Impact of Compaction Pressure and Heat Treatment Temperature on the Performance of FeSiBCuNb/FeNi Soft Magnetic Composites

Abstract

1. Introduction

2. Experimental Details

2.1. Preparation of FeSiBCuNb/FeNi NMPCs

2.2. Experimental Materials

3. Results and Discussion

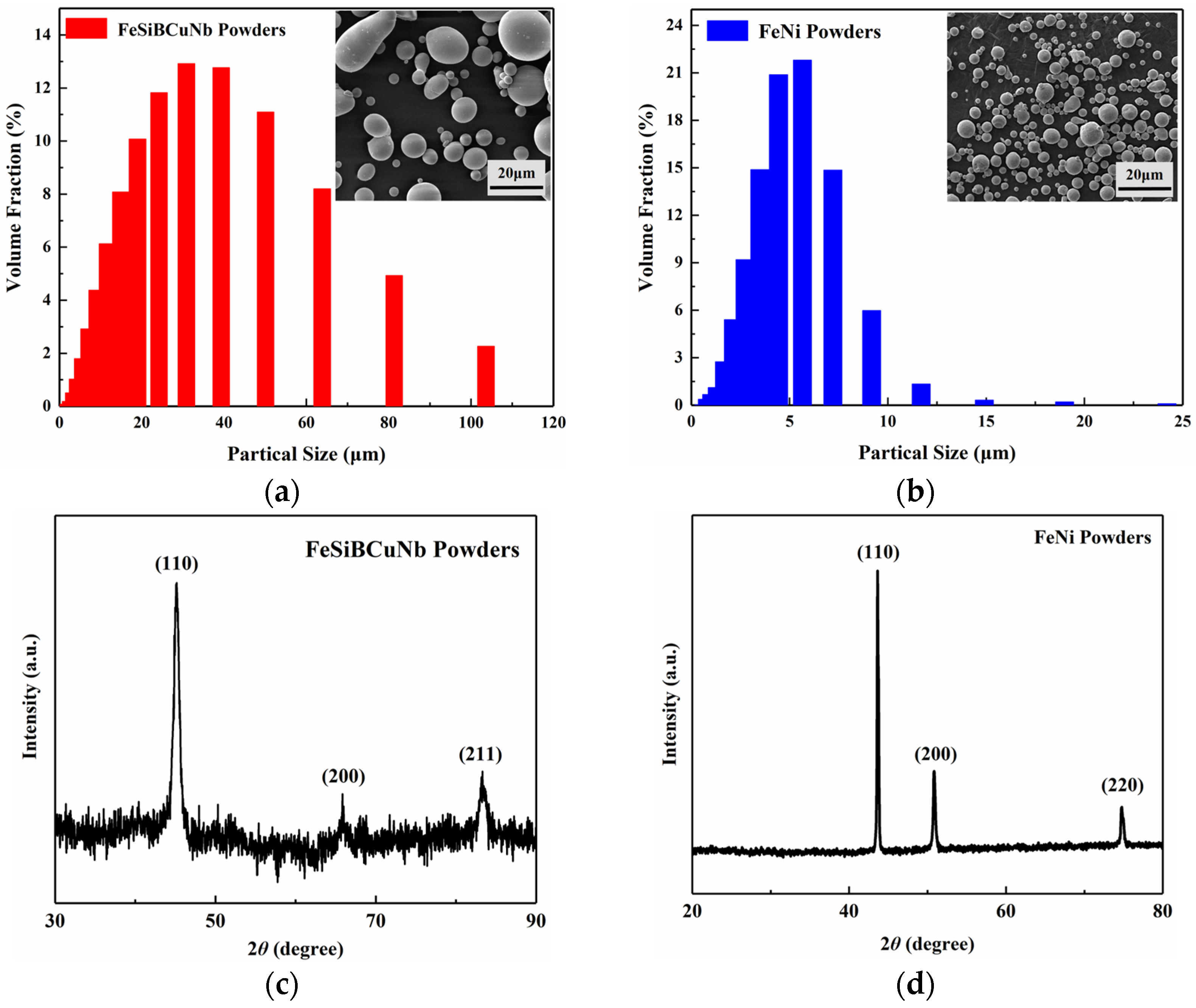

3.1. Characteristics of Raw Powders

3.2. Impact of Compaction Pressure on Soft Magnetic Properties of NMPCs

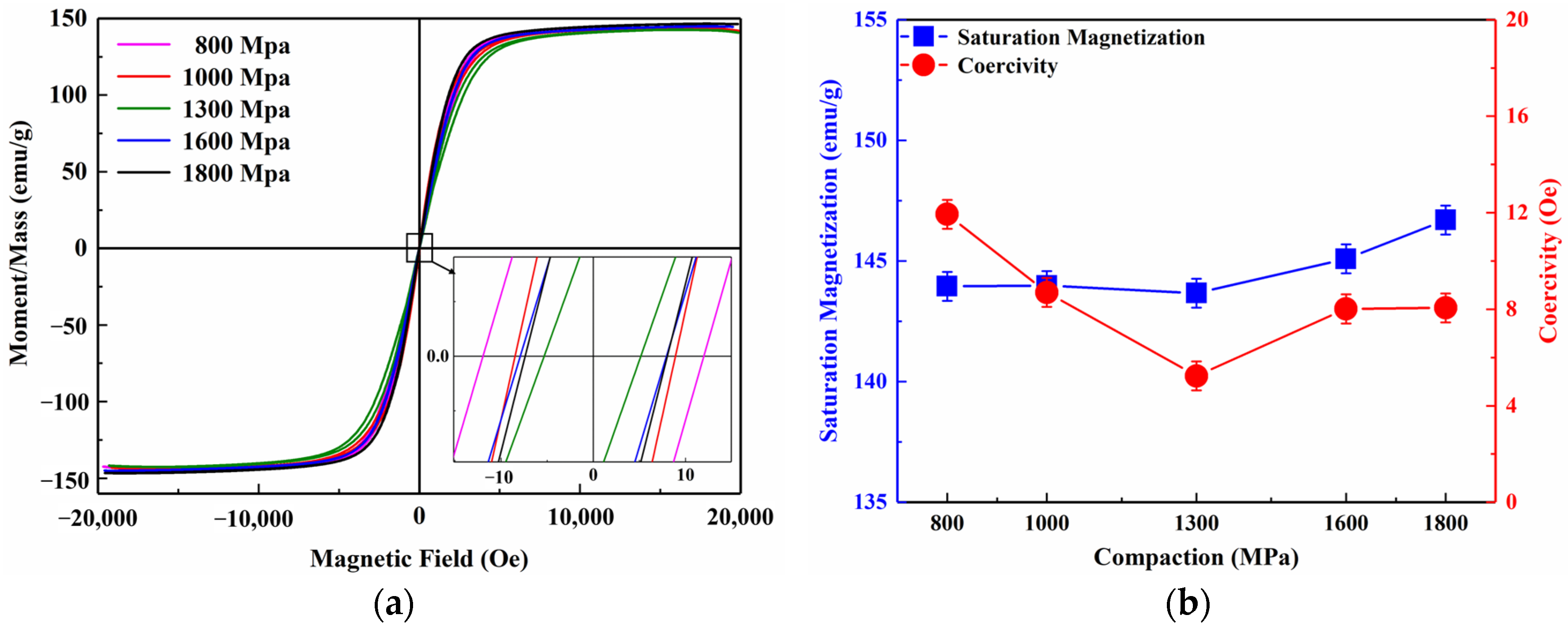

3.2.1. Coercivity and Saturation Magnetization

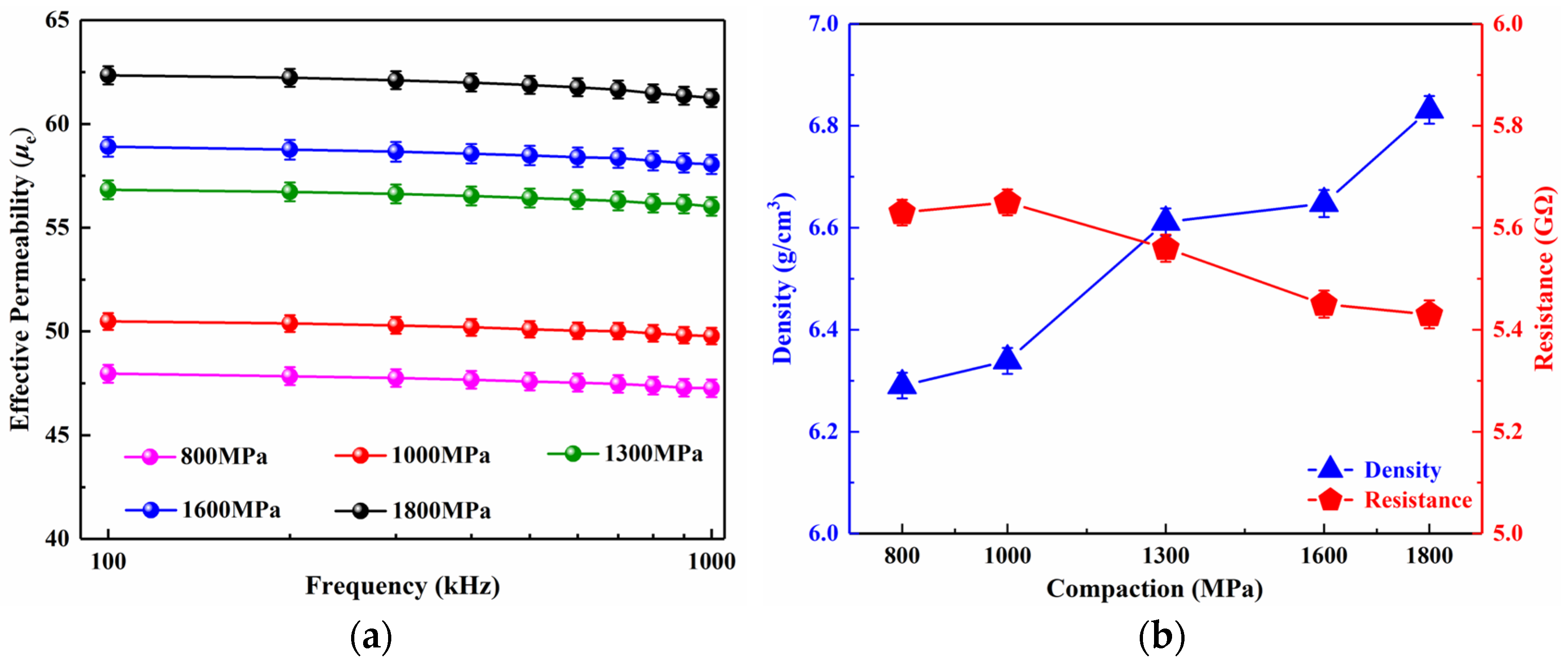

3.2.2. Effective Permeability

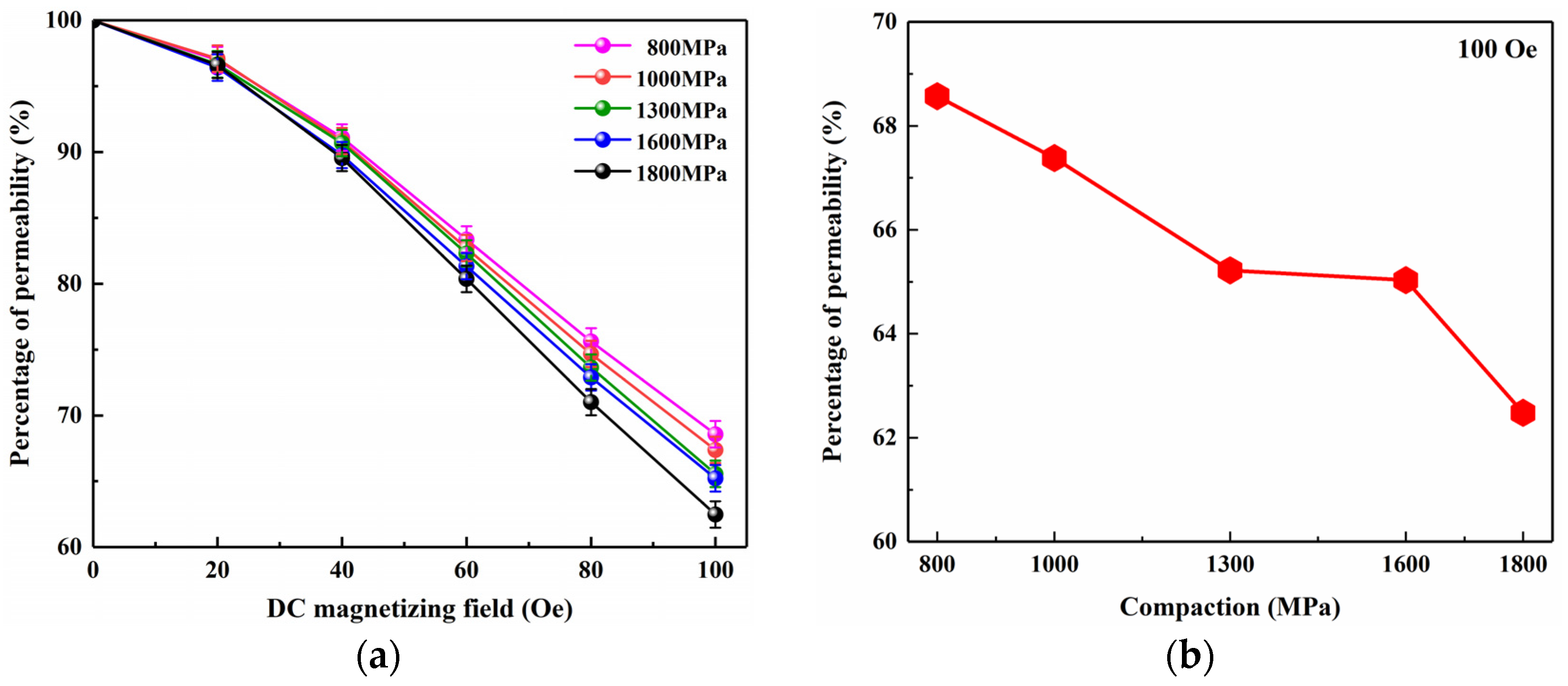

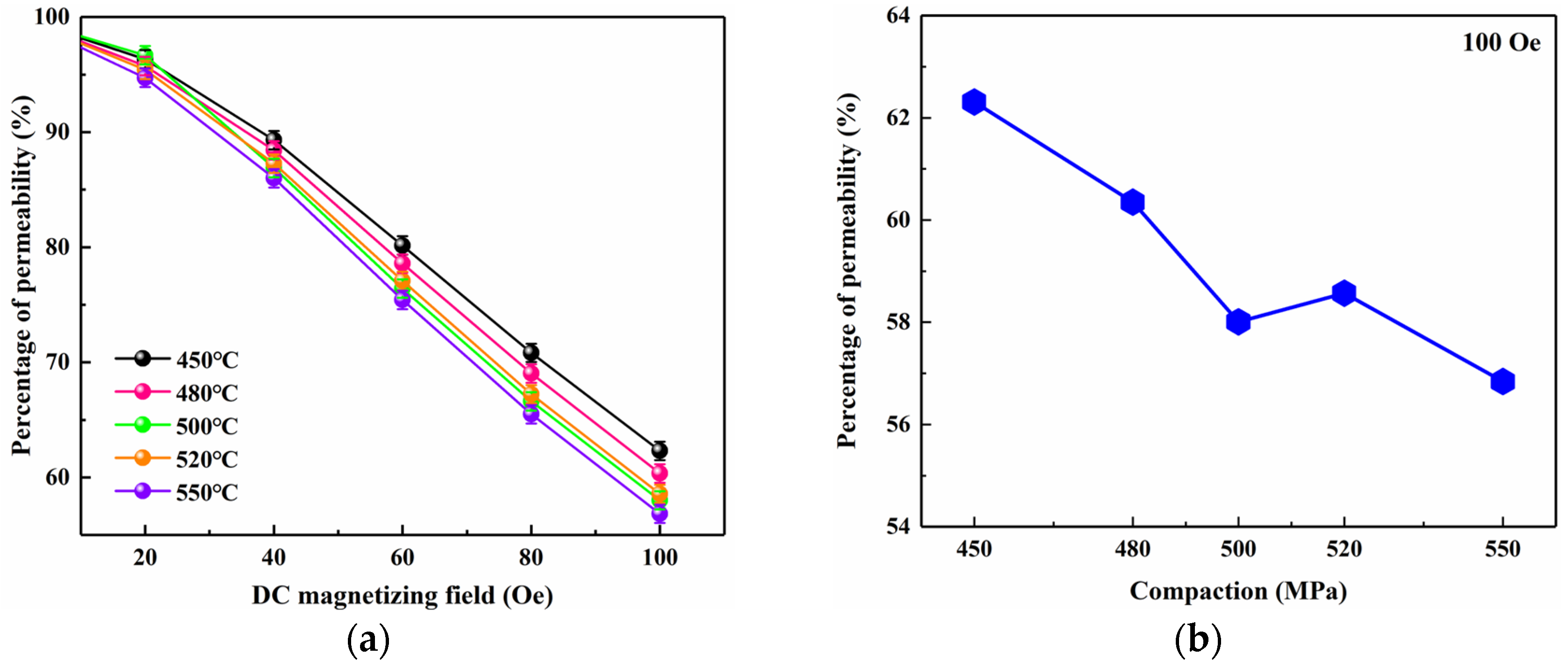

3.2.3. DC-Bias Performance

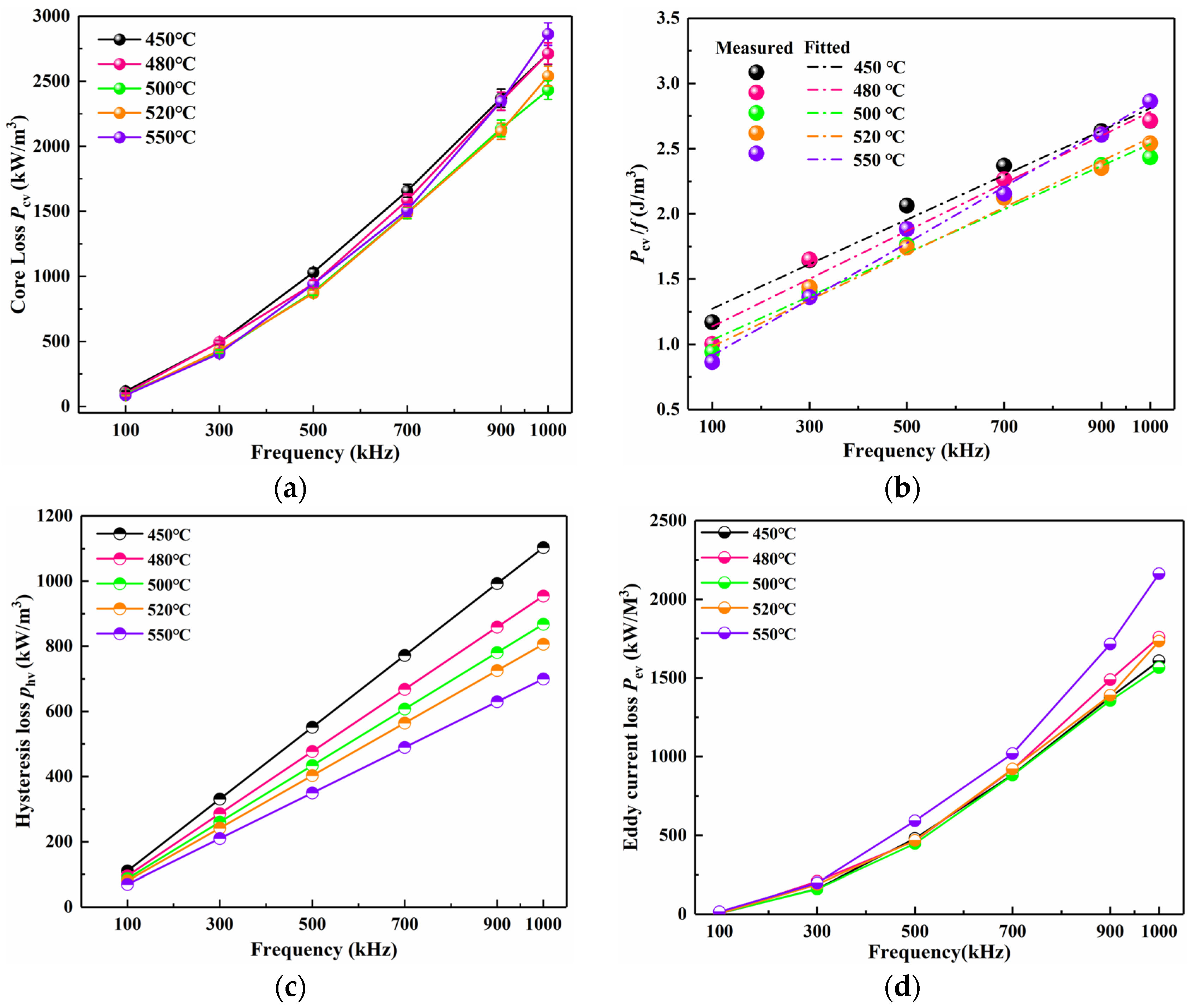

3.2.4. Core Loss

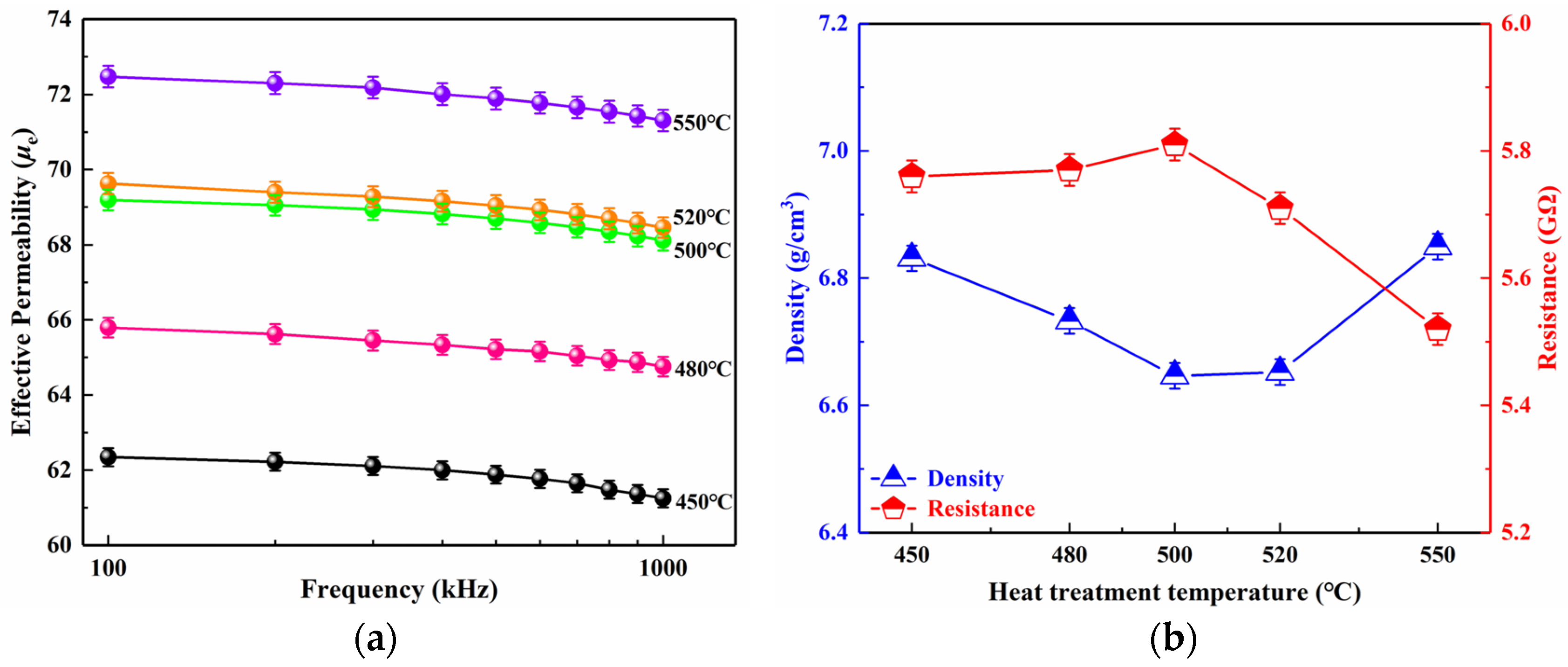

3.3. Impact of Heat Treatment Temperatures on Soft Magnetic Properties of NMPCs

3.3.1. Coercivity and Saturation Magnetization

3.3.2. Effective Permeability

3.3.3. DC-Bias Performance

3.3.4. Core Loss

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, Y.; Yi, Y.; Shao, W.; Shao, Y. Microstructure and magnetic properties of soft magnetic powder cores of amorphous and nanocrystalline alloys. J. Magn. Magn. Mater. 2013, 330, 119–133. [Google Scholar] [CrossRef]

- Lv, W. Advances on FeCuNbSiB nanocrystalline soft magnetic powder cores. Mater. Sci. Forum 2015, 815, 233–237. [Google Scholar] [CrossRef]

- Yoshizawa, Y.; Oguma, S.; Yamauchi, K. New Fe-based soft magnetic alloys composed of ultrafine grain structure. J. Appl. Phys. 1988, 64, 6044–6046. [Google Scholar] [CrossRef]

- Aradhya, R.; Kumar, R.S. Recent Trends in Development of Soft Magnetic Material for Power Electronics Applications: A Review. In Proceedings of the 2023 International Conference on Smart Systems for Applications in Electrical Sciences (ICSSES), Tumakuru, India, 7–8 July 2023; IEEE: New York, NY, USA, 2023; pp. 1–6. [Google Scholar] [CrossRef]

- He, J.; Yuan, H.; Nie, M.; Guo, H.; Yu, H.; Liu, Z.; Sun, R. Soft magnetic materials for power inductors: State of art and future development. Mater. Today Phys. 2023, 6, 100066. [Google Scholar] [CrossRef]

- Jiang, C.; Li, X.; Ghosh, S.S.; Zhao, H.; Shen, Y.; Long, T. Nanocrystalline powder cores for high-power high-frequency power electronics applications. IEEE Trans. Power Electron. 2020, 35, 10821–10830. [Google Scholar] [CrossRef]

- Li, F.C.; Liu, T.; Zhang, J.Y.; Shuang, S.; Wang, Q.; Wang, A.D.; Wang, J.G.; Yang, Y. Amorphous–nanocrystalline alloys: Fabrication, properties, and applications. Mater. Today Adv. 2019, 4, 100027. [Google Scholar] [CrossRef]

- Akai, H.; Akai, M.; Blügel, S.; Zeller, R.; Dedetichs, P.H. Hyperfine fields of impurities in ferromagnets. J. Magn. Magn. Mater. 1984, 45, 291–297. [Google Scholar] [CrossRef]

- McHenry, M.E.; Willard, M.A.; Laughlin, D.E. Amorphous and nanocrystalline materials for applications as soft magnets. Prog. Mater. Sci. 1999, 44, 291–433. [Google Scholar] [CrossRef]

- Suryanarayana, C. Structure and properties of nanocrystalline materials. Bull. Mater. Sci. 1994, 17, 307–346. [Google Scholar] [CrossRef]

- Voevodin, A.A.; Prasad, S.V.; Zabinski, J.S. Nanocrystalline carbide/amorphous carbon composites. J. Appl. Phys. 1997, 82, 855–858. [Google Scholar] [CrossRef]

- Suryanarayana, C.C.K.C.; Koch, C.C. Nanocrystalline materials–Current research and future directions. Hyperfine Interact. 2000, 130, 5–44. [Google Scholar] [CrossRef]

- Zhang, L.; Wu, Y.; Dong, Y.; Jia, X.; He, A.; Li, J.; Wang, W.; Shen, B. Fabrication of FeSiBPCNbCu nanocrystalline soft magnetic powders with high saturation magnetization and low core loss. J. Mater. Sci. 2024, 59, 8784–8795. [Google Scholar] [CrossRef]

- Wang, L.; Zheng, Z.; Chen, Y.; Chen, X.; Qiu, Z.; Zeng, D.; Yuan, S. The influence of Co on the magnetic properties of Fe–Si–B–Nb–Cu system. Physica B 2023, 660, 414906. [Google Scholar] [CrossRef]

- Li, G.; Shi, G.; Miao, H.; Liu, D.; Li, Z.; Wang, M.; Wang, L. Effects of the gas-atomization pressure and annealing temperature on the microstructure and performance of FeSiBCuNb nanocrystalline soft magnetic composites. Materials 2023, 16, 1284. [Google Scholar] [CrossRef] [PubMed]

- Tian, M.; Xu, J.; Yang, S.; Wang, J.; Yang, T.; Li, G.; Chen, Q.; Liu, X. Effects of heat treatment and compaction pressure on the microstructure and magnetic properties of core-shell structured FeSiBNbCu/SiO2 soft magnetic composites. J. Alloys Compd. 2022, 923, 166394. [Google Scholar] [CrossRef]

- Shin, J.H.; Jeong, Y.M.; Sohn, K.Y.; Park, W.W. A Study on the Soft Magnetic Properties and Compaction Density of Fe-based Nanocrystalline Powder Cores Mixed with Permalloy Powders. Korean J. Met. Mater. 2017, 55, 645–650. [Google Scholar] [CrossRef]

- Jakubas, A.; Chwastek, K. A simplified Sablik’s approach to model the effect of compaction pressure on the shape of hysteresis loops in soft magnetic composite cores. Materials 2020, 13, 170. [Google Scholar] [CrossRef]

- Pan, Y.; Peng, J.; Qian, L.; Xiang, Z.; Lu, W. Effects of compaction and heat treatment on the soft magnetic properties of iron-based soft magnetic composites. Mater. Res. Express 2020, 7, 016115. [Google Scholar] [CrossRef]

- Song, M.; Luo, F.; Shang, Y.; Duan, Z. Influence of Polytetrafluoroethylene Content, Compaction Pressure, and Annealing Treatment on the Magnetic Properties of Iron-Based Soft Magnetic Composites. Molecules 2024, 29, 4019. [Google Scholar] [CrossRef]

- Nguyen, M.P.; Yoshida, S.; Okamoto, S.; Miyazaki, T.; Endo, Y. Effect of compaction pressure on core loss in Fe-Ni powder cores for high frequency applications. IEEE Trans. Magn. 2024, 60, 2800104. [Google Scholar] [CrossRef]

- Wang, P.; Zhu, Z.; Liu, J.; Wang, H.; Pang, J.; Zhang, J. Finemet nanocrystalline magnetic powder cores: Application of binder and warm compaction process. J. Magn. Magn. Mater. 2024, 596, 171985. [Google Scholar] [CrossRef]

- Shokrollahi, H.; Janghorban, K. Different annealing treatments for improvement of magnetic and electrical properties of soft magnetic composites. J. Magn. Magn. Mater. 2007, 317, 61–67. [Google Scholar] [CrossRef]

- Li, Z.; Dong, Y.; Pauly, S.; Chang, C.; Wei, R.; Li, F.; Wang, X.M. Enhanced soft magnetic properties of Fe-based amorphous powder cores by longitude magnetic field annealing. J. Alloys Compd. 2017, 706, 1–6. [Google Scholar] [CrossRef]

- Dong, Y.; Li, Z.; Liu, M.; Chang, C.; Li, F.; Wang, X.M. The effects of field annealing on the magnetic properties of FeSiB amorphous powder cores. Mater. Res. Bull. 2017, 96, 160–163. [Google Scholar] [CrossRef]

- Zhao, T.; Yu, H.; Sun, C.; Chen, C.; Hao, J. Effects of the substitution of Si with P on the glass forming ability, crystallization behavior, and magnetic properties of FeCuNbSiBP atomized powder. J. Magn. Magn. Mater. 2022, 550, 169087. [Google Scholar] [CrossRef]

- Wu, Y.; Dong, Y.; Yang, M.; Jia, X.; Liu, Z.; Lu, H.; Zhang, H.; He, A.; Li, J. Effect of annealing process on microstructure and magnetic properties of FeSiBPCNbCu nanocrystalline soft magnetic powder cores. Metals 2022, 12, 845. [Google Scholar] [CrossRef]

- Meng, Y.; Yang, Y.; Chen, D.; Zhang, Y.; Chen, C. Effect of adding Fe11Ni6 alloy and annealing temperature on magnetic properties of Fe32Si4.4B4CrC1.4 powder cores. J. Mater. Sci. Mater. 2023, 34, 684. [Google Scholar] [CrossRef]

- Song, Y.; Zhou, S.; Zhang, Z.; Zhang, R.; Li, X.; Jing, X. Improvement for soft magnetic properties of FeSiBCuNb nanocrystalline powder cores by adding FeNi powder. J. Non-Cryst. Solids 2024, 646, 123260. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, X.; Jiang, Y.; Xing, B.; Li, W.; Jing, X.; Ge, P.; Zhang, R.; Xu, F. Enhanced high-frequency electromagnetic properties of Fe-based amorphous soft magnetic composites by adding carbonyl iron powder. J. Mater. Sci. Mater. 2024, 35, 411. [Google Scholar] [CrossRef]

- Li, Y.; Shen, N.; Wu, Y.; Zhang, S.; He, Z.; Li, F.; Hui, X. High Bs Fe-B-P-C-Cu nanocrystalline alloy with longtime annealing stability and low heating rate sensitivity. J. Magn. Magn. Mater. 2022, 543, 168623. [Google Scholar] [CrossRef]

- Škorvánek, I.; Kim, C.G.; Kováč, J.; Švec, P.; Sato-Turtelli, R. Soft magnetic behaviour and permeability spectra in amorphous and nanocrystalline Fe80.5Nb7B12.5 alloys. J. Magn. Magn. Mater. 2000, 215, 215–216. [Google Scholar] [CrossRef]

- Nguyen, M.P.; Yoshida, S.; Okamoto, S.; Muroga, S.; Miyazaki, T.; Endo, Y. Soft magnetic properties of Fe-Ni powder cores in the high frequency range. AIP Adv. 2024, 14, 015034. [Google Scholar] [CrossRef]

- Huang, M.; Wu, C.; Jiang, Y.; Yan, M. Evolution of phosphate coatings during high-temperature annealing and its influence on the Fe and FeSiAl soft magnetic composites. J. Alloys Compd. 2015, 644, 124–130. [Google Scholar] [CrossRef]

- Wang, B.; Zhang, Z.; Shen, J.; Tian, Y.; Wang, B.; Cai, L.; Liu, L.; Yu, Y.; Wang, G. Mechanism of adding carbonyl iron powder to enhance the magnetic properties of Fe-Si-B-Cu-Nb nanocrystalline soft magnetic composites. J. Alloys Compd. 2024, 972, 172812. [Google Scholar] [CrossRef]

- Zhang, C.; Liu, X.; Feng, S.; Kan, X.; Yang, Y.; Zhu, Y.; Zhang, Z. High frequency electromagnetic properties of Fe73.5Si13.5B9Nb3Cu1/carbonyl Fe composites. J. Mater. Sci. Mater. 2023, 34, 658. [Google Scholar] [CrossRef]

- Chen, Z.; Liu, X.; Kan, X.; Wang, Z.; Zhu, R.; Yang, W.; Zhang, Z.; Wang, W.; Rehman, K.M.U. Improved soft magnetic properties of Fe83.5Si7.5B5Cr4 amorphous nanocrystalline powder cores by adding Permalloy. J. Mater. Sci. Mater. 2018, 29, 19316–19321. [Google Scholar] [CrossRef]

- Ph, R.; De Marsily, G. Calculating equivalent permeability: A review. Adv. Water Resour. 1997, 20, 253–278. [Google Scholar] [CrossRef]

- Guo, J.; Dong, Y.; Man, Q.; Li, Q.; Chang, C.; Wang, X.M.; Li, R.W. Fabrication of FeSiBPNb amorphous powder cores with high DC-bias and excellent soft magnetic properties. J. Magn. Magn. Mater. 2016, 401, 432–435. [Google Scholar] [CrossRef]

- Bertotti, G. General properties of power losses in soft ferromagnetic materials. IEEE Trans. Magn. 2002, 24, 621–630. [Google Scholar] [CrossRef]

- Cao, P.; Liu, Y.; Li, J.; Du, J.; Wang, R.; Zhou, T. Enhanced magnetic properties of hot-pressed Fe-based nanocrystalline powder cores with low-melted glass-modified insulating. IEEE Trans. Magn. 2021, 57, 2800407. [Google Scholar] [CrossRef]

- Shokrollahi, H.E.J.K.; Janghorban, K. Soft magnetic composite materials (SMCs). J. Mater. Process. Technol. 2007, 189, 1–12. [Google Scholar] [CrossRef]

- Ye, K.; Zhang, Y. Microstructure evolution and magnetic properties of Fe65Ni35 nanocrystalline composite powders prepared by mechanical alloying. J. Funct. Mater./Gongneng Cailiao 2019, 59, 11089. [Google Scholar] [CrossRef]

- Périgo, E.A.; Weidenfeller, B.; Kollár, P.; Füzer, J. Past, present, and future of soft magnetic composites. Appl. Phys. Rev. 2018, 5, 031301. [Google Scholar] [CrossRef]

- Li, X.; Dong, Y.; Liu, X.; Wu, S.; Zhao, R.; Wu, H.; Wang, X. Structure evolution of Fe-based nanocrystalline soft magnetic powder cores with excellent properties. Mater. Sci. Eng. B 2022, 285, 115965. [Google Scholar] [CrossRef]

- Shi, G.; Wang, M.; Miao, H.; Li, G.; Li, B.; Zang, J.; Yin, G.; Wang, L.; Li, Z. Optimization of electromagnetic properties for soft magnetic powder cores prepared by gas-atomized FeSiBCuNb powders with continuously distributed the phase structures. Mater. Sci. Eng. B 2023, 298, 116852. [Google Scholar] [CrossRef]

- Shi, G.; Li, M.; Wang, H.; Zang, J.; Yin, G.; Wang, M.; Wang, L. Effect of the shape and content for added iron powder on properties of nanocrystalline soft magnetic composites. Mater. Today Commun. 2024, 39, 108888. [Google Scholar] [CrossRef]

| Samples | μe 100 kHz | Pcv (kW/m3) | DC Bias (%) 100 Oe | References | |

|---|---|---|---|---|---|

| 50 mT/ 100 kHz | 20 mT/ 1000 kHz | ||||

| FeSiBCuNb/50 wt.% FeNi (550 °C,1800 Mpa) | 71.9 | 86.3 | 351.5 | 56.8 | This work |

| FeSiBPCNbCu | 51.5 | 107 | / | 52 | [13] |

| FeSiBCuNb | 33.32 | / | / | 85 | [15] |

| FeSiBCuNb | 49.1 | 135.6 | / | 60.3 | [45] |

| FeSiBCuNb | 29.38 | / | 786 | 67.28 | [46] |

| FeSiBCuNb/CIP | 35.3 | 281.8 | 915.2 | / | [35] |

| FeSiBCuNb/CIP | 74.8 | / | 607 | / | [36] |

| FeSiBCuNb/CIP | / | / | 748.4 | >94 | [47] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, Y.; Zhang, Z.; Zhou, S.; Zhang, R.; Li, X.; Yu, H. Impact of Compaction Pressure and Heat Treatment Temperature on the Performance of FeSiBCuNb/FeNi Soft Magnetic Composites. Magnetochemistry 2025, 11, 29. https://doi.org/10.3390/magnetochemistry11040029

Song Y, Zhang Z, Zhou S, Zhang R, Li X, Yu H. Impact of Compaction Pressure and Heat Treatment Temperature on the Performance of FeSiBCuNb/FeNi Soft Magnetic Composites. Magnetochemistry. 2025; 11(4):29. https://doi.org/10.3390/magnetochemistry11040029

Chicago/Turabian StyleSong, Yanyan, Zhi Zhang, Shaoxiong Zhou, Ruibiao Zhang, Xiantao Li, and Haichen Yu. 2025. "Impact of Compaction Pressure and Heat Treatment Temperature on the Performance of FeSiBCuNb/FeNi Soft Magnetic Composites" Magnetochemistry 11, no. 4: 29. https://doi.org/10.3390/magnetochemistry11040029

APA StyleSong, Y., Zhang, Z., Zhou, S., Zhang, R., Li, X., & Yu, H. (2025). Impact of Compaction Pressure and Heat Treatment Temperature on the Performance of FeSiBCuNb/FeNi Soft Magnetic Composites. Magnetochemistry, 11(4), 29. https://doi.org/10.3390/magnetochemistry11040029