On the State of Usability for Lithium–Ion Batteries

Abstract

:1. Introduction

2. Derivation of the State of Usability

- Second life usability;

- Recyclability;

- Limited recyclability after required safe handling.

- External

- Sensor faults (SF)

- Cell connection faults (CCF)

- Cooling system faults (CSF)

- Internal:

- Overcharge (OC)

- Overdischarge (OD)

- Internal short circuit (ISC)

- External short circuit (ESC)

- Overheating (OH)

- Accelerated degradation (AD)

- Thermal runaway (TR)

- SEI growth (SEI)

- Lithium plating (LP)

- Electrolyte leakage (EL)

- Open current interrupt device (CID)

- -

- A high impact means that an occurrence leads to a cell with limited recyclability and a safety risk. This applies for mechanisms like a thermal runaway, where a contamination of the electrode active materials is inevitable or a severe overcharge that usually also leads to a thermal runaway of the cell [14,15].

- -

- A moderate impact means that an occurrence leads to a cell that does not require safety handling but the usability for second life may be limited to low power demanding applications. This applies for mechanisms like sensor or cooling system faults, where the single battery is usually not damaged and may be used in a newly built second life battery pack [12,16].

- -

- A low impact either means that the cell is usually not affected by the mechanism (e.g., cooling system faults are usually detected by the BMS and do not severely affect the single cells) or that the effect is limited and does not necessarily limit the general usability (e.g., mild capacity losses due to conditions causing accelerated degradation) [12].

- -

- -

- A moderate likelihood means that the mechanisms should normally not occur but may occur due to incorrect handling. For instance, this might be the case for a cell that is exposed to AD mechanisms such as high ambient temperatures [17].

- -

- ❖

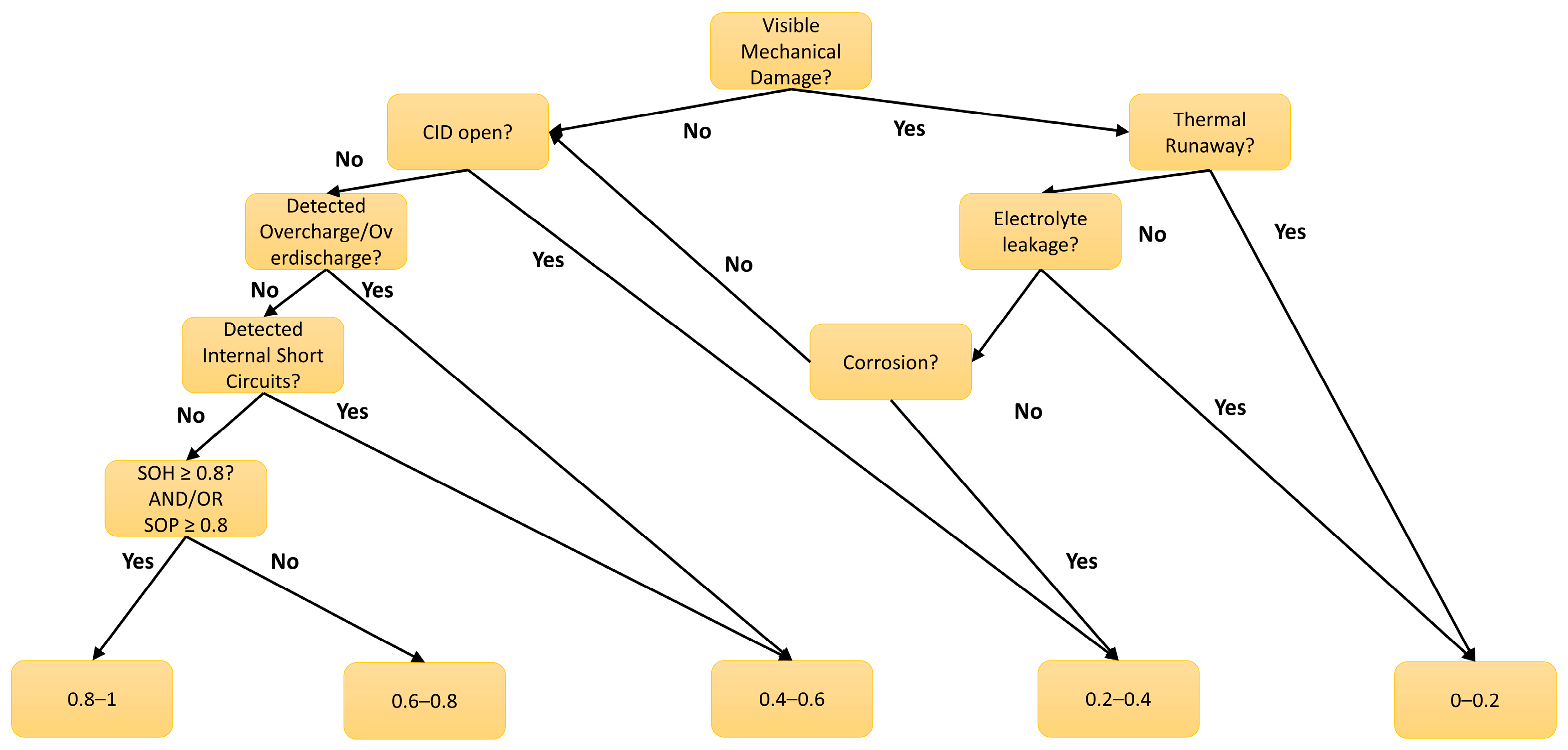

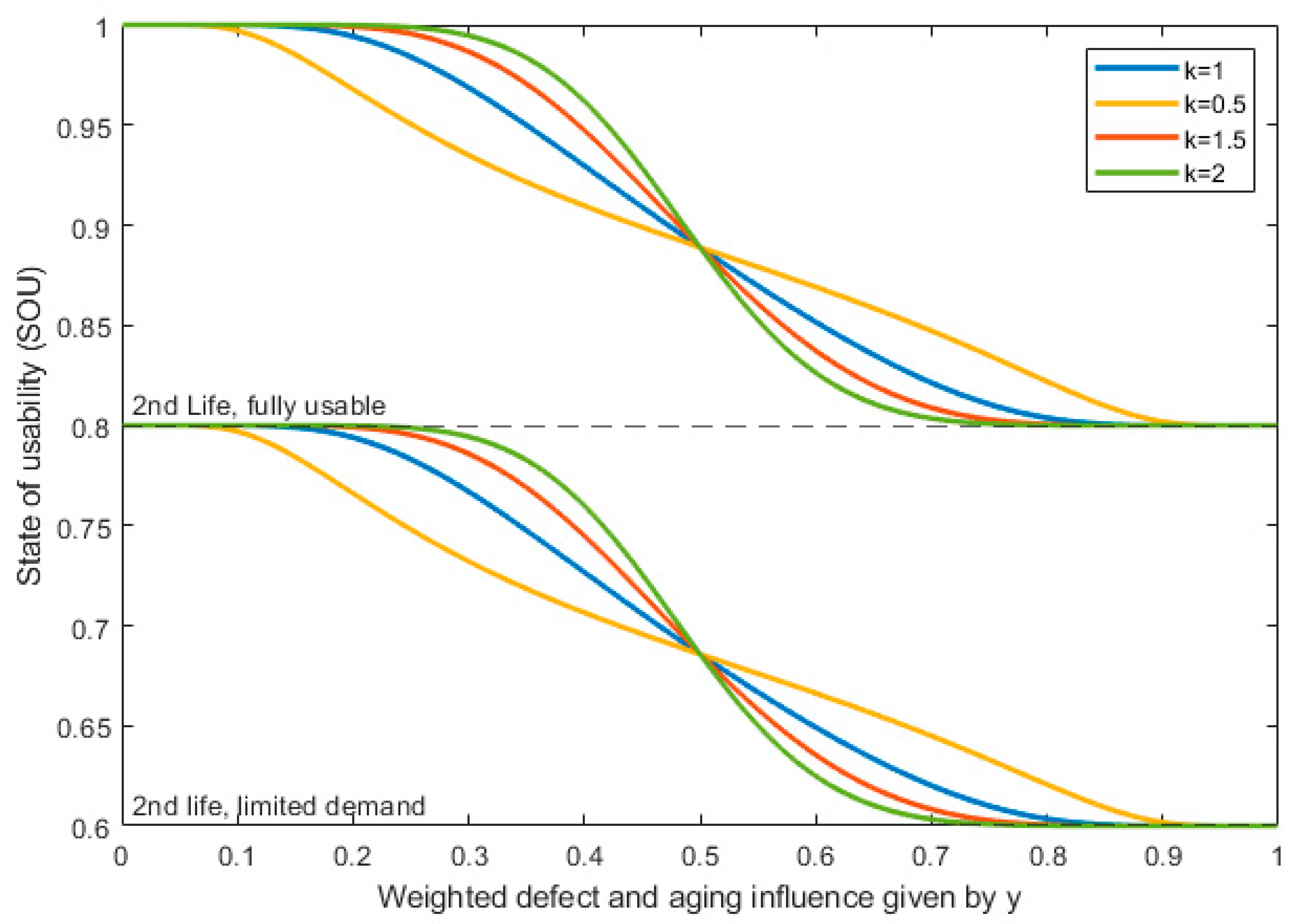

- 1 ≥ SOU > 0.8: Fully usable for second life applications, only mild capacity or power losses (SOH and SOP > 80%).

- ❖

- 0.8 ≥ SOU > 0.6: Usable for certain second life applications, e.g., with limited power demands.

- ❖

- 0.6 ≥ SOU > 0.4: Not usable for second life, still fully recyclable.

- ❖

- 0.4 ≥ SOU > 0.2: Limited recyclability because of unknown components or safety issues due to defects (e.g., CID is open, but cell did not catch fire), minor active material contamination or mechanical damage on the cell casing.

- ❖

- 0.2 ≥ SOU ≥ 0: Very limited recyclability, safe handling is required, severe active material contamination.

3. Classification Scheme

3.1. Decision Tree

- -

- No visible mechanical damage.

- -

- CID is not open.

- -

- No overcharge or deep discharge.

- -

- No detected internal short circuits.

- -

- SOH = 0.85.

- -

- SOP = 0.72.

- -

- No visible mechanical damage.

- -

- CID is not open.

- -

- No overcharge or deep discharge.

- -

- Detection of internal short circuits.

- -

- SOH = 0.65.

- -

- SOP = 0.93.

3.2. Calculation of SOU for Second Life Application

- -

- Mechanical damage (MD)

- -

- Thermal runaway (TR) .

- -

- Open CID (CID) .

- -

- Overcharge/overdischarge (OC/OD)

- -

- Electrolyte leakage (EL) .

- -

- Corrosion (CR) .

- -

- Internal short circuits (ISC)

- -

- State of health (SOH) .

- -

- State of power (SOP) .

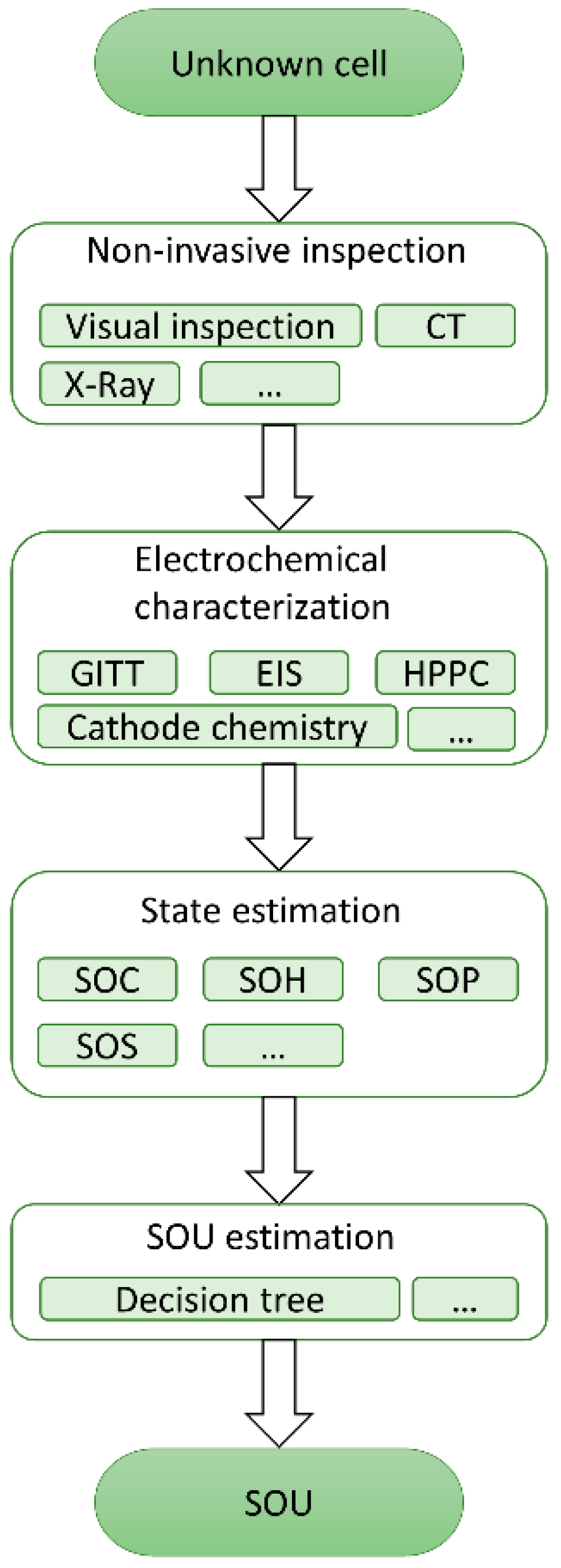

4. Experimental SOU Determination

4.1. State Estimation

4.2. Defect and Aging Mechanism Detection by EIS

4.3. Non-Invasive Defect Detection

4.4. Data-Driven Approaches

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Etacheri, V.; Marom, R.; Elazari, R.; Salitra, G.; Aurbach, D. Challenges in the development of advanced Li-ion batteries: A review. Energy Environ. Sci. 2011, 4, 3243–3262. [Google Scholar] [CrossRef]

- Dobó, Z.; Dinh, T.; Kulcsár, T. A review on recycling of spent lithium-ion batteries. Energy Rep. 2023, 9, 6362–6395. [Google Scholar] [CrossRef]

- Li, Y.; Zhong, S.; Zhong, Q.; Shi, K. Lithium-Ion Battery State of Health Monitoring Based on Ensemble Learning. IEEE Access 2019, 7, 8754–8762. [Google Scholar] [CrossRef]

- Balagopal, B.; Chow, M.-Y. The state of the art approaches to estimate the state of health (SOH) and state of function (SOF) of lithium Ion batteries. In Proceedings of the 2015 IEEE 13th International Conference on Industrial Informatics (INDIN), Cambridge, UK, 22–24 July 2015; pp. 1302–1307. [Google Scholar] [CrossRef]

- Wang, D.; Yang, F.; Gan, L.; Li, Y. Fuzzy Prediction of Power Lithium Ion Battery State of Function Based on the Fuzzy c-Means Clustering Algorithm. World Electr. Veh. J. 2019, 10, 1. [Google Scholar] [CrossRef]

- Feng, T.; Yang, L.; Zhao, X.; Zhang, H.; Qiang, J. Online identification of lithium-ion battery parameters based on an improved equivalent-circuit model and its implementation on battery state-of-power prediction. J. Power Sources 2015, 281, 192–203. [Google Scholar] [CrossRef]

- Cabrera-Castillo, E.; Niedermeier, F.; Jossen, A. Calculation of the state of safety (SOS) for lithium ion batteries. J. Power Sources 2016, 324, 509–520. [Google Scholar] [CrossRef]

- Harper, G.; Sommerville, R.; Kendrick, E.; Driscoll, L.; Slater, P.; Stolkin, R.; Walton, A.; Christensen, P.; Heidrich, O.; Lambert, S.; et al. Recycling lithium-ion batteries from electric vehicles. Nature 2019, 575, 75–86. [Google Scholar] [CrossRef]

- Christensen, P.A.; Anderson, P.A.; Harper, G.D.; Lambert, S.M.; Mrozik, W.; Rajaeifar, M.A.; Wise, M.S.; Heidrich, O. Risk management over the life cycle of lithium-ion batteries in electric vehicles. Renew. Sustain. Energy Rev. 2021, 148, 111240. [Google Scholar] [CrossRef]

- Saxena, S.; Le Floch, C.; MacDonald, J.; Moura, S. Quantifying EV battery end-of-life through analysis of travel needs with vehicle powertrain models. J. Power Sources 2015, 282, 265–276. [Google Scholar] [CrossRef]

- Assunção, A.; Moura, P.S.; de Almeida, A.T. Technical and economic assessment of the secondary use of repurposed electric vehicle batteries in the residential sector to support solar energy. Appl. Energy 2016, 181, 120–131. [Google Scholar] [CrossRef]

- Tran, M.-K.; Fowler, M. A Review of Lithium-Ion Battery Fault Diagnostic Algorithms: Current Progress and Future Challenges. Algorithms 2020, 13, 62. [Google Scholar] [CrossRef]

- Guo, J.; Jin, S.; Sui, X.; Huang, X.; Xu, Y.; Li, Y.; Kristensen, P.K.; Wang, D.; Pedersen, K.; Gurevich, L.; et al. Unravelling and quantifying the aging processes of commercial Li(Ni0.5Co0.2Mn0.3)O2/graphite lithium-ion batteries under constant current cycling. J. Mater. Chem. A 2023, 11, 41–52. [Google Scholar] [CrossRef]

- Doughty, D.H.; Roth, E.P. A General Discussion of Li Ion Battery Safety. Electrochem. Soc. Interface 2012, 21, 37–44. [Google Scholar] [CrossRef]

- Kong, L.; Li, C.; Jiang, J.; Pecht, M.G. Li-Ion Battery Fire Hazards and Safety Strategies. Energies 2018, 11, 2191. [Google Scholar] [CrossRef]

- Wolff, B.; Hausen, F. Mechanical Evolution of Solid Electrolyte Interphase on Metallic Lithium Studied by in situ Atomic Force Microscopy. J. Electrochem. Soc. 2023, 170, 010534. [Google Scholar] [CrossRef]

- Xing, Y.; Ma, E.W.M.; Tsui, K.L.; Pecht, M. Battery Management Systems in Electric and Hybrid Vehicles. Energies 2011, 4, 1840–1857. [Google Scholar] [CrossRef]

- Karlsen, H.; Dong, T.; Yang, Z.; Carvalho, R. Temperature-Dependence in Battery Management Systems for Electric Vehicles: Challenges, Criteria, and Solutions. IEEE Access 2019, 7, 142203–142213. [Google Scholar] [CrossRef]

- Li, W.; Crompton, K.; Hacker, C.; Ostanek, J.K. Comparison of Current Interrupt Device and Vent Design for 18650 Format Lithium-ion Battery Caps. J. Energy Storage 2020, 32, 101890. [Google Scholar] [CrossRef]

- Attidekou, P.S.; Milojevic, Z.; Muhammad, M.; Ahmeid, M.; Lambert, S.; Das, P.K. Methodologies for Large-Size Pouch Lithium-Ion Batteries End-of-Life Gateway Detection in the Second-Life Application. J. Electrochem. Soc. 2020, 167, 160534. [Google Scholar] [CrossRef]

- Zhao, Y.; Pohl, O.; Bhatt, A.I.; Collis, G.E.; Mahon, P.J.; Rüther, T.; Hollenkamp, A.F. A Review on Battery Market Trends, Second-Life Reuse, and Recycling. Sustain. Chem. 2021, 2, 167–205. [Google Scholar] [CrossRef]

- Neogi, S.; Chakraborty, J. Size-dependent effects sensitively determine buckling of a cylindrical silicon electrode particle in a lithium-ion battery. J. Appl. Phys. 2018, 124, 154302. [Google Scholar] [CrossRef]

- Tong, S.J.; Same, A.; Kootstra, M.A.; Park, J.W. Off-grid photovoltaic vehicle charge using second life lithium batteries: An experimental and numerical investigation. Appl. Energy 2013, 104, 740–750. [Google Scholar] [CrossRef]

- Tommiska, M.T. Efficient digital implementation of the sigmoid function for reprogrammable logic. IEE Proc. Comput. Digit. Tech. 2003, 150, 403. [Google Scholar] [CrossRef]

- How, D.N.T.; Hannan, M.A.; Hossain Lipu, M.S.; Ker, P.J. State of Charge Estimation for Lithium-Ion Batteries Using Model-Based and Data-Driven Methods: A Review. IEEE Access 2019, 7, 136116–136136. [Google Scholar] [CrossRef]

- He, H.; Xiong, R.; Fan, J. Evaluation of Lithium-Ion Battery Equivalent Circuit Models for State of Charge Estimation by an Experimental Approach. Energies 2011, 4, 582–598. [Google Scholar] [CrossRef]

- Li, W.; Fan, Y.; Ringbeck, F.; Jöst, D.; Han, X.; Ouyang, M.; Sauer, D.U. Electrochemical model-based state estimation for lithium-ion batteries with adaptive unscented Kalman filter. J. Power Sources 2020, 476, 228534. [Google Scholar] [CrossRef]

- Schwunk, S.; Armbruster, N.; Straub, S.; Kehl, J.; Vetter, M. Particle filter for state of charge and state of health estimation for lithium–iron phosphate batteries. J. Power Sources 2013, 239, 705–710. [Google Scholar] [CrossRef]

- Malysz, P.; Ye, J.; Gu, R.; Yang, H.; Emadi, A. Battery State-of-Power Peak Current Calculation and Verification Using an Asymmetric Parameter Equivalent Circuit Model. IEEE Trans. Veh. Technol. 2015, 65, 4512–4522. [Google Scholar] [CrossRef]

- Yang, R.; Xiong, R.; Shen, W. On-board soft short circuit fault diagnosis of lithium-ion battery packs for electric vehicles using extended Kalman filter. CSEE J. Power Energy Syst. 2020, 8, 258–270. [Google Scholar] [CrossRef]

- Kim, J.; Kowal, J. A Method for Monitoring State-of-Charge of Lithium-Ion Cells Using Multi-Sine Signal Excitation. Batteries 2021, 7, 76. [Google Scholar] [CrossRef]

- Zhang, Q.; Wang, D.; Schaltz, E.; Stroe, D.-I.; Gismero, A.; Yang, B. Degradation mechanism analysis and State-of-Health estimation for lithium-ion batteries based on distribution of relaxation times. J. Energy Storage 2022, 55, 105386. [Google Scholar] [CrossRef]

- Iurilli, P.; Brivio, C.; Wood, V. On the use of electrochemical impedance spectroscopy to characterize and model the aging phenomena of lithium-ion batteries: A critical review. J. Power Sources 2021, 505, 229860. [Google Scholar] [CrossRef]

- Tröltzsch, U.; Kanoun, O.; Tränkler, H.-R. Characterizing aging effects of lithium ion batteries by impedance spectroscopy. Electrochim. Acta 2006, 51, 1664–1672. [Google Scholar] [CrossRef]

- Kim, J.; Kowal, J. A Method for Detecting the Existence of an Over-Discharged Cell in a Lithium-Ion Battery Pack via Measuring Total Harmonic Distortion. Batteries 2022, 8, 26. [Google Scholar] [CrossRef]

- Murer, N.; Diard, J.-P.; Petrescu, B. The effects of time-variance on impedance measurements: Examples of a corroding electrode and a battery cell. J. Electrochem. Sci. Eng. 2020, 10, 127–140. [Google Scholar] [CrossRef]

- Yufit, V.; Shearing, P.; Hamilton, R.; Lee, P.; Wu, M.; Brandon, N. Investigation of lithium-ion polymer battery cell failure using X-ray computed tomography. Electrochem. Commun. 2011, 13, 608–610. [Google Scholar] [CrossRef]

- Chen, H.; Kalamaras, E.; Abaza, A.; Tripathy, Y.; Page, J.; Barai, A. Experimental Study of Sidewall Rupture of Cylindrical Lithium-Ion Batteries under Radial Nail Penetration. J. Electrochem. Soc. 2022, 169, 120528. [Google Scholar] [CrossRef]

- Wu, Y.; Saxena, S.; Xing, Y.; Wang, Y.; Li, C.; Yung, W.K.C.; Pecht, M. Analysis of Manufacturing-Induced Defects and Structural Deformations in Lithium-Ion Batteries Using Computed Tomography. Energies 2018, 11, 925. [Google Scholar] [CrossRef]

- Beltran, H.; Sansano, E.; Pecht, M. Machine learning techniques suitability to estimate the retained capacity in lithium-ion batteries from partial charge/discharge curves. J. Energy Storage 2023, 59, 106346. [Google Scholar] [CrossRef]

- Yang, S.; Xu, B.; Peng, H. Isolation and Grading of Faults in Battery Packs Based on Machine Learning Methods. Electronics 2022, 11, 1494. [Google Scholar] [CrossRef]

- Chen, H.; Shen, J. A degradation-based sorting method for lithium-ion battery reuse. PLoS ONE 2017, 12, e0185922. [Google Scholar] [CrossRef] [PubMed]

| Feasible Information On | SOC | SOH | SOP/SOF | SOS | SOU |

|---|---|---|---|---|---|

| Current battery state | √ | ✗ | ✗ | ✗ | ✗ |

| Degradation | ✗ | √ | √ | √ | √ |

| Safety | ✗ | ✗ | ✗ | √ | √ |

| Recyclability | ✗ | ✗ | ✗ | ✗ | √ |

| Second life usability | ✗ | ✗ | ✗ | ✗ | √ |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wett, C.; Lampe, J.; Haß, J.; Seeger, T.; Turan, B. On the State of Usability for Lithium–Ion Batteries. Batteries 2024, 10, 57. https://doi.org/10.3390/batteries10020057

Wett C, Lampe J, Haß J, Seeger T, Turan B. On the State of Usability for Lithium–Ion Batteries. Batteries. 2024; 10(2):57. https://doi.org/10.3390/batteries10020057

Chicago/Turabian StyleWett, Christopher, Jörg Lampe, Jan Haß, Thomas Seeger, and Bugra Turan. 2024. "On the State of Usability for Lithium–Ion Batteries" Batteries 10, no. 2: 57. https://doi.org/10.3390/batteries10020057

APA StyleWett, C., Lampe, J., Haß, J., Seeger, T., & Turan, B. (2024). On the State of Usability for Lithium–Ion Batteries. Batteries, 10(2), 57. https://doi.org/10.3390/batteries10020057