Prediction Method of the Moisture Content of Black Tea during Processing Based on the Miniaturized Near-Infrared Spectrometer

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Sample

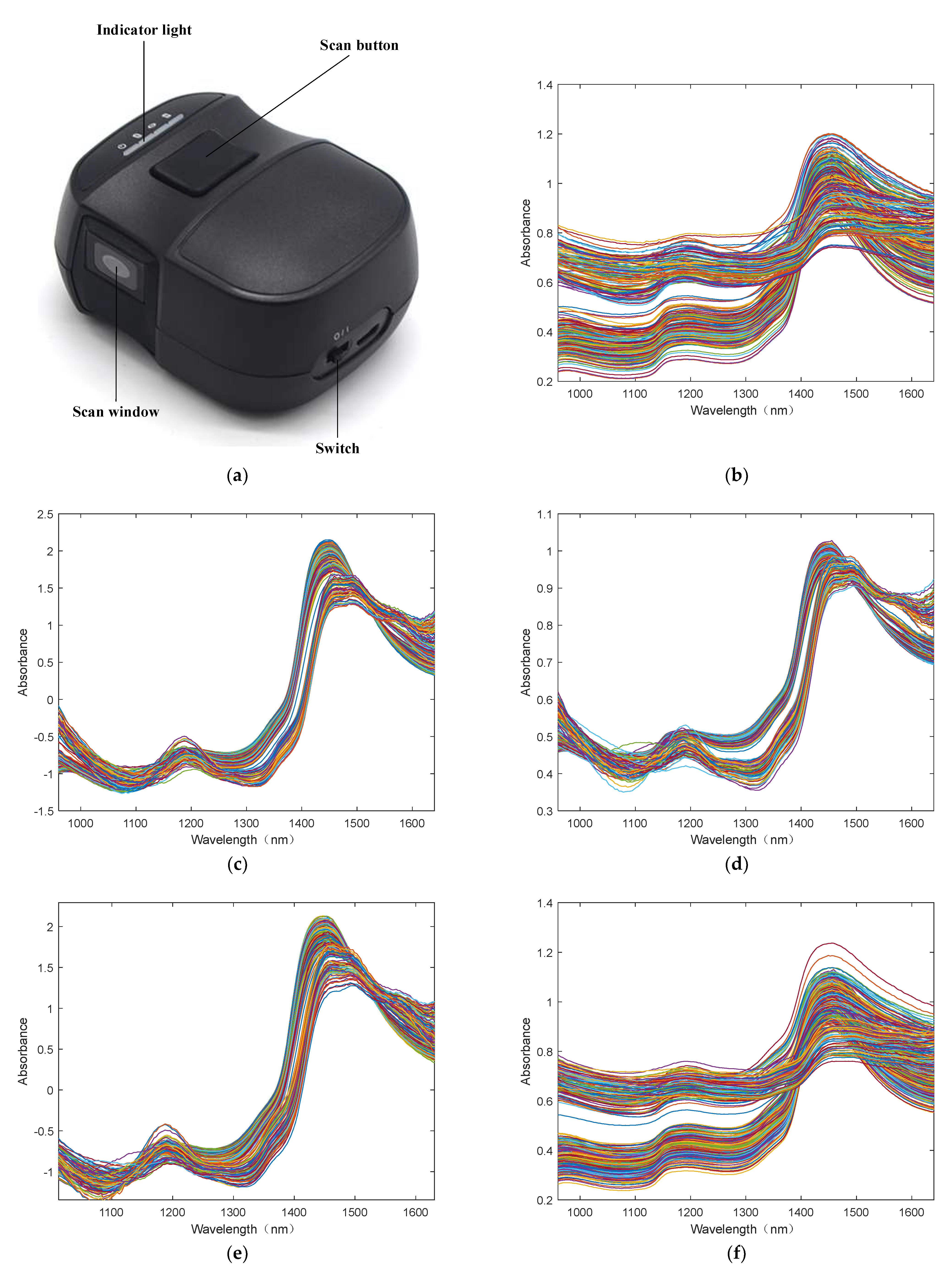

2.2. Data Acquisition

2.3. Determination of Moisture Content

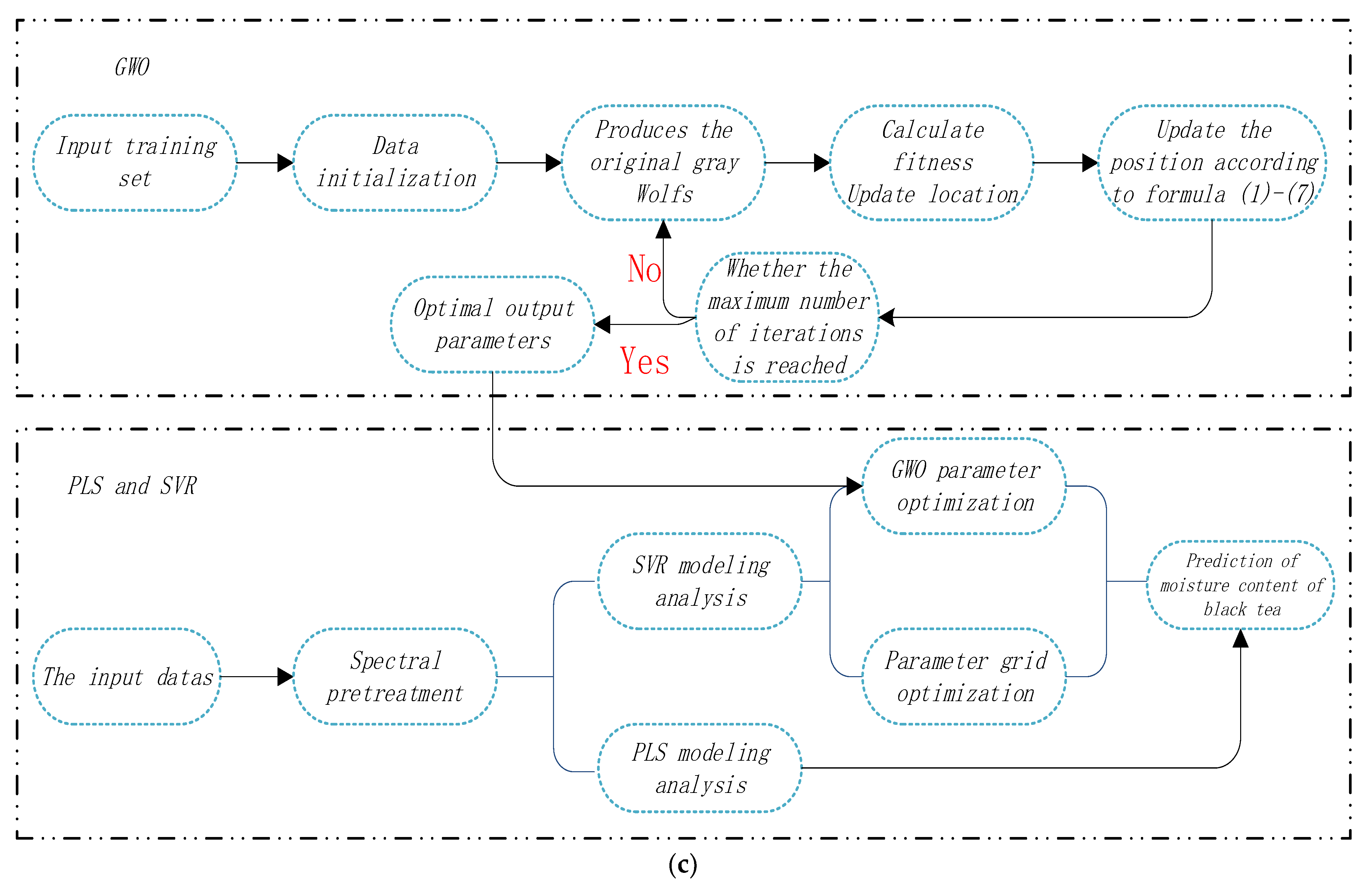

2.4. Establishment of Models

2.4.1. Spectral Pre−Processing Methods

2.4.2. Partial Least Squares (PLS)

2.4.3. Support Vector Regression

2.4.4. GWO Algorithm

Social Level Stratification

Encircling the Prey

Tracking the Prey

Aggressive Behaviour

2.4.5. Model Establishment and Performance Evaluation

3. Results and Analysis

3.1. Spectral Characteristics

3.2. Comparison of Models

3.2.1. Data Set Partitioning

3.2.2. PLS

3.2.3. SVR

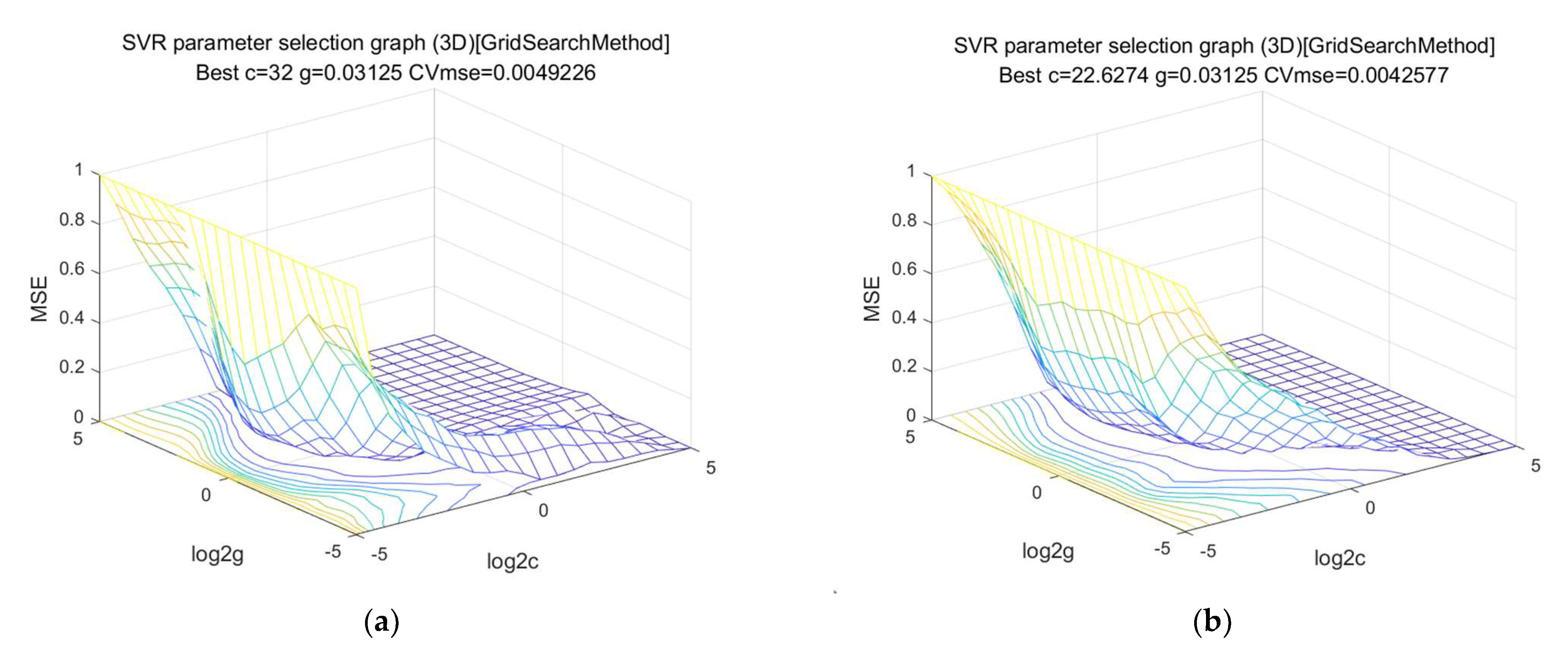

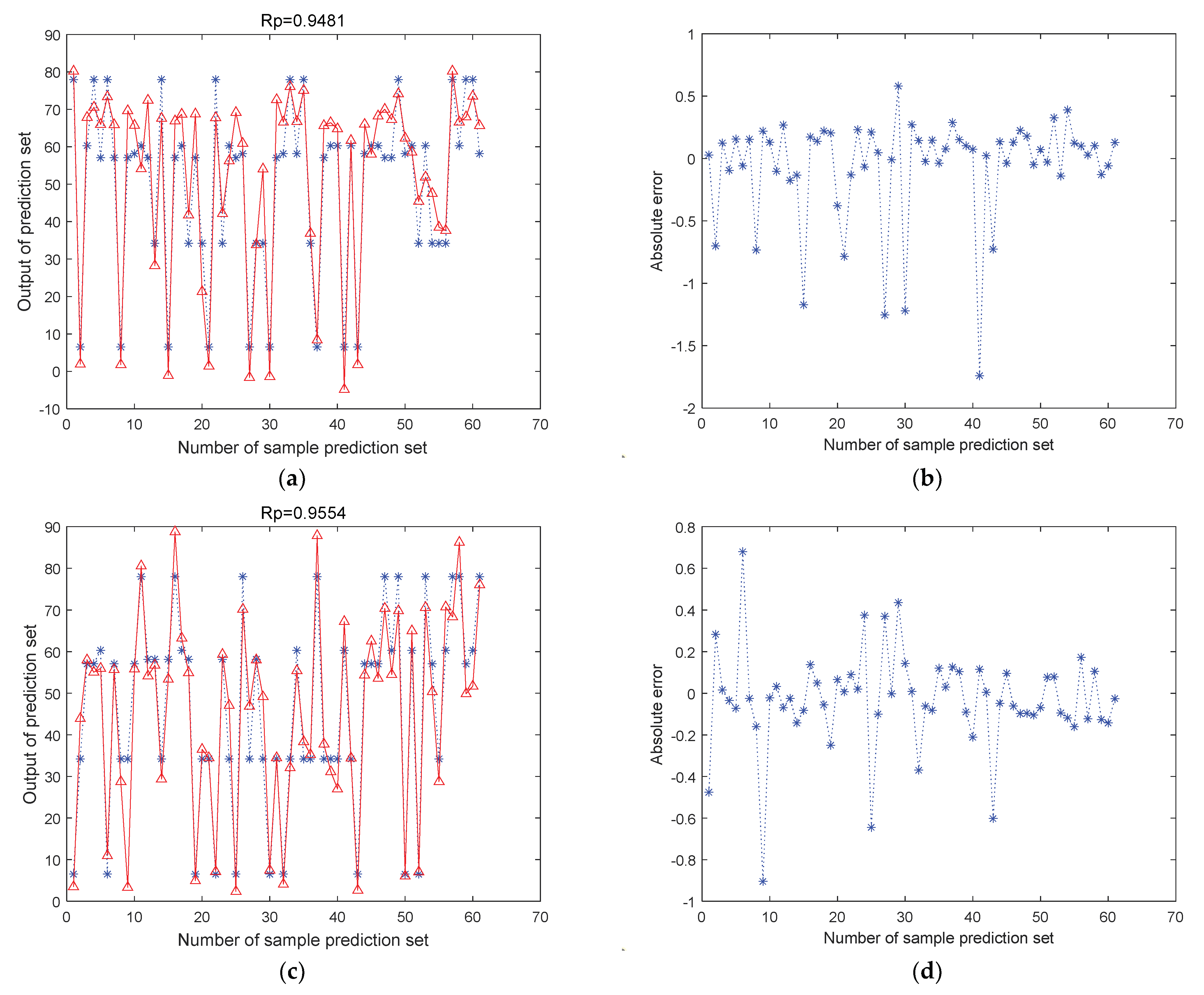

3.2.4. SNV−PCA−SVR

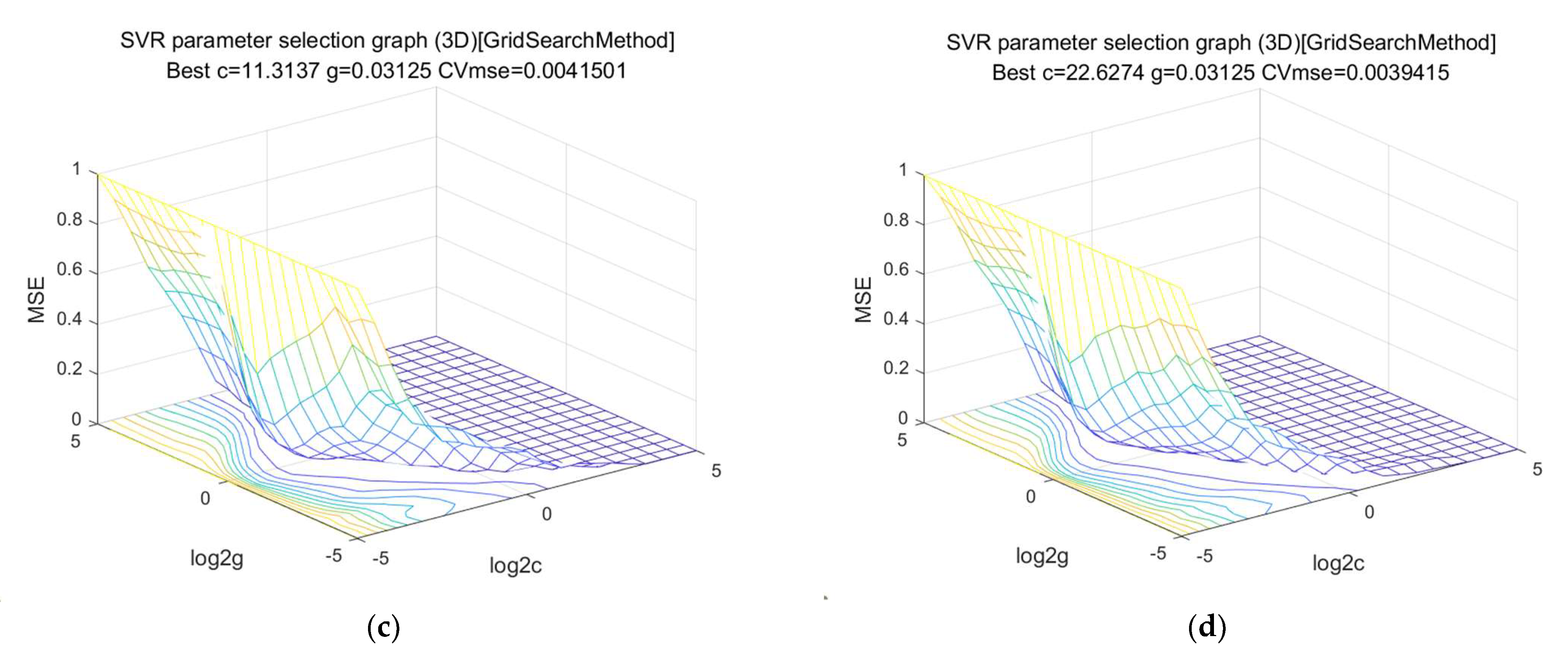

3.2.5. SNV−PCA−GWO−SVR

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, J.H.; Wang, Y.F.; Cheng, J.J.; Wang, J.; Sun, X.D.; Sun, S.; Zhang, Z.Y. Enhanced cross-category models for predicting the total polyphenols, caffeine and free amino acids contents in Chinese tea using NIR spectroscopy. Lwt 2018, 96, 90–97. [Google Scholar] [CrossRef]

- Wang, Y.J.; Ren, Z.Y.; Li, M.Y.; Yuan, W.X.; Zhang, Z.Z.; Ning, J.M. pH indicator-based sensor array in combination with hyperspectral imaging for intelligent evaluation of withering degree during processing of black tea. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2022, 271, 120959. [Google Scholar] [CrossRef] [PubMed]

- Liang, G.Z.; Dong, C.W.; Hu, B.; Zhu, H.K.; Yuan, H.B.; Jiang, Y.W.; Hao, G.S. Prediction of Moisture Content for Congou Black Tea Withering Leaves Using Image Features and Nonlinear Method. Sci. Rep. 2018, 8, 7854. [Google Scholar] [CrossRef]

- Vargas, R.; Vecchietti, A. Influence of raw material moisture on the synthesis of black tea production process. J. Food Eng. 2016, 173, 76–84. [Google Scholar] [CrossRef]

- Dong, C.W.; An, T.; Yang, M.; Yang, C.S.; Liu, Z.Y.; Li, Y.; Duan, D.D.; Fan, S.X. Quantitative prediction and visual detection of the moisture content of withering leaves in black tea (Camellia sinensis) with hyperspectral image. Infrared Phys. Technol. 2022, 123, 104118. [Google Scholar] [CrossRef]

- Hossain, M.A.; Ahmed, T.; Hossain, M.S.; Dey, P.; Ahmed, S.; Hossain, M.M. Optimization of the factors affecting BT-2 black tea fermentation by observing their combined effects on the quality parameters of made tea using Response Surface Methodology (RSM). Heliyon 2022, 8, e08948. [Google Scholar] [CrossRef]

- Qu, F.F.; Zhu, X.J.; Ai, Z.Y.; Ai, Y.J.; Qiu, F.F.; Ni, D.J. Effect of different drying methods on the sensory quality and chemical components of black tea. Lwt 2019, 99, 112–118. [Google Scholar] [CrossRef]

- Chen, A.; Chen, H.Y.; Chen, C.C. Use of Temperature and Humidity Sensors to Determine Moisture Content of Oolong Tea. Sensors 2014, 14, 15593–15609. [Google Scholar] [CrossRef]

- Wei, Y.Z.; Wu, F.Y.; Xu, J.; Sha, J.J.; Zhao, Z.F.; He, Y.; Li, X.L. Visual detection of the moisture content of tea leaves with hyperspectral imaging technology. J. Food Eng. 2019, 248, 89–96. [Google Scholar] [CrossRef]

- Jia, J.M.; Zhou, X.F.; Li, Y.; Wang, M.; Liu, Z.Y.; Dong, C.W. Establishment of a rapid detection model for the sensory quality and components of Yuezhou Longjing tea using near-infrared spectroscopy. Lwt 2022, 164, 113625. [Google Scholar] [CrossRef]

- Wang, Y.J.; Cui, Q.Q.; Jin, S.S.; Zhuo, C.; Luo, Y.H.; Yu, Y.L.; Ning, J.M.; Zhang, Z.Z. Tea Analyzer: A low-cost and portable tool for quality quantification of postharvest fresh tea leaves. Lwt 2022, 159, 113248. [Google Scholar] [CrossRef]

- Shen, S.; Hua, J.J.; Zhu, H.K.; Yang, Y.Q.; Deng, Y.L.; Li, J.; Yuan, H.B.; Wang, J.J.; Zhu, J.Y.; Jiang, Y.W. Rapid and real-time detection of moisture in black tea during withering using micro-near-infrared spectroscopy. Lwt 2022, 155, 112970. [Google Scholar] [CrossRef]

- Wang, Y.J.; Liu, Y.; Cui, Q.Q.; Li, L.Q.; Ning, J.M.; Zhang, Z.Z. Monitoring the withering condition of leaves during black tea processing via the fusion of electronic eye (E-eye), colorimetric sensing array (CSA), and micro-near-infrared spectroscopy (NIRS). J. Food Eng. 2021, 300, 110534. [Google Scholar] [CrossRef]

- Kang, R.X.; Wang, X.; Zhao, M.; Henihan, L.E.; O’Donnell, C.P. A comparison of benchtop and micro NIR spectrometers for infant milk formula powder storage time discrimination and particle size prediction using chemometrics and denoising methods. J. Food Eng. 2022, 329, 111087. [Google Scholar] [CrossRef]

- Lan, Z.W.; Zhang, Y.F.; Zhang, Y.; Liu, F.; Ji, D.; Cao, H.; Wang, S.M.; Lu, T.L.; Meng, J. Rapid evaluation on pharmacodynamics of Curcumae Rhizoma based on Micro-NIR and benchtop-NIR. J. Pharm. Biomed. Anal. 2021, 200, 114074. [Google Scholar] [CrossRef]

- Sandak, J.; Niemz, P.; Hansel, A.; Mai, J.N.; Sandak, A. Feasibility of portable NIR spectrometer for quality assurance in glue-laminated timber production. Constr. Build. Mater. 2021, 308, 125026. [Google Scholar] [CrossRef]

- Li, L.Q.; Wang, Y.J.; Jin, S.S.; Li, M.H.; Chen, Q.S.; Ning, J.M.; Zhang, Z.Z. Evaluation of black tea by using smartphone imaging coupled with micro-near-infrared spectrometer. Acta Part A Mol. Biomol. Spectrosc. 2020, 246, 118991. [Google Scholar] [CrossRef]

- Nagy, M.M.; Wang, S.P.; Farag, M.A. Quality analysis and authentication of nutraceuticals using near IR (NIR) spectroscopy: A comprehensive review of novel trends and applications. Trends Food Sci. Technol. 2022, 123, 290–309. [Google Scholar] [CrossRef]

- Miloš, B.; Bensa, A.; Japundžić-Palenkić, B. Evaluation of Vis-NIR preprocessing combined with PLS regression for estimation soil organic carbon, cation exchange capacity and clay from eastern Croatia. Geoderma Reg. 2022, 30, e00558. [Google Scholar] [CrossRef]

- Santos, C.E.D.; Sampaio, R.C.; Coelho, L.D.; Bestard, G.A.; Llanos, C.H. Multi-objective adaptive differential evolution for SVM/SVR hyperparameters selection. Pattern Recognit. 2020, 110, 107649. [Google Scholar] [CrossRef]

- Lee, H.; Torres-Verdin, C. Compositions of liquid mixtures from near-infrared spectrum data via radial basis functions and artificial neural networks. Vib. Spectrosc. 2020, 110, 103108. [Google Scholar] [CrossRef]

- Balogun, A.L.; Rezaie, F.; Pham, Q.B.; Gigovic, L.; Drobnjak, S.; Aina, Y.A.; Panahi, M.; Yekeen, S.T.; Lee, S. Spatial prediction of landslide susceptibility in western Serbia using hybrid support vector regression (SVR) with GWO, BAT and COA algorithms. Geosci. Front. 2020, 12, 101104. [Google Scholar] [CrossRef]

- An, T.; Yu, H.; Yang, C.S.; Liang, G.Z.; Chen, J.Y.; Hu, Z.H.; Hu, B.; Dong, C.W. Black tea withering moisture detection method based on convolution neural network confidence. J. Food Process. Eng. 2020, 43, e13428. [Google Scholar] [CrossRef]

- Rady, A.; Fischer, J.; Reeves, S.; Logan, B.; Watson, N.J. The Effect of Light Intensity, Sensor Height, and Spectral Pre-Processing Methods When Using NIR Spectroscopy to Identify Different Allergen-Containing Powdered Foods. Sensors 2019, 20, 230. [Google Scholar] [CrossRef]

- Leng, T.; Li, F.; Chen, Y.; Tang, L.J.; Xie, J.H.; Yu, Q. Fast quantification of total volatile basic nitrogen (TVB-N) content in beef and pork by near-infrared spectroscopy: Comparison of SVR and PLS model. Meat Sci. 2021, 180, 108559. [Google Scholar] [CrossRef]

- Xie, G.; Qian, Y.T.; Wang, S.Y. Forecasting Chinese cruise tourism demand with big data: An optimized machine learning approach. Tour. Manag. 2020, 82, 104208. [Google Scholar] [CrossRef]

- Wei, X.; Li, S.; Zhu, S.P.; Zheng, W.Q.; Xie, Y.; Zhou, S.L.; Hu, M.D.; Miao, Y.J.; Ma, L.K.; Wu, W.J.; et al. Terahertz spectroscopy combined with data dimensionality reduction algorithms for quantitative analysis of protein content in soybeans. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2021, 253, 119571. [Google Scholar] [CrossRef]

- Chang, C.C.; Lin, C.J. LIBSVM: A Library for Support Vector Machines. ACM Trans. Intell. Syst. Technol. 2011, 2, 1–27. [Google Scholar] [CrossRef]

- Mirjalili, S.; Mirjalili, S.M.; Lewis, A. Grey Wolf Optimizer. Adv. Eng. Softw. 2014, 69, 46–61. [Google Scholar] [CrossRef]

- Ghalambaz, M.; Yengejeh, R.J.; Davami, A.H. Building energy optimization using Grey Wolf Optimizer (GWO). Case Stud. Therm. Eng. 2021, 27, 101250. [Google Scholar] [CrossRef]

- Liu, S.Y.; Wang, S.T.; Hu, C.H.; Zhan, S.J.; Kong, D.M.; Wang, J.Z. Rapid and accurate determination of diesel multiple properties through NIR data analysis assisted by machine learning. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2022, 277, 121261. [Google Scholar] [CrossRef] [PubMed]

- Viegas, T.R.; Mata, A.L.M.L.; Duarte, M.M.L.; Lima, K.M.G. Determination of quality attributes in wax jambu fruit using NIRS and PLS. Food Chem. 2016, 190, 1–4. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.Y.; Zhang, R.T.; Yang, C.S.; Hu, B.; Luo, X.; Li, Y.; Dong, C.W. Research on moisture content detection method during green tea processing based on machine vision and near-infrared spectroscopy technology. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2022, 271, 120921. [Google Scholar] [CrossRef] [PubMed]

- Dong, C.W.; Ye, Y.L.; Yang, C.S.; An, T.; Jiang, Y.W.; Ye, Y.; Li, Y.Q.; Yang, Y.Q. Rapid detection of catechins during black tea fermentation based on electrical properties and chemometrics. Food Biosci. 2021, 40, 100855. [Google Scholar] [CrossRef]

- Jin, G.; Wang, Y.J.; Li, L.Q.; Shen, S.S.; Deng, W.W.; Zhang, Z.Z.; Ning, J.M. Intelligent evaluation of black tea fermentation degree by FT-NIR and computer vision based on data fusion strategy. Lwt 2020, 125, 109216. [Google Scholar] [CrossRef]

- Wu, C.Y.; Qian, J.; Zhang, J.Y.; Wang, J.; Li, B.; Wei, Z.B. Moisture measurement of tea leaves during withering using multifrequency microwave signals optimized by ant colony optimization. J. Food Eng. 2022, 335, 111174. [Google Scholar] [CrossRef]

| Processing Step | Moisture Content Range/% | Average Moisture Content/% | Variance of Moisture Content | Standard Deviation of Moisture Content | Number of Samples |

|---|---|---|---|---|---|

| Fresh leaves | 78.62–76.85 | 77.97 | 0.1044 | 0.3960 | 51 |

| Withering | 62.66–59.24 | 60.31 | 0.3986 | 0.7730 | 55 |

| Rolling | 58.29–56.43 | 57.08 | 0.5415 | 0.9013 | 50 |

| Fermentation | 58.95–57.33 | 58.15 | 0.1771 | 0.5154 | 40 |

| First drying | 34.85–33.90 | 34.22 | 0.1216 | 0.4271 | 50 |

| Second drying | 6.68–6.36 | 6.52 | 0.0300 | 0.2122 | 59 |

| Prediction Method | Models | Pre-Processing | Prediction Data Set | RPD | |

|---|---|---|---|---|---|

| Rp | RMSEP | ||||

| Micro-NIRS | SVR | Raw | 0.9239 | 0.1146 | 1.7531 |

| SNV | 0.9481 | 0.0829 | 3.0186 | ||

| SG | 0.9245 | 0.0973 | 2.0101 | ||

| Z-score | 0.9436 | 0.0694 | 2.9069 | ||

| MSC | 0.9344 | 0.0961 | 1.9103 | ||

| PLS | Raw | 0.8387 | 0.1376 | 1.5490 | |

| SNV | 0.9425 | 0.0786 | 2.9276 | ||

| SG | 0.9397 | 0.1211 | 2.0872 | ||

| Z-score | 0.9467 | 0.0895 | 2.8344 | ||

| MSC | 0.8961 | 0.1115 | 2.0054 | ||

| Prediction Method | Models | c | g | Pre-Processing | Prediction Data Set | RPD | |

|---|---|---|---|---|---|---|---|

| Rp | RMSEP | ||||||

| Micro-NIRS | SVR | 22.6274 | 0.03125 | SNV | 0.9481 | 0.0829 | 3.0186 |

| 32.000 | 0.03125 | MSC | 0.9344 | 0.0961 | 1.9103 | ||

| 11.3137 | 0.03125 | Z-score | 0.9436 | 0.0694 | 2.9069 | ||

| 22.6274 | 0.03125 | SG | 0.9245 | 0.0973 | 2.0101 | ||

| 22.6274 | 0.03125 | SNV−PCA | 0.9554 | 0.0704 | 3.3896 | ||

| GWO-SVR | 1.000 | 4.000 | SNV−PCA | 0.9892 | 0.0362 | 6.5001 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zou, H.; Shen, S.; Lan, T.; Sheng, X.; Zan, J.; Jiang, Y.; Du, Q.; Yuan, H. Prediction Method of the Moisture Content of Black Tea during Processing Based on the Miniaturized Near-Infrared Spectrometer. Horticulturae 2022, 8, 1170. https://doi.org/10.3390/horticulturae8121170

Zou H, Shen S, Lan T, Sheng X, Zan J, Jiang Y, Du Q, Yuan H. Prediction Method of the Moisture Content of Black Tea during Processing Based on the Miniaturized Near-Infrared Spectrometer. Horticulturae. 2022; 8(12):1170. https://doi.org/10.3390/horticulturae8121170

Chicago/Turabian StyleZou, Hanting, Shuai Shen, Tianmeng Lan, Xufeng Sheng, Jiezhong Zan, Yongwen Jiang, Qizhen Du, and Haibo Yuan. 2022. "Prediction Method of the Moisture Content of Black Tea during Processing Based on the Miniaturized Near-Infrared Spectrometer" Horticulturae 8, no. 12: 1170. https://doi.org/10.3390/horticulturae8121170

APA StyleZou, H., Shen, S., Lan, T., Sheng, X., Zan, J., Jiang, Y., Du, Q., & Yuan, H. (2022). Prediction Method of the Moisture Content of Black Tea during Processing Based on the Miniaturized Near-Infrared Spectrometer. Horticulturae, 8(12), 1170. https://doi.org/10.3390/horticulturae8121170