Rapid Detection of Moisture Content in the Processing of Longjing Tea by Micro-Near-Infrared Spectroscopy and a Portable Colorimeter Based on a Data Fusion Strategy

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample Preparation

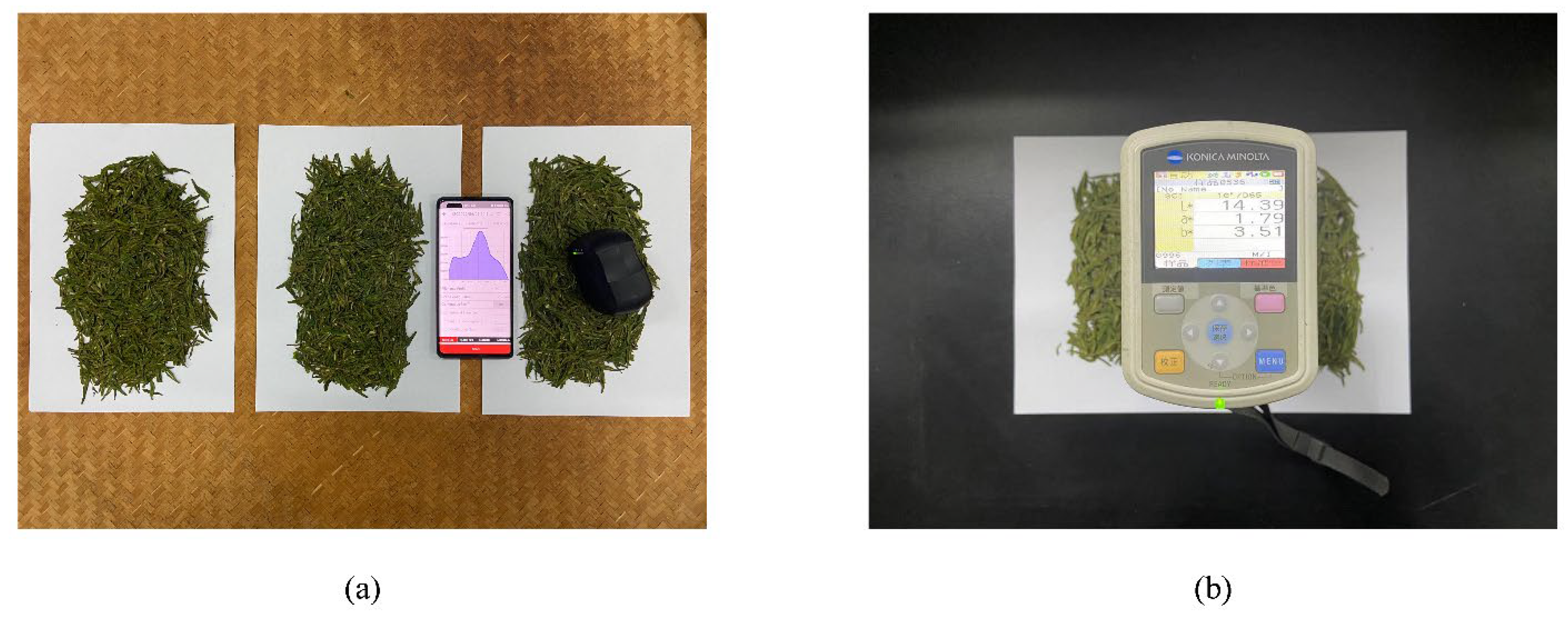

2.2. Spectral Data Collection

2.3. Colorimeters Data Acquisition

2.4. Moisture Content Measurement

2.5. NIR Spectral and Colorimeter Data Processing

2.5.1. Spectral Preprocessing

2.5.2. Colorimeter Data Optimization and Extraction

2.6. Spectral and Colorimetric Sensor Data Fusion

2.7. Quantitative Prediction Model Establishment and Evaluation

2.8. Software

3. Results and Discussion

3.1. Spectral Characteristic Extraction Results

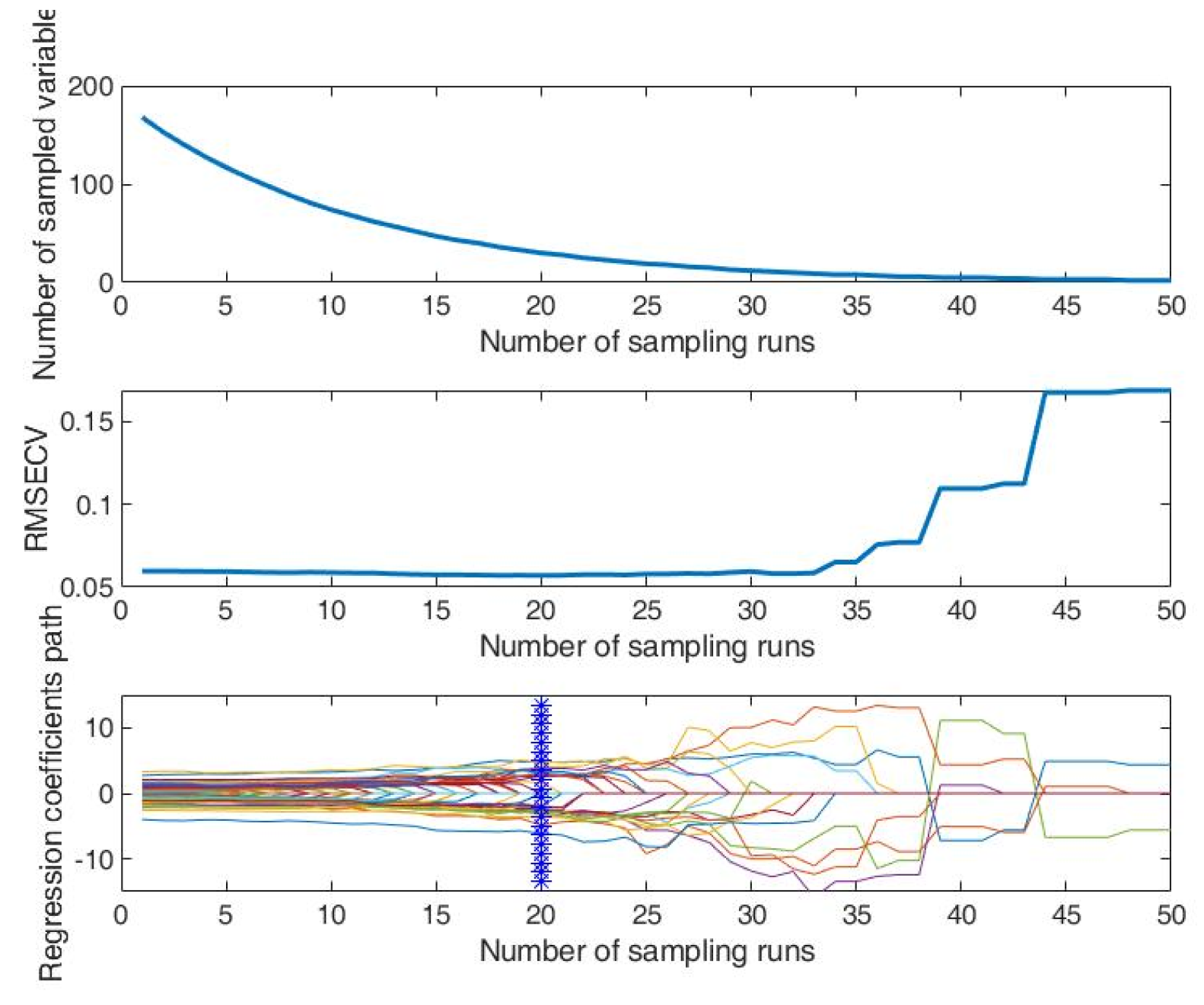

3.2. Selection of Spectral Characteristic Wavelengths

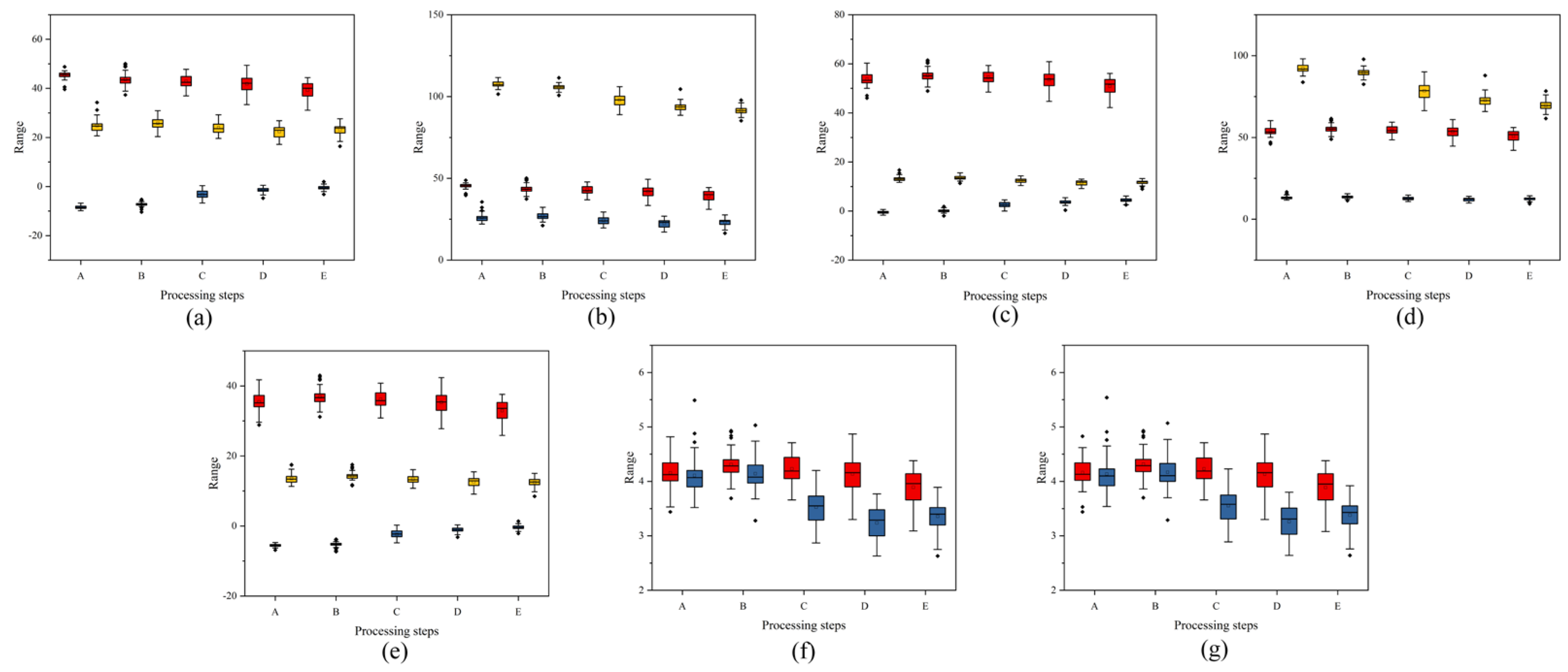

3.3. Characterization of Colorimetric Factors during Processing

3.4. Data Fusion and Moisture Content Prediction of Tea Processing

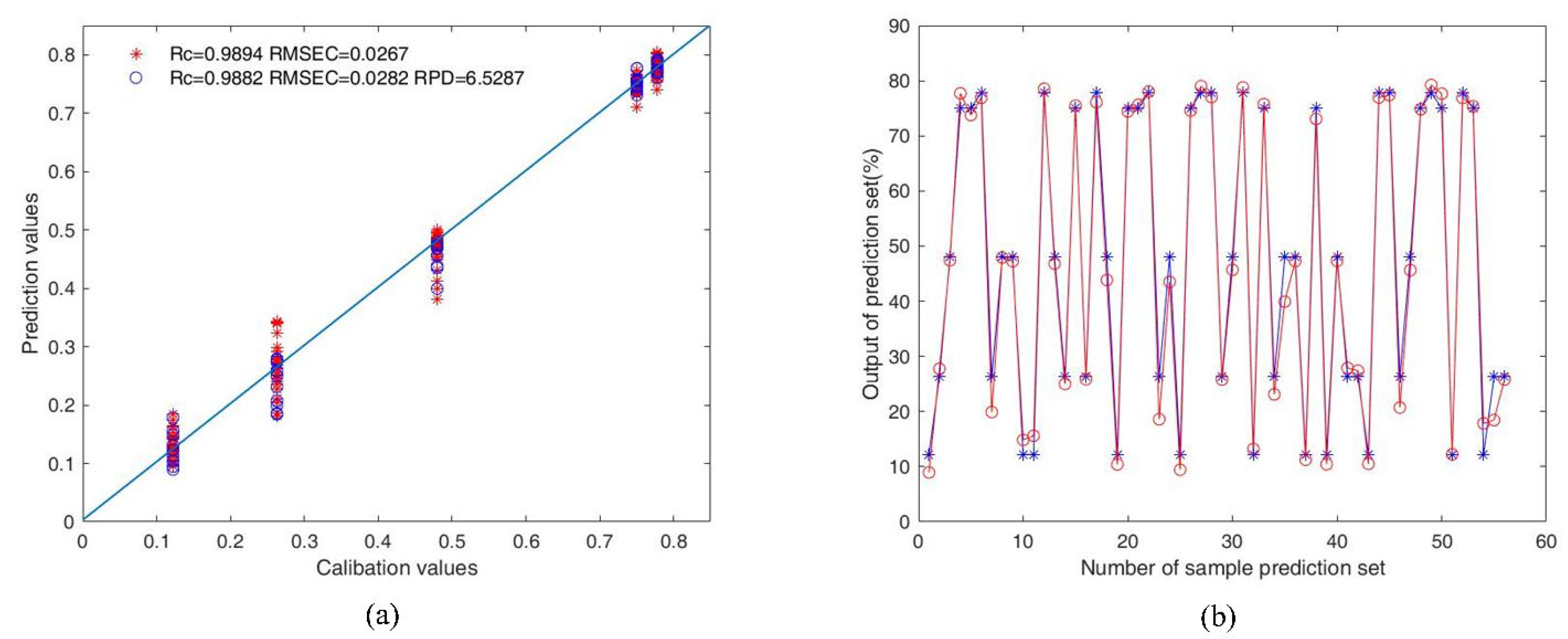

3.4.1. Moisture Prediction Model Based on Single Sensor Data

3.4.2. Moisture Prediction Model Based on Multi-Sensor Data Fusion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Khanali, M.; Hosseinzadeh-Bandbafha, H.; Salehpour, T. Chapter 10-Environmental impact of tea production/consumption chain. In Environmental Impact of Agro-Food Industry and Food Consumption; Galanakis, C.M., Ed.; Academic Press: New York, NY, USA, 2021; pp. 217–237. [Google Scholar] [CrossRef]

- Luo, F.; Du, X.-H.; Zeng, Q.; Wang, Y.; Ma, W.-W. Research on the Suitability for Different Tea Cultivars Processed into Flat Green Tea. Adv. Mater. Res. 2013, 726–731, 4405–4410. [Google Scholar] [CrossRef]

- Ni, K.; Wang, J.; Zhang, Q.; Yi, X.; Ma, L.; Shi, Y.; Ruan, J. Multi-element composition and isotopic signatures for the geographical origin discrimination of green tea in China: A case study of Xihu Longjing. J. Food Compos. Anal. 2018, 67, 104–109. [Google Scholar] [CrossRef]

- Wang, J.-Q.; Fu, Y.-Q.; Chen, J.-X.; Wang, F.; Feng, Z.-H.; Yin, J.-F.; Zeng, L.; Xu, Y.-Q. Effects of baking treatment on the sensory quality and physicochemical properties of green tea with different processing methods. Food Chem. 2022, 380, 132217. [Google Scholar] [CrossRef] [PubMed]

- Zhu, H.; Ye, Y.; He, H.; Dong, C. Evaluation of green tea sensory quality via process characteristics and image information. Food Bioprod. Process. 2017, 102, 116–122. [Google Scholar] [CrossRef]

- Huang, W.; Lu, G.; Deng, W.-W.; Ning, J. Effects of different withering methods on the taste of Keemun black tea. LWT 2022, 166, 113791. [Google Scholar] [CrossRef]

- Deng, S.; Zhang, G.; Olayemi Aluko, O.; Mo, Z.; Mao, J.; Zhang, H.; Liu, X.; Ma, M.; Wang, Q.; Liu, H. Bitter and astringent substances in green tea: Composition, human perception mechanisms, evaluation methods and factors influencing their formation. Food Res. Int. 2022, 157, 111262. [Google Scholar] [CrossRef]

- Dong, C.; An, T.; Yang, M.; Yang, C.; Liu, Z.; Li, Y.; Duan, D.; Fan, S. Quantitative prediction and visual detection of the moisture content of withering leaves in black tea (Camellia sinensis) with hyperspectral image. Infrared Phys. Technol. 2022, 123, 104118. [Google Scholar] [CrossRef]

- Mendes Novo, J.; Iriel, A.; Lagorio, M.G. Rapid spectroscopic method to assess moisture content in free and packaged oregano (Origanum vulgare L.). J. Appl. Res. Med. Aromat. Plants 2016, 3, 211–214. [Google Scholar] [CrossRef]

- Zhu, M.-Z.; Wen, B.; Wu, H.; Li, J.; Lin, H.; Li, Q.; Li, Y.; Huang, J.; Liu, Z. The Quality Control of Tea by Near-Infrared Reflectance (NIR) Spectroscopy and Chemometrics. J. Spectrosc. 2019, 2019, 8129648. [Google Scholar] [CrossRef]

- Dong, C.; Li, J.; Wang, J.; Liang, G.; Jiang, Y.; Yuan, H.; Yang, Y.; Meng, H. Rapid determination by near infrared spectroscopy of theaflavins-to-thearubigins ratio during Congou black tea fermentation process. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2018, 205, 227–234. [Google Scholar] [CrossRef]

- Li, L.; Xie, S.; Ning, J.; Chen, Q.; Zhang, Z. Evaluating green tea quality based on multisensor data fusion combining hyperspectral imaging and olfactory visualization systems. J. Sci. Food Agric. 2019, 99, 1787–1794. [Google Scholar] [CrossRef]

- Lee, M.-S.; Hwang, Y.-S.; Lee, J.; Choung, M.-G. The characterization of caffeine and nine individual catechins in the leaves of green tea (Camellia sinensis L.) by near-infrared reflectance spectroscopy. Food Chem. 2014, 158, 351–357. [Google Scholar] [CrossRef]

- Jin, G.; Wang, Y.-J.; Li, M.; Li, T.; Huang, W.-J.; Li, L.; Deng, W.-W.; Ning, J. Rapid and real-time detection of black tea fermentation quality by using an inexpensive data fusion system. Food Chem. 2021, 358, 129815. [Google Scholar] [CrossRef]

- Wang, Y.; Li, L.; Liu, Y.; Cui, Q.; Ning, J.; Zhang, Z. Enhanced quality monitoring during black tea processing by the fusion of NIRS and computer vision. J. Food Eng. 2021, 304, 110599. [Google Scholar] [CrossRef]

- Hu, Y.; Youli, W.; Jie, S.; Jinping, G.; Rongsheng, F.; Zhiliang, K. Distinguishing Different Varieties of Oolong Tea by Fluorescence Hyperspectral Technology Combined with Chemometrics. Foods 2022, 11, 2344. [Google Scholar] [CrossRef]

- Jiang, H.; Wang, J.; Chen, Q. Comparison of wavelength selected methods for improving of prediction performance of PLS model to determine aflatoxin B1 (AFB1) in wheat samples during storage. Microchem. J. 2021, 170, 106642. [Google Scholar] [CrossRef]

- Yang, J.; Wang, J.; Lu, G.; Fei, S.; Yan, T.; Zhang, C.; Lu, X.; Yu, Z.; Li, W.; Tang, X. TeaNet: Deep learning on Near-Infrared Spectroscopy (NIR) data for the assurance of tea quality. Comput. Electron. Agric. 2021, 190, 106431. [Google Scholar] [CrossRef]

- Rinnan, Å.; van den Berg, F.; Engelsen, S.B. Review of the most common pre-processing techniques for near-infrared spectra. TrAC Trends Anal. Chem. 2009, 28, 1201–1222. [Google Scholar] [CrossRef]

- Yang, Y.; She, X.; Cao, X.; Yang, L.; Huang, J.; Zhang, X.; Su, L.; Wu, M.; Tong, H.; Ji, X. Comprehensive evaluation of Dendrobium officinale from different geographical origins using near-infrared spectroscopy and chemometrics. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2022, 277, 121249. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Shao, Y.; Yao, Y.; Yu, Y.; Cao, G.; Zou, H.; Yan, Y. A novel quality evaluation method for magnolia bark using electronic nose and colorimeter data with multiple statistical algorithms. J. Tradit. Chin. Med. Sci. 2020, 7, 221–227. [Google Scholar] [CrossRef]

- Bossart, R.; Keller, H.; Kellerhals, H.; Oelichmann, J. Principal components analysis as a tool for identity control using near-infrared spectroscopy. J. Mol. Struct. 2003, 661–662, 319–323. [Google Scholar] [CrossRef]

- Ouyang, Q.; Zhao, J.; Chen, Q. Instrumental intelligent test of food sensory quality as mimic of human panel test combining multiple cross-perception sensors and data fusion. Anal. Chim. Acta 2014, 841, 68–76. [Google Scholar] [CrossRef]

- Borràs, E.; Ferré, J.; Boqué, R.; Mestres, M.; Aceña, L.; Busto, O. Data fusion methodologies for food and beverage authentication and quality assessment–A review. Anal. Chim. Acta 2015, 891, 1–14. [Google Scholar] [CrossRef]

- Di Rosa, A.R.; Leone, F.; Cheli, F.; Chiofalo, V. Fusion of electronic nose, electronic tongue and computer vision for animal source food authentication and quality assessment—A review. J. Food Eng. 2017, 210, 62–75. [Google Scholar] [CrossRef]

- Zhang, X.; Li, H.; Zhang, Y.; Qi, H.; Yang, X.; Wang, Q.; Li, D. Quantitative analysis of the oil mixture using PLS combined with spectroscopy detection. Optik 2021, 244, 167611. [Google Scholar] [CrossRef]

- Câmara, A.B.F.; de Oliveira, K.G.; Santos, M.C.D.; de Lima, R.R.S.; de Lima, K.M.G.; de Carvalho, L.S. Multivariate assessment for predicting antioxidant activity from clove and pomegranate extracts by MCR-ALS and PLS models combined to IR spectroscopy. Food Chem. 2022, 384, 132321. [Google Scholar] [CrossRef]

- Zareef, M.; Chen, Q.; Ouyang, Q.; Arslan, M.; Hassan, M.M.; Ahmad, W.; Viswadevarayalu, A.; Wang, P.; Ancheng, W. Rapid screening of phenolic compounds in congou black tea (Camellia sinensis) during in vitro fermentation process using portable spectral analytical system coupled chemometrics. J. Food Process. Preserv. 2019, 43, e13996. [Google Scholar] [CrossRef]

- Li, X.; Jin, J.; Sun, C.; Ye, D.; Liu, Y. Simultaneous determination of six main types of lipid-soluble pigments in green tea by visible and near-infrared spectroscopy. Food Chem. 2019, 270, 236–242. [Google Scholar] [CrossRef]

- Wang, Y.; Hu, X.; Jin, G.; Hou, Z.; Ning, J.; Zhang, Z. Rapid prediction of chlorophylls and carotenoids content in tea leaves under different levels of nitrogen application based on hyperspectral imaging. J. Sci. Food Agric. 2019, 99, 1997–2004. [Google Scholar] [CrossRef]

- Bi, Y.; Yuan, K.; Xiao, W.; Wu, J.; Shi, C.; Xia, J.; Chu, G.; Zhang, G.; Zhou, G. A local pre-processing method for near-infrared spectra, combined with spectral segmentation and standard normal variate transformation. Anal. Chim. Acta 2016, 909, 30–40. [Google Scholar] [CrossRef] [PubMed]

- Jiang, H.; Xu, W.; Chen, Q. Determination of tea polyphenols in green tea by homemade color sensitive sensor combined with multivariate analysis. Food Chem. 2020, 319, 126584. [Google Scholar] [CrossRef] [PubMed]

- Shahabi, M.; Rafiee, S.; Mohtasebi, S.S.; Hosseinpour, S. Image analysis and green tea color change kinetics during thin-layer drying. Food Sci. Technol. Int. 2014, 20, 465–476. [Google Scholar] [CrossRef]

| Processing Procedure | Average Moisture Content (%) | Number of Samples | |

|---|---|---|---|

| Spectrum | Colorimetric | ||

| Fresh | 77.81 | 225 | 225 |

| Spreading | 75.03 | ||

| First drying | 47.98 | ||

| Compressing | 26.28 | ||

| Second drying | 12.22 | ||

| Pretreatment Methods | PCs | Calibration Set | Prediction Set | ||

|---|---|---|---|---|---|

| RMSEC | RMSEP | ||||

| RAW | 10 | 0.9283 | 0.0720 | 0.7855 | 0.0996 |

| Smooth | 16 | 0.9290 | 0.0714 | 0.7873 | 0.0992 |

| SNV | 14 | 0.8499 | 0.1012 | 0.8228 | 0.0964 |

| S-G | 12 | 0.9094 | 0.0796 | 0.7943 | 0.0917 |

| MSC | 13 | 0.8560 | 0.0974 | 0.8210 | 0.0990 |

| Processing Procedure | Parameter Range | Average Parameter | ||||

|---|---|---|---|---|---|---|

| L* | a* | b* | L* | a* | b* | |

| Fresh | 37.34~48.80 | −9.86~−6.76 | 20.61~34.25 | 45.38 | −8.46 | 24.78 |

| Spreading | 37.34~50.07 | −10.40~−5.29 | 20.38~30.91 | 43.64 | −7.26 | 25.84 |

| First drying | 36.94~47.78 | −6.74~0.36 | 19.58~29.25 | 42.89 | −3.33 | 23.95 |

| Carding | 33.39~49.45 | −4.74~0.50 | 18.27~26.81 | 41.91 | −1.41 | 22.45 |

| Second drying | 31.09~44.41 | −3.19~1.95 | 16.4~26.12 | 35.61 | −0.51 | 23.19 |

| Prediction Data Source | Data Processing Methods | PCs | Calibration Set | Prediction Set | ||

|---|---|---|---|---|---|---|

| RMSEC | RMSEP | |||||

| Near-infrared spectroscopy | Smooth-SNV-PLS | 15 | 0.9631 | 0.0496 | 0.9423 | 0.0621 |

| Smooth-SNV-CARS-PLS | 13 | 0.9666 | 0.0430 | 0.9643 | 0.0445 | |

| colorimeter | Z-score-PLS | 16 | 0.9011 | 0.0806 | 0.9033 | 0.0838 |

| Z-score-PCA-PLS | 3 | 0.8678 | 0.0927 | 0.8607 | 0.0855 | |

| Degree of Data Fusion | Data Processing Methods | PCs | Calibration Set | Prediction Set | RPD | ||

|---|---|---|---|---|---|---|---|

| RMSEC | RMSEP | ||||||

| Low-level | SNV + Z-score | 18 | 0.9587 | 0.0523 | 0.9578 | 0.0457 | 3.4790 |

| Middle-level | SNV-CARS + Z-score-PCA | 13 | 0.9894 | 0.0267 | 0.9882 | 0.0282 | 6.5287 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zong, X.; Sheng, X.; Li, L.; Zan, J.; Jiang, Y.; Zou, H.; Shen, S.; Yuan, H. Rapid Detection of Moisture Content in the Processing of Longjing Tea by Micro-Near-Infrared Spectroscopy and a Portable Colorimeter Based on a Data Fusion Strategy. Horticulturae 2022, 8, 1007. https://doi.org/10.3390/horticulturae8111007

Zong X, Sheng X, Li L, Zan J, Jiang Y, Zou H, Shen S, Yuan H. Rapid Detection of Moisture Content in the Processing of Longjing Tea by Micro-Near-Infrared Spectroscopy and a Portable Colorimeter Based on a Data Fusion Strategy. Horticulturae. 2022; 8(11):1007. https://doi.org/10.3390/horticulturae8111007

Chicago/Turabian StyleZong, Xuyan, Xufeng Sheng, Li Li, Jiezhong Zan, Yongwen Jiang, Hanting Zou, Shuai Shen, and Haibo Yuan. 2022. "Rapid Detection of Moisture Content in the Processing of Longjing Tea by Micro-Near-Infrared Spectroscopy and a Portable Colorimeter Based on a Data Fusion Strategy" Horticulturae 8, no. 11: 1007. https://doi.org/10.3390/horticulturae8111007