit ripeness and juice chaptalisation on the sensory properties and degree of typicality expressed by Sauvignon Blanc wines from Marlborough, New Zealand. Aust. J. Grape Wine Res. 2011, 17, 358–367. [Google Scholar] [CrossRef]

- Jeffery, D.W. Spotlight on Varietal Thiols and Precursors in Grapes and Wines. Aust. J. Chem. 2016, 69, 1323. [Google Scholar] [CrossRef]

- Roland, A.; Schneider, R.; Razungles, A.; Le Guerneve, C.; Cavelier, F. Straightforward synthesis of deuterated precursors to demonstrate the biogenesis of aromatic thiols in wine. J. Agric. Food Chem. 2010, 58, 10684–10689. [Google Scholar] [CrossRef]

- Peyrot Des Gachons, C.; Tominaga, T.; Dubourdieu, D. Sulfur aroma precursor present in S-glutathione conjugate form: Identification of S-3-(hexan-1-ol)-glutathione in must from Vitis vinifera L. cv. Sauvignon blanc. J. Agric. Food Chem. 2002, 50, 4076–4079. [Google Scholar] [CrossRef] [PubMed]

- Fedrizzi, B.; Pardon, K.H.; Sefton, M.A.; Elsey, G.M.; Jeffery, D.W. First identification of 4-S-glutathionyl-4-methylpentan-2-one, a potential precursor of 4-mercapto-4-methylpentan-2-one, in Sauvignon Blanc juice. J. Agric. Food Chem. 2009, 57, 991–995. [Google Scholar] [CrossRef] [PubMed]

- Peña-Gallego, A.; Hernández-Orte, P.; Cacho, J.; Ferreira, V. S-Cysteinylated and S-glutathionylated thiol precursors in grapes. A review. Food Chem. 2012, 131, 1–13. [Google Scholar] [CrossRef]

- Sarrazin, E.; Dubourdieu, D.; Darriet, P. Characterization of key-aroma compounds of botrytized wines, influence of grape botrytization. Food Chem. 2007, 103, 536–545. [Google Scholar] [CrossRef]

- Cerreti, M.; Ferranti, P.; Benucci, I.; Liburdi, K.; De Simone, C.; Esti, M. Thiol precursors in Grechetto grape juice and aromatic expression in wine. Eur. Food Res. Technol. 2016, 243, 753–760. [Google Scholar] [CrossRef]

- Lund, C.M.; Thompson, M.K.; Benkwitz, F.; Wohler, M.W.; Triggs, C.M.; Gardner, R.; Heymann, H.; Nicolau, L. New Zealand Sauvignon blanc Distinct Flavor Characteristics: Sensory, Chemical, and Consumer Aspects. Am. J. Enol. Vitic. 2009, 60, 1–12. [Google Scholar] [CrossRef]

- Lei, Y.; Xie, S.; Guan, X.; Song, C.; Zhang, Z.; Meng, J. Methoxypyrazines biosynthesis and metabolism in grape: A review. Food Chem. 2018, 245, 1141–1147. [Google Scholar] [CrossRef]

- Sala, C.; Mestres, M.; Martí, M.P.; Busto, O.; Guasch, J. Headspace solid-phase microextraction analysis of 3-alkyl-2-methoxypyrazines in wines. J. Chromatogr. A 2002, 953, 1–6. [Google Scholar] [CrossRef]

- Sidhu, D.; Lund, J.; Kotseridis, Y.; Saucier, C. Methoxypyrazine analysis and influence of viticultural and enological procedures on their levels in grapes, musts, and wines. Crit. Rev. Food Sci. Nutr. 2015, 55, 485–502. [Google Scholar] [CrossRef]

- Hernandez-Orte, P.; Concejero, B.; Astrain, J.; Lacau, B.; Cacho, J.; Ferreira, V. Influence of viticulture practices on grape aroma precursors and their relation with wine aroma. J. Sci. Food Agric. 2015, 95, 688–701. [Google Scholar] [CrossRef]

- Alem, H.; Rigou, P.; Schneider, R.; Ojeda, H.; Torregrosa, L. Impact of agronomic practices on grape aroma composition: A review. J. Sci. Food Agric. 2019, 99, 975–985. [Google Scholar] [CrossRef] [PubMed]

- Cataldo, E.; Salvi, L.; Paoli, F.; Fucile, M.; Mattii, G.B. Effect of Agronomic Techniques on Aroma Composition of White Grapevines: A Review. Agronomy 2021, 11, 2027. [Google Scholar] [CrossRef]

- Song, J.; Shellie, K.C.; Wang, H.; Qian, M.C. Influence of deficit irrigation and kaolin particle film on grape composition and volatile compounds in Merlot grape (Vitis vinifera L.). Food Chem. 2012, 134, 841–850. [Google Scholar] [CrossRef] [PubMed]

- Bindon, K.A.; Dry, P.R.; Loveys, B.R. Influence of Plant Water Status on the Production of C13-Norisoprenoid Precursors in Vitis vinifera L. Cv. Cabernet Sauvignon Grape Berries. J. Agric. Food Chem. 2007, 55, 4493–4500. [Google Scholar] [CrossRef]

- Qian, M.C.; Fang, Y.; Shellie, K. Volatile Composition of Merlot Wine from Different Vine Water Status. J. Agric. Food Chem. 2009, 57, 7459–7463. [Google Scholar] [CrossRef]

- Koundouras, S.; Marinos, V.; Gkoulioti, A.; Kotseridis, Y.; van Leeuwen, C. Influence of Vineyard Location and Vine Water Status on Fruit Maturation of Nonirrigated Cv. Agiorgitiko (Vitis vinifera L.). Effects on Wine Phenolic and Aroma Components. J. Agric. Food Chem. 2006, 54, 5077–5086. [Google Scholar] [CrossRef]

- Savoi, S.; Herrera, J.C.; Carlin, S.; Lotti, C.; Bucchetti, B.; Peterlunger, E.; Castellarin, S.D.; Mattivi, F. From grape berries to wines: Drought impacts on key secondary metabolites. OENO One 2020, 54, 569–582. [Google Scholar] [CrossRef]

- Delgado, J.A.; Osorio Alises, M.; Alonso-Villegas, R.; Sánchez-Palomo, E.; González-Viñas, M.A. Effects of the Irrigation of Chelva Grapevines on the Aroma Composition of Wine. Beverages 2022, 8, 38. [Google Scholar] [CrossRef]

- Lizama, V.; Pérez-Álvarez, E.P.; Intrigliolo, D.S.; Chirivella, C.; Álvarez, I.; García-Esparza, M.J. Effects of the irrigation regimes on grapevine cv. Bobal in a Mediterranean climate: II. Wine, skins, seeds, and grape aromatic composition. Agric. Water Manag. 2021, 256, 107078. [Google Scholar] [CrossRef]

- Sivilotti, P.; Falchi, R.; Herrera, J.C.; Škvarč, B.; Butinar, L.; Sternad Lemut, M.; Bubola, M.; Sabbatini, P.; Lisjak, K.; Vanzo, A. Combined Effects of Early Season Leaf Removal and Climatic Conditions on Aroma Precursors in Sauvignon Blanc Grapes. J. Agric. Food Chem. 2017, 65, 8426–8434. [Google Scholar] [CrossRef]

- Alessandrini, M.; Battista, F.; Panighel, A.; Flamini, R.; Tomasi, D. Effect of pre-bloom leaf removal on grape aroma composition and wine sensory profile of Semillon cultivar. J. Sci. Food Agric. 2018, 98, 1674–1684. [Google Scholar] [CrossRef]

- Verdenal, T.; Zufferey, V.; Dienes-Nagy, A.; Bieri, S.; Bourdin, G.; Reynard, J.-S.; Spring, J.-L. Exploring grapevine canopy management: Effects of removing main leaves or lateral shoots before flowering. IVES Tech. Rev. Vine Wine 2024, 58, 2. [Google Scholar] [CrossRef]

- Bubola, M.; Lukic, I.; Radeka, S.; Sivilotti, P.; Grozic, K.; Vanzo, A.; Bavcar, D.; Lisjak, K. Enhancement of Istrian Malvasia wine aroma and hydroxycinnamate composition by hand and mechanical leaf removal. J. Sci. Food Agric. 2019, 99, 904–914. [Google Scholar] [CrossRef] [PubMed]

- Yue, X.; Ma, X.; Tang, Y.; Wang, Y.; Wu, B.; Jiao, X.; Zhang, Z.; Ju, Y. Effect of cluster zone leaf removal on monoterpene profiles of Sauvignon Blanc grapes and wines. Food Res. Int. 2020, 131, 109028. [Google Scholar] [CrossRef] [PubMed]

- Hickey, C.C.; Kwasniewski, M.T.; Wolf, T.K. Leaf Removal Effects on Cabernet franc and Petit Verdot: II. Grape Carotenoids, Phenolics, and Wine Sensory Analysis. Am. J. Enol. Vitic. 2018, 69, 231–246. [Google Scholar] [CrossRef]

- Verzera, A.; Tripodi, G.; Dima, G.; Condurso, C.; Scacco, A.; Cincotta, F.; Giglio, D.M.; Santangelo, T.; Sparacio, A. Leaf removal and wine composition of Vitis vinifera L. cv. Nero d’Avola: The volatile aroma constituents. J. Sci. Food Agric. 2016, 96, 150–159. [Google Scholar] [CrossRef]

- Feng, H.; Skinkis, P.A.; Qian, M.C. Pinot noir wine volatile and anthocyanin composition under different levels of vine fruit zone leaf removal. Food Chem. 2017, 214, 736–744. [Google Scholar] [CrossRef]

- Condurso, C.; Cincotta, F.; Tripodi, G.; Sparacio, A.; Giglio, D.M.L.; Sparla, S.; Verzera, A. Effects of cluster thinning on wine quality of Syrah cultivar (Vitis vinifera L.). Eur. Food Res. Technol. 2016, 242, 1719–1726. [Google Scholar] [CrossRef]

- Rutan, T.E.; Herbst-Johnstone, M.; Kilmartin, P.A. Effect of Cluster Thinning Vitis vinifera cv. Pinot Noir on Wine Volatile and Phenolic Composition. J. Agric. Food Chem. 2018, 66, 10053–10066. [Google Scholar] [CrossRef]

- Mucalo, A.; Lukšić, K.; Budić-Leto, I.; Zdunić, G. Cluster Thinning Improves Aroma Complexity of White Maraština (Vitis vinifera L.) Wines Compared to Defoliation under Mediterranean Climate. Appl. Sci. 2022, 12, 7327. [Google Scholar] [CrossRef]

- Wang, Y.; He, Y.N.; He, L.; He, F.; Chen, W.; Duan, C.Q.; Wang, J. Changes in global aroma profiles of Cabernet Sauvignon in response to cluster thinning. Food Res. Int. 2019, 122, 56–65. [Google Scholar] [CrossRef] [PubMed]

- Kok, D. Influences of pre- and post-veraison cluster thinning treatments on grape composition variables and monoterpene levels of Vitis vinifera L. cv. Sauvignon Blanc. J. Food Agric. Environ. 2011, 9, 22–26. [Google Scholar]

- Diago, M.P.; Vilanova, M.; Blanco, J.A.; Tardaguila, J. Effects of mechanical thinning on fruit and wine composition and sensory attributes of Grenache and Tempranillo varieties (Vitis vinifera L.). Aust. J. Grape Wine Res. 2010, 16, 314–326. [Google Scholar] [CrossRef]

- Mendez-Costabel, M.P.; Wilkinson, K.L.; Bastian, S.E.P.; Jordans, C.; McCarthy, M.; Ford, C.M.; Dokoozlian, N.K. Effect of increased irrigation and additional nitrogen fertilisation on the concentration of green aroma compounds in Vitis vinifera L. Merlot fruit and wine. Aust. J. Grape Wine Res. 2014, 20, 80–90. [Google Scholar] [CrossRef]

- Black, C.A.; Parker, M.; Siebert, T.E.; Capone, D.L.; Francis, I.L. Terpenoids and their role in wine flavour: Recent advances. Aust. J. Grape Wine Res. 2015, 21, 582–600. [Google Scholar] [CrossRef]

- Espinase Nandorfy, D.; Siebert, T.; Bilogrevic, E.; Likos, D.; Watson, F.; Barter, S.; Pisaniello, L.; Kulcsar, A.; Shellie, R.A.; Keast, R.; et al. The Role of Potent Thiols in “Empyreumatic” Flint/Struck-Match/Mineral Odours in Chardonnay Wine. Aust. J. Grape Wine Res. 2023, 2023, 1–17. [Google Scholar] [CrossRef]

- Geffroy, O.; Morere, M.; Lopez, R.; Pasquier, G.; Condoret, J.S. Investigating the Aroma of Syrah Wines from the Northern Rhone Valley Using Supercritical CO(2)-Dearomatized Wine as a Matrix for Reconstitution Studies. J. Agric. Food Chem. 2020, 68, 11512–11523. [Google Scholar] [CrossRef]

- Lytra, G.; Tempere, S.; Le Floch, A.; de Revel, G.; Barbe, J.-C. Study of Sensory Interactions among Red Wine Fruity Esters in a Model Solution. J. Agric. Food Chem. 2013, 61, 8504–8513. [Google Scholar] [CrossRef]

- Gammacurta, M.; Marchand, S.; Albertin, W.; Moine, V.; de Revel, G. Impact of Yeast Strain on Ester Levels and Fruity Aroma Persistence during Aging of Bordeaux Red Wines. J. Agric. Food Chem. 2014, 62, 5378–5389. [Google Scholar] [CrossRef]

- Cordente, A.G.; Espinase Nandorfy, D.; Solomon, M.; Schulkin, A.; Kolouchova, R.; Francis, I.L.; Schmidt, S.A. Aromatic Higher Alcohols in Wine: Implication on Aroma and Palate Attributes during Chardonnay Aging. Molecules 2021, 26, 4979. [Google Scholar] [CrossRef]

- Mele, M.A.; Kang, H.M.; Lee, Y.T.; Islam, M.Z. Grape terpenoids: Flavor importance, genetic regulation, and future potential. Crit. Rev. Food Sci. Nutr. 2021, 61, 1429–1447. [Google Scholar] [CrossRef] [PubMed]

- Csutoras, C.; Bakos-Barczi, N.; Burkus, B. Medium chain fatty acids and fatty acid esters as potential markers of alcoholic fermentation of white wines. Acta Aliment. 2022, 51, 33–42. [Google Scholar] [CrossRef]

- Lacroux, F.; Trégoat, O.; Van Leeuwen, C.; Pons, A.; Tominaga, T.; Lavigne-Cruège, V.; Dubourdieu, D. Effect of foliar nitrogen and sulphur application on aromatic expression of Vitis vinifera L. cv. Sauvignon blanc. OENO One 2008, 42, 125–132. [Google Scholar] [CrossRef]

- Darriet, P.B.; Bouchilloux, P.; Poupot, C.; Bugaret, Y.; Clerjeau, M.; Sauris, P.; Medina, B.; Dubourdieu, D. Effects of copper fungicide spraying on volatile thiols of the varietal aroma of Sauvignon blanc, Cabernet Sauvignon and Merlot wines. Vitis 2001, 40, 93–99. [Google Scholar]

- Olejar, K.J.; Fedrizzi, B.; Kilmartin, P.A. Influence of harvesting technique and maceration process on aroma and phenolic attributes of Sauvignon blanc wine. Food Chem. 2015, 183, 181–189. [Google Scholar] [CrossRef]

- Wamhoff, H.; Gribble, G.W. Wine and Heterocycles. Adv. Heterocycl. Chem. 2012, 106, 185–225. [Google Scholar] [CrossRef]

- Gonzalez-Neves, G.; Favre, G.; Gil, G.; Ferrer, M.; Charamelo, D. Effect of cold pre-fermentative maceration on the color and composition of young red wines cv. Tannat. J. Food Sci. Technol. 2015, 52, 3449–3457. [Google Scholar] [CrossRef]

- Álvarez, I.; Aleixandre, J.L.; García, M.J.; Lizama, V. Impact of prefermentative maceration on the phenolic and volatile compounds in Monastrell red wines. Anal. Chim. Acta 2006, 563, 109–115. [Google Scholar] [CrossRef]

- Carpena, M.; Fraga-Corral, M.; Otero, P.; Nogueira, R.A.; Garcia-Oliveira, P.; Prieto, M.A.; Simal-Gandara, J. Secondary Aroma: Influence of Wine Microorganisms in Their Aroma Profile. Foods 2020, 10, 51. [Google Scholar] [CrossRef]

- Mihnea, M.; González-SanJosé, M.L.; Ortega-Heras, M.; Pérez-Magariño, S. A comparative study of the volatile content of Mencía wines obtained using different pre-fermentative maceration techniques. LWT Food Sci. Technol. 2015, 64, 32–41. [Google Scholar] [CrossRef]

- Rogerson, F.S.S.; Vale, E.; Grande, H.J.; Silva, M.C.M. Alternative Processing of Port-Wine Using Pectolytic Enzymes Procesado Alternativo Del Vino De Oporto Usando Enzimas PectolÍticos Procesado Alternativo Do ViÑo De Oporto Usando Enzimas PectolÍticos. CYTA-J. Food 2000, 2, 222–227. [Google Scholar] [CrossRef]

- Maggu, M.; Winz, R.; Kilmartin, P.A.; Trought, M.C.T.; Nicolau, L. Effect of Skin Contact and Pressure on the Composition of Sauvignon Blanc Must. J. Agric. Food Chem. 2007, 55, 10281–10288. [Google Scholar] [CrossRef] [PubMed]

- Massera, A.; Assof, M.; Sari, S.; Ciklic, I.; Mercado, L.; Jofré, V.; Combina, M. Effect of low temperature fermentation on the yeast-derived volatile aroma composition and sensory profile in Merlot wines. LWT 2021, 142, 111069. [Google Scholar] [CrossRef]

- Beltran, G.; Novo, M.; Guillamon, J.M.; Mas, A.; Rozes, N. Effect of fermentation temperature and culture media on the yeast lipid composition and wine volatile compounds. Int. J. Food Microbiol. 2008, 121, 169–177. [Google Scholar] [CrossRef]

- Samoticha, J.; Wojdyło, A.; Chmielewska, J.; Nofer, J. Effect of Different Yeast Strains and Temperature of Fermentation on Basic Enological Parameters, Polyphenols and Volatile Compounds of Aurore White Wine. Foods 2019, 8, 599. [Google Scholar] [CrossRef]

- Mayr, C.M.; Geue, J.P.; Holt, H.E.; Pearson, W.P.; Jeffery, D.W.; Francis, I.L. Characterization of the key aroma compounds in Shiraz wine by quantitation, aroma reconstitution, and omission studies. J. Agric. Food Chem. 2014, 62, 4528–4536. [Google Scholar] [CrossRef]

- Vilanova, M.; Campo, E.; Escudero, A.; Grana, M.; Masa, A.; Cacho, J. Volatile composition and sensory properties of Vitis vinifera red cultivars from north west Spain: Correlation between sensory and instrumental analysis. Anal. Chim. Acta 2012, 720, 104–111. [Google Scholar] [CrossRef]

- Buican, B.-C.; Colibaba, L.C.; Luchian, C.E.; Kallithraka, S.; Cotea, V.V. “Orange” Wine—The Resurgence of an Ancient Winemaking Technique: A Review. Agriculture 2023, 13, 1750. [Google Scholar] [CrossRef]

- Beckner Whitener, M.E.; Carlin, S.; Jacobson, D.; Weighill, D.; Divol, B.; Conterno, L.; Du Toit, M.; Vrhovsek, U. Early fermentation volatile metabolite profile of non-Saccharomyces yeasts in red and white grape must: A targeted approach. LWT Food Sci. Technol. 2015, 64, 412–422. [Google Scholar] [CrossRef]

- Beckner Whitener, M.E.; Stanstrup, J.; Panzeri, V.; Carlin, S.; Divol, B.; Du Toit, M.; Vrhovsek, U. Untangling the wine metabolome by combining untargeted SPME–GCxGC-TOF-MS and sensory analysis to profile Sauvignon blanc co-fermented with seven different yeasts. Metabolomics 2016, 12, 53. [Google Scholar] [CrossRef]

- Belda, I.; Navascues, E.; Marquina, D.; Santos, A.; Calderon, F.; Benito, S. Dynamic analysis of physiological properties of Torulaspora delbrueckii in wine fermentations and its incidence on wine quality. Appl. Microbiol. Biotechnol. 2015, 99, 1911–1922. [Google Scholar] [CrossRef] [PubMed]

- Belda, I.; Ruiz, J.; Beisert, B.; Navascués, E.; Marquina, D.; Calderón, F.; Rauhut, D.; Benito, S.; Santos, A. Influence of Torulaspora delbrueckii in varietal thiol (3-SH and 4-MSP) release in wine sequential fermentations. Int. J. Food Microbiol. 2017, 257, 183–191. [Google Scholar] [CrossRef] [PubMed]

- Loira, I.; Morata, A.; Comuzzo, P.; Callejo, M.J.; González, C.; Calderón, F.; Suárez-Lepe, J.A. Use of Schizosaccharomyces pombe and Torulaspora delbrueckii strains in mixed and sequential fermentations to improve red wine sensory quality. Food Res. Int. 2015, 76, 325–333. [Google Scholar] [CrossRef] [PubMed]

- Azzolini, M.; Tosi, E.; Lorenzini, M.; Finato, F.; Zapparoli, G. Contribution to the aroma of white wines by controlled Torulaspora delbrueckii cultures in association with Saccharomyces cerevisiae. World J. Microbiol. Biotechnol. 2015, 31, 277–293. [Google Scholar] [CrossRef]

- Nardi, T.; Panero, L.; Petrozziello, M.; Guaita, M.; Tsolakis, C.; Cassino, C.; Vagnoli, P.; Bosso, A. Managing wine quality using Torulaspora delbrueckii and Oenococcus oeni starters in mixed fermentations of a red Barbera wine. Eur. Food Res. Technol. 2018, 245, 293–307. [Google Scholar] [CrossRef]

- Herbst-Johnstone, M.; Araujo, L.D.; Allen, T.A.; Logan, G.; Nicolau, L.; Kilmartin, P.A. Effects of Mechanical Harvesting on ’Sauvignon Blanc’ Aroma. Acta Hortic. 2013, 978, 179–186. [Google Scholar] [CrossRef]

- Allen, T.; Herbst-Johnstone, M.; Girault, M.; Butler, P.; Logan, G.; Jouanneau, S.; Nicolau, L.; Kilmartin, P.A. Influence of grape-harvesting steps on varietal thiol aromas in Sauvignon blanc wines. J. Agric. Food Chem. 2011, 59, 10641–10650. [Google Scholar] [CrossRef]

- Cejudo-Bastante, M.J.; Castro-Vazquez, L.; Hermosin-Gutierrez, I.; Perez-Coello, M.S. Combined effects of prefermentative skin maceration and oxygen addition of must on color-related phenolics, volatile composition, and sensory characteristics of Airen white wine. J. Agric. Food Chem. 2011, 59, 12171–12182. [Google Scholar] [CrossRef]

- Diana De Santis, M.T.F. Effect of prefermentative cold maceration on the aroma and phenolic profiles of a Merlot red wine Italian. Ital. J. Food Sci. 2010, 22, 2–8. [Google Scholar]

- Rocha, S.M.; Coutinho, P.; Delgadillo, I.; Cardoso, A.D.; Coimbra, M.A. Effect of enzymatic aroma release on the volatile compounds of white wines presenting different aroma potentials. J. Sci. Food Agric. 2005, 85, 199–205. [Google Scholar] [CrossRef]

- Armada, L.; Fernández, E.; Falqué, E. Influence of several enzymatic treatments on aromatic composition of white wines. LWT Food Sci. Technol. 2010, 43, 1517–1525. [Google Scholar] [CrossRef]

- Patel, P.; Herbst-Johnstone, M.; Lee, S.A.; Gardner, R.C.; Weaver, R.; Nicolau, L.; Kilmartin, P.A. Influence of Juice Pressing Conditions on Polyphenols, Antioxidants, and Varietal Aroma of Sauvignon blanc Microferments. J. Agric. Food Chem. 2010, 58, 7280–7288. [Google Scholar] [CrossRef] [PubMed]

- Minas, M.; Dimitrios, T. Contribution of Yeast in Wine Aroma and Flavour. In Yeast; Antonio, M., Iris, L., Eds.; IntechOpen: Rijeka, Croatia, 2017; p. Ch. 5. [Google Scholar]

- Morales, M.L.; Fierro-Risco, J.; Callejón, R.M.; Paneque, P. Monitoring volatile compounds production throughout fermentation by Saccharomyces and non-Saccharomyces strains using headspace sorptive extraction. J. Food Sci. Technol. 2017, 54, 538–557. [Google Scholar] [CrossRef] [PubMed]

- Molina, A.M.; Swiegers, J.H.; Varela, C.; Pretorius, I.S.; Agosin, E. Influence of wine fermentation temperature on the synthesis of yeast-derived volatile aroma compounds. Appl. Microbiol. Biotechnol. 2007, 77, 675–687. [Google Scholar] [CrossRef]

- Lerno, L.; Reichwage, M.; Ponangi, R.; Hearne, L.; Block, D.E.; Oberholster, A. Effects of Cap and Overall Fermentation Temperature on Phenolic Extraction in Cabernet Sauvignon Fermentations. Am. J. Enol. Vitic. 2015, 66, 444–453. [Google Scholar] [CrossRef]

- Scutarașu, E.C.; Luchian, C.E.; Cioroiu, I.B.; Trincă, L.C.; Cotea, V.V. Increasing Amino Acids Content of White Wines with Enzymes Treatments. Agronomy 2022, 12, 1406. [Google Scholar] [CrossRef]

- Ruiz, J.; de Celis, M.; de Toro, M.; Mendes-Ferreira, A.; Rauhut, D.; Santos, A.; Belda, I. Phenotypic and transcriptional analysis of Saccharomyces cerevisiae during wine fermentation in response to nitrogen nutrition and co-inoculation with Torulaspora delbrueckii. Food Res. Int. 2020, 137, 109663. [Google Scholar] [CrossRef]

- Canonico, L.; Comitini, F.; Ciani, M. Torulaspora delbrueckii for secondary fermentation in sparkling wine production. Food Microbiol. 2018, 74, 100–106. [Google Scholar] [CrossRef]

- Renault, P.; Coulon, J.; de Revel, G.; Barbe, J.-C.; Bely, M. Increase of fruity aroma during mixed T. delbrueckii/S. cerevisiae wine fermentation is linked to specific esters enhancement. Int. J. Food Microbiol. 2015, 207, 40–48. [Google Scholar] [CrossRef]

- Del Fresno, J.M.; Morata, A.; Loira, I.; Bañuelos, M.A.; Escott, C.; Benito, S.; González Chamorro, C.; Suárez-Lepe, J.A. Use of non-Saccharomyces in single-culture, mixed and sequential fermentation to improve red wine quality. Eur. Food Res. Technol. 2017, 243, 2175–2185. [Google Scholar] [CrossRef]

- Tsai, P.-C.; Araujo, L.D.; Tian, B. Varietal Aromas of Sauvignon Blanc: Impact of Oxidation and Antioxidants Used in Winemaking. Fermentation 2022, 8, 686. [Google Scholar] [CrossRef]

- Buțerchi, I.; Colibaba, L.C.; Luchian, C.E.; Lipșa, F.D.; Ulea, E.; Zamfir, C.I.; Scutarașu, E.C.; Nechita, C.B.; Irimia, L.M.; Cotea, V.V. Impact of Sulfur Dioxide and Dimethyl Dicarbonate Treatment on the Quality of White Wines: A Scientific Evaluation. Fermentation 2025, 11, 86. [Google Scholar] [CrossRef]

- Makhotkina, O.; Herbst-Johnstone, M.; Logan, G.; du Toit, W.; Kilmartin, P.A. Influence of Sulfur Dioxide Additions at Harvest on Polyphenols, C6-Compounds, and Varietal Thiols in Sauvignon blanc. Am. J. Enol. Vitic. 2013, 64, 203–213. [Google Scholar] [CrossRef]

- Lyu, X.; Dias Araujo, L.; Quek, S.Y.; Kilmartin, P.A. Effects of antioxidant and elemental sulfur additions at crushing on aroma profiles of Pinot Gris, Chardonnay and Sauvignon Blanc wines. Food Chem. 2021, 346, 128914. [Google Scholar] [CrossRef]

- Nikolantonaki, M.; Waterhouse, A.L. A method to quantify quinone reaction rates with wine relevant nucleophiles: A key to the understanding of oxidative loss of varietal thiols. J. Agric. Food Chem. 2012, 60, 8484–8491. [Google Scholar] [CrossRef]

- Webber, V.; Dutra, S.V.; Spinelli, F.R.; Carnieli, G.J.; Cardozo, A.; Vanderlinde, R. Effect of glutathione during bottle storage of sparkling wine. Food Chem. 2017, 216, 254–259. [Google Scholar] [CrossRef]

- Clark, A.C.; Deed, R.C. The Chemical Reaction of Glutathione and trans-2-Hexenal in Grape Juice Media To Form Wine Aroma Precursors: The Impact of pH, Temperature, and Sulfur Dioxide. J. Agric. Food Chem. 2018, 66, 1214–1221. [Google Scholar] [CrossRef]

- Makhotkina, O.; Araujo, L.D.; Olejar, K.; Herbst-Johnstone, M.; Fedrizzi, B.; Kilmartin, P.A. Aroma Impact of Ascorbic Acid and Glutathione Additions to Sauvignon blanc at Harvest to Supplement Sulfur Dioxide. Am. J. Enol. Vitic. 2014, 65, 388–393. [Google Scholar] [CrossRef]

- Ruberto, G.; Renda, A.; Amico, V.; Tringali, C. Volatile components of grape pomaces from different cultivars of Sicilian Vitis vinifera L. Bioresour. Technol. 2008, 99, 260–268. [Google Scholar] [CrossRef]

- Almanza-Oliveros, A.; Bautista-Hernandez, I.; Castro-Lopez, C.; Aguilar-Zarate, P.; Meza-Carranco, Z.; Rojas, R.; Michel, M.R.; Martinez-Avila, G.C.G. Grape Pomace-Advances in Its Bioactivity, Health Benefits, and Food Applications. Foods 2024, 13, 580. [Google Scholar] [CrossRef]

- Karastergiou, A.; Gancel, A.L.; Jourdes, M.; Teissedre, P.L. Valorization of Grape Pomace: A Review of Phenolic Composition, Bioactivity, and Therapeutic Potential. Antioxidants 2024, 13, 1131. [Google Scholar] [CrossRef] [PubMed]

- Abreu, T.; Sousa, P.; Gonçalves, J.; Hontman, N.; Teixeira, J.; Câmara, J.S.; Perestrelo, R. Grape Pomace as a Renewable Natural Biosource of Value-Added Compounds with Potential Food Industrial Applications. Beverages 2024, 10, 45. [Google Scholar] [CrossRef]

- Spinei, M.; Oroian, M. Structural, functional and physicochemical properties of pectin from grape pomace as affected by different extraction techniques. Int. J. Biol. Macromol. 2023, 224, 739–753. [Google Scholar] [CrossRef] [PubMed]

- Câmara, J.S.; Lourenço, S.; Silva, C.; Lopes, A.; Andrade, C.; Perestrelo, R. Exploring the potential of wine industry by-products as source of additives to improve the quality of aquafeed. Microchem. J. 2020, 155, 104758. [Google Scholar] [CrossRef]

- Ledauphin, J.; Guichard, H.; Saint-Clair, J.F.; Picoche, B.; Barillier, D. Chemical and sensorial aroma characterization of freshly distilled Calvados. 2. Identification of volatile compounds and key odorants. J. Agric. Food Chem. 2003, 51, 433–442. [Google Scholar] [CrossRef]

- Gerogiannaki-Christopoulou, M.; Kyriakidis, N.V.; Athanasopoulos, P.E. The evaluation of grape pomace distillates from selected red grape varieties. Int. J. Food Sci. Technol. 2006, 41, 854–860. [Google Scholar] [CrossRef]

- Coldea, T.E.; Mudura, E.; Ranta, N.; Hadarean, D. The Impact of Grape Marc Distillation Process on the Major Volatile Compounds. Bull. Univ. Agric. Sci. Vet. Med. Cluj-Napoca Anim. Sci. Biotechnol. 2013, 70, 223–229. [Google Scholar]

- EUR-Lex. Regulation (EU) 2019/787 of the European Parliament and of the Council. Off. J. Eur. Union. 2019, 62, 1–55. [Google Scholar]

- Aurand, J.-M.; Hodson, G.; Wilkes, E.; Azevedo, S.; Battaglene, T. Methanol in wine. BIO Web Conf. 2017, 9, 02028. [Google Scholar] [CrossRef]

- Plata, C.; Millán, C.; Mauricio, J.C.; Ortega, J.M. Formation of ethyl acetate and isoamyl acetate by various species of wine yeasts. Food Microbiol. 2003, 20, 217–224. [Google Scholar] [CrossRef]

- Soles, R.M.; Ough, C.S.; Kunkee, R.E. Ester Concentration Differences in Wine Fermented by Various Species and Strains of Yeasts. Am. J. Enol. Vitic. 1982, 33, 94–98. [Google Scholar] [CrossRef]

- Cortés, S.; Rodríguez, R.; Salgado, J.M.; Domínguez, J.M. Comparative study between Italian and Spanish grape marc spirits in terms of major volatile compounds. Food Control 2011, 22, 673–680. [Google Scholar] [CrossRef]

- Etievant, P.X.; Bayonove, C.L. Aroma components of pomaces and wine from the variety muscat de frontignan. J. Sci. Food Agric. 1983, 34, 393–403. [Google Scholar] [CrossRef]

- TGSC. The Good Scents Company Information System. Available online: http://www.thegoodscentscompany.com (accessed on 1 January 2025).

- Liang, Z.; Pai, A.; Liu, D.; Luo, J.; Wu, J.; Fang, Z.; Zhang, P. Optimizing extraction method of aroma compounds from grape pomace. J. Food Sci. 2020, 85, 4225–4240. [Google Scholar] [CrossRef]

- Lopez de Lerma, N.; Bellincontro, A.; Mencarelli, F.; Moreno, J.; Peinado, R.A. Use of electronic nose, validated by GC–MS, to establish the optimum off-vine dehydration time of wine grapes. Food Chem. 2012, 130, 447–452. [Google Scholar] [CrossRef]

- Vazquez-Pateiro, I.; Arias-Gonzalez, U.; Miras-Avalos, J.M.; Falque, E. Evolution of the Aroma of Treixadura Wines during Bottle Aging. Foods 2020, 9, 1419. [Google Scholar] [CrossRef]

- Perestrelo, R.; Silva, C.; Camara, J.S. Madeira Wine Volatile Profile. A Platform to Establish Madeira Wine Aroma Descriptors. Molecules 2019, 24, 3028. [Google Scholar] [CrossRef]

- Vilela, A. Modulating Wine Pleasantness Throughout Wine-Yeast Co-Inoculation or Sequential Inoculation. Fermentation 2020, 6, 22. [Google Scholar] [CrossRef]

- Kim, B.-H.; Park, S.K. Volatile aroma and sensory analysis of black raspberry wines fermented by different yeast strains. J. Inst. Brew. 2015, 121, 87–94. [Google Scholar] [CrossRef]

- Xia, Y.-n.; Suo, R.; Wang, H.; Cerbin, S.; Wang, J. Analysis on Flavor Compounds of Jujube Brandy from Different Fermentation Heights by HS-SPME-GC/MS, E-nose and E-tongue. Am. J. Food Technol. 2017, 12, 332–344. [Google Scholar] [CrossRef]

- Martin, V.; Giorello, F.; Farina, L.; Minteguiaga, M.; Salzman, V.; Boido, E.; Aguilar, P.S.; Gaggero, C.; Dellacassa, E.; Mas, A.; et al. De Novo Synthesis of Benzenoid Compounds by the Yeast Hanseniaspora vineae Increases the Flavor Diversity of Wines. J. Agric. Food Chem. 2016, 64, 4574–4583. [Google Scholar] [CrossRef] [PubMed]

- Ribéreau-Gayon, P.; Glories, Y.; Maujean, A.; Dubourdieu, D. Varietal Aroma. In Handbook of Enology; Wiley: Hoboken, NJ, USA, 2006; pp. 205–230. [Google Scholar]

- Fariña, L.; Villar, V.; Ares, G.; Carrau, F.; Dellacassa, E.; Boido, E. Volatile composition and aroma profile of Uruguayan Tannat wines. Food Res. Int. 2015, 69, 244–255. [Google Scholar] [CrossRef]

- Park, H.J.; Lee, S.M.; Song, S.H.; Kim, Y.S. Characterization of volatile components in makgeolli, a traditional Korean rice wine, with or without pasteurization, during storage. Molecules 2013, 18, 5317–5325. [Google Scholar] [CrossRef] [PubMed]

- Romano, P.; Braschi, G.; Siesto, G.; Patrignani, F.; Lanciotti, R. Role of Yeasts on the Sensory Component of Wines. Foods 2022, 11, 1921. [Google Scholar] [CrossRef]

- Tarasov, A.; Giuliani, N.; Dobrydnev, A.; Schuessler, C.; Volovenko, Y.; Rauhut, D.; Jung, R. 1,1,6-Trimethyl-1,2-dihydronaphthalene (TDN) Sensory Thresholds in Riesling Wine. Foods 2020, 9, 606. [Google Scholar] [CrossRef]

- Li, X.-l.; Kang, L.; Hu, J.-j.; Li, X.-f.; Shen, X. Aroma Volatile Compound Analysis of SPME Headspace and Extract Samples from Crabapple (Malus sp.) Fruit Using GC-MS. Agric. Sci. China 2008, 7, 1451–1457. [Google Scholar] [CrossRef]

- Nie, C.N.; Gao, Y.; Du, X.; Bian, J.L.; Li, H.; Zhang, X.; Wang, C.M.; Li, S.Y. Characterization of the effect of cis-3-hexen-1-ol on green tea aroma. Sci. Rep. 2020, 10, 15506. [Google Scholar] [CrossRef]

- Zhang, H.; Pu, D.; Sun, B.; Ren, F.; Zhang, Y.; Chen, H. Characterization and comparison of key aroma compounds in raw and dry porcini mushroom (Boletus edulis) by aroma extract dilution analysis, quantitation and aroma recombination experiments. Food Chem. 2018, 258, 260–268. [Google Scholar] [CrossRef]

- Bayarri, S.; Costell, E. Sensory Evaluation of Fruit and Vegetable Flavors; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2010; pp. 45–57. [Google Scholar] [CrossRef]

- Scutarașu, E.C.; Luchian, C.E.; Vlase, L.; Nagy, K.; Colibaba, L.C.; Trinca, L.C.; Cotea, V.V. Influence Evaluation of Enzyme Treatments on Aroma Profile of White Wines. Agronomy 2022, 12, 2897. [Google Scholar] [CrossRef]

- Li, Y.; Li, Q.; Zhang, B.; Shen, C.; Xu, Y.; Tang, K. Identification, quantitation and sensorial contribution of lactones in brandies between China and France. Food Chem. 2021, 357, 129761. [Google Scholar] [CrossRef]

- Howard, C. Skin contact whites: Perhaps amber is the new “orange”. Wine Vitic. 2017, 32, 21–25. [Google Scholar]

- Palomo, E.S.; Díaz-Maroto, M.C.; Viñas, M.A.G.; Soriano-Pérez, A.; Pérez-Coello, M.S. Aroma profile of wines from Albillo and Muscat grape varieties at different stages of ripening. Food Control 2007, 18, 398–403. [Google Scholar] [CrossRef]

- Tominaga, T.; Murat, M.-L.; Dubourdieu, D. Development of a method for analyzing the volatile thiols involved in the characteristic aroma of wines made from Vitis vinifera L. Cv. Sauvignon blanc. J. Agric. Food Chem. 1998, 46, 1044–1048. [Google Scholar] [CrossRef]

- Şener, H. Effect of Temperature and Duration of Maceration on Colour and Sensory Properties of Red Wine: A Review. South. Afr. J. Enol. Vitic. 2018, 32, 227–234. [Google Scholar] [CrossRef]

- Lukic, I.; Lotti, C.; Vrhovsek, U. Evolution of free and bound volatile aroma compounds and phenols during fermentation of Muscat blanc grape juice with and without skins. Food Chem. 2017, 232, 25–35. [Google Scholar] [CrossRef]

- Fedrizzi, B.; Versini, G.; Finato, F.; Casarotti, E.M.; Nicolis, E.; Ferrarini, R. Evaluation of the Impact of an Archaic Protocol on White Wine Free Aroma Compounds. Flavor Chem. Wine Other Alcohol. Beverages 2012, 1104, 117–131. [Google Scholar] [CrossRef]

- Radeka, S.; Bestulić, E.; Rossi, S.; Orbanić, F.; Bubola, M.; Plavša, T.; Lukić, I.; Jeromel, A. Effect of Different Vinification Techniques on the Concentration of Volatile Aroma Compounds and Sensory Profile of Malvazija Istarska Wines. Fermentation 2023, 9, 676. [Google Scholar] [CrossRef]

- Lukic, I.; Jedrejcic, N.; Ganic, K.K.; Staver, M.; Persuric, D. Phenolic and Aroma Composition of White Wines Produced by Prolonged Maceration and Maturation in Wooden Barrels. Food Technol. Biotechnol. 2015, 53, 407–418. [Google Scholar] [CrossRef]

- Peinado, R.A.; Moreno, J.; Bueno, J.E.; Moreno, J.A.; Mauricio, J.C. Comparative study of aromatic compounds in two young white wines subjected to pre-fermentative cryomaceration. Food Chem. 2004, 84, 585–590. [Google Scholar] [CrossRef]

- Slaghenaufi, D.; Ugliano, M. Norisoprenoids, Sesquiterpenes and Terpenoids Content of Valpolicella Wines During Aging: Investigating Aroma Potential in Relationship to Evolution of Tobacco and Balsamic Aroma in Aged Wine. Front. Chem. 2018, 6, 6. [Google Scholar] [CrossRef]

- Ferreira, V. Volatile Aroma Compounds and Wine Sensory Attributes; Woodhead Publishing: Cambridge, UK, 2010; pp. 3–28. [Google Scholar] [CrossRef]

- Prezioso, I.; Fioschi, G.; Rustioni, L.; Mascellani, M.; Natrella, G.; Venerito, P.; Gambacorta, G.; Paradiso, V.M. Influence of prolonged maceration on phenolic compounds, volatile profile and sensory properties of wines from Minutolo and Verdeca, two Apulian white grape varieties. LWT 2024, 192, 115698. [Google Scholar] [CrossRef]

- Wang, J.; Huo, S.; Zhang, Y.; Liu, Y.; Fan, W. Impact of various maceration techniques on the phenolic and volatile composition of Chenin Blanc wines. Int. J. Food Sci. Technol. 2016, 51, 2360–2366. [Google Scholar] [CrossRef]

- Du Plessis, H.; Du Toit, M.; Nieuwoudt, H.; Van der Rijst, M.; Kidd, M.; Jolly, N. Effect of Saccharomyces, Non-Saccharomyces Yeasts and Malolactic Fermentation Strategies on Fermentation Kinetics and Flavor of Shiraz Wines. Fermentation 2017, 3, 64. [Google Scholar] [CrossRef]

- Rodríguez Madrera, R.; Pando Bedriñana, R.; Suárez Valles, B. Production and characterization of aroma compounds from apple pomace by solid-state fermentation with selected yeasts. LWT Food Sci. Technol. 2015, 64, 1342–1353. [Google Scholar] [CrossRef]

- Lainez-Cerón, E.; Jiménez-Munguía, M.T.; López-Malo, A.; Ramírez-Corona, N. Effect of process variables on heating profiles and extraction mechanisms during hydrodistillation of eucalyptus essential oil. Heliyon 2021, 7, e08234. [Google Scholar] [CrossRef]

- Ibrahim, I.A.; Khoo, K.S.; Rawindran, H.; Lim, J.W.; Ng, H.-S.; Shahid, M.K.; Tong, W.-Y.; Hatshan, M.R.; Sun, Y.-M.; Lan, J.C.-W.; et al. Environmental Sustainability of Solvent Extraction Method in Recycling Marine Plastic Waste. Sustainability 2023, 15, 15742. [Google Scholar] [CrossRef]

- Khaw, K.Y.; Parat, M.O.; Shaw, P.N.; Falconer, J.R. Solvent Supercritical Fluid Technologies to Extract Bioactive Compounds from Natural Sources: A Review. Molecules 2017, 22, 1186. [Google Scholar] [CrossRef]

- Bagade, S.B.; Patil, M. Recent Advances in Microwave Assisted Extraction of Bioactive Compounds from Complex Herbal Samples: A Review. Crit. Rev. Anal. Chem. 2021, 51, 138–149. [Google Scholar] [CrossRef]

- Liang, Z.; Zhang, P.; Fang, Z. Modern technologies for extraction of aroma compounds from fruit peels: A review. Crit. Rev. Food Sci. Nutr. 2022, 62, 1284–1307. [Google Scholar] [CrossRef]

- Fernandez, C.M.; Ramos, M.J.; Perez, A.; Rodriguez, J.F. Production of biodiesel from winery waste: Extraction, refining and transesterification of grape seed oil. Bioresour. Technol. 2010, 101, 7030–7035. [Google Scholar] [CrossRef]

- Chowdhary, P.; Gupta, A.; Gnansounou, E.; Pandey, A.; Chaturvedi, P. Current trends and possibilities for exploitation of Grape pomace as a potential source for value addition. Environ. Pollut. 2021, 278, 116796. [Google Scholar] [CrossRef] [PubMed]

- Muñoz-González, C.; Rodríguez-Bencomo, J.J.; Martín-Álvarez, P.J.; Moreno-Arribas, M.V.; Pozo-Bayón, M.Á. Recovery of Aromatic Aglycones from Grape Pomace Winemaking By-Products by Using Liquid-Liquid and Pressurized-Liquid Extraction. Food Anal. Methods 2013, 7, 47–57. [Google Scholar] [CrossRef]

- Jelley, R.E.; Herbst-Johnstone, M.; Klaere, S.; Pilkington, L.I.; Grose, C.; Martin, D.; Barker, D.; Fedrizzi, B. Optimization of Ecofriendly Extraction of Bioactive Monomeric Phenolics and Useful Flavor Precursors from Grape Waste. ACS Sustain. Chem. Eng. 2016, 4, 5060–5067. [Google Scholar] [CrossRef]

- Rebecchi, S.; Pinelli, D.; Bertin, L.; Zama, F.; Fava, F.; Frascari, D. Volatile fatty acids recovery from the effluent of an acidogenic digestion process fed with grape pomace by adsorption on ion exchange resins. Chem. Eng. J. 2016, 306, 629–639. [Google Scholar] [CrossRef]

- Kohajdová, V.; Karovičová, J.; Lauková, M. Physical, Textural and Sensory Properties of Cookies Incorporated with Grape Skin and Seed Preparations. Pol. J. Food Nutr. Sci. 2018, 68, 309–317. [Google Scholar] [CrossRef]

- Pasqualone, A.; Bianco, A.M.; Paradiso, V.M.; Summo, C.; Gambacorta, G.; Caponio, F. Physico-chemical, sensory and volatile profiles of biscuits enriched with grape marc extract. Food Res. Int. 2014, 65, 385–393. [Google Scholar] [CrossRef]

- Tseng, A.; Zhao, Y. Wine grape pomace as antioxidant dietary fibre for enhancing nutritional value and improving storability of yogurt and salad dressing. Food Chem. 2013, 138, 356–365. [Google Scholar] [CrossRef]

- Mammadova, S.M.; Fataliyev, H.K.; Gadimova, N.S.; Aliyeva, G.R.; Tagiyev, A.T.; Baloglanova, K.V. Production of functional products using grape processing residuals. Food Sci. Technol. 2020, 40, 422–428. [Google Scholar] [CrossRef]

- Chevance, F.F.; Farmer, L.J.; Desmond, E.M.; Novelli, E.; Troy, D.J.; Chizzolini, R. Effect of some fat replacers on the release of volatile aroma compounds from low-fat meat products. J. Agric. Food Chem. 2000, 48, 3476–3484. [Google Scholar] [CrossRef]

- Costa, J.R.; Monteiro, M.J.; Tonon, R.V.; Cabral, L.M.C.; Pastrana, L.; Pintado, M.E. Fortification of coconut water with microencapsulated grape pomace extract towards a novel electrolyte beverage: Biological, sensorial and quality aspects. Future Foods 2021, 4, 100079. [Google Scholar] [CrossRef]

- Xu, Y.; Burton, S.; Kim, C.; Sismour, E. Phenolic compounds, antioxidant, and antibacterial properties of pomace extracts from four Virginia-grown grape varieties. Food Sci. Nutr. 2016, 4, 125–133. [Google Scholar] [CrossRef]

- Bocsan, I.C.; Magureanu, D.C.; Pop, R.M.; Levai, A.M.; Macovei, S.O.; Patrasca, I.M.; Chedea, V.S.; Buzoianu, A.D. Antioxidant and Anti-Inflammatory Actions of Polyphenols from Red and White Grape Pomace in Ischemic Heart Diseases. Biomedicines 2022, 10, 2337. [Google Scholar] [CrossRef]

- Harlander, S. Biotechnology for the Production of Flavoring Materials. In Source Book of Flavors; Reineccius, G., Ed.; Springer US: Boston, MA, USA, 1994; pp. 155–175. [Google Scholar]

| Grape Variety | Class of Examined Parameters | Volatile Compounds | Conc (µg/L) | Aroma Descriptor ** |

|---|---|---|---|---|

| Garganega [177] | Monoterpenes | Linalool | 5.3–7.5 | Ginger, flowers, grape-like, sweet, citrus [165] |

| α-Terpineol | 2.2–3.9 | Flowers, lilies, sweet [180] | ||

| Citronellol | 2.4–6.7 | Citrus, clove, floral, fresh, green, rose, sour, sweet [156] | ||

| Geraniol | 4.7–5.7 | Citrus, floral, geranium [157] | ||

| Esters | Isoamylacetate | 182.5–278.9 | Banana, pear [181] | |

| Ethyloctanoate | 305.7–413.0 | Fruit, musty, soapy, sweet, waxy [156] | ||

| Ethyldecanoate | 90.7–90.9 | Brandy, fruity, grape [180] | ||

| Norisoprenoids | 3-oxo--ionol | 81.2–90.9 | Burnt, spicy [181] | |

| Benzenoids | Vanillin | 12.8–51.3 | Sweet, vanilla [156] | |

| Verdicchio [177] | Monoterpenes | Linalool | 5.4 | Ginger, flowers, grape-like, sweet, citrus [165] |

| α-Terpineol | 8.6 | Flowers, lilies, sweet [180] | ||

| Citronellol | 3.1 | Citrus, clove, floral, fresh, green, rose, sour, sweet [156] | ||

| Geraniol | 2.2 | Citrus, floral, geranium [157] | ||

| Esters | Isoamylacetate | 572.8 | Banana, pear [181] | |

| Ethyloctanoate | 649.4 | Fruit, musty, soapy, sweet, waxy [156] | ||

| Ethyldecanoate | 144.9 | Brandy, fruity, grape [180] | ||

| Norisoprenoids | 3-oxo--ionol | 119.5 | Burnt, spicy [181] | |

| Benzenoids | Vanillin | 117.6 | Sweet, vanilla [156] | |

| Malvazija istarska [178] | Monoterpenes | Linalool | 111.65–113.91 | Ginger, flowers, grape-like, sweet, citrus [165] |

| Geraniol | 40.22–44.79 | Citrus, floral, geranium [157] | ||

| α-Terpineol | 46.52–76.68 | Flowers, lilies, sweet [180] | ||

| Norisoprenoides | β-damascenone | 11.08–19.27 | Floral, red berries [36] | |

| Alcohols | 1-Hexanol | 4329–4752 | Floral, cut grass, herbaceous [154,155] | |

| Fatty acids | Hexanoic acid | 3820–9834 | Fruity, fresh, sweet [182] | |

| Ethyl 3-methylbutanoate | 46.74–53.14 | Fusel [104], herbaceous, whiskey, malty, burnt [105] | ||

| Ethyl octanoate | 732–871 | Fruit, musty, soapy, sweet, waxy [156] | ||

| 2-Phenethylacetate | 43.27–47.89 | Floral, rose [103] | ||

| Isoamyl acetate | 1030–1062 | Banana, pear [181] | ||

| Ethyl lactate | 152,14–160,33 | Floral, fruity, sweet [183] | ||

| Malvazija istarska (in oak) [179] | Monoterpenes | α-Terpineol | 114.7 | Flowers, lilies, sweet [180] |

| Linalool | 37.4 | Ginger, flowers, grape-like, sweet, citrus [165] | ||

| C13-norisoprenoids | Vitispirane | 37.1 | Camphor, spicy, wood [156] | |

| Higher alcohols | Isobutanol * | 48.3 | Alcohol, nail polish, fusel [180] | |

| Isoamyl alcohol * | 243.5 | Fusel [104], herbaceous, whiskey, malt, burnt [105] | ||

| Esters | Ethyl acetate | 75.1 | Fruity [160], nail polish remover [103] | |

| Ethyl hexanoate | 145.7 | Anise, caramel, fruit, wine [156] | ||

| Ethyl octanoate | 128.1 | Fruit, musty, soapy, sweet, waxy [156] | ||

| Volatile phenols | 4-Ethylguaiacol | 445.7 | Phenolic, sweet [164] | |

| 4-Ethylphenol | 119.0 | Medicinal, stable [164] | ||

| Chenin Blanc [184] | Monoterpenes | Linalool | 1.94 | Ginger, flowers, grape-like, sweet, citrus [165] |

| Alcohols | Isopentanol | 353.3 | Fusel, alcoholic, fermented, pungent, bready, yeasty [185] | |

| Esters | Isoamyl acetate | 183.2 | Banana, pear [181] | |

| Ethyl hexanoate | 295.5 | Anise, caramel, fruit, wine [156] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Buican, B.-C.; Luchian, C.E.; Colibaba, L.C.; Niculaua, M.; Bordean, M.-E.; Kallithraka, S.; Cotea, V.V. Aroma Compounds from Grape Pomace: Investigation of Key Winemaking Factors for Future Extraction Applications—A Review. Horticulturae 2025, 11, 302. https://doi.org/10.3390/horticulturae11030302

Buican B-C, Luchian CE, Colibaba LC, Niculaua M, Bordean M-E, Kallithraka S, Cotea VV. Aroma Compounds from Grape Pomace: Investigation of Key Winemaking Factors for Future Extraction Applications—A Review. Horticulturae. 2025; 11(3):302. https://doi.org/10.3390/horticulturae11030302

Chicago/Turabian StyleBuican, Bettina-Cristina, Camelia Elena Luchian, Lucia Cintia Colibaba, Marius Niculaua, Maria-Evelina Bordean, Stamatina Kallithraka, and Valeriu V. Cotea. 2025. "Aroma Compounds from Grape Pomace: Investigation of Key Winemaking Factors for Future Extraction Applications—A Review" Horticulturae 11, no. 3: 302. https://doi.org/10.3390/horticulturae11030302

APA StyleBuican, B.-C., Luchian, C. E., Colibaba, L. C., Niculaua, M., Bordean, M.-E., Kallithraka, S., & Cotea, V. V. (2025). Aroma Compounds from Grape Pomace: Investigation of Key Winemaking Factors for Future Extraction Applications—A Review. Horticulturae, 11(3), 302. https://doi.org/10.3390/horticulturae11030302